The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives

Abstract

1. Introduction

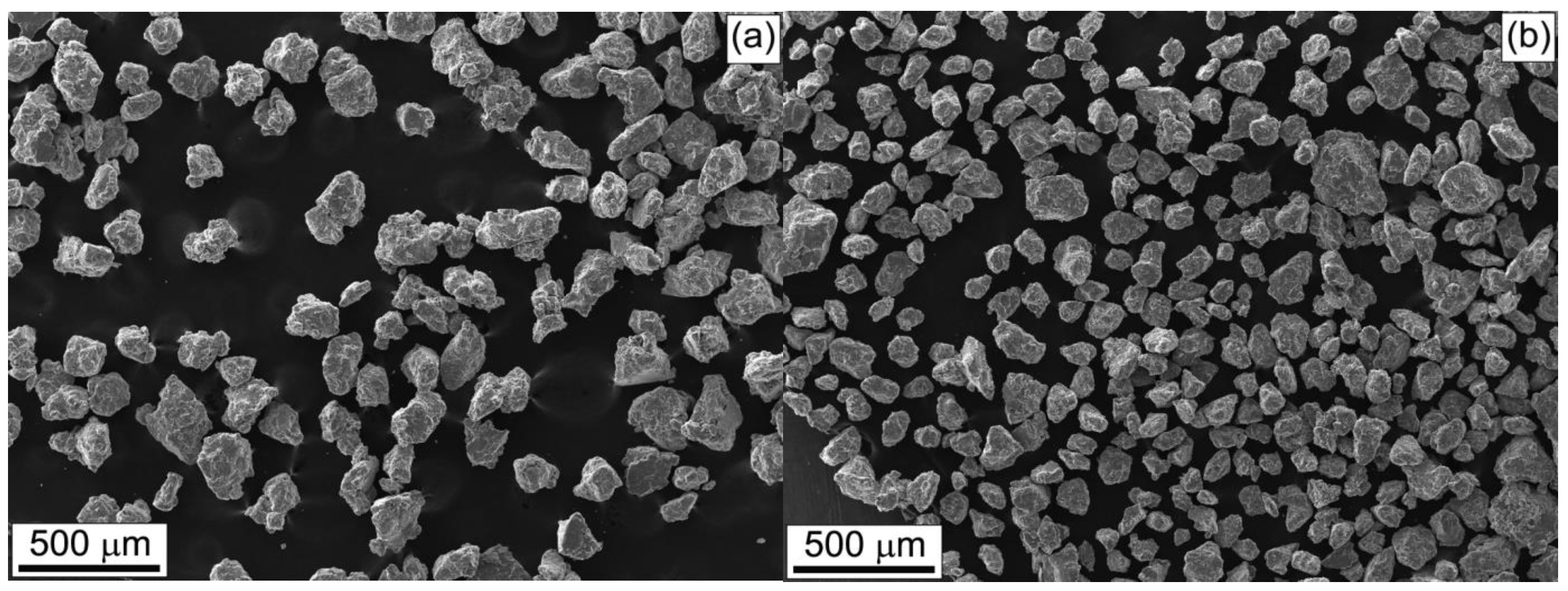

2. Materials and Methods

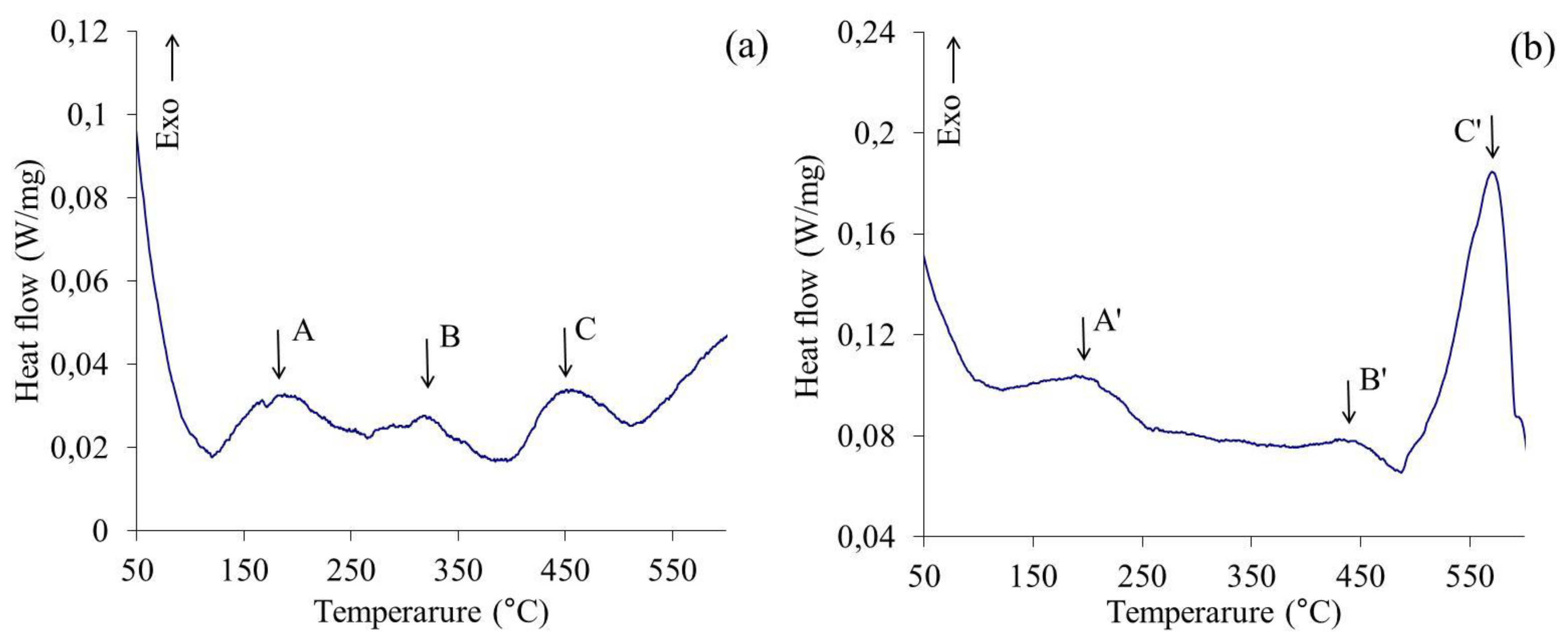

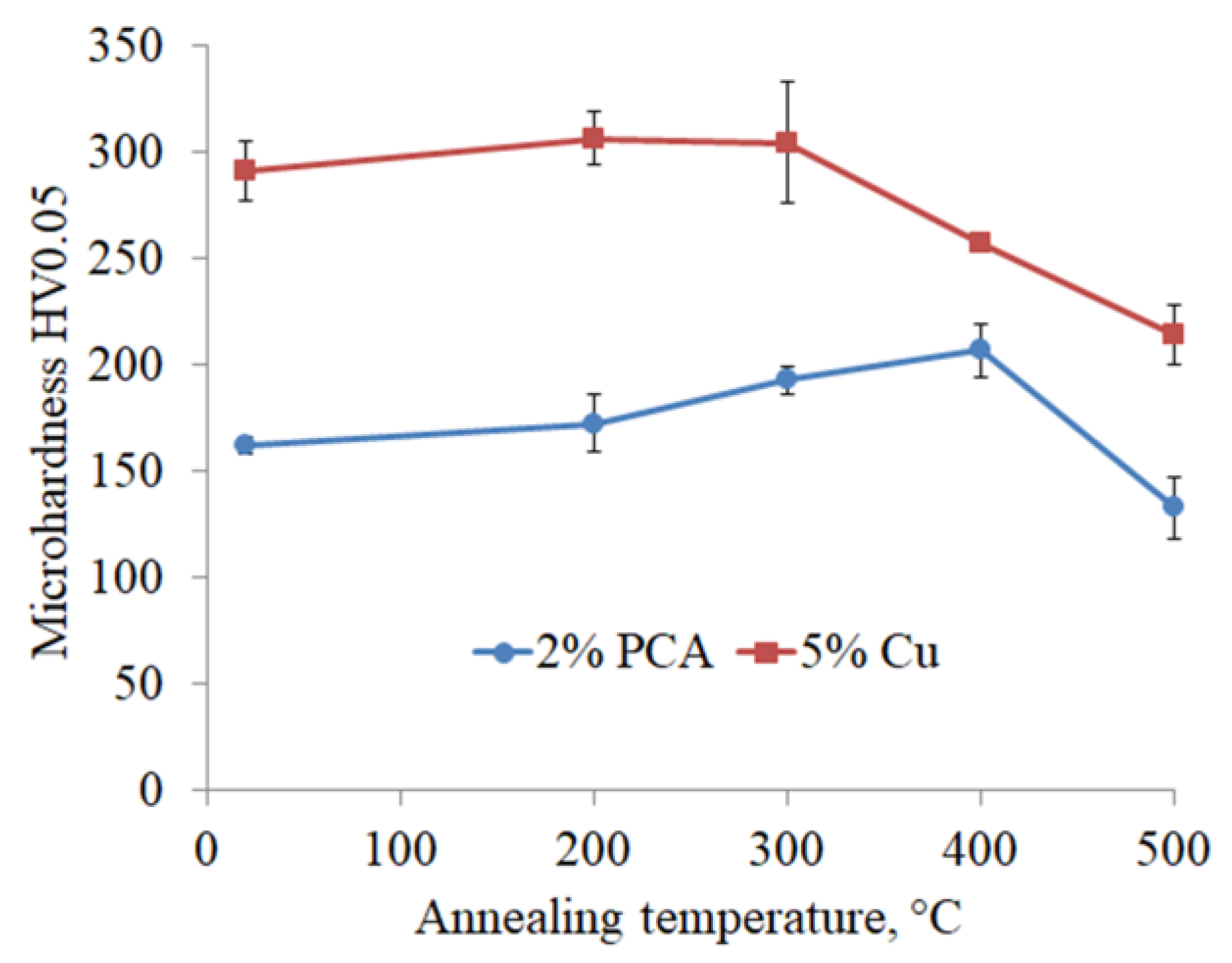

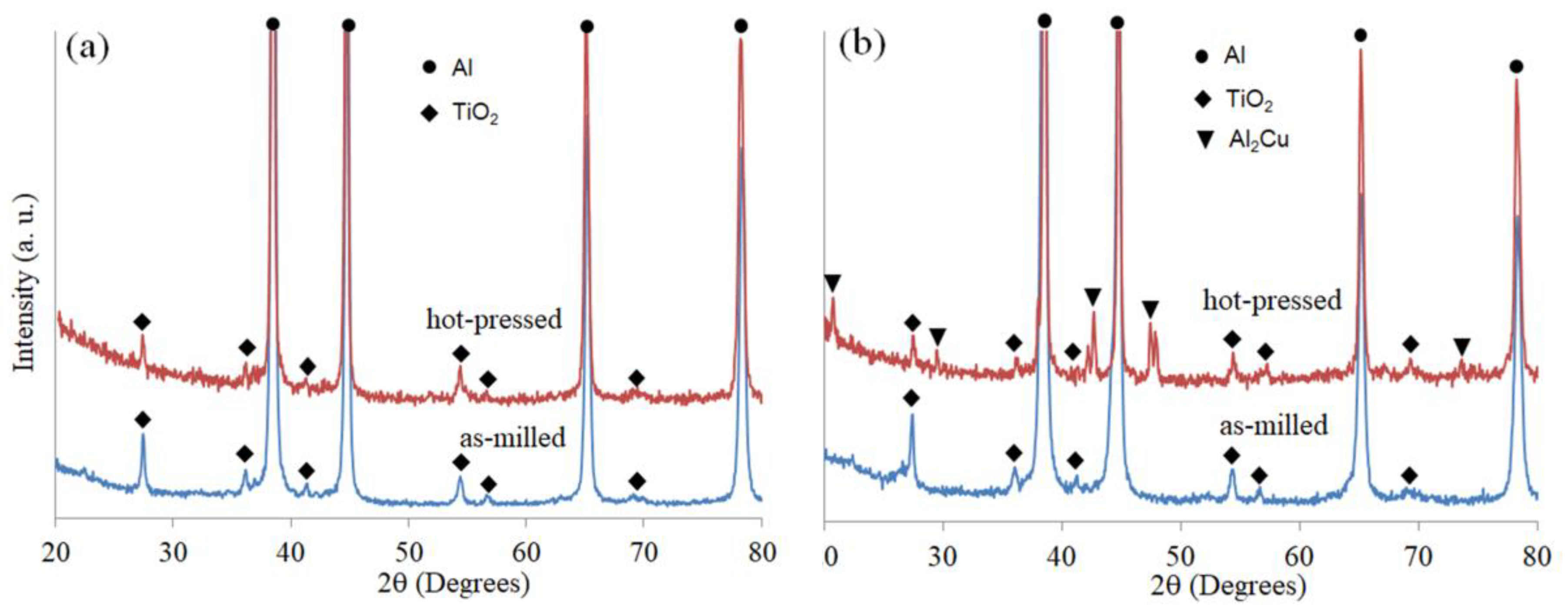

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Singh, H.; Singh, K.; Vardhan, S.; Mohan, S.; Singh, V. A comprehensive review of aluminium matrix composite reinforcement and fabrication methodologies. Funct. Compos. Struct. 2021, 3, 015007. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S. Aluminum metal matrix composites—A review. Rev. Adv. Mater. Sci. 2014, 38, 55–60. [Google Scholar]

- Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Microstructural Analysis and Mechanical Properties of a Hybrid Al/Fe2O3/Ag Nano-Composite. Appl. Sci. 2022, 12, 4730. [Google Scholar] [CrossRef]

- Shukla, M.; Dhakad, S.K.; Agarwal, P.; Pradhan, M.K. Characteristic behaviour of aluminium metal matrix composites: A review. Mater. Today Proc. 2018, 5, 5830–5836. [Google Scholar] [CrossRef]

- Rofman, O.V.; Prosviryakov, A.S.; Kotov, A.D.; Bazlov, A.I.; Milovich, P.O.; Karunakaran, G.; Mikhaylovskaya, A.V. Fabrication of AA2024/SiCp Metal Matrix Composite by Mechanical Alloying. Met. Mater. Int. 2022, 28, 811–822. [Google Scholar] [CrossRef]

- Nayak, K.C.; Rane, K.K.; Date, P.P.; Srivatsan, T.S. Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters. Appl. Sci. 2022, 12, 8843. [Google Scholar] [CrossRef]

- Kang, Y.-C.; Chan, S.L.-I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Poirier, D.; Drew, R.A.L.; Trudeau, M.L.; Gauvin, R. Fabrication and properties of mechanically milled alumina/aluminum nanocomposites. Mater. Sci. Eng. A 2010, 527, 7605–7614. [Google Scholar] [CrossRef]

- Mazahery, A.; Ostadshabani, M. Investigation on mechanical properties of nano-Al2O3-reinforced aluminum matrix composites. J. Alloy. Compd. 2011, 45, 2579–2586. [Google Scholar] [CrossRef]

- Pazhouhanfar, Y.; Eghbali, B. Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater. Sci. Eng. A 2018, 710, 172–180. [Google Scholar] [CrossRef]

- Xi, L.X.; Zhang, H.; Wang, P.; Li, H.C.; Prashanth, K.G.; Lin, K.J.; Kaban, I.; Gu, D.D. Comparative investigation of microstructure, mechanical properties and strengthening mechanisms of Al-12Si/TiB2 fabricated by selective laser melting and hot pressing. Ceram. Int. 2018, 44, 17635–17642. [Google Scholar] [CrossRef]

- Zhang, Z.; Topping, T.; Li, Y.; Vogt, R.; Zhou, Y.; Haines, C.; Paras, J.; Kapoor, D.; Schoenung, J.M.; Lavernia, E.J. Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles. Scr. Mater. 2011, 65, 652–655. [Google Scholar] [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E. Mechanical properties and wear behavior of Al–2 wt.% Cu alloy composites reinforced by B4C nanoparticles and fabricated by mechanical milling and hot extrusion. Mater. Charact. 2012, 67, 119–128. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R.; Kambali, R.S. An investigation of the synthesis, consolidation and mechanical behaviour of Al 6061 nanocomposites reinforced by TiC via mechanical alloying. Mater. Des. 2014, 57, 394–404. [Google Scholar] [CrossRef]

- Mohapatra, S.; Chaubey, A.K.; Mishra, D.K.; Singh, S.K. Fabrication of Al–TiC composites by hot consolidation technique: Its microstructure and mechanical properties. J. Mater. Res. Technol. 2016, 5, 117–122. [Google Scholar] [CrossRef]

- Arora, R.; Kumar, S.; Singh, G.; Pandey, O.P. Influence of particle size and temperature on the wear properties of rutile-reinforced aluminium metal matrix composite. J. Compos. Mater. 2015, 49, 843–852. [Google Scholar] [CrossRef]

- Karunanithi, R.; Ghosh, K.S.; Bera, S. Effect of Dispersoid Size and Volume Fraction on Aging Behavior and Mechanical Properties of TiO2-Dispersed AA7075 Alloy Composites. Metall. Mater. Trans. A 2014, 45, 4062–4072. [Google Scholar] [CrossRef]

- Kumar, A.P.; Meignanamoorthy, M.; Ravichandran, M. Influence of sintering temperature and the amount of reinforcement on the microstructure and properties of Al–TiO2 composites. Int. J. Mech. Eng. Technol. 2018, 9, 826–832. [Google Scholar]

- Kumar, C.A.V.; Rajadurai, J.S. Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy. Trans. Nonferrous Met. Soc. China 2016, 26, 63–73. [Google Scholar] [CrossRef]

- Lata, S.; Pandey, A.; Labhansh; Sharma, A.; Meena, K.; Rana, R.; Lal, R. An Experimental Study and Analysis of the Mechanical Properties of Titanium Dioxide Reinforced Aluminum (AA 5051) Composite. Mater. Today Proc. 2018, 5, 6090–6097. [Google Scholar] [CrossRef]

- Mathur, V.; Prabhu, S.R.B.; Patel, M.G.C.; Shettigar, A.K. Reinforcement of titanium dioxide nanoparticles in aluminium alloy AA 5052 through friction stir process. Adv. Mater. Process. Technol. 2019, 5, 329–337. [Google Scholar] [CrossRef]

- Abraham, S.J.; Dinaharan, I.; Selvam, J.D.R.; Akinlabi, E.T. Microstructural Characterization and Tensile Behavior of Rutile (TiO2)-Reinforced AA6063 Aluminum Matrix Composites Prepared by Friction Stir Processing. Acta Metall. Sin. 2019, 32, 52–62. [Google Scholar] [CrossRef]

- Madhu, H.C.; Kumar, P.A.; Perugu, C.S.; Kailas, S.V. Microstructure and Mechanical Properties of Friction Stir Process Derived Al-TiO2 Nanocomposite. J. Mater. Eng. Perform. 2018, 27, 1318–1326. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Ebadzadeh, T. TiO2 ceramic particles-reinforced aluminum matrix composite prepared by conventional, microwave, and spark plasma sintering. J. Compos. Mater. 2018, 52, 2609–2619. [Google Scholar] [CrossRef]

- Ma, K.; Lavernia, E.J.; Schoenung, J.M. Particulate reinforced aluminum alloy matrix composites—A review on the effect of microconstituents. Rev. Adv. Mater. Sci. 2017, 48, 91–104. [Google Scholar]

- Jia, D.C. Influence of SiC particulate size on the microstructural evolution and mechanical properties of Al–6Ti–6Nb matrix composites. Mater. Sci. Eng. A 2000, 289, 83–90. [Google Scholar] [CrossRef]

- Mula, S.; Padhi, P.; Panigrani, S.C.; Pabi, S.K.; Gosh, S. On structure and mechanical properties of ultrasonically cast Al–2%Al2O3nanocomposite. Mater. Res. Bull. 2009, 44, 1154–1160. [Google Scholar] [CrossRef]

- Travitzky, N.A. Effect of metal volume fraction on the mechanical properties of alumina/aluminum composites. J. Mater. Sci. 2001, 36, 4459–4463. [Google Scholar] [CrossRef]

- Miserez, A.; Stucklin, S.; Rossoll, A.; San Marchi, C.; Mortensen, A. Influence of heat treatment and particle shape on mechanical properties of infiltrated Al2O3 particle reinforced Al–2 wt% Cu. Mater. Sci. Technol. 2002, 18, 1461–1470. [Google Scholar] [CrossRef]

- Luan, B.F.; Wu, G.H.; Liu, W.; Hansen, N.; Lei, T. High strength Al2O3 composites—effect of particles, subgrains and precipitates. Mater. Sci. Technol. 2005, 21, 1440–1443. [Google Scholar] [CrossRef]

- Qin, X.H.; Jiang, D.L.; Dong, S.M. Nanometer, submicron and micron sized aluminum powder prepared by semi-solid mechanical stirring method with addition of ceramic particles. Mater. Sci. Eng. A 2004, 385, 31–37. [Google Scholar] [CrossRef]

- Ozdemir, I.; Ahrens, S.; Mucklich, S. Nanocrystaline Al–Al2O3 and SiC composites produced by high energy ball milling. J. Mater. Proc. Technol. 2008, 205, 111–118. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Zhou, D.S.; Tang, J.; Qiu, F.; Wang, J.G.; Jiang, Q.C. Effects of nano-TiCp on the microstructures and tensile properties of TiCp/Al–Cu composites. Mater. Charact. 2014, 94, 80–85. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Liu, J.; Wang, H.; Wang, J.; Zhu, L.; Jiang, Q. Microstructure and tensile properties of in situ synthesized nano-sized TiCx/2009Al composites. Mater. Des. 2015, 79, 68–72. [Google Scholar] [CrossRef]

- Han, B.Q.; Huang, J.Y.; Zhu, Y.T.; Lavernia, E.J. Effect of strain rate on the ductility of a nanostructured Al alloy. Scripta Mater. 2006, 54, 1175–1180. [Google Scholar] [CrossRef]

- Ramezanalizadeh, H.; Emamy, M.; Shokouhimehr, M. A novel aluminum based nanocomposite with high strength and good ductility. J. Alloys Compd. 2015, 649, 461–473. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical Alloying and Milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Lü, L.; Lai, M.O. Mechanical Alloying; Kluwer Academic Publishers: Boston, MA, USA, 1998. [Google Scholar]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Kumar, A.P.; Muthaiah, V.S.; Mula, S. Effect of Nb, Y and Zr on thermal stability of nanocrystalline Al-4.5 wt.% Cu alloy prepared by mechanical alloying. J. Alloys Compd. 2017, 722, 617–627. [Google Scholar] [CrossRef]

- Moon, K.I.; Chang, K.Y.; Lee, K.S. The effect of ternary addition on the formation and the thermal stability of L12 Al3Zr alloy with nanocrystalline structure by mechanical alloying. J. Alloys Compd. 2000, 312, 273–283. [Google Scholar] [CrossRef]

- Al-Aqeeli, N.; Mendoza-Suarez, G.; Suryanarayana, C.; Drew, R.A.L. Development of new Al-based nanocomposites by mechanical alloying. Mater. Sci. Eng. A 2008, 480, 392–396. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D. Strengthening of mechanically alloyed Al-based alloy with high Zr contents. Mater. Sci. Eng. A 2018, 713, 174–179. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D.; Tabachkova, N.Y. Microstructural characterization of mechanically alloyed Al–Cu–Mn alloy with zirconium. Mater. Sci. Eng. A 2015, 623, 109–113. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Shcherbachev, K.D.; Tabachkova, N.Y. Investigation of nanostructured Al-10 wt.% Zr material prepared by ball milling for high temperature applications. Mater. Charact. 2017, 123, 173–177. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Klassen, T.; Ivanov, E. Synthesis of nanocomposites and amorphous alloys by mechanical alloying. J. Mater. Sci. 2011, 46, 6301–6315. [Google Scholar] [CrossRef]

- Nguyen, H.-V.; Kim, J.-S.; Kwon, Y.-S.; Kim, J.-C. Amorphous Ti–Cu–Ni–Al alloys prepared by mechanical alloying. J. Mater. Sci. 2009, 44, 2700–2704. [Google Scholar] [CrossRef]

- Urban, P.; Ternero, F.; Caballero, E.S.; Nandyala, S.; Montes, J.M.; Cuevas, F.G. Amorphous Al-Ti Powders Prepared by Mechanical Alloying and Consolidated by Electrical Resistance Sintering. Metals 2019, 9, 1140. [Google Scholar] [CrossRef]

- Lakra, S.; Bandyopadhyay, T.K.; Das, S.; Das, K. Synthesis and characterization of in-situ (Al-Al3Ti-Al2O3)/Al dual matrix composite. J. Alloys Compd. 2020, 842, 155745. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Reddy, B.S.B.; Das, S.; Das, K. In-situ Al-based bulk nanocomposites by solid-state aluminothermic reaction in Al–Ti–O system. J. Alloys Compd. 2009, 475, 178–183. [Google Scholar] [CrossRef]

- Liu, Z.; Raynova, S.; Zhang, D.; Gabbitas, B. Study on the self sustained reactions in an Al-TiO2 composite powder produced by high-energy mechanical milling. Mater. Sci. Eng. A 2007, 448–451, 1107–1110. [Google Scholar] [CrossRef]

- Feng, C.F.; Froyen, L. Formation of Al3Ti and Al2O3 from an Al-TiO2 system for preparing in-situ aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 385–390. [Google Scholar] [CrossRef]

- Welham, N.J. Mechanical activation of the formation of an alumina-titanium trialuminide composite. Intermetallics 1998, 6, 363–368. [Google Scholar] [CrossRef]

- Shen, Y.F.; Zou, Z.G.; Xiao, Z.G.; Liu, K.; Long, F.; Wu, Y. Properties and electronic structures of titanium aluminides-alumina composites from in-situ SHS process. Mater. Sci. Eng. A 2011, 528, 2100–2105. [Google Scholar] [CrossRef]

- Zhang, D.L.; Ying, D.Y.; Munroe, P. Formation of Al2O3 during heating of an Al/TiO2nanocomposite powder. J. Mater. Res. 2005, 20, 307–313. [Google Scholar] [CrossRef]

- Ying, D.Y.; Zhang, D.L.; Newby, M. Solid-state reactions during heating mechanically milled Al/TiO2 composite powders. Metall. Mater. Trans. A 2004, 35, 2115–2125. [Google Scholar] [CrossRef]

- Liu, Z.G.; Raynova, S.; Zhang, D.L. Investigation of a discus-milling process using a powder mixture of Al and TiO2. Metall. Mater. Trans. A 2006, 37, 225–233. [Google Scholar] [CrossRef]

- Alamolhoda, S.; Heshmati-Manesh, S.; Ataie, A. Mechano-thermal treatment of TiO2-Al powder mixture to prepare TiAl/Al2O3 composite. Met. Mater. Int. 2011, 17, 743–748. [Google Scholar] [CrossRef]

- Alamolhoda, S.; Heshmati-Manesh, S.; Ataie, A. Role of intensive milling in mechano-thermal processing of TiAl/Al2O3nano-composite. Adv. Powder Technol. 2012, 23, 343–348. [Google Scholar] [CrossRef]

- Chen, W.; Xiao, H.; Fu, Z.; Fang, S.; Zhu, D. Reactive hot pressing and mechanical properties of TiAl3/Ti3AlC2/Al2O3 in situ composite. Mater. Des. 2013, 49, 929–934. [Google Scholar] [CrossRef]

- Welham, N.J. Mechanical activation of the solid-state reaction between Al and TiO2. Mater. Sci. Eng. A 2002, 255, 81–89. [Google Scholar] [CrossRef]

- Setoudeh, N.; Welham, N.J. Effect of carbon on mechanically induced self-sustaining reactions (MSR) in TiO2–Al–C mixtures. Int. J. Refract. Met. Hard Mater. 2016, 54, 210–215. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Bazlov, A.I.; Loginova, I.S. Effect of Cu addition on microstructural evolution and hardening of mechanically alloyed Al-Ti-O in-situ composite. Trans. Nonferrous Met. Soc. China 2020, 30, 1135–1147. [Google Scholar] [CrossRef]

- Shelekhov, E.V.; Sviridova, T.A. Programs for X-ray analysis of polycrystals. Met. Sci. Heat. Treat. 2000, 42, 309–313. [Google Scholar] [CrossRef]

- Starink, M.J. Analysis of aluminium based alloys by calorimetry: Quantitative analysis of reactions and reaction kinetics. Int. Mater. Rev. 2004, 49, 191–226. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Amador, D.; Ruiz-Navas, E.M.; Torralba, J.M. Solid solution in Al–4.5 wt% Cu produced by mechanical alloying. Mater. Sci. Eng. A 2006, 433, 45–49. [Google Scholar] [CrossRef]

- Kleiner, S.; Bertocco, F.; Khalid, F.A.; Beffort, O. Decomposition of process control agent during mechanical milling and its influence on displacement reactions in the Al–TiO2 system. Mater. Chem. Phys. 2005, 89, 362–366. [Google Scholar] [CrossRef]

- Zhou, F.; Lee, J.; Dallek, S.; Lavernia, E.J. High grain size stability of nanocrystalline Al prepared by mechanical attrition. J. Mater. Res. 2001, 16, 3451–3458. [Google Scholar] [CrossRef]

- Evirgen, A.; Öveçoğlu, M.L. Characterization investigations of a mechanically alloyed and sintered Al–2wt%Cu alloy reinforced with WC particles. J. Alloys Compd. 2010, 496, 212–217. [Google Scholar] [CrossRef]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef]

- Adachi, H.; Miyajima, Y.; Sato, M.; Tsuji, N. Evaluation of Dislocation Density for 1100 Aluminum with Different Grain Size during Tensile Deformation by Using In-Situ X-ray Diffraction Technique. Mater. Trans. 2015, 56, 671–678. [Google Scholar] [CrossRef]

- Morris, D.G. The origins of strengthening in nanostructured metals and alloys. Rev. Metal. 2010, 46, 173–186. [Google Scholar] [CrossRef]

| Initial Composition | Preparation Method | Final Phase Composition | Hardness | Strength (Compressive/Tensile/Bending) | Ref. |

|---|---|---|---|---|---|

| AA7075–(5–30) vol.% TiO2 | MA + sintering | Al, TiO2, MgTiO3, ZnO | 100–168 HV | — | [18] |

| Al–(3–12) wt.% TiO2 | ball milling + sintering | Al, TiO2 | 86 HV (max.) | σUCS = 158 MPa (max.) | [19] |

| Al–15%SiC–(4–12) wt.% TiO2 | mixing + sintering | Al, TiO2, SiC | 45–75 HV | — | [20] |

| AA5051–(5–15) wt.% TiO2 | stir casting | Al, TiO2 | 42–83 HB | σUTS = 185–450 MPa | [21] |

| AA6063–(6–18) vol.% TiO2 | friction stir processing | Al, TiO2 | 80–142 HV | σUTS = 250–325 MPa | [23] |

| Al–16, 32 wt.% TiO2 | MA + sintering | Al, Al2O3, Al3Ti | 139 HV (max) | σUCS = 375 MPa (max.) | [51] |

| Al–10 wt.% TiO2 | mixing + sintering: SPS conventional microwave | Al, TiO2 Al, Al3Ti, TiO2 Al, Al3Ti | 134 HV 92 HV 234 HV | σUBS = 161 MPa σUBS = 75 MPa σUBS = 254 MPa | [25] |

| Material/State | Lattice Parameter (nm) | Crystallite Size (nm) | Microstrain (%) | Dislocation Density (m−2) | Microhardness (HV0.05) |

|---|---|---|---|---|---|

| Al-5TiO2-2PCA as-milled | 0.4047 | 30 | 0.11 | 4.3∙10–14 | 162 ± 4 |

| hot-pressed | 0.4051 | 53 | 0.16 | 3.5∙10–14 | 187 ± 15 |

| Al-5TiO2-5Cu as-milled | 0.4043 | 28 | 0.19 | 7.9∙10–14 | 291 ± 14 |

| hot-pressed | 0.4049 | 60 | 0.18 | 3.5∙10–14 | 233 ± 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prosviryakov, A.; Bazlov, A. The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives. Appl. Sci. 2023, 13, 1104. https://doi.org/10.3390/app13021104

Prosviryakov A, Bazlov A. The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives. Applied Sciences. 2023; 13(2):1104. https://doi.org/10.3390/app13021104

Chicago/Turabian StyleProsviryakov, Alexey, and Andrey Bazlov. 2023. "The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives" Applied Sciences 13, no. 2: 1104. https://doi.org/10.3390/app13021104

APA StyleProsviryakov, A., & Bazlov, A. (2023). The Study of Thermal Stability of Mechanically Alloyed Al-5 wt.% TiO2 Composites with Cu and Stearic Acid Additives. Applied Sciences, 13(2), 1104. https://doi.org/10.3390/app13021104