Vehicle State and Road Adhesion Coefficient Joint Estimation Based on High-Order Cubature Kalman Algorithm

Abstract

:1. Introduction

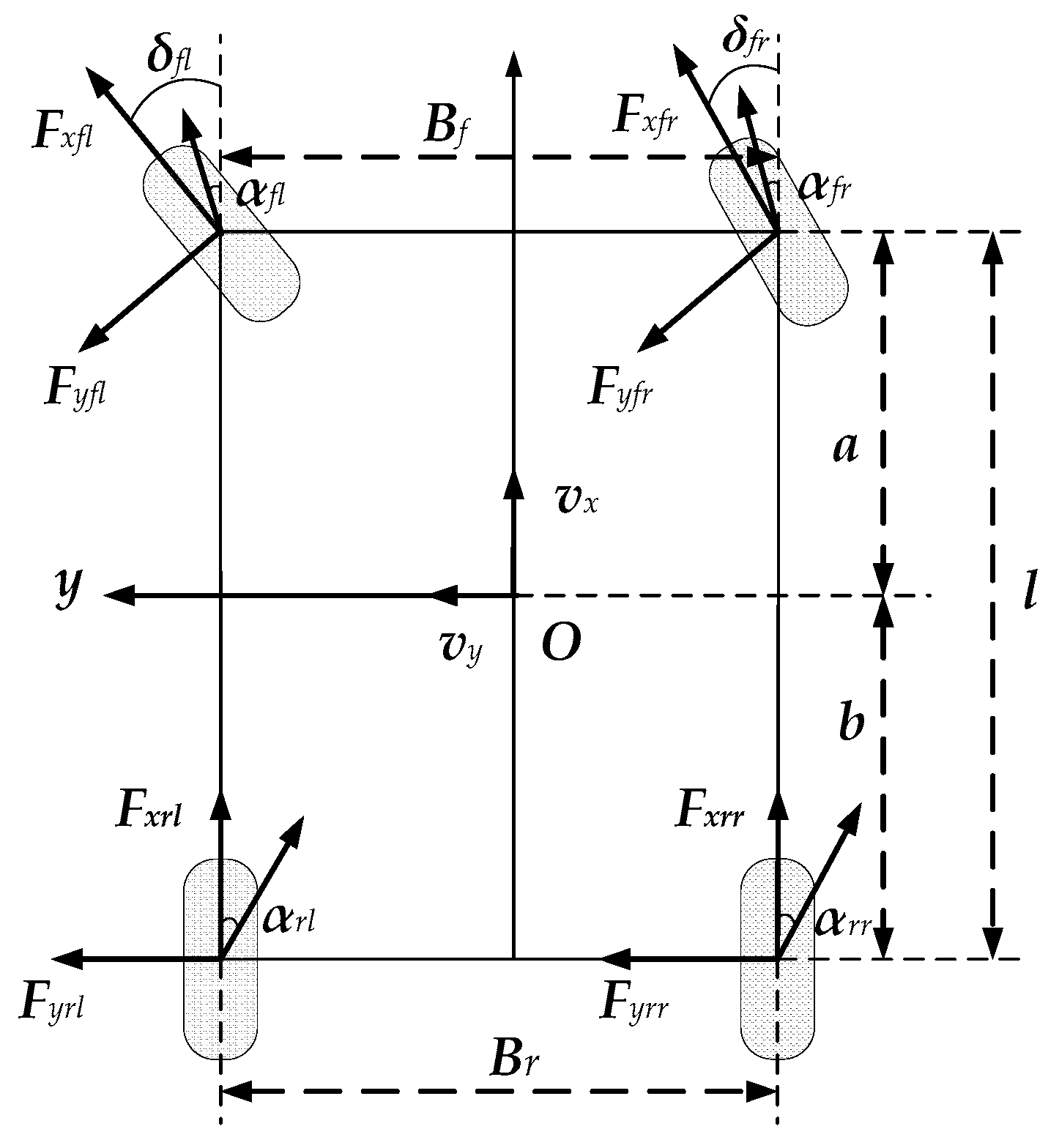

2. Nonlinear Dynamic Vehicle Model

2.1. Seven Degrees of Freedom Vehicle Model

2.2. Magic Formula

3. Normalized Tire Force

4. Higher-Order Cubature Kalman Filter Design

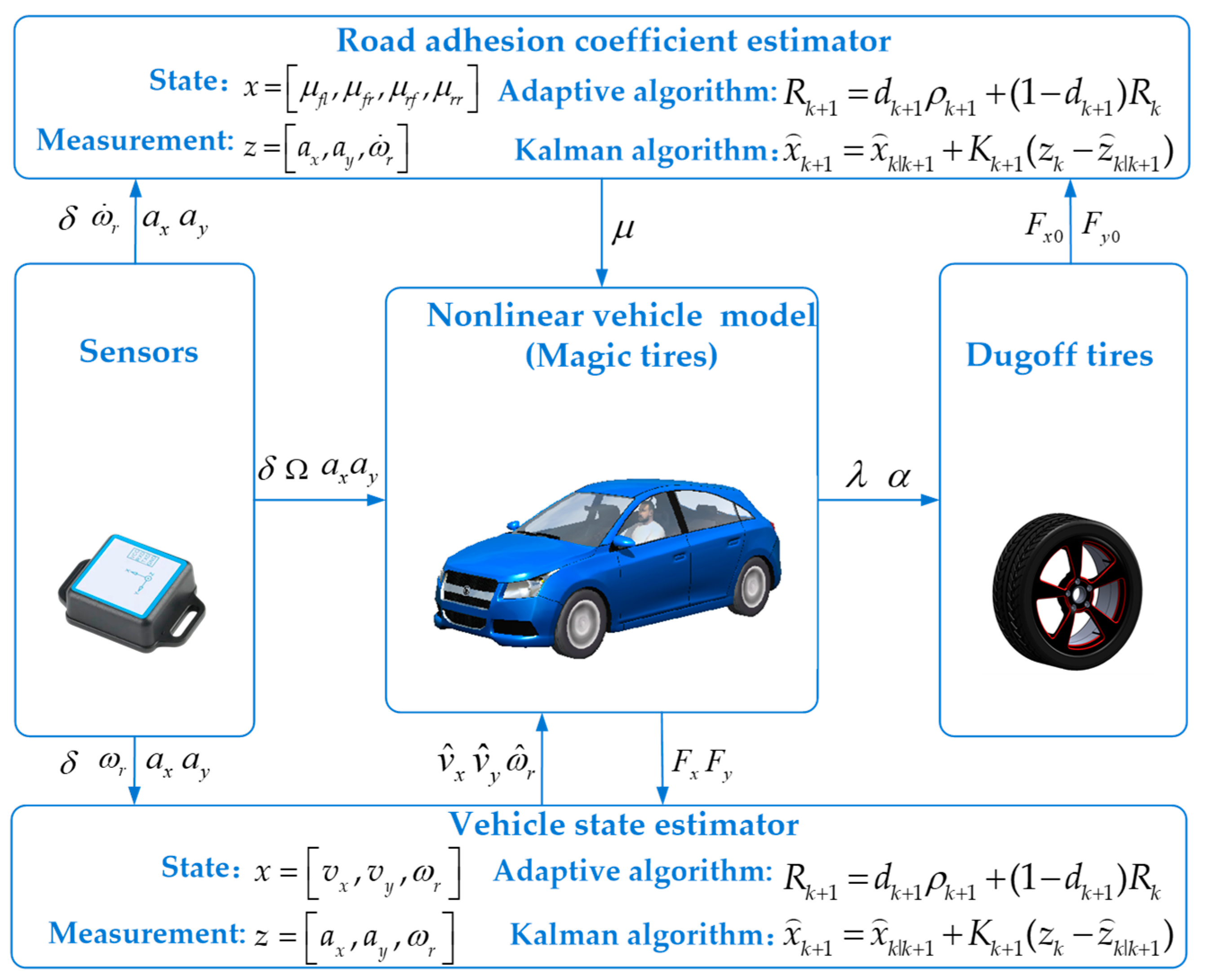

4.1. Vehicle State Estimation Algorithm

4.2. Road Adhesion Coefficient Estimation Algorithm

4.3. Design GHCKF/AGHCKF Filter

- Initialize state estimated values and error covariance:

- 2.

- Time update

- 3.

- Measurement update

- 4.

- Update the filter gain matrix Kk+1, the state variable matrix k+1, the error covariance matrix Pk+1:

- 5.

- Measurement noise covariance update:

5. Research Methods

5.1. Simulation Design

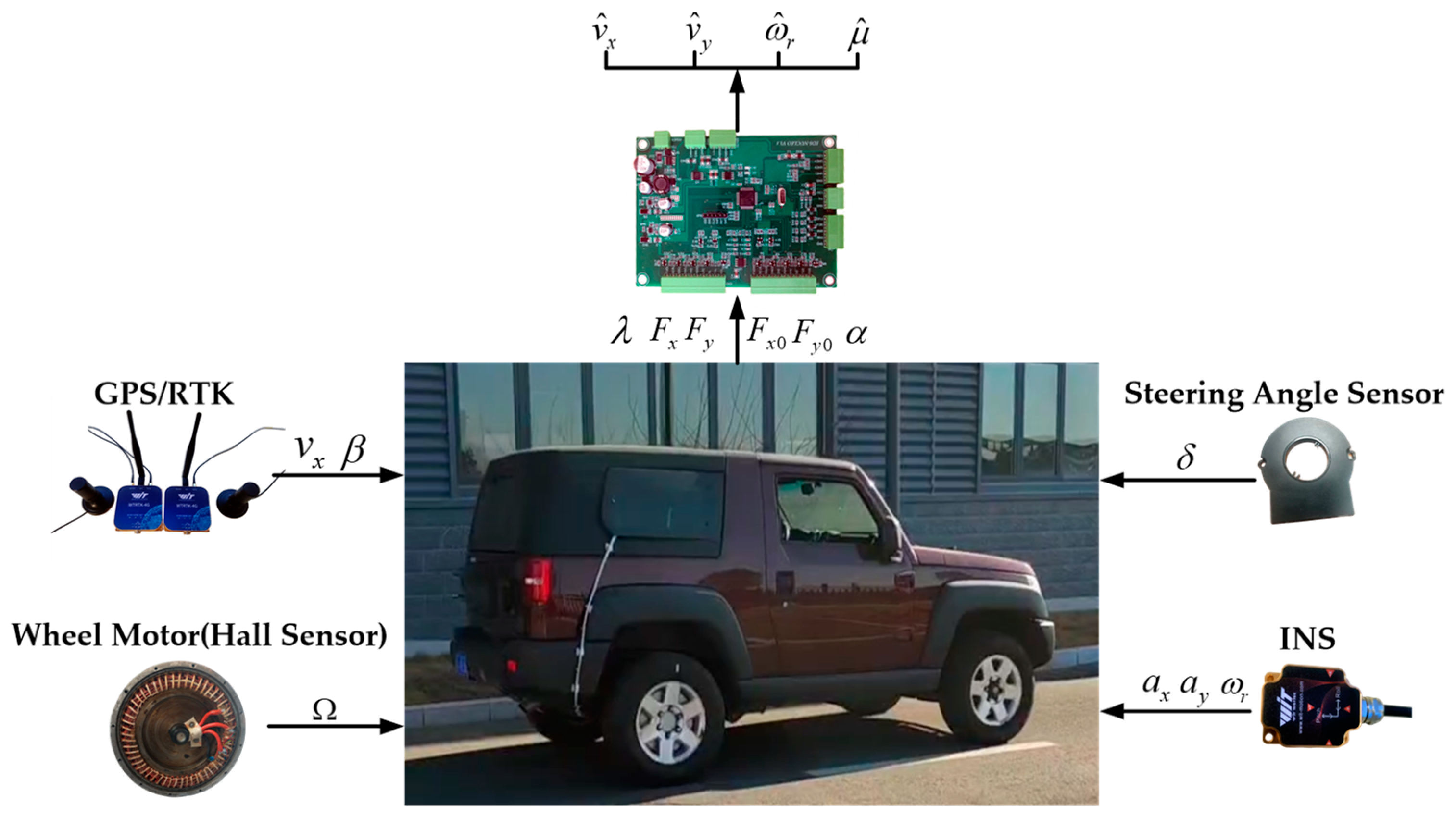

5.2. Experiment Design

6. Result Analysis

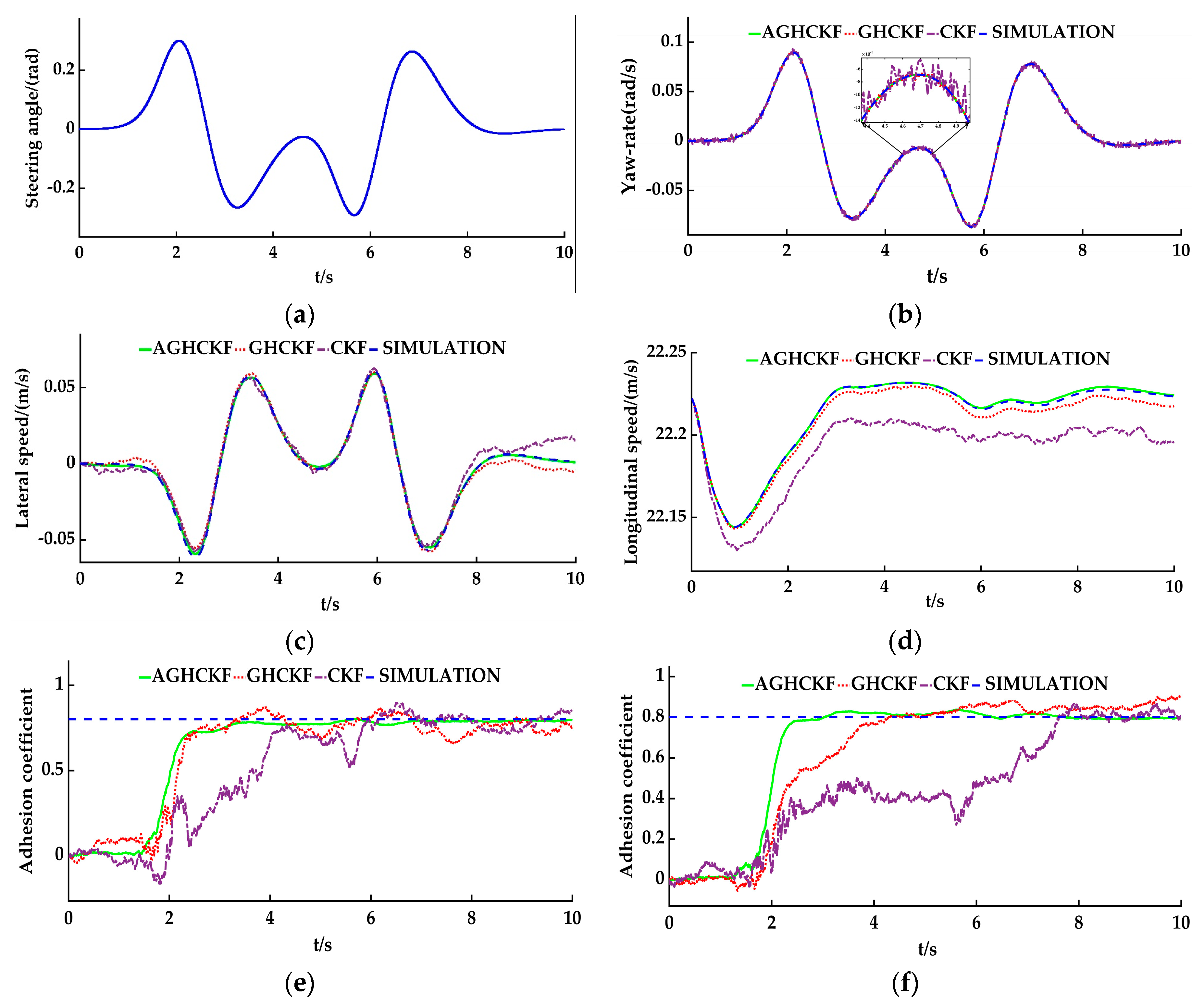

6.1. Simulation Analysis

6.1.1. The Double-Lane Change Simulation

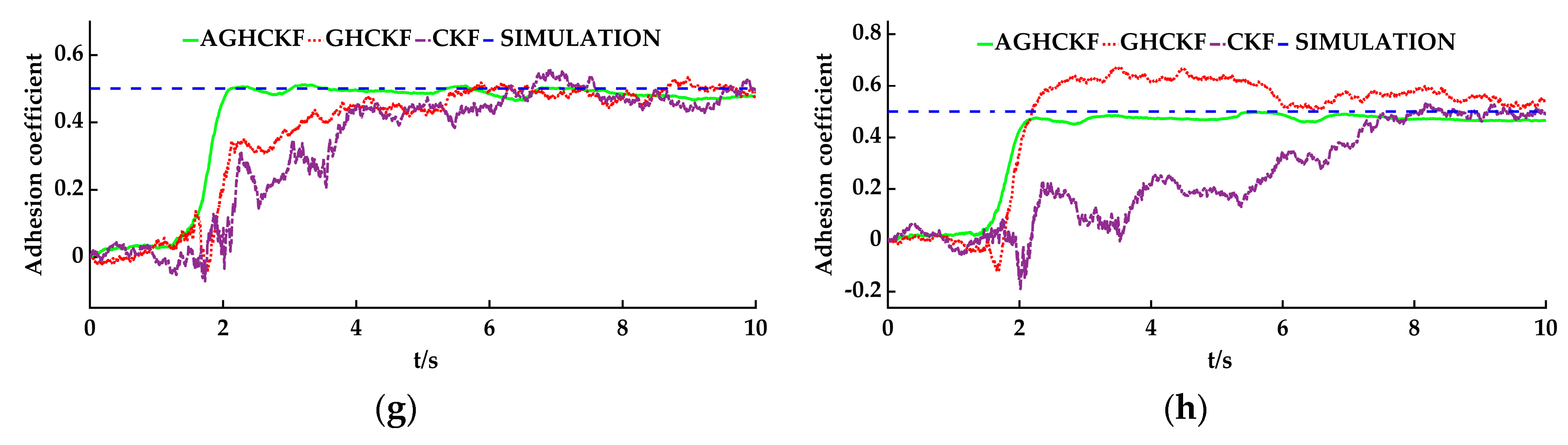

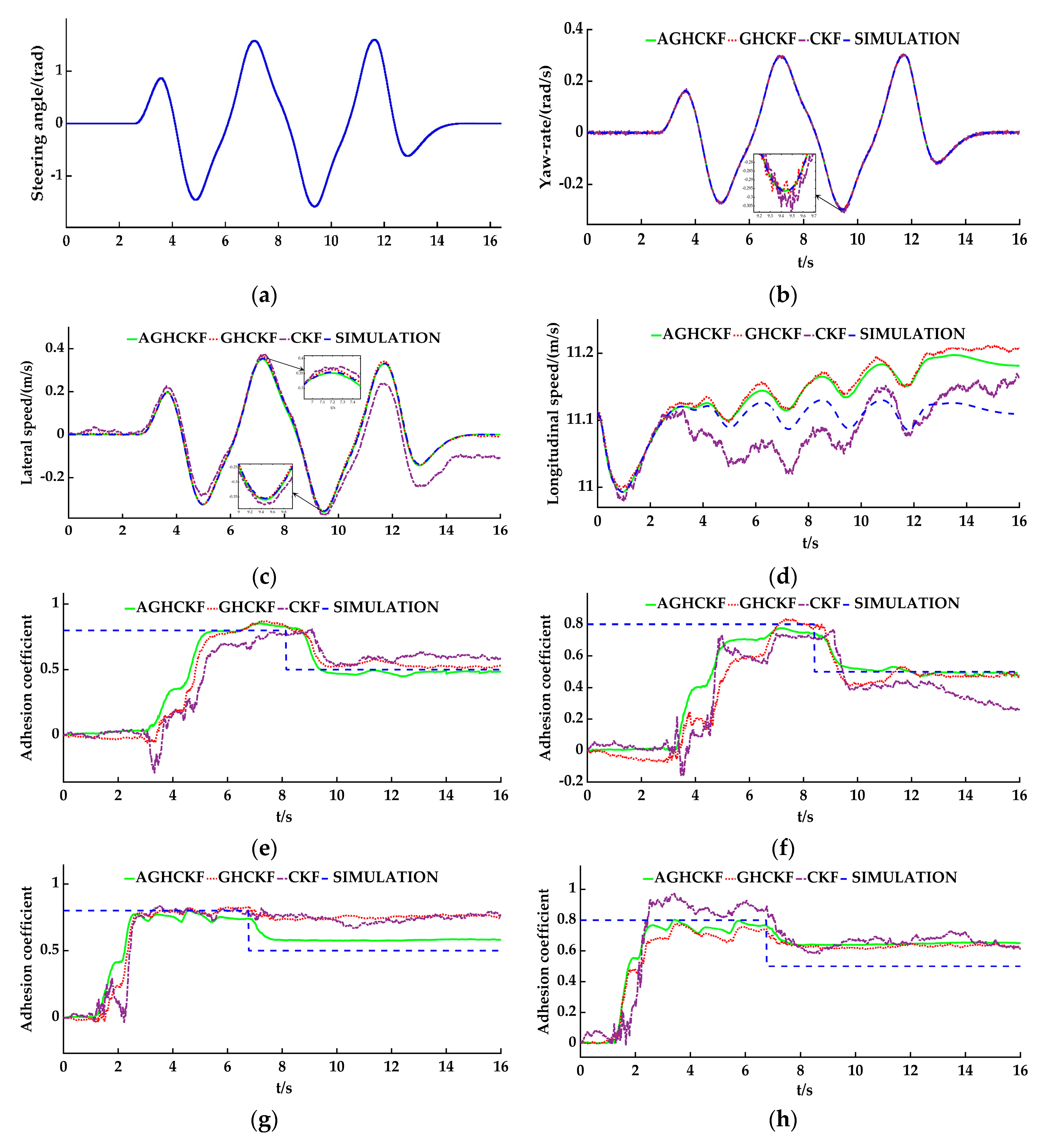

6.1.2. The Slalom Simulation

6.2. Experiment Analysis

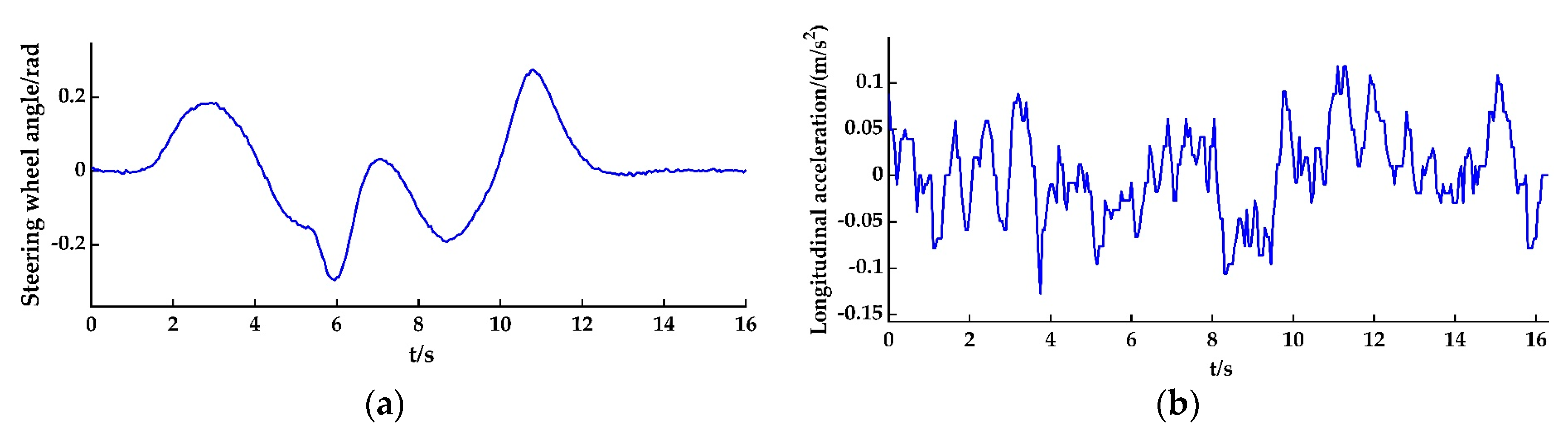

6.2.1. The Double-Lane Change Experiment

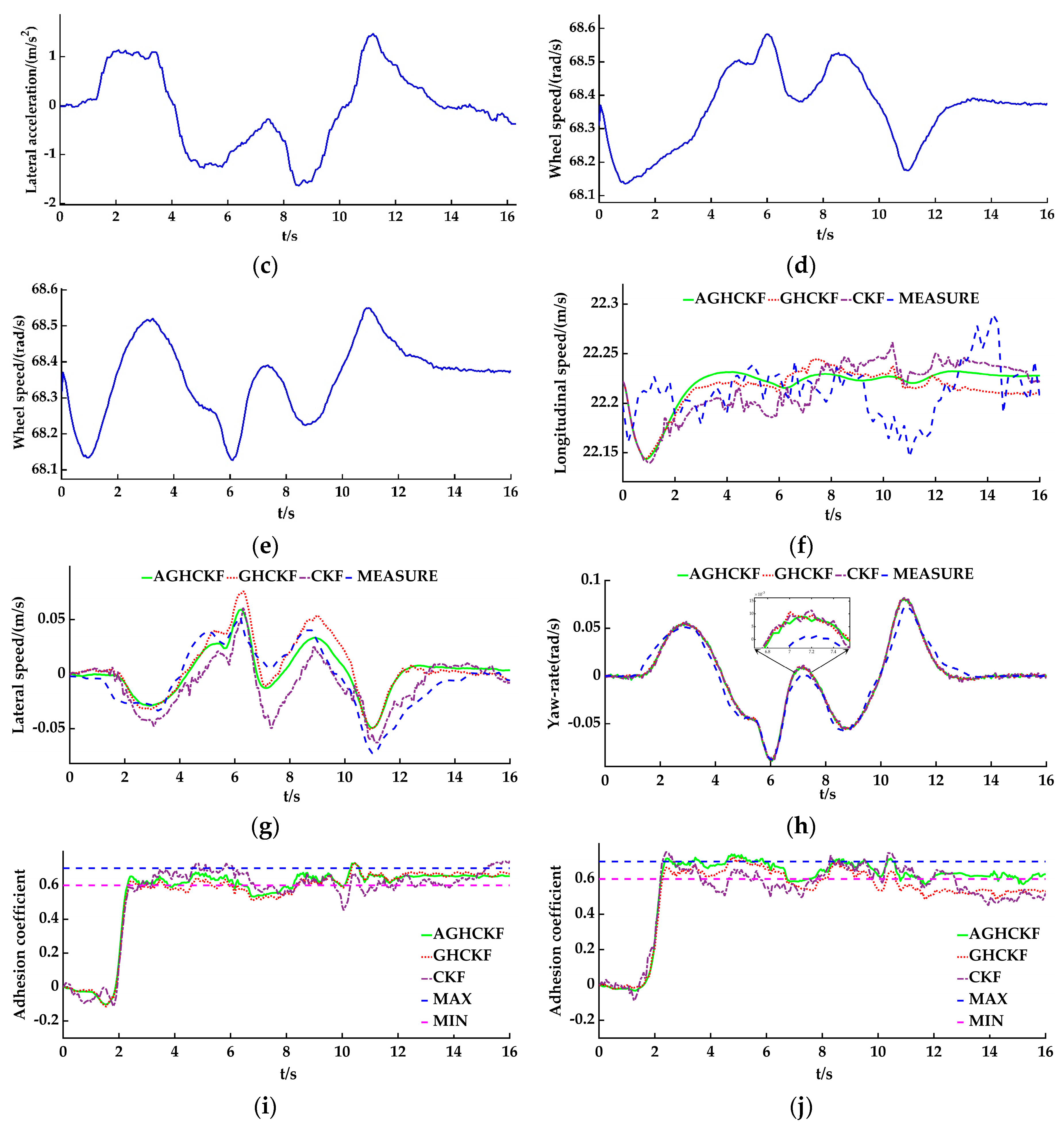

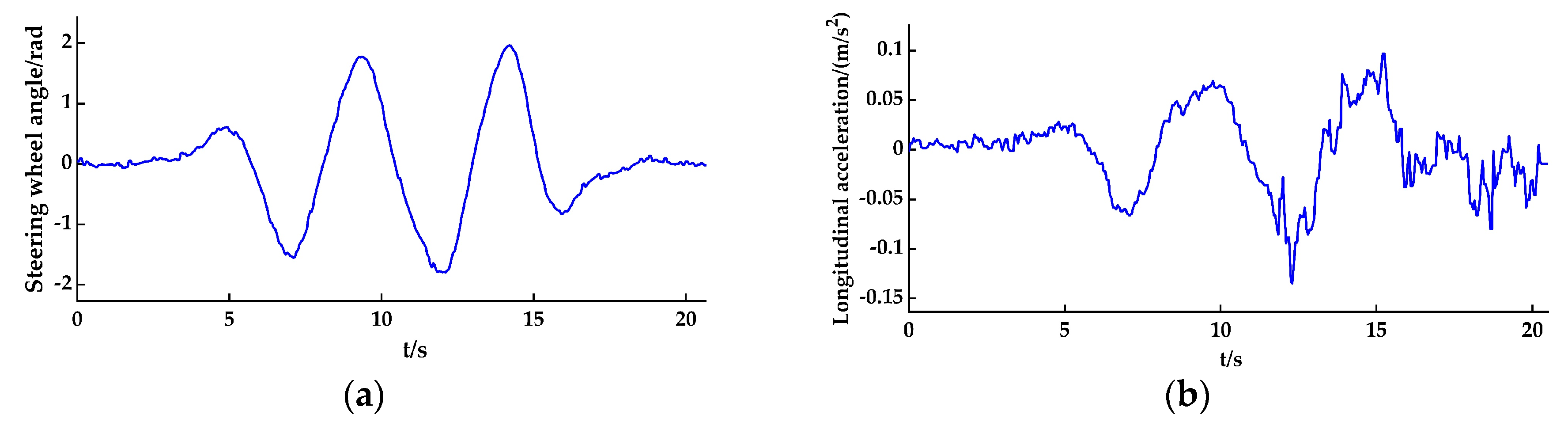

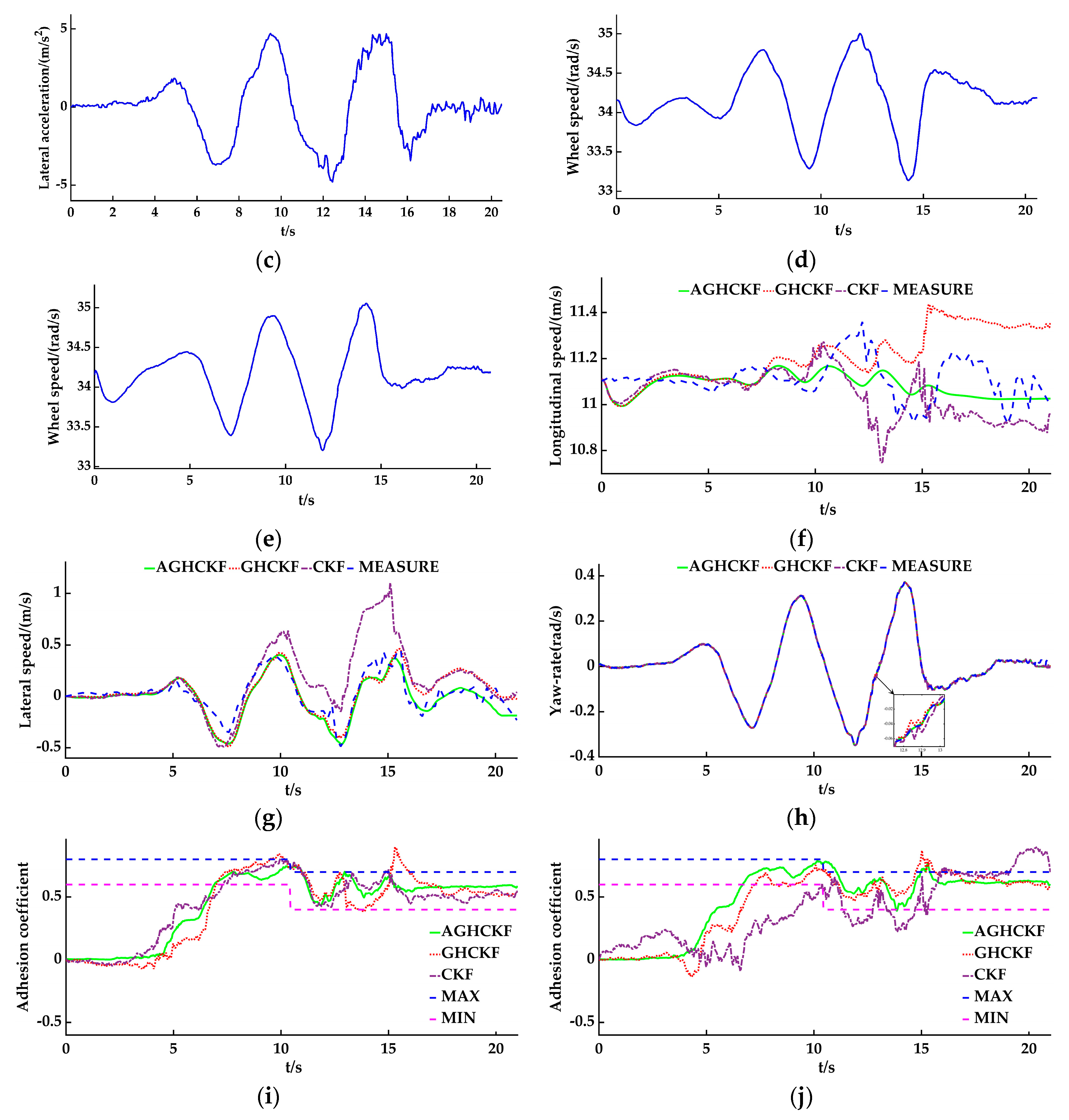

6.2.2. The Slalom Experiment

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cha, Y.F.; Lu, X.L.; Chen, H.Q.; Yi, Y.C.; Wang, Y.Y. Vehicle trajectory tracking control based on road surface attachment coefficient estimation. Automot. Eng. 2023, 45, 1010–1039. [Google Scholar] [CrossRef]

- Zhu, B.; Pu, Q.; Li, L.; Zhao, J.; Wu, J.; Deng, W.W. Vehicle longitudinal collision warning strategy based on road adhesive coefficient estimation. Automot. Eng. 2016, 38, 446–452. [Google Scholar] [CrossRef]

- Ping, X.Y.; Li, L.; Cheng, S.; Wang, H.Y. Tire-road friction coefficient estimators for 4 WID electric vehicles on diverse road conditions. J. Mech. Eng. 2019, 55, 80–92. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, L.; Ma, X.J.; Zhang, Y.Y.; Chen, L. Driving force coordinated control of an 8x8 in-wheel motor drive vehicle with tire-road friction coefficient identification. Def. Technol. 2022, 18, 119–132. [Google Scholar] [CrossRef]

- Wang, Y.; Geng, K.; Xu, L.; Ren, Y.; Dong, H.; Yin, G.D. Estimation of sideslip angle and tire cornering stiffness using fuzzy adaptive robust cubature Kalman filter. IEEE Trans. Syst. Man Cybern. 2020, 52, 1451–1462. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Chen, J. Fusion algorithm design based on adaptive SCKF and integral correction for side-slip angle observation. IEEE Trans. Industr. Electr. 2017, 65, 5754–5763. [Google Scholar] [CrossRef]

- Li, S.H.; Wang, G.Y.; Yang, Z.K.; Wang, X.W. Dynamic joint estimation of vehicle sideslip angle and road adhesion coefficient based on DRBF-EKF algorithm. Chin. J. Theor. Appl. Mech. 2022, 54, 1853–1865. [Google Scholar] [CrossRef]

- Huang, B.; Fu, X.; Wu, S.; Huang, S. Calculation algorithm of tire-road friction coefficient based on limited-memory adaptive extended Kalman filter. Math. Probl. Eng. 2019, 2019, 1056269. [Google Scholar] [CrossRef]

- Jin, X.J.; Yang, J.P.; Yin, G.D.; Wang, J.X.; Chen, N.; Lu, Y.B. Combined state and parameter observation of distributed drive electric vehicle via dual unscented Kalman filter. J. Mech. Eng. 2019, 55, 93–102. [Google Scholar] [CrossRef]

- Jin, X.J.; Yang, J.P.; Li, Y.J.; Zhu, B.; Yin, G.D. Online estimation of inertial parameter for lightweight electric vehicle using dual unscented Kalman filter approach. IET Intell. Transp. Syst. 2020, 14, 412–422. [Google Scholar] [CrossRef]

- Arasaratnam, I.; Haykin, S. Cubature Kalman filters. IEEE Trans. Autom. Control 2009, 54, 1254–1269. [Google Scholar] [CrossRef]

- Arasaratnam, I.; Haykin, S.; Hurd, T.R. Cubature Kalman filtering for continuous-discrete systems: Theory and simulations. IEEE T Signal Process 2010, 58, 4977–4993. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, G.D.; Geng, K.K.; Dong, H.X.; Lu, Y.B.; Zhang, F.J. Tire lateral forces and sideslip angle estimation for distributed drive electric vehicle using noise adaptive cubature Kalman filter. J. Mech. Eng. 2019, 55, 103–112. [Google Scholar] [CrossRef]

- Xing, D.X.; Wei, M.X.; Zhao, W.Z.; Wang, Y.; Wu, S.F. Vehicle state estimation based on adaptive volumetric particle filtering. J. Nanjing Univ. Aeronaut. Astronaut. 2020, 52, 445–453. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Zheng, L.; Li, Y.N.; Wu, X.; Yu, Y.H. Robust adaptive SCKF-based target state tracking for intelligent vehicles. J. Mech. Eng. 2021, 57, 181–193. [Google Scholar] [CrossRef]

- Wu, H.; Chen, S.X.; Yang, B.F.; Chen, K. Robust cubature Kalman filter target tracking algorithm based on genernalized M-estiamtion. Acta Phys. Sin. 2015, 64, 456–463. [Google Scholar] [CrossRef]

- Qi, D.L.; Feng, J.G.; Li, Y.B.; Wang, L.; Song, B. A Robust hierarchical estimation scheme for vehicle state based on maximum correntropy square-root cubature Kalman filter. Entropy 2023, 25, 453. [Google Scholar] [CrossRef]

- Chen, X.; Li, S.; Zhao, W.; Cheng, S. Longitudinal-lateral-cooperative estimation algorithm for vehicle dynamics states based on adaptive square root cubature Kalman filter and similarity-principle. Mech. Syst. Signal Process. 2022, 176, 109162–109183. [Google Scholar] [CrossRef]

- Mcnamee, J.; Stenger, F. Construction of fully symmetric numerical integration formulas. Numer. Mathmatik 1967, 10, 327–344. [Google Scholar] [CrossRef]

- Su, B.Z.; Mu, R.J.; Long, T.; Cheng, C.; Cui, N.G. Performance Evaluation of HCKF and Its Application in Transfer Alignment. J. Astronaut. 2019, 40, 1313–1321. [Google Scholar]

- Zhang, X.F.; Guo, C.; Qin, K.; Yao, B. High-degree cubature Kalman filter with colored measurement niose and its application. Comput. Eng. Appl. 2017, 53, 263–270. [Google Scholar] [CrossRef]

- Li, W.; Hao, S.Y.; Huang, G.R.; Ma, S.J. Improved adaptive ADMCC-HCKF algorithm and application in SINS/CNS/GNSS integrated navigation. J. Electron. Meas. Instrum. 2021, 35, 79–85. [Google Scholar] [CrossRef]

- Qin, K.; Dong, X.M.; Chen, Y.; Liu, Z.C.; Li, H.B. Huber-based robust generalized high-degree cubature Kalman filter. Control Decis. 2018, 3, 88–94. [Google Scholar] [CrossRef]

- Hao, S.Y.; Lu, H.; Wei, X.; Xu, M.Q. Reduced high-degree strong tracking cubature Kalman filter and its application in inte-grated navigation system. Control Decis. 2019, 34, 2105–2114. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, P. A more general class of cubature Kalman filters. Comput. Eng. Appl. 2015, 51, 207–210. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, H.H.; Gao, C.; Li, Q.W. The linear three-degree-of-freedom vehicle model based on Simulink simula-tion. Intell. Comput. Appl. 2020, 10, 200–207. [Google Scholar]

- Qiu, C.F.; Zhou, L.; Chen, R.Q.; Sun, X.Y.; Jia, C.H.; Qiu, J.W.; Zhang, C.; Yang, H.T. Calculation Method of Tire Longitudinal Slip Characteristic Parameters Based on Magic Formula. Tire Ind. 2021, 41, 607–611. [Google Scholar] [CrossRef]

- Ružinskas, A.; Sivilevičius, H. Magic formula tyre model application for a tyre-ice interaction. Procedia Eng. 2017, 187, 335–341. [Google Scholar] [CrossRef]

- Zheng, X.M.; Gao, X.W.; Zhao, Z.Z. Simulation analysis of tire dynamic based on “Magic Formula”. Mach. Electron. 2012, 9, 16–20. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, P.L.; Zhou, L.H.; Jiang, J.X.; Liang, M.L.; Hou, J.W. Estimation of vehicle sideslip angle based on Dugoff tire model. J. Guangxi Univ. 2021, 46, 1523–1532. [Google Scholar] [CrossRef]

- Dugoff, H.; Fancher, P.S.; Segel, L. An analysis of tire action properties and their influence on vehicle dynamic performance. SAE Trans. 1970, 79, 1219–1243. [Google Scholar] [CrossRef]

- Peng, Z.Y.; Xia, H.B.; Xu, Y.S. Adaptive generalized high-degree Cubature Kalman Filter based on target tracking. Comput. Eng. Appl. 2018, 54, 46–52. [Google Scholar] [CrossRef]

- Zhang, X.C.; Teng, S.J. A New Derivation of the Cubature Kalman Filters. Asian J. Control 2014, 16, 1501–1510. [Google Scholar] [CrossRef]

- Liu, D.; Chen, X.Y.; Xu, Y.; Liu, X.; Shi, C.F. Maximum correntropy generalized high-degree cubature Kalman filter with application to the attitude determination system of missile. Aerosp. Sci. Technol. 2019, 95, 105441. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, S.B.; He, H.L. Adaptive Cubature Kalman Filter Based on Unknown Noise Covariance. J. Air Force Eng. Univ. 2021, 22, 42–47. [Google Scholar] [CrossRef]

- Ge, J.; Dong, H.B.; Liu, H.; Bai, M.M.; Qiu, X.Y.; Yuan, Z.W.; Liu, Y.H.; Zhu, J.; Zhang, H.Y. Real-time Reduction of Magnetic Noise Associated with Ocean Waves via Sage-Husa lgorithm for Towed Overhauser Marine Geomagnetic Sensor. Earth Sci. 2018, 43, 3792–3798. [Google Scholar] [CrossRef]

| Estimated Value | AGHCKFRMSE | GHCKFRMSE | CKFRMSE |

|---|---|---|---|

| The longitudinal velocity | 0.0010 | 0.0039 | 0.0216 |

| The lateral velocity | 0.0011 | 0.0034 | 0.0051 |

| The yaw rate | 0.0001 | 0.0003 | 0.0015 |

| The left rear wheel adhesion coefficient (μrl = 0.8) | 0.3373 | 0.3394 | 0.4336 |

| The right rear wheel adhesion coefficient (μrl = 0.8) | 0.3375 | 0.3759 | 0.4414 |

| The left rear wheel adhesion coefficient (μrl = 0.5) | 0.1921 | 0.2218 | 0.2492 |

| The right rear wheel adhesion coefficient (μrl = 0.5) | 0.2010 | 0.2880 | 0.3365 |

| Estimated Value | AGHCKFRMSE | GHCKFRMSE | CKFRMSE |

|---|---|---|---|

| The longitudinal velocity | 0.0446 | 0.0521 | 0.0354 |

| The lateral velocity | 0.0042 | 0.0068 | 0.0613 |

| The yaw rate | 0.0004 | 0.0022 | 0.0029 |

| The left rear wheel adhesion coefficient (vx = 40 km/h) | 0.3910 | 0.4287 | 0.4441 |

| The right rear wheel adhesion coefficient (vx = 40 km/h) | 0.3912 | 0.4319 | 0.4407 |

| The left rear wheel adhesion coefficient (vx = 80 km/h) | 0.2685 | 0.3441 | 0.3413 |

| The right rear wheel adhesion coefficient (vx = 80 km/h) | 0.2759 | 0.2768 | 0.2963 |

| Estimated Value | AGHCKFRMSE | GHCKFRMSE | Difference |

|---|---|---|---|

| The longitudinal velocity | 0.0320 | 0.0339 | 0.0371 |

| The lateral velocity | 0.0163 | 0.0181 | 0.0202 |

| The yaw rate | 0.0064 | 0.0065 | 0.0068 |

| The left rear wheel adhesion coefficient | 0.2469 | 0.2500 | 0.2537 |

| The right rear wheel adhesion coefficient | 0.2335 | 0.2416 | 0.2392 |

| Estimated Value | AGHCKFRMSE | GHCKFRMSE | CKFRMSE |

|---|---|---|---|

| The longitudinal velocity | 0.0199 | 0.0203 | 0.185 |

| The lateral velocity | 0.0881 | 0.1160 | 0.2456 |

| The yaw rate | 0.0041 | 0.0044 | 0.0051 |

| The left rear wheel adhesion coefficient | 0.3496 | 0.3896 | 0.3406 |

| The right rear wheel adhesion coefficient | 0.3404 | 0.3688 | 0.3983 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, L.; Chang, R.; Guo, C. Vehicle State and Road Adhesion Coefficient Joint Estimation Based on High-Order Cubature Kalman Algorithm. Appl. Sci. 2023, 13, 10734. https://doi.org/10.3390/app131910734

Quan L, Chang R, Guo C. Vehicle State and Road Adhesion Coefficient Joint Estimation Based on High-Order Cubature Kalman Algorithm. Applied Sciences. 2023; 13(19):10734. https://doi.org/10.3390/app131910734

Chicago/Turabian StyleQuan, Lingxiao, Ronglei Chang, and Changhong Guo. 2023. "Vehicle State and Road Adhesion Coefficient Joint Estimation Based on High-Order Cubature Kalman Algorithm" Applied Sciences 13, no. 19: 10734. https://doi.org/10.3390/app131910734

APA StyleQuan, L., Chang, R., & Guo, C. (2023). Vehicle State and Road Adhesion Coefficient Joint Estimation Based on High-Order Cubature Kalman Algorithm. Applied Sciences, 13(19), 10734. https://doi.org/10.3390/app131910734