Simulation Analysis of Working Circuit Performance of Mountain Pepper Harvester Based on Improved Load-Sensitive System

Abstract

:1. Introduction

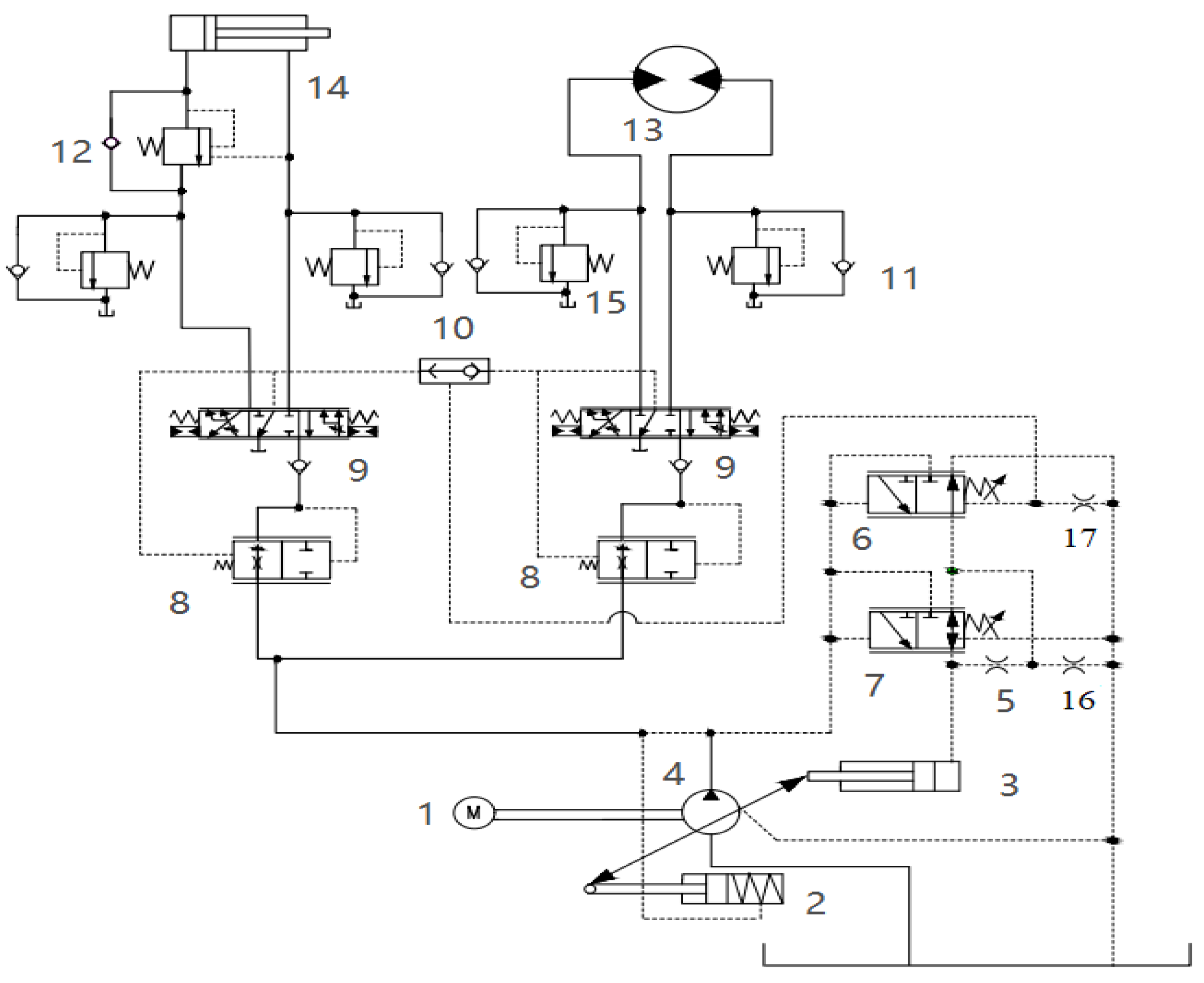

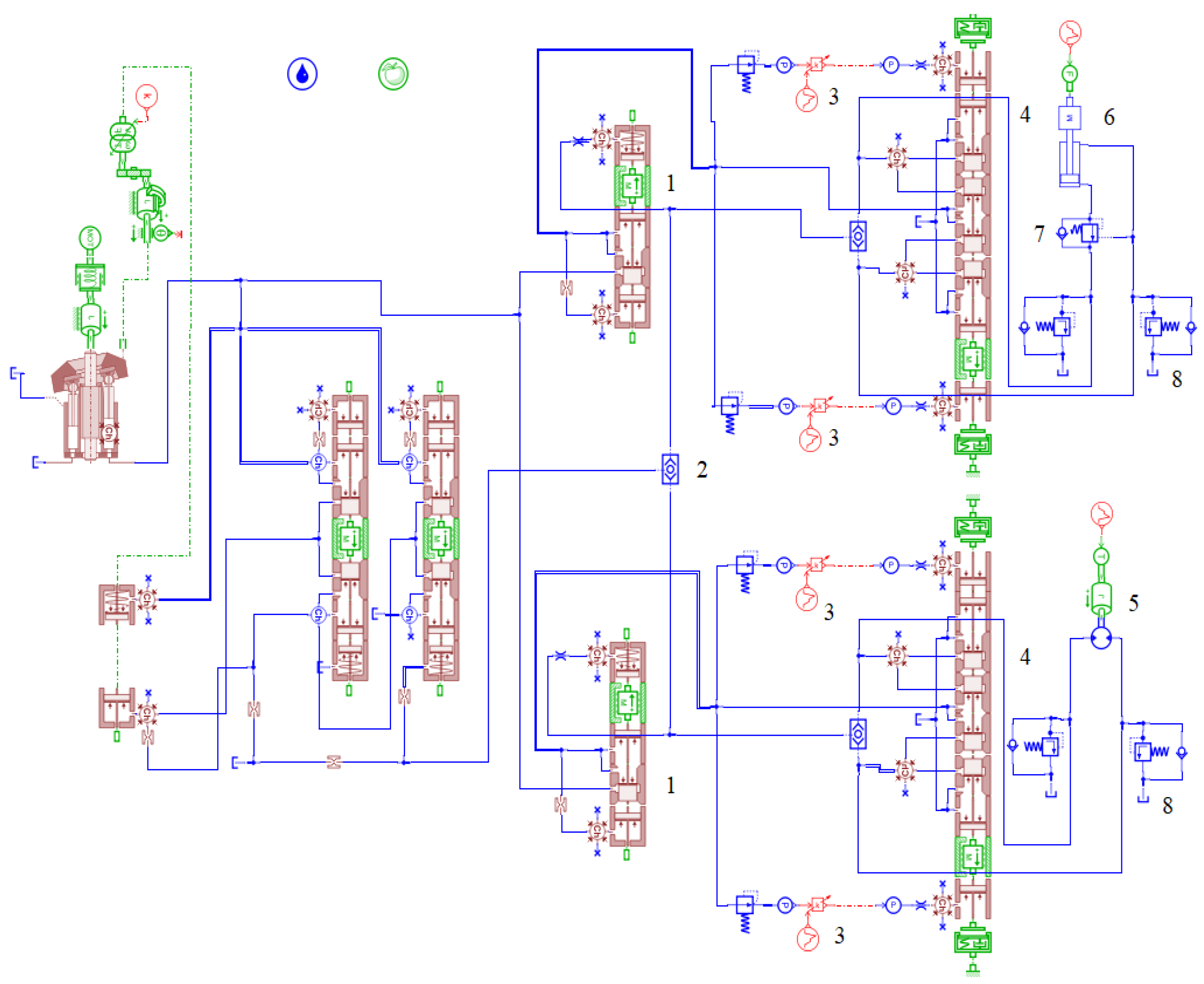

2. Working Circuit Hydraulic System Design and Working Principle Analysis

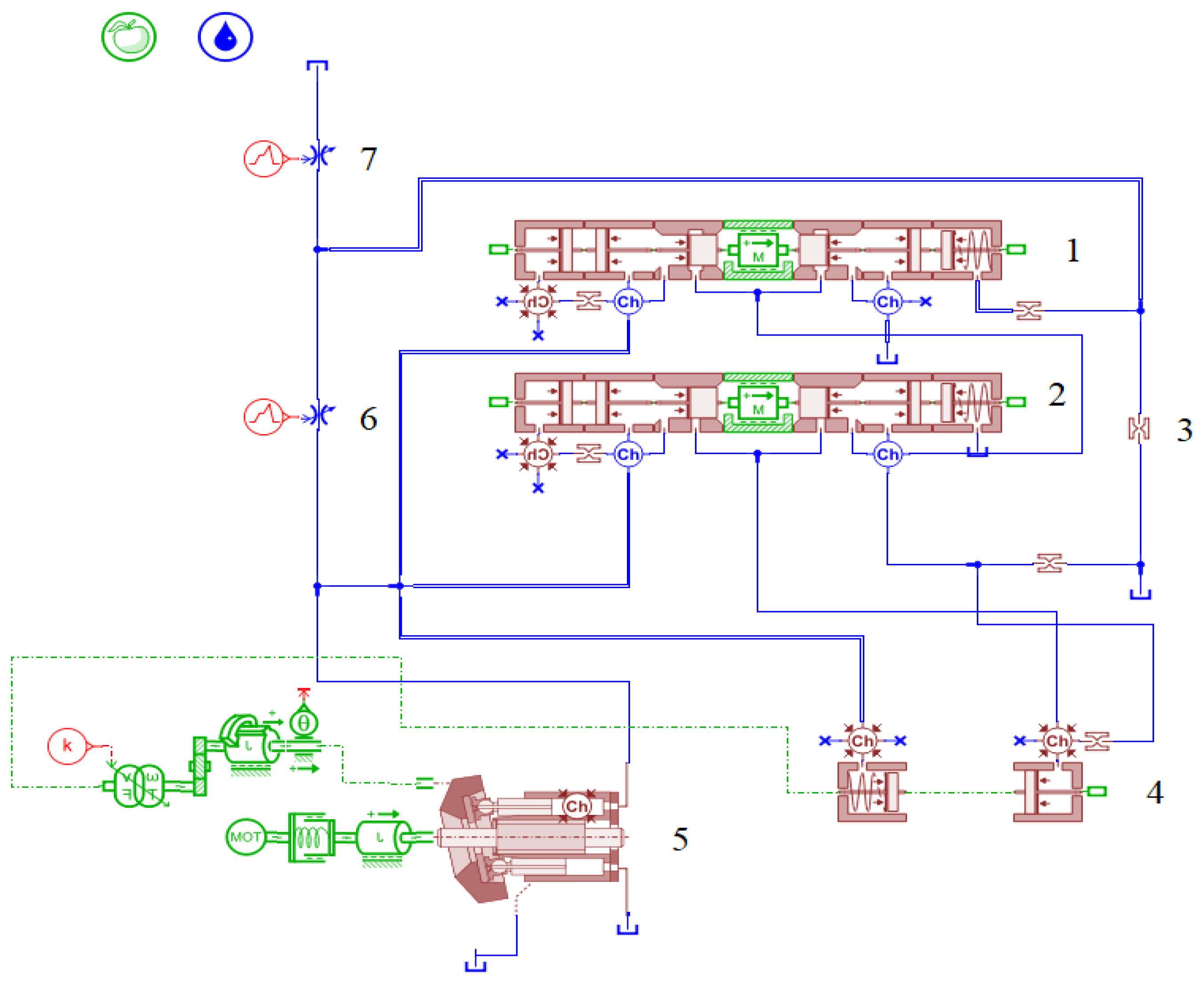

3. Modeling of the Hydraulic System of Mountain Pepper Harvester

3.1. Load-Sensitive Pump Model Construction

3.2. Working Circuit Model Building

4. Characterization of the Hydraulic System of Mountain Pepper Harvester

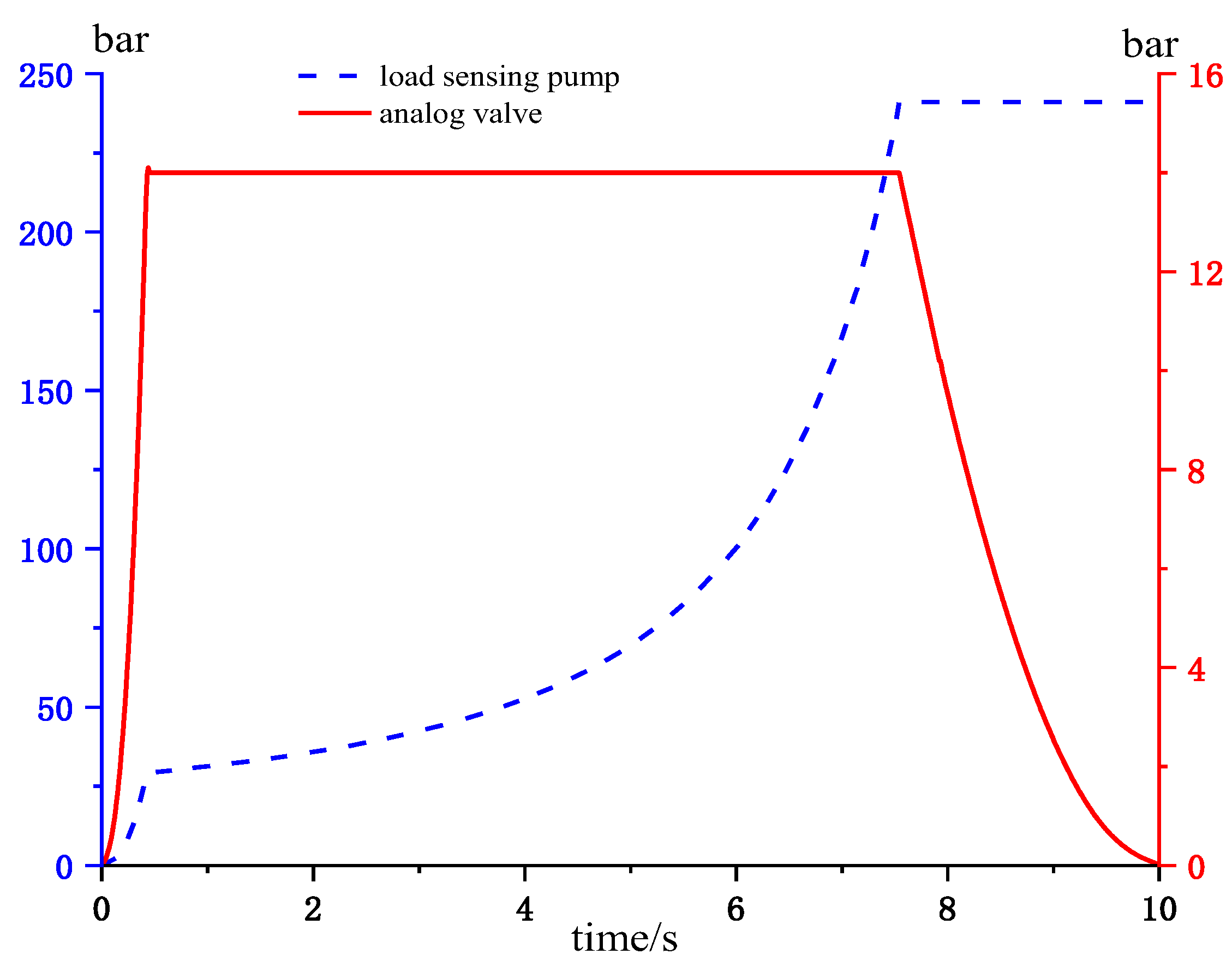

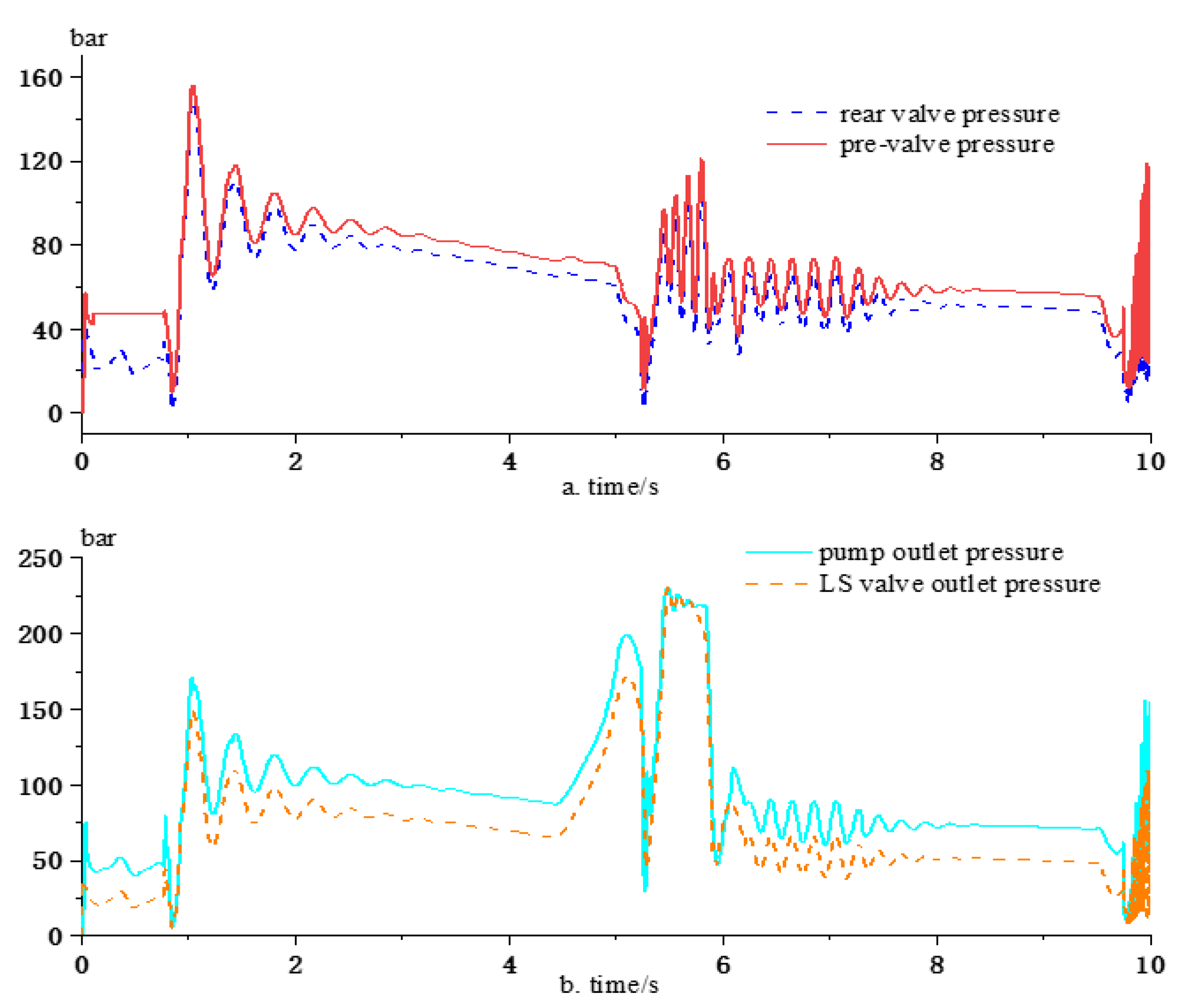

4.1. Variable Flow Rate System Analysis

4.2. Characterization of Variable Load Conditions

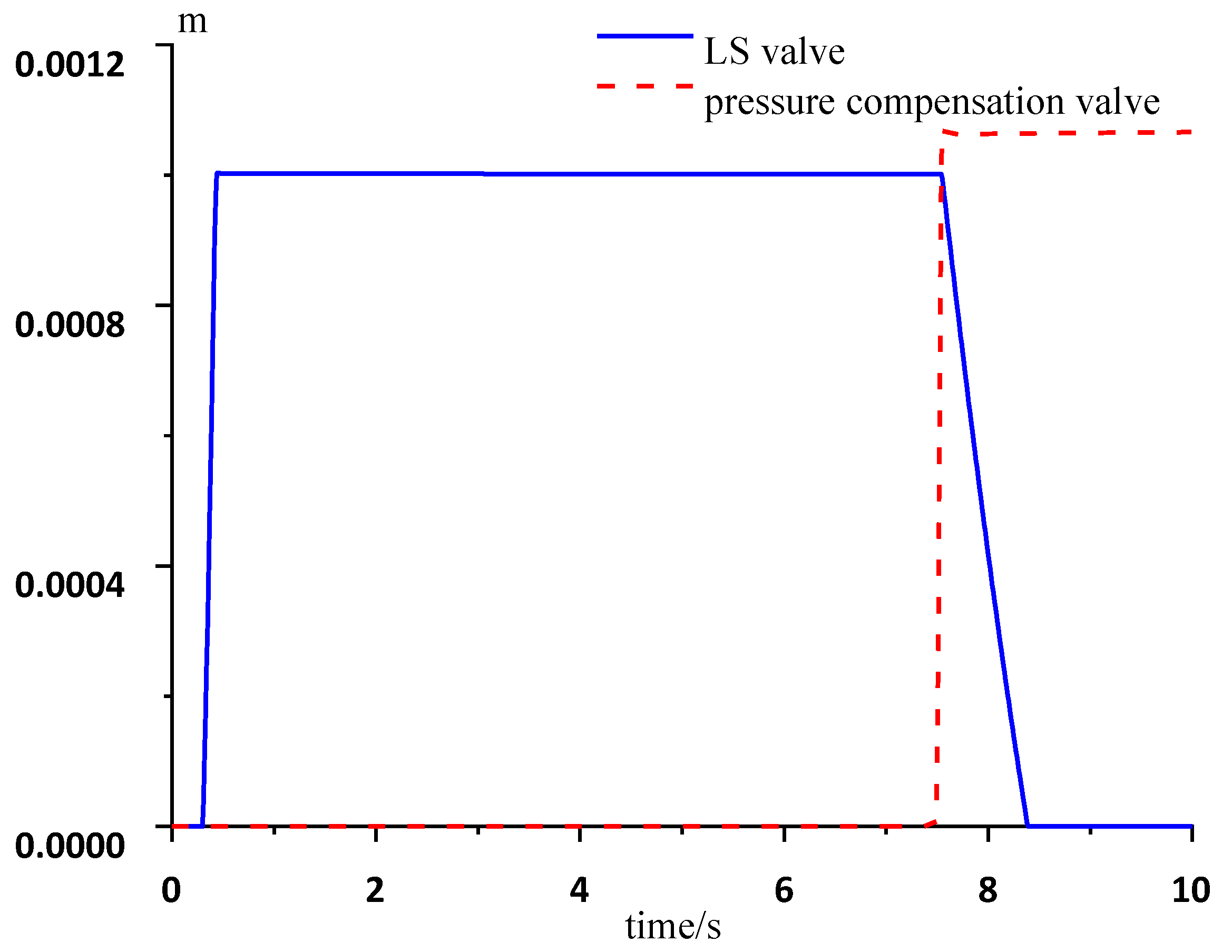

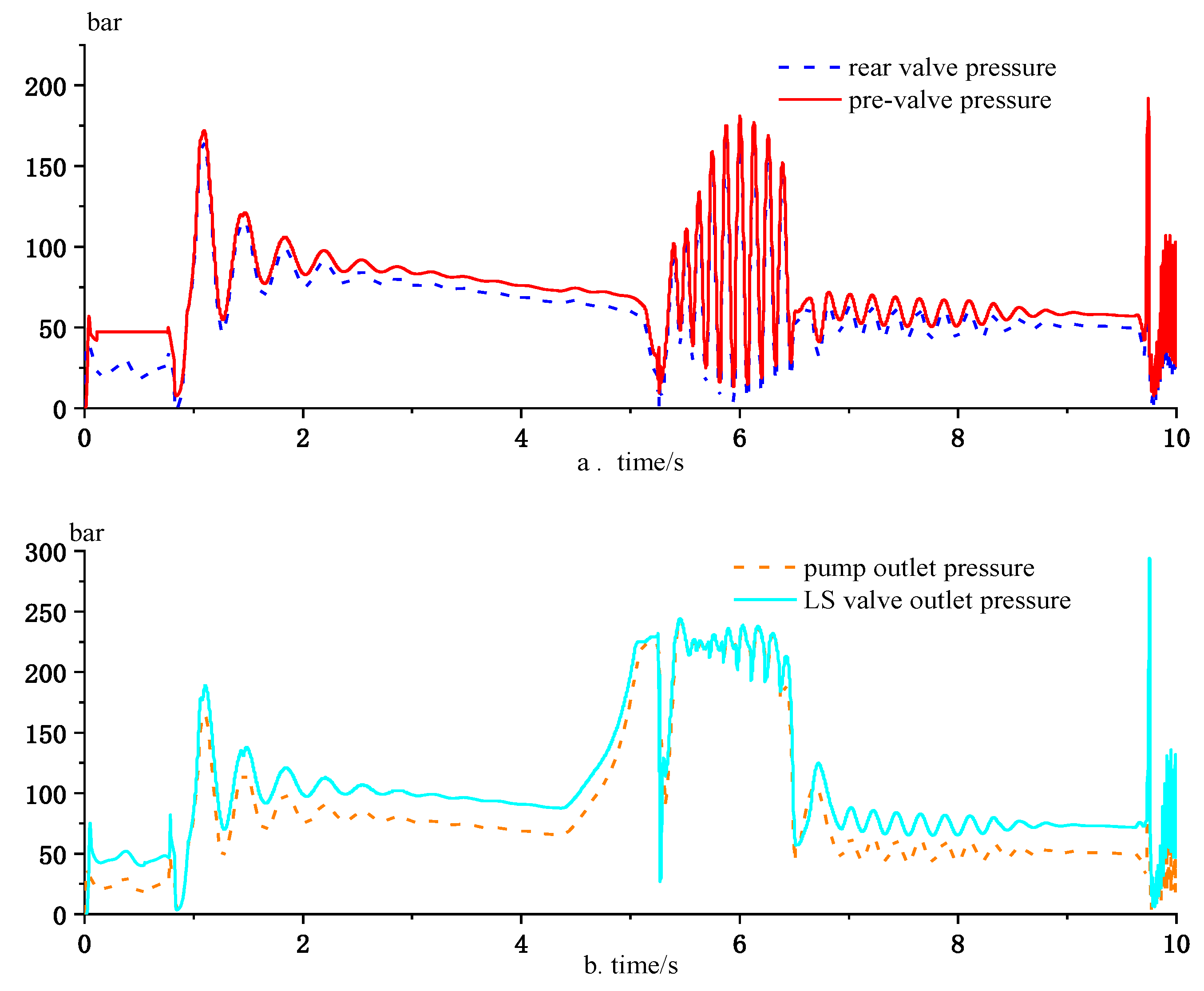

4.3. Improved Load-Sensitive System Characterization

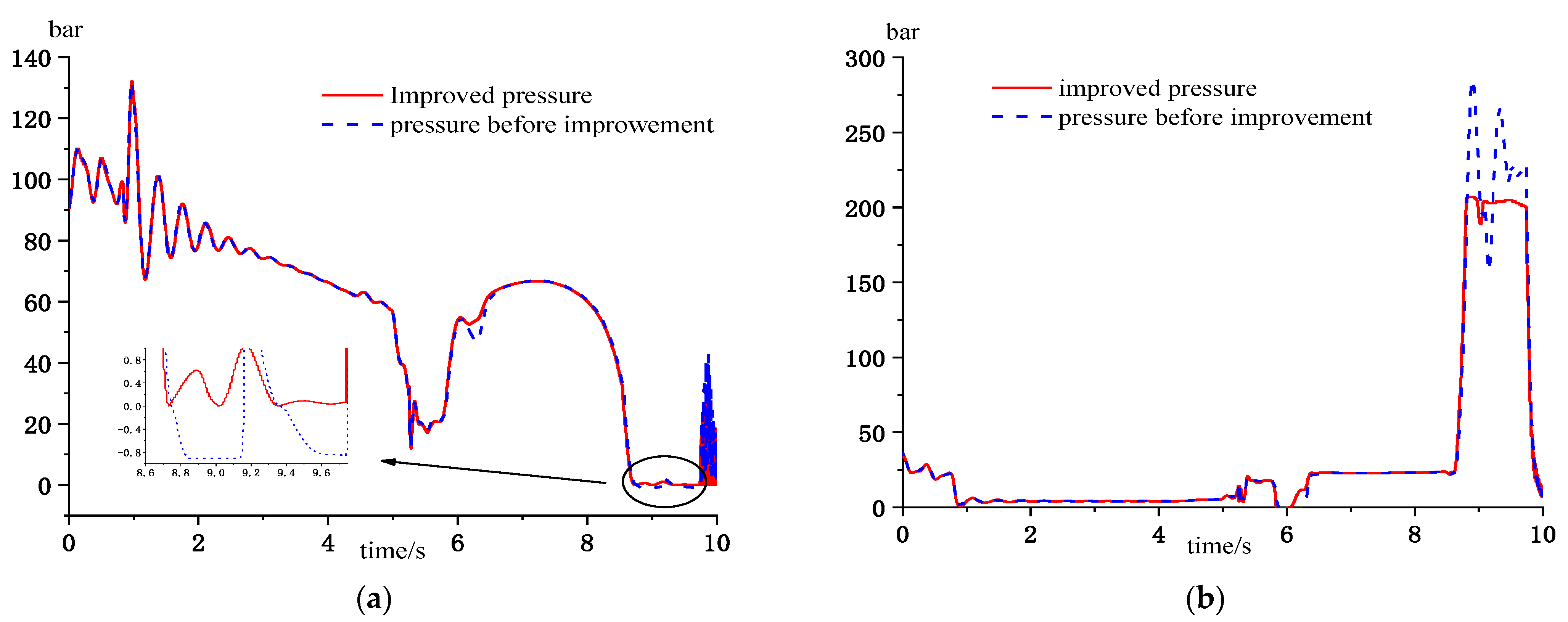

4.3.1. Characterization after Adding the Charge Reduction Valve

4.3.2. Characterization after Adding Balancing Valve

5. Experimental Results and Discussion

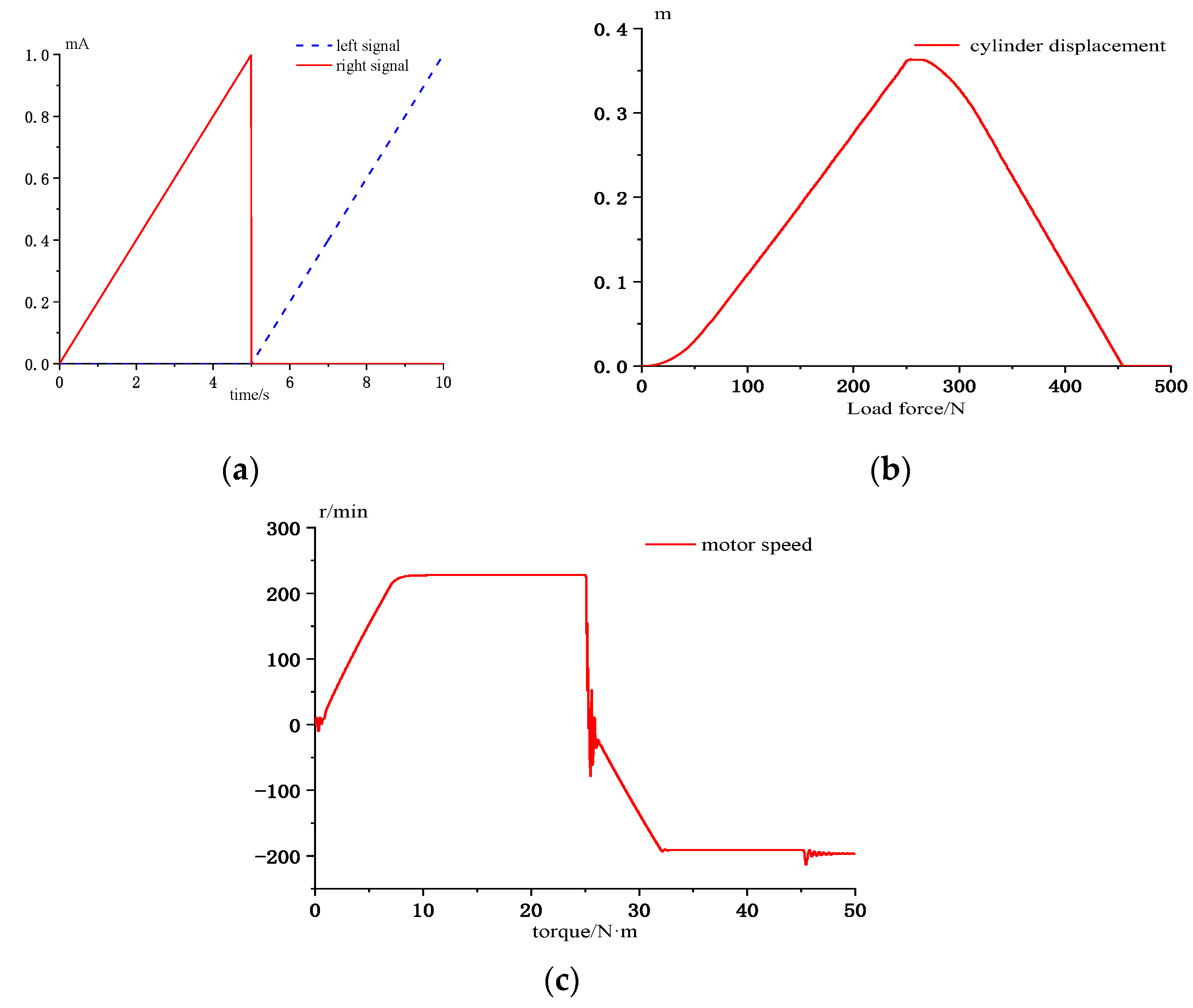

5.1. Verification Test of the Performance of the Working Circuit System

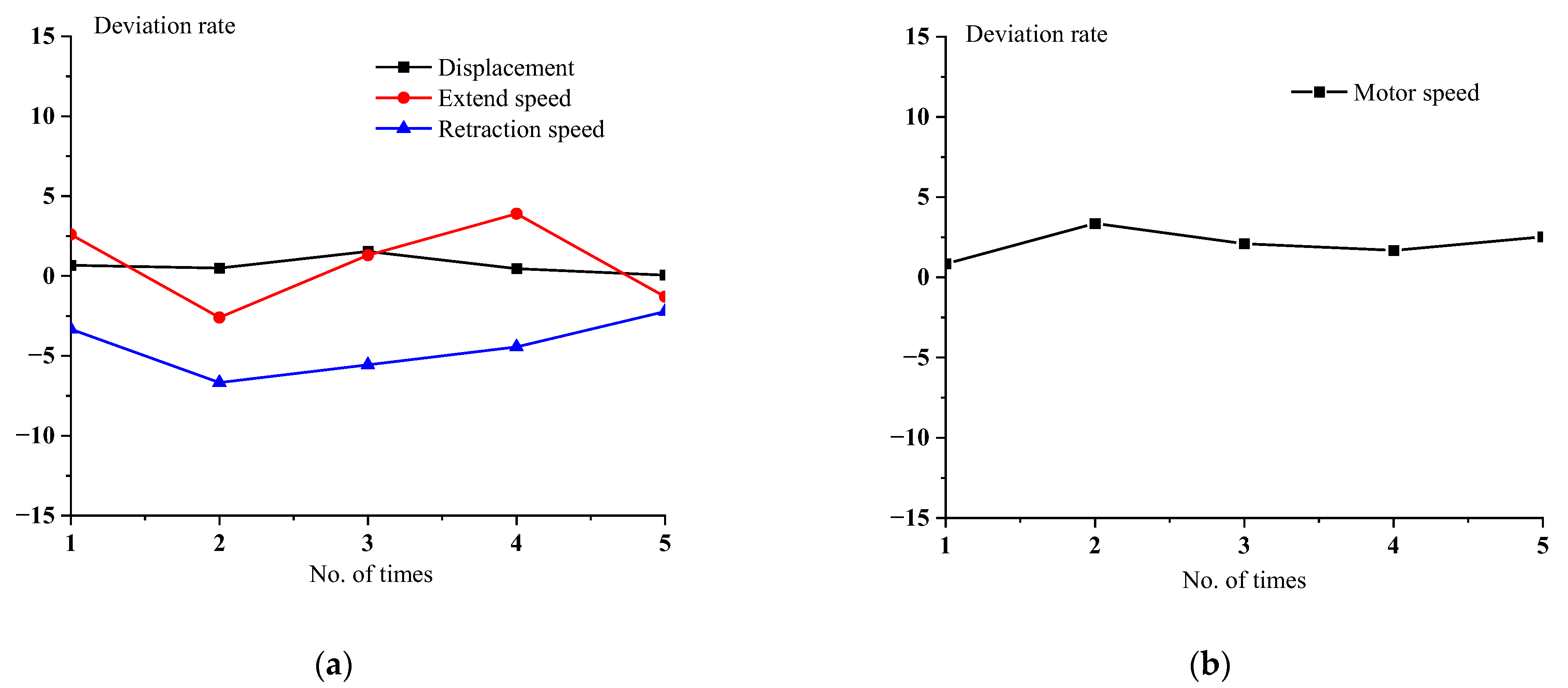

5.1.1. Lift Cylinder Performance Test

5.1.2. Comb Motor Performance Test

5.2. Experimental Results and Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, P.D.; Liu, C.B.; Zhang, P. Current situation of agricultural mechanization development in mountainous areas of Guizhou and suggestions for countermeasures. China J. Agric. Mech. 2020, 41, 6. [Google Scholar]

- Zhao, Q. Enhancing the level of agricultural mechanization in hilly and mountainous areas to accelerate the construction of agricultural modernization. Shandong Agric. Mech. 2020, 1. [Google Scholar] [CrossRef]

- Mou, Y.M.; Mao, F.F.; Zhang, S.G. Current situation and development suggestions of pepper industry in Guizhou Province. Chin. Veg. 2020, 2, 10–12. [Google Scholar] [CrossRef]

- Ringdahl, O.; Kurtser, P.; Edan, Y. Evaluation of approach strategies for harvesting robots: Case study of sweet pepper harvesting. J. Intell. Robot Syst. 2019, 95, 149–164. [Google Scholar] [CrossRef]

- Agarwal, A.; Purohit, A. Performance Evaluation of Flutter-Based Energy Harvester Under Different Vortex Flow Regimes: An Experimental Study. Arab. J. Sci. Eng. 2022, 48, 3491–3501. [Google Scholar] [CrossRef]

- Chen, Y.C.; Hu, S.I.; Yuan, Y. Design and experimental research of comb-tooth type pepper picking device. In Proceedings of the International Academic Conference of Chinese Agricultural Machinery Society, Hangzhou, China, 27–30 October 2012. [Google Scholar]

- Qin, X.Y.; Chen, Y.C.; Zhang, F.Q.; Liu, X.F.; Hu, S.J.; Xiong, Z.Y.; Yuan, Y.X. Design study of 4LZ-3.0 self-propelled pepper harvester. Agric. Mech. Res. 2012, 34, 53–56. [Google Scholar]

- Xin, D.Z.; Chen, S.L.; Wang, Q.F. Technology of load-sensitivity used in the hydraulic system of an all-hydraulic core rig. J. Coal Sci. Eng. China 2009, 15, 318–323. [Google Scholar] [CrossRef]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Li, Z.; Chen, Q. A double variable control load sensing system for electric hydraulic excavator. Energy 2021, 223, 119999. [Google Scholar] [CrossRef]

- Shen, H.J.; Liu, T. Optimization design and simulation analysis of load-sensitive hydraulic system of loader. Hydraul. Pneum. 2022, 46, 7. [Google Scholar]

- Qiu, P. Design and research of load-sensitive control system for rocker arm lifting of roadheader. Mach. Tools Hydraul. 2021, 49, 6. [Google Scholar]

- Luo, Y.L.; Tu, S.T.; Shi, L.; Luo, Y. Research on the working circuit of mountain hydraulic mower based on load-sensitive system. Hydraul. Pneum. 2020, 2, 71–77. [Google Scholar]

- Luo, Y.; Du, L.; Li, Y. Analysis of load-sensitive system of hydraulic rotary tiller working device. Hydraul. Pneum. 2021, 45, 52–57. [Google Scholar]

- He, G.H.; Luo, Y.L.; Shi, L. Modeling and simulation analysis of hydrostatic drive circuit of mountain tractor based on AMESim. Mach. Tools Hydraul. 2020, 48, 150–153. [Google Scholar]

- Chen, Y.L.; Chen, C.Z.; Peng, Z.; Chen, H.; Wang, X. Energy-saving design of hydraulic system for cutting roller of sugarcane combine harvester. Hydraul. Pneum. 2022, 46, 10. [Google Scholar]

- Chen, J.C.; Zhang, X.K.; Wen, H.J.; Zhang, H.; Wang, H.; Ji, C. Simulation analysis of load-sensitive hydraulic system of spray bar sprayer suspension. Hydraul. Pneum. 2022, 46, 24–30. [Google Scholar]

- Wang, G.; Tao, L. Energy-efficient design of load-sensitive hydraulic system and AMESim simulation analysis. Mach. Tools Hydraul. 2021, 49, 164–168. [Google Scholar]

- Zhang, L.J.; Wang, L.H.; Li, D.X.; Wang, S. Principle analysis of load-sensitive valve front compensation system. Hydraul. Pneum. 2015, 7, 63–67. [Google Scholar]

- Wu, X.M.; Gao, D.R. Principles and Applications of Variable Regulation of Hydraulic Variable Pumps (Motors); Mechanical Industry Press: Beijing, China, 2012. [Google Scholar]

- Wu, G.M. New Practical Electro-Hydraulic Proportional Technology: Electro-Hydraulic Proportional Technology; Zhejiang University Press: Hangzhou, China, 2006. [Google Scholar]

- Miao, M.Y.; Zhong, G.X.; Dai, G.T. Improvement of load-sensitive control system of excavator. Constr. Mach. Maint. 2013, 1, 228. [Google Scholar]

- Li, Z.L.; Yue, L.H.; Yang, J. Characterization of variable speed load sensitive import/export independent control system. J. Beijing Univ. Aeronaut. Astronaut. 2022. Available online: http://kns.cnki.net/kcms/detail/11.2625.V.20220513.2154.002.html (accessed on 1 September 2023).

- Tao, L.; Xu, H.W.; Fang, T. Optimized design and AMESim simulation of load-sensitive hydraulic system with post-valve compensation. Mach. Tools Hydraul. 2021, 49, 150–153. [Google Scholar]

- Cheng, M.; Yu, J.; Ding, R.Q.; Cai, L.P. Electro-hydraulic load-sensitive system based on compound control of flow feedforward and pressure feedback. J. Mech. Eng. 2018, 54, 262–270. [Google Scholar] [CrossRef]

- Zhao, S.L.; Zhao, D.X.; Wang, J.T.; Chen, X.; Yang, H.; Tang, H. Research on unloading pressure shock suppression in load-sensitive system of quantitative pump. J. Agric. Mach. 2020, 51, 408–417+407. [Google Scholar]

- Liu, G.; Lin, S.Y.; Liang, Y.; Tang, Y.; Xu, W.P. Design of an inclined double-spiral comb-finger pepper harvesting test stand. Agric. Mech. Res. 2020, 42, 133–137. [Google Scholar]

- Liu, J.; Xie, H.; Hu, L.; Yang, H.; Fu, X. Realization of direct flow control with load pressure compensation on a load control valve applied in overrunning load hydraulic systems. Flow Meas. Instrum. 2016, 53, 261–268. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J. Energy recovery for hybrid hydraulic excavators: Flywheel-based solutions. Autom. Constr. 2021, 125, 103648. [Google Scholar] [CrossRef]

- Ni, Y.; Jin, C.; Chen, M.; Yuan, W.; Qian, Z.; Yang, T.; Cai, Z. Computational model and adjustment system of header height of soybean harvesters based on soil-machine system. Comput. Electron. Agric. 2021, 183, 105907. [Google Scholar] [CrossRef]

- Li, L.; Huang, H.; Zhao, F.; Sutherland, J.W.; Liu, Z. An Energy-Saving Method by Balancing the Load of Operations for Hydraulic Press. IEEE/ASME Trans. Mechatron. 2017, 22, 2673–2683. [Google Scholar] [CrossRef]

| Main Parameters | Numerical Value | Main Parameters | Numerical Value |

|---|---|---|---|

| Hydraulic cylinder bore/mm | 80 | Pressure compensation valve spring force/N | 660 |

| Hydraulic cylinder rod diameter/mm | 40 | Multiway valve spool displacement/m | 0.006 |

| Hydraulic Pump Displacement/mL·r−1 | 250 | Balancing valve setting pressure/bar | 200 |

| Hydraulic pump motor speed/r·min−1 | 1500 | Multi-way valve spool diameter/mm | 10 |

| Load sensitive valve spring force/N | 40 | Rated speed of hydraulic motor/r·min−1 | 258 |

| Number of Times | Cylinder Displacement (mm) | Boost Time (s) | Boost Speed (m/s) | Descent Time (s) | Reach Back Speed (m/s) | Displacement Deviation Amount (mm) |

|---|---|---|---|---|---|---|

| 1 | 365.5 | 4.9 | 0.075 | 4.0 | 0.093 | 1.9 |

| 2 | 368.2 | 4.7 | 0.079 | 3.8 | 0.096 | 2.1 |

| 3 | 364.3 | 4.8 | 0.076 | 3.7 | 0.095 | 1.6 |

| 4 | 368.3 | 5.0 | 0.074 | 3.9 | 0.094 | 1.3 |

| 5 | 369.8 | 4.7 | 0.078 | 4.0 | 0.092 | 1.8 |

| Number of Times | Load Torque (N.m) | Rotational Speed (r/min) |

|---|---|---|

| 1 | 30 | 236 |

| 2 | 35 | 230 |

| 3 | 40 | 233 |

| 4 | 45 | 234 |

| 5 | 50 | 232 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Ma, Z.; Zhang, J.; Xu, W.; He, H.; Li, Z. Simulation Analysis of Working Circuit Performance of Mountain Pepper Harvester Based on Improved Load-Sensitive System. Appl. Sci. 2023, 13, 10008. https://doi.org/10.3390/app131810008

Wu D, Ma Z, Zhang J, Xu W, He H, Li Z. Simulation Analysis of Working Circuit Performance of Mountain Pepper Harvester Based on Improved Load-Sensitive System. Applied Sciences. 2023; 13(18):10008. https://doi.org/10.3390/app131810008

Chicago/Turabian StyleWu, Di, Zhihao Ma, Jianlong Zhang, Weiping Xu, Haifeng He, and Zhenlin Li. 2023. "Simulation Analysis of Working Circuit Performance of Mountain Pepper Harvester Based on Improved Load-Sensitive System" Applied Sciences 13, no. 18: 10008. https://doi.org/10.3390/app131810008

APA StyleWu, D., Ma, Z., Zhang, J., Xu, W., He, H., & Li, Z. (2023). Simulation Analysis of Working Circuit Performance of Mountain Pepper Harvester Based on Improved Load-Sensitive System. Applied Sciences, 13(18), 10008. https://doi.org/10.3390/app131810008