An Improved Impact Damage Monitoring Method for High-Speed Trains Using Lamb Waves and Multi-Task Learning

Abstract

:1. Introduction

2. Methodology

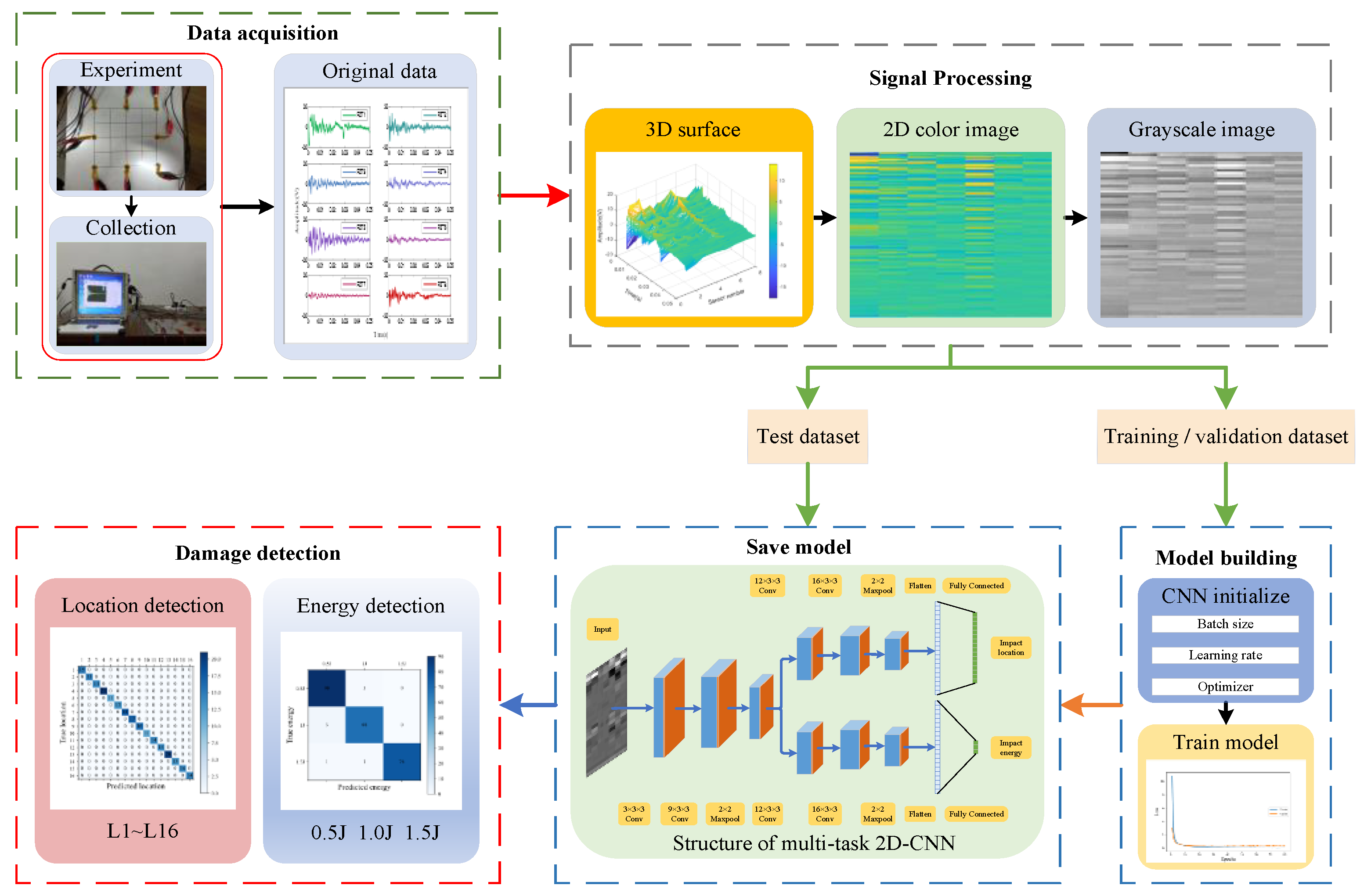

2.1. Impact Damage Monitoring Framework

- (1)

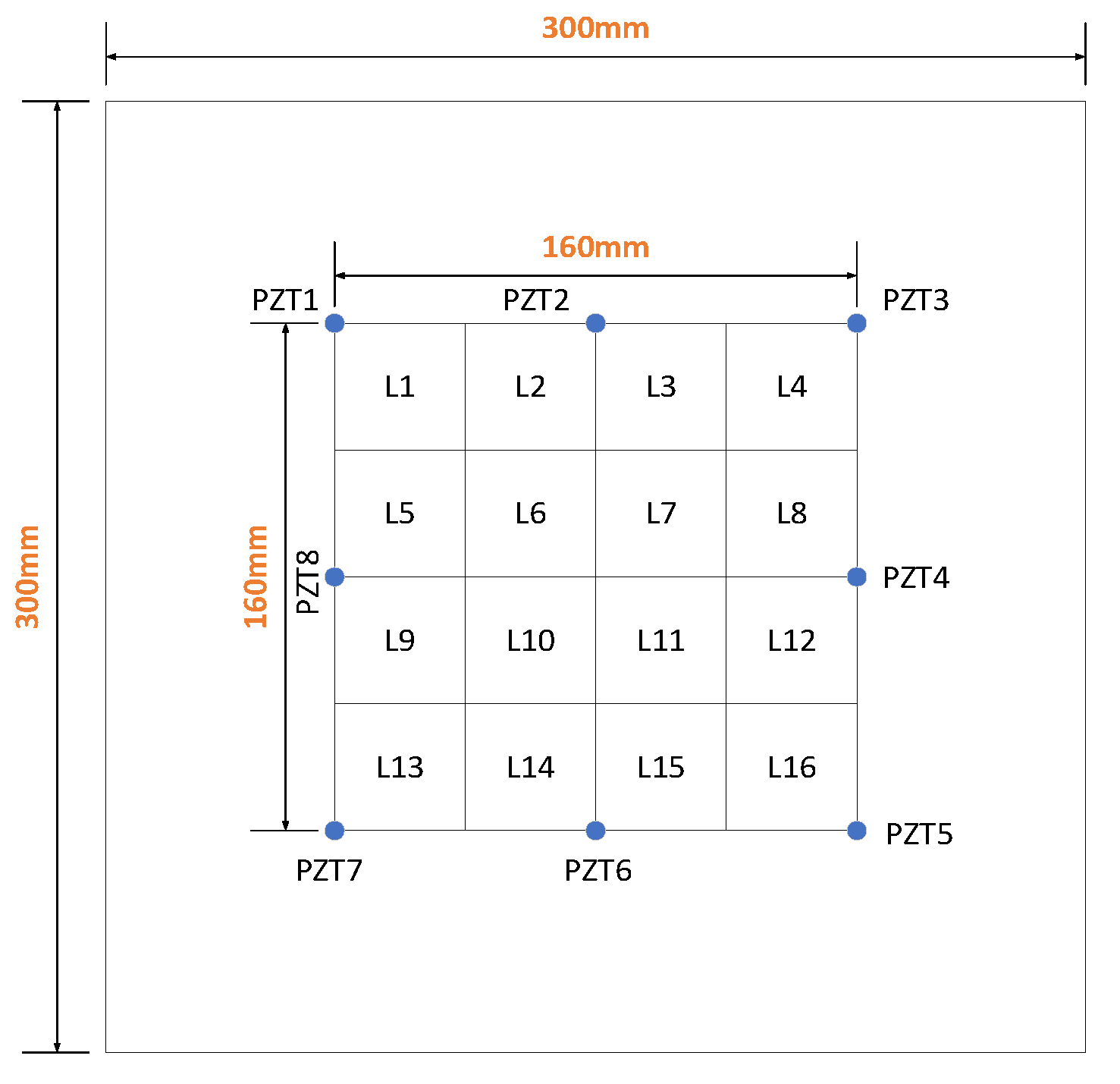

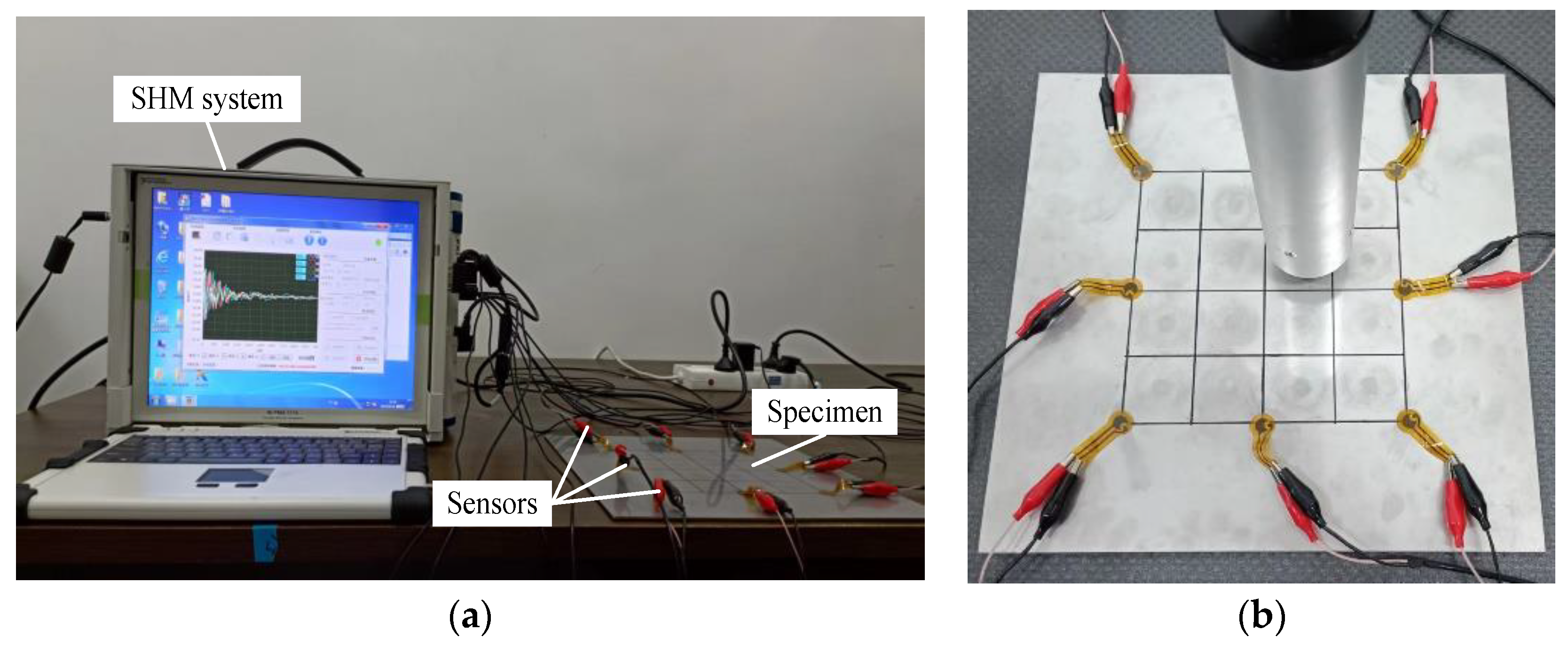

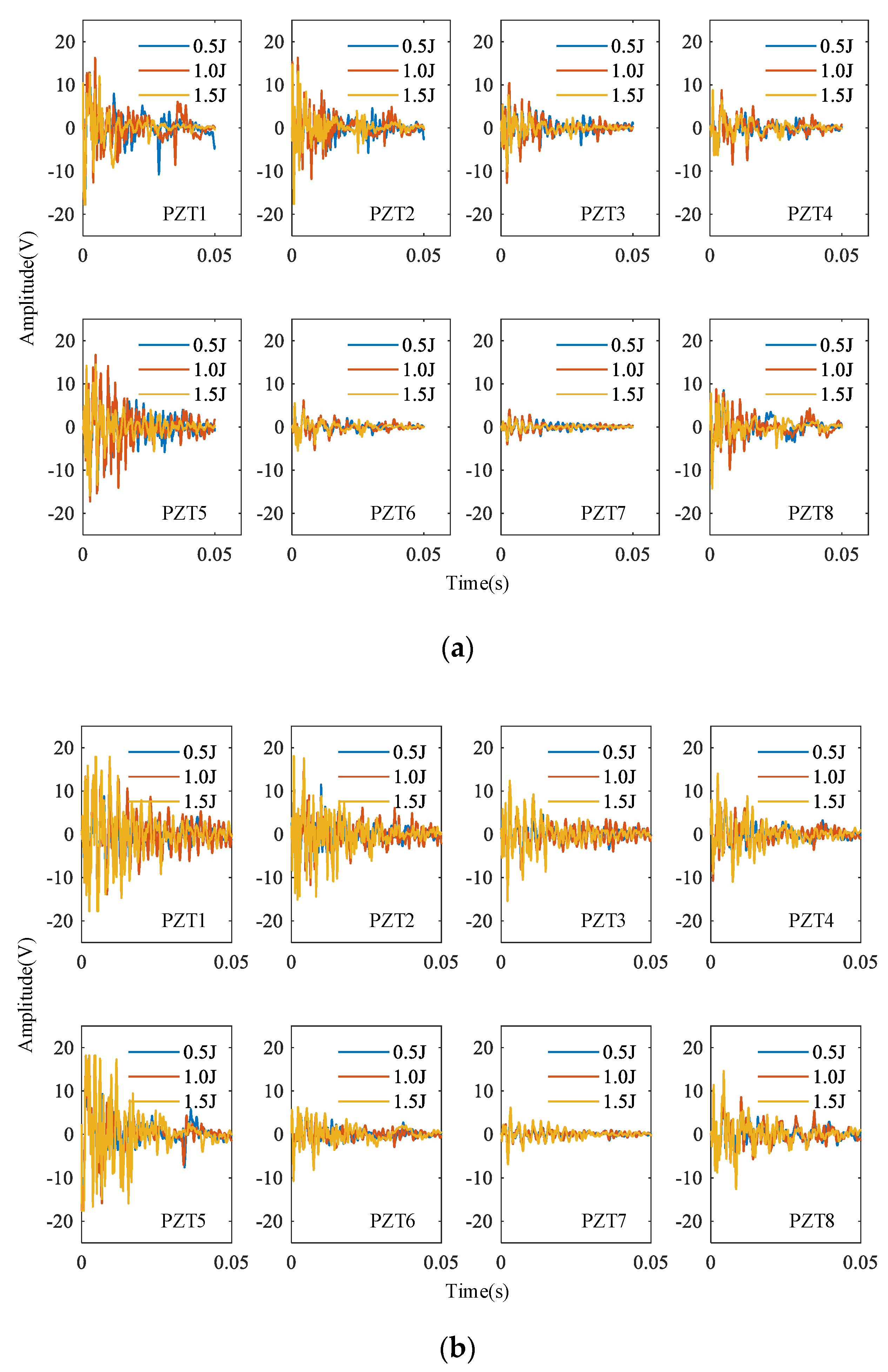

- Original data acquisition stage: The impact damage monitoring method that is data-driven needs a lot of data, and Lamb wave data can be used to reflect the impact damage information. PZT sensors are pasted on the tested structure to receive Lamb wave signals. Spring impact hammers are used to apply impact loads to simulate impact damage. Lamb wave signals with different impact locations and different impact energies are collected.

- (2)

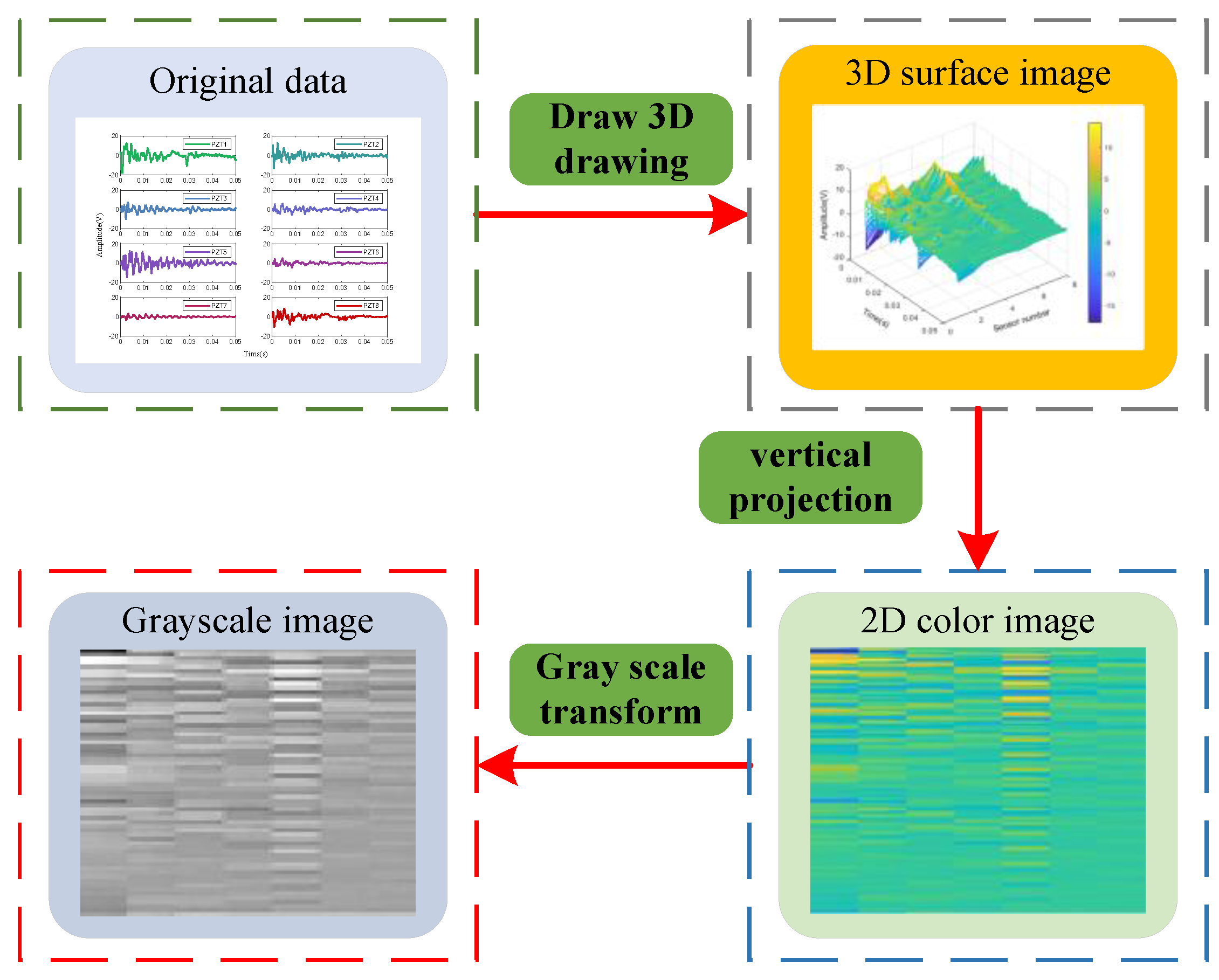

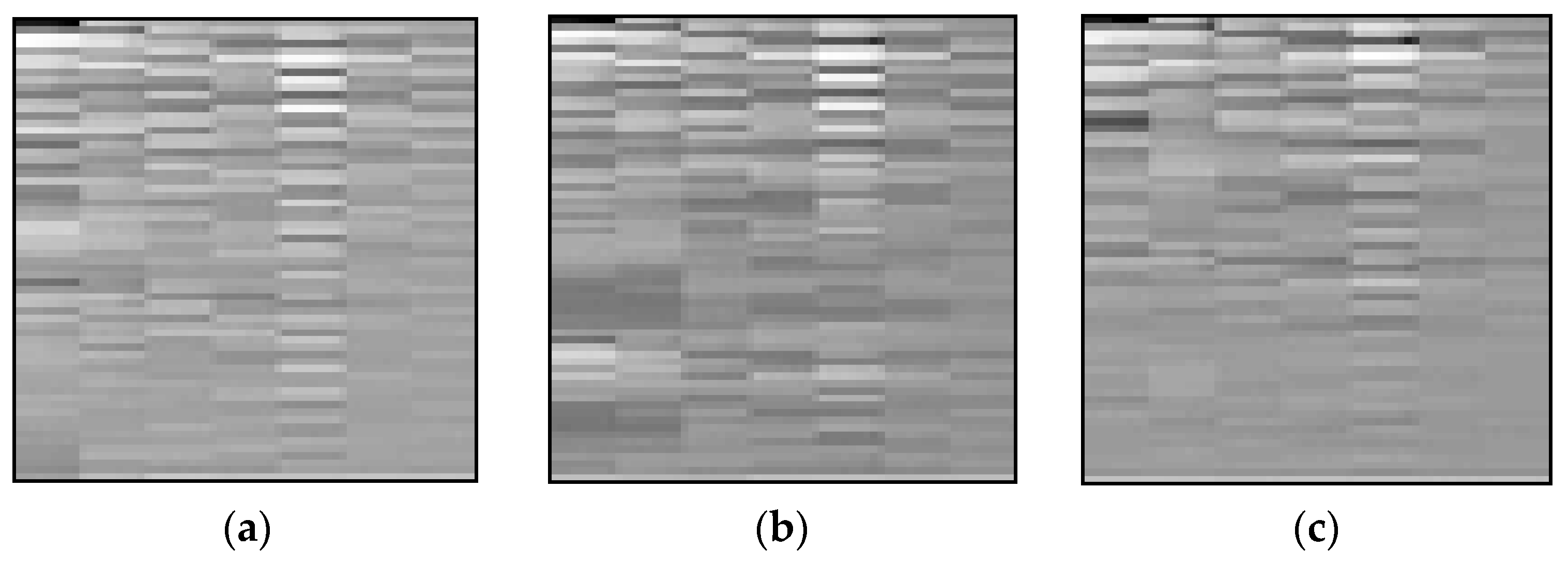

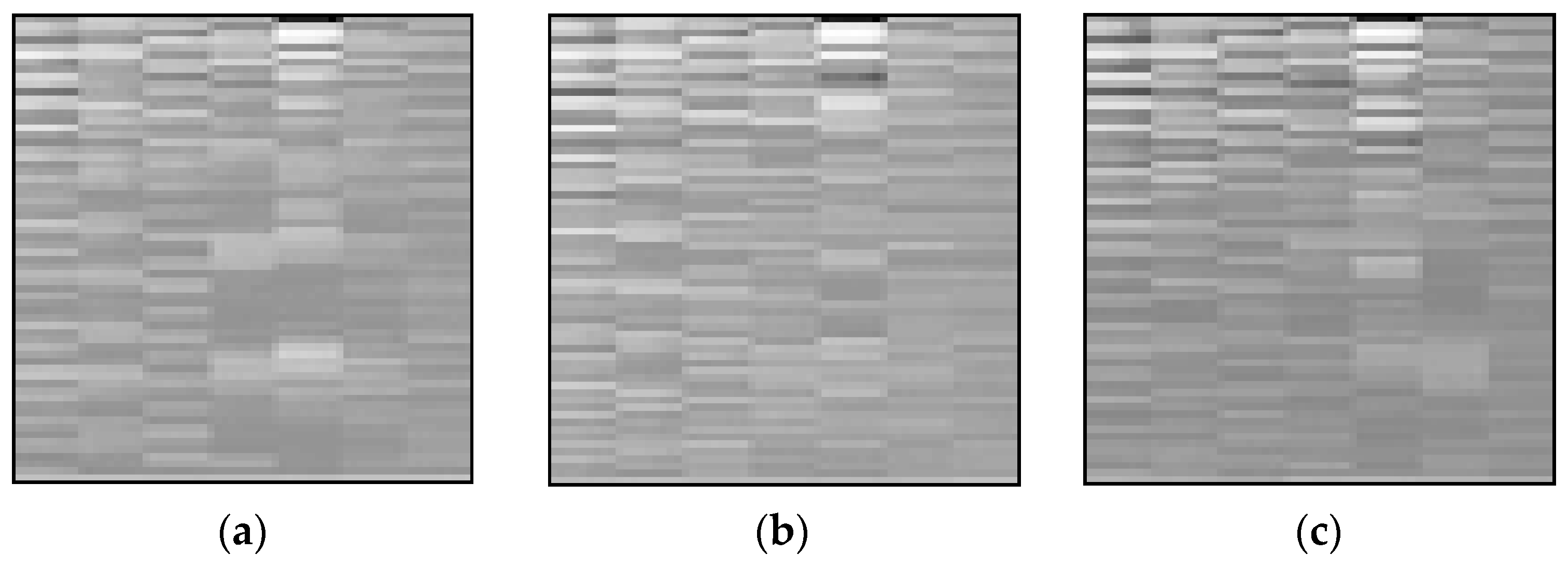

- Signal processing stage: Lamb wave signals collected by each sensor are one-dimensional time domain signals. In order to achieve multi-sensor data fusion, a three-dimensional surface maps method is applied to integrate the information of all the sensor data. Vertical projection transformation converts a three-dimensional image to a two-dimensional color image. The gray image algorithm is used to convert color images into gray images and is used for model training and diagnosis.

- (3)

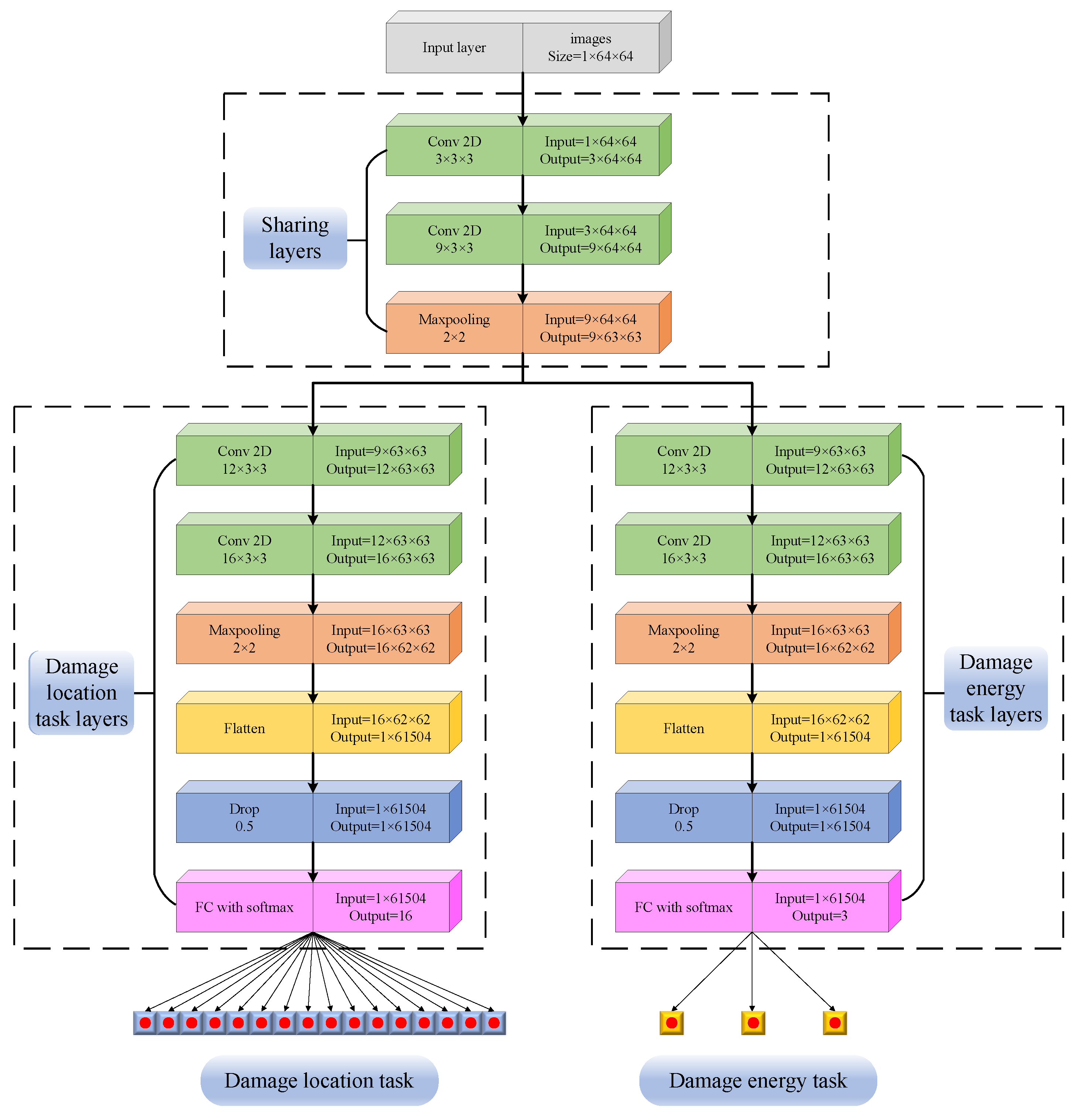

- Impact damage detection stage: Input the gray image data into the multi-task 2D-CNN model to train the model and adjust the parameters of the multi-task 2D-CNN model through verification. The damage feature information is extracted from the gray image. The two classification tasks of the model are used to monitor the impact damage location and energy.

2.2. Signal Processing Stage

2.3. Impact Damage Detection Stage

3. Experiment

4. Results and Discussion

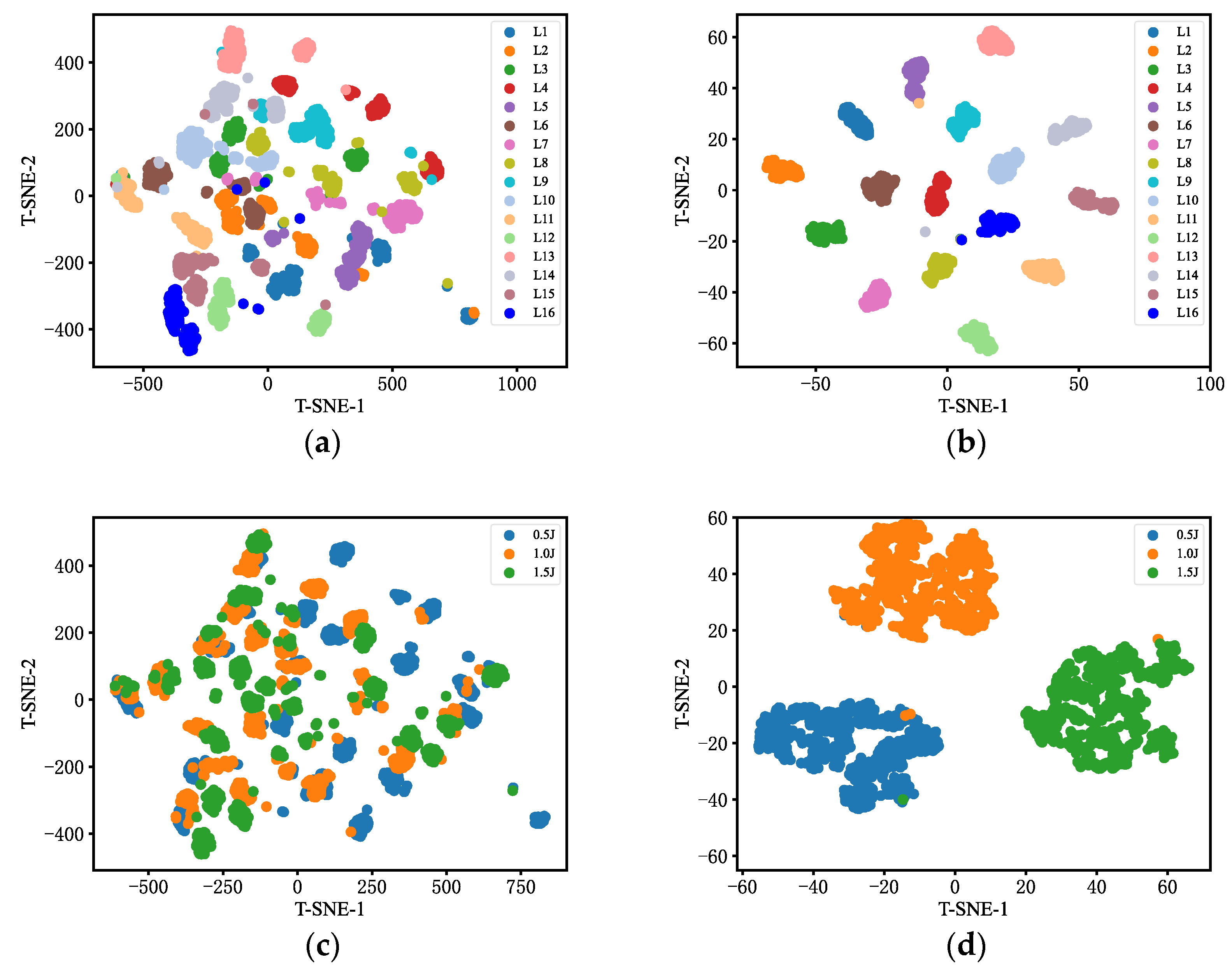

4.1. Multi-Task 2D-CNN Training

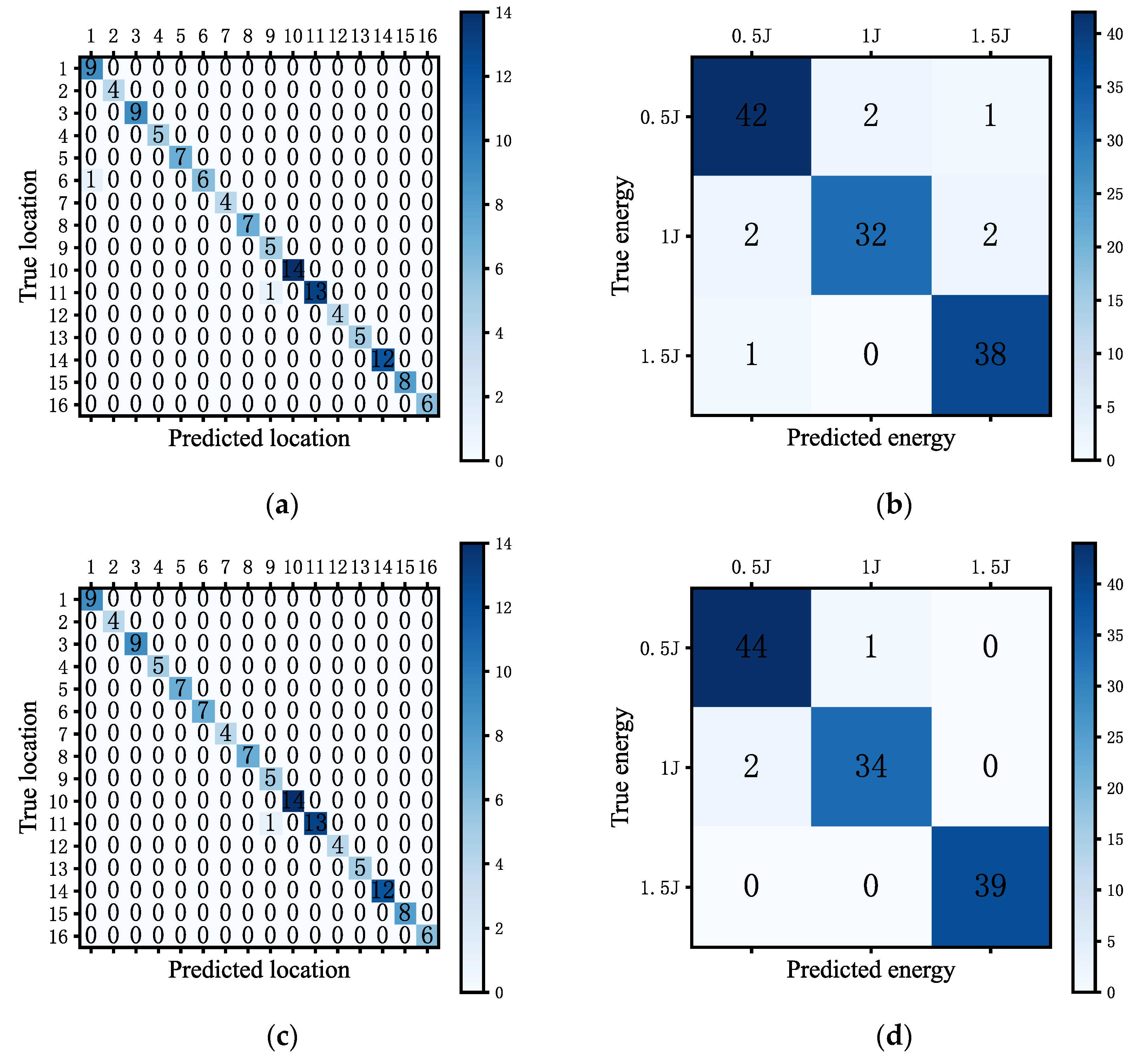

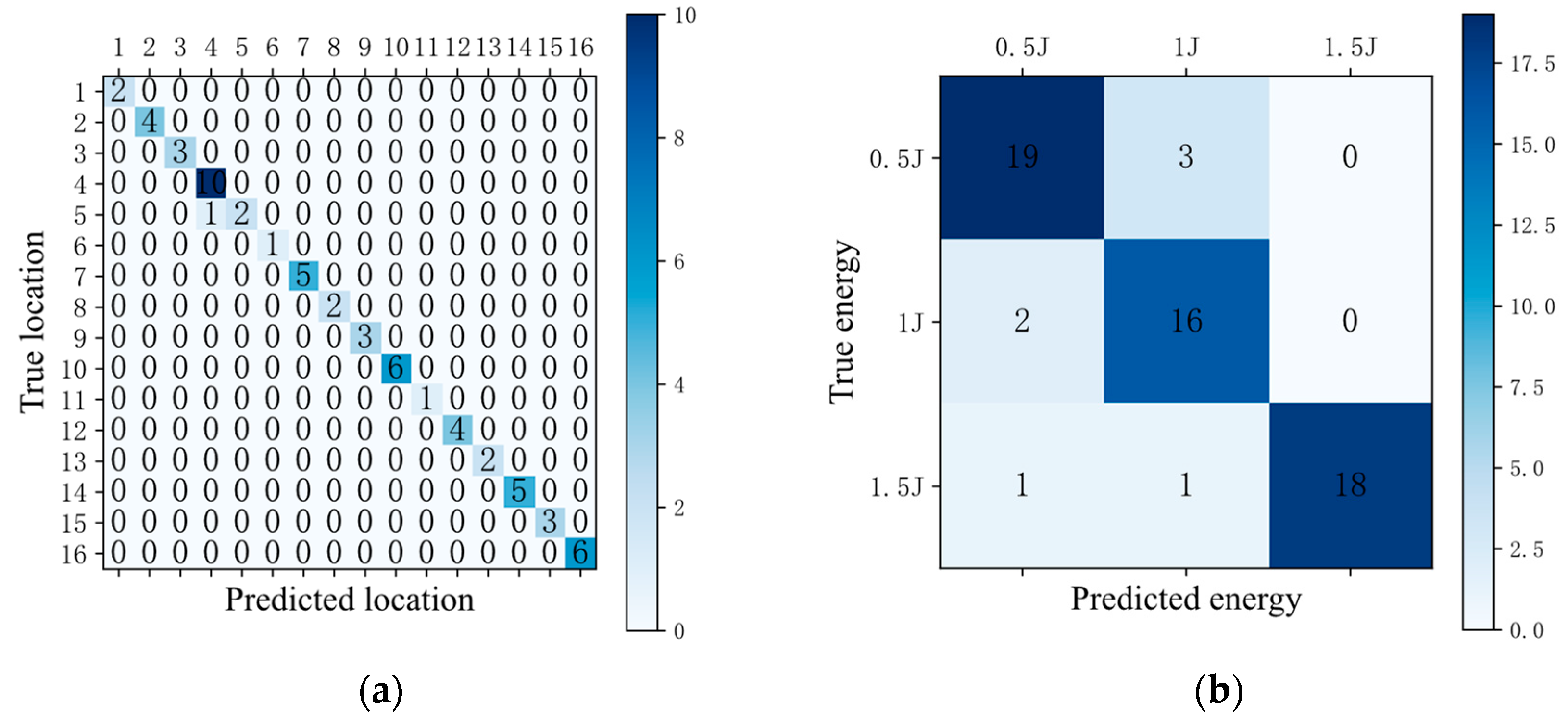

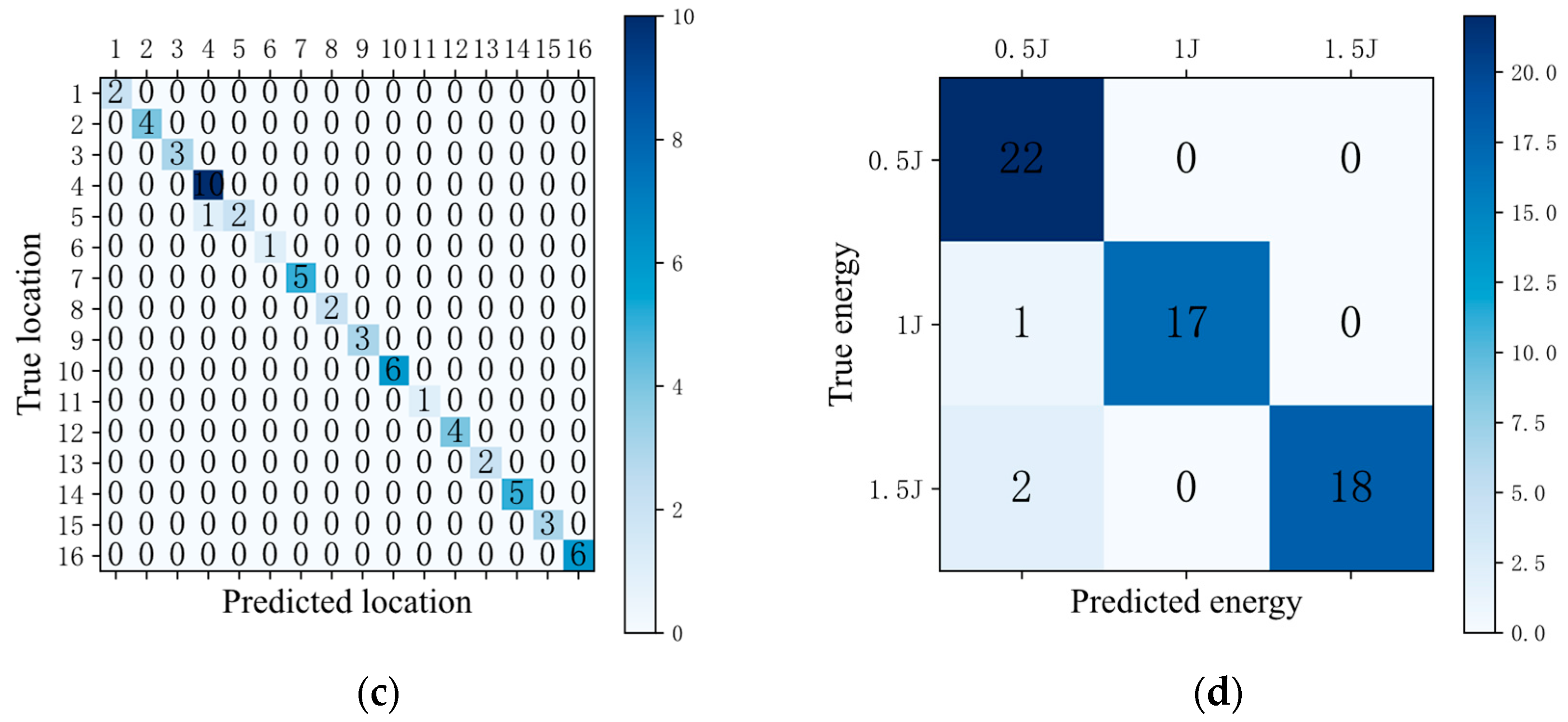

4.2. Model Evaluation and Comparison

5. Conclusions

- (1)

- A new image processing method is proposed to closely link the sensor signals from multiple channels and finally convert the original Lamb wave signal into a grayscale image to realize multi-sensor data fusion. The constructed grayscale image contains rich impact information, so it is used as the input to the multi-task 2D-CNN.

- (2)

- The multi-task 2D-CNN can automatically extract deep-level damage features without physical a priori information, and the accuracy of the impact damage location identification and impact energy identification are higher than traditional machine learning methods.

- (3)

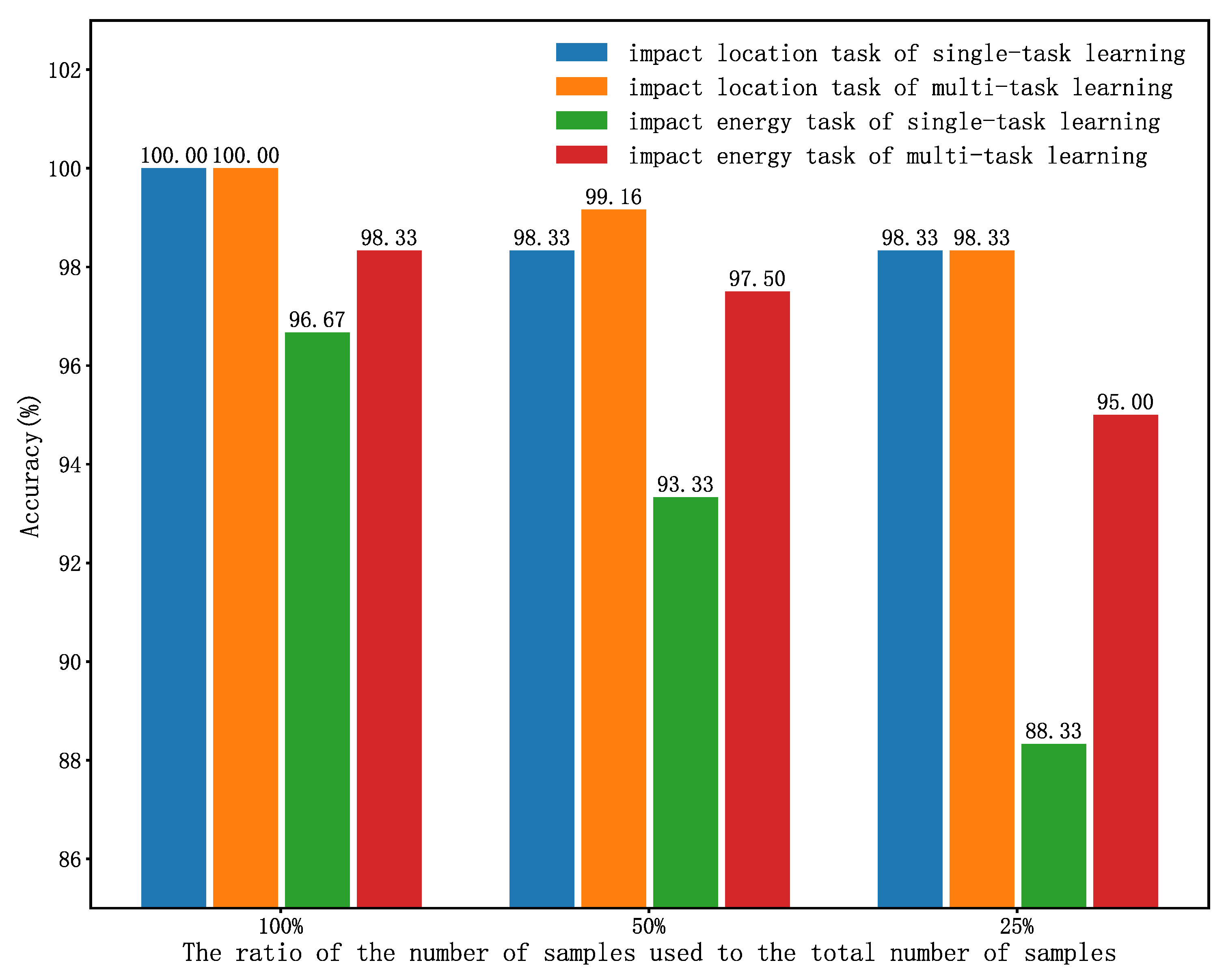

- The multi-task 2D-CNN can understand the commonality and characteristics of each task by sharing the network structure and parameters. Experimental results show that the model can effectively recognize the location and severity of impact damage simultaneously. Compared with single-task learning, multi-task learning performs better on various metrics of the impact energy task, reducing the training time by 30.83%.

- (4)

- In the case of reducing the number of samples, the accuracy degradation of multi-task learning is small compared to single-task learning, which proves that there is an implicit data enhancement mechanism in multi-task learning, which can effectively increase the number of training instances, making multi-task learning prediction accuracy higher and more stable, and more independent of the number of samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yüksel, K.; Kinet, D.; Moeyaert, V.; Kouroussis, G.; Caucheteur, C. Railway monitoring system using optical fiber grating accelerometers. Smart Mater. Struct. 2018, 27, 105033. [Google Scholar] [CrossRef]

- Khodaei, Z.S.; Aliabadi, M.H.F.; Shen, Y.; Cesnik, C.E.S.; Banerjee, S.; Shrestha, S.; Ostachowicz, W.M.; Malinowski, P.H.; Wandowski, T.; Rocha, B.; et al. Structural Health Monitoring for Advanced Composite Structures; World Scientific Publishing: Singapore, 2017. [Google Scholar]

- Yang, B.; Xuan, F.-Z.; Chen, S.; Zhou, S.; Gao, Y.; Xiao, B. Damage localization and identification in WGF/epoxy composite laminates by using Lamb waves: Experiment and simulation. Compos. Struct. 2017, 165, 138–147. [Google Scholar] [CrossRef]

- Su, C.; Jiang, M.; Liang, J.; Tian, A.; Sun, L.; Zhang, L.; Zhang, F.; Sui, Q. Damage Localization of Composites Based on Difference Signal and Lamb Wave Tomography. Materials 2020, 13, 218. [Google Scholar] [CrossRef]

- Schäfer, F.; Janovsky, R. Impact sensor network for detection of hypervelocity impacts on spacecraft. Acta Astronaut. 2007, 61, 901–911. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, G.; Lu, W.; Li, C.; Lu, C. Nonlinear lamb wave imaging method for testing Barely Visible Impact Damage of CFRP laminates. Appl. Acoust. 2022, 192, 108699. [Google Scholar] [CrossRef]

- Su, C.; Jiang, M.; Liang, J.; Tian, A.; Sun, L.; Zhang, L.; Zhang, F.; Sui, Q. Damage Identification in Composites Based on Hilbert Energy Spectrum and Lamb Wave Tomography Algorithm. IEEE Sens. J. 2019, 19, 11562–11572. [Google Scholar] [CrossRef]

- Zhu, K.; Qing, X.P.; Liu, B. A two-step impact localization method for composite structures with a parameterized laminate model. Compos. Struct. 2018, 192, 500–506. [Google Scholar] [CrossRef]

- Holford, K.M.; Eaton, M.J.; Hensman, J.J.; Pullin, R.; Evans, S.L.; Dervilis, N.; Worden, K. A new methodology for automating acoustic emission detection of metallic fatigue fractures in highly demanding aerospace environments: An overview. Prog. Aerosp. Sci. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Gao, F.; Zeng, L.; Lin, J.; Shao, Y. Damage assessment in composite laminates via broadband Lamb wave. Ultrasonics 2018, 86, 49–58. [Google Scholar] [CrossRef]

- Kundu, T.; Nakatani, H.; Takeda, N. Acoustic source localization in anisotropic plates. Ultrasonics 2012, 52, 740–746. [Google Scholar] [CrossRef]

- Harley, J.B. Predictive Guided Wave Models Through Sparse Modal Representations. Proc. IEEE 2016, 104, 1604–1619. [Google Scholar] [CrossRef]

- Liu, C.; Harley, J.B.; Bergés, M.; Greve, D.W.; Oppenheim, I.J. Oppenheim. Robust ultrasonic damage detection under complex environmental conditions using singular value decomposition. Ultrasonics 2015, 58, 75–86. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Su, Y.; He, Y.; Zhou, P.; Xu, L.; Su, Z. Machine learning-enabled resolution-lossless tomography for composite structures with a restricted sensing capability. Ultrasonics 2022, 125, 106801. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Huo, H.; Guan, X.; Yang, J. A Lamb wave quantification model for inclined cracks with experimental validation. Chin. J. Aeronaut. 2021, 34, 601–611. [Google Scholar] [CrossRef]

- Gao, F.; Shao, Y.; Hua, J.; Zeng, L.; Lin, J. Enhanced wavefield imaging method for impact damage detection in composite laminates via laser-generated Lamb waves. Measurement 2021, 173, 108639. [Google Scholar] [CrossRef]

- Donda, K.; Zhu, Y.; Merkel, A.; Fan, S.-W.; Cao, L.; Wan, S.; Assouar, B. Ultrathin acoustic absorbing metasurface based on deep learning approach. Smart Mater. Struct. 2021, 30, 085003. [Google Scholar] [CrossRef]

- Humer, C.; Höll, S.; Kralovec, C.; Schagerl, M. Damage identification using wave damage interaction coefficients predicted by deep neural networks. Ultrasonics 2022, 124, 106743. [Google Scholar] [CrossRef]

- Jiang, K.; Han, Q.; Du, X. Lost data neural semantic recovery framework for structural health monitoring based on deep learning. Comput. Aided Civ. Infrastruct. Eng. 2022, 37, 1160–1187. [Google Scholar] [CrossRef]

- Liu, G.; Li, L.; Zhang, L.; Li, Q.; Law, S.S. Sensor faults classification for SHM systems using deep learning-based method with Tsfresh features. Smart Mater. Struct. 2020, 29, 075005. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, S.-X.; Ni, Y.-Q.; Jiang, L. Pitch-catch UGW-based multiple damage inference: A heterogeneous graph interpretation. Smart Mater. Struct. 2022, 31, 015005. [Google Scholar] [CrossRef]

- Ewald, V.; Venkat, R.S.; Asokkumar, A.; Benedictus, R.; Boller, C.; Groves, R.M. Perception modelling by invariant representation of deep learning for automated structural diagnostic in aircraft maintenance: A study case using DeepSHM. Mech. Syst. Signal Process. 2022, 165, 108153. [Google Scholar] [CrossRef]

- Qian, C.; Ran, Y.; He, J.; Ren, Y.; Sun, B.; Zhang, W.; Wang, R. Application of artificial neural networks for quantitative damage detection in unidirectional composite structures based on Lamb waves. Adv. Mech. Eng. 2020, 12, 1687814020914732. [Google Scholar] [CrossRef]

- Ribeiro, M.G.D.; Kubrusly, A.C.; Ayala, H.V.H. Damage Detection in Composite Plates with Ultrasonic Guided-waves and Nonlinear System Identification. In Proceedings of the 2020 IEEE Symposium Series on Computational Intelligence (SSCI), Canberra, ACT, Australia, 1–4 December 2020. [Google Scholar]

- Ziaja, D.; Nazarko, P. SHM system for anomaly detection of bolted joints in engineering structures. Structures 2021, 33, 3877–3884. [Google Scholar] [CrossRef]

- Wu, J.; Xu, X.; Liu, C.; Deng, C.; Shao, X. Lamb wave-based damage detection of composite structures using deep convolutional neural network and continuous wavelet transform. Compos. Struct. 2021, 276, 114590. [Google Scholar] [CrossRef]

- Zhang, S.; Li, C.M.; Ye, W. Damage localization in plate-like structures using time-varying feature and one-dimensional convolutional neural network. Mech. Syst. Signal Process. 2021, 147, 107107. [Google Scholar] [CrossRef]

- Su, C.; Jiang, M.; Lv, S.; Lu, S.; Zhang, L.; Zhang, F.; Sui, Q. Improved Damage Localization and Quantification of CFRP Using Lamb Waves and Convolution Neural Network. IEEE Sens. J. 2019, 19, 5784–5791. [Google Scholar] [CrossRef]

- Pandey, P.; Rai, A.; Mitra, M. Explainable 1-D convolutional neural network for damage detection using Lamb wave. Mech. Syst. Signal Process. 2022, 164, 108220. [Google Scholar] [CrossRef]

- Rautela, M.; Senthilnath, J.; Moll, J.; Gopalakrishnan, S. Combined two-level damage identification strategy using ultrasonic guided waves and physical knowledge assisted machine learning. Ultrasonics 2021, 115, 106451. [Google Scholar] [CrossRef]

- Sattarifar, A.; Nestorović, T. Damage localization and characterization using one-dimensional convolutional neural network and a sparse network of transducers. Eng. Appl. Artif. Intell. 2022, 115, 105273. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Q. An overview of multi-task learning. Natl. Sci. Rev. 2018, 5, 30–43. [Google Scholar] [CrossRef]

- Vandenhende, S.; Georgoulis, S.; Van Gansbeke, W.; Proesmans, M.; Dai, D.; Van Gool, L. Multi-Task Learning for Dense Prediction Tasks: A Survey. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 44, 3614–3633. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Hou, L.; Chen, Y.; Lu, Z. An effective crack position diagnosis method for the hollow shaft rotor system based on the convolutional neural network and deep metric learning. Chin. J. Aeronaut. 2022, 35, 242–254. [Google Scholar] [CrossRef]

- Xie, J.; Li, Z.; Zhou, Z.; Liu, S. A Novel Bearing Fault Classification Method Based on XGBoost: The Fusion of Deep Learning-Based Features and Empirical Features. IEEE Trans. Instrum. Meas. 2021, 70, 3506709. [Google Scholar] [CrossRef]

| Parameter | Density | Elastic Modulus | Poisson Ratio |

|---|---|---|---|

| Value | 7.93 (g/cm³) | 195 (GPa) | 0.247 |

| PZT Sensor Model | Diameter (mm) | Thickness (mm) | Density (g/m3) |

|---|---|---|---|

| PZT-51 | 8 | 0.48 | 7.80 |

| Model | Energy | Precision (%) | Recall (%) | F1-score (%) |

|---|---|---|---|---|

| Single-task learning | 0.5 J | 95.74 | 98.90 | 97.29 |

| 1.0 J | 97.05 | 92.96 | 94.96 | |

| 1.5 J | 97.43 | 97.44 | 97.43 | |

| Multi-task learning | 0.5 J | 95.79 | 100 | 97.85 |

| 1.0 J | 100 | 95.77 | 97.84 | |

| 1.5 J | 100 | 98.71 | 99.35 |

| Comparison Parameters | Single-Task Learning (Impact Location/Energy) | Multi-Task Learning | Reduction |

|---|---|---|---|

| Training time | 16.68 s 17.63 s | 23.73 s | 30.83% |

| Total time | 34.31 s | 23.73 s |

| Model | Location | Energy |

|---|---|---|

| SVM | 94.79% | 90.83% |

| DT | 93.33% | 87.08% |

| RF | 96.67% | 94.16% |

| Single-task learning | 100% | 96.67% |

| Multi-task learning | 100% | 98.33% |

| Model | Location with 50% Samples | Location with 25% Samples | Energy with 50% Samples | Energy with 25% Samples |

|---|---|---|---|---|

| Single-task learning | 1.67% | 1.67% | 3.34% | 8.34% |

| Multi-task learning | 0.84% | 1.67% | 0.83% | 3.33% |

| Comparison Parameters | Single-Task Learning (Impact Location/Energy) | Multi-Task Learning | Reduction |

|---|---|---|---|

| Training time | 8.63 s 8.56 s | 17.19 s | 26.64% |

| Total time | 12.61 s | 12.61 s |

| Comparison Parameters | Single-Task Learning (Impact Location/Energy) | Multi-Task Learning | Reduction |

|---|---|---|---|

| Training time | 4.49 s 4.42 s | 8.91 s | 30.19% |

| Total time | 6.22 s | 6.22 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Gan, Z.; Zhang, X.; Wang, T.; Xie, J. An Improved Impact Damage Monitoring Method for High-Speed Trains Using Lamb Waves and Multi-Task Learning. Appl. Sci. 2023, 13, 10235. https://doi.org/10.3390/app131810235

Yang J, Gan Z, Zhang X, Wang T, Xie J. An Improved Impact Damage Monitoring Method for High-Speed Trains Using Lamb Waves and Multi-Task Learning. Applied Sciences. 2023; 13(18):10235. https://doi.org/10.3390/app131810235

Chicago/Turabian StyleYang, Jinsong, Zhiqiang Gan, Xiaozhen Zhang, Tiantian Wang, and Jingsong Xie. 2023. "An Improved Impact Damage Monitoring Method for High-Speed Trains Using Lamb Waves and Multi-Task Learning" Applied Sciences 13, no. 18: 10235. https://doi.org/10.3390/app131810235

APA StyleYang, J., Gan, Z., Zhang, X., Wang, T., & Xie, J. (2023). An Improved Impact Damage Monitoring Method for High-Speed Trains Using Lamb Waves and Multi-Task Learning. Applied Sciences, 13(18), 10235. https://doi.org/10.3390/app131810235