Abstract

This paper focuses on the application of the hardware-in-the-loop (HIL) technique in the winemaking process. The HIL technique provides an effective methodology to test and verify the automatic control of industrial processes in 3D laboratory environments. Two parts are considered: (i) software, which consists of the virtualization of the wine process in order to generate a realistic work environment that allows the student to manipulate the system while visualizing the changes in the process; and (ii) hardware, through which the process control is implemented in ladder language in a PLC S7 1200 AC/DC/RLY (programmable logic controller). Bidirectional Ethernet TCP/IP communication is established, achieving a client–server architecture. This article highlights the main advantages of the HIL technique, such as its ability to simulate complex and extreme scenarios that would be difficult or expensive to recreate in a real environment. In addition, real-time testing of the hardware and software to implement the control system is performed, allowing for fast and accurate responses. Finally, a usability table is obtained that demonstrates the benefits of performing industrial process control work in virtual work environments, focusing the development on meaningful learning processes for engineering students.

1. Introduction

Currently, industrial processes encompass various types of procedures, including chemical, physical, electrical, and mechanical methods. Automation plays a pivotal role in manufacturing high-quality products by enabling the efficient and precise execution of these procedures. Additionally, automation crucially contributes to industrial safety by preventing accidents and adverse events that could result in equipment damage or, in extreme cases, loss of human life. This is achieved through the implementation of control and monitoring systems that regulate plant operations, thus ensuring continuous and safe functioning within specific time intervals [1,2,3]. These paradigm shifts in the industrial sector have led technological companies to increasingly adopt automation solutions as a strategy to enhance performance and efficiency in their industrial operations [4,5]. This shift in focus has resulted in a notable increase in production capacity, consequently necessitating the incorporation of advanced control technologies that enable real-time manipulation through a supervisory control and data acquisition (SCADA) system [6,7,8]. When such a system is connected with a human–machine interface (HMI), this allows the visualization and control of variables and manipulation of the process. Also, every process requires a database to store these variables, and subsequently the decisions made at the managerial level [9,10]. This interaction between the HMI and the database in the SCADA system facilitates the exchange of information about process variables in real time [10,11].

As described, industrial processes are made up of actuators, transducers, and controllers that work together in order to automate industrial processes. The main objective of industrial automation is to improve production and product quality; for this, it is considered essential to control, manipulate, and visualize the process through SCADA systems. However, it is relevant to consider the communication or exchange of data in real time during the operation of the process. Communication between devices from different vendors can be performed by means of generic drivers such as OLE for process control (OPC) [11,12]. These allow communication between programmable logic controllers (PLC) programming software, such as Tia Portal V16, Step7 v5.6, and Micro Ladder, and software focused on the visualization of industrial processes, such as LabVIEW 2022, InTouch v9.5, and WinCC V8.0.

The use of these software programs in the field of education allows teachers to impart their knowledge about the design and implementation of process control through the manipulation of teaching modules made up of industry-specific actuators and transducers [13,14]. However, a limitation is that the equipment cannot be used for all types of processes, which limits the development of industrial process control [5,15]. This is the reason why the development of new tools that complement this teaching–learning process focuses on allowing the student to achieve a better understanding of the behavior of industrial processes. Tools such as simulators do not offer user-friendly interaction with the results of the process; therefore, various research works have focused on developing virtual environments that represent industrial jobs through real PLC controllers using the HIL technique [16,17]. This allows students to manipulate the process control hardware, that is, PLC or InTouch screens of a real process in a virtual work environment.

This is achieved by implementing the HIL technique, which allows real-time communication between the physical parts, i.e., the controller or device that controls the characteristics of the real process, and the virtual environment that simulates the industrial process. This allows testing and evaluation of hardware operation in a safe and controlled environment, preventing possible failures or even equipment breakdowns, and also allows modifications of gains or dynamic parameters of the system in order to improve the designed control. HIL applications are diverse, from the development and testing of control systems to the simulation of the behavior of inputs and outputs of a plant in a graphical environment, thus improving the user experience. Furthermore, this technique was shown to be effective in reducing testing costs and times, as well as in the early detection of hardware system failures [18,19,20].

For this reason, the development of virtual environments focused on learning processes known as serious gaming allows people to work with video game environments specifically designed for the purpose of teaching, training, or transmitting information effectively while providing a playful and attractive experience [21,22]. Such environments may include the development of specific skills, acquisition of knowledge, improvement of decision making, promotion of teamwork, implementation of control algorithms, control of programmable automation, and manipulation of actuators and transducers. Serious games focus on providing immediate feedback to the user. This allows the user to learn from mistakes and continually improve their skills. Serious games in the educational field allow engineering students to simulate industrial processes since there is a lack of equipment in higher education institutes [23,24]. Furthermore, in industries, virtualization provides training to workers. It is important to optimize resources and reduce risks of possible failures, since companies cannot stop when they are in operation because such a stoppage represents a loss of money for the industry [25,26].

This article is divided into six sections: Section 1, the introduction, presents a literature review of the use of the HIL technique, focused on industrial automation processes; Section 2, the work proposal, describes the use of the HIL technique between InTouch Software, Tia Portal, and Unity with the physical part of the PLC S7 1200; Section 3, process development, describes each phase of the process such as the automation of the industrial process, the elaboration of the SCADA system, and the virtualization of the work environment; Section 4 focuses on the description of the communication process between the physical part and the real-time process control software; Section 5, the results, presents the functional tests of the virtualized plant implementation, as well as the usability test of the process; and finally, the discussion and conclusions are described in Section 6.

2. Work Proposal

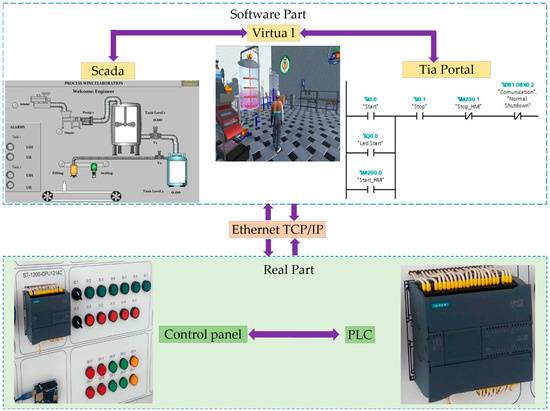

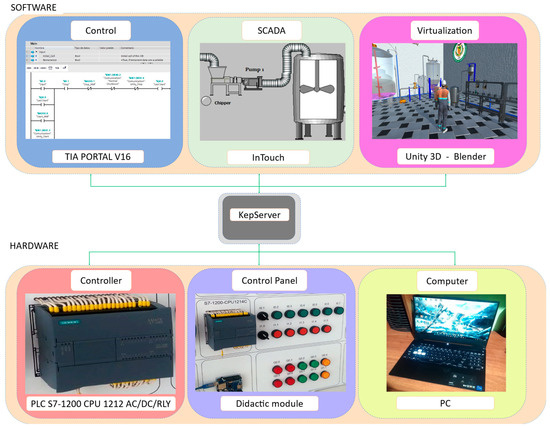

This work proposes the development and implementation of an HIL system based on experimental methodology. To achieve this, the parameters and characteristics of the wine production system must be determined in order to design the process control and to continue with the simulation and communication between the implemented software. Finally, system tests are performed to verify its operation. The proposed HIL system is described in Figure 1, which shows two development stages. The first stage focuses on the software implemented for the control, manipulation, and visualization of the process. The second stage corresponds to the real part, which is a PLC-1200 connected to the Unity 3D virtual environment by Ethernet TCP/IP protocol.

Figure 1.

Bidirectional communication between software and hardware.

2.1. Software Part

This part consists of three components: (i) Process Control: Tia Portal software is used to control the winemaking process using a Ladder language. Sequential control is implemented in the different actuators using sensors. (ii) SCADA. Crushing: A motor is used to extract the pulp from the grapes. Chipping: Impurities, such as stems, leaves, and stones, are separated from the grape pulp. Batting: The grape pulp is sent to the batting tank, where fermentation occurs. A mixer is used to stir the pulp. Visualization: The InTouch software is used to visualize the process in real time. The operator can choose the dimensions for a touch panel and use industrial elements, such as actuators, sensors, and transmitters, to design the process. The software also allows data to be logged and saved to an Excel 2016 spreadsheet. (iii) Virtualization: The Unity 3D program is used to create a virtual representation of the process. This allows an operator to control, monitor, and supervise the process. The student can interact with the real process and observe its behavior at each stage. This allows them to diagnose any failures or verify that the process is correct with the respective HMI.

2.2. Real Part

This system uses a physical PLC-1200 1214 DC/DC/RLY connected to a control panel with LED indicators and start/stop buttons. The PLC is also linked to the Unity 3D virtual environment by an Ethernet TCP/IP protocol, allowing the plant to be started from either the control panel or the program itself. However, the TIA Portal program must incorporate OPC communication (KepServer in this case) to facilitate communication with InTouch for visualizing the winemaking process with its respective human–machine interfaces (HMIs). All of these actions are taken to create a hardware-in-the-loop (HIL) system that allows students to interact with the process through a SCADA system and a control panel. Additionally, real-time observation of the process behavior in a virtual environment is provided, giving students an experience similar to working in a real plant. This equips students with comprehensive knowledge of the process operation, critical protocols in case of errors, appropriate responses, and efficient process execution.

3. Development of the Environment

This section describes four important points: (i) Control: This section describes the stages of the winemaking process and how they are automated using the HIL system. (ii) SCADA: This section visualizes the HMI, which is the user interface for interacting with the HIL system. (iii) Virtualization: This section explains how the animations and the developed environment of the HIL system work. (iv) Communication: This section explains the communication protocols used between the hardware and software components of the HIL system, as well as between the different software components.

3.1. Process Control

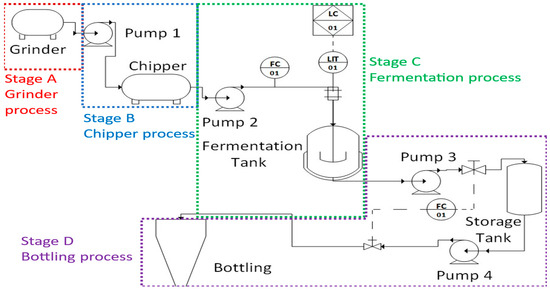

In the development of the HIL system, different stages of the wine production process were taken into account, as shown in the P&ID diagram in Figure 2. This diagram is based on the standards of the International Society of Automation (ISA S5.1) [2], which allows for the identification of the various types of actuators and sensors used in the wine production process.

Figure 2.

P&ID diagram for wine production.

The wine process consists of four stages: (i) Crusher: The process begins with the activation of the crusher motor to extract the pulp from the grapes. When the motor is running, an indicator light (LED) turns on. The pulp is then sent through a pipe to the chipper. (ii) Chipper: The chipper has a motor that is activated when the separation of impurities, such as stems, leaves, and small stones, begins. The total pulp is then sent to the fermentation tank. (iii) Fermentation: In the fermentation tank, the pulp is mixed for a certain time and then allowed to rest to ferment. (iv) Bottling: The fermented pulp is then transferred to a storage tank. From there, it is passed through a valve to the bottling plant via a pipeline. A conveyor belt carries the bottles past a sensor, and each bottle is filled.

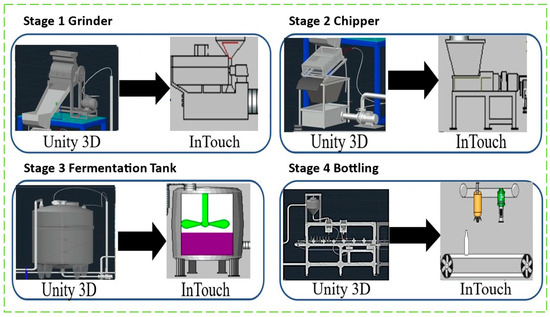

The Tia Portal V16 program with Ladder programming language is used to control the wine process in four stages, as shown in Figure 3. Stage 1: The crusher is turned on when the grapes are loaded. Timers (TOF) are used to set the crusher’s operating time. Stage 2: This stage is activated once Stage 1 is complete. Timers are used to set the operating time of Stage 2. Stage 3: A compact PID is used in the Tia Portal program to control the pulp level. Stage 4: A valve is opened to fill the bottles. Sensors on the conveyor belt stop the conveyor when the bottles are 90% full.

Figure 3.

Stages of wine production.

3.2. SCADA

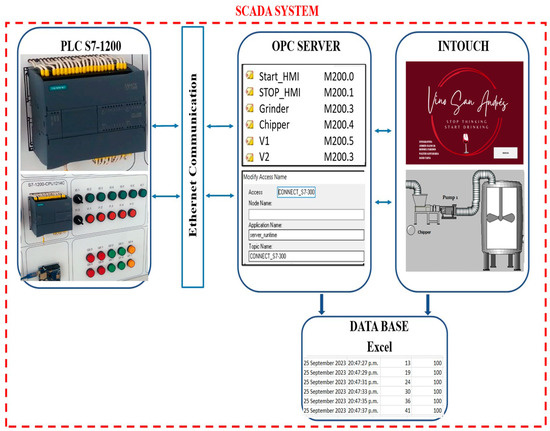

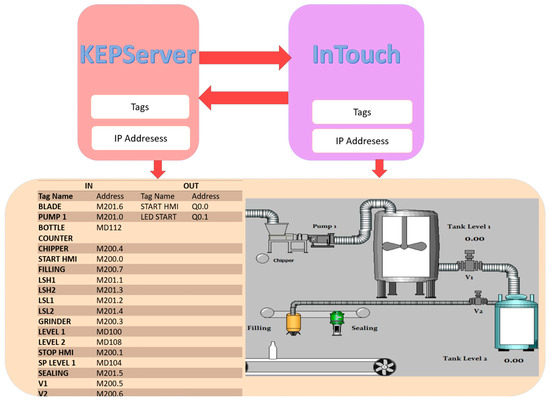

In addition, a SCADA system was developed to allow users to visualize and control the wine process. Figure 4 shows the communication of the SCADA system with the physical controller and the indicators of the teaching module. The system consists of alarms, trends, records, and data. It is made up of different elements with which users can interact. Once the winemaking process is created, addresses or tags are assigned to each element of the process (tank, engine, valve, sensor, etc.) according to the programming that was carried out in Tia Portal. This is necessary to communicate through the KepServer OPC, which must first have a channel configured. Next, communication is performed using the Ethernet TCP/IP protocol. The PLC used in Tia Portal is selected, and its default IP address of 192.168.0.1 is entered. Then, the respective tags or addresses are added. For the InTouch program, the inputs only accept tags in the form M0.0 (Start), and the outputs accept tags in the form Q0.0. Once all of the variables have been added, it is verified that there is a connection, and then the process in operation can be observed.

Figure 4.

SCADA System.

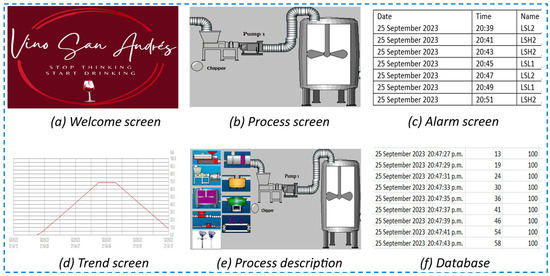

Figure 5 shows the HMI, which contains the navigation windows for the wine process. The HMI has six navigation screens.

Figure 5.

Windows containing the wine production HMI.

(a) Welcome screen: This screen allows the operator to access the HMI of the process. It is intended to provide security to the system by assigning different permissions to each user. For example, engineers can modify the process, operators can control the process, and visitors can only view the process in real time. (b) Process: This screen shows the bottling and sealing process. Depending on their hierarchy, managers may only have access to the process visualization and a history window. (c) History: This screen shows alarms and the history of process variables. (d) Graphs: This screen shows the liquid level in each tank. (e) Process description: This screen shows a description of each element in the process and details its operation. (f) Database: This database is presented in an Excel spreadsheet that communicates with InTouch and Tia Portal. In Excel, the option to program in Visual Basic is enabled, which allows the cell of the data record to be specified.

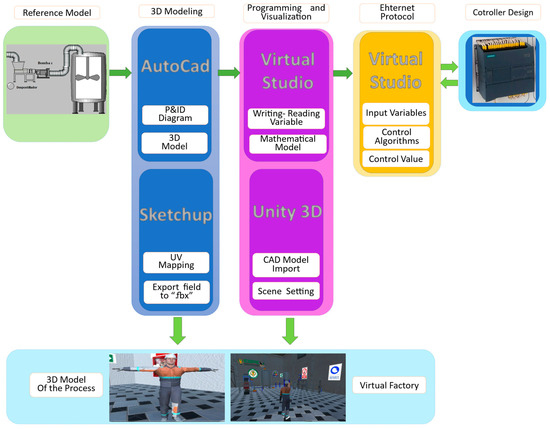

3.3. Virtualization

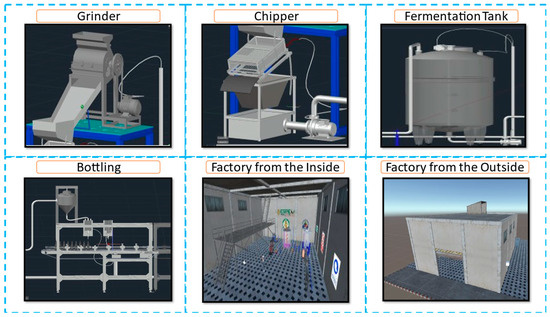

The development of the virtual environment for the winemaking process was designed based on the P&ID diagram. Figure 6 presents the phases considered for the virtualization of the winemaking process. Using the graphic design software Blender, we visualized all of the elements contained in the diagram, such as sensors, actuators, transmitters, tanks, and conveyor belts. Once the 3D environment was created in Blender, it was saved as a *.fbx file for import into Unity 3D. The *.fbx file contains all of the textures and can be found in the objects folder. To import the *.fbx file into Unity 3D, follow these steps: (1) In the Unity menu bar, click Assets > Import New Asset. (2) Find and open the *.fbx file. Once the environment is imported, you can configure the textures, add terrain, and perform other functions to make it more realistic. For animation, you must program in C++ using scripts in Microsoft Visual Studio 2019 software.

Figure 6.

Elaboration of the virtual environment of the wine process.

For the sounds of the actuators, liquid, and explosions, the audio files that represent each element were chosen. Then, the folder containing the stereo audio files was linked to the elements created in the virtual scene by programming in Visual Studio 2019, version 16.1.6. To create the avatar, an FBX model file must be imported into Unity 3D. This is a file of the humanoid character, with the characteristics of an operator. To animate the avatar, a joint hierarchy or skeleton must be structured to define the bones within the mesh and their movement relative to each other. The mesh or mask must be connected to the joint hierarchy to define which parts of the character mesh will move when a given joint is animated.

4. Communication

This work uses the HIL technique, which allows for bilateral communication between hardware and software. The process is controlled by three different software programs that operate simultaneously and communicate bidirectionally with the physical part, which consists of a control panel and a PLC S7-1200. The PLC was previously pre-programmed with the ladder language for the process automation. This can be visualized through KepServer (KepServer, Barcelona, Spain), which allows for real-time communication with negligible delay time. The communication architecture is shown in Figure 7.

Figure 7.

Software-to-hardware communication.

4.1. Tia Portal–KepServer–InTouch Communication

This section describes the communication between KepServer and InTouch (Schneider Electric Paris-Francia), as shown in Figure 8. Assuming that the wine process control program has already been loaded into the memory of the PLC S7-1200, we open the KepServer program. This program allows communication through addresses or tags on each element of the winemaking process, such as sensors, actuators, and tanks. To link to the InTouch software, where the SCADA system for the program was developed, we select the configuration of the Access Name, where the Alias configured in the OPC is configured. In the Application Name field, we enter “server_runtime”, since SuiteLink is a communication protocol based on TCP/IP with client/server architecture developed by Wonderware. Once connected, we can observe the operation of the winemaking process in real time.

Figure 8.

Communication between KepServer and InTouch.

4.2. Ethernet TCP/IP Protocol Communication

The hardware consists of a didactic module made up of indicators, push buttons, and a PLC controller S7-1200 CPU 1214 AC/DC/RLY (Siemens, Alemania-Berlín, Germany). The PLC has 14 digital inputs and 10 outputs, as well as 2 inputs and 1 analog output for sending and receiving control signals to the plant. Communication is performed through Sharp7, a multiplatform software for communication between Tia Portal and Unity 3D. It ensures that the variables of the elements are linked and can be seen in real time, as would be the case natively with Siemens PLCs using Ethernet TCP/IP technology and the S7 protocol. It communicates with Unity software in the same way that they communicate via Ethernet TCP/IP protocol. Communication between Tia Portal and Unity is achieved through the use of functions in a portion of code or script, focused on relating the variables of the data blocks in Tia Portal with the variables created in Visual Studio.

5. Experimental Results

This section presents the results obtained from using the HIL technique to control a wine production process through Ethernet TCP/IP communication. A SCADA system was developed to control and manipulate the process variables, store historical information, and display real-time operational trends. Additionally, the process communicates with a virtual work environment that realistically represents the process in terms of actuators and sensors, including industrial aspects.

5.1. System Performance Tests

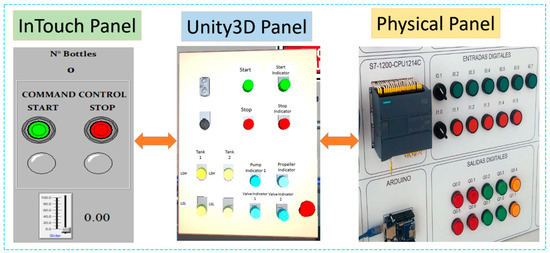

The developed process can be considered a teaching–learning tool because it allows students to interact with the winemaking process. Students can manipulate the system and obtain a real-time response to its operation. In this context, the communication, control, and visualization of the process are considered through three components, as shown in Figure 9. The process is manipulated through these three components as follows: (i) With the Didactic Module, which consists of the S7-1200 PLC that contains the program that controls the system, the student emits signals about the operation of the system through the buttons, and the system provides feedback on the output through the indicators. (ii) The SCADA system panel allows the student to manipulate and visualize the process through the InTouch program, which presents an animation of the system’s operation. Finally, an immersive work environment is considered: (iii) the virtual environment, which is developed to meet the real physical characteristics of the winemaking process. The student can manipulate the process from the virtual environment, and the HTC Vive Pro is used to immerse the student in the virtual plant. In the virtual environment, students can manipulate the process variables, observe the operation of the actuators, and even experience industry-specific surround sound.

Figure 9.

Control and communication of the virtual process.

In this context, three wine process control panels were developed. These panels interact with the process in real time, allowing students to manipulate the process from the physical panel, the InTouch panel, or the virtualized panel (see Figure 10). When the system is manipulated from any control panel, the system outputs information to the three programmed presentations, which are controlled by the PLC S7-1200 and communicate through the Ethernet TCP/IP protocol.

Figure 10.

Control panel in the three scenarios for user interaction.

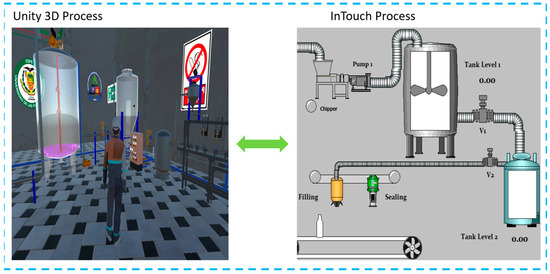

By executing the communication commands of the TIA PORTAL software and the virtualized wine plant, the two systems cooperate to carry out bilateral communication through the online connection of the software. This allows students to visualize the behavior of the process in real time. The operating stages are considered sequentially as shown in Figure 11. The process is developed in an industrial scenario typical of wine production, considering the location of the virtualized equipment so that it meets the real physical characteristics of a winemaking process. In order to create a realistic environment, different aspects are considered, such as (a) texturing of the floor, walls, and equipment to provide a user-friendly environment; (b) animation that is consistent with the operation, such as the ignition of pumps and the movement of liquids; and finally (c) sound, which represents the operation of the equipment and increases or decreases in frequency according to the user’s location.

Figure 11.

Virtualization stages of the wine process.

In this context, Figure 12 presents the behavior of the winemaking process. The interaction between the developed programs is instantaneous, occurring in milliseconds, so it can be considered real time. When the process is started from any scenario, it begins immediately, and the visualizations with the indicators show how the user can interact with the process. For example, the user can determine how the storage tank is filled and detect possible failures.

Figure 12.

User interaction with the HMI and the virtual wine production environment.

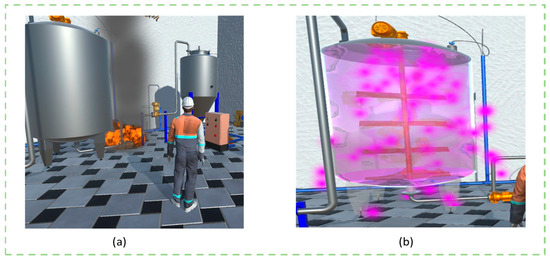

These characteristics are considered to prepare students to prevent failures such as liquid overflow, actuator explosion, pump failure, and pipe rupture, among others. These actions can occur in the winemaking process, triggering an emergency deactivation response. The industry is paralyzed due to the failure. However, the user can interact with the process from within the process or from a control room where their respective HMI (human–machine interface) is located. The user can view each component of the process and have control through a physical panel using the HIL technique.

In addition, an avatar is presented in the winemaking process to interact and navigate within the process. The avatar simulates an operator due to its suit and protective gear, such as a helmet and gloves. In this way, the character is used to help the user interact with each stage of the process, as shown in Figure 13. On the other hand, the user can control, supervise, visualize, store data, and monitor the process from InTouch, depending on their range.

Figure 13.

Visualization of the factory in the virtual environment.

The avatar shown in Figure 14 allows the user to move through the entire virtualized plant, interact with each stage, and visualize the operation of each instrument and the behavior of the winemaking process. The avatar is important because it allows users to simulate taking control and manipulating a virtual plant. It also has the realism of an operator, with its own suit, gloves, helmet, and all the safety measures that an operator has in real life.

Figure 14.

Scene in the virtual environment: explosion.

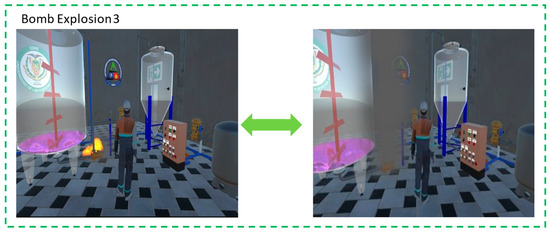

The process was tested using limit values to observe possible failures before inadequate control of the system, as shown in Figure 15. The work focused on two possible failures: (a) the explosion of the filling pump, which can be caused by overvoltage or extreme stress due to the pulp density, and (b) liquid spill when the setpoint limit values are outside the operating ranges. These values are modified by the operator.

Figure 15.

Tests at limit values in the virtual environment. (a) shows an explosion; (b) shows a liquid overflow.

In Figure 16, in the fermentation stage, the pump that fills the storage tank is visualized. In this case, the animation shown in the pump is an explosion, which represents an incident in the industry. As a result, the process will automatically stop to avoid further damage in the industry, allowing the user representing the operator to go to the place of the incident to extinguish the fire and make the respective change, in addition to considering the reason that caused the explosion.

Figure 16.

Graphical representation of the user in the environment.

5.2. Usability and Performance Testing of the Learning Process

The teaching–learning process has experienced constant evolution, with the focus of allowing the student to be an active part of education. The contribution of Information and Communication Technologies (ICTs) has allowed the development of techniques that allow teachers to provide meaningful teaching and to allow students to generate new knowledge from the theoretical classes taught in the classroom. In this context, the work environment presented allows the Electronic Engineering in Automatics student to manipulate, control, and supervise the automation of an industrial process, focused on wine production, applying concepts of automation and control of industrial processes. The developed process was analyzed in relation to the usability of the system, for which the System Usability Evaluation System (SUS) was used, which is considered a metric to evaluate the usability of user interfaces. To do this, a group of 28 Industrial Automation students were asked to complete a series of specific tasks on a system, then rate the ease of use on a Likert scale of 1 to 5 and provide qualitative comments. The results were averaged and converted into a score from 0 to 100. To evaluate the wine production process, 10 questions were asked relating to the manipulation and ease of operation of the developed environment, obtaining a response of 85% acceptance, i.e., the usability of the virtual wine production process was considered excellent [27] (see Appendix A).

In addition, tests were carried out based on the learning of Industrial Automation students, for which two groups of 20 students each from the Industrial Automation department were considered. The two groups received theoretical classes on the topics approved by the department. However, the first group carried out the practical part in simulators and teaching modules, while the second group carried out the practical part in the virtualized plants, demonstrating that the second group had greater aptitude for designing the control proposal of a process. The ease of manipulation of the variables allowed the students to have better performance in professional practices in different national industries.

5.3. Hardware Performance

To analyze the experimental results of the operation of the wine process by applying the HIL technique, we considered the communication between the virtualized environment in Unity, the SCADA system in InTouch, and sequential control in Tia Portal. We used a computer with advanced features (Intel(R) Core(TM) i7-8700K CPU@, NVIDIA® GeForce® GTX 1080 Ti video card, 32 GB RAM, Windows 10 Pro 64-bit operating system), sound sources, and the virtual reality glasses HTC Vive Pro (Valve, Washington, DC, USA).

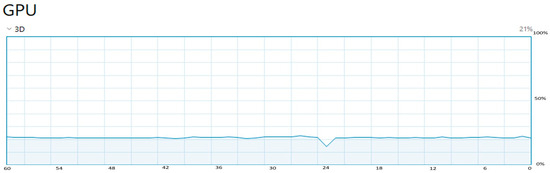

The velocity and fluidity to carry out the simulation of the virtual environment was affected by the characteristics of the developed work environments, with the computational performance of the graphic processing unit (GPU) briefly reaching 21% of the nominal performance. The moderate consumption of the graphics card’s computing capacity is attributed to the optimization of graphics resources considered in the design phase, as shown in Appendix B.

The performance of the central processing unit (CPU) when running the virtual simulator showed a performance of 34% capacity, during the simultaneous execution of the Unity, InTouch, and Tia Portal software when controlling the winemaking process during experimental tests (see Appendix C).

6. Discussion and Conclusions

In recent years, the teaching–learning process has integrated technology into the techniques of imparting knowledge. For this reason, several works are focused on the development of new tools that allow students to undertake meaningful learning. The COVID-19 pandemic accelerated this transition, generating the need to implement new means of teaching [28,29]. The implementation of ICT has allowed the development of new teaching methods [30,31]. As described, different investigations have sought to generate new solutions that complement student learning. In the field of engineering, there are various virtualization works that allow students to test the operation of advanced robot control algorithms, in addition to learning about the operation of high-cost and difficult-to-acquire equipment through a real work environment that respects the characteristics of the system by obtaining mathematical models [16,17,32]. In the industrial sector, it allows students to learn about the behavior of oil, food, and automotive processes, among other things [33].

The implementation of HIL in engineering processes has been a focus of study in recent years, since it allows control of the variables of a process while visualizing the behavior of the plant before said variations without the need to alter a real process [34]. The implementation of virtualized environments in virtual reality, augmented reality, and even mixed reality allow the teaching–learning process to provide the student with new tools to control and manipulate industrial processes [35,36]. It should be noted that the didactic modules of educational institutions must work according to operating limits and that their acquisition has a high cost, which is why various industrial processes cannot be developed, while the development of virtualized industrial environments allows the generation of different work environments that can be controlled by the same controller.

In this context, this study focused on the development of a virtualized industrial environment that allows the student to immerse and interact with the winemaking process using the HIL technique. For this reason, the integration of software and hardware allows the student to understand the management of automation processes in wine production more easily. This experience has proven to be a valuable tool to enhance learning and understanding of complex concepts in the field of automation and process control. Furthermore, the practical approach and the resulting interactivity have contributed to enriching the training of students and their preparation to face the challenges of the industrial world. Undoubtedly, this approach has opened new perspectives for education and the application of advanced technologies in the wine industry. The fundamental key to meaningful learning for automation engineering students lies in the understanding of the fundamental principles for designing, analyzing, and implementing industrial processes. This work focuses on presenting the Ladder programming process in the S7 1200 PLC, as well as the use of SCADA systems for monitoring and data acquisition in the InTouch program. In addition, the relevant communication protocols for the software and hardware part are addressed. To provide a more realistic experience, the manufacturing process of an industrial system was implemented in Unity 3D, allowing students to immerse themselves in the industrial environment and gain in-depth knowledge of each instrument and piece of equipment present in various industries. This interdisciplinary and hands-on approach offers students a valuable opportunity to acquire fundamental skills and knowledge that will enable them to excel in the field of industrial automation. By integrating into this environment, students will be prepared to face the real challenges of industry and contribute to technological advancement in the field of automation. Finally, the results obtained from the usability table, applied to a group of students from the Electronics and Automation course of the University of the Armed Forces ESPE, strongly support the effectiveness of the HIL technique in teaching Electronics and Automation students. By providing a more interactive and immersive experience for the understanding and management of industrial process control, this methodology has contributed significantly to strengthening students’ knowledge and has laid the foundation for a more solid training in the field of industrial automation. It is important to mention that this tool complements student learning. Since the manipulation of real equipment found in the industry is relevant for the complete training of students, this learning method allows the student to have a greater understanding of the complete process. It should be noted that this work is part of a research project focused on the development of industrial processes for teaching-learning processes in the Electronics and Automation degree.

Author Contributions

Conceptualization, D.T., D.I., W.S. and J.S.O.; methodology, J.S.O.; software, D.T., D.I. and W.S.; validation, D.T., D.I., W.S. and J.S.O.; formal analysis, J.S.O.; investigation, D.T., D.I. and W.S.; resources, D.T., D.I., W.S. and J.S.O.; data curation, D.T., D.I. and W.S.; writing—original draft preparation, D.T., D.I., W.S. and J.S.O.; writing—review and editing, D.T., D.I., W.S. and J.S.O.; visualization, D.T., D.I. and W.S.; supervision, J.S.O.; project administration, J.S.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Universidad de las Fuerzas Armadas ESPE and the ARSI Research Group for their support in developing this work.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Usability test for the wine production process.

Table A1.

Usability test for the wine production process.

| No. | Questions | Score |

|---|---|---|

| 1 | The manipulation of the variables of the wine production process is interactive. | 5 |

| 2 | I consider that the computer to be used to execute the virtual environment requires a high-end computer. | 2 |

| 3 | It is intuitive to manage the virtualization process of the wine production process. | 4 |

| 4 | The real wine production system is not considered real. | 1 |

| 5 | Allows student interaction with the actuators and sensors of the process. | 4 |

| 6 | It is necessary to implement greater safety regulations in the wine production process. | 1 |

| 7 | Automation through a virtualized process complements the design knowledge of a controller. | 4 |

| 8 | The events presented by the bombs and tanks do not behave realistically. | 1 |

| 9 | The student considers a friendly environment to develop control of the wine process. | 4 |

| 10 | It is required to have knowledge of how to manipulate the system before using it. | 2 |

Score of even questions .

Score of odd questions .

Usability percentage .

Appendix B

Figure A1.

GPU performance.

Appendix C

Figure A2.

CPU performance.

References

- Sandberg, J.; Holmström, J.; Lyytinen, K. Digitization and Phase Transitions in Platform Organizing Logics: Evidence from the Process Automation Industry. Manag. Inf. Syst. Q. 2020, 44, 129–153. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature Review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Attaran, M. The Impact of 5G on the Evolution of Intelligent Automation and Industry Digitization. J. Ambient Intell. Humaniz. Comput. 2023, 14, 5977–5993. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Shi, P.; Yu, H. A Virtual Reality Rehabilitation Training System Based on Upper Limb Exoskeleton Robot. In Proceedings of the 2018 10th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 25–26 August 2018; Volume 1, pp. 220–223. [Google Scholar]

- Ipiales, J.S.; Araque, E.J.; Andaluz, V.H.; Naranjo, C.A. Virtual Training System for the Teaching-Learning Process in the Area of Industrial Robotics. Electronics 2023, 12, 974. [Google Scholar] [CrossRef]

- Upadhyay, D.; Sampalli, S. SCADA (Supervisory Control and Data Acquisition) Systems: Vulnerability Assessment and Security Recommendations. Comput. Secur. 2020, 89, 101666. [Google Scholar] [CrossRef]

- Toma, C.; Popa, M.; Iancu, B.; Doinea, M.; Pascu, A.; Ioan-Dutescu, F. Edge Machine Learning for the Automated Decision and Visual Computing of the Robots, IoT Embedded Devices or UAV-Drones. Electronics 2022, 11, 3507. [Google Scholar] [CrossRef]

- Soete, N.; Claeys, A.; Hoedt, S.; Mahy, B.; Cottyn, J. Towards Mixed Reality in SCADA Applications. IFAC-Pap. 2015, 48, 2417–2422. [Google Scholar] [CrossRef][Green Version]

- Babayigit, B.; Sattuf, H. An IIoT and Web-Based Low-Cost SCADA System for Industrial Automation. In Proceedings of the 2019 11th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 28–30 November 2019; pp. 890–894. [Google Scholar]

- Bengler, K.; Rettenmaier, M.; Fritz, N.; Feierle, A. From HMI to HMIs: Towards an HMI Framework for Automated Driving. Information 2020, 11, 61. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Figueiredo, J.; Sousa, J.M.C. A Literature Survey on Open Platform Communications (OPC) Applied to Advanced Industrial Environments. Electronics 2019, 8, 510. [Google Scholar] [CrossRef]

- Bruckner, D.; Stănică, M.-P.; Blair, R.; Schriegel, S.; Kehrer, S.; Seewald, M.; Sauter, T. An Introduction to OPC UA TSN for Industrial Communication Systems. Proc. IEEE 2019, 107, 1121–1131. [Google Scholar] [CrossRef]

- Pico, L.; Marroquín, F.; Ortiz, J.S.; Varela-Aldás, J. Design and Virtualization of an Automated System with Hardware in the Loop for the Virtualized Water Bottling Process in a Unity Environment. In Advances in Information and Communication; Arai, K., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 570–577. [Google Scholar]

- Vasiliev, V.A.; Aleksandrova, S.V.; Aleksandrov, M.N. Integration of Quality Management Tools into a Digital Management System. In Proceedings of the 2021 International Conference on Quality Management, Transport and Information Security, Information Technologies (IT&QM&IS), Yaroslavl, Russia, 6–10 September 2021; pp. 352–354. [Google Scholar]

- Cadena, M.S.; Novillo, K.; Ruiz, B.; Ortiz, J.S.; Rodríguez, D.; Varela-Aldás, J. Hardware in the Loop Simulation for Soda Can Palletizing Process Applying Ethernet TCP/IP Communication Protocols Based on Unity 3D. In Advances in Information and Communication; Arai, K., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 558–569. [Google Scholar]

- Ortiz, J.S.; Palacios-Navarro, G.; Andaluz, V.H.; Guevara, B.S. Virtual Reality-Based Framework to Simulate Control Algorithms for Robotic Assistance and Rehabilitation Tasks through a Standing Wheelchair. Sensors 2021, 21, 5083. [Google Scholar] [CrossRef] [PubMed]

- Villarroel, A.; Toapanta, D.; Naranjo, S.; Ortiz, J.S. Hardware in the Loop Simulation for Bottle Sealing Process Virtualized on Unity 3D. Electronics 2023, 12, 2799. [Google Scholar] [CrossRef]

- Isermann, R.; Schaffnit, J.; Sinsel, S. Hardware-in-the-Loop Simulation for the Design and Testing of Engine-Control Systems. IFAC Proc. Vol. 1998, 31, 1–10. [Google Scholar] [CrossRef]

- Granda, P.N.; Andaluz, V.H. Virtual Training System for Oxygen Distribution Control Through Hardware-in-the-Loop. In Advances in Information and Communication; Arai, K., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 753–765. [Google Scholar]

- Pogo, S.I.; Arias, J.F.; Andaluz, V.H. Control of the Malt Mashing and Boiling Process in Craft Beer Production: Hardware-in-The-Loop-Technique. In Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Arpaia, P., Bourdot, P., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 701–716. [Google Scholar]

- Karavidas, L.; Apostolidis, H.; Tsiatsos, T. Usability Evaluation of an Adaptive Serious Game Prototype Based on Affective Feedback. Information 2022, 13, 425. [Google Scholar] [CrossRef]

- Urgo, M.; Terkaj, W.; Mondellini, M.; Colombo, G. Design of Serious Games in Engineering Education: An Application to the Configuration and Analysis of Manufacturing Systems. CIRP J. Manuf. Sci. Technol. 2022, 36, 172–184. [Google Scholar] [CrossRef]

- Udeozor, C.; Russo Abegão, F.; Glassey, J. An Evaluation of the Relationship Between Perceptions and Performance of Students in a Serious Game. J. Educ. Comput. Res. 2022, 60, 322–351. [Google Scholar] [CrossRef]

- Ye, L.; Zhou, X.; Yang, S.; Hang, Y. Serious Game Design and Learning Effect Verification Supporting Traditional Pattern Learning. Interact. Learn. Environ. 2022, 1–15. [Google Scholar] [CrossRef]

- Mian, S.H.; Salah, B.; Ameen, W.; Moiduddin, K.; Alkhalefah, H. Adapting Universities for Sustainability Education in Industry 4.0: Channel of Challenges and Opportunities. Sustainability 2020, 12, 6100. [Google Scholar] [CrossRef]

- Abidi, M.H.; Al-Ahmari, A.; Ahmad, A.; Ameen, W.; Alkhalefah, H. Assessment of Virtual Reality-Based Manufacturing Assembly Training System. Int. J. Adv. Manuf. Technol. 2019, 105, 3743–3759. [Google Scholar] [CrossRef]

- Lewis, J.R.; Sauro, J. Usability and User Experience: Design and Evaluation. In Handbook of Human Factors And Ergonomics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 972–1015. ISBN 978-1-119-63611-3. [Google Scholar]

- Wiyono, B.B.; Indreswari, H.; Prestiadi, D. The Use of Technology-Based Communication Media in The Teaching-Learning Interaction of Educational Study Programs in The Pandemic of COVID-19. In Proceedings of the 2021 IEEE 11th International Conference on Electronics Information and Emergency Communication (ICEIEC), Beijing, China, 18–20 June 2021; pp. 1–5. [Google Scholar]

- Gangahagedara, R.; Karunarathna, M.; Athukorala, W.; Subasinghe, S.; Ekanayake, P. Emergency Teaching–Learning Methods (ETLM) during COVID-19: Lessons Learned from Sri Lanka. Educ. Sci. 2021, 11, 579. [Google Scholar] [CrossRef]

- Kamp, L. Engineering Education in Sustainable Development at Delft University of Technology. J. Clean. Prod. 2006, 14, 928–931. [Google Scholar] [CrossRef]

- Lin, K.-Y.; Wu, Y.-T.; Hsu, Y.-T.; Williams, P.J. Effects of Infusing the Engineering Design Process into STEM Project-Based Learning to Develop Preservice Technology Teachers’ Engineering Design Thinking. Int. J. STEM Educ. 2021, 8, 1. [Google Scholar] [CrossRef]

- Ruiz, R.J.; Saravia, J.L.; Andaluz, V.H.; Sánchez, J.S. Virtual Training System for Unmanned Aerial Vehicle Control Teaching–Learning Processes. Electronics 2022, 11, 2613. [Google Scholar] [CrossRef]

- Hernandez-de-Menendez, M.; Morales-Menendez, R. Technological Innovations and Practices in Engineering Education: A Review. Int. J. Interact. Des. Manuf. IJIDeM 2019, 13, 713–728. [Google Scholar] [CrossRef]

- Abidi, M.H.; El-Tamimi, A.M.; Al-Ahmari, A.M.; Abouel Nasr, E.S. Assessment and Comparison of Immersive Virtual Assembly Training System. Int. J. Rapid Manuf. 2013, 3, 266–283. [Google Scholar] [CrossRef]

- Byvaltsev, S.V. Augmented Reality for SCADA. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 052022. [Google Scholar] [CrossRef]

- Antonijević, M.; Sučić, S.; Keserica, H. Augmented Reality Applications for Substation Management by Utilizing Standards-Compliant SCADA Communication. Energies 2018, 11, 599. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).