Study on the Factors Affecting the Performance of a Pressure Filtration–Flocculation–Solidification Combined Method for Mud Slurry Treatment

Abstract

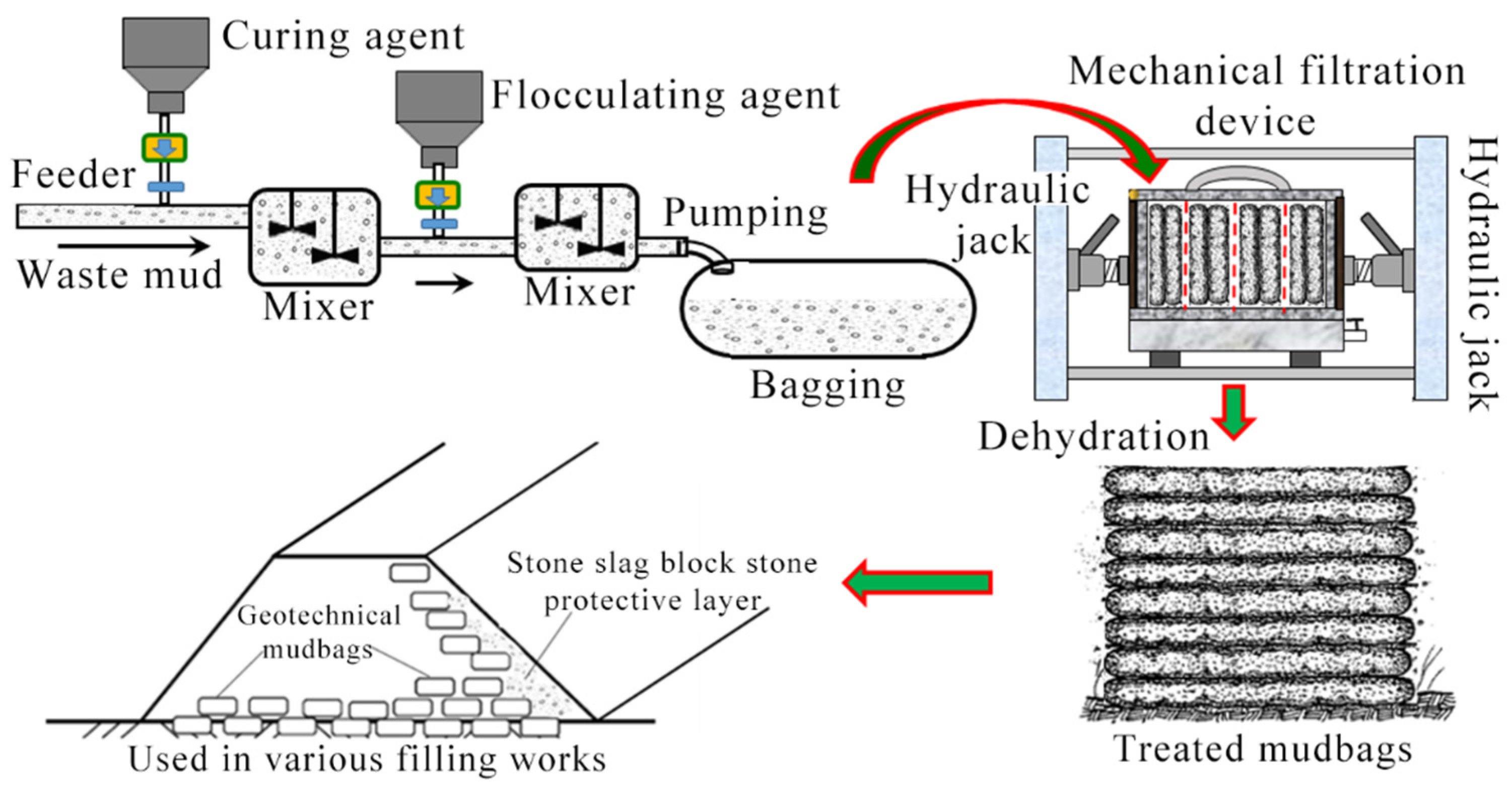

:1. Introduction

2. Laboratory Pressure Filtration Model Test

2.1. Materials and Methods

2.2. Results of Pressure Filtration Model Test

2.2.1. Influence of Initial Mud Cake Thickness on the Pressure Filtration Effect

2.2.2. Influence of the Dewatering Time on the Pressure Filtration Effect

3. Introduction of One-Dimensional Large Strain Consolidation Theory

- The soil is homogeneous and completely saturated, the soil particles and pore water are incompressible, and the self-weight of the soil is considered;

- The seepage in the soil obeys Darcy’s law;

- Only the vertical deformation of water and soil particles is considered;

- The external load is applied instantaneously and held constant

- The thickness of the soil layer changes with the consolidation process

- The permeability coefficient and compressibility coefficient change nonlinearly

4. Calculation Model and Parameter Selection

4.1. Pressure Filtration Calculation Model

4.2. Calculation Parameter Values

4.3. Validation of the Computational Model

5. Influence of Pressure Filtration Parameters on Mud Cake Deformation

5.1. Effect of Initial Cake Thickness and Dewatering Time on Cake Deformation

5.2. The Effect of Filtration Pressure on Mud Cake Deformation and Dewatering Time

5.3. Optimization of the Pressure Filtration Parameters

- An increased initial cake thickness will lead to a non-linear increase in the dewatering time, resulting in a reduction in the processing efficiency; the initial cake thickness should be appropriately reduced.

- Under the same initial mud cake thickness, a continuous increase in filtration pressure after the pressure is increased to the critical value has less effect on the dewatering time.

6. Conclusions

- The mud cake thickness after pressure filtration obtained by the calculation model proposed in this paper combined with the one-dimensional large-strain consolidation theory is only slightly larger than the measured mud cake thickness, and the trend of the mud cake thickness against the dewatering time is basically the same. It is feasible to use the calculation model proposed in this paper to analyze the relationship between mud cake deformation and dewatering time.

- An increased initial cake thickness greatly affects the pressure filtration efficiency. In order to achieve the same dewatering effect, doubling the initial cake thickness will lead to an increase several times over in the dewatering time. Reducing the initial cake thickness within a certain range can improve the pressure filtration efficiency.

- An increased filtration pressure increases the final compression deformation of the mud cake. In order to treat the mud cake to the same water content, an increase in pressure when the filtration pressure is small effectively reduces the dewatering time, but a continuous increase in the filtration pressure after the pressure has been increased to the critical value had less effect on the dewatering time.

- Considering the processing efficiency and energy consumption, the initial mud cake thickness of 240 mm, filtration pressure of 1.0 MPa, and dewatering time of 30 min obtained from the calculation model in this paper are recommended for slurry treatment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, W.; Liu, D.; Song, H.F.; Pu, G.J. Development and experimental study on environmental slurry for slurry shield tunneling. Constr. Build. Mater. 2019, 216, 416–423. [Google Scholar] [CrossRef]

- Jiang, L.B.; Zhen, L.; Wang, J.F.; Zhang, T.; Huang, X.W. Research on dewatering characteristics of waste slurry from pipe jacking construction. Materials 2022, 15, 2242. [Google Scholar] [CrossRef] [PubMed]

- Riviera, P.P.; Bellopede, R.; Marini, P.; Bassani, M. Performance-based re-use of tunnel muck as granular material for subgrade and sub-base formation in road construction. Tunn. Undergr. Space Technol. 2014, 40, 160–173. [Google Scholar] [CrossRef]

- Wang, B.; Wei, R.; Xiao, J.Z.; Cai, H.; Feng, Y.; Wu, S.F.; Wang, Z.W. Curing soft clay to improve its strength with composite mi-crobially induced carbonate precipitation (micp) and coal fly ash. Adv. Civ. Eng. Mater. 2022, 11, 155–174. [Google Scholar]

- Liu, W.; Yuan, H.; Fan, Z.; Li, J.; Sun, L. Using water-based drilling cuttings from shale gas development to manufacture sintered bricks: A case study in the southern Sichuan Basin, China. Environ. Sci. Pollut. Res. 2021, 28, 29379–29393. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.P.; Feng, X.H.; Chen, Z.G.; Li, S.S.; Liu, C.W. Conversion of the waste drilling mud to renewable grouting materials in deep shaft sinking. Constr. Build. Mater. 2023, 364, 129851. [Google Scholar] [CrossRef]

- Farooq, N.; Luque, R.; Len, T.; Osman, S.M.; Qureshi, A.M.; Nazir, M.A.; Rehman, A.U. Design of SrZr0.1Mn0.4Mo0.4Y0.1O3-δ heterostructured with ZnO as electrolyte material: Structural, optical and electrochemical behavior at low temperatures. Ceram. Int. 2023, 49, 2174–2182. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Liu, D.R.; Fang, G.W.; Wang, H.; Cheng, D. Utilization of excavated loess and gravel soil in controlled low strength material: Laboratory and field tests. Constr. Build. Mater. 2022, 360, 129604. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, W.B.; Zhao, R.D.; Jin, Y.F.; Yin, J.H. Solidification/stabilization treatment of Hong Kong marine deposits slurry at high water content by ISSA and GGBS. Constr. Build. Mater. 2023, 392, 130817. [Google Scholar]

- Wang, J.; Cai, Y.; Ma, J.; Chu, J.; Fu, H.; Wang, P.; Jin, Y. Improved Vacuum Preloading Method for Consolidation of Dredged Clay-Slurry Fill. J. Geotech. Geoenviron. 2016, 142, 06016012. [Google Scholar] [CrossRef]

- Zeng, L.L.; Bian, X.; Zhao, L.; Wang, Y.J.; Hong, Z.S. Effect of phosphogypsum on physiochemical and mechanical behaviour of cement stabilized dredged soil from Fuzhou, China. Geomech. Energy Environ. 2021, 25, 100195. [Google Scholar] [CrossRef]

- Yu, C.Y.; Cui, C.Y.; Zhao, J.Y.; Liu, F.; Wu, Y.J.; Liu, K.W. Novel carbonation solidification process for recovery of Zn-contaminated slurry: Strength and leachability aspects. Constr. Build. Mater. 2023, 370, 130585. [Google Scholar] [CrossRef]

- Liu, J.B.; Wei, Y.S.; Wang, Y.W.; Cai, X.; Shao, C.Y. Enhancement of Excess Sludge Dewatering by Pretreatment: A Review. China Water Wastewater 2014, 30, 1–6. [Google Scholar]

- Yi, Y.; Gu, L.; Liu, S. Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl. Clay Sci. 2015, 103, 71–76. [Google Scholar] [CrossRef]

- Dassekpo, J.B.M.; Ning, J.; Zha, X. Potential solidification/stabilization of clay-waste using green geopolymer remediation technologies. Process. Saf. Environ. 2018, 117, 684–693. [Google Scholar] [CrossRef]

- He, J.; Shi, X.K.; Li, Z.X.; Zhang, L.; Feng, X.Y.; Zhou, L.R. Strength properties of dredged soil at high water content treated with soda residue, carbide slag, and ground granulated blast furnace slag. Constr. Build. Mater. 2020, 242, 118126. [Google Scholar] [CrossRef]

- Wu, D.Q.; Xu, W.Y.; Zhu, D.P. The chemical-physicalcombined method for improving clay slurry in land reclamation. Geotech. Spec. Publ. 2013, 232, 308–315. [Google Scholar]

- Zhang, R.J.; Santoso, A.M.; Tan, T.S. Strength of highwater content marine clay stabilized by low amount of cement. J. Geotech. Geoenviron. 2013, 139, 2170–2181. [Google Scholar] [CrossRef]

- Cao, B.D.; Zhang, T.; Zhang, W.J.; Wang, D.S. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650. [Google Scholar] [CrossRef]

- Tan, X.; Chen, Y.; Xue, Q.; Wan, Y.; Liu, L. Conditioning of resuspension excess sludge with chemical oxidation technology: The respective performance of filtration and expression stage in compression dewatering. Sep. Purif. Technol. 2020, 237, 116317. [Google Scholar] [CrossRef]

- Zhang, J.; Yue, Q.; Xia, C.; Yang, K.; Zhao, P.; Gao, B. The study of Na2SiO3 as conditioner used to deep dewater the urban sewage dewatered sludge by filter press. Sep. Purif. Technol. 2017, 174, 331–337. [Google Scholar] [CrossRef]

- Wang, J.; Shi, W.; Wu, W.; Liu, F.; Fu, H.; Cai, Y.; Hai, J.; Hu, X.Q.; Zhu, X.X. Influence of composite flocculant FeCl3-APAM on vacuum drainage of river-dredged sludge. Can. Geotech. J. 2019, 56, 868–875. [Google Scholar] [CrossRef]

- Dong, C.Q.; Zhang, R.J.; Zheng, J.J.; Jiang, W.H. Strength behavior of dredged mud slurry treated jointly by cement, metakaolin and flocculant. Appl. Clay Sci. 2020, 193, 105676. [Google Scholar] [CrossRef]

- Sun, X.H.; Chen, Z.Y.; Sun, Z.B.; Wu, S.L.; Guo, K.Y.; Dong, Z.J.; Peng, Y.S. High-Efficiency utilization of waste shield slurry: A geopolymeric Flocculation-Filtration-Solidification method. Constr. Build. Mater. 2023, 387, 131569. [Google Scholar] [CrossRef]

- Sheehan, C.; Harrington, J. Management of dredge material in the republic of Ireland—A review. Waste Manag. 2012, 32, 1031–1044. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.H.; Chen, Y.Z.; Guo, K.Y.; Fei, J.B.; Dong, Z.J.; Xiong, H. Geopolymeric flocculation-solidification of tail slurry of shield tunnelling spoil after sand separation. Constr. Build. Mater. 2023, 374, 130954. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Zhang, R.J.; Zheng, J.J.; Dong, C.Q.; Lu, Z. Experimental study of flocculation-solidification combined treatment of hydraulically dredged mud slurry at extra high-water content. Rock Soil Mech. 2019, 40, 3107–3114. [Google Scholar]

- Zhang, R.J.; Dong, C.Q.; Zheng, J.J. Physicochemical Treatment of Dredged Clay Slurry Waste for Land Reclamation Purpose. In Environmental Science and Engineering, Proceedings of the 8th International Congress on Environmental Geotechnics Volume 1: Towards a Sustainable Geoenvironment 8th; Springer: Singapore, 2018; pp. 243–249. [Google Scholar]

- Qin, X.H.; Zhou, Z.Q.; He, B.; Xu, B.; Yu, S.L.; Qin, G.L.; Liu, K.; Ma, Y.J.; Han, P.J. Characteristics of waste mud treated by construction waste-slag based flocculation-solidification combined method. Constr. Build. Mater. 2023, 370, 130699. [Google Scholar] [CrossRef]

- Zhao, S.; Zeng, F.; Wang, J.; Fu, H.T.; Wang, Y. Experimental study of flocculation combined with vacuum preloading to reinforce silt foundation. Chin. J. Rock Mech. Eng. 2016, 35, 1291–1296. [Google Scholar]

- Wu, Y.; Gu, S.S.; Qiang, X.B.; Huang, W.J.; Luo, J.C. Experimental study on ultra-soft soil reinforced by vacuum preloading with flocculation based on skeleton construction. J. Zhejiang Univ. Eng. Sci. 2018, 52, 735–743. [Google Scholar]

- Min, F.L.; Wang, D.; Du, J.; Song, H.; Wang, Y.; Lv, H.; Ma, J. Laboratory Study of Flocculation and Pressure Filtration Dewatering of Waste Slurry. Adv. Civ. Eng. 2020, 2020, 2423071. [Google Scholar] [CrossRef]

- Han, C.; Yu, Y.Z.; Bai, B.; Dong, C.Q.; Zhang, R.J.; Fan, Z.; Wu, W.; Sun, K. Experimental study on flocculation-solidification combinedwith vacuum preloading treatment of waste mud. J. Civ. Environ. Eng. 2022, 43, 10–18. [Google Scholar]

- Cui, Y.; Zhu, W.; Wu, S.L.; Liu, J.M.; Lin, N.X. The role of lime in dredged mud dewatered by a plate and frame filter press and potential substitutes. Environ. Sci. Pollut. Res. 2021, 28, 17331–17342. [Google Scholar] [CrossRef] [PubMed]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2019.

- Gibson, R.E.; Hussey, M.J.L.; England, G.L. The theory of one-dimensional consolidation of saturated clays. I. finite non-linear consolidation of thin homogeneous layers. Geotechnique 1967, 17, 261–273. [Google Scholar] [CrossRef]

- Gibson, R.E.; Schiffman, R.L.; Cargill, K.W. The theory of one-dimensional consolidation of saturated clays. II. Finite nonlinear consolidation of thick homogeneous layers. Can. Geotech. J. 1981, 18, 280–293. [Google Scholar] [CrossRef]

- Xie, K.H.; Zheng, H.; Li, B.H.; Liu, X.W. Analysis of one dimensional nonlinear consolidation of layered soils under time-dependent loading. J. Zhejiang Univ. Eng. Sci. 2003, 37, 50–55. [Google Scholar]

- Zhu, H.; Sun, H.; Wang, F.; Zou, J.; Fan, J. Preparation of chitosan-based flocculant for high density waste drilling mud slurry solid-liquid separation. J. Appl. Polym. Sci. 2012, 125, 2646–2651. [Google Scholar] [CrossRef]

- Leroueil, S.; Leart, P.; Hight, D.W.; Powell, J.J.M. Hydraulic conductivity of a recent estuarine silty clay at Bothkennar. Geotechnique 1992, 42, 275–288. [Google Scholar] [CrossRef]

- Cao, Y.C.; Chen, Y.M.; Huang, M.S. One-dimensional nonlinear consolidation analysis of structured natural soft clay subjected to arbitrarily time-dependent construction loading. Chin. J. Geotech. Eng. 2006, 28, 569–574. [Google Scholar]

- Zeng, L.L.; Hong, Z.S.; Chen, F.Q. A law of change in permeability coefficient during compression of remolded clays. Rock Soil Mech. 2012, 33, 1286–1292. [Google Scholar]

- Zeng, L.L.; Hong, Z.S.; Hong, Z.S. Hydraulic conductivity of naturally sedimented and reconstituted clays interpreted from consolidation tests. Eng. Geol. 2020, 272, 105638. [Google Scholar] [CrossRef]

- Zeng, L.L.; Cai, Y.Q.; Cui, Y.J.; Hong, Z.S. Hydraulic conductivity of reconstituted clays based on intrinsic compression. Géotechnique 2020, 70, 268–275. [Google Scholar] [CrossRef]

- Wu, S.L.; Zhu, W.; Min, F.L. Clogging mechanism and effect of cake permeability in soil-water separation using vacuum fil-tration. Chin. J. Geotech. Eng. 2017, 39, 1530–1537. [Google Scholar]

- Lou, C.H.; Zhang, Z.M.; Fang, K. Theoretical and Experimental Analysis on the Pressure Filtration Technology in Slurries Treatment. J. Civ. Environ. Eng. 2018, 34, 57–61. [Google Scholar]

| Specific Gravity Gs | Liquid Limit wL/% | Plastic Limit wp/% | Sand Content/% | Silt Content/% | Clay Content/% |

|---|---|---|---|---|---|

| 2.70 | 53.7 | 26.5 | 14.9 | 79.5 | 5.6 |

| Working Condition | Dewatering Time (min) | Mass of Dry Mud Slurry (kg) | Calculated Initial Thickness (mm) | Pressure Filtration Press (MPa) | Equivalent Initial Water Content |

|---|---|---|---|---|---|

| A1 | 10 | 3 | 102 | 0.3 | 250% |

| A2 | 10 | 4 | 136 | ||

| A3 | 10 | 5 | 170 | ||

| B1 | 6 | 3 | 102 | ||

| B2 | 8 | 3 | 102 | ||

| B3 | 10 | 3 | 102 | ||

| B4 | 12 | 3 | 102 |

| Calculation Parameters | A1 | A2 | A3 |

|---|---|---|---|

| Initial thickness of mixed mud slurry, h01 (mm) | 102 | 136 | 170 |

| Initial void ratio of mixed mud slurry, | 6.75 | 6.75 | 6.75 |

| Initial mud cake thickness, h0 (mm) | 66.5 | 88.6 | 110.8 |

| Initial void ratio of mud cake, | 4.05 | 4.05 | 4.05 |

| Initial effective stress of mud cake, (KPa) | 1.0 | 1.0 | 1.0 |

| Initial permeability coefficient of mud cake, (cm/s) | 1.82 × 10−2 | 1.82 × 10−2 | 1.82 × 10−2 |

| Compression index, Cc | 1.2 | 1.2 | 1.2 |

| Permeability index, Ck | 1.08 | 1.08 | 1.08 |

| Initial Thickness (mm) | Filtration Pressure (MPa) | |||||

|---|---|---|---|---|---|---|

| 0.4 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | |

| 180 | 8.61 | 12.14 | 15.10 | 17.28 | 18.23 | 19.30 |

| 240 | 6.40 | 9.61 | 12.05 | 14.12 | 15.09 | 16.29 |

| 300 | - | 7.73 | 10.06 | 11.56 | 12.84 | 13.73 |

| 360 | - | 6.71 | 8.77 | 9.97 | 11.07 | 11.98 |

| 420 | - | 5.91 | 7.51 | 8.88 | 9.89 | 10.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Xie, H.; Bai, B.; Liu, D.; Huang, Y.; Zhang, R. Study on the Factors Affecting the Performance of a Pressure Filtration–Flocculation–Solidification Combined Method for Mud Slurry Treatment. Appl. Sci. 2023, 13, 11299. https://doi.org/10.3390/app132011299

Han C, Xie H, Bai B, Liu D, Huang Y, Zhang R. Study on the Factors Affecting the Performance of a Pressure Filtration–Flocculation–Solidification Combined Method for Mud Slurry Treatment. Applied Sciences. 2023; 13(20):11299. https://doi.org/10.3390/app132011299

Chicago/Turabian StyleHan, Chao, Hongping Xie, Bin Bai, Dongrui Liu, Yue Huang, and Rongjun Zhang. 2023. "Study on the Factors Affecting the Performance of a Pressure Filtration–Flocculation–Solidification Combined Method for Mud Slurry Treatment" Applied Sciences 13, no. 20: 11299. https://doi.org/10.3390/app132011299

APA StyleHan, C., Xie, H., Bai, B., Liu, D., Huang, Y., & Zhang, R. (2023). Study on the Factors Affecting the Performance of a Pressure Filtration–Flocculation–Solidification Combined Method for Mud Slurry Treatment. Applied Sciences, 13(20), 11299. https://doi.org/10.3390/app132011299