Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets

Abstract

:1. Introduction

2. Materials and Methods

- Neglection of heat conduction in the casting direction compared to convective heat transport and other heat conduction;

- Modelling of convective heat transport perpendicular to the casting direction in fluid phase by an effective thermal conductivity [5].

3. Results

3.1. Dynamic Temperature and Solidification Model DynSolidCC

3.1.1. Submodels for Boundary Conditions

- Mould area;

- Secondary cooling zones with spray water loops;

- Radiation zone behind spray water loops.

3.1.2. FOTS Measurements in Mould Walls at ESF

- The symmetry assumption regarding heat flows across top/bottom and left/right strand surfaces and related measured FOTS temperatures fits better for the lower part of the mould (i.e., fibres 2 and 3) compared to the upper part (i.e., fibres 0 and 1). Moreover, the associated sensors near the middle of the walls show better congruence than those near corners.

- After a significant decrease in measured mould wall temperatures from fibre 0 to fibre 1 to a level, which is more or less also measured at fibre 2, it increases again at fibre 3. At fibres 0 and 1, the top wall sensors have measured higher averaged temperatures than the left wall sensors. At fibre 2, all sensor measurements are quite close together, with mid-wall sensor results slightly higher than corner sensor results. At fibre 3, a symmetric temperature distribution can be observed with mid-wall values on an equal level significantly higher than the corner values, also on an equal level. This can be expected from the geometry with higher cooling effect from two faces near the edges and is related to the higher strand surface temperatures calculated at the middle of the strand compared to the temperatures at strand corners.

- Thus, the heat transfer from the strand to the mould walls is homogenised in the range between fibre 1 and fibre 3, and for the lower part of the mould, the boundary conditions can be considered to be symmetric with respect to top/down and left/right strand surfaces.

- Because the strand surface temperatures decrease with increasing distance from the meniscus, the observed increase in the mould wall temperatures at fibre 3 indicates an increase in the heat flow density by a better heat transfer at this mould length, e.g., due to better contact between strand surfaces and mould walls. This has been taken into account in the model parametrisation by choosing a more or less constant heat flow density at the strand surfaces along the mould length instead of a decreasing behaviour, which usually is suggested in the literature (see Equation (1)). However, simulations revealed no significant influence of the parameter α in Equation (1) on the strand temperatures and shell thicknesses at the mould exit if the total heat extraction across the mould is kept constant.

- The comparison of temporal evolutions of measured mould wall temperatures and associated calculated strand surface temperatures shows a correlation where a decrease/increase in wall temperatures is related to an increase/decrease in strand surface temperatures with a delay of about 45 s. The FOTS along the mould measure decreasing/increasing heat flows between strand and mould, which lead to increasing/decreasing surface temperatures.

- All in all, it seems justified to use the assumption of symmetric boundary conditions in the mould with a more or less constant heat flow density across the different strand surfaces. In the upper part of the mould, the non-homogenous steel flow conditions after inflow of the steel via the submerged entry nozzle (SEN) as well as the thinner strand shells and higher influences of mould-level fluctuations and non-uniform distributions of lubrication oil or powder lead to deviations from the symmetric boundary conditions which are reflected in the FOTS measurements at fibres 0 and 1. At fibre 2, there are already more homogenous heat transfer conditions which evolve towards fibre 3 to the expected case of more or less symmetric boundary conditions.

3.1.3. Infrared Camera Measurements of Strand Surface Temperatures at ESF

- On curved area;

- After straightening;

- Before descaling;

- After descaling;

- Before cutting torch.

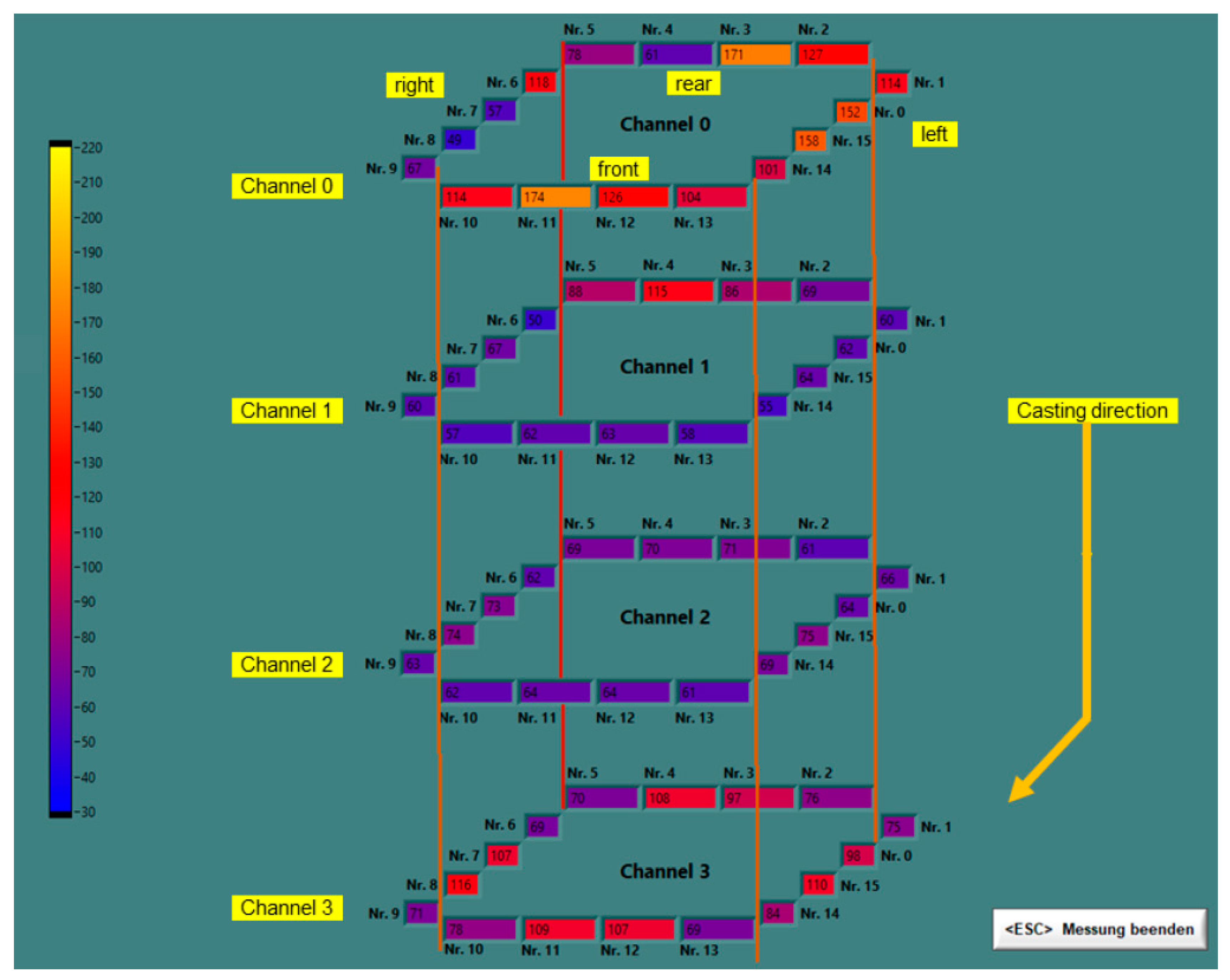

3.2. Vibrometer Measurements of Crater End Position at ESF

- First campaign with varying measurement positions and fixed casting conditions.

- Second campaign with a fixed measurement position and varying casting conditions, i.e., increasing casting speed.

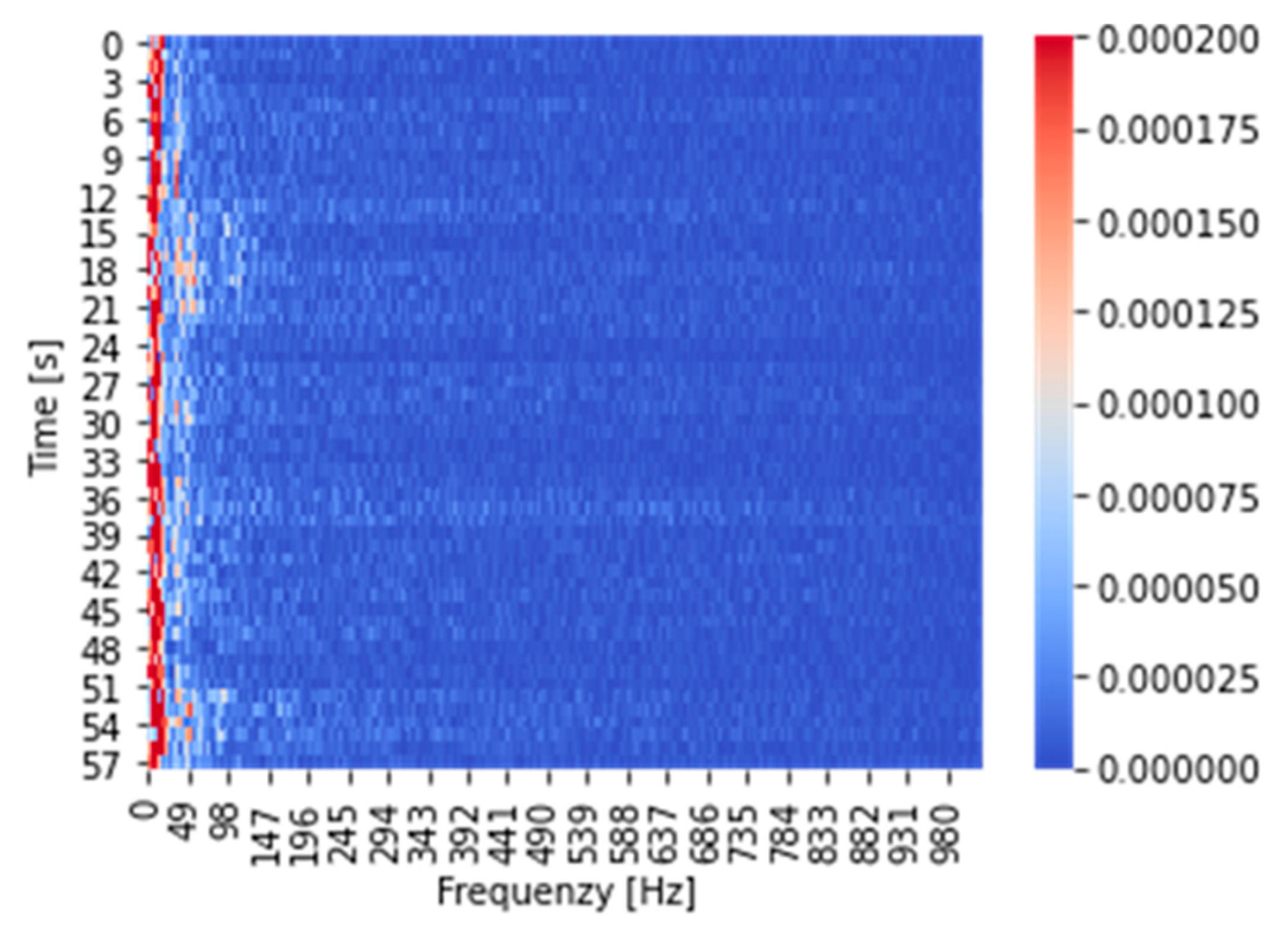

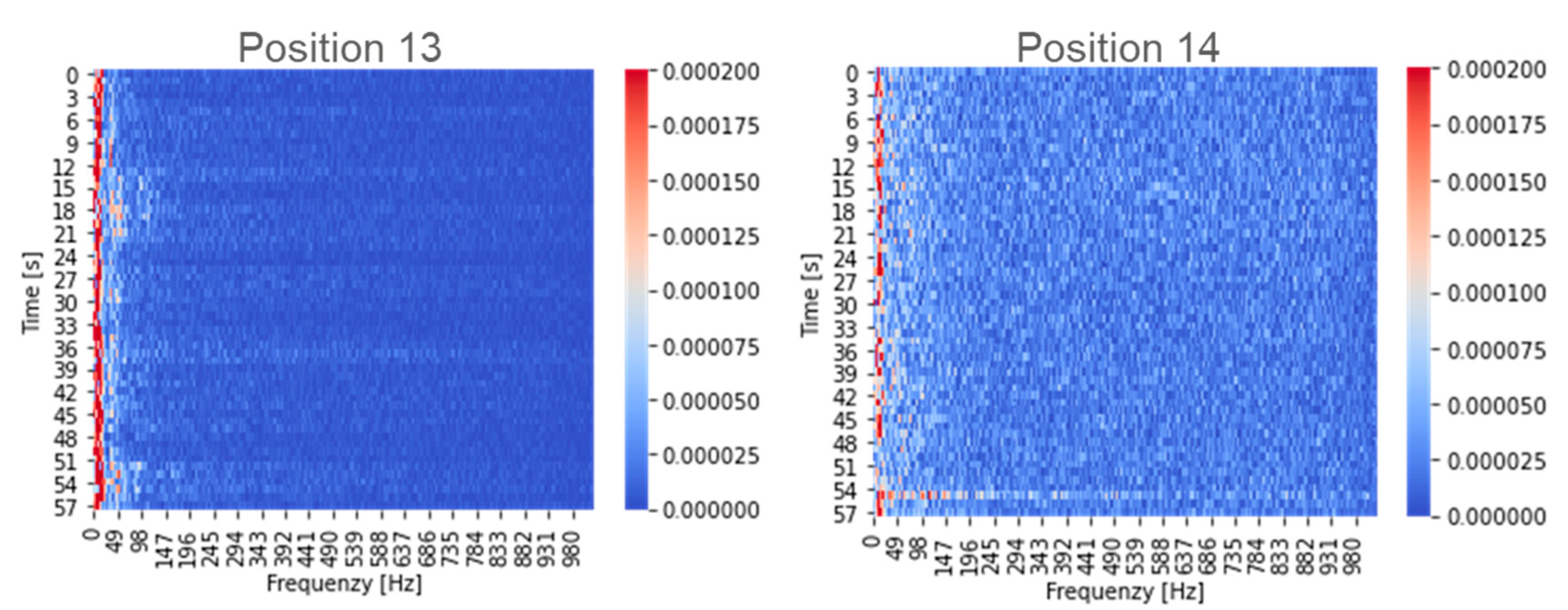

3.2.1. Vibrometer Measurement Campaign with Varying Strand Positions

- 20 measurement points on strand from torch cutter over a length of 5 m;

- 60 s measurement time for each measurement position;

- 900 s measurement time at nearest and most distant position to the torch cutter;

- 2 measurement sequences with two different casting speeds.

- Two hidden layers with 64 and 128 neurons;

- Rectifier activation function;

- Max. number of iterations = 500.

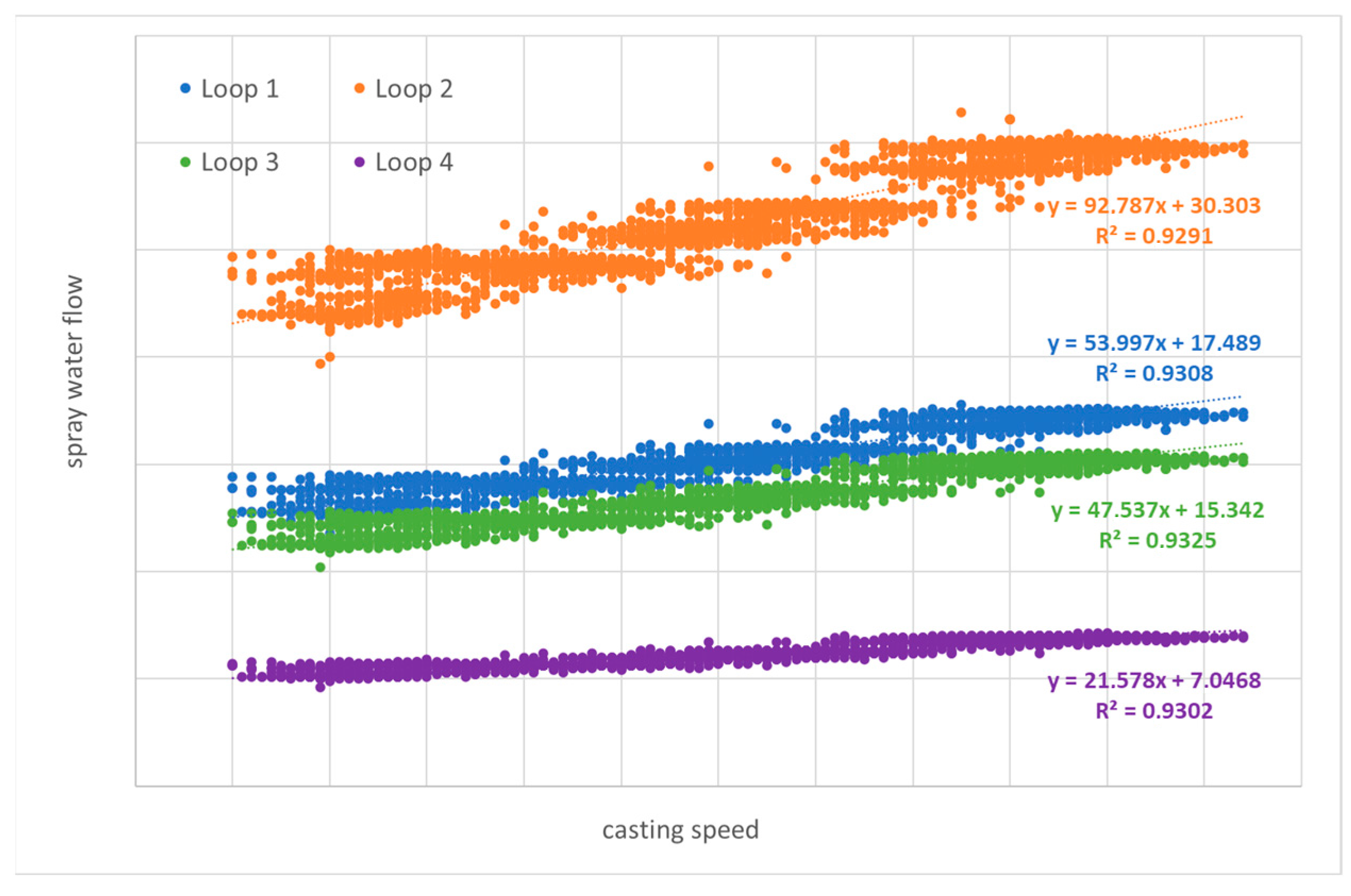

3.2.2. Vibrometer Measurement Campaign with Varying Casting Speeds

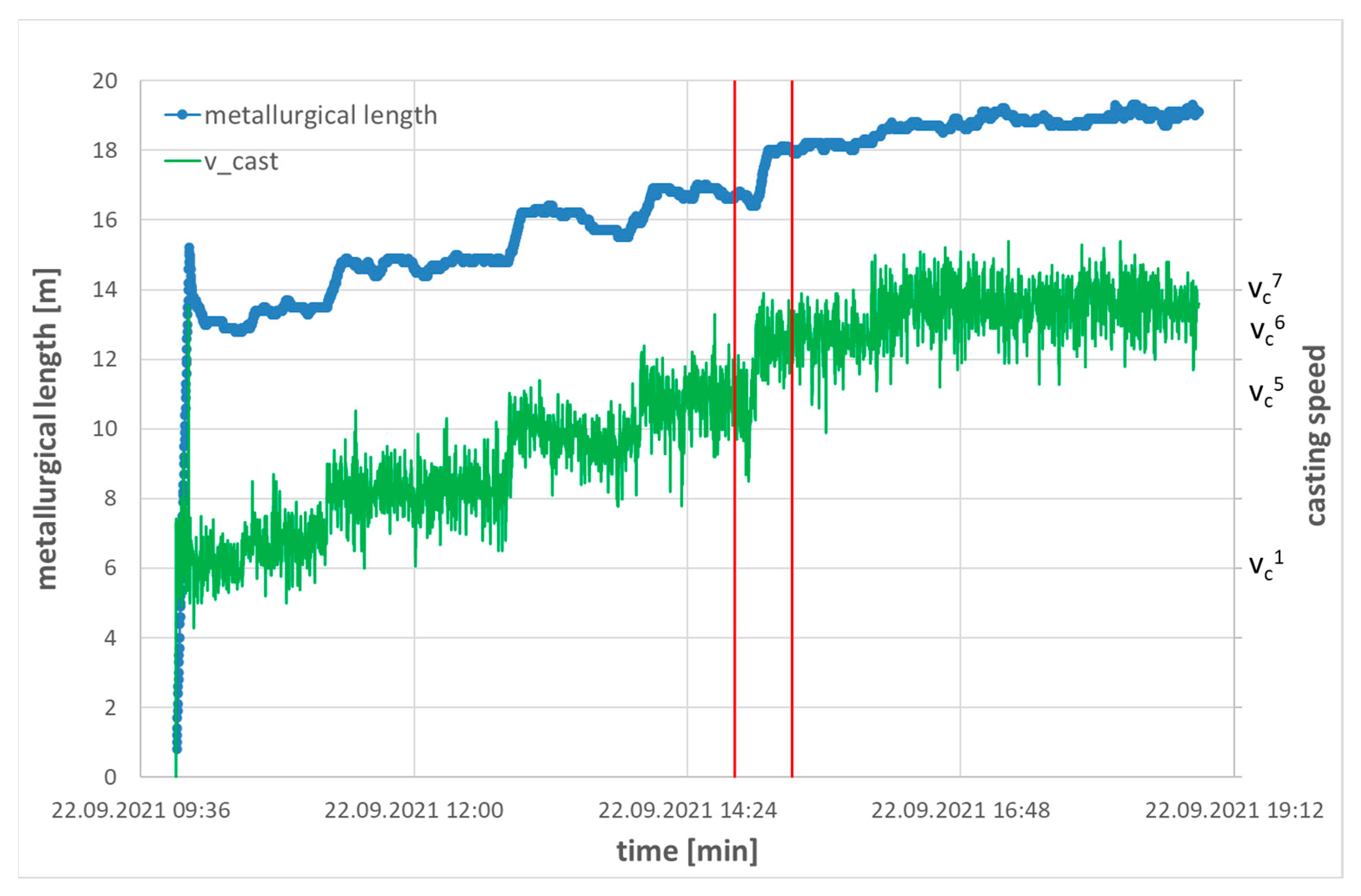

- Continuous measurement at 17.5 m below the meniscus with seven casting speeds increasing from vc1 to vc7.

- Two 30 min measurements after changes in casting speed to measure during transitional and stationary conditions.

- K-means;

- Gaussian mixture model;

- Hierarchical clustering with Ward linkage.

- (1)

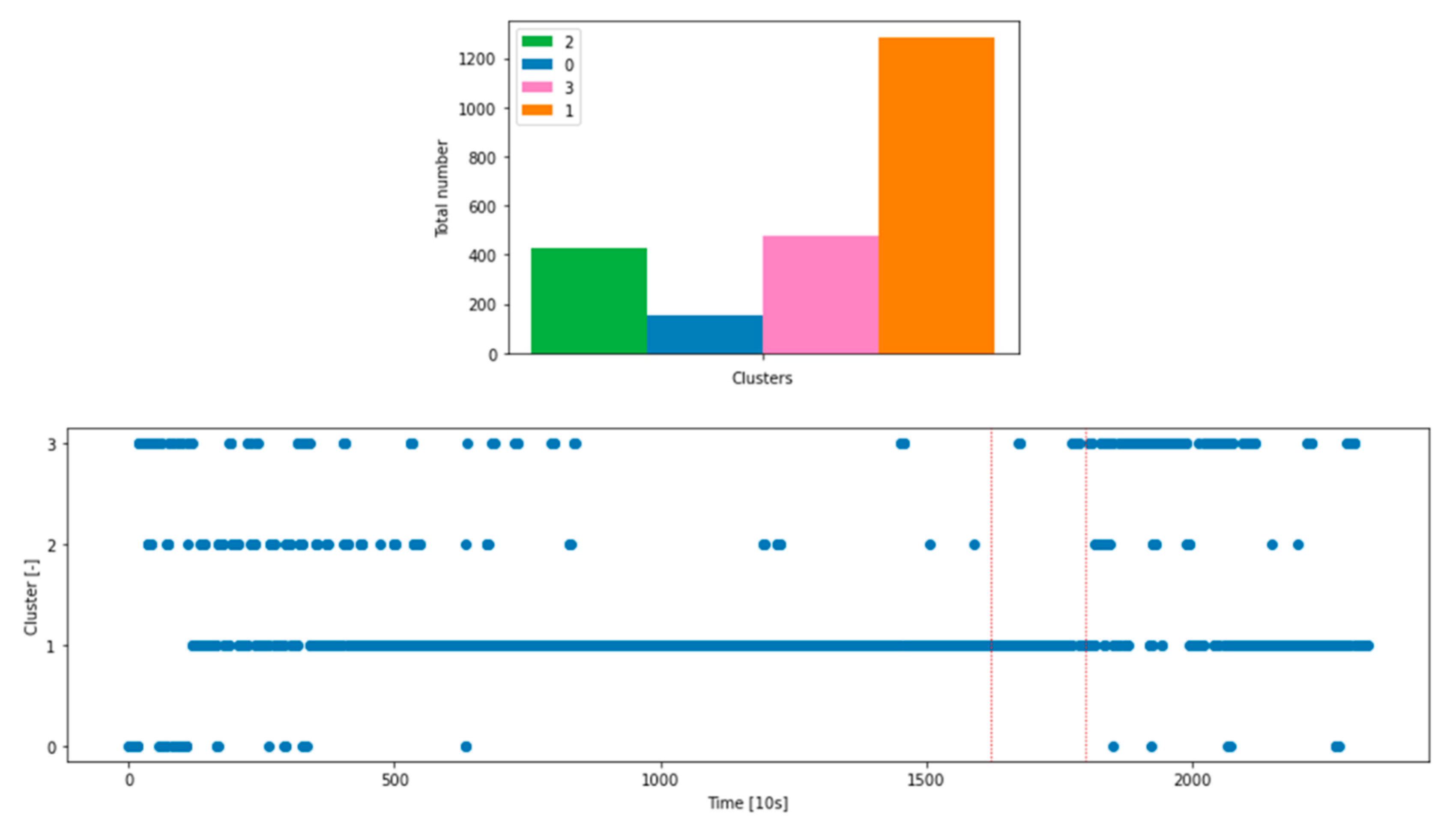

- K-means algorithm

- (2)

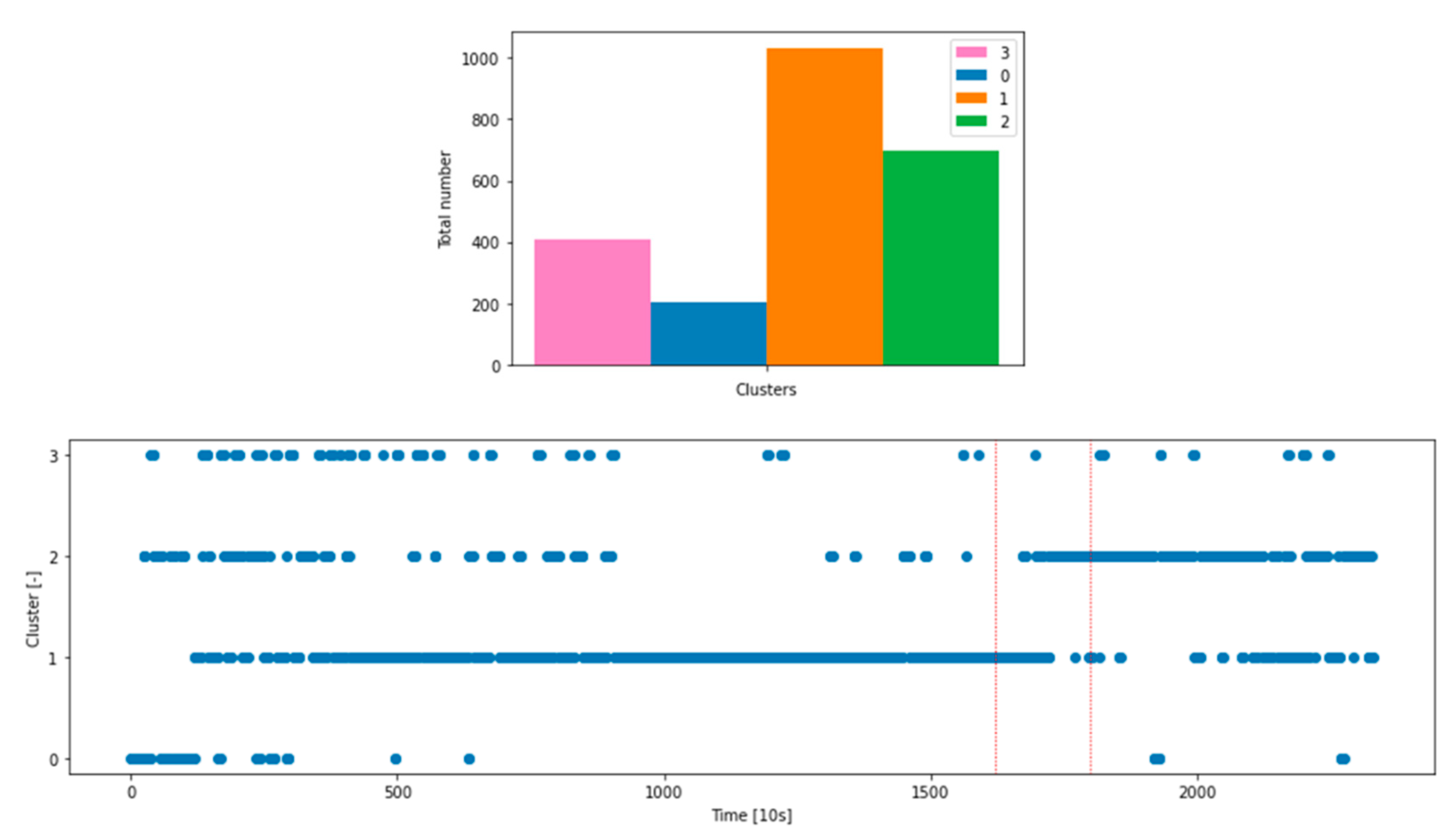

- Gaussian mixture model

- (3)

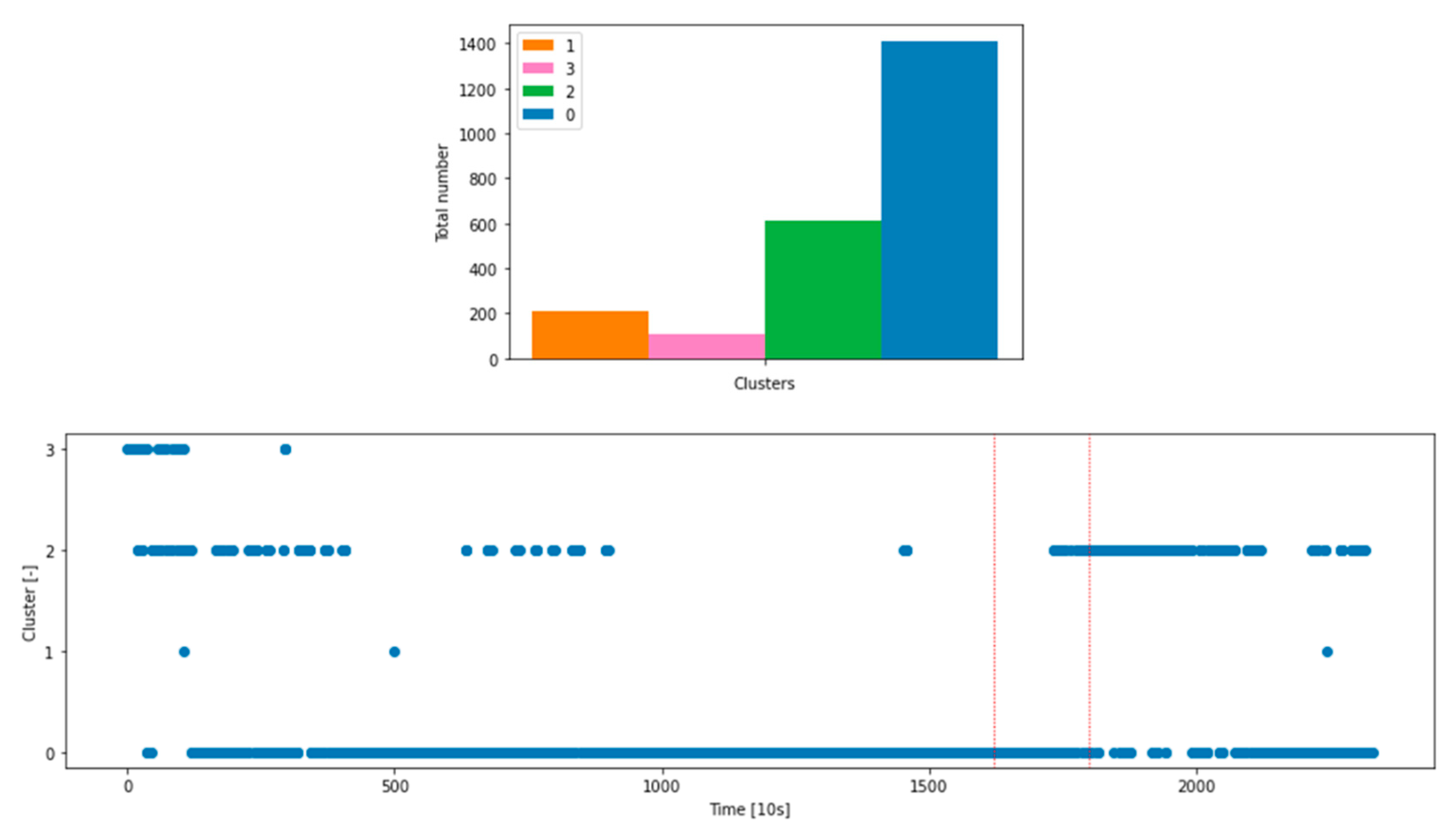

- Hierarchical clustering

- Transient effects during the beginning of the measurement campaign with significant population of more than two clusters, which reflects the associated unsteady strand conditions of the start of casting phase;

- A transition in population of the two most frequently predicted clusters after a measurement time between 16,200 and 18,000 s (4.5–5.0 h, indicated by red vertical lines), where the casting speed increased from vc5 to vc6.

3.3. Dynamic Control of Crater End Position

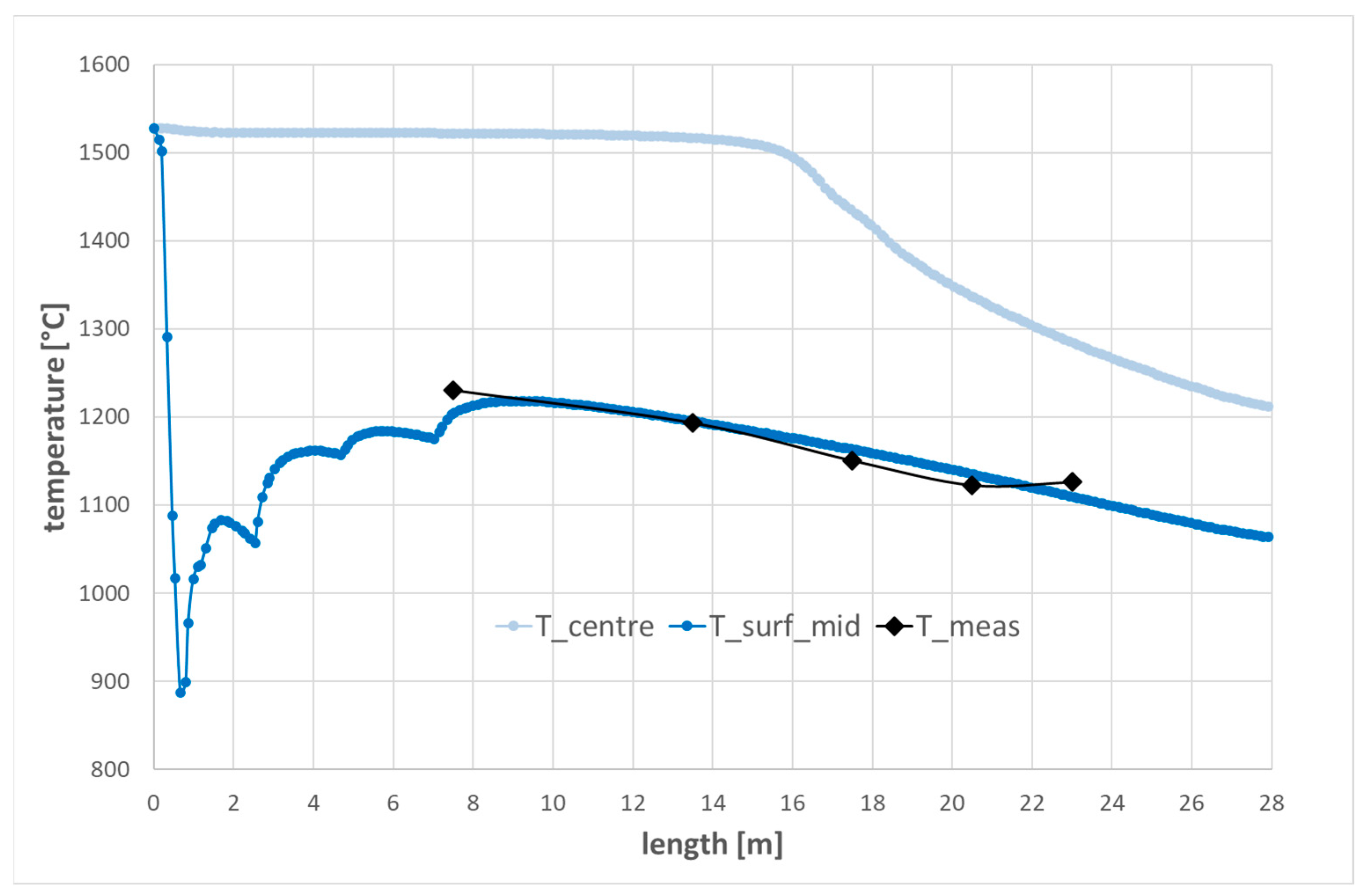

3.3.1. Parameter Studies Regarding Influence of Different Casting Parameters on Strand Temperature and Solidification Front

- Spray water flows in secondary cooling zone;

- Casting speed;

- Initial superheat of steel.

- (1)

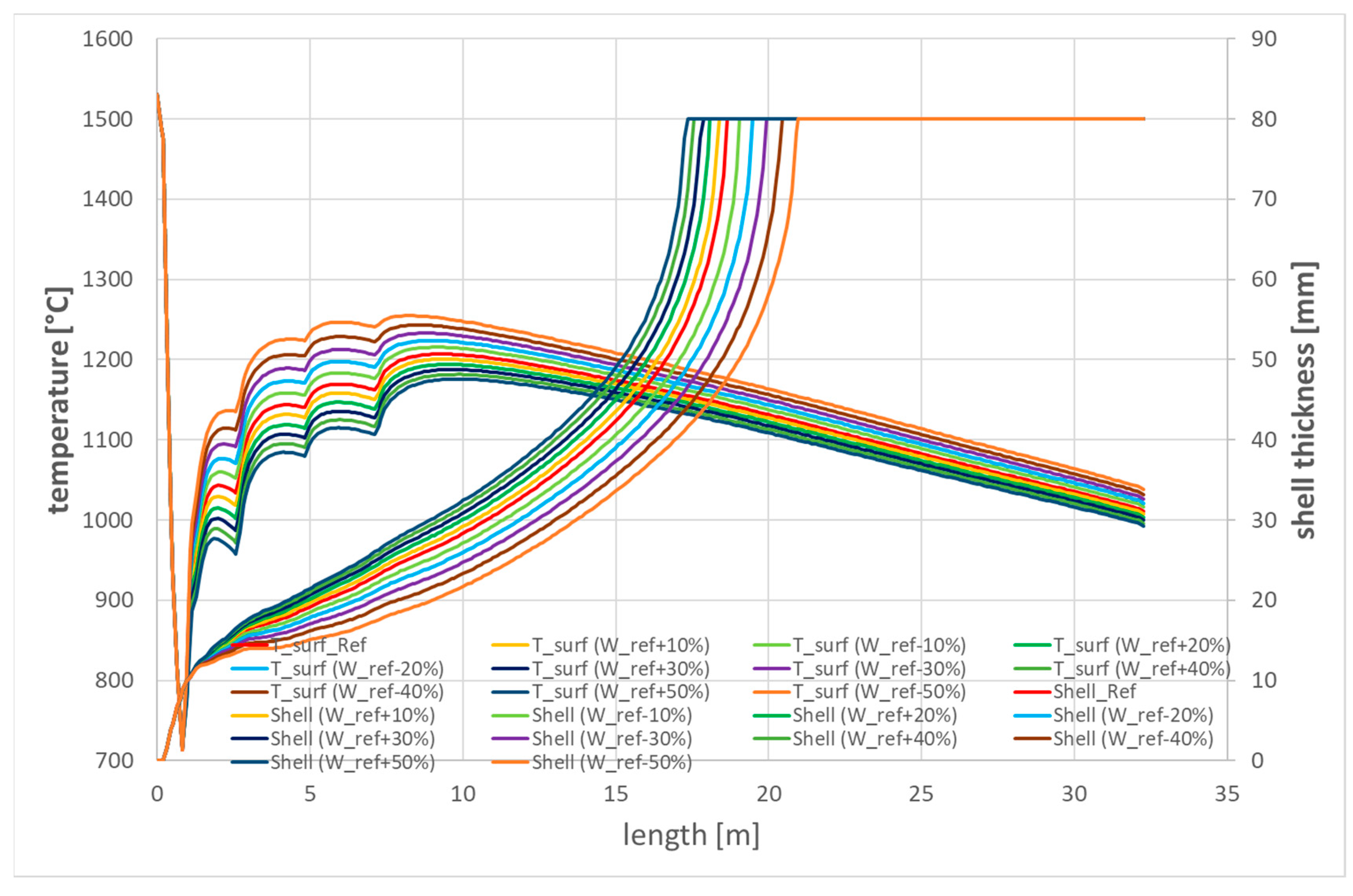

- Variation of spray water flows in secondary cooling zone

- At the end of the last spray water cooling loop, the mid-surface temperatures decrease with the first 10% increase in spray water (from 50% to 60% of reference flow rates) by 19 K and with the last 10% increase (from 140% to 150% of reference flow rates) by 10 K.

- The maximum difference in surface temperatures between the cases of 50% and 150% of reference spray water flow at the end of the last cooling loop is about 135 K;

- It decreases to about 54 K at a length of 23 m, where the cutting torch is located.

- The crater end position moves from 17.4 m for the case with the highest spray water cooling to 21.0 m for the case with the lowest cooling.

- With the first 10% increase in spray water (from 50% to 60% of reference flow rates), the crater end position decreases by 0.58 m, and with the last 10% increase (from 140% to 150% of reference flow rates) by 0.26 m.

- (2)

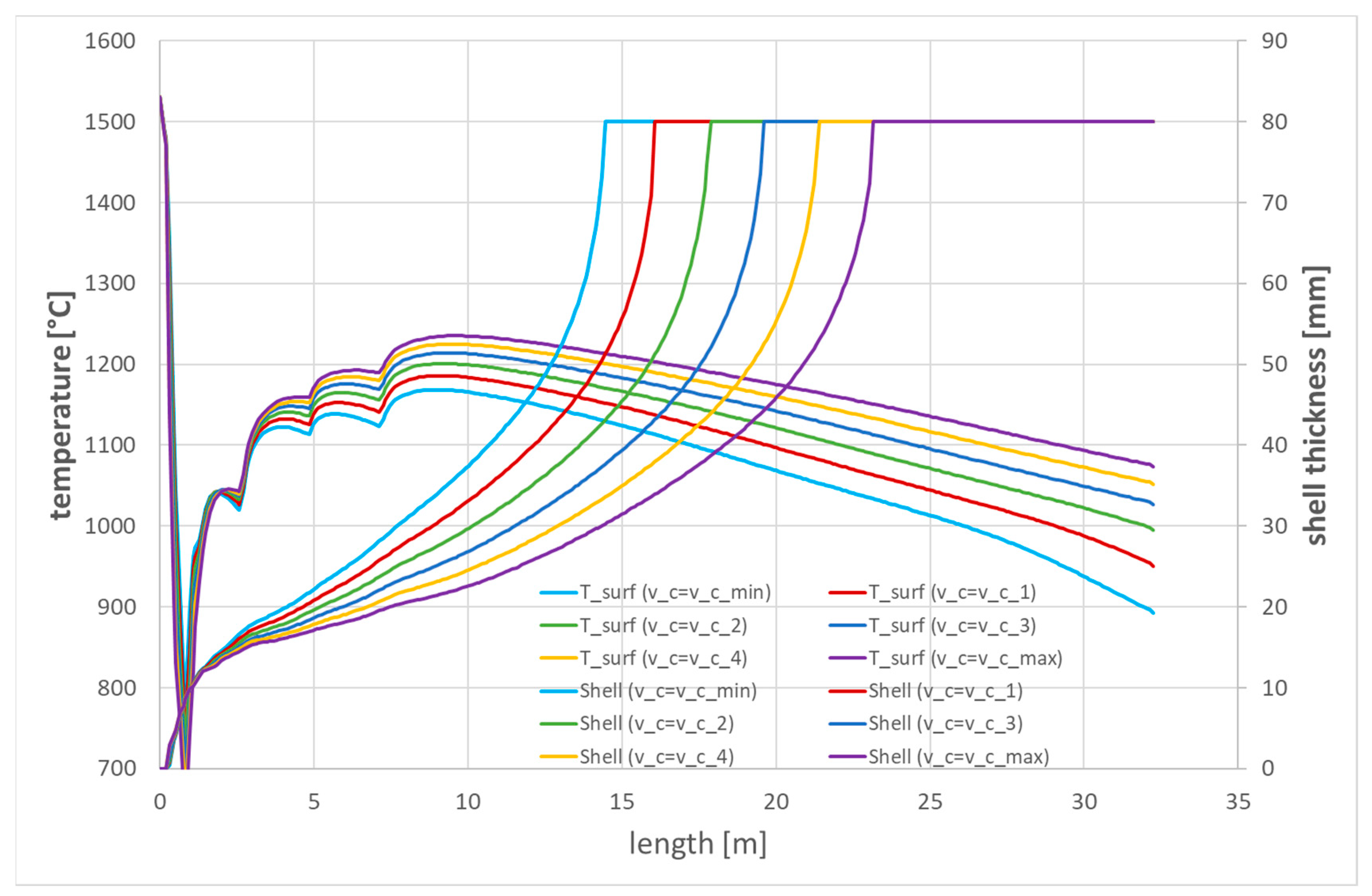

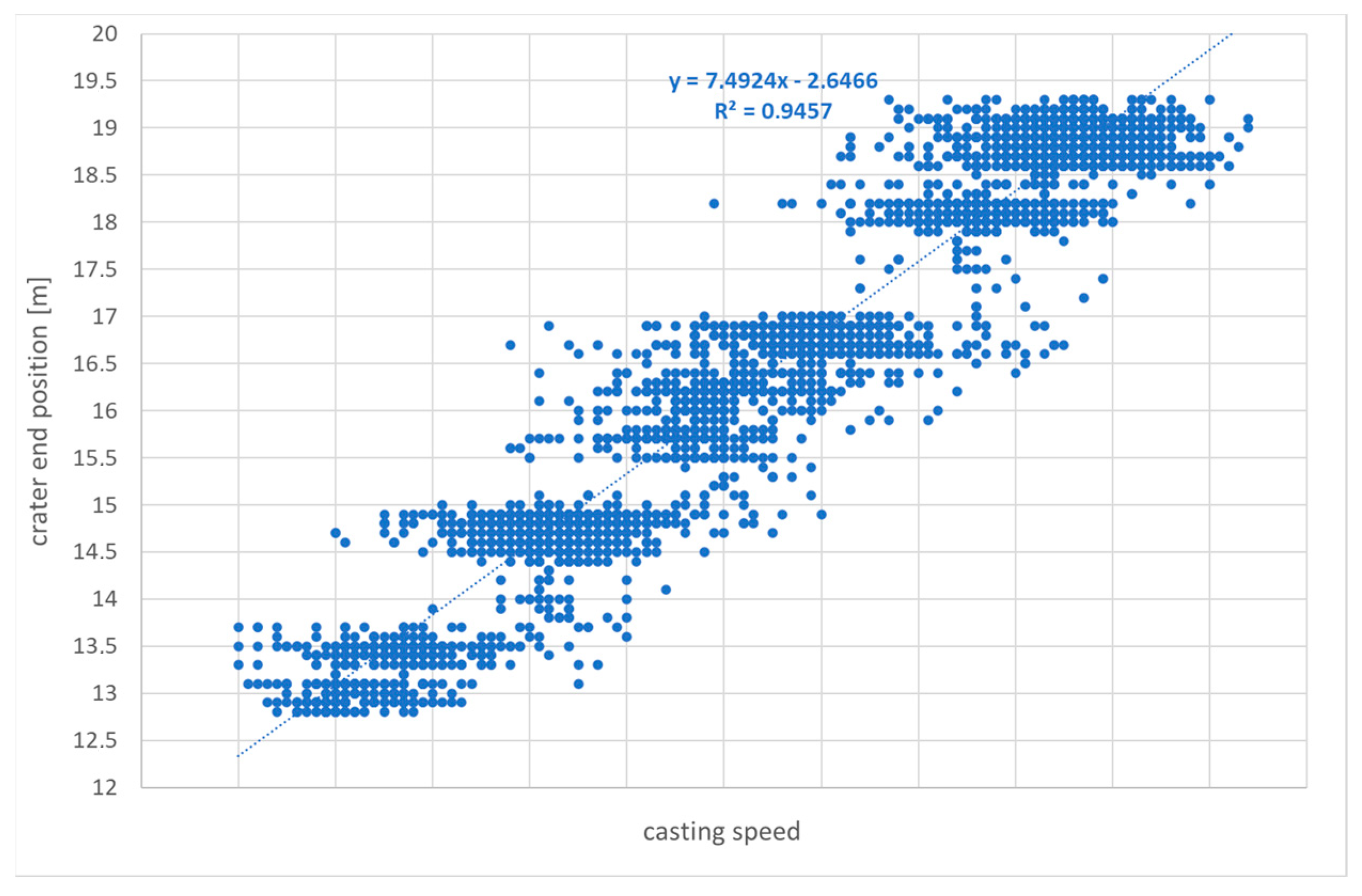

- Variation of casting speed

- At the end of the last spray water cooling loop, the mid-surface temperatures increase with the first increase in casting speed Δvc by 18 K and with the last increase by 9 K.

- The maximum difference in surface temperatures between the casting speed cases of vcmin and vcmax at the end of the last cooling loop is about 66 K;

- It increases to about 113 K at a length of 23 m, where the cutting torch is located.

- The crater end position moves from 14.5 m for the case with the lowest casting speed to 23.2 m for the case with the highest casting speed.

- With the first increase in casting speed Δvc, the crater end position increases by 1.6 m, and with the last increase by 1.8 m.

- (3)

- Variation of superheat of steel poured into the mould

- At the end of the last spray water cooling loop, the mid-surface temperatures increase with each increase of 5 K regarding the initial steel temperature by about 3.4 K.

- The maximum difference in surface temperatures between the cases with initial steel temperature of T0min and T0max at the end of the last cooling loop is about 17 K;

- It decreases to about 13 K at a length of 23 m, where the cutting torch is located.

- With each increase of 5 K regarding the initial steel temperature, the crater end position moves by about 0.2 m towards the cutting torch.

- By increasing the initial steel temperature from T0min to T0max, the crater end position moves from 18.0 m to 19.0 m.

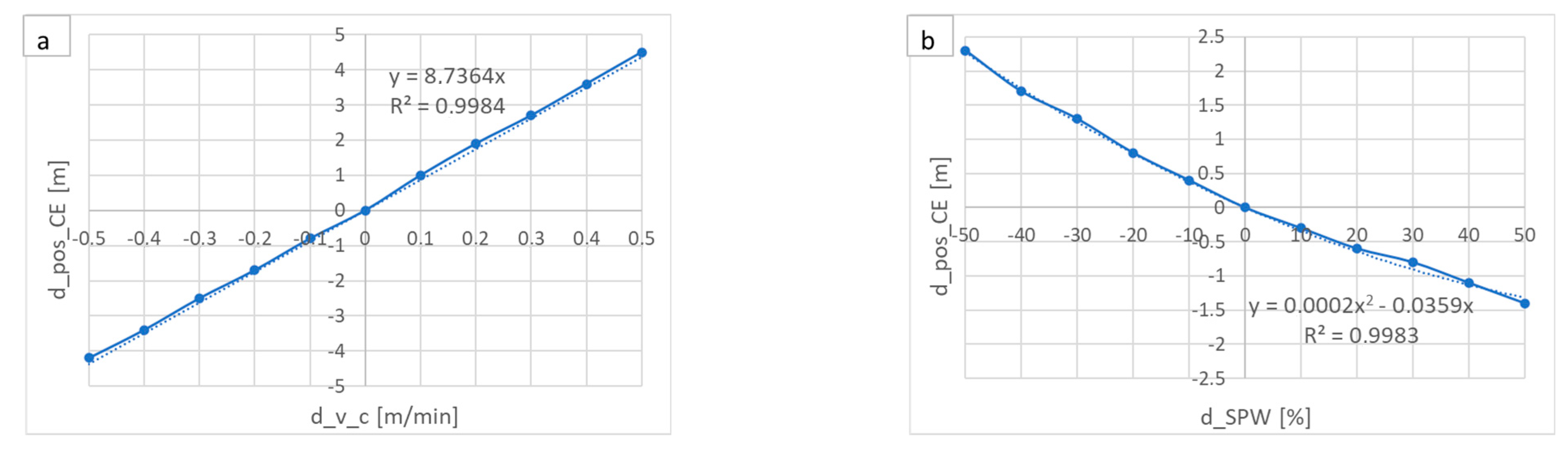

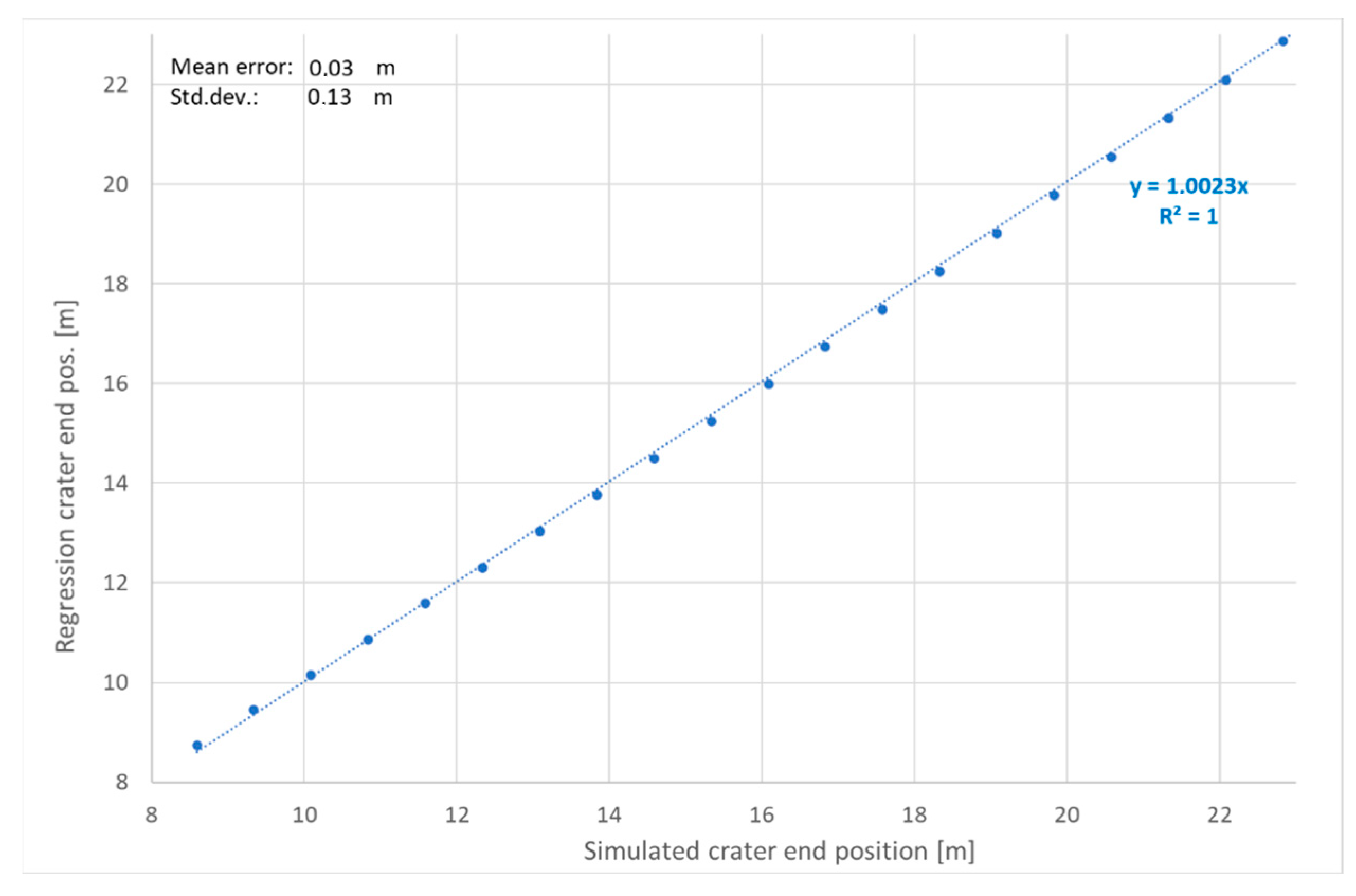

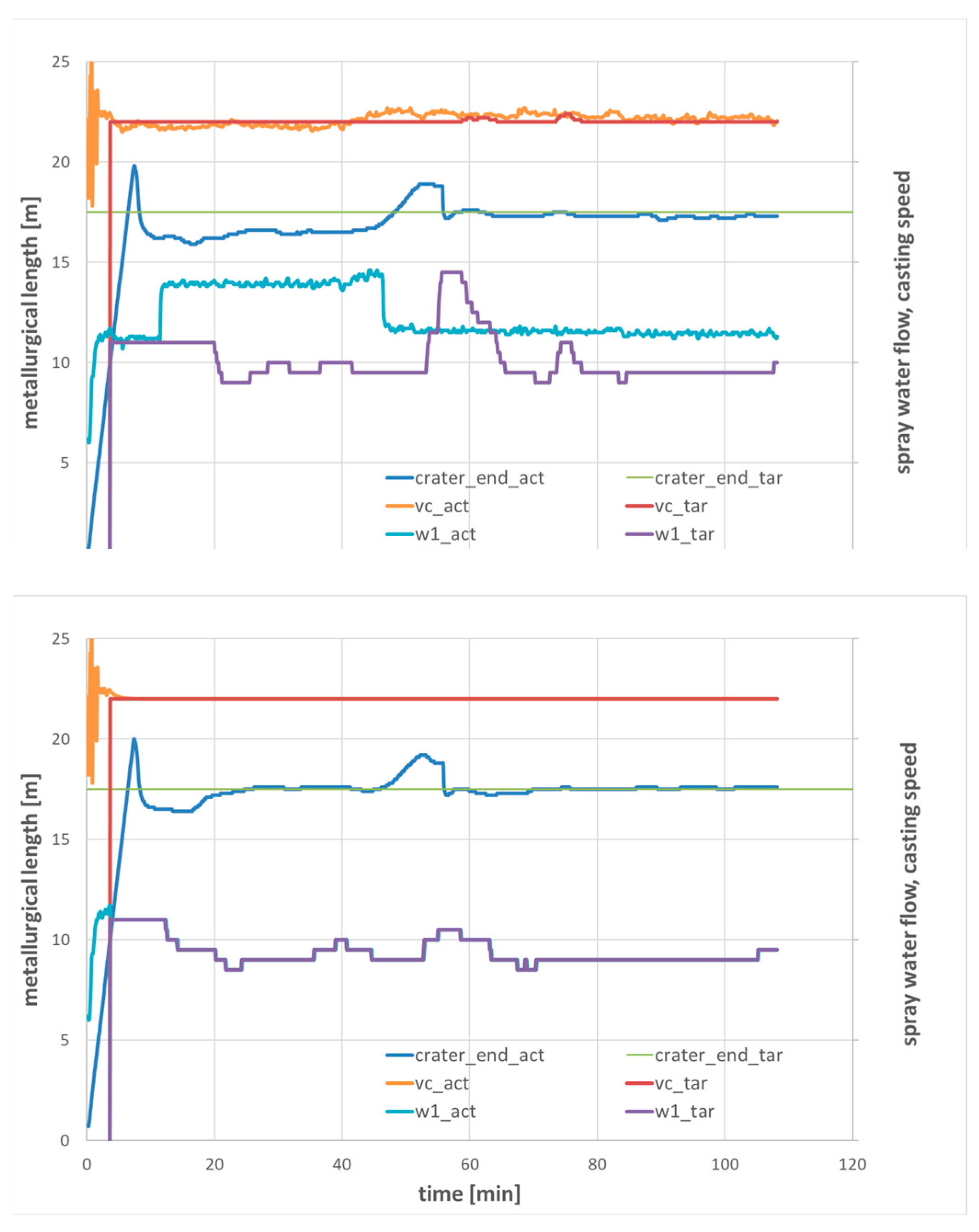

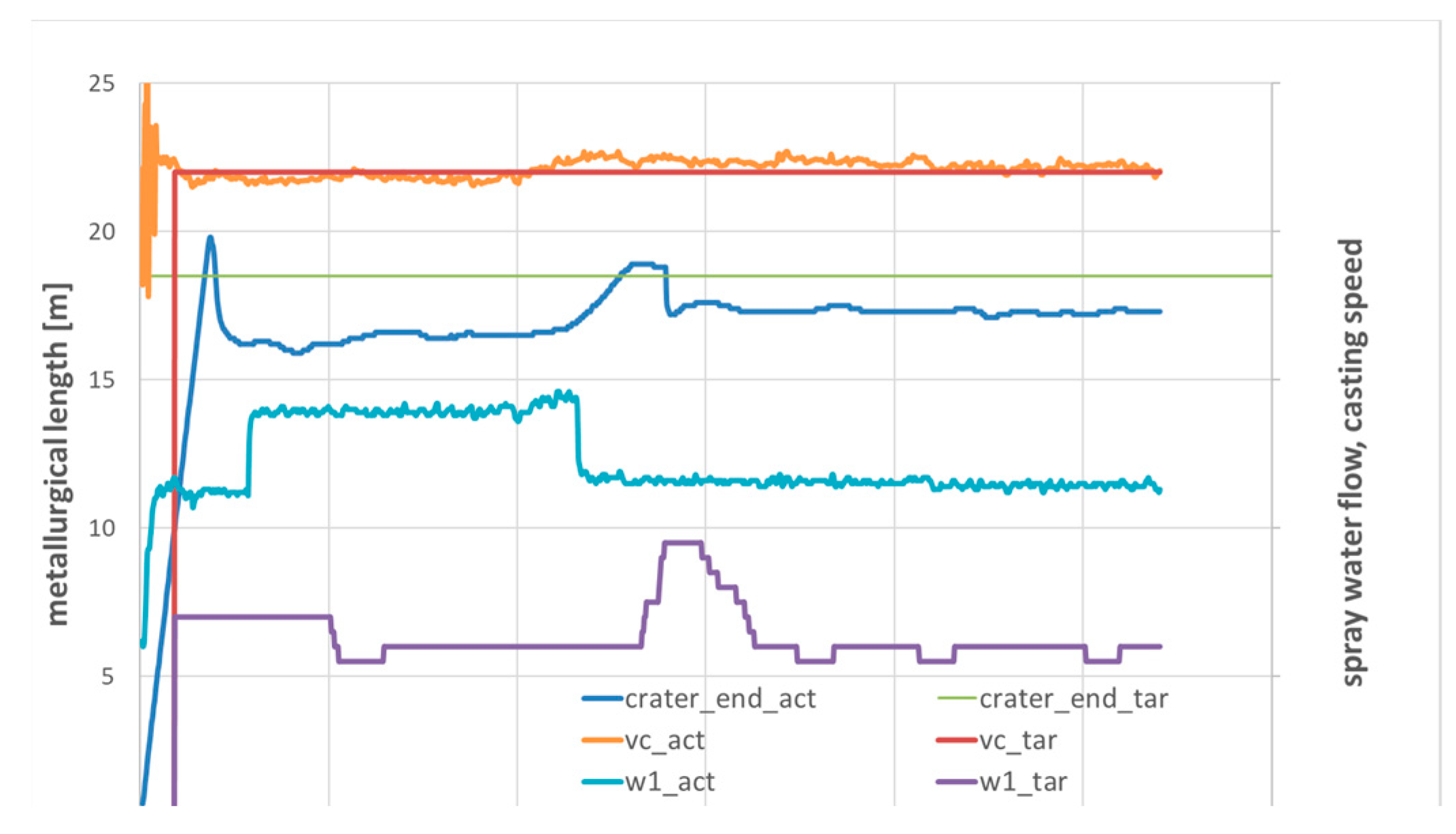

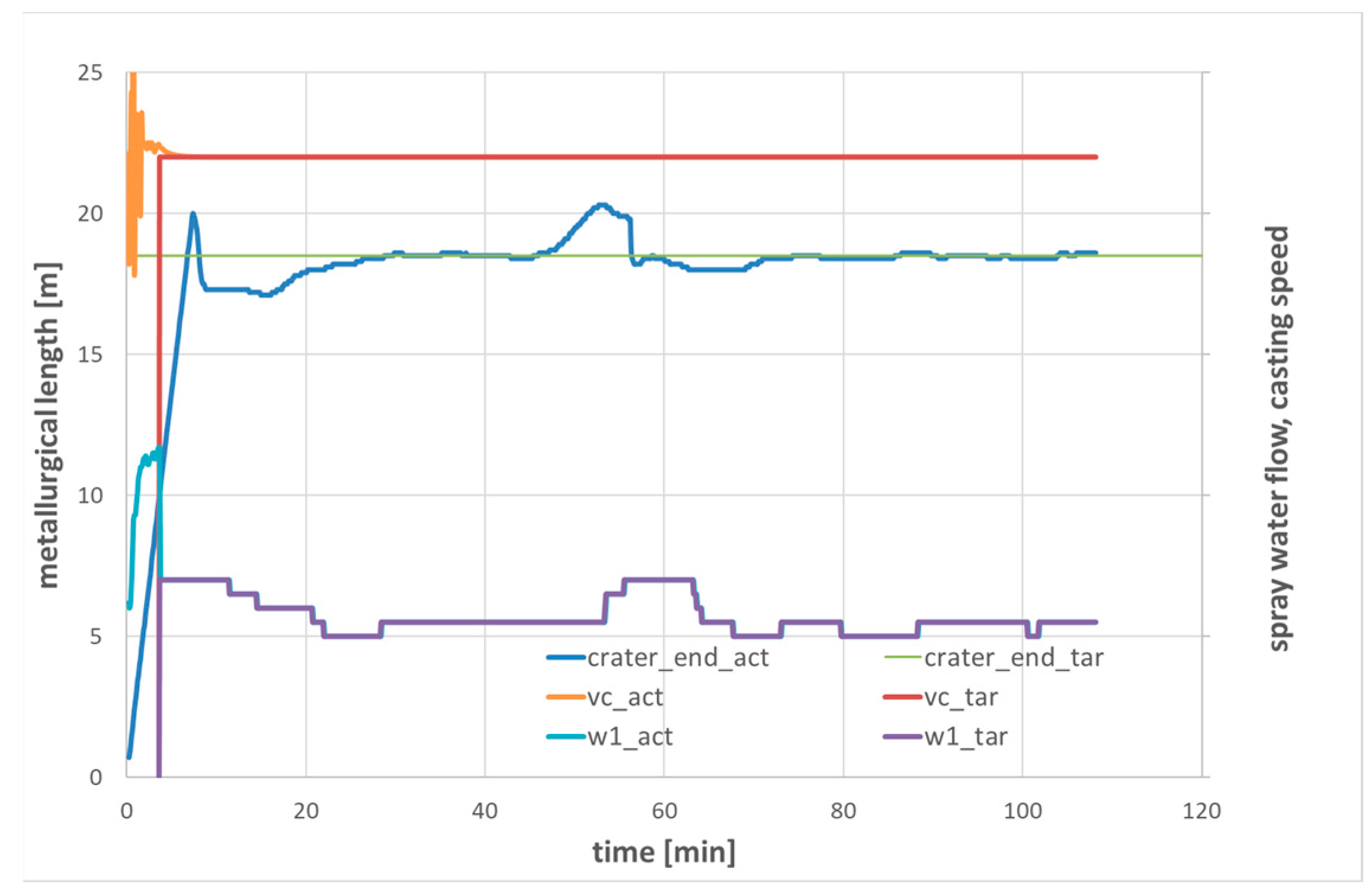

3.3.2. Dynamic Adaptation of Casting Speed and Spray Water Flow Rates

3.4. Operator Information and Advisory System

- Temperature in tundish (“Verteilertemperatur”);

- Temperature of mould water inlet (“Kokillenwasser-EinlassTemp.”);

- Temperature difference between mould water outlet and inlet (“Kokillenwasser-Temp.-Diff.”);

- Flow rate of mould water (“Kokillenwasserdurchfluss”);

- Pressure of spray water zones 1–4 (“Spritzwasserdruck”);

- Crater end position calculated by DynSolidCC model (“Position Sumpfspitze”);

- Shell thickness at mould exit calculated by DynSolidCC model (“Schalendicke …”).

4. Discussion

- Measured casting parameters;

- Simulated 3D temperature field, shell thickness along the strand length and actual crater end position;

- Traffic lights regarding possibly critical or dangerous values for selected casting parameters, shell thickness and crater end position;

- Suggested casting speed and spray water flow rates to adjust a given target crater end position.

- Higher machine availability, i.e., productivity;

- Higher safety;

- Lower maintenance costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- After achievement of defined minimum casting length:Initialise target casting parameters based on regression Formula (7) for given target crater end position with default reference value.

- Check stationary casting conditions, i.e., variations of casting speed, spray water flows and simulated crater end position are within defined tolerances.

- Instationary state → keep target casting parameters from previous cyclic calculation.

- Check deviation of simulated crater end position from target value:∆pos_CE = pos_CE – pos_CE_tar

- Stationary state and |∆pos_CE| within defined tolerance:→ keep actual casting parameters:SPW_i_tar = SPW_iv_c_tar = v_c

- Stationary state and |∆pos_CE| outside defined tolerance:→ calculate target casting parameters from regression Formula (7):

- o

- Determine reference crater end position:pos_CE_ref = pos_CE – (c * d_SPW2 – b * d_SPW + a * d_v_c)

- o

- Check d_pos_CE_tar = pos_CE_tar – pos_CE_ref:

- i.

- d_pos_CE_tar ≥ d_pos_CE_min and d_pos_CE_tar ≤ d_pos_CE_max:d_SPW_tar = b/(2c) – (b2/(4c2) + d_pos_CE_tar/c)1/2d_v_c_tar = 0

- ii.

- d_pos_CE_tar < d_pos_CE_min:d_SPW_tar = d_SPW_maxd_v_c_tar = (d_pos_CE_tar - d_pos_CE_min)/a

- iii.

- d_pos_CE_tar > d_pos_CE_max:d_SPW_tar = d_SPW_mind_v_c_tar = (d_pos_CE_tar - d_pos_CE_max)/a

- o

- Check correction of target casting parameters based on comparison with actual ones: ∆SPW = 100 * (SPW – SPW_tar)/SPW_ref, ∆v_c = v_c – v_c_tarwith thresholds εSPW, εv_c > 0 to be exceeded in case of significant difference |∆pos_CE| > εCE:

- i.

- ∆pos_CE > εCE and ∆SPW > - εSPW and ∆v_c < εv_c:d_SPW_tar’ = d_SPW_tar + εSPW, d_v_c_tar’ = d_v_c_tarif d_SPW_tar’ > d_SPW_max:d_SPW_tar’ = d_SPW_max, d_v_c_tar’ = d_v_c_tar - εv_c

- ii.

- ∆pos_CE < - εCE and ∆SPW < εSPW and ∆v_c > - εv_c:d_SPW_tar’ = d_SPW_tar - εSPW, d_v_c_tar’ = d_v_c_tarif d_SPW_tar’ < d_SPW_min:d_SPW_tar’ = d_SPW_min, d_v_c_tar’ = d_v_c_tar + εv_c

- iii.

- In the remaining cases, no correction is necessary:d_SPW_tar’ = d_SPW_tar, d_v_c_tar’ = d_v_c_tar

- o

- Calculate new target spray water flows and casting speed:SPW_i_tar = SPW_i_ref * (1 + d_SPW_tar’/100)v_c_tar = v_c_ref + d_v_c_tar’

- Use smoothing factor α < 1 to determine moving average values SPW_i_tarav and v_c_tarav for the target casting parameters:SPW_i_tarav = α* SPW_i_taravprev + (1 – α) * SPW_i_tarv_c_tarav = α * v_c_taravprev + (1 – α) * v_c_tarwhere SPW_i_taravprev and v_c_taravprev are the respective average values of the previous cyclic step.

References

- Ramirez Lopez, P.; Björkvall, J.; Sjöström, U.; Lee, P.D.; Mills, K.C.; Jönsson, B.; Janis, J.; Petäjäjärvi, M.; Pirinen, J. Experimental Validation and Industrial Application of a Novel Numerical Model for Continuous Casting of Steel. In Proceedings of the 9th International Conference on CFD in the Minerals and Process Industries, Melbourne, Australia, 10–12 December 2012. [Google Scholar]

- Rödl, S.; Tscheuschner, C. New approaches for numerical simulation of solidification and resulting strains/stresses in the strand shell also for transient casting conditions. In Proceedings of the 8th European Continuous Casting Conference (ECCC), Graz, Austria, 23–26 June 2014. [Google Scholar]

- Jaouen, O.; Costes, F.; Lasne, P. Simulation of continuous casting processes and its thermo-mechanical approach. MPT Int. 2012, 6, 38–39. [Google Scholar]

- Harste, K.; Deisinger, M.; Steinert, I.; Tacke, K.-H. Thermische und mechanische Modelle zum Stranggießen. Stahl Eisen 1995, 115, 111–118. [Google Scholar]

- Spitzer, K.-H.; Harste, K.; Weber, B.; Monheim, P.; Schwerdtfeger, K. Mathematical Model for Thermal Tracking and On-line Control in Continuous Casting. ISIJ Int. 1992, 32, 848–856. [Google Scholar] [CrossRef]

- Schwerdtfeger, K. Heat Withdrawal in Continuous Casting of Steel. In The Making, Shaping and Treating of Steel, 11th ed.; Casting Volume; AISE Steel Foundation: Pittsburgh, PA, USA, 2003. [Google Scholar]

- Holzhauser, J.; Spitzer, K.-H.; Schwerdtfeger, K. Study of Heat Transfer through Layers of Casting Flux, Experiments with a Laboratory Setup Simulating the Conditions in Continuous Casting. Steel Res. Int. 1999, 70, 252. [Google Scholar] [CrossRef]

- Stetina, J.; Klimes, L.; Mauder, T.; Kavicka, F. Numerical Models and their Indispensability for Flexible Control of Continuous Steel Casting. In Proceedings of the 24th International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 3–5 June 2015. [Google Scholar]

- Klimes, L.; Mauder, T.; Stetina, J. Comparison of Regulation Algorithms for Secondary Cooling of Continuous Casting Process. In Proceedings of the 24th International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 3–5 June 2015. [Google Scholar]

- Wang, Z.; Wang, X.; Liu, F.; Yao, M.; Zhang, X.; Vang, L.; Lu, H.; Wang, X. Vibration Method to detect liquid-solid fraction and final solidifying end for continuous casting slab. Steel Res. Int. 2013, 84, 724–731. [Google Scholar] [CrossRef]

- Yukinori, I.; Jun, K.; Koichi, T. Method for Detecting Solidification Completion Position of Continuous Casting Cast Piece, Detector, and Method for Producing Continuous Casting Piece. Patent EP 1707290B1, 10 February 2010. [Google Scholar]

- Lamp, T.; Köchner, H. Method for Determining a Liquid Phase Inside a Billet already Solidified on the Surface Thereof. BFI Patent for vibrometer measurement DE 102006047013, 29 May 2008. [Google Scholar]

- ConSolCast—Materials Processing Institute. Available online: https://www.mpiuk.com/research-project-con-sol-cast.htm (accessed on 29 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schlautmann, M.; Köster, M.; Krieger, W.; Groll, M.; Schuster, R.; Bellmann, J.; Frittella, P. Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets. Appl. Sci. 2023, 13, 885. https://doi.org/10.3390/app13020885

Schlautmann M, Köster M, Krieger W, Groll M, Schuster R, Bellmann J, Frittella P. Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets. Applied Sciences. 2023; 13(2):885. https://doi.org/10.3390/app13020885

Chicago/Turabian StyleSchlautmann, Martin, Marc Köster, Waldemar Krieger, Matthias Groll, Ralf Schuster, Jörg Bellmann, and Piero Frittella. 2023. "Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets" Applied Sciences 13, no. 2: 885. https://doi.org/10.3390/app13020885

APA StyleSchlautmann, M., Köster, M., Krieger, W., Groll, M., Schuster, R., Bellmann, J., & Frittella, P. (2023). Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets. Applied Sciences, 13(2), 885. https://doi.org/10.3390/app13020885