Process Quality Control Method for Three-Cylinder Engine Balance Shaft System Oriented to Manufacturing Supply Chain

Abstract

:1. Introduction

2. Process Quality Control Demand and Construction of Control Network

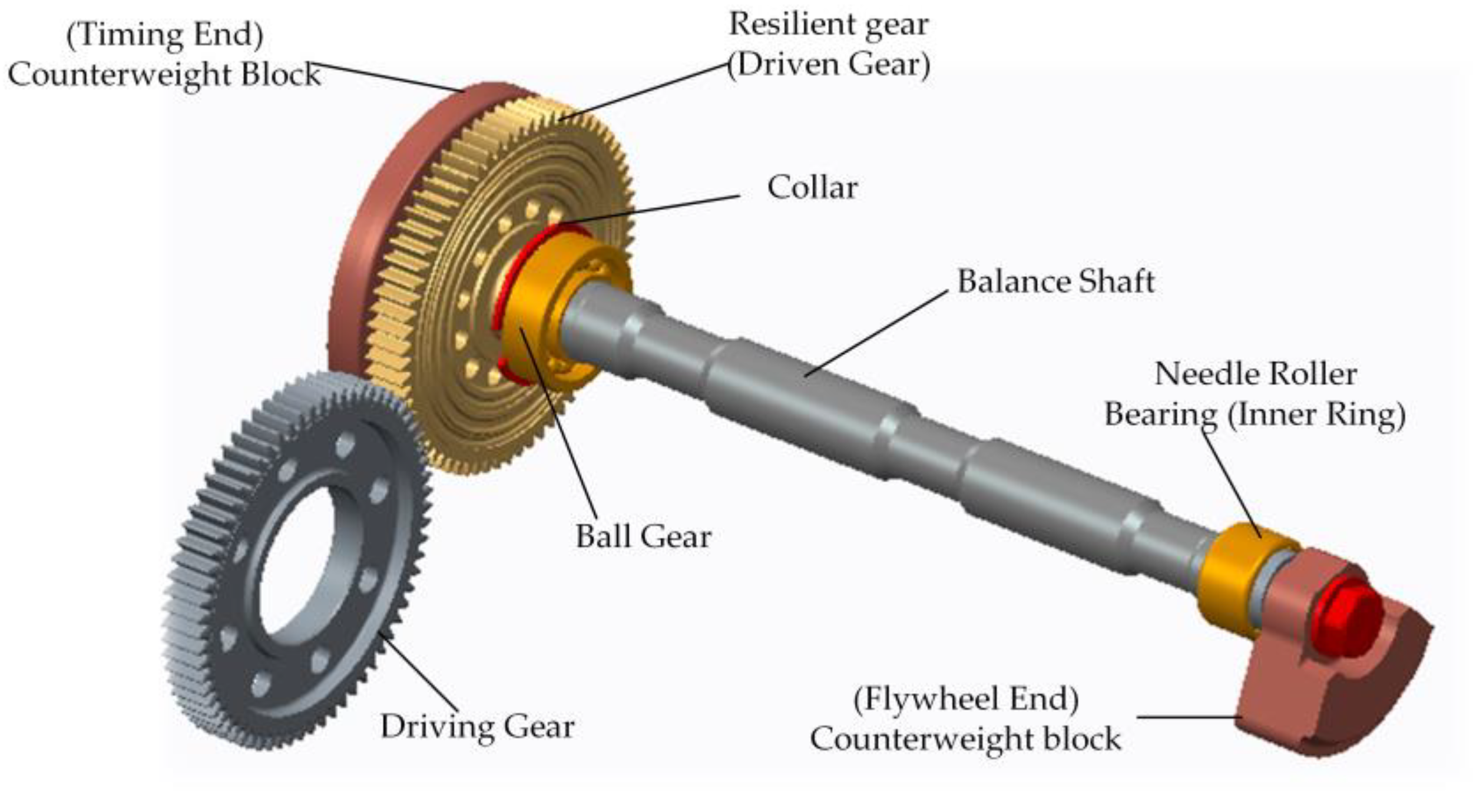

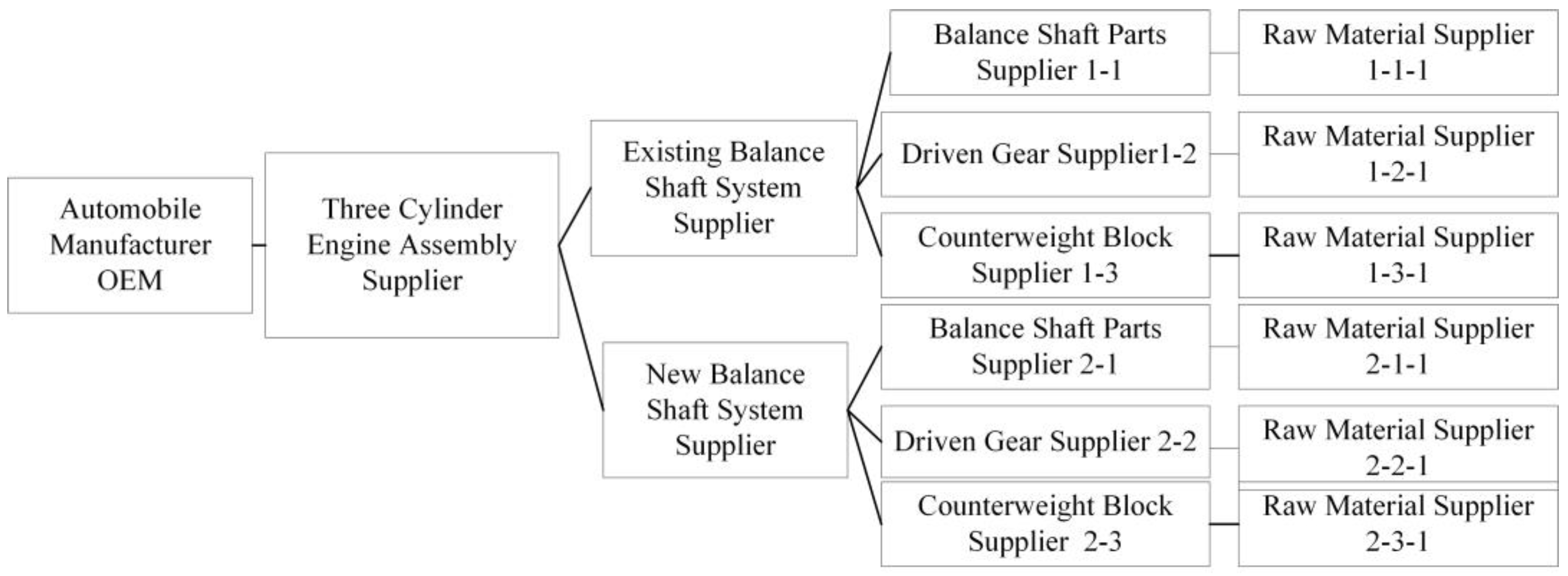

2.1. Composition of Three-Cylinder Engine Balance Shaft System and Demand Analysis of Product Process Quality Control Oriented to Manufacturing Supply Chain

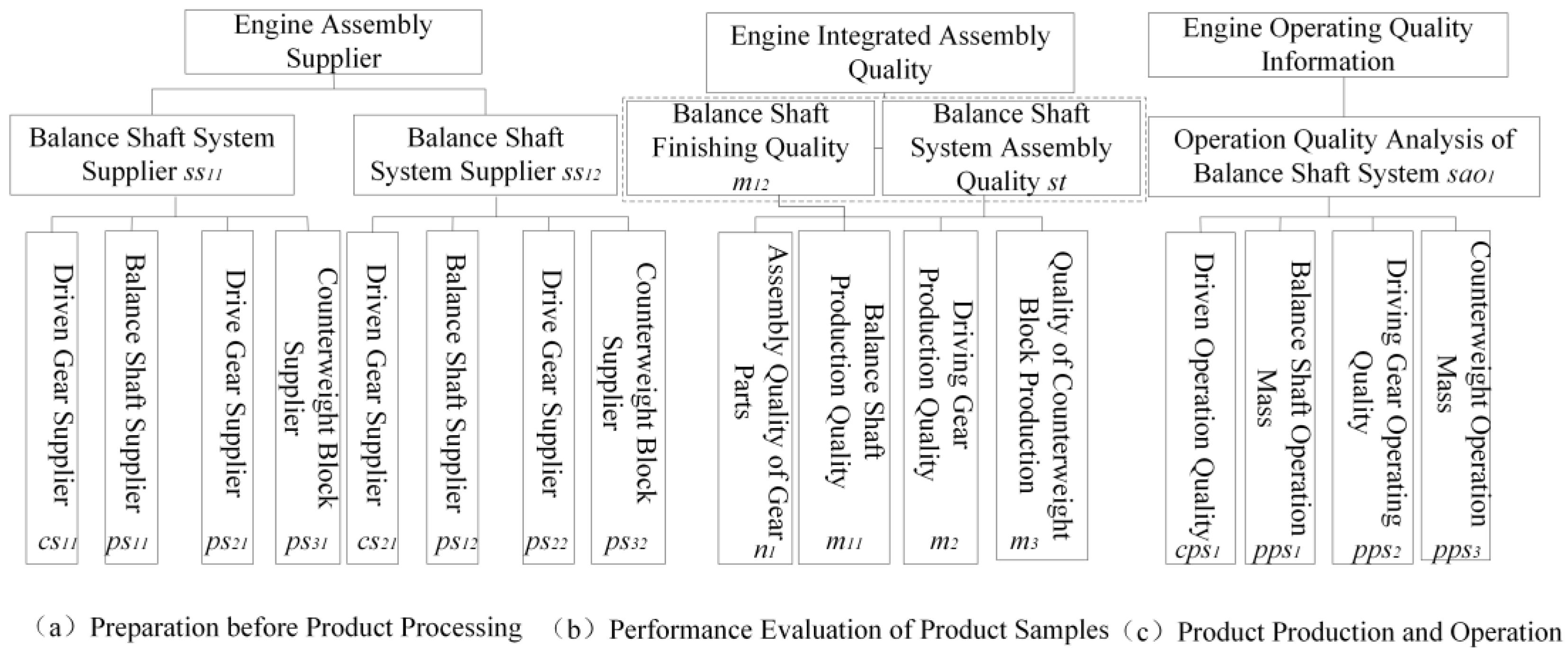

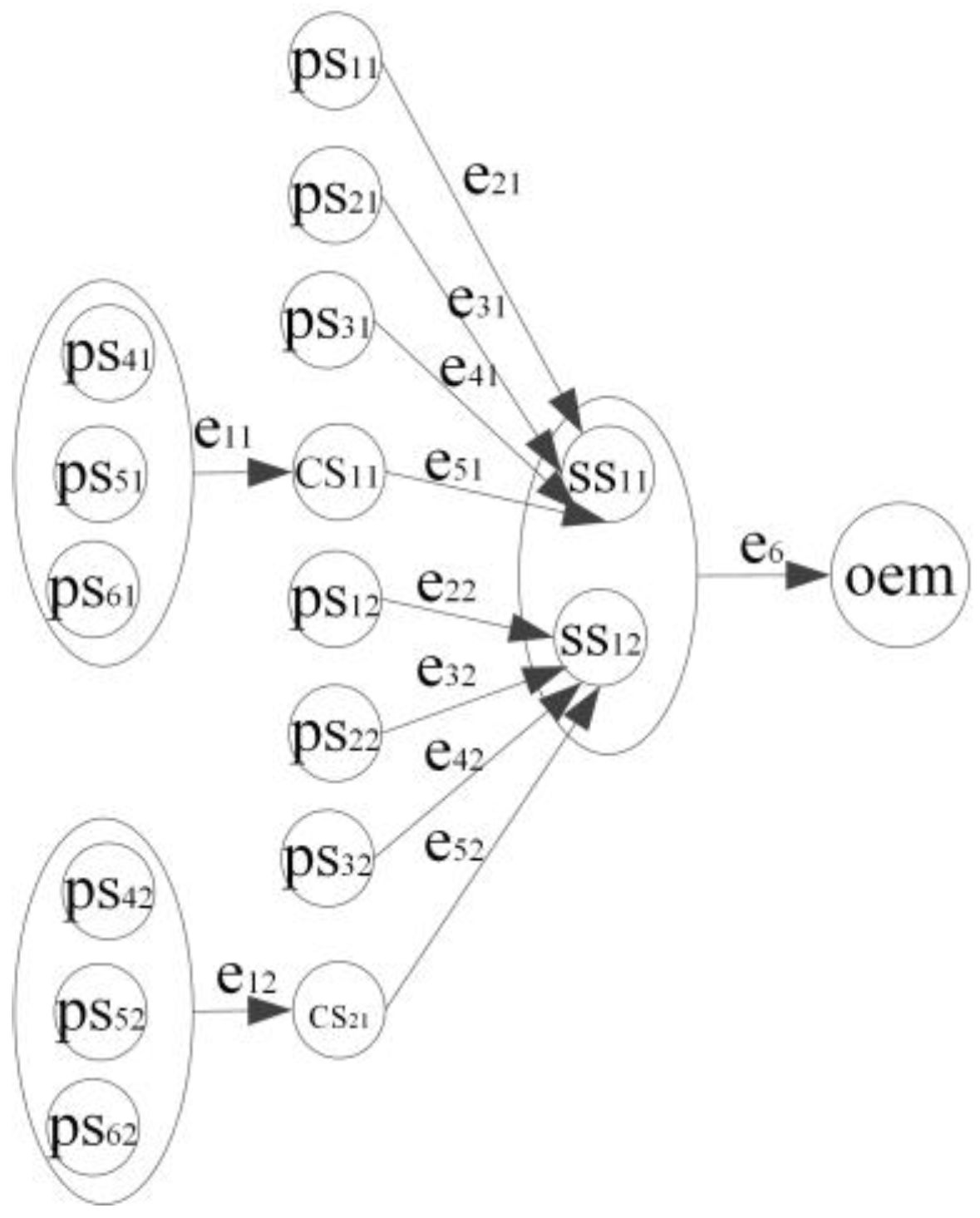

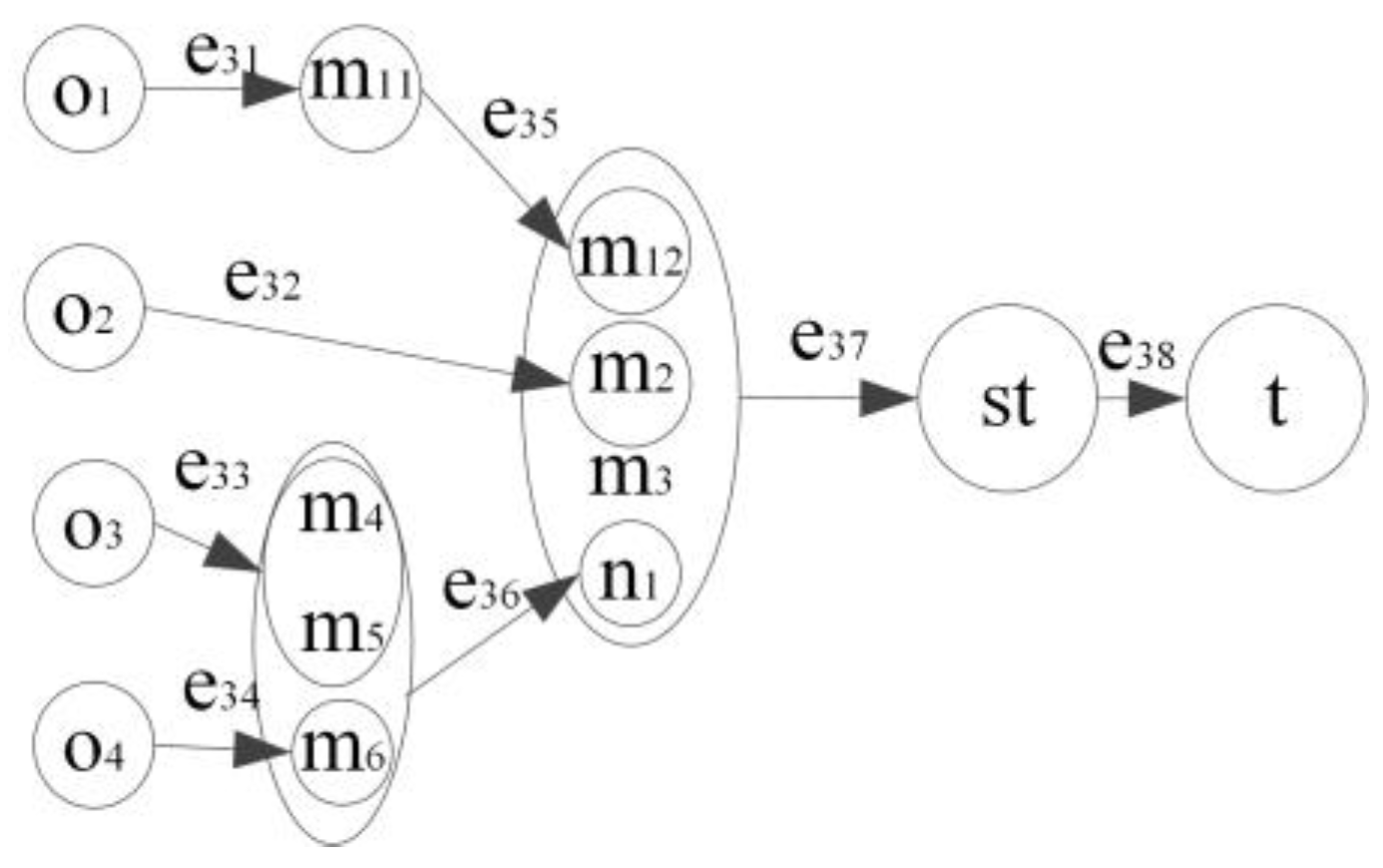

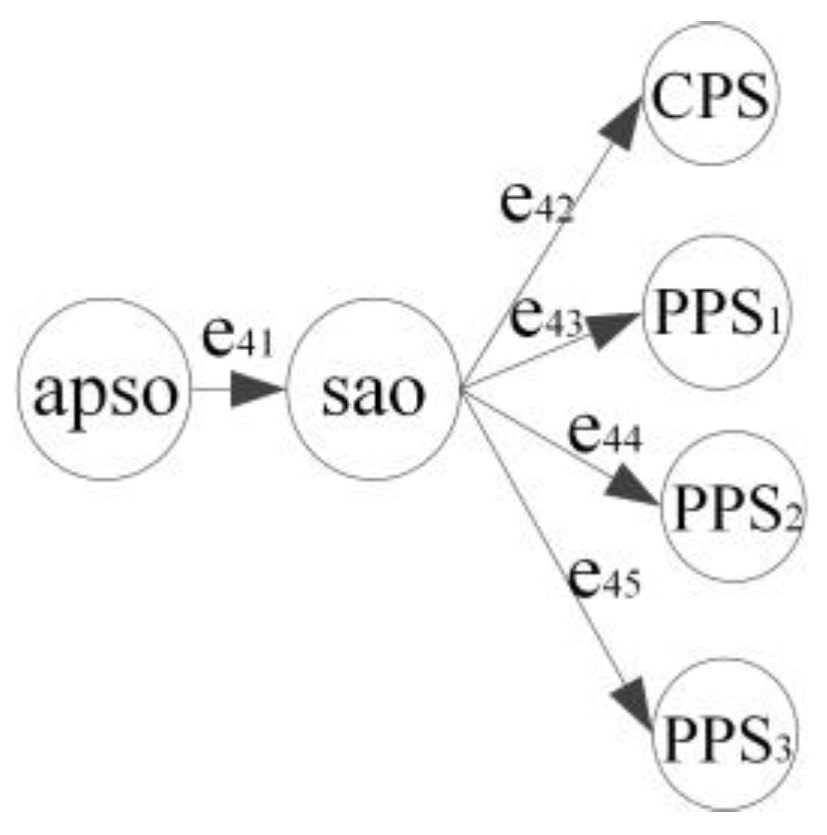

2.2. Construction of Process quality Network for the Three-Cylinder Engine Balance Shaft System Oriented to the Manufacturing Supply Chain

3. Construction of Product Process Quality Control Model for the Three-Cylinder Engine Balance Shaft System Oriented to the Manufacturing Supply Chain

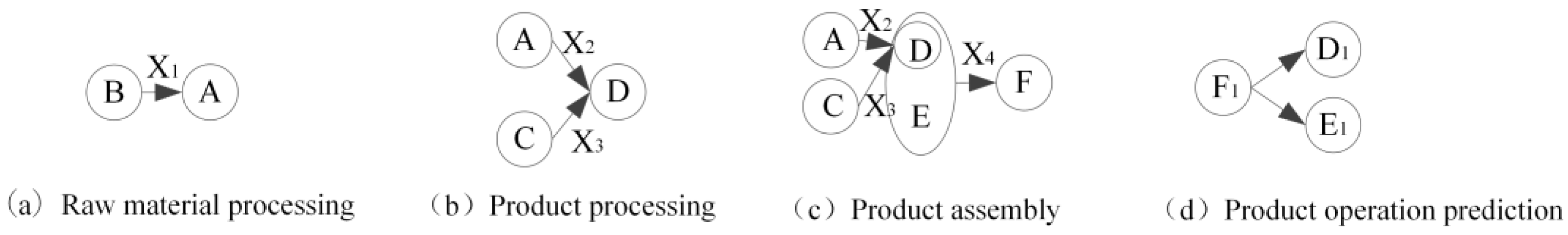

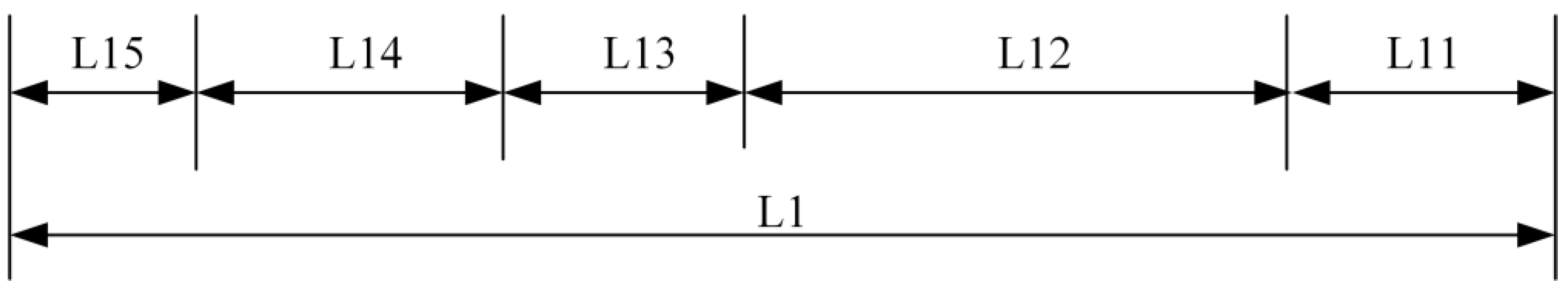

3.1. Expression Method of Key Elements in Product Process Quality Control Network for the Three-Cylinder Engine Balance Shaft System Oriented to the Manufacturing Supply Chain

3.2. Process Quality Control Model for the Three-Cylinder Engine Balance Shaft System Oriented to the Manufacturing Supply Chain

3.2.1. Quality Control Model of the Three Cylinder Engine Balancing Shaft System Based on the Manufacturing Supply Chain Cycle

3.2.2. Benefit and Cost Analysis of Process Quality Control Model of the Three-Cylinder Engine Balance Shaft System for Manufacturing Supply Chain

4. Case Application and Benefit–Cost Analysis

4.1. Application and Benefit–Cost Analysis of the Stage of Preparation before Product Processing

4.2. Application and Benefit–Cost Analysis of the Stage of Sample Product Performance Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alkahtani, M. Mathematical Modelling of Inventory and Process Outsourcing for Optimization of Supply Chain Management. Mathematics 2022, 10, 1142. [Google Scholar] [CrossRef]

- Esmaeili-Najafabadi, E.; Nezhad, M.; Pourmohammadi, H.; Honarvar, M.; Vahdatzad, M.A. A joint supplier selection and order allocation model with disruption risks in centralized supply chain. Comput. Ind. Eng. 2018, 127, 734–748. [Google Scholar] [CrossRef]

- Albloushi, B.; Alharmoodi, A.; Jabeen, F.; Mehmood, K.; Farouk, S. Total quality management practices and corporate sustainable development in manufacturing companies: The mediating role of green innovation. Manag. Res. Rev. 2023, 46, 20–45. [Google Scholar] [CrossRef]

- Bottani, E.; Montanari, R.; Volpi, A.; Tebaldi, L. Statistical process control of assembly lines in manufacturing. J. Ind. Inf. Integr. 2023, 32, 100435. [Google Scholar] [CrossRef]

- Lee, D.H.; Yang, J.K.; Kim, S.H.; Kim, K.J. Optimizing mean and variance of multiresponse in a multistage manufacturing process using operational data. Qual. Eng. 2020, 32, 627–642. [Google Scholar] [CrossRef]

- Peng, X.; Prybutok, V.; Xie, H. Integration of supply chain management and quality management within a quality focused organizational framework. Int. J. Prod. Res. 2020, 58, 448–466. [Google Scholar] [CrossRef]

- Shi, J. In-Process Quality Improvement: Concepts, Methodologies, and Applications. IISE Trans. 2022, 55, 2–21. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G.; Dreyfus, P.A.; Kiritsis, D. Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res. 2020, 58, 1–17. [Google Scholar] [CrossRef]

- Psarommatis, F.; Sousa, J.; Mendonça, J.P.; Kiritsis, D. Zero-defect manufacturing the approach for higher manufacturing sustainability in the era of industry 4.0: A position paper. Int. J. Prod. Res. 2022, 60, 73–91. [Google Scholar] [CrossRef]

- Psarommatis, F.; Kiritsis, D. A hybrid Decision Support System for automating decision making in the event of defects in the era of Zero Defect Manufacturing. J. Ind. Inf. Integr. 2021, 26, 100263. [Google Scholar] [CrossRef]

- Wang, P.; Li, G.; Li, Y. Product process quality demand analysis for medium auto parts enterprise in supply chain. Integr. Ferroelectr. 2021, 218, 97–107. [Google Scholar] [CrossRef]

- Shen, B.; Chen, C. Quality management in outsourced global fashion supply chains: An exploratory case study. Prod. Plan. Control 2020, 31, 757–769. [Google Scholar] [CrossRef]

- Chino, M.; Khojasteh, Y.; Furuhata, T.; Kainuma, Y. Empirical analysis of supply chain risk management in the Japanese automotive industry. J. Jpn. Ind. Manag. Assoc. 2017, 67, 285–294. [Google Scholar] [CrossRef]

- Onari, M.A.; Rezaee, M.J. A fuzzy cognitive map based on Nash bargaining game for supplier selection problem: A case study on auto parts industry. Oper. Res. 2020, 22, 2133–2171. [Google Scholar] [CrossRef]

- Gündüz, Ç.; Gündüz, G.Ş. Supplier selection under fuzzy environment. Tekst. Konfeksiyon 2019, 29, 344–352. [Google Scholar] [CrossRef]

- Kabadayi, N.; Dehghanimohammadabadi, M. Multi-objective supplier selection process: A simulation–optimization framework integrated with MCDM. Ann. Oper. Res. 2022, 319, 1607–1629. [Google Scholar] [CrossRef]

- Yousefi, S.; Rezaee, M.J.; Solimanpur, M. Supplier selection and order allocation using two-stage hybrid supply chain model and game-based order price. Oper. Res. 2021, 21, 553–588. [Google Scholar] [CrossRef]

- Yang, H.; Peng, J. Coordinating a supply chain with demand information updating. J. Ind. Manag. Optim. 2022, 20, 18. [Google Scholar] [CrossRef]

- Yang, Z.; Mei, Q.; Wang, Q.; Liu, S.; Zhang, J. Research on Contract Coordination in the Manufacturing Supply Chain Given China’s Work Safety Constraints. Complexity 2021, 2021, 1779098. [Google Scholar] [CrossRef]

- Magnanini, M.C.; Eger, F.; Reiff, C.; Colledani, M.; Verl, A. A control model for downstream compensation strategy in multi-stage manufacturing systems of complex parts. IFAC-Pap. Line 2019, 52, 1473–1478. [Google Scholar] [CrossRef]

- Kou, Z. Association rule mining using chaotic gravitational search algorithm for discovering relations between manufacturing system capabilities and product features. Concurr. Eng. 2019, 27, 213–232. [Google Scholar] [CrossRef]

- Gao, Z.; Xu, F.; Zhou, C.; Zhang, H. Critical Procedure Identification Method Considering the Key Quality Characteristics of the Product Manufacturing Process. Processes 2022, 10, 1343. [Google Scholar] [CrossRef]

- Hu, S.; Song, S.; Liu, W. A Framework of Cloud Model Similarity-Based Quality Control Method in Data-Driven Production Process. Math. Probl. Eng. 2020, 2020, 7153841. [Google Scholar] [CrossRef]

- Xu, X.; Tatge, L.; Xu, X.; Liu, Y. Blockchain applications in the supply chain management in German automotive industry. Prod. Plan. Control 2022, 1–15. [Google Scholar] [CrossRef]

- Janjić, G.; Tanasić, Z.; Tomić Stojković, R. Development of a Quality Management Model in the Automotive Industry with a Focus on the Quality of Incoming Products (Part I). Trans. Famena 2022, 46, 115–126. [Google Scholar] [CrossRef]

- Rosyidi, C.N.; Murtisari, R.; Jauhari, W.A. A concurrent optimization model for supplier selection with fuzzy quality loss. J. Ind. Eng. Manag. 2017, 10, 98–110. [Google Scholar] [CrossRef]

- Wang, C.H.; Ali, M.H.; Chen, K.S.; Negash, Y.T.; Tseng, M.L.; Tan, R.R. Data driven supplier selection as a circular economy enabler: A Taguchi capability index for manufactured products with asymmetric tolerances. Adv. Eng. Inform. 2021, 47, 101249. [Google Scholar] [CrossRef]

- Attri, R.; Grover, S. Structural modelling and analysis of production system life cycle: A graph theoretic approach. Int. J. Oper. Res. 2019, 34, 467–506. [Google Scholar] [CrossRef]

- Wang, C.N.; Tsou, M.C.; Wang, C.H.; Nguyen, V.T.; Phuong, P.N.T. Improving Supply Chain Performance Through Supplier Selection and Order Allocation Problem. Comput. Mater. Contin. 2022, 1, 15. [Google Scholar] [CrossRef]

- Shuo, L.I.; Meng, J.; Pan, E.S. Optimal Tolerance Allocation Plan for the Combination of the Assembly and Manufacturing. Ind. Eng. Manag. 2017, 22, 6. [Google Scholar] [CrossRef]

| Stage | Node Enterprises | Product Processing Tasks | Objectives |

|---|---|---|---|

| Preparation before Product Processing | Assembly Suppliers for Three-Cylinder Engine | To propose control requirements for balance shaft system process quality and assessment standards for supplier quality | To confirm suppliers for balance shaft system and parts |

| Suppliers for Balance Shaft System | To decompose requirements for balance shaft system process quality, design assurance system for balance shaft system process quality, and analyze requirements for product testing | ||

| Parts Suppliers | To propose the design plan for processing techniques of the balance shaft, the counterweight block, and the driven gear, and improve implementation plan for parts processing | ||

| Sample Product Performance Evaluation | Assembly Suppliers for Three-Cylinder Engine | To propose inspection standards for balance shaft system process quality and propose requirements for sample improvement | To optimize the tolerance allocation plan according to the product improvement plan |

| Suppliers for Balance Shaft System | To propose the implementation plan for balance shaft system process quality improvement/optimization, and parts process quality control and prediction | ||

| Parts Suppliers | To adjust the implementation plan for parts process quality improvement, and ensure the process quality performance of parts | ||

| Production and Operation | Assembly Suppliers for Three-Cylinder Engine | To track the balance shaft system operation quality | To guarantee the quality of product operation |

| Suppliers for Balance Shaft System | To predict and control the quality risk during balance shaft system operation | ||

| Parts Suppliers | To further maintain/improve the qualityof balance shaft system operation |

| Parts | Performance Indicators | Processing Cost | Damping Effect | ||

|---|---|---|---|---|---|

| Mass | Static Unbalance | Rotational Inertia | |||

| Balance Shaft | 558 g | mxa = ±5 g·cm mya = 475 ± 12 g·cm | 1939 g∙cm2 | 48 | Connector |

| Drive Gear | 290 g | ±0.1 g/cm | 4450–5000g∙cm2 | 112 | Power Transmission |

| Driven Gear | 449 g | ±0.15 g·cm | 4450–5000g∙cm2 | 120 | Power Transmission |

| Counterweight A | 327 g | myg = ±5 g·cm mzg = 475 ± 12 g·cm | 3483 g∙cm2 | 57 | Balancing Torque |

| Counterweight B | 273 g | mxa = ±5 g·cm mya = 475 ± 12 g·cm | 1630 g∙cm2 | 45 | Balancing Torque |

| Supplier | Performance Parameters | Processing Cost | Damping Rate | ||

|---|---|---|---|---|---|

| Mass | Static Unbalance | Rotational Inertia | |||

| Current Supplier | 449 g | ±0.15 g·cm | 4.45–5 kg∙cm2 | 120 | 100% |

| Supplier SS1 | 449 g ± 5% | ±0.15 g·cm | 4.45–5 ± 10% kg∙cm2 | 80 | 55% |

| Supplier SS2 | 449 g ± 3% | ±0.15 g·cm | 4.45–5 ± 5% kg∙cm2 | 88 | 95% |

| Key Parameter | Decentralized Decision-Making/ without Considering Inspection | Centralized Decision-Making/ without Considering Inspection | Decentralized Decision-Making/ Considering Inspection | Centralized Decision-Making/ Considering Inspection |

|---|---|---|---|---|

| Existing Research Methods [16,17] | Method Proposed in this Paper | |||

| Maximum Profit for Engine Assembly Supplier (RMB) | 2500 | 1500 | 4210 | 4863 |

| Maximum Profit for Balance Shaft System Small Assembly Supplier (RMB) | 3700 | 3600 | 6104 | 4268 |

| Maximum Profit for Manufacturing Supply Chain (RMB) | 5300 | 4800 | 10,315 | 9130 |

| Key Parameter | Direct Assembly by Engine Assembly Supplier | Engine Supplier Dominance | Manufacturing Supply Chain Profit Maximization Dominance |

|---|---|---|---|

| Without Considering Process Quality Level | With Process Quality Level | ||

| Inspection Quality | - | 40 | 58 |

| Wholesale Price (CNY) | 260 | 258 | 258 |

| Maximum Profit for Engine Assembly Suppliers (CNY) | 2500 | 6990 | 4783 |

| Maximum Profit for Balance Shaft System Small Assembly Supplier (CNY) | 3700 | 5616 | 8431 |

| Maximum Profit for Manufacturing Supply Chain (CNY) | 5300 | 8710 | 9308 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Li, G.; Li, X. Process Quality Control Method for Three-Cylinder Engine Balance Shaft System Oriented to Manufacturing Supply Chain. Appl. Sci. 2023, 13, 10788. https://doi.org/10.3390/app131910788

Wang P, Li G, Li X. Process Quality Control Method for Three-Cylinder Engine Balance Shaft System Oriented to Manufacturing Supply Chain. Applied Sciences. 2023; 13(19):10788. https://doi.org/10.3390/app131910788

Chicago/Turabian StyleWang, Pingjun, Gangyan Li, and Xueping Li. 2023. "Process Quality Control Method for Three-Cylinder Engine Balance Shaft System Oriented to Manufacturing Supply Chain" Applied Sciences 13, no. 19: 10788. https://doi.org/10.3390/app131910788

APA StyleWang, P., Li, G., & Li, X. (2023). Process Quality Control Method for Three-Cylinder Engine Balance Shaft System Oriented to Manufacturing Supply Chain. Applied Sciences, 13(19), 10788. https://doi.org/10.3390/app131910788