Abstract

This article presents the results of an assessment of the combustion process of blends of n-hexane and canola oil. Tests were conducted for pure canola oil and its blends with n-hexane, with a max. n-hexane content of 20% by volume. The tests were carried out using the constant volume combustion chamber (CVCC) method as well as a diesel engine. For comparison purposes, the results for typical diesel fuel are also presented. Tests on the self-ignition properties of the n-hexane–canola oil blend, conducted in a CVCC according to the normative method for diesel fuel, showed little effect on the combustion process. However, previous tests conducted on a diesel engine of a passenger car showed a favorable effect of the n-hexane addition to canola oil on the combustion process in the engine, the performance and environmental parameters obtained. This shows that for some fuels, the evaluation of self-ignition and combustion properties in a constant volume combustion chamber, under conditions corresponding to diesel fuel tests, is not sufficient. The findings of this research may be beneficial in optimizing the diesel engine combustion systems fueled by renewable fuels. As the results of the tests have shown, the standardized method for determining the combustion process of the CVCC method does not always fully reflect the results obtained in engine tests. The results obtained by the CVCC method can be successfully used when comparing fuels, but when considering the selection of fuel for the engine, the results obtained in engine tests should be relied on first and foremost.

1. Introduction

The problem of climate warming requires reducing greenhouse gas emissions in all branches of the human economy. This is particularly important in the transportation and power generation sectors [1,2]. This is leading to the replacement of fossil fuels with renewable fuels [3]. These fuels include vegetable oils and their esters [4,5,6]. Research on the use of vegetable oils as engine fuels is being conducted by many scientists [7,8,9]. However, the results of studies when the engine is fueled with pure vegetable oil tend to be unfavorable compared to the results obtained when fueled with diesel [10,11,12,13,14]. The main problems associated with the use of vegetable oils in diesel engines are low thermal efficiency due to high viscosity and carbon residues, and high smoke levels. Many publications deal with fuels that are blends of vegetable oils and other components [15,16,17]. Potential additives to improve blend properties over pure canola oil include n-hexane [18]. An example of a paper confirming the beneficial properties of n-hexane and fuel blends with waste plastic fuel and jatropha biodiesel and diesel fuel is [19]. The results presented there confirm that the addition of n-hexane can improve the physicochemical properties of the fuel and enable the reduction in CO and NOX in the engine exhaust. Additionally, engine research reveals that the fuel samples with n-hexane added have improved thermal and volumetric efficiencies and lower BSFC (brake specific fuel consumption) [19].

Among other things, the addition of n-hexane results in improved low-temperature properties, as well as improved auto-ignition and combustion properties. Note that it is particularly important to test fuels and their blends on diesel engines, which are equipped with common rail injection systems that allow the fuel dose to be divided into several parts.

Testing of self-ignition and combustion properties can be carried out using various methods. These methods include engine methods and methods implemented in a constant volume chamber. Depending on the method adopted and the test conditions, the results may vary. In particular, it should be borne in mind that tests in a constant volume chamber are carried out under established conditions that may differ from those in the engine tests [20].

Tests of blends of canola oil and n-hexane carried out in a constant volume chamber under conditions corresponding to diesel fuel tests in accordance with ASTM-D7668 [21] showed little effect of the addition of n-hexane on the value of the derived cetane number and the parameters of the combustion process. On the other hand, tests conducted under dynamic conditions on a passenger car with a diesel engine showed a significant effect of the n-hexane additive on the combustion process and the performance parameters that depend on it.

The novelty of the article, in addition to proposing the use of n-hexane as an additive to canola oil, is the study of the self-ignition properties of the blends in question under constant volume chamber combustion conditions. Due to the invariability of the fuel injection conditions, this ensures very high repeatability of the results in terms of both DCN and ignition delay.

2. Experimental Methodology

2.1. Fuel Tested Physicochemical Properties and Sample Characterization

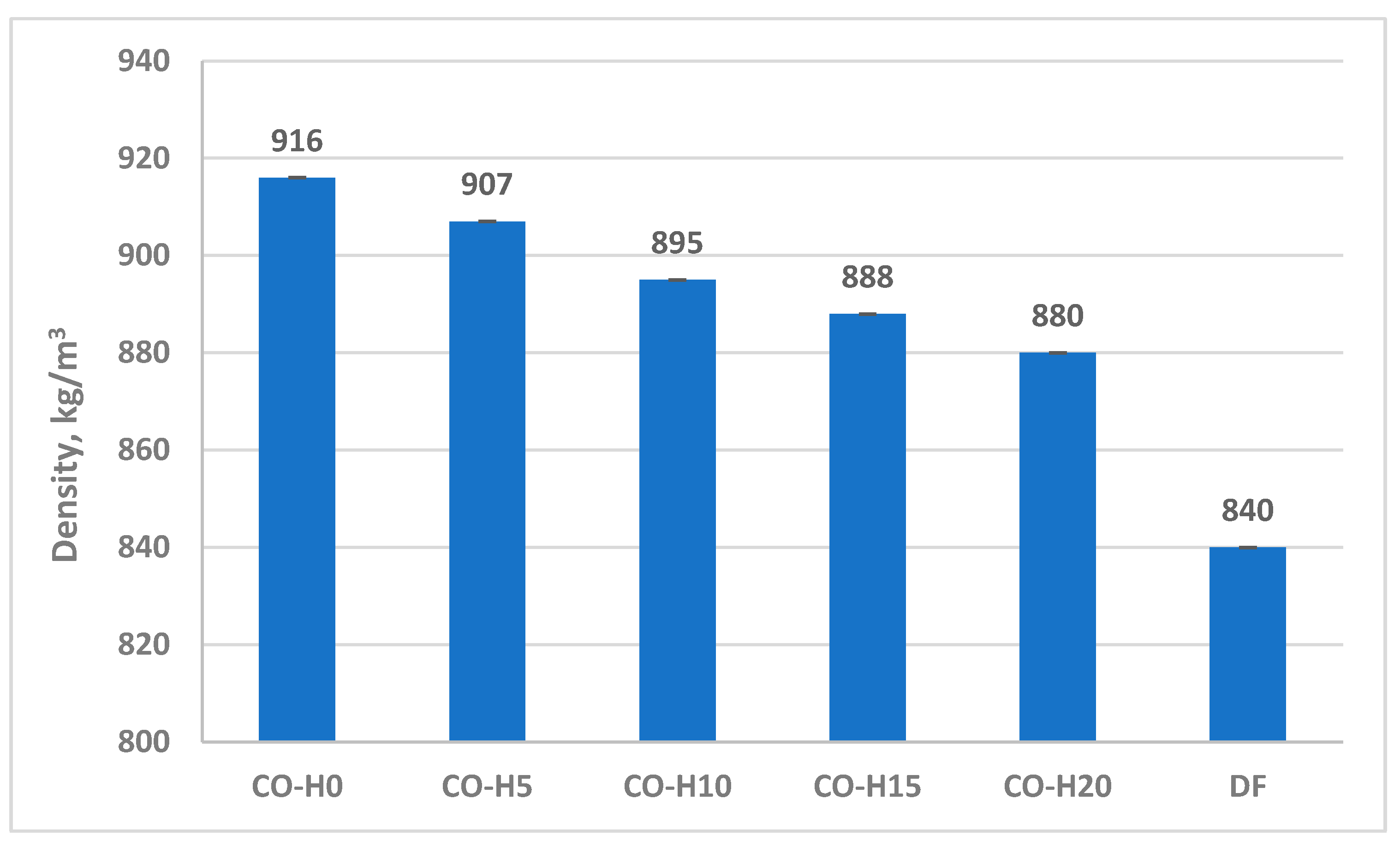

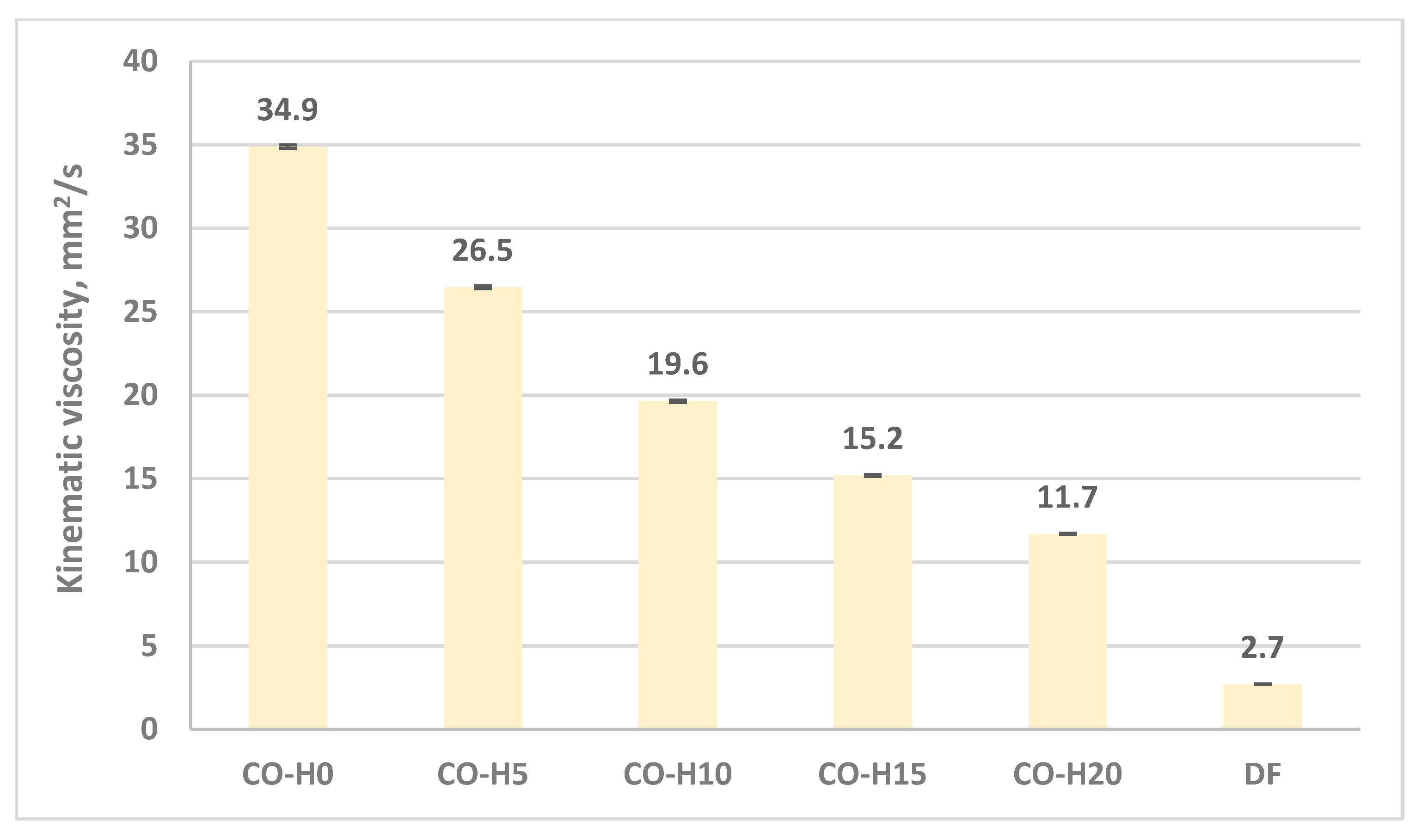

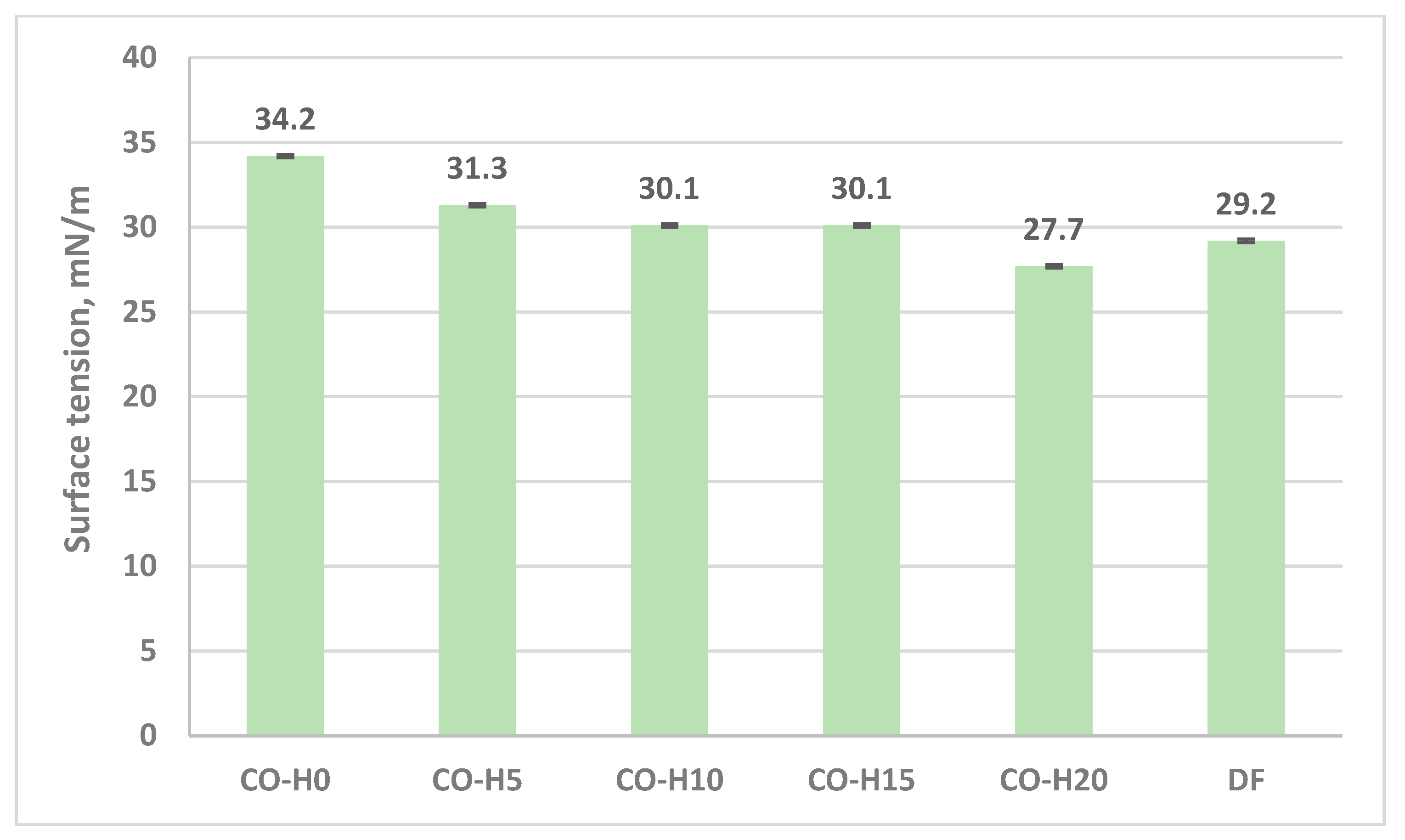

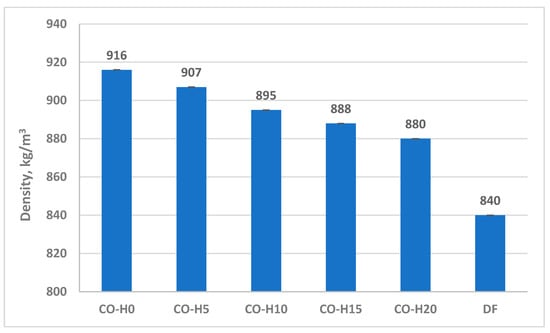

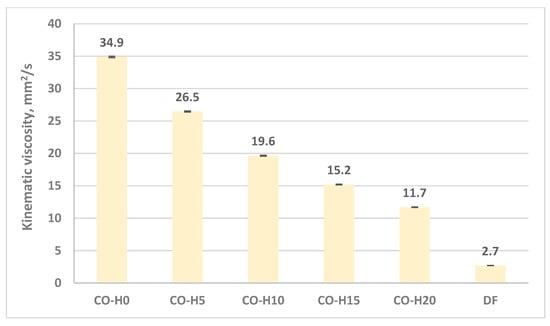

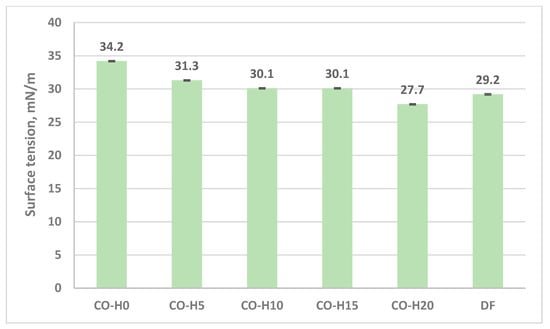

Considering the use of fuel for a diesel engine, it is advantageous for the fuel’s properties to be as close as possible to those of diesel fuel. To this end, an attempt was made to change the physical properties of canola oil by adding n-hexane. Adding n-hexane to canola oil in a relatively small amount had a beneficial effect on the physical and chemical parameters of the canola oil-based blend. The chemical compound n-hexane has specific properties, i.e., surface tension, density and viscosity, which are much lower than those of diesel fuel. The tests were carried out for blends of canola oil and n-hexane, the basic physicochemical parameters of which are summarized in Table 1. The determinations of the prepared blends are shown in Table 2. The values of selected physicochemical properties of canola oil–n-hexane blends are shown in Figure 1, Figure 2 and Figure 3 [18]. Density measurements were made in accordance with the procedure contained in PN-EN ISO 12185 [22]. An accurate density meter of type DMA 4500 was used. The results were presented as the mean value of two measurements. Uncertainty for density measurement ±0.00005 g/cm3 was determined by the supplier of the test device and was confirmed by a calibration certificate of the measuring device. The accuracy of the temperature given by the manufacturer was equal to ±0.001 K. Commercially available refined canola oil was blended with n-butanol in volume fractions of 5 to 20%. The main components of canola oil are unsaturated fatty acids, such as oleic, linoleic and linolenic acids. Their content in canola oil exceeds 90%. On the other hand, n-hexane (C6H14) is an organic chemical compound from the alkane group. Hexane isomers are highly unreactive and are often used as solvents in organic reactions because they are highly non-polar. They are also included in gasoline. N-hexane is produced during petroleum refining. The industrial product is a fraction boiling at 65–70 °C. For comparison, tests were also conducted for typical diesel fuel (DF). The physicochemical properties and test methods of the diesel used in the study were in accordance with the Polish standardPN-EN 590 [23]. The surface tension of the canola oil and n-hexane blends was measured by the Krüss K9 tensiometer according to the platinum ring detachment method at 293 K. In all cases, 10 measurements were performed. The standard deviation was 0.1 mN/m. The viscosity measurements of the canola oil and n-hexane blends were performed with the Anton Paar viscometer, AMVn, with a precision of 0.0001 mPas and an uncertainty of 0.3% [18]. The addition of n-hexane to canola oil reduced the density of the fuel, the values of which approach that of diesel fuel (Figure 1). For the addition of 20% vol. n-hexane, the density value of the blend with canola oil was lower than that of pure canola oil by approx. 4%. A similar effect of the addition of n-hexane to canola oil applied to kinematic viscosity (Figure 2) and surface tension (Figure 3). The addition of 20% n-hexane reduced kinematic viscosity by about 23 mm2/s and surface tension by about 6.5 mN/m (this is a lower surface tension value than for the diesel fuel under test).

Table 1.

Canola oil and n-hexane parameters [24].

Table 2.

Samples’ symbols.

Figure 1.

Density of the fuels tested at temperature 15 °C.

Figure 2.

Kinematic viscosity of the fuels tested at temperature 40 °C.

Figure 3.

Surface tension of the fuels tested at temperature 20 °C.

2.2. Test Setup and Procedures

2.2.1. Research Using the CVCC Method

The research used a CVCC-based CID 510 analyzer (Figure 4). The measurements were aimed at determining the effect of the addition of n-hexane on the self-ignition properties of blends of canola oil with n-hexane, including the values of the derived cetane number DCN and the parameters of the combustion process (ID, CD, MPR).

Figure 4.

View of the CID 510 analyzer.

The tests were carried out according to the method in accordance with ASTM-D7668 standard [21]). The key purpose of this instrument is to determine the DCN according to standard testing procedures [21,28]. The same instrument was used by Lapuerta et al. [29] and Kuszewski et al. [30]. The calibration parameters, as summarized in Table 3, were maintained throughout the test cycle.

Table 3.

Calibration parameters of test instrument.

According to standard ASTM-D7668, the combustion chamber of the device is mounted with an injector of Bosch Serial No. 0445110181. The injector has a 6-hole atomizer with holes of 0.17 mm diameter. For each fuel, 15 injections were performed, and the following parameters were recorded: injection pressure (pinj), temperature of the combustion chamber wall (tch), static pressure in the chamber (p0), MPR in the combustion chamber with respect to p0, ID and CD. Ambient pressure during testing was 101 ± 0.5 kPa.

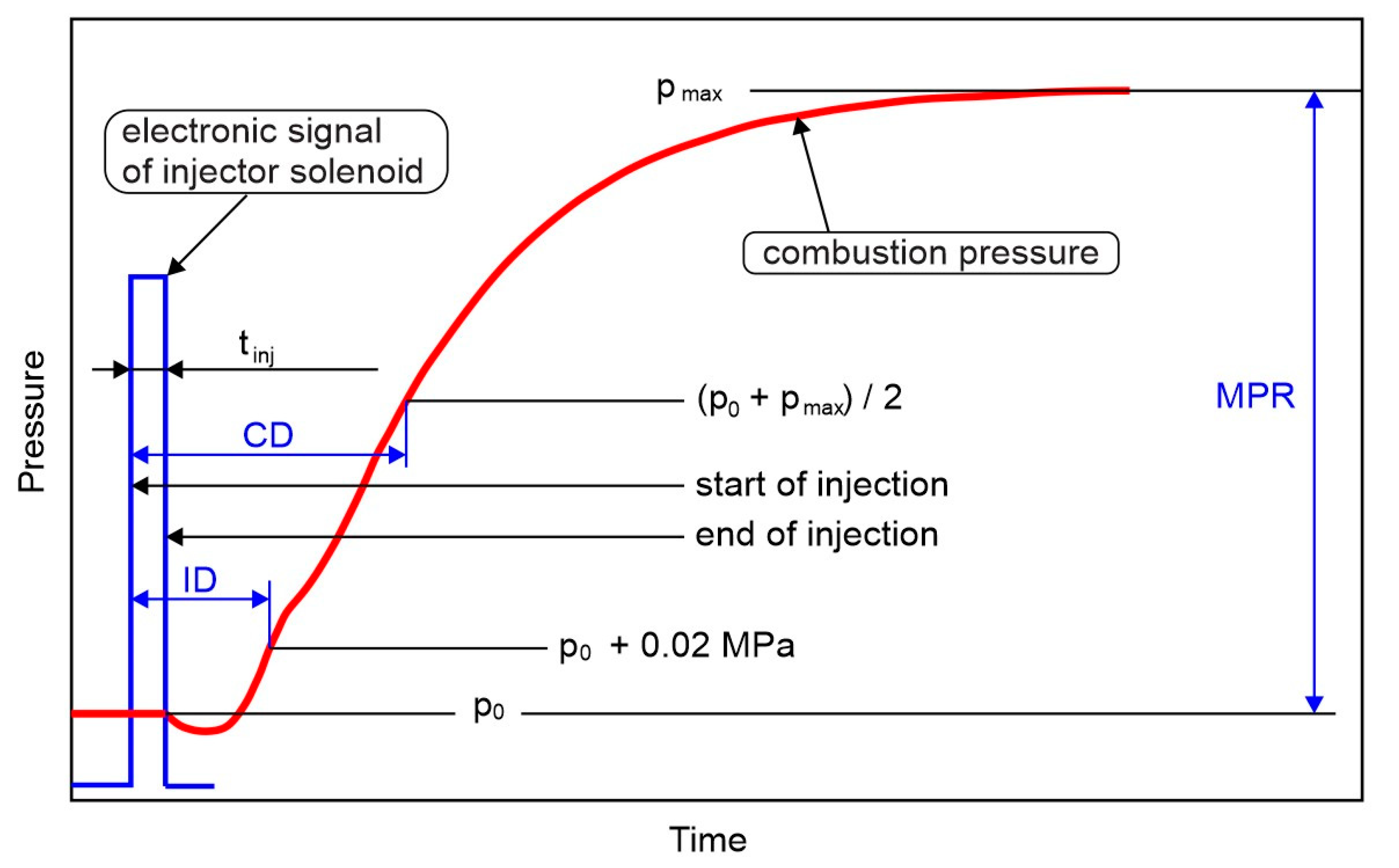

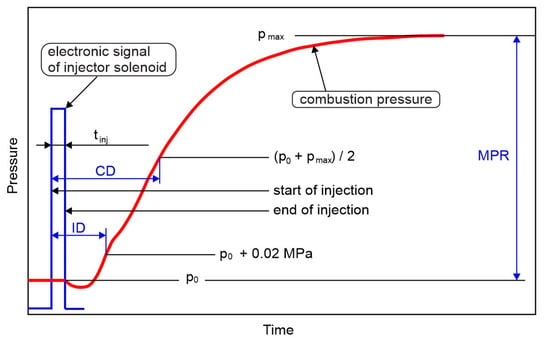

Figure 5 shows a scheme for determining ID, CD and MPR parameters. The beginning of the ignition delay period corresponds to the triggering of the control signal of the injector solenoid valve, while the end of this period is taken as the moment when the pressure in the combustion chamber reaches a value above 0.02 MPa relative to the static pressure po. The injection time (tinj) corresponds in the presented method to the length of the injector control signal. The combustion delay period is defined as the time between the triggering of the control signal of the injector solenoid valve and the moment corresponding to reaching half of the increase in combustion chamber pressure (pch) relative to the static initial pressure in the chamber (p0). More detailed descriptions of MPR, ID and CD measurements can also be found in [30,31].

Figure 5.

Scheme for determining ID, CD and MPR parameters [31].

The synthetic air temperature was taken as the measured combustion chamber wall temperature (tch). Other parameters, such as injection pulse width (tinj), injection pressure (pinj), static pressure in the chamber (p0), injector coolant temperature (tco) and oxygen concentration in synthetic air, had the same values at each measurement stage.

Table 4 shows the specifications of the synthetic air.

Table 4.

Specification of the synthetic air.

2.2.2. Engine Tests

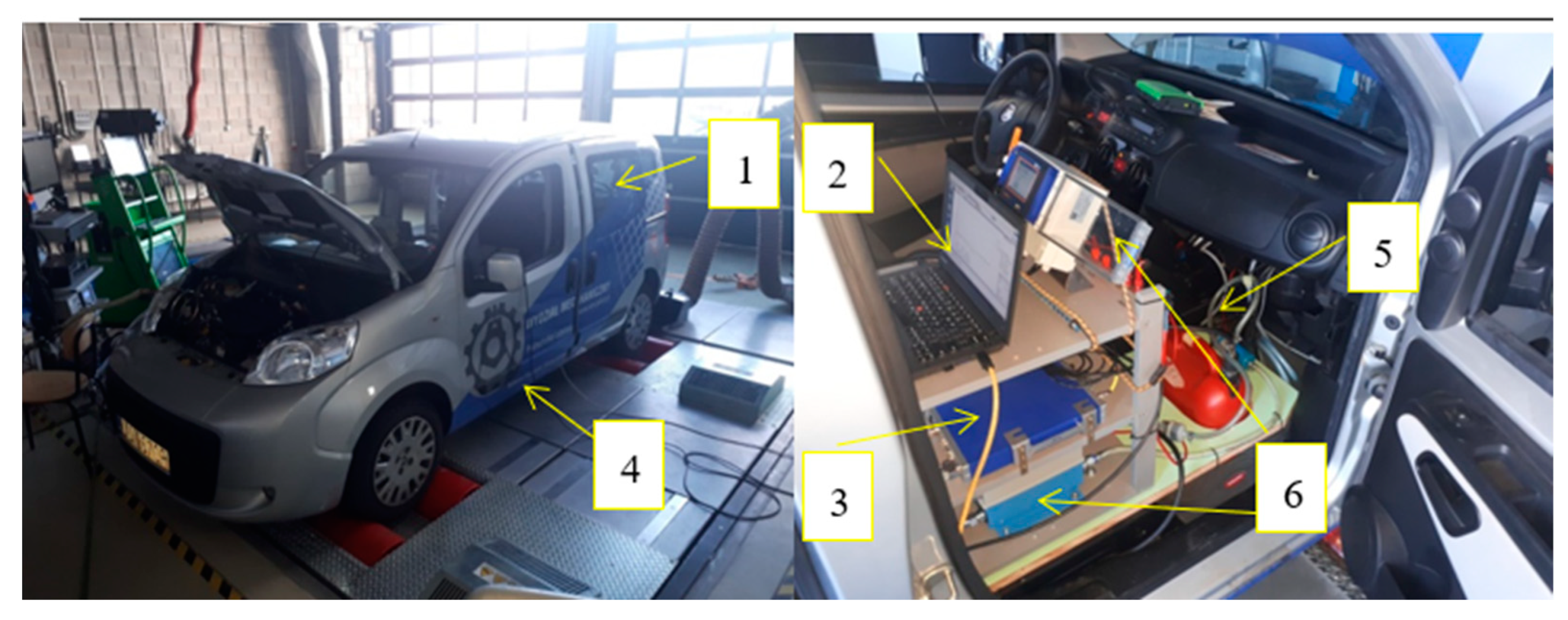

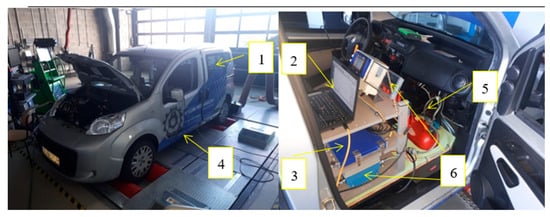

Engine tests were carried out on a diesel engine with a common rail fuel injection system installed in a Fiat Qubo vehicle that met Euro 5 emission standards. The indication of the compression ignition engine under traction conditions was carried out by simulating driving on a DF4FS-HLS chassis dynamometer. A schematic diagram of the test stand is shown in Figure 6, and detailed engine data are given in Table 5.

Figure 6.

Test bed: 1. Fiat Qubo test car with 1.3 Multijet engine; 2. computer with installed AVL IndiCom V2.7 software; 3. Indimicro 602 engine indicator system; 4. DF4FS-HLS chassis dynamometer; 5. additional fuel system tank; 6. rotameter with Multicon CMC-99 module by Simex [32].

Table 5.

Technical data of the 1.3 Multijet engine in the Fiat Qubo test vehicle [32].

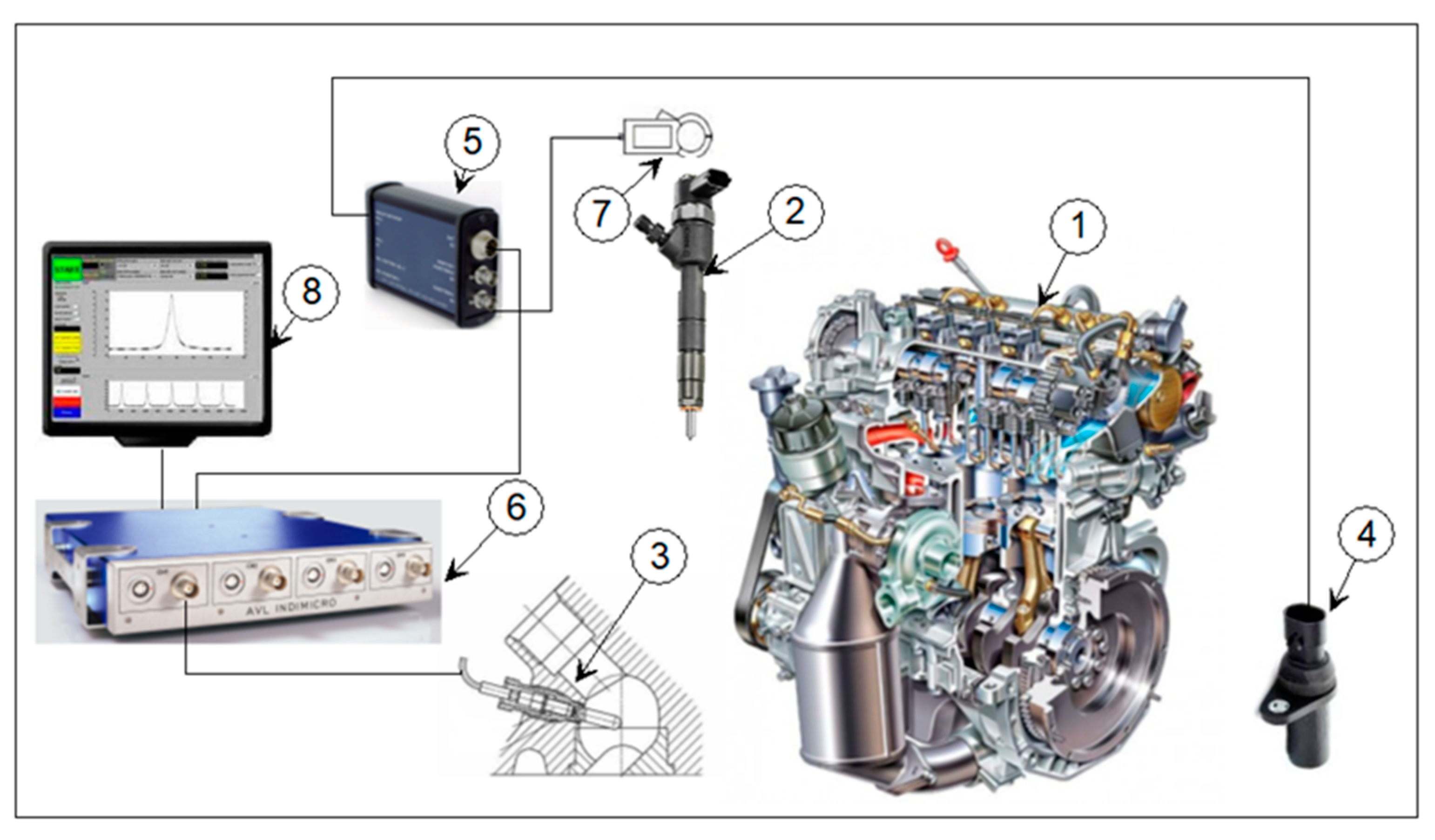

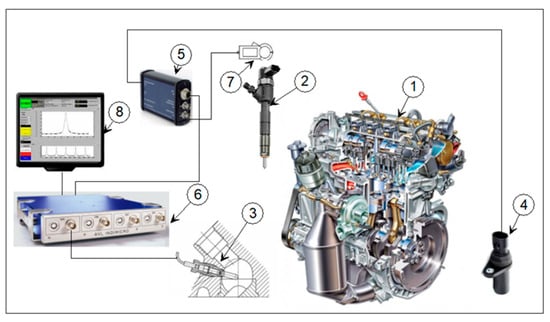

AVL’s Indimicro 602 recording system was used to measure the prevailing internal cylinder pressure. A general schematic of this system is shown in Figure 7.

Figure 7.

AVL connection diagram: 1. diesel engine of the test vehicle; 2. electromagnetic injector and cylinder; 3. piezoelectric sensor AVLGH13P integrated with adapter for glow plug and cylinder socket; 4. crankshaft inductive sensor; 5. AVL Universal Pulse Conditioner 389Z01 transmitter; 6. AVL Indimicro 602 measuring module; 7. measuring rod; 8. mobile computer with AVL Indicom software [32].

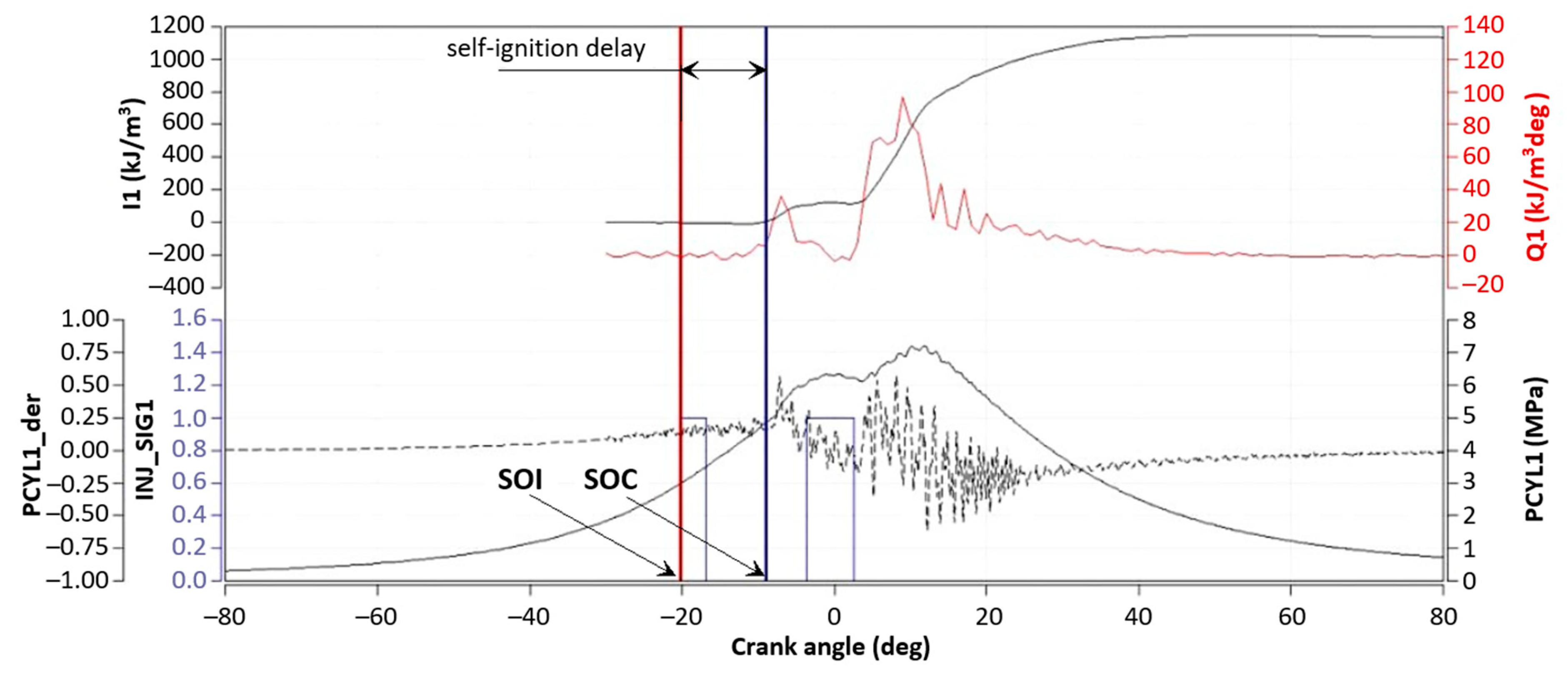

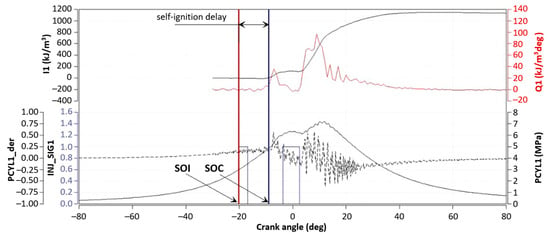

A detailed description of the test stand can be found in the authors’ article [32]. Engine tests were conducted on a chassis dynamometer at a constant engine speed of 3000 ± 10 rpm, under constant wheel drag load conditions. During the tests, the pressure inside 1 cylinder, engine speed and injector control signal, among others, were recorded and used to determine the self-ignition delay angle (αid). Figure 8 shows the adopted methodology for determining the self-ignition delay angle in engine tests. Due to the difficulty in unambiguously determining the combustion onset parameter for an engine that had a common rail type reservoir power system, whose injection course was controlled by an ECU algorithm that takes into account a number of variables, a 5% fuel dose burnout was used as the combustion onset (αsc). The auto-ignition delay angle (αid) was defined as the angle of crankshaft rotation from the start of fuel injection (SOI) to the start of combustion (SOC). The engine combustion chamber pressure measurements were carried out using the AVL Indimicro system, whose linearity specified by the manufacturer is ±0.01% of the measurement range. The uncertainty in measuring the crankshaft rotation angle was ±0.1 °CA. The results shown in the graphs are determined as averages for 100 consecutive duty cycles. It can be concluded that the observed differences between fuels are significant in the context of the high measurement accuracy of the device.

Figure 8.

Parameters of combustion process of diesel engine with direct fuel injection system: (INJ_SIGI1) denotes fuel injection, (Q1) rate of heat release, (PCYL1) pressure in the combustion chamber of 1 cylinder, SOC—start of combustion, SOI—start of injection, (l1) heat discharge and (Pcyl1_der) rate of combustion [18].

3. Results and Discussion

3.1. Results for the CVCC Method

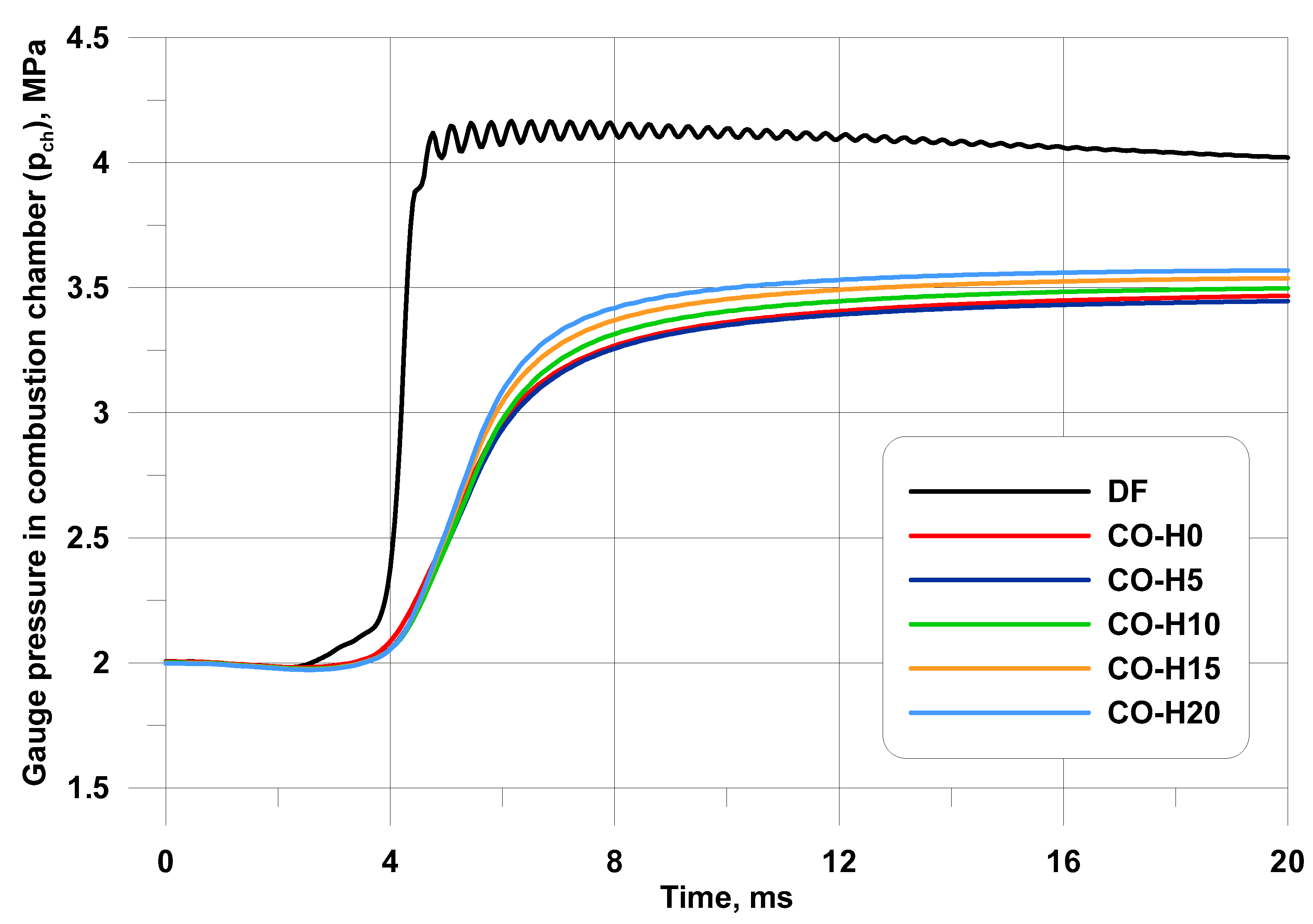

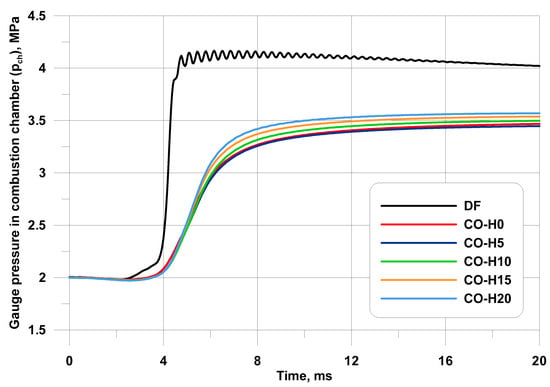

The values of the test results obtained and the standard deviations of the measurements for MPR, ID and CD uncertainties are shown in Table 6. For each fuel sample, the values of the standard deviation of the mean were determined from 15 tests (combustion cycles). Table 6 also includes data related to fuel injection for each fuel sample. Figure 9 shows the changes in pressure in a constant volume chamber for the fuels tested. These are graphically represented average values from 15 combustion cycles.

Table 6.

Recorded fuel injection parameters and standard deviations.

Figure 9.

Pressure changes in a constant volume combustion chamber for the tested fuel samples.

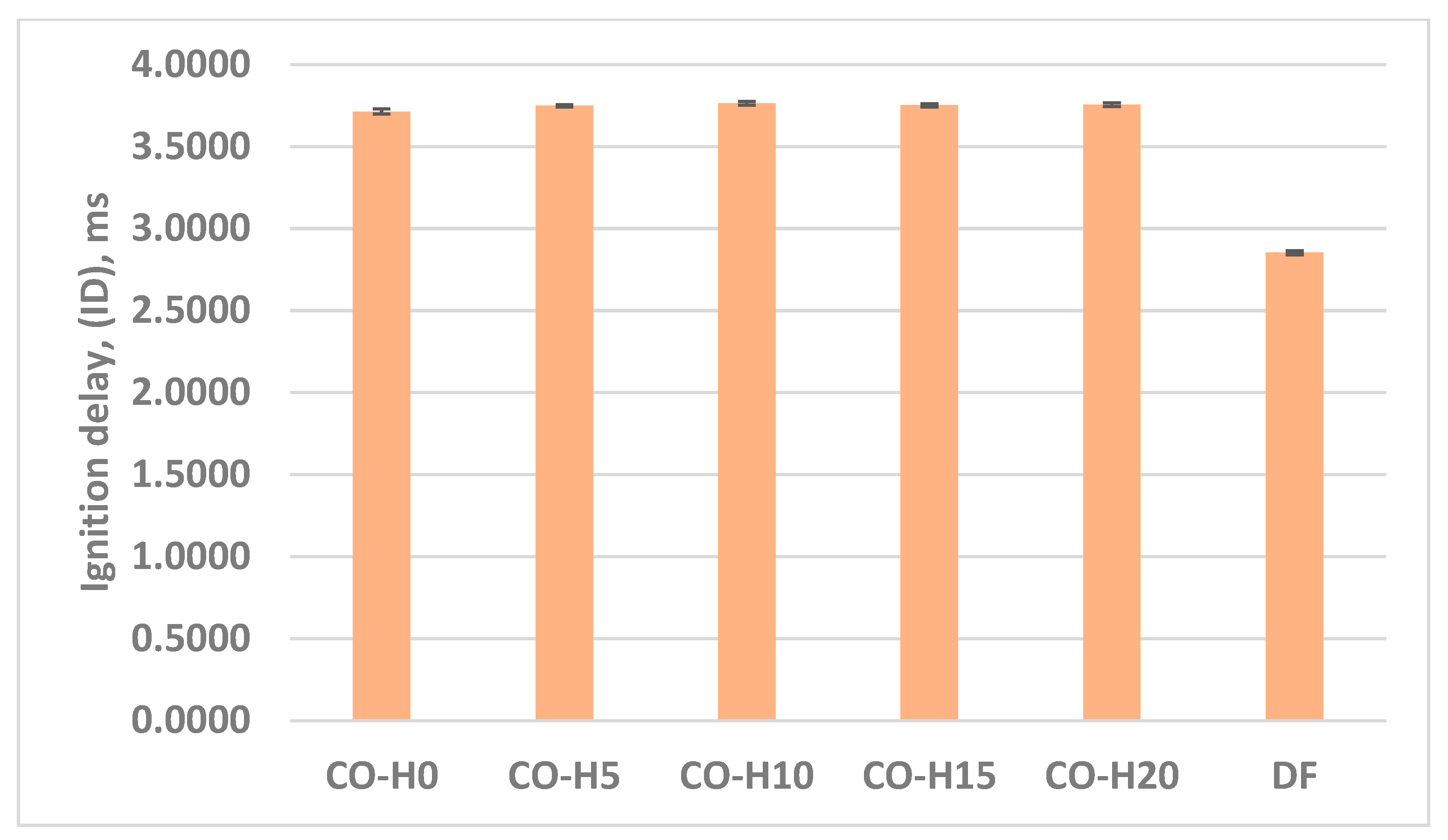

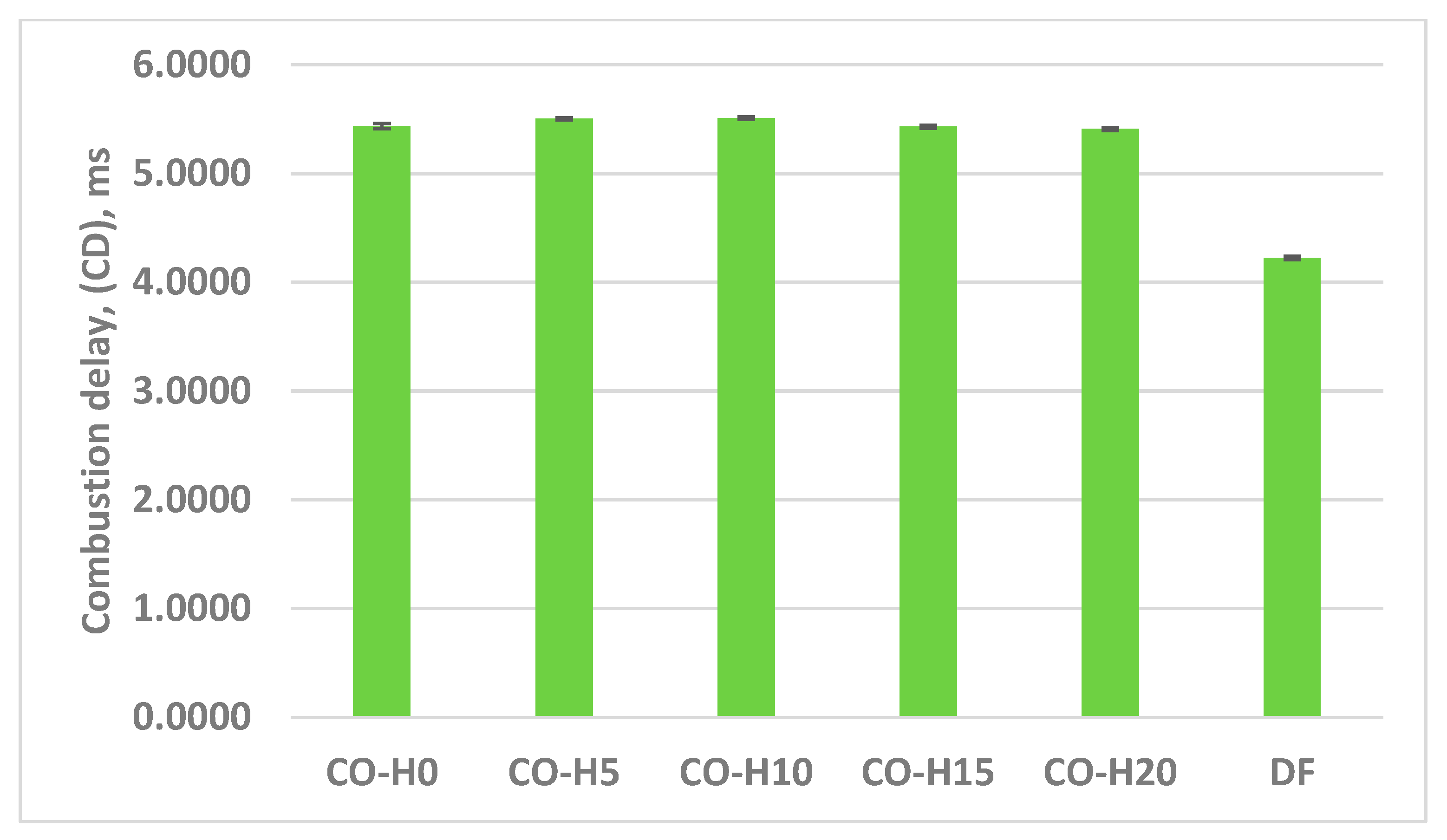

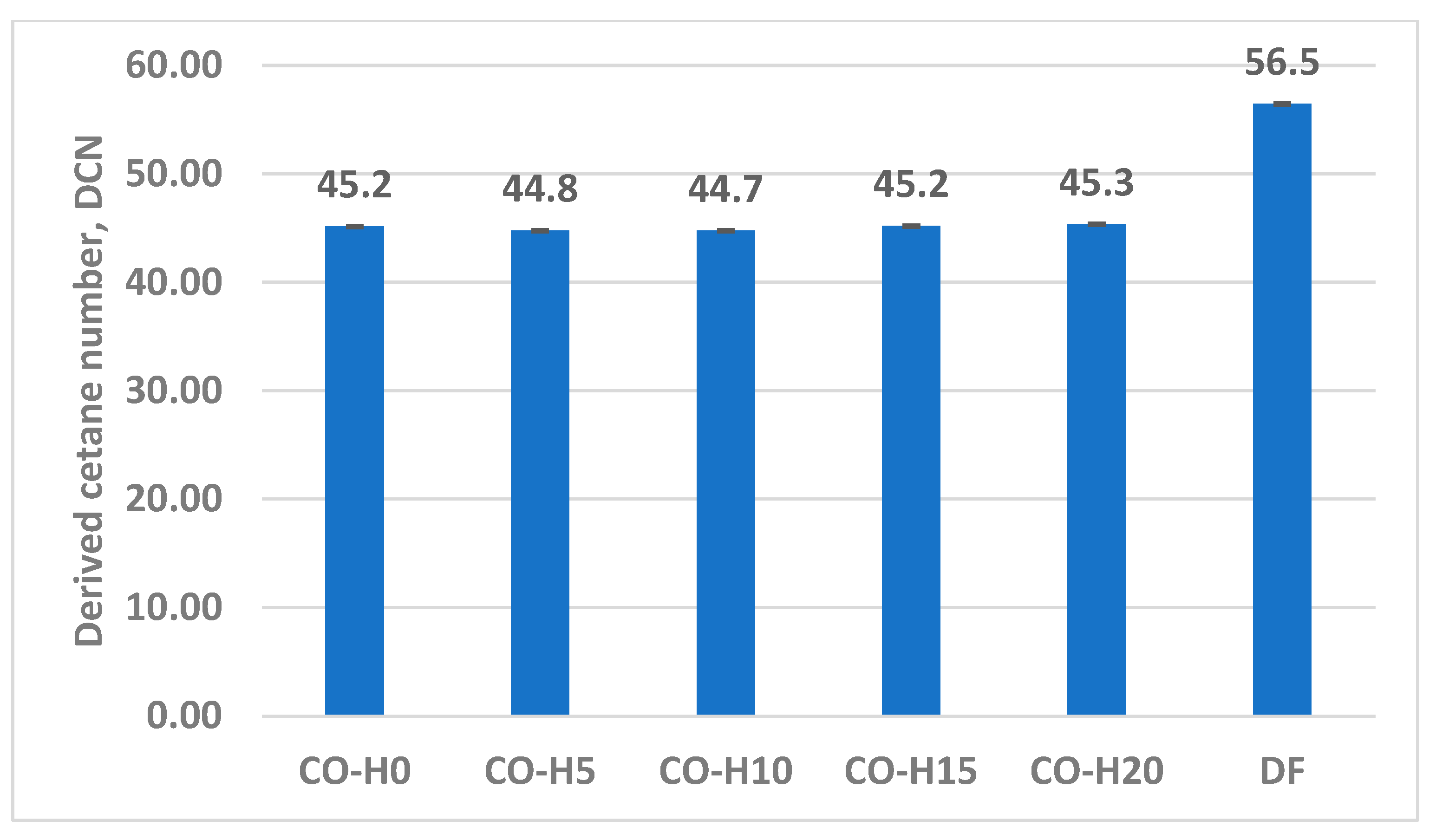

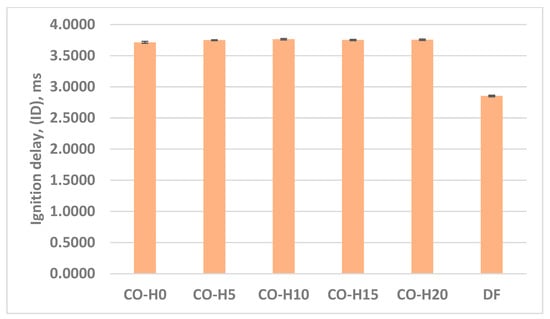

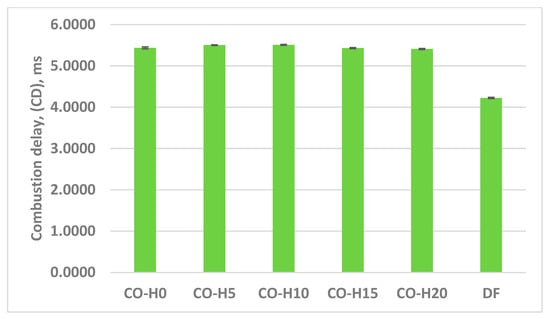

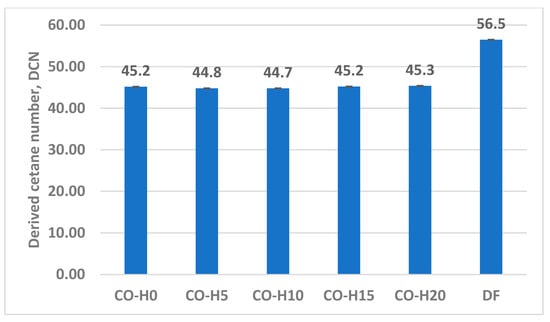

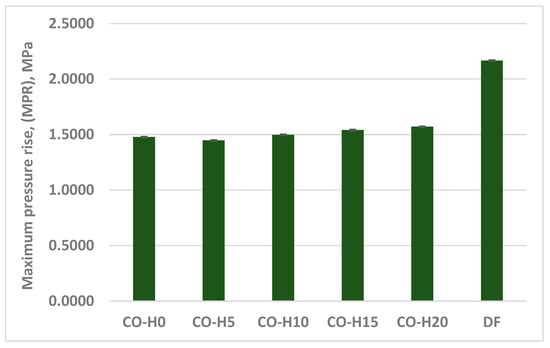

The results of comparative tests conducted in a constant volume chamber and under fixed conditions showed that the addition of n-hexane to canola oil has little effect on changes in the values of ignition delay (ID) (Figure 10) and combustion delay (CD) (Figure 11). Accordingly, small changes in the value of the derived cetane number (DCN) (Figure 12) were also noted. The results of these tests were obtained under fixed test conditions, i.e., single-phase injection at a constant value of injection pressure, pinj, equal injector opening time, tinj, and at constant initial values of pressure, p0, and combustion chamber temperature, tch.

Figure 10.

ID parameter values for the tested fuel samples.

Figure 11.

CD parameter values for the tested fuel samples.

Figure 12.

DCN parameter values for the tested fuel samples.

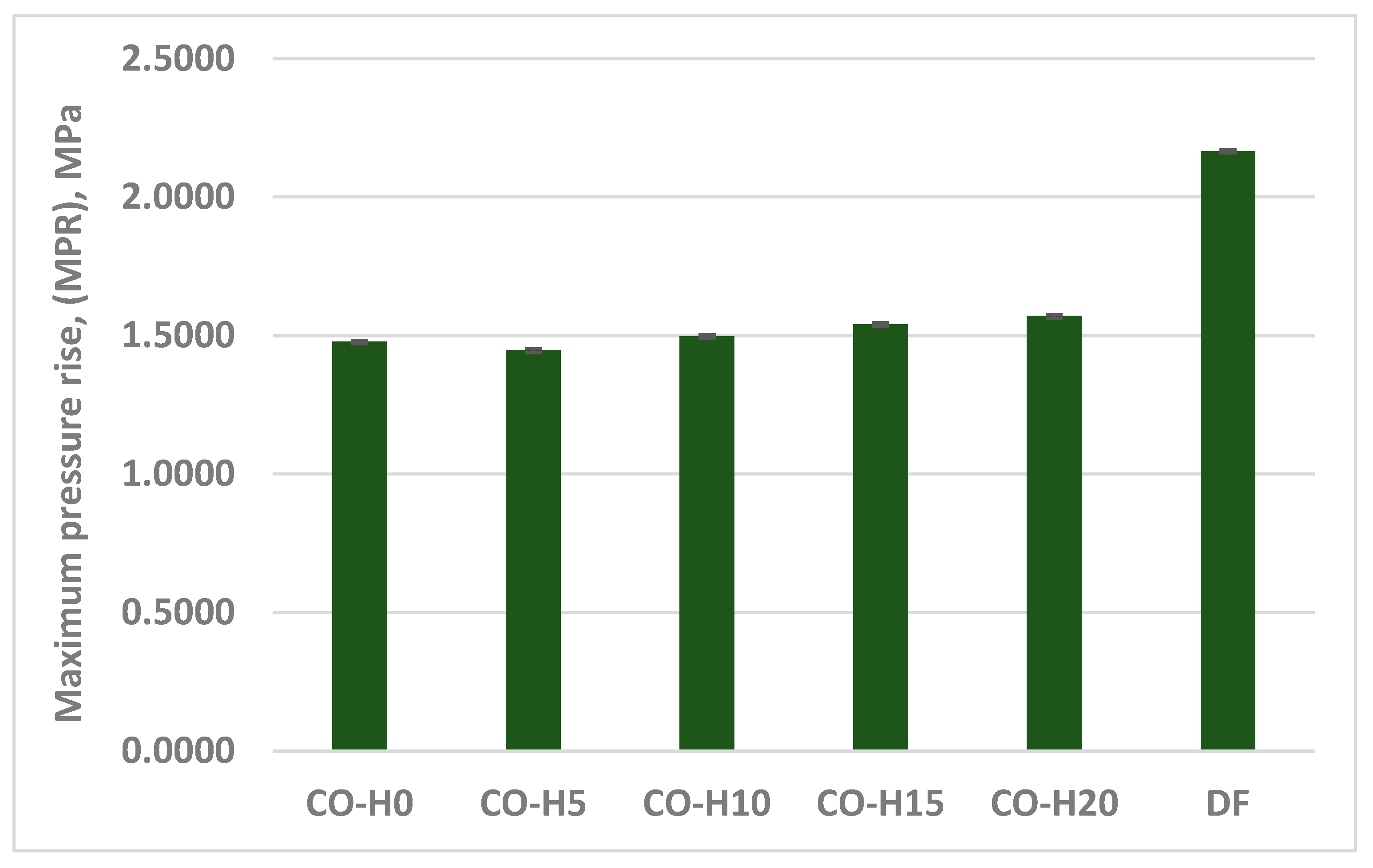

The pressure changes in the combustion chamber (pch), shown in Figure 9, show a significant difference in the pattern of pressure increase for diesel fuel and the blends of canola oil and n-hexane analyzed. At the same time, it can be noted that in the case of blends, the pressure in the combustion chamber builds up significantly more slowly than in the case of diesel, and an increase in the proportion of n-hexane in canola oil resulted in a slight increase in the rate of build-up of this pressure in relation to pure canola oil. As a result, changes were noted as to the value of the CD parameter and the MPR parameter (Figure 13).

Figure 13.

MPRR parameter values for the tested fuel samples.

3.2. Results for the Engine Tests

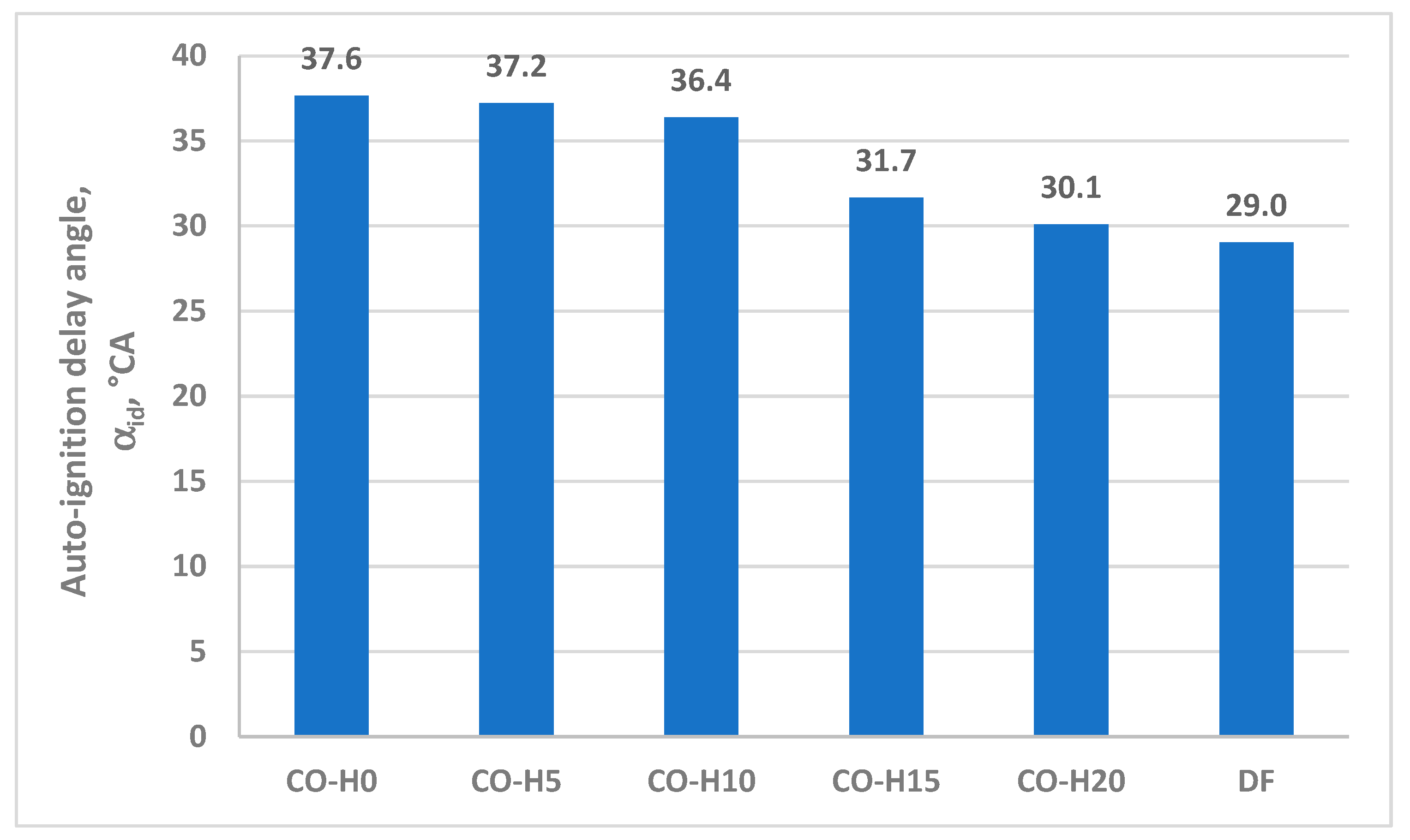

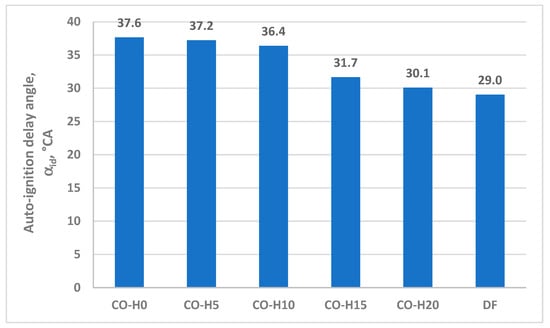

The value of the fuel auto-ignition delay angle in a diesel engine is one of the most important parameters of the combustion process. In modern engines with a common rail injection system, control over the auto-ignition delay is achieved through an appropriate injection strategy implemented by the ECU algorithm. The auto-ignition delay in a traction compression ignition engine depended mainly on the physicochemical properties of the fuels, i.e., the cetane number of the fuel (self-ignition capability), viscosity, density and surface tension (affecting the quality of atomization and dispersion of the fuel), the turbulence of the air in the cylinder, the mixing of fuel particles with the air, and subjecting the fuel to physical (evaporation) and chemical (partial oxidation of the fuel) transformations. The above parameters had a significant effect on the angle of onset of combustion in the engine during static engine operation and during acceleration, which directly affected the auto-ignition delay period. The effect of the addition of n-hexane to canola oil on the auto-ignition delay was found, as shown in Figure 14. The differences in auto-ignition delay obtained are mainly due to the different physicochemical properties of the canola oil, particularly viscosity. The issues discussed are described in detail in the authors’ publication [18].

Figure 14.

Values of the auto-ignition delay angle (αid) for a diesel engine operating at a crankshaft speed of 3000 rpm.

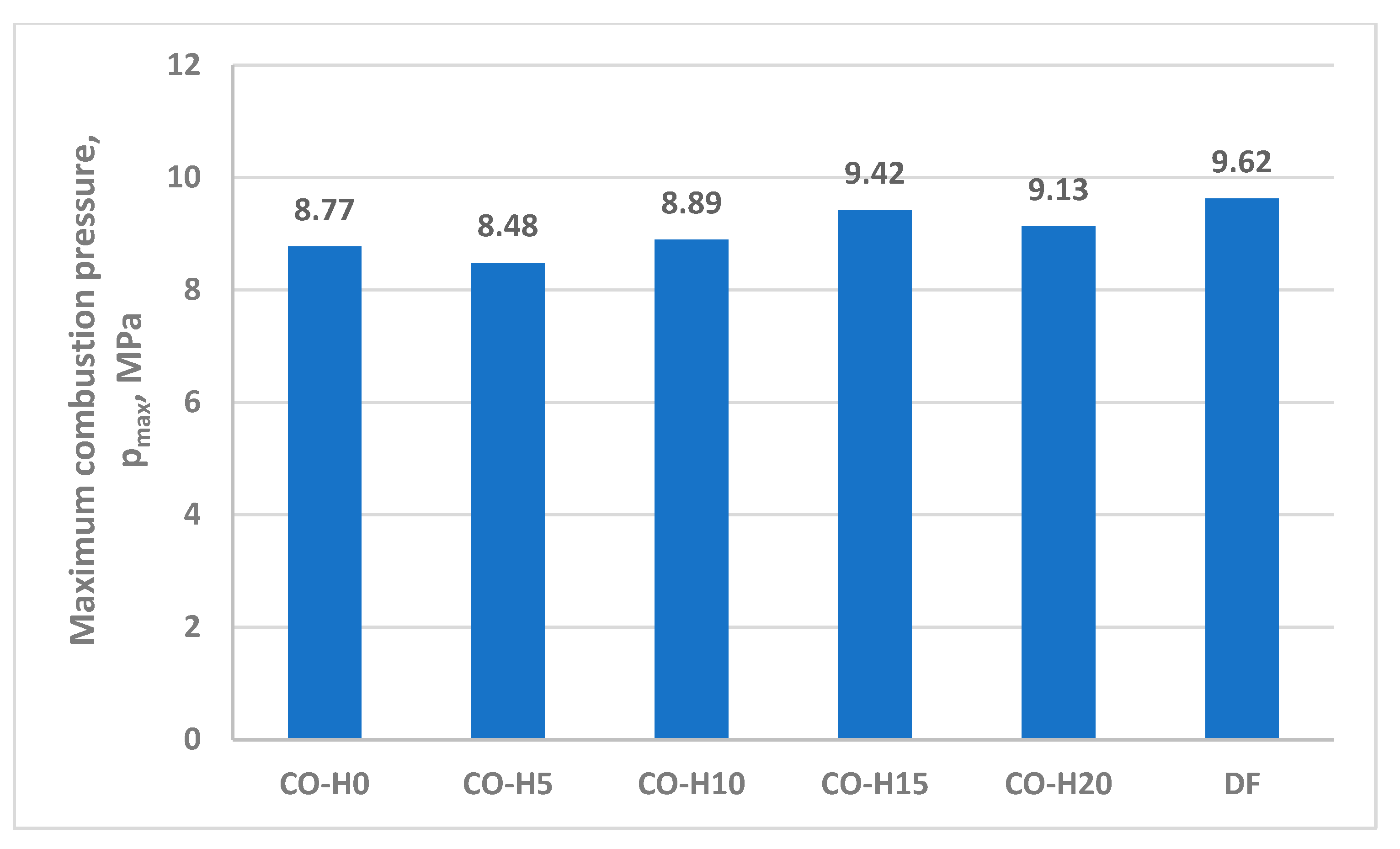

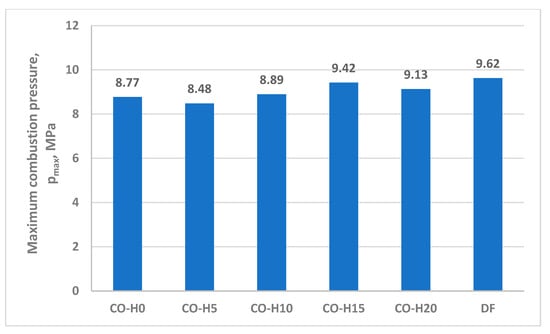

Figure 15 shows a comparison of maximum engine combustion chamber pressures. It can be seen that the maximum combustion pressures were higher for the diesel-fueled engine compared to canola oil-based fuels. The effect of the addition of n-hexane on the increase in maximum cylinder pressure is also apparent.

Figure 15.

Values of maximum combustion pressure, pmax, for diesel engine operated with crankshaft speed 3000 rpm.

Indeed, the course of the combustion process in an internal combustion engine depends not only on the type of fuel, but on many parameters, such as the temperature and pressure in the combustion chamber at the beginning of fuel injection, the fuel injection timing, the fuel amount and its distribution. This is also confirmed by the results of tests on other fuel blends carried out in a constant volume chamber, however, not for the diesel fuel normative method but for different values of combustion chamber temperature at the beginning of fuel injection [33], fuel injection pressure and fuel–air ratio [34,35]. Considering n-hexane, a study in the article [36] showed that the initial fuel temperature is also an important factor affecting the ID parameter.

4. Conclusions

The findings of the experiments allow the drawing of the following conclusions:

- Under standard CVCC test conditions, an increase in the proportion of n-hexane in the blend with canola oil resulted in slight changes in the values of ID, CD and MPR parameters.

- The values of the derived cetane number for the blends analyzed were similar to those for pure canola oil and significantly lower in relation to the derived cetane number for typical diesel fuel.

- Engine test results showed a significant effect of n-hexane addition on lowering the auto-ignition delay angle.

These test results complement studies referring to the combustion of alternative fuels for diesel engines. The results presented in the article confirm that in order to evaluate the suitability of fuels and their self-ignition properties, it is necessary to conduct tests on a modern diesel engine with split injection. This is due, among other things, to the variable conditions in the engine combustion chamber and the different fuel injection timing with split pilot injection and main injection, which has a significant impact on the combustion process.

Author Contributions

Conceptualization, A.J., R.L. and H.K.; methodology, A.J., R.L., P.S. and H.K.; formal analysis, A.J., R.L., P.S. and H.K.; investigation, A.J., R.L., P.S. and H.K.; resources, A.J., R.L., H.K. and P.S.; data curation, A.J. and H.K.; writing—original draft preparation, A.J., R.L., H.K. and P.S.; writing—review and editing, A.J., R.L., H.K. and P.S.; visualization, A.J. and H.K.; supervision, A.J., R.L. and H.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results has received funding from the commissioned task entitled “VIA CARPATIA Universities of Technology Network named after the President of the Republic of Poland Lech Kaczyński” contract no. MEiN/2022/DPI/2578, action entitled “In the neighborhood—inter-university research internships and study visits”.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data supporting this study are included within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BSFC | brake specific fuel consumption |

| CD | combustion delay (period), ms |

| CVCC | constant volume combustion chamber |

| CFPP | cold filter plugging point, °C |

| DCN | derived cetane number |

| HHV | higher heating value, kJ/kg |

| ID | ignition delay (period), ms |

| MPR | maximum pressure rise, MPa |

| p0 | chamber static pressure (gauge), MPa |

| pch | gauge pressure in the chamber, MPa |

| pinj | injection pressure, MPa |

| pmax | maximum combustion pressure of the cylinder, MPa |

| SOC | start of combustion, °CA |

| SOI | start of fuel injection, °CA |

| tch | chamber wall temperature, °C |

| tco | injector nozzle coolant jacket temperature, °C |

| tinj | injection period (injection pulse width), ms |

| δCD | standard deviation of the mean of CD, ms |

| δID | standard deviation of the mean of ID, ms |

| δMPR | standard deviation of the mean of MPR, MPa |

| αid | self-ignition delay angle, °CA |

| αsc | start of combustion angle, °CA |

References

- Rodrigue, J.P. The Geography of Transport Systems, 5th ed.; Routledge: Abingdon-on-Thames, UK, 2020. [Google Scholar] [CrossRef]

- Global Energy Review: CO2 Emissions in 2021. Global Emissions Rebound Sharply to Highest ever Level. Available online: https://www.iea.org/data-and-statistics/data-tools/greenhouse-gas-emissions-from-energy-data-explorer (accessed on 20 February 2023).

- Eurostat. Share of Energy from Renewable Sources. 2020. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nrg_ind_ren&lang=en) (accessed on 8 November 2021).

- Agarwal, D.; Agarwal, A.K. Performance and emissions characteristics of Jatropha oil (preheated and blends) in a direct injection compression ignition engine. Appl. Therm. Eng. 2007, 27, 2314–2323. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Kim, M.S.; Choi, N.J. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Appl. Sci. 2017, 7, 34. [Google Scholar] [CrossRef]

- Chotwichien, A.; Luengnaruemitchai, A.; Jai-In, S. Utilization of palm oil alkyl esters as an additive in ethanol-diesel and butanol–diesel blends. Fuel 2009, 88, 1618–1624. [Google Scholar] [CrossRef]

- Belale, R.A.; Alaoui, F.E.M.; Chhiti, Y.; Sahibeddine, A.; Rujas, N.M.; Aguilar, F. Study on the thermophysical properties of waste cooking oil biodiesel fuel blends with 1-butanol. Fuel 2021, 287, 119540. [Google Scholar] [CrossRef]

- Li, Q.; Backes, F.; Wachtmeister, G. Application of canola oil operation in a diesel engine with common rail system. Fuel 2015, 159, 141–149. [Google Scholar] [CrossRef]

- Yoon, S.K.; Kim, M.S.; Kim, H.J.; Choi, N.J. Effects of canola oil biodiesel fuel blends on combustion, performance, and emissions reduction in a common rail diesel engine. Energies 2014, 7, 8132–8149. [Google Scholar] [CrossRef]

- Chidambaranathan, B.; Kumarasami, D.P.; Soundararajan, G.; Thulasiram, R. Performance and environmental impact assessment of diesel engine operating on high viscous punnai oil–diesel blends. Environ. Sci. Pollut. Res. 2023, 30, 61177–61189. [Google Scholar] [CrossRef]

- Agarwal, D.; Kumar, L.; Agarwal, A.K. Performance evaluation of a vegetable oil fuelled compression ignition engine. Renew. Energy 2008, 33, 1147–1156. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A. Experimental investigations of performance, emission and combustion characteristics of Karanja oil blends fuelled DICI engine. Renew. Energy 2013, 52, 283–291. [Google Scholar] [CrossRef]

- Che Mat, S.; Idroas, M.Y.; Hamid, M.F.; Zainal, Z.A. Performance and emissions of straight vegetable oils and its blends as a fuel in diesel engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 808–823. [Google Scholar] [CrossRef]

- Górski, K.; Lotko, W.; Litak, G.; Longwic, R.; Sen, A.K. Cycle-to-cycle variation of the combustion process in a diesel engine powered by different fuels. J. Vibroeng. 2011, 13, 120–127. [Google Scholar]

- Prabu, S.S.; Asokan, M.A.; Prathiba, S.; Ahmed, S.; Puthean, G. Effect of additives on performance, combustion and emission behavior of preheated palm oil/diesel blends in DI diesel engine. Renew. Energy 2018, 122, 196–205. [Google Scholar] [CrossRef]

- Prabu, S.S.; Asokan, M.A.; Roy, R.; Francis, S.; Sreelekh, M.K. Performance, combustion and emission characteristics of diesel engine fueled with waste cooking oil bio-diesel or diesel blends with additives. Energy 2017, 122, 638–648. [Google Scholar] [CrossRef]

- Górski, K.; Smigins, R.; Longwic, R. Research on Physico-Chemical Properties of Diethyl Ether/Linseed Oil Blends for the Use as Fuel in Diesel Engines. Energies 2020, 13, 6564. [Google Scholar] [CrossRef]

- Longwic, R.; Sander, P.; Jańczuk, B.; Zdziennicka, A.; Szymczyk, K. Modification of Canola Oil Physicochemical Properties by Hexane and Ethanol with Regards of Its Application in Diesel Engine. Energies 2021, 14, 4469. [Google Scholar] [CrossRef]

- Kumar, R.; Mishra, M.K.; Roy, M.K. Effects of Hexane Addition in Waste Plastic Fuel-Biodiesel-Diesel Blends on the Performance and Emission Characteristics of DI Diesel Engine. Automot. Exp. 2022, 5, 416–432. [Google Scholar] [CrossRef]

- Yanowitz, J.; Ratcliff, M.A.; McCormick, R.L.; Taylor, J.D.; Murphy, M.J. Compendium of Experimental Cetane Numbers. National Renewable Energy Laboratory. NREL/TP-5400-61693. 2014. Available online: https://www.nrel.gov/docs/fy17osti/67585.pdf (accessed on 12 September 2023).

- ASTM D7668; Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel Oils—Ignition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method. ASTM: West Conshohocken, PA, USA, 2017.

- PN-EN ISO 12185; Crude Petroleum and Petroleum Products. Determination of Density. Oscillating u-Tube Method. Polish Standardization Committee: Warsaw, Poland, 2002.

- PN-EN 590:2022-08; Automotive Fuels–Diesel–Requirements and Test Methods. Polish Standardization Committee: Warsaw, Poland, 2022.

- Available online: https://cameochemicals.noaa.gov/chris/HXA.pdf (accessed on 12 April 2023).

- PN-EN 116:2015-09; Diesel and Domestic Heating Fuels—Determination of Cold Filter Plugging Point—Stepwise Cooling Bath Method. Polish Standardization Committee: Warsaw, Poland, 2016.

- ISO 1716:2018; Reaction to Fire Tests For Products—Determination of the Gross Heat of Combustion (Calorific Value). International Organization for Standardization: Geneva, Switzerland, 2018.

- PN-EN ISO 2719:2016-08; Determination of Flash Point—Pensky-Martens Closed Crucible Method. Polish Standardization Committee: Warsaw, Poland, 2018.

- EN 16715; Liquid Petroleum Products—Determination of Ignition Delay and Derived Cetane Number (DCN) of Middle Distillate Fuels—Ignition Delay and Combustion Delay Determination Using a Constant Volume Combustion Chamber with Direct Fuel Injection. BSI: London, UK, 2017.

- Lapuerta, M.; Hernández, J.J.; Fernández-Rodríguez, D.; Cova-Bonillo, A. Autoignition of blends of n-butanol and ethanol with diesel or biodiesel fuels in a constant-volume combustion chamber. Energy 2017, 118, 613–621. [Google Scholar] [CrossRef]

- Kuszewski, H. Experimental study of the autoignition properties of n-butanol-diesel fuel blends at various ambient gas temperatures. Fuel 2019, 235, 1316–1326. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A.; Lejda, K.; Balawender, K.; Woś, P. Use of the constant volume combustion chamber to examine the properties of autoignition and derived cetane number of mixtures of diesel fuel and ethanol. Fuel 2017, 200, 564–575. [Google Scholar] [CrossRef]

- Longwic, R.; Sander, P.; Zdziennicka, A.; Szymczyk, K.; Jańczuk, B. Combustion Process of Canola Oil and n-Hexane Mixtures in Dynamic Diesel Engine Operating Conditions. Appl. Sci. 2020, 10, 80. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Mądziel, M.; Woś, P. The investigation of auto-ignition properties of 1-butanol-biodiesel blends under various temperatures conditions. Fuel 2023, 346, 128388. [Google Scholar] [CrossRef]

- Kuszewski, H. Effect of Injection Pressure and Air-Fuel Ratio on the Self-Ignition Properties of 1-Butanol-Diesel Fuel Blends: Study Using a Constant-Volume Combustion Chamber. Energy Fuels 2019, 33, 2335–2347. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The Effects of Pressure and Temperature on the Process of Auto-Ignition and Combustion of Rape Oil and Its Mixtures. Sustainability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Kapusta, Ł.; Pielecha, I.; Wisłocki, K.; Teodorczyk, A. Autoignition and combustion of n-hexane spray in subcritical and supercritical environments. J. Therm. Anal. Calorim. 2016, 123, 819–828. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).