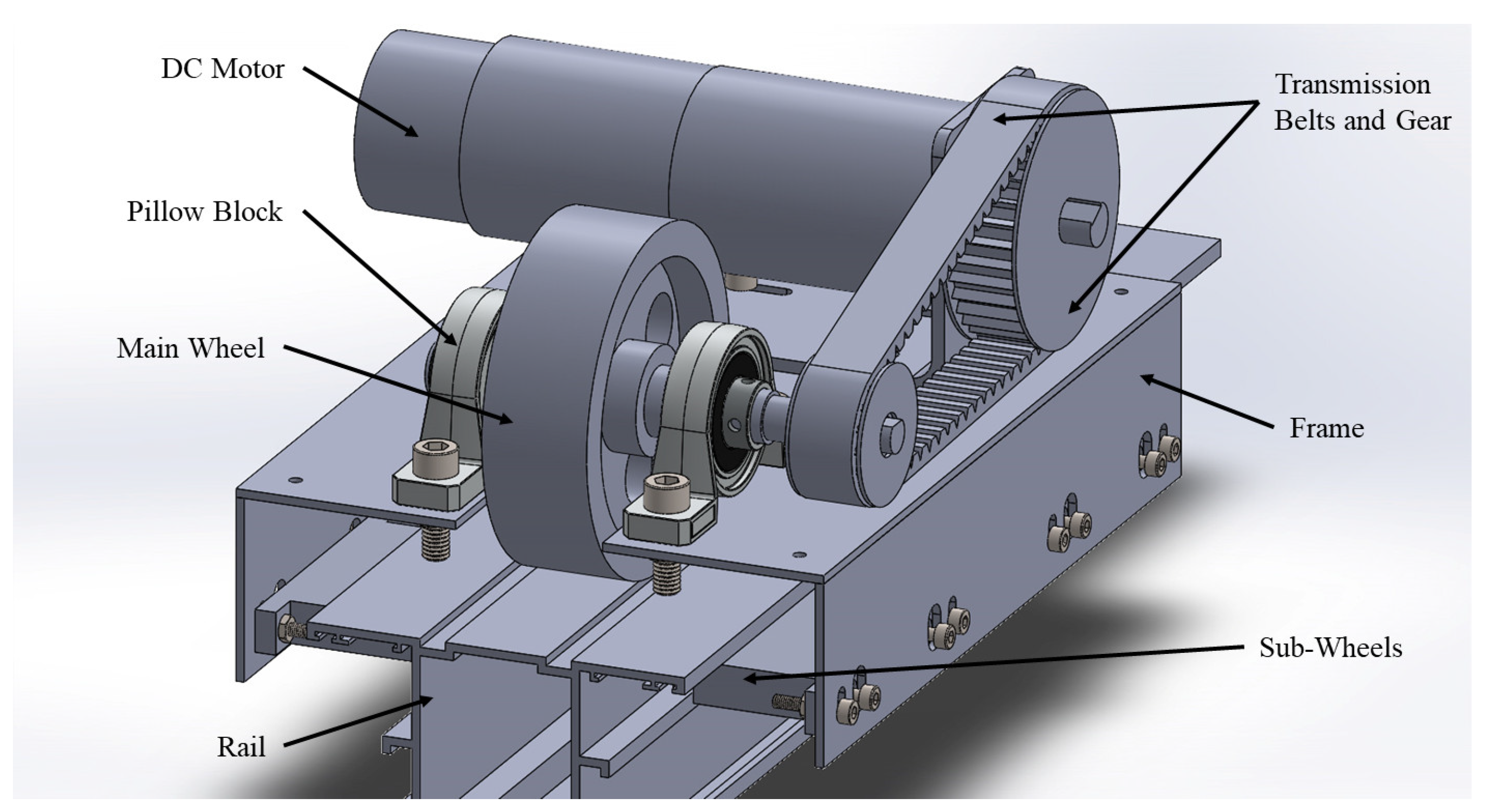

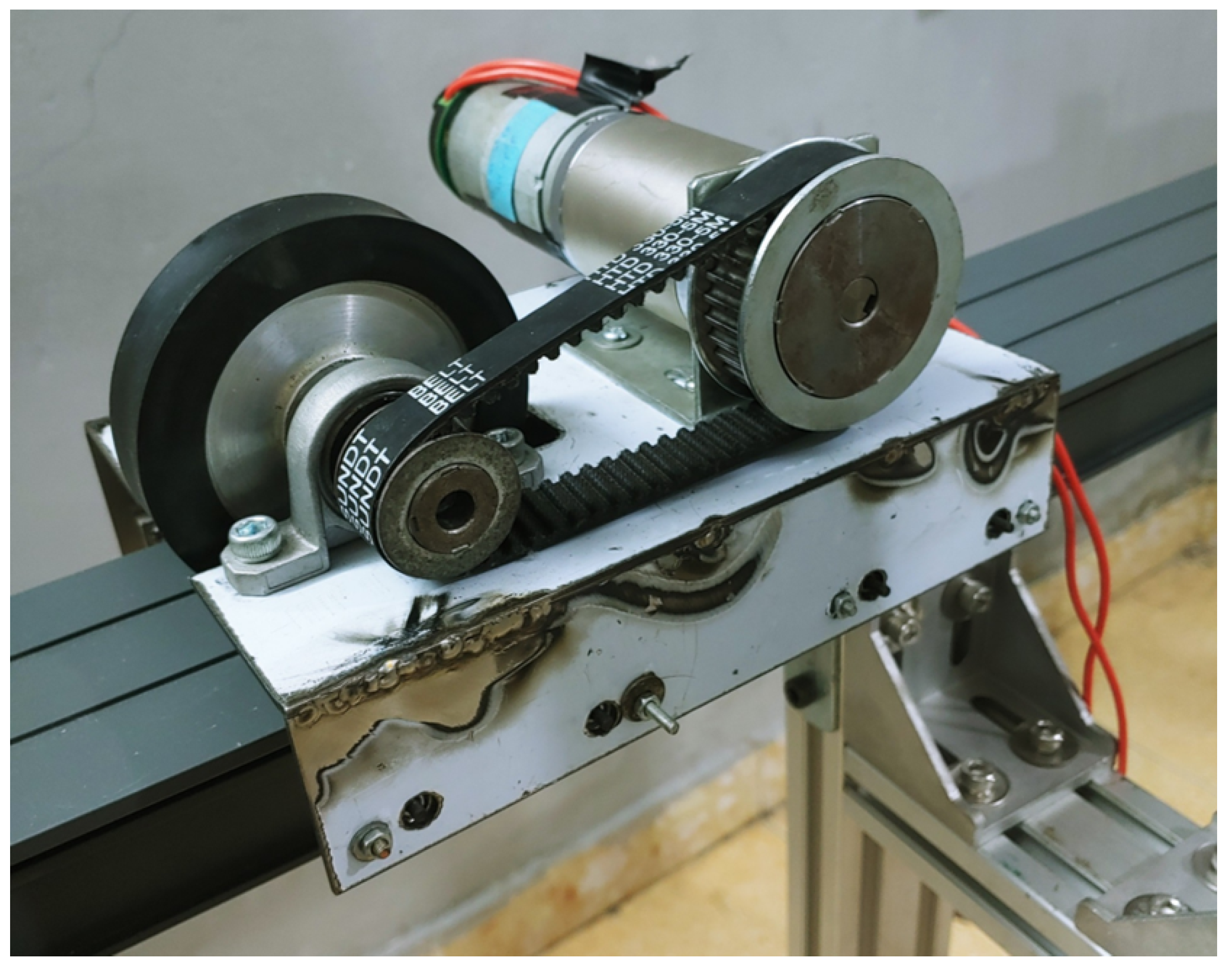

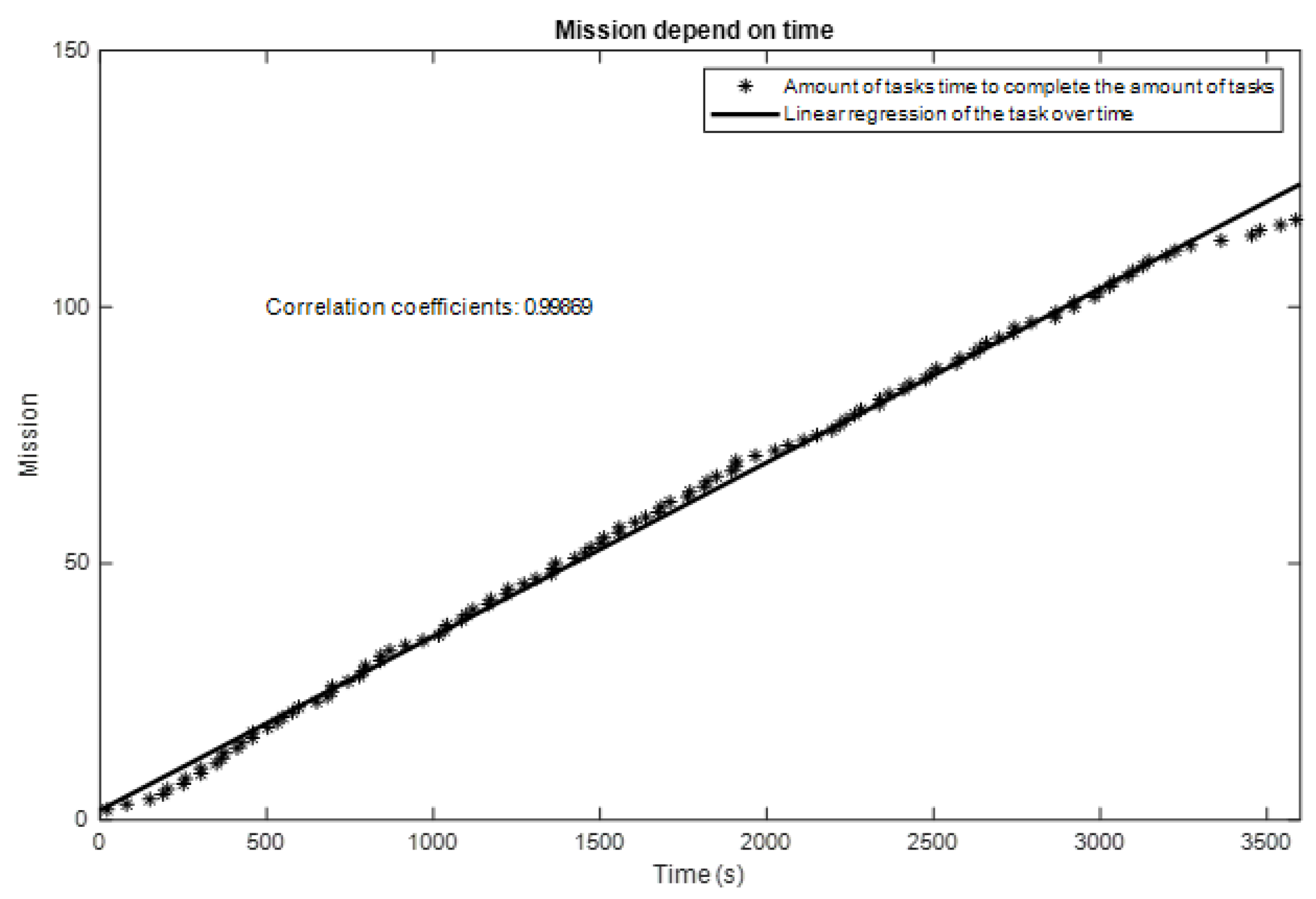

Figure 1.

The mechanism design of the shuttle.

Figure 1.

The mechanism design of the shuttle.

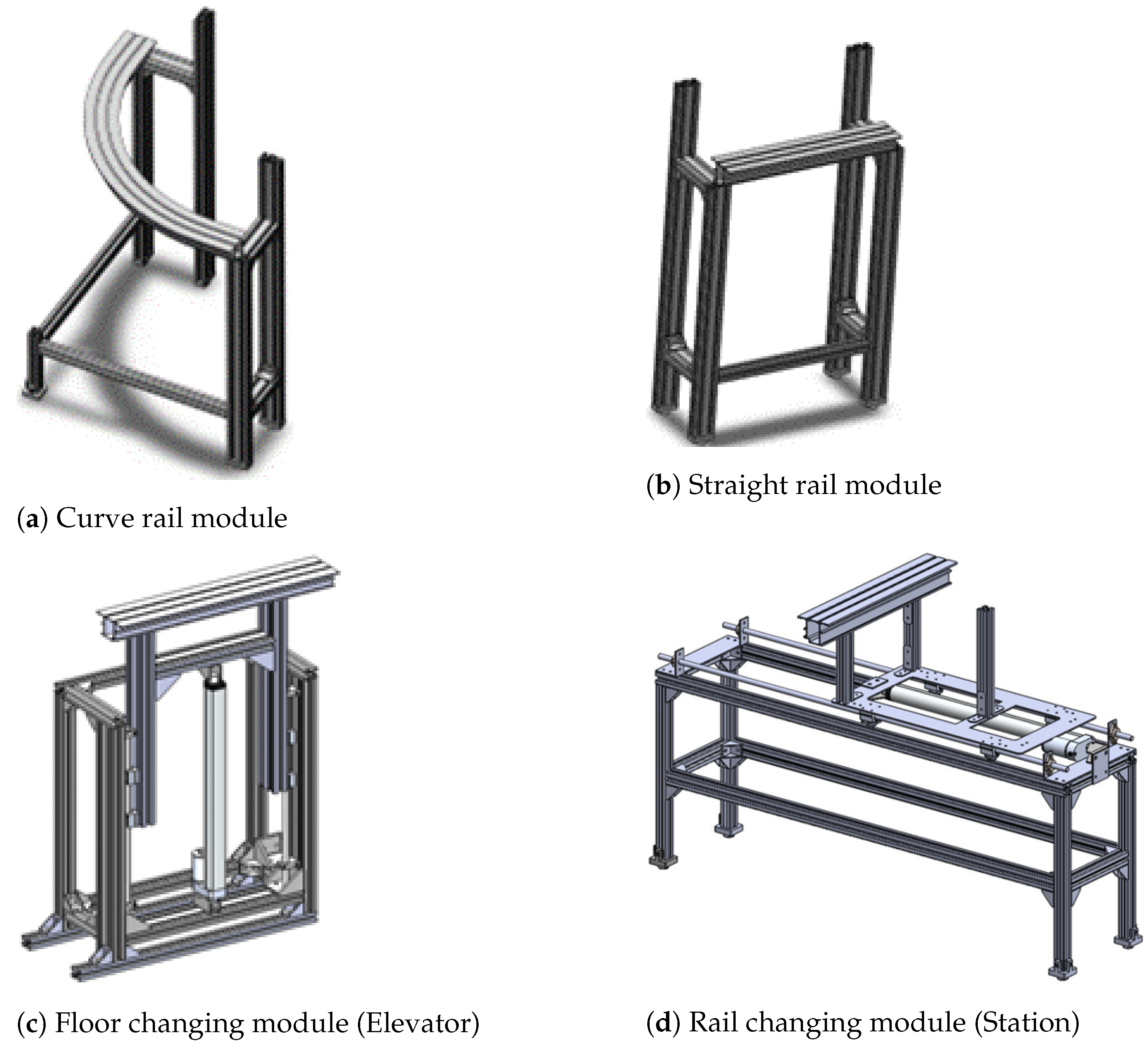

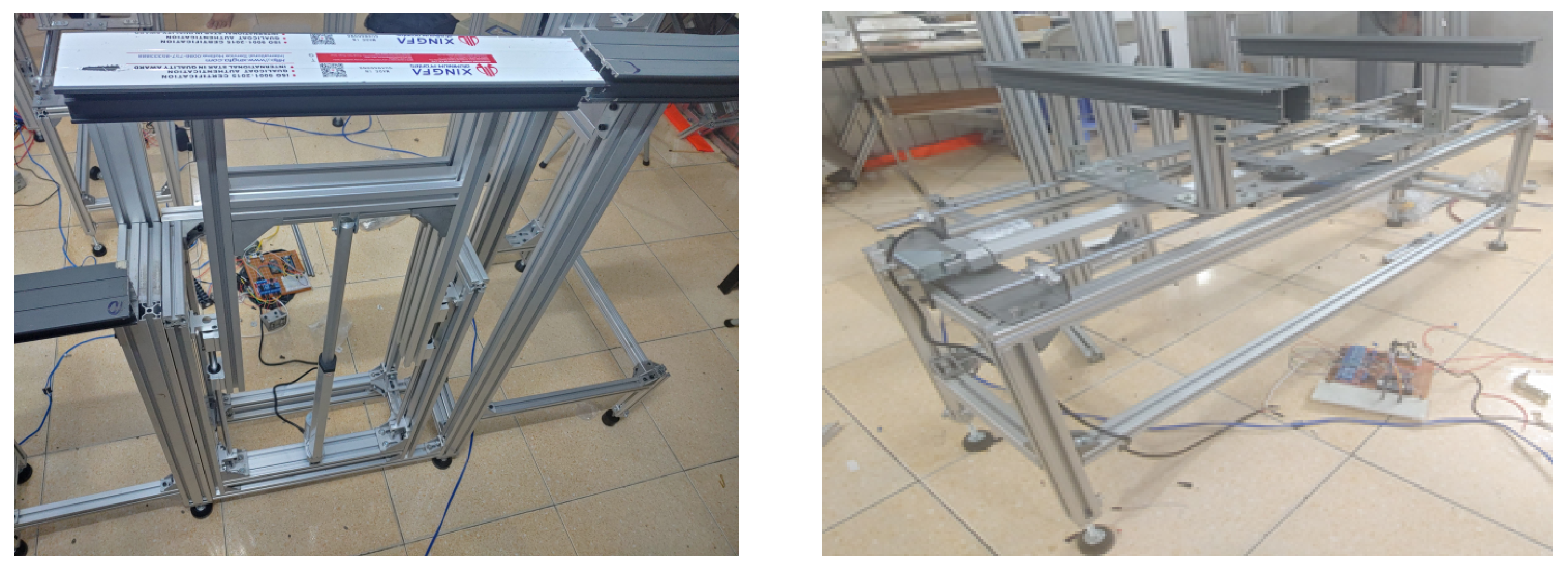

Figure 2.

Design of the main elements of the rails module.

Figure 2.

Design of the main elements of the rails module.

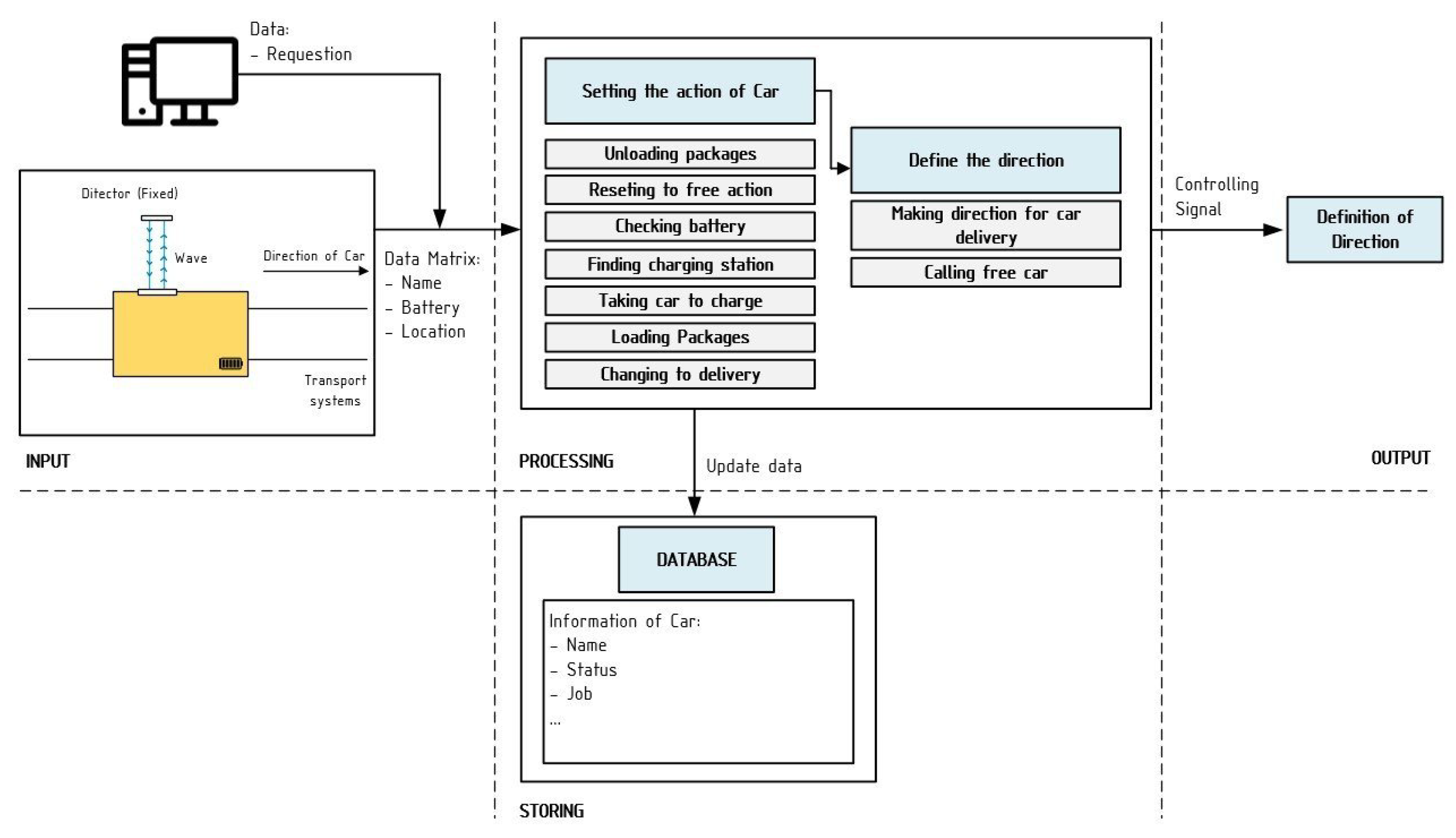

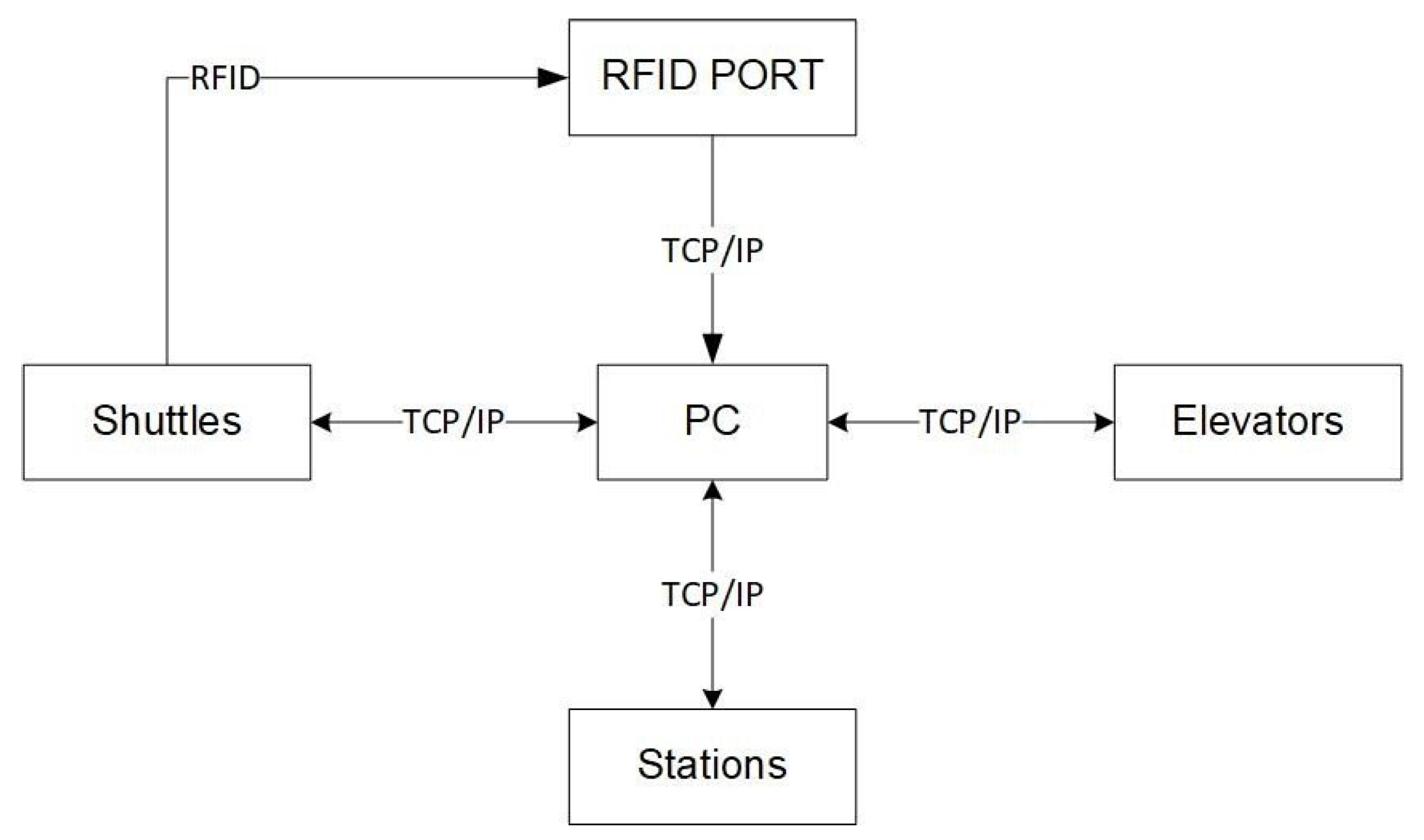

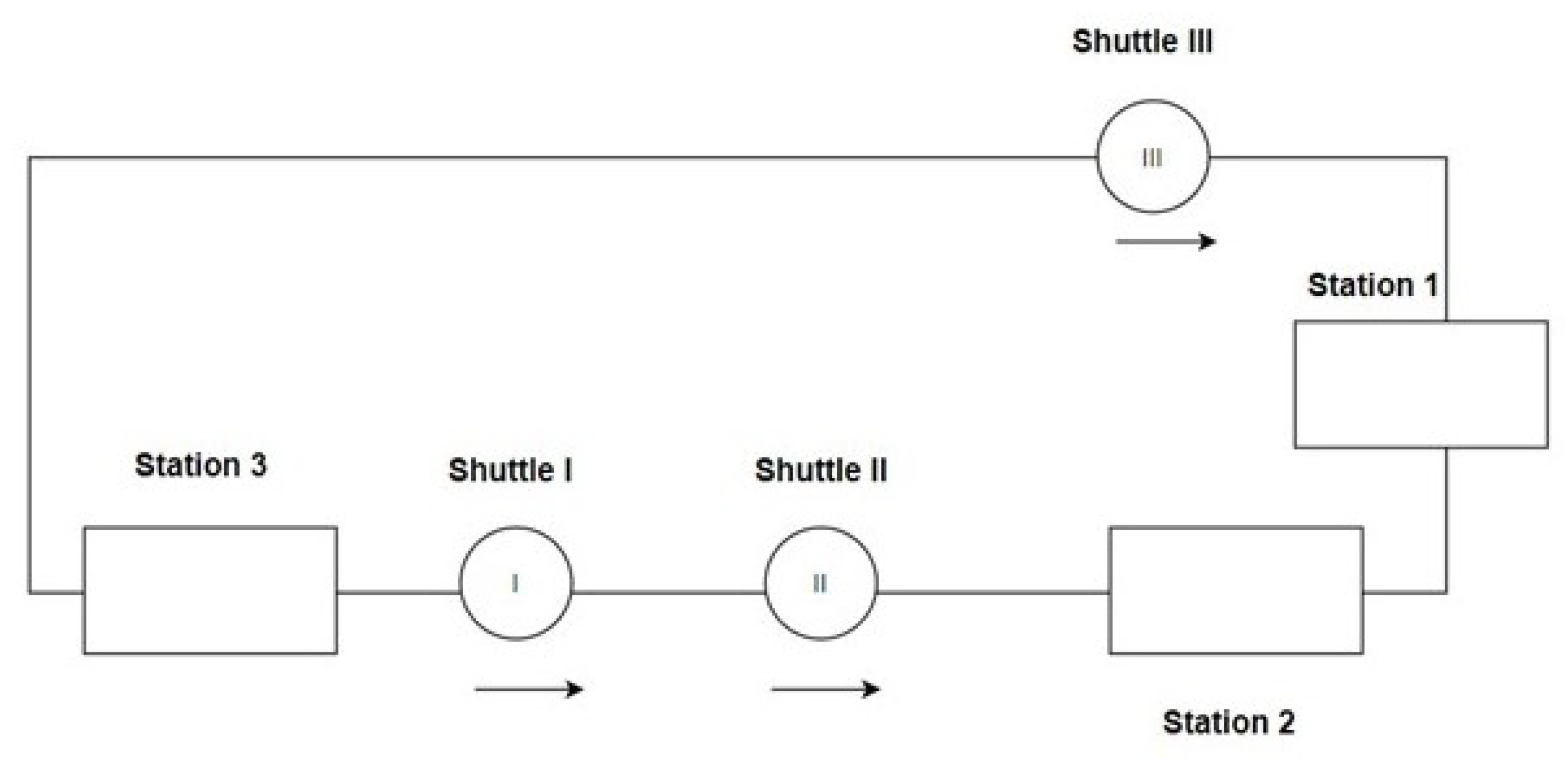

Figure 3.

The schematic diagram of the system.

Figure 3.

The schematic diagram of the system.

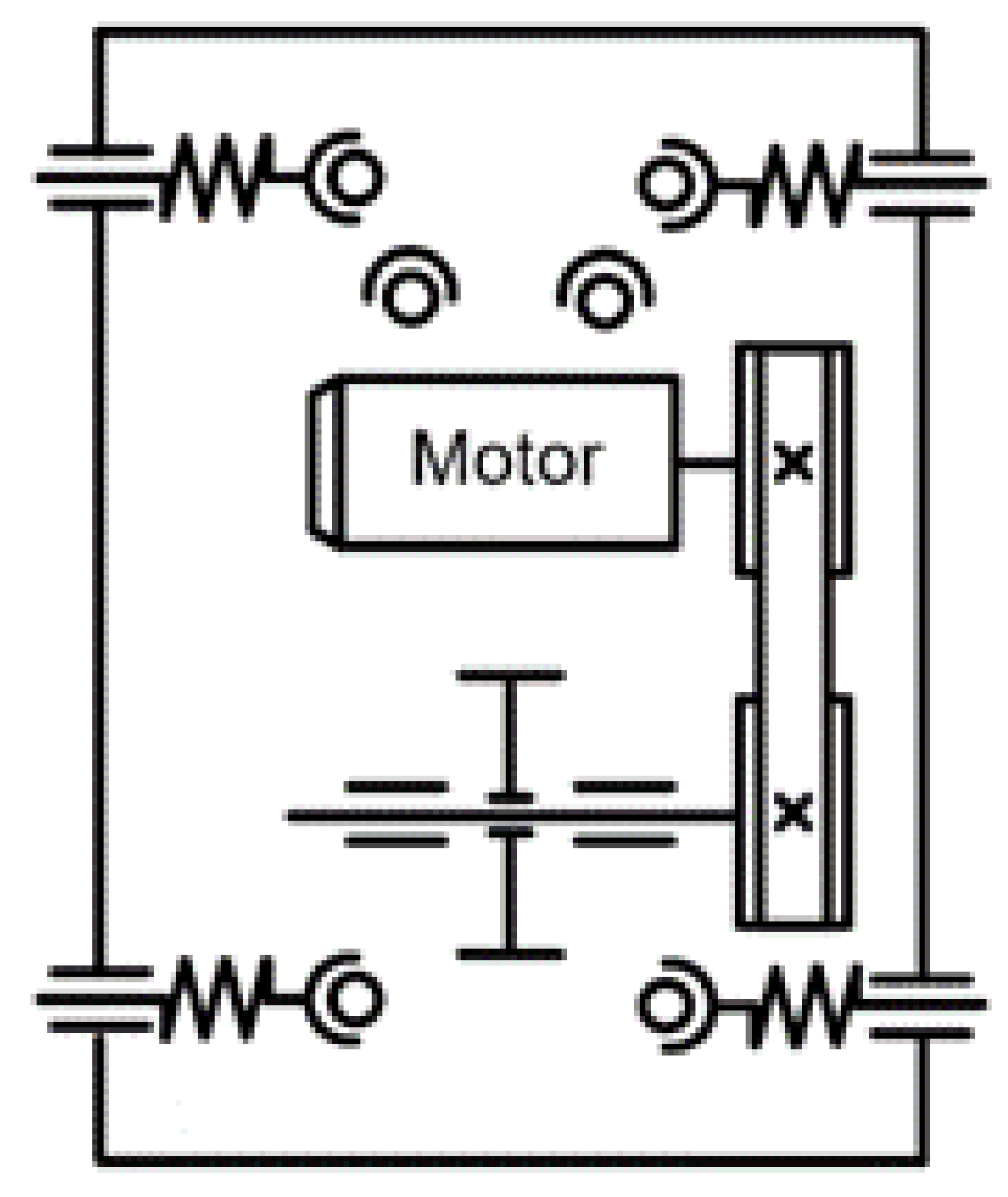

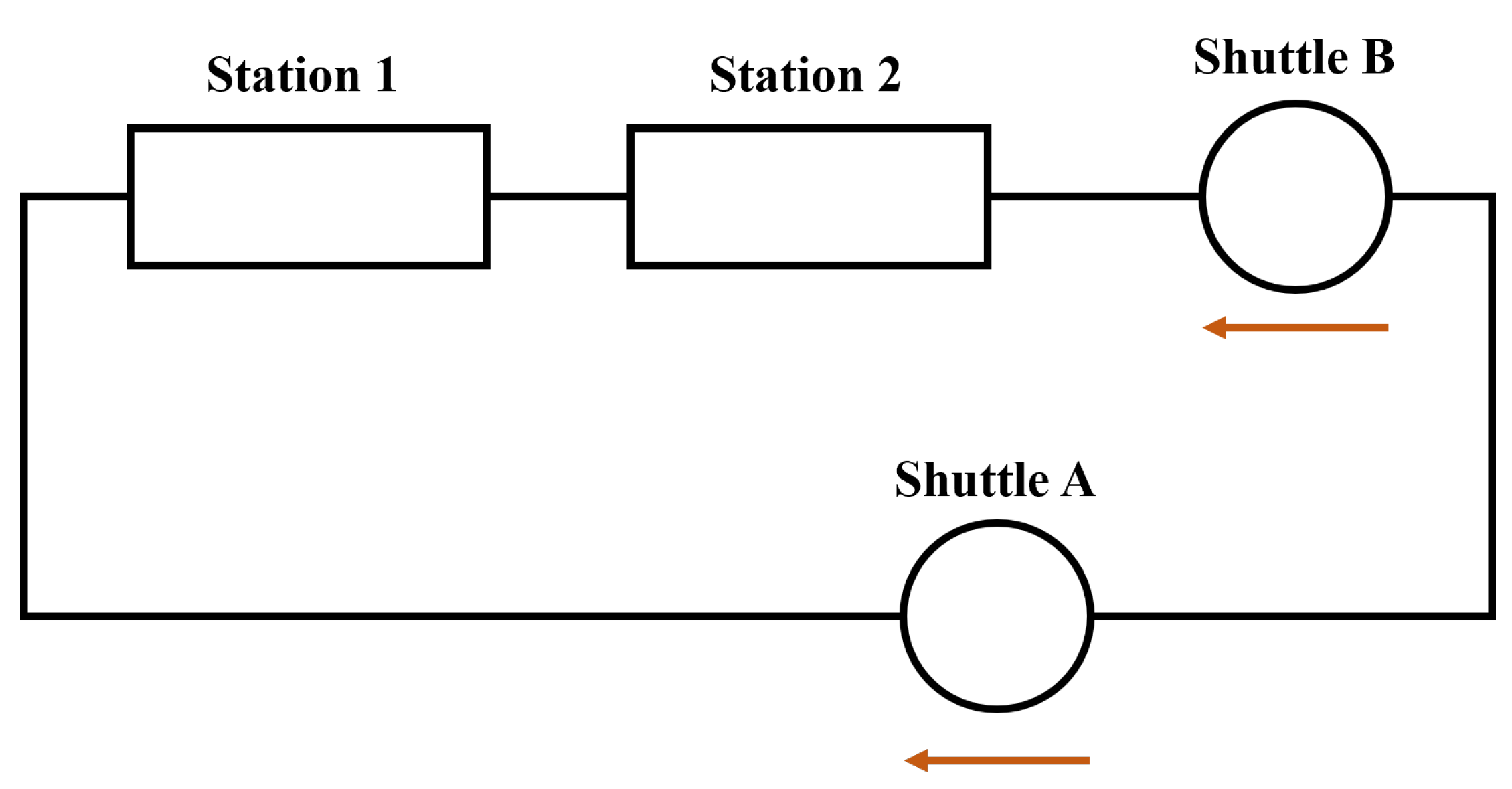

Figure 4.

The principle diagram of the shuttle.

Figure 4.

The principle diagram of the shuttle.

Figure 5.

The real shuttle base for experiment.

Figure 5.

The real shuttle base for experiment.

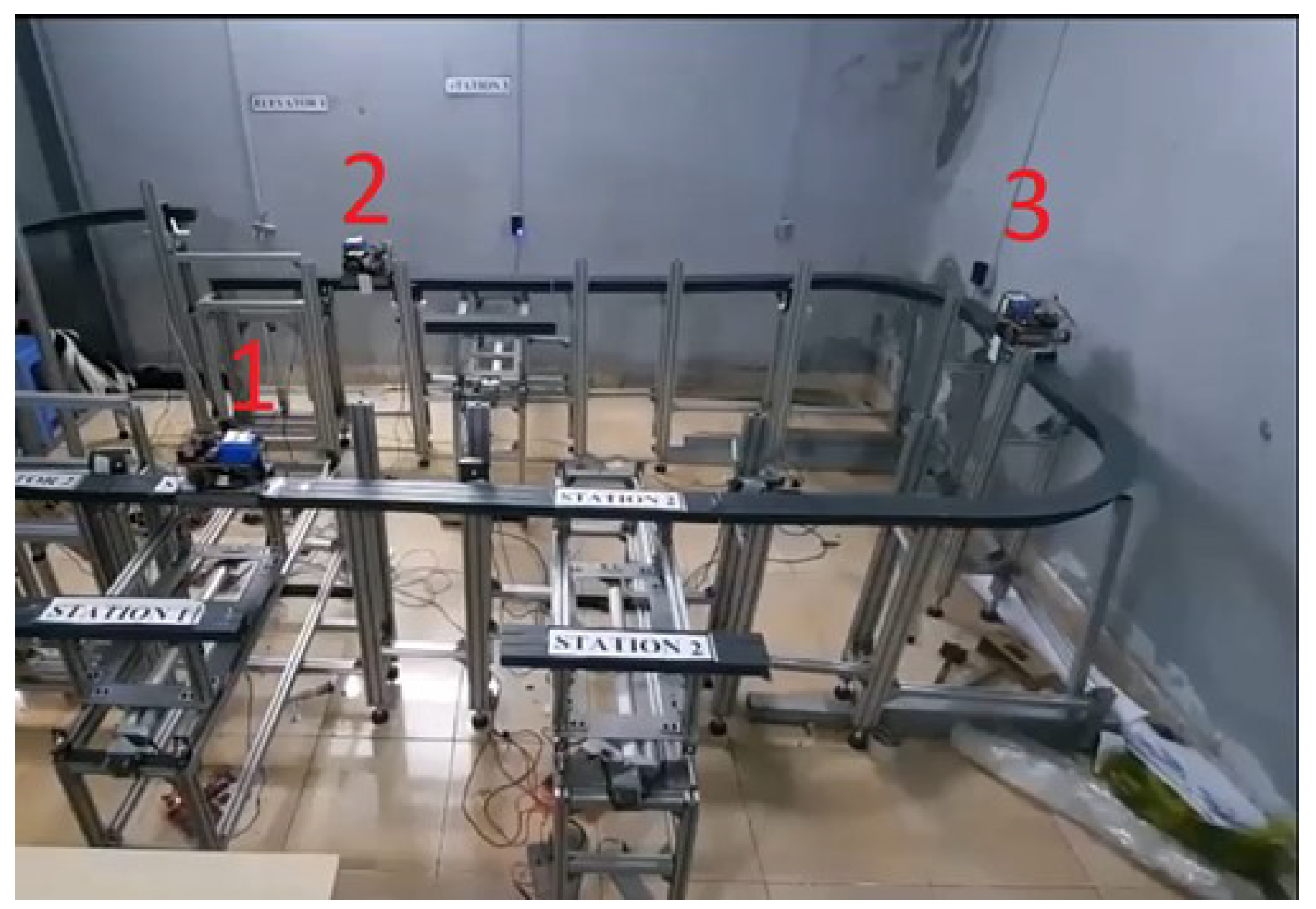

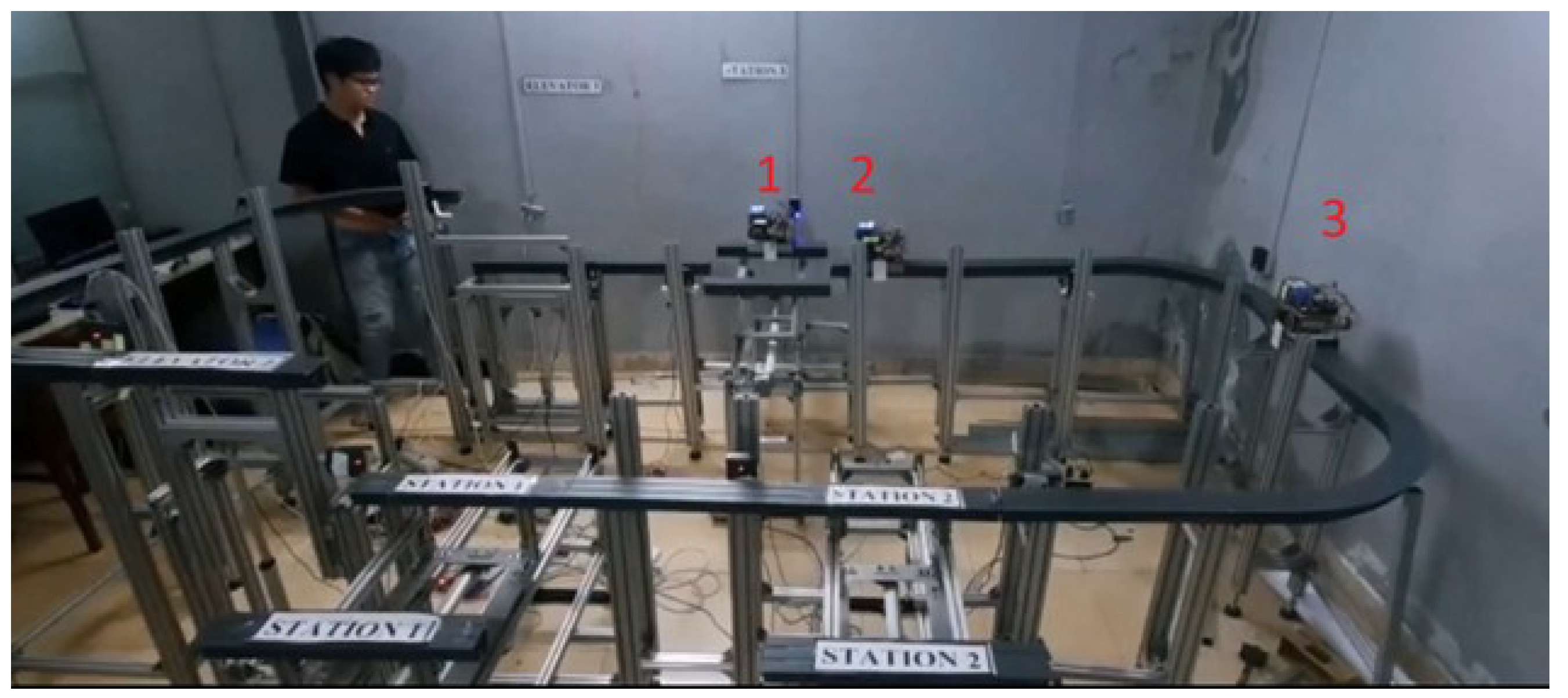

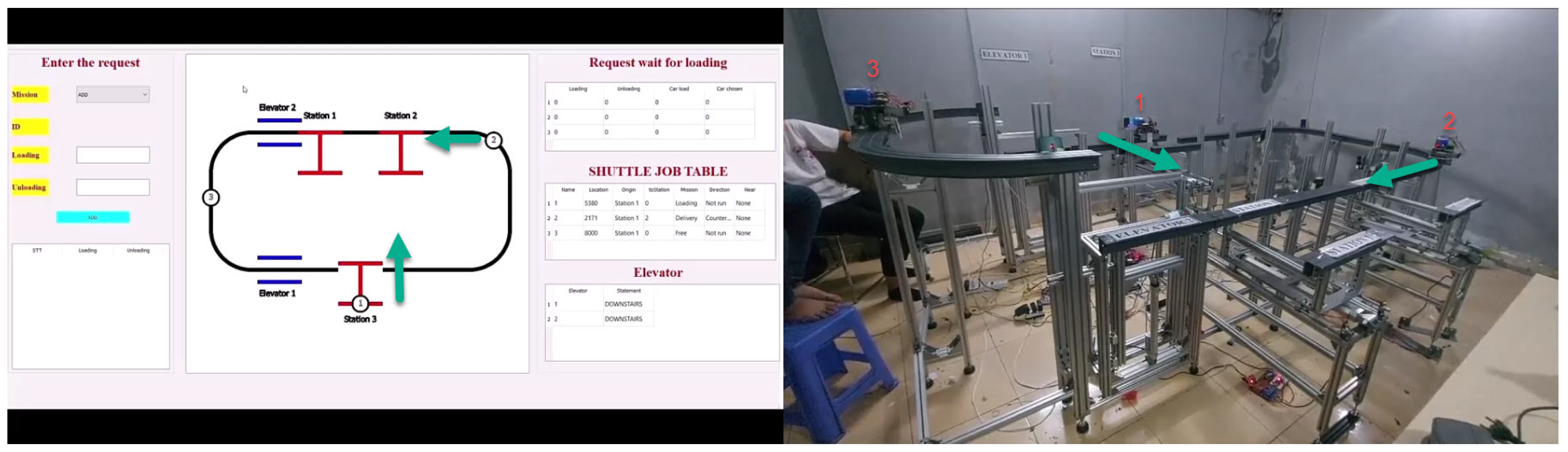

Figure 6.

An experimental station and elevator.

Figure 6.

An experimental station and elevator.

Figure 7.

The transmission and reception diagram for the system’s electrical signals.

Figure 7.

The transmission and reception diagram for the system’s electrical signals.

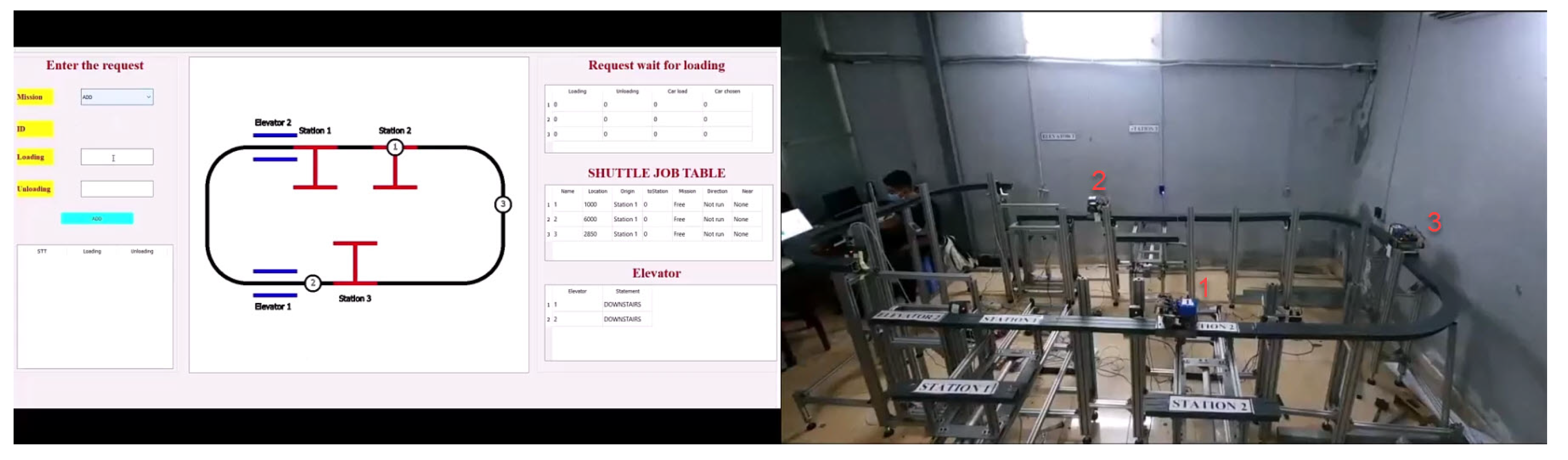

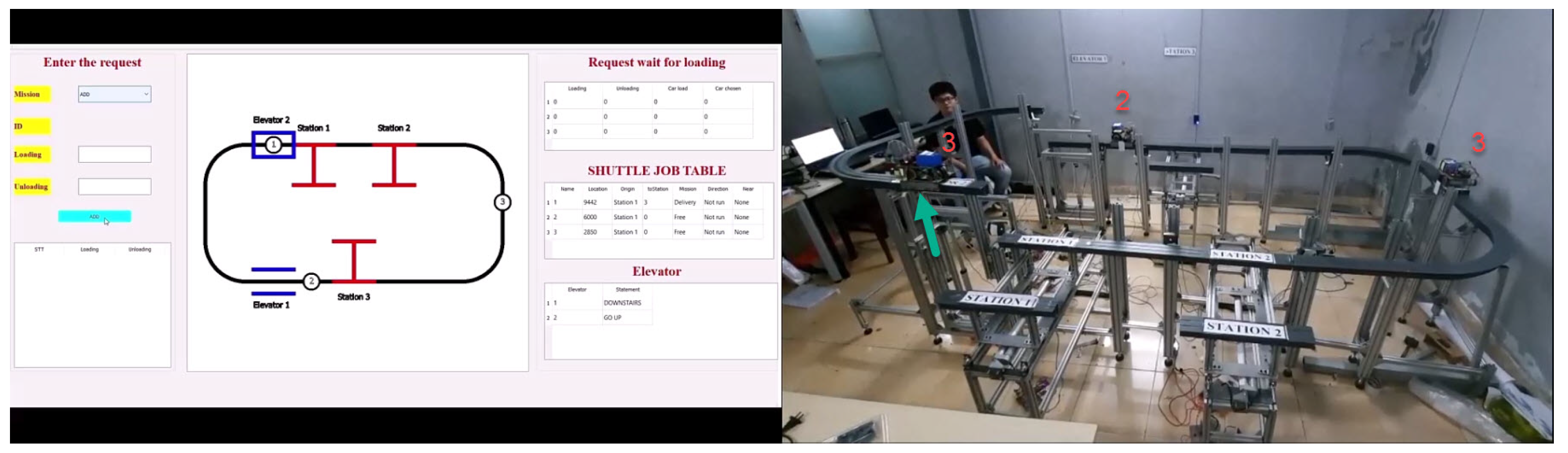

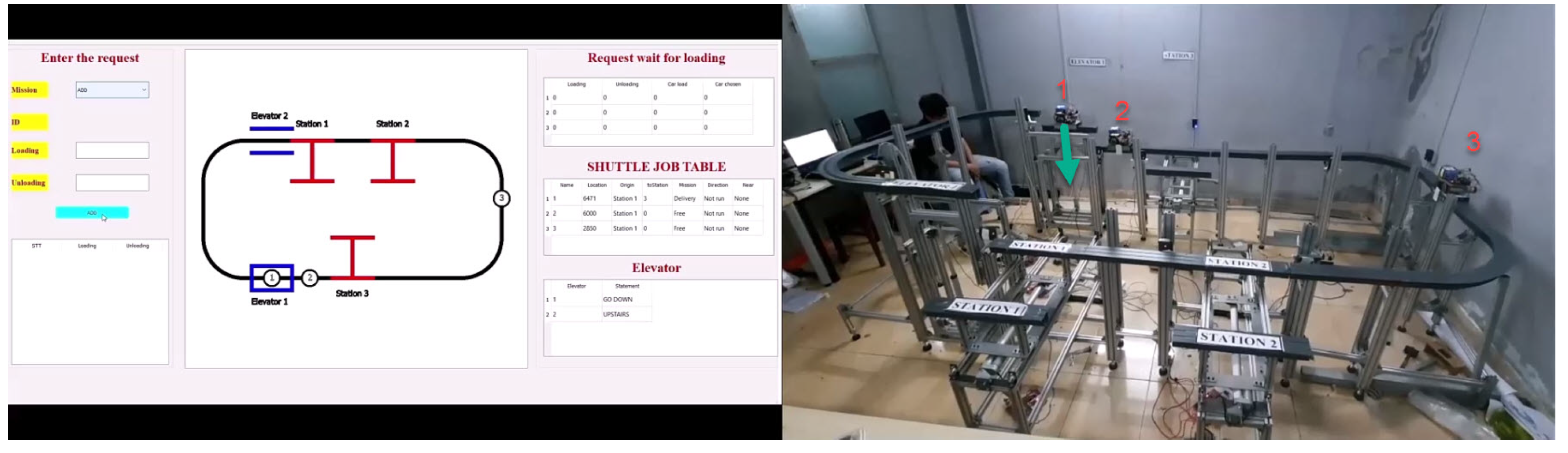

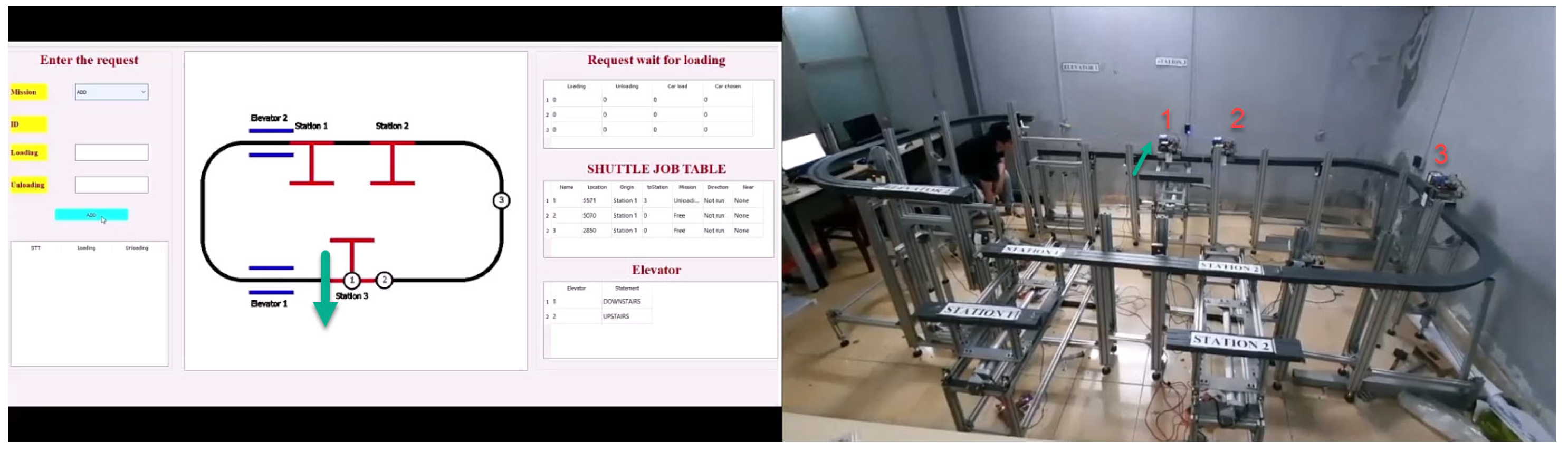

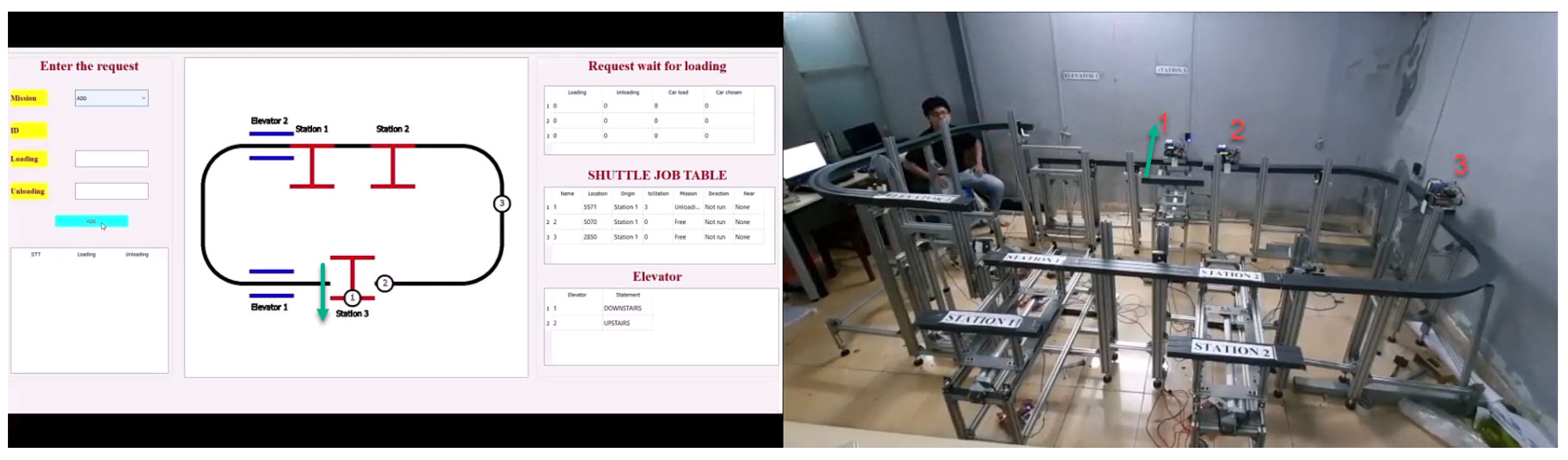

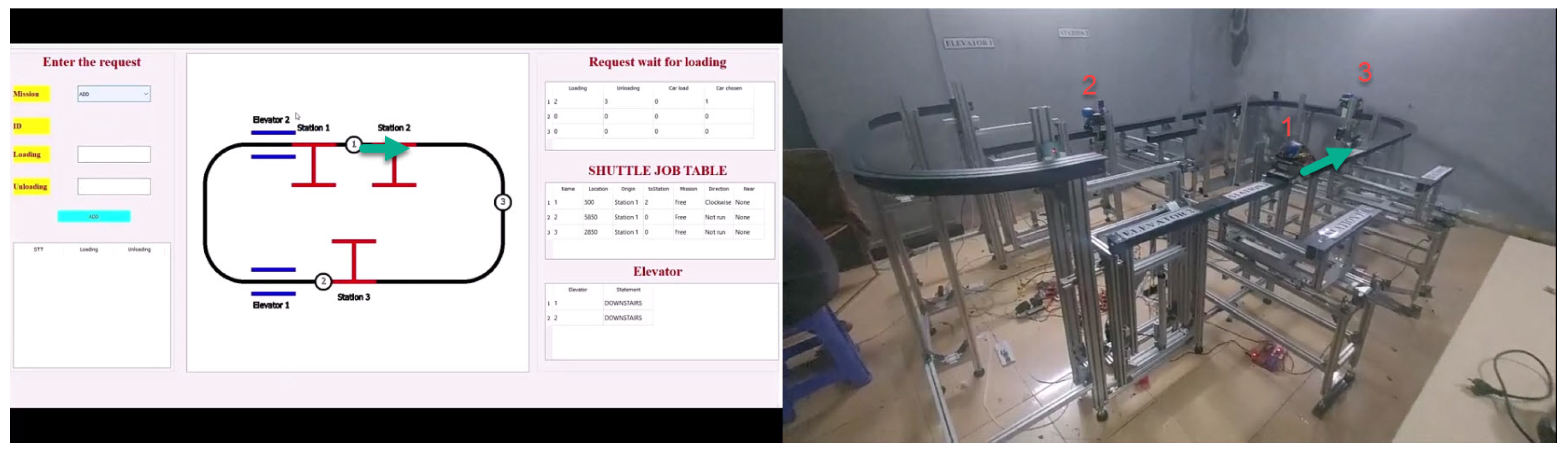

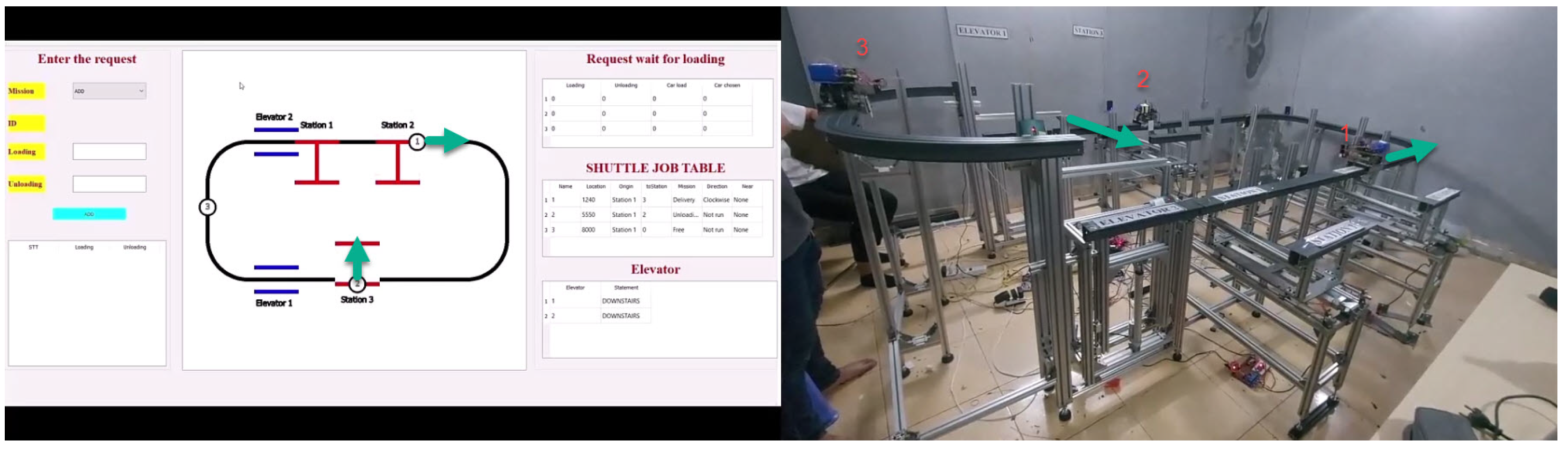

Figure 8.

The position of the shuttle at the time 0 s.

Figure 8.

The position of the shuttle at the time 0 s.

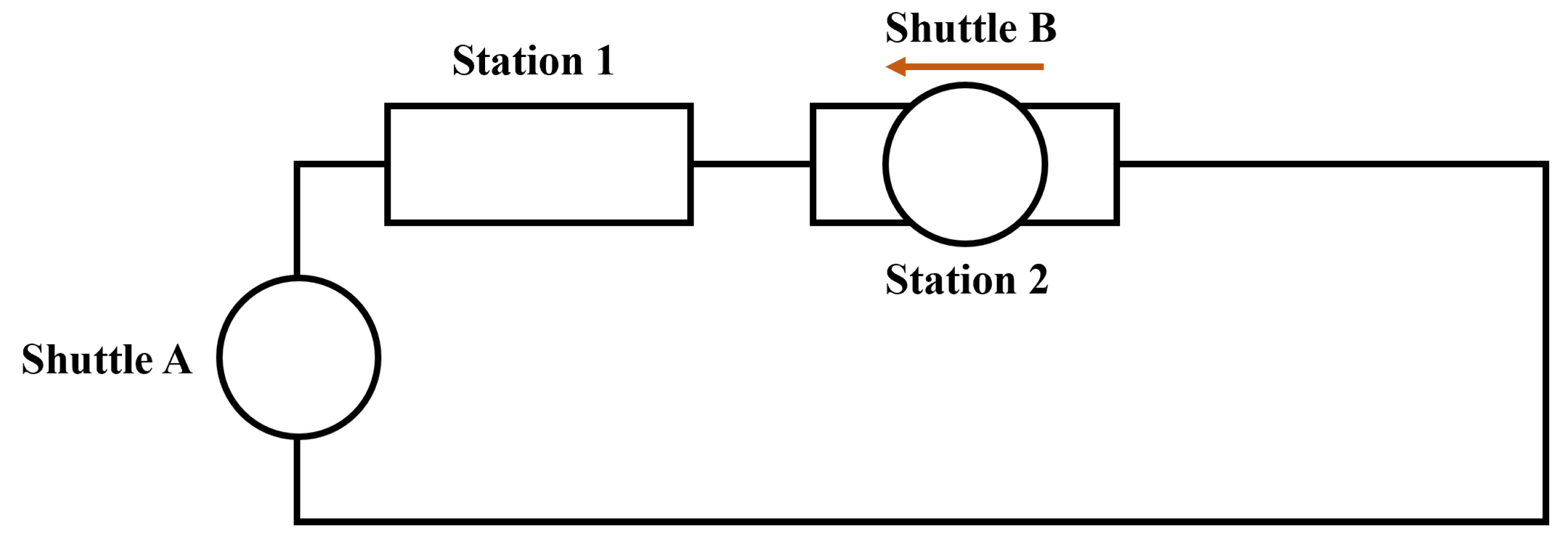

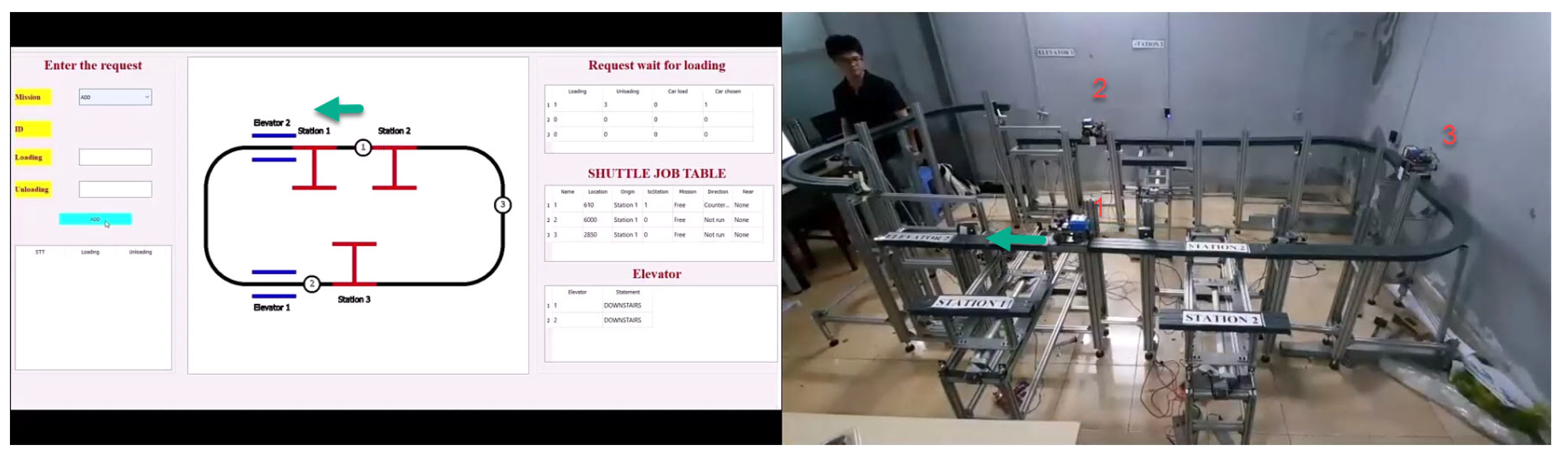

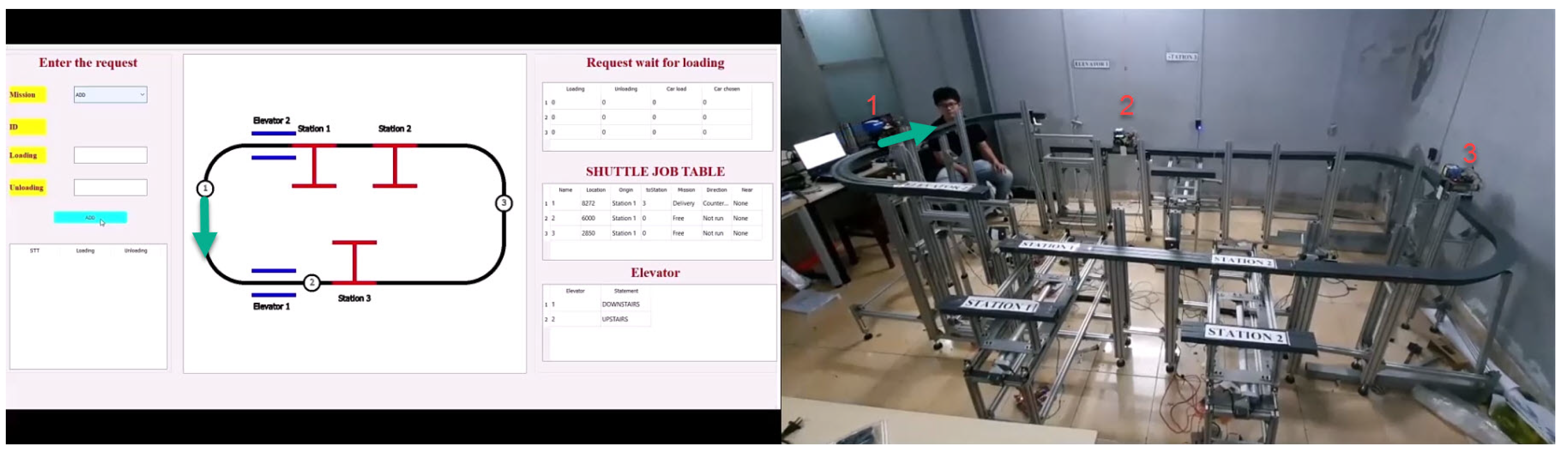

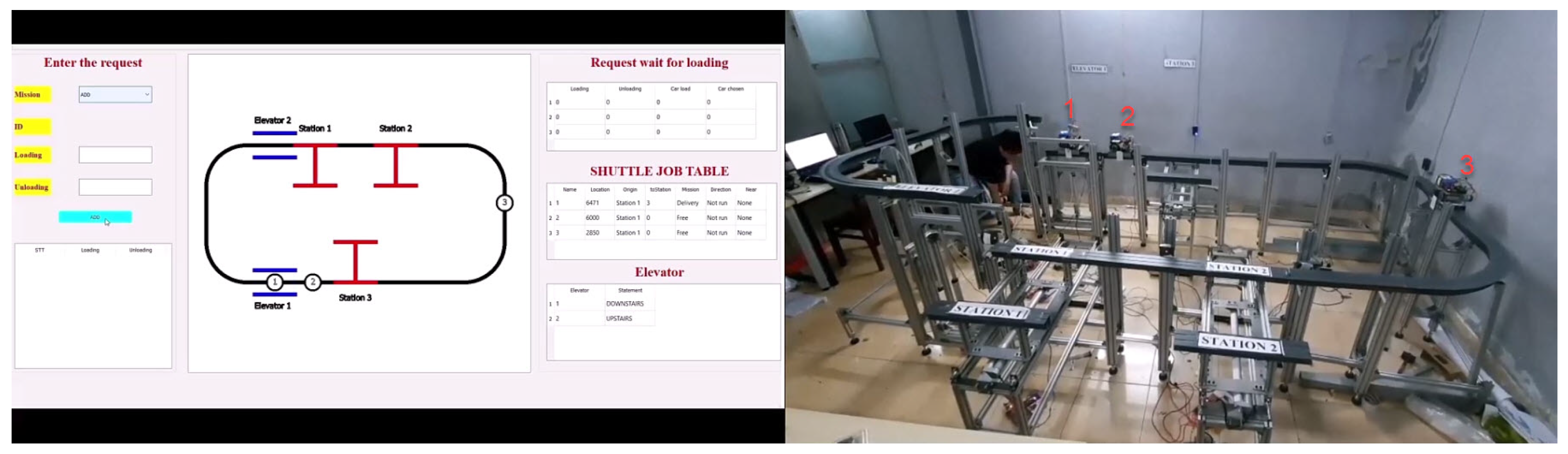

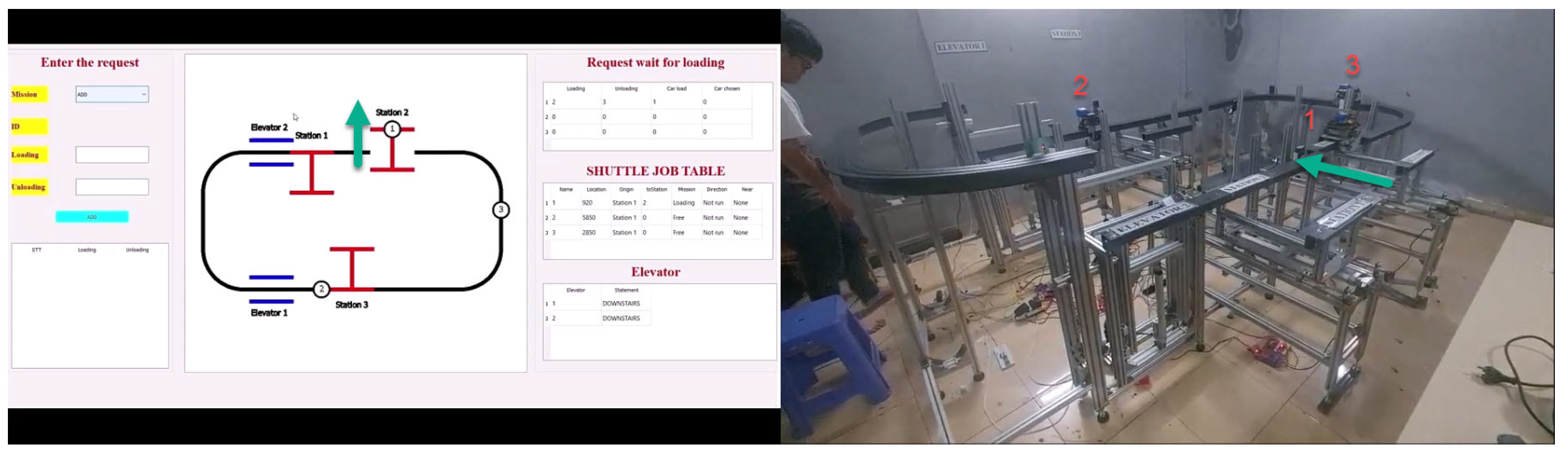

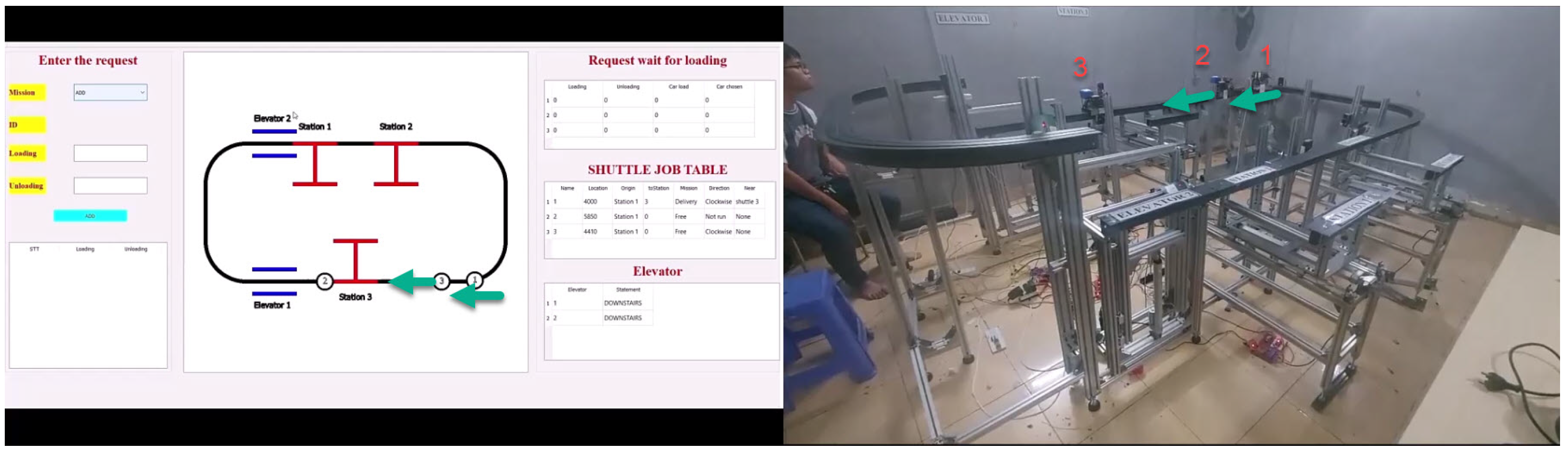

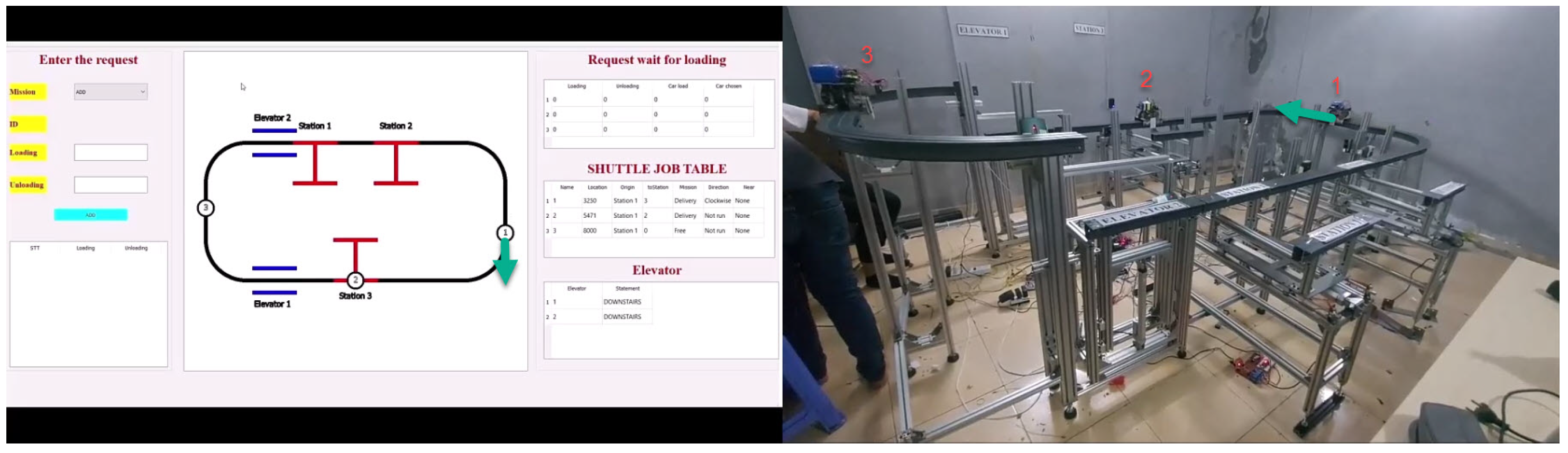

Figure 9.

The position of the shuttle at the time 5 s.

Figure 9.

The position of the shuttle at the time 5 s.

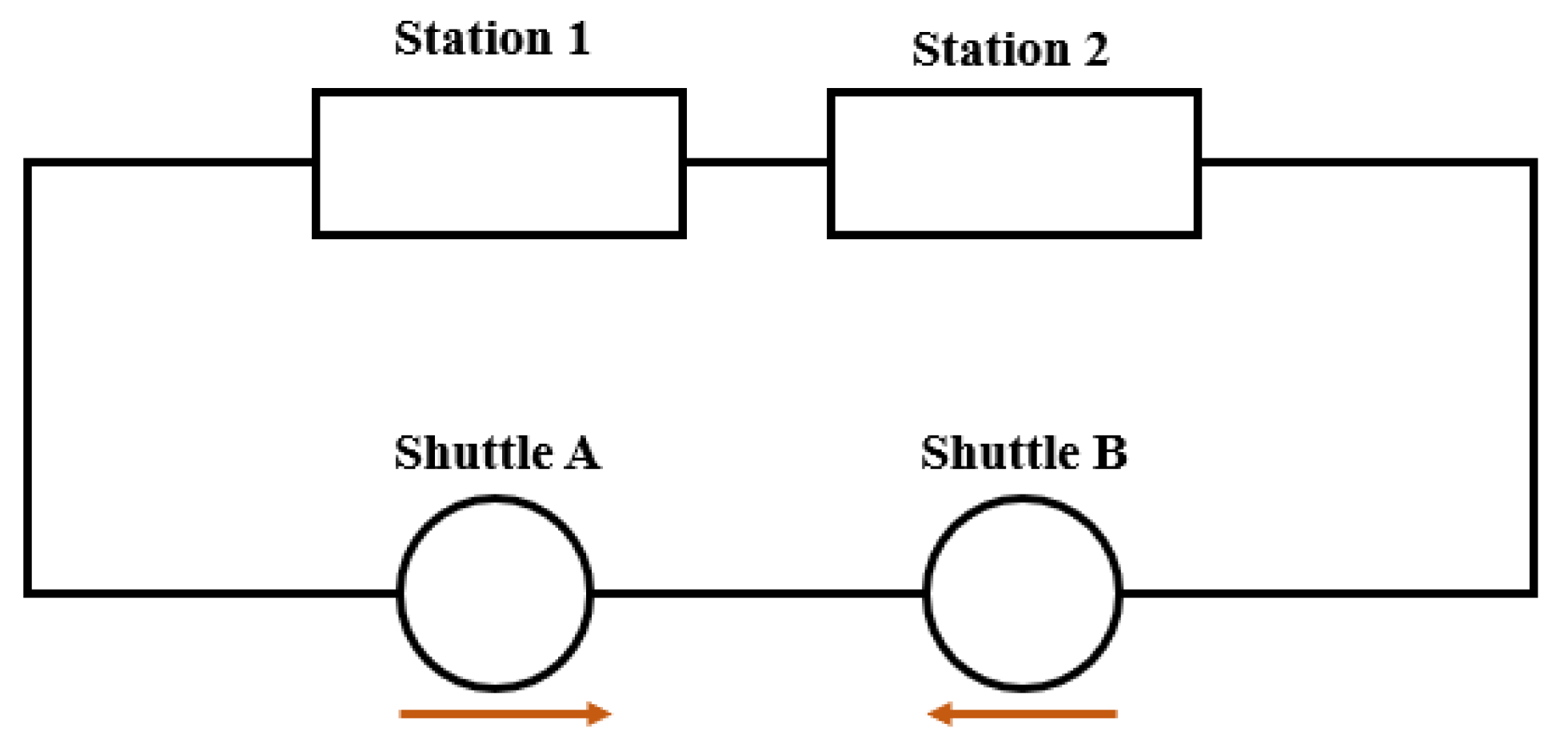

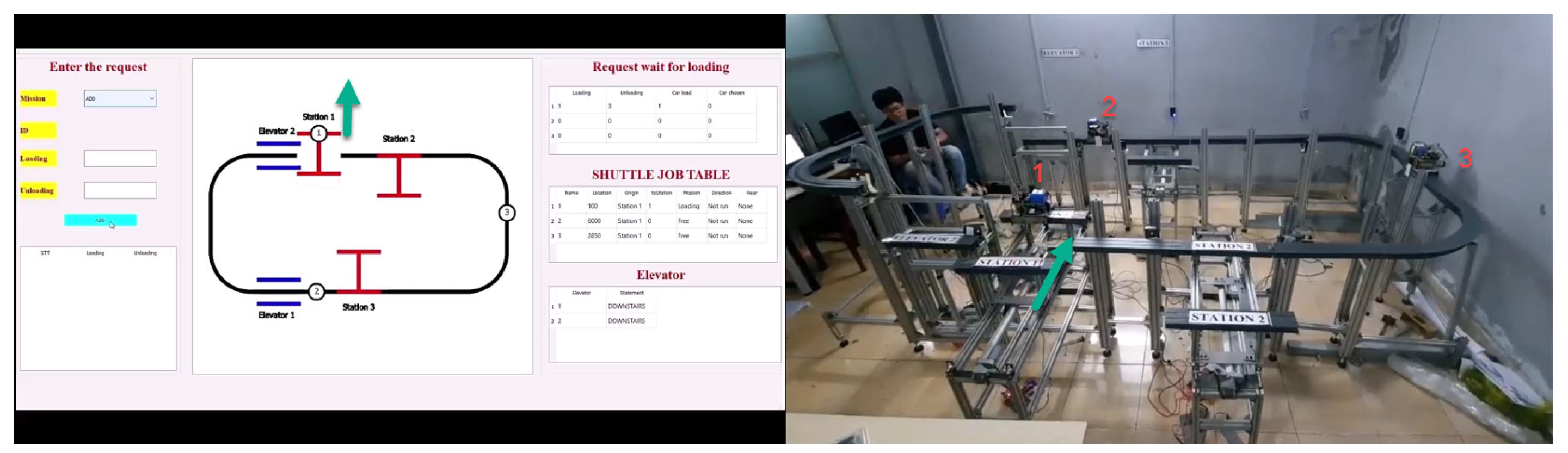

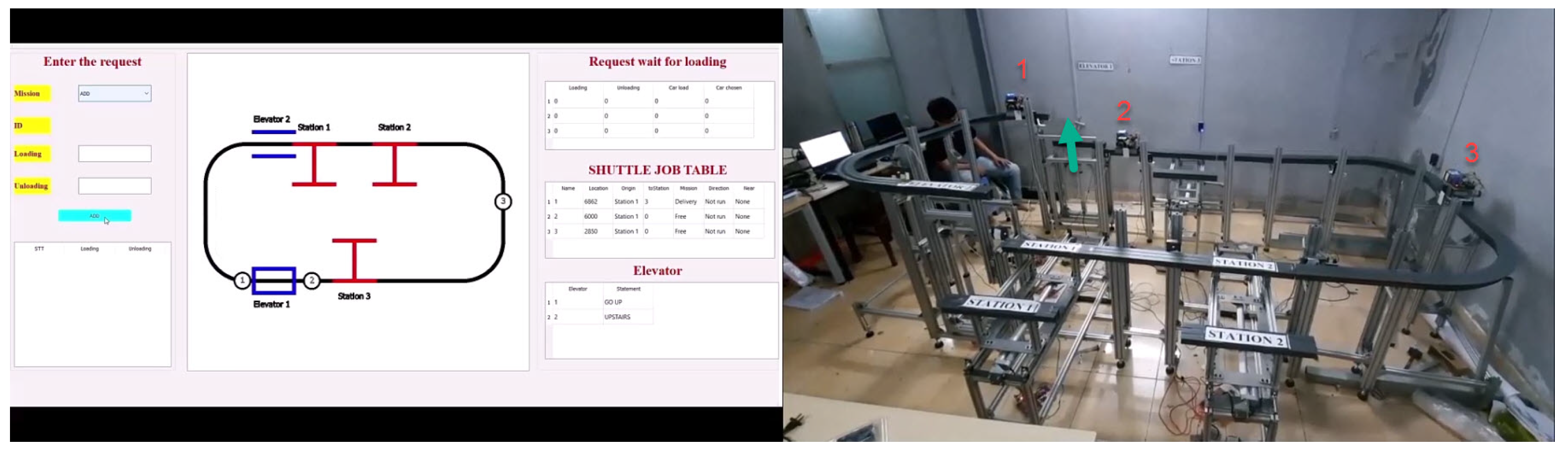

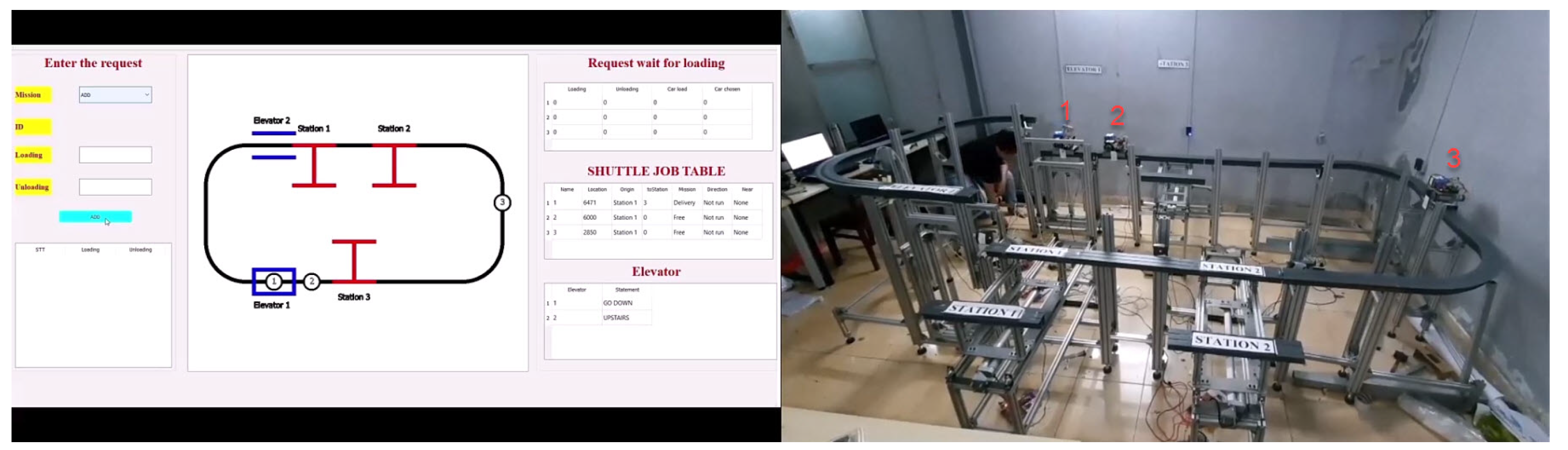

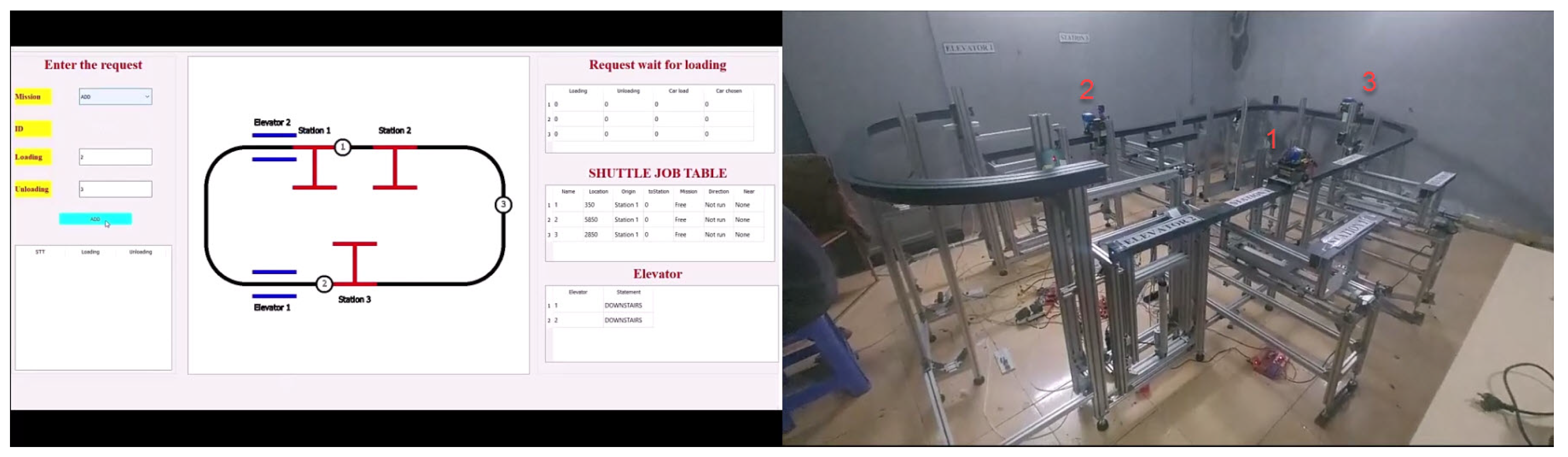

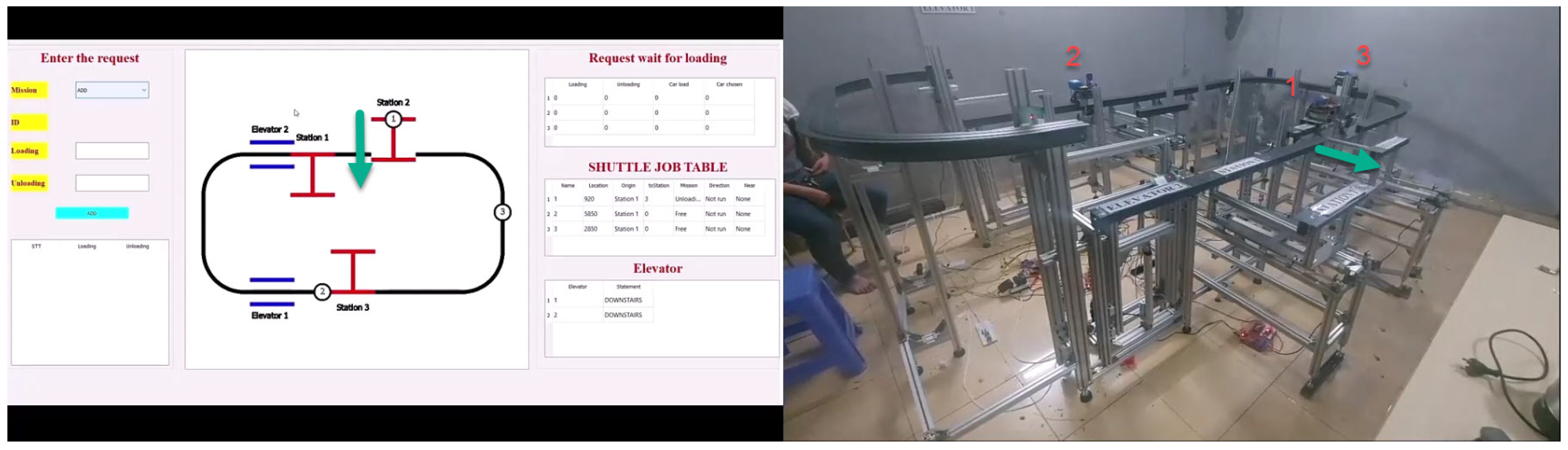

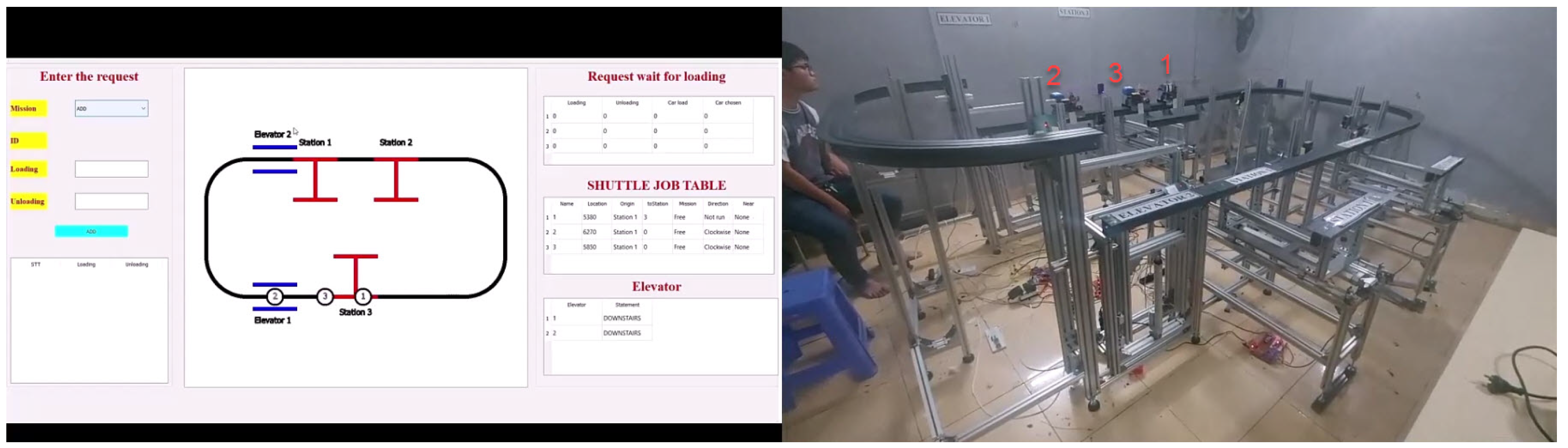

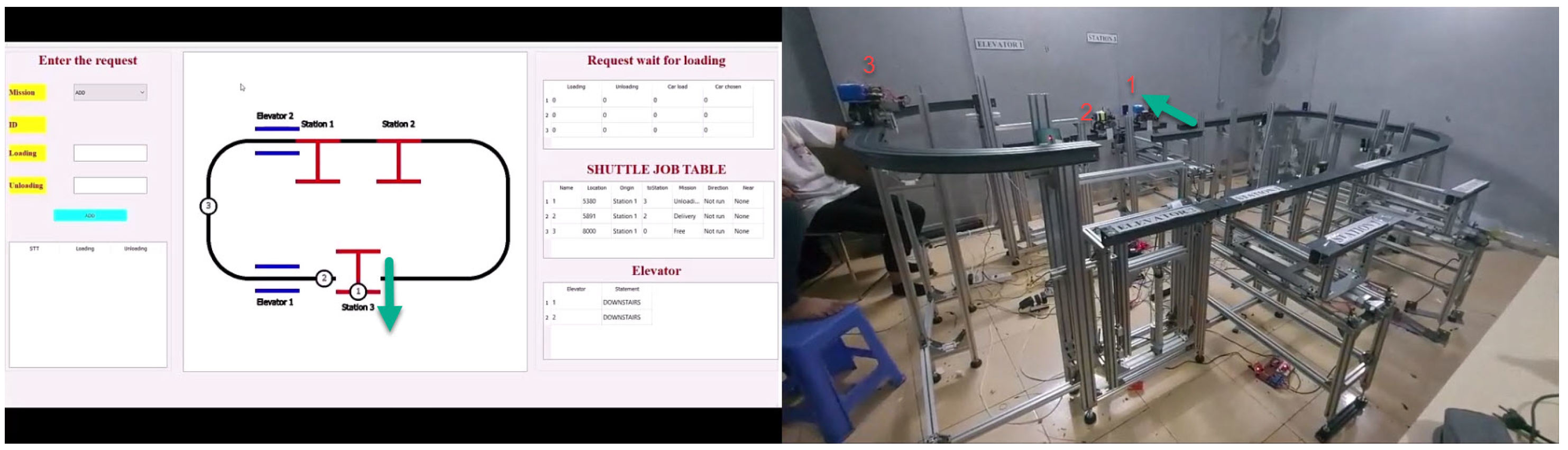

Figure 10.

The position of the shuttle at the time 45 s.

Figure 10.

The position of the shuttle at the time 45 s.

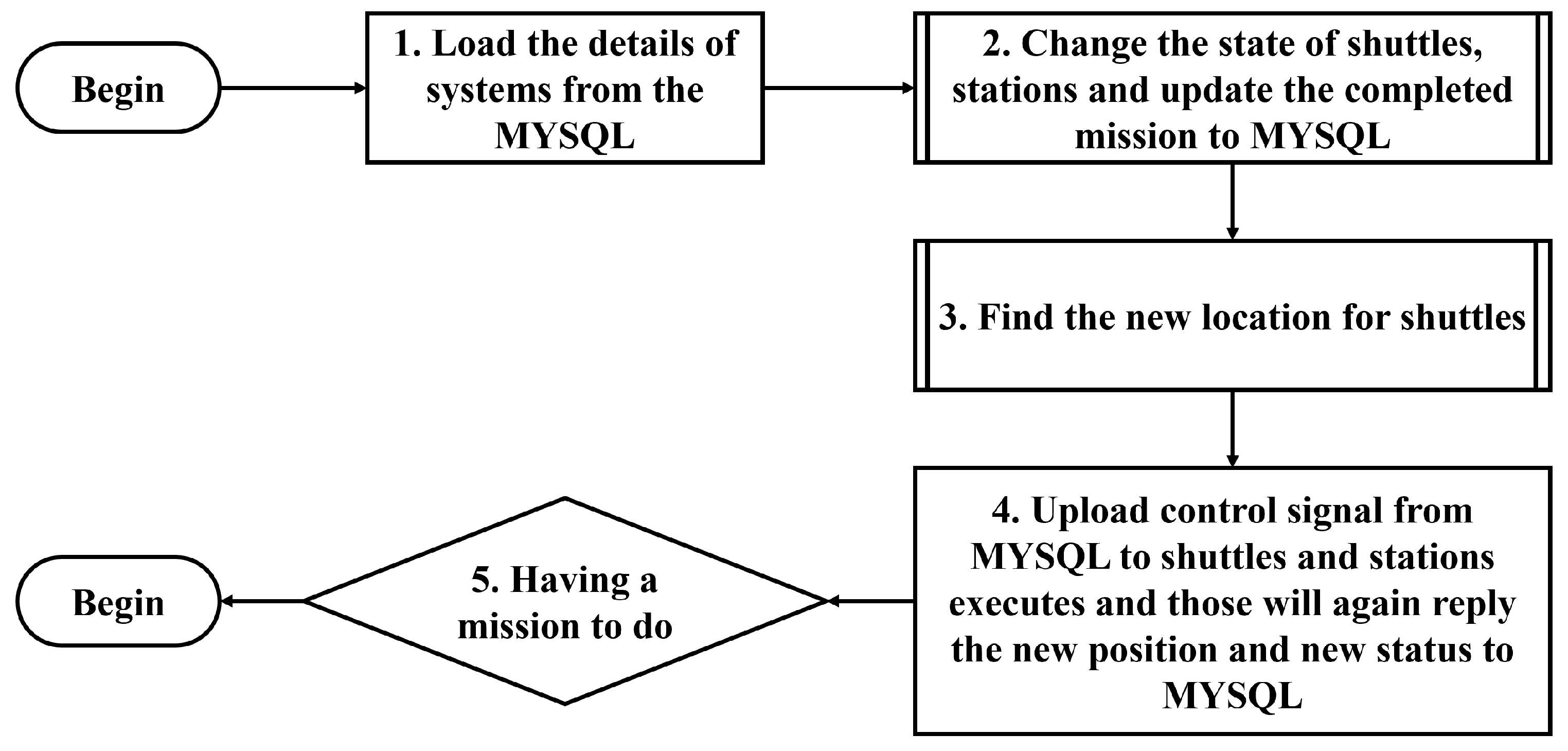

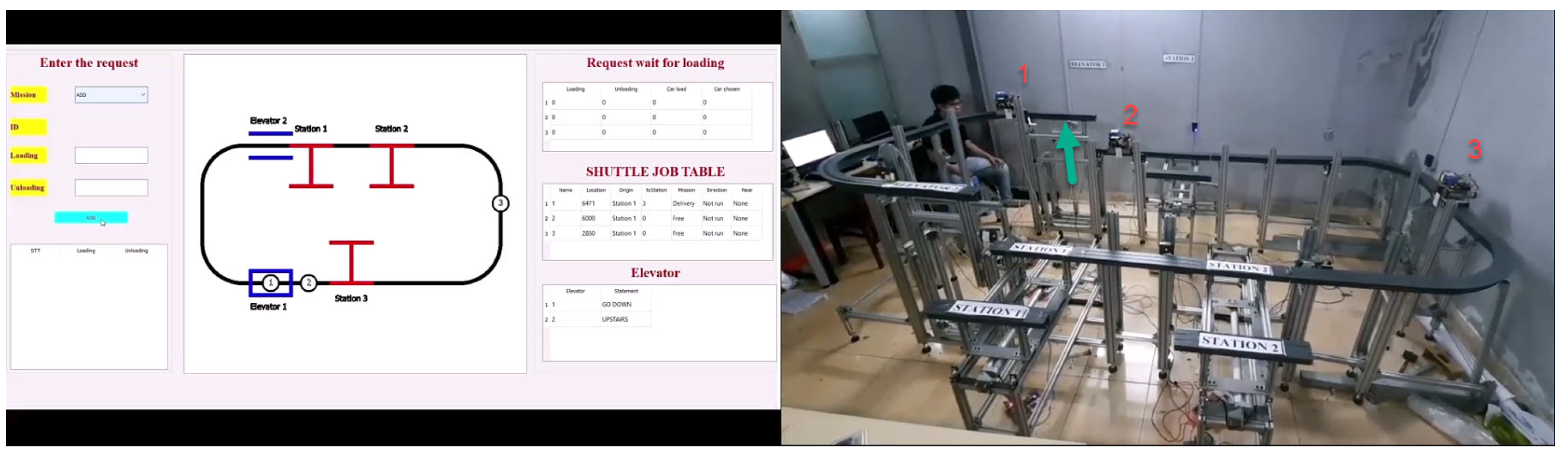

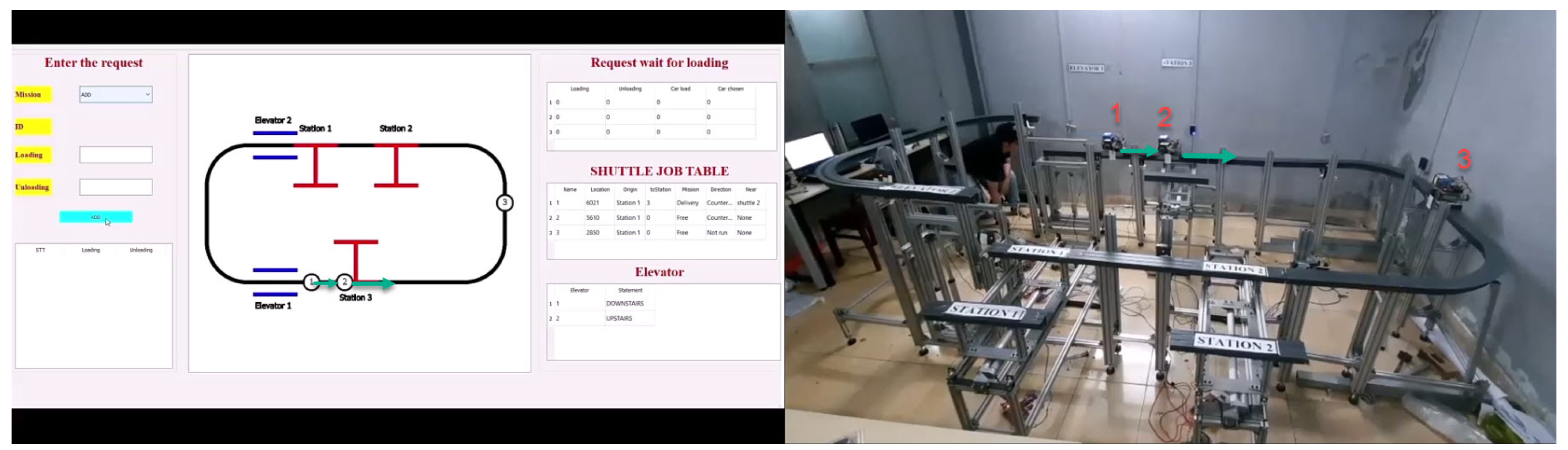

Figure 11.

Algorithm flowchart of the whole system.

Figure 11.

Algorithm flowchart of the whole system.

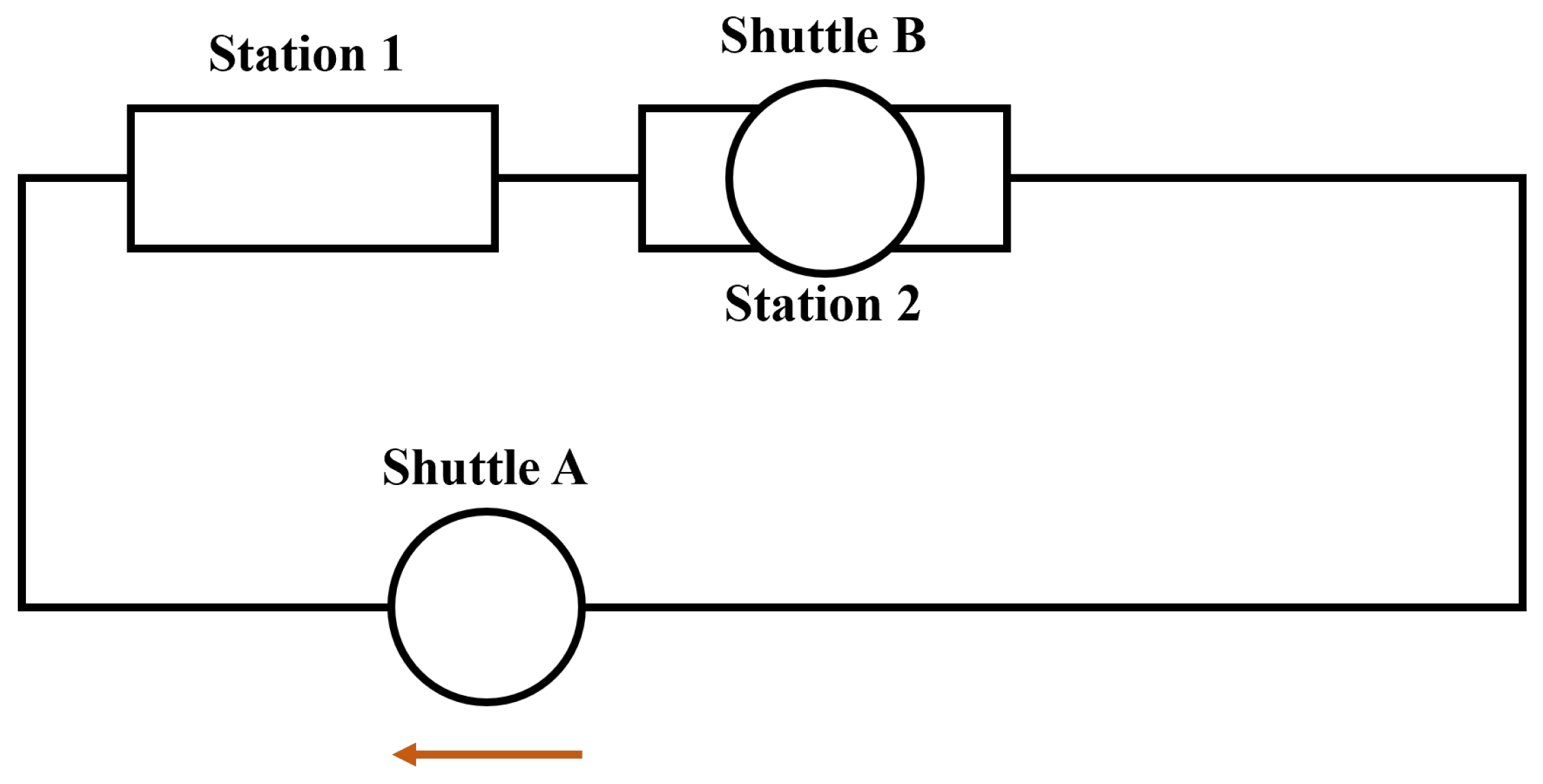

Figure 12.

Two shuttles will cause jam situation when traveling as marked direction.

Figure 12.

Two shuttles will cause jam situation when traveling as marked direction.

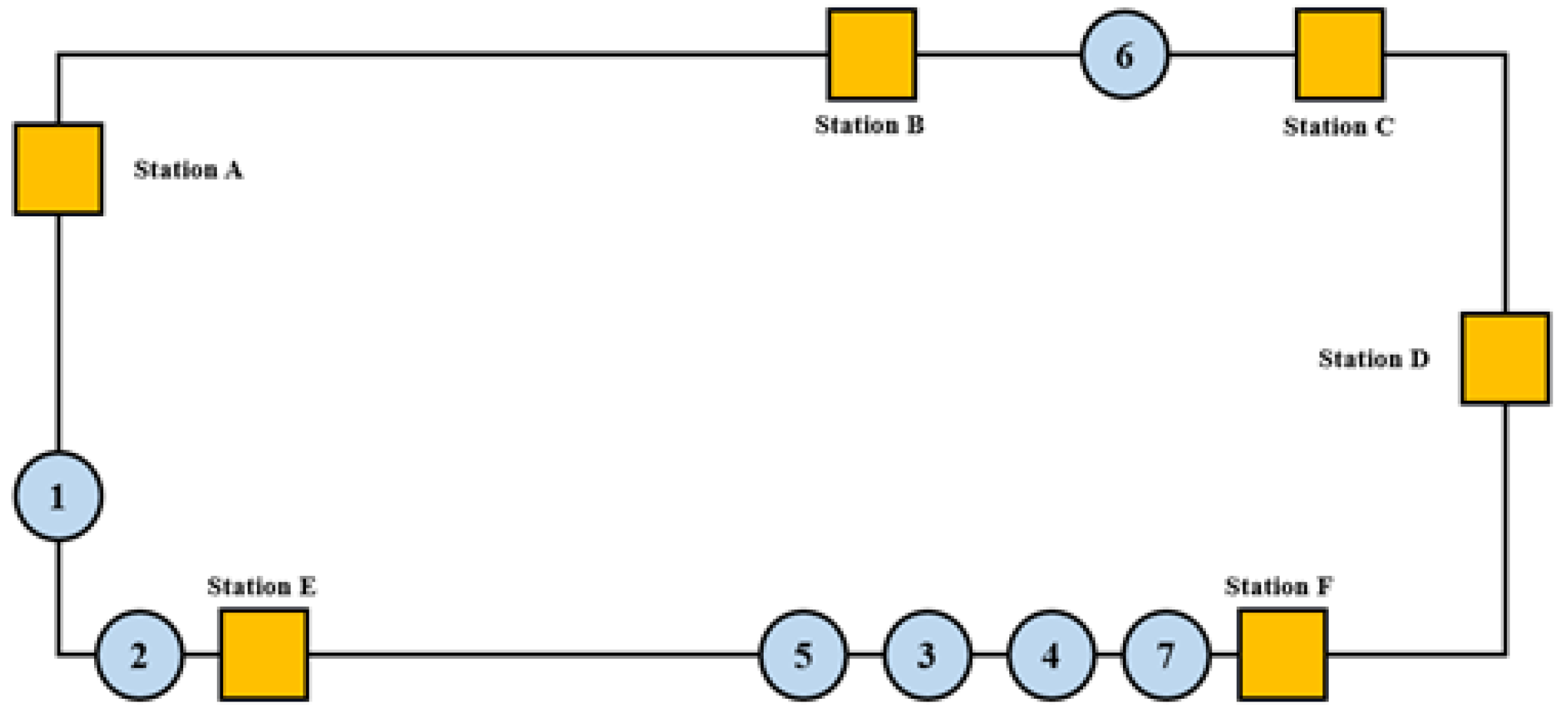

Figure 13.

Illustration of the position of three shuttles.

Figure 13.

Illustration of the position of three shuttles.

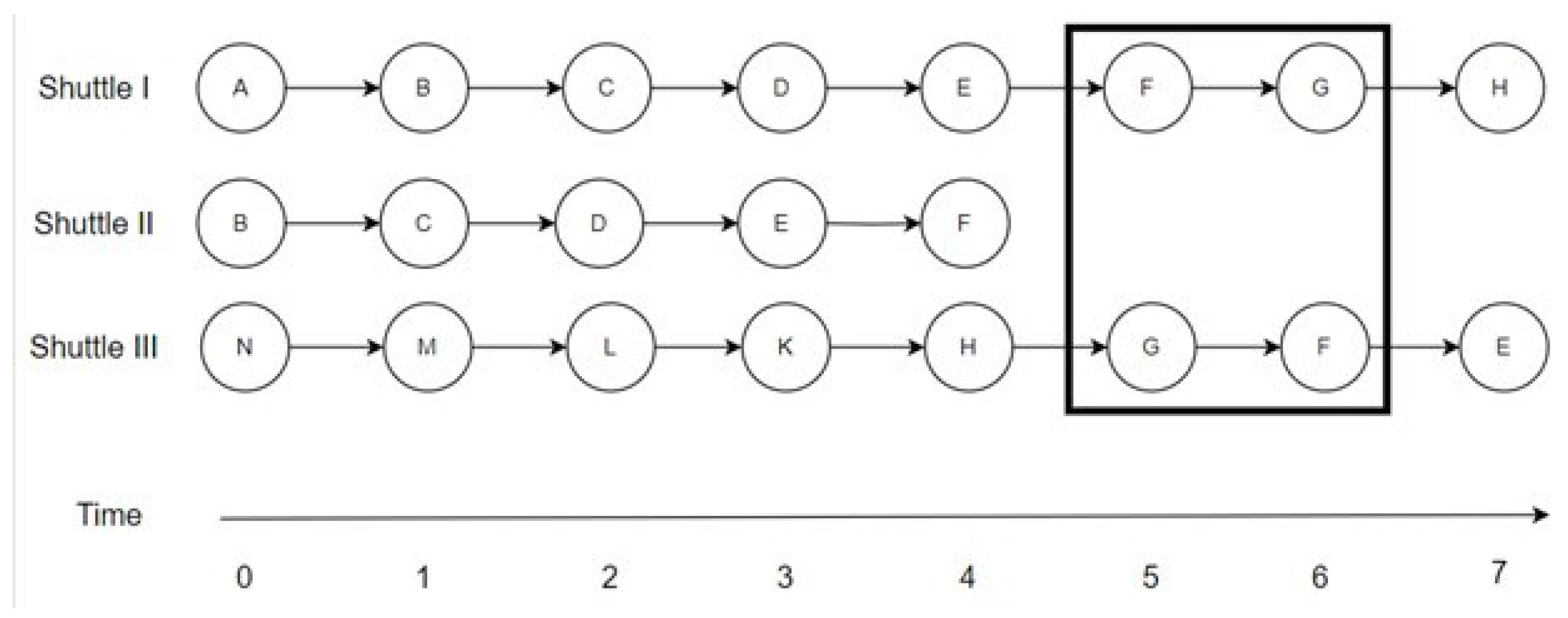

Figure 14.

The shortest route to complete the tasks of each Shuttle (I, II, and III).

Figure 14.

The shortest route to complete the tasks of each Shuttle (I, II, and III).

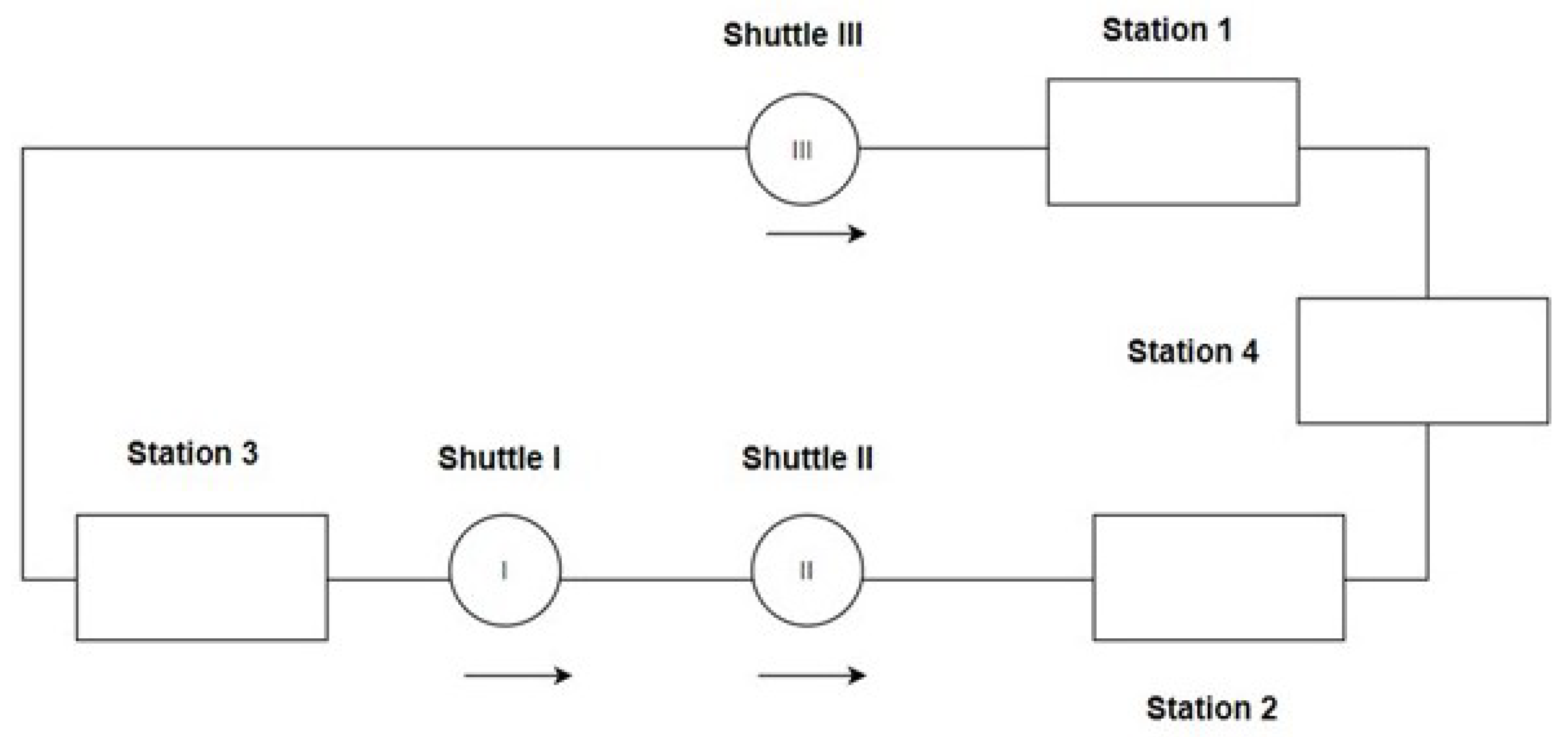

Figure 15.

Station 4 in the route of Shuttle III.

Figure 15.

Station 4 in the route of Shuttle III.

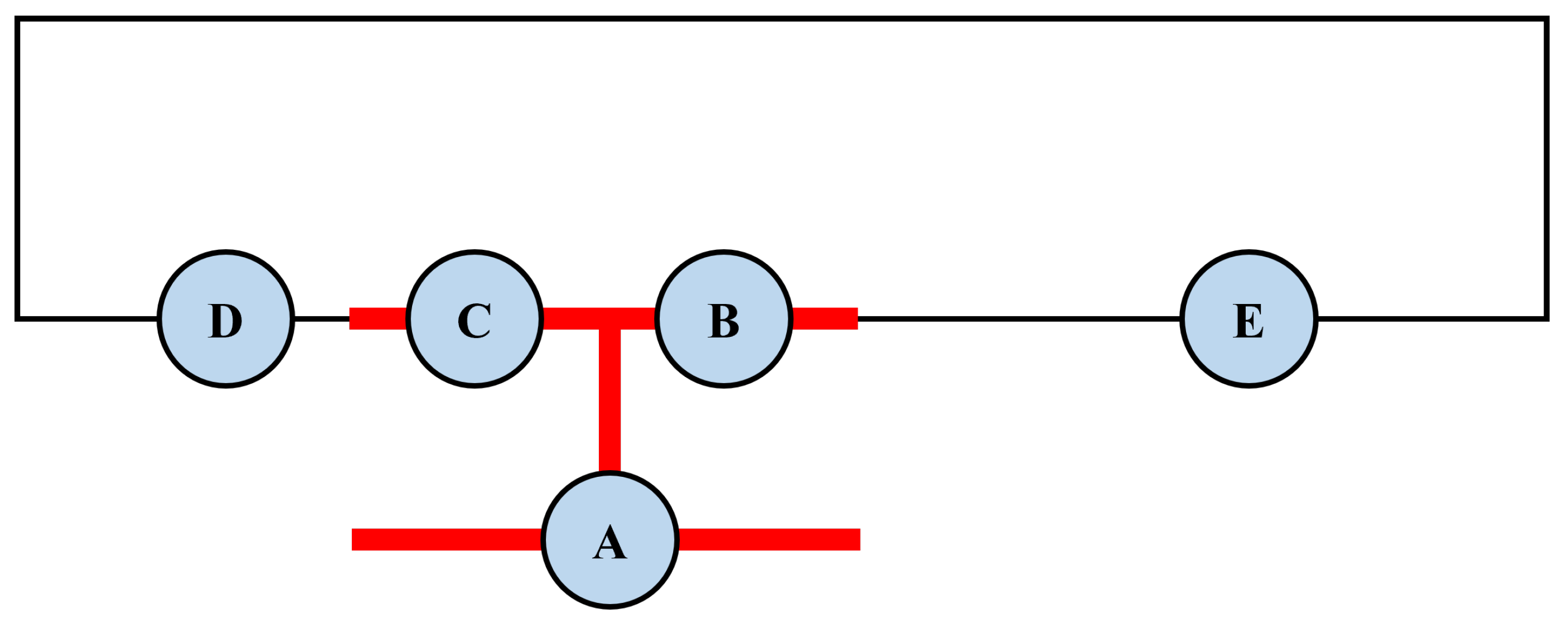

Figure 16.

Shuttle A wants to return to the old route but shuttles B and C are standing in front of the station.

Figure 16.

Shuttle A wants to return to the old route but shuttles B and C are standing in front of the station.

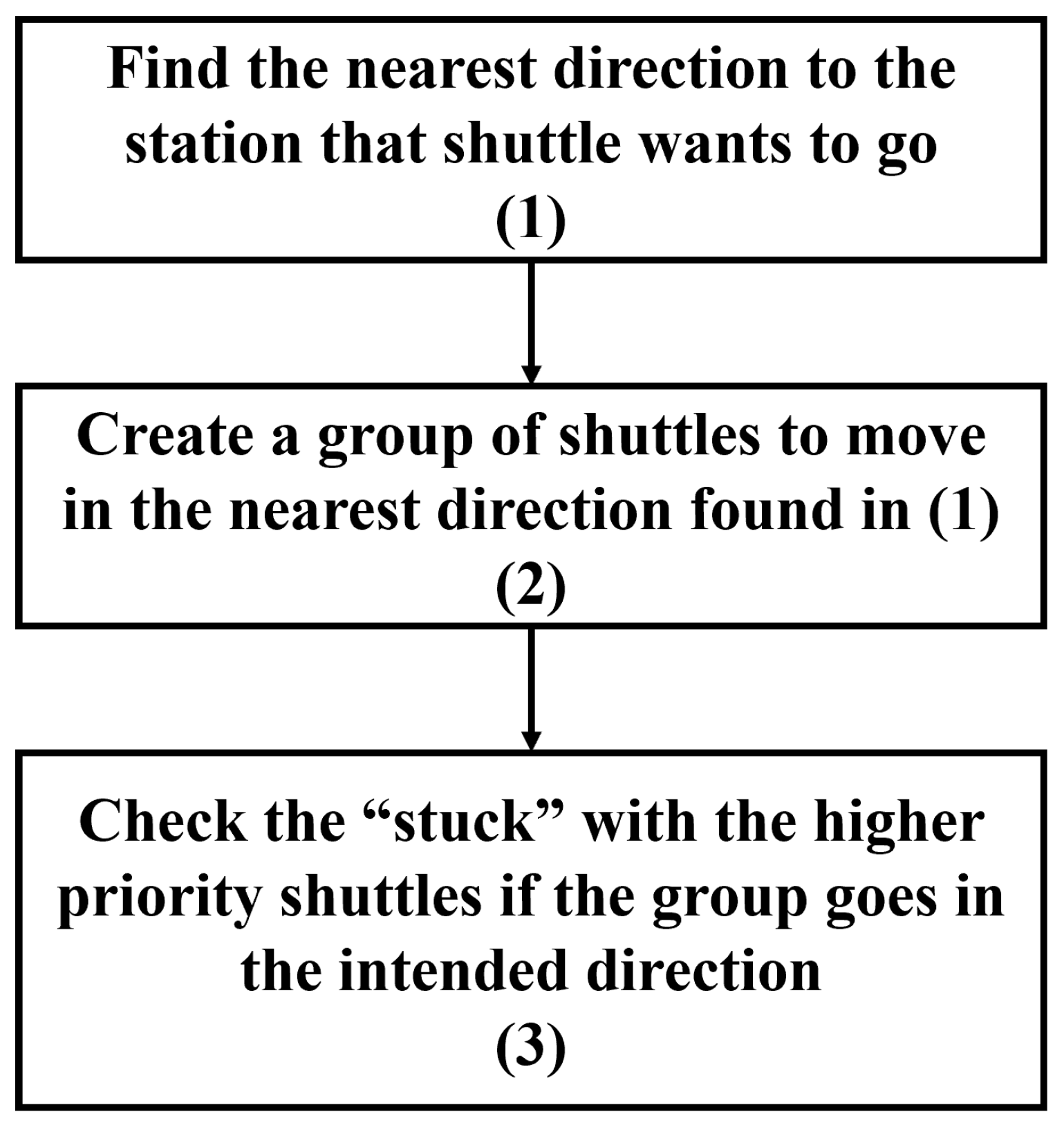

Figure 17.

The flow chart for “Find the direction for each shuttles”.

Figure 17.

The flow chart for “Find the direction for each shuttles”.

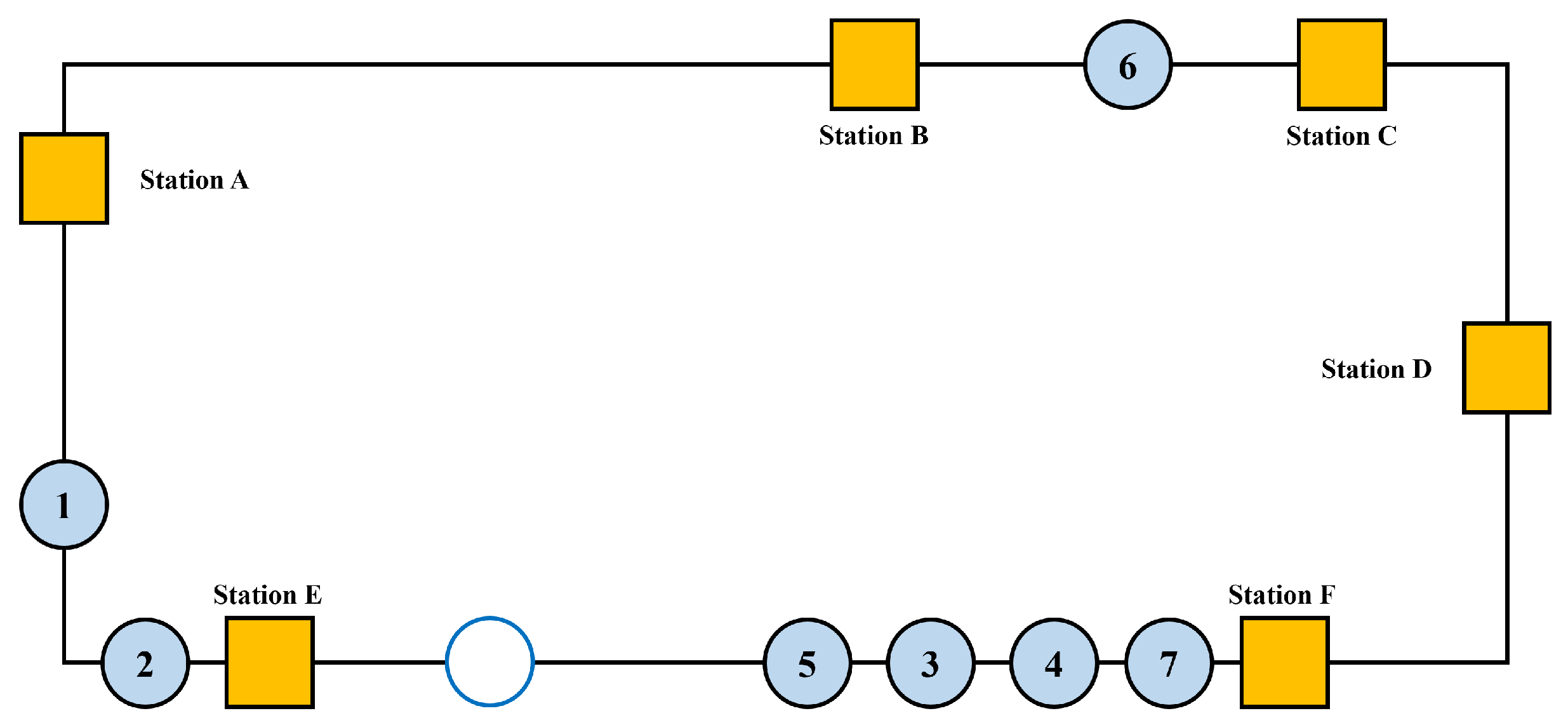

Figure 18.

The sytems at the time .

Figure 18.

The sytems at the time .

Figure 19.

The “stuck” happens at “O” position if Shuttle 5 is directed to move in a counter-clockwise direction.

Figure 19.

The “stuck” happens at “O” position if Shuttle 5 is directed to move in a counter-clockwise direction.

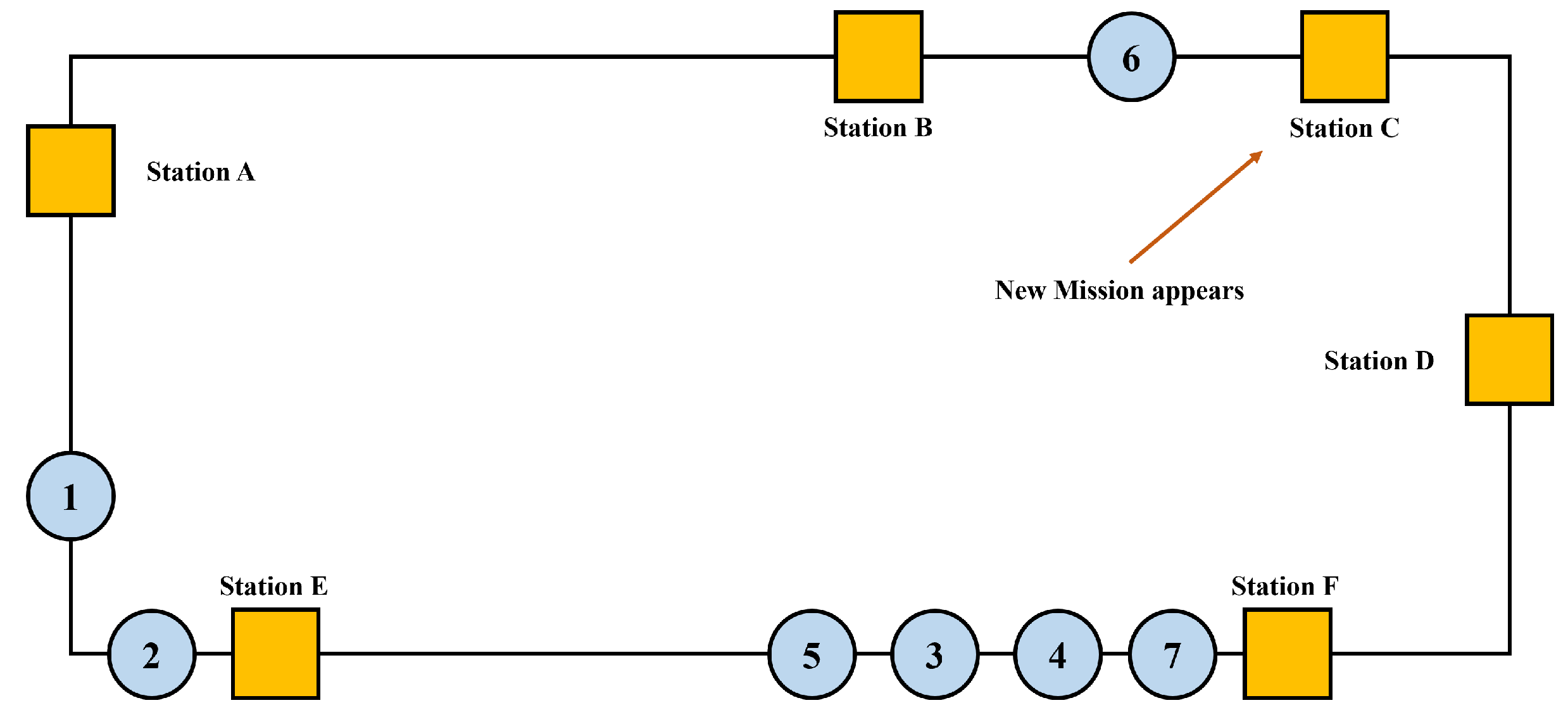

Figure 20.

A new mission appears while the shuttles are doing their job at the time .

Figure 20.

A new mission appears while the shuttles are doing their job at the time .

Figure 21.

The mission was completed on time.

Figure 21.

The mission was completed on time.

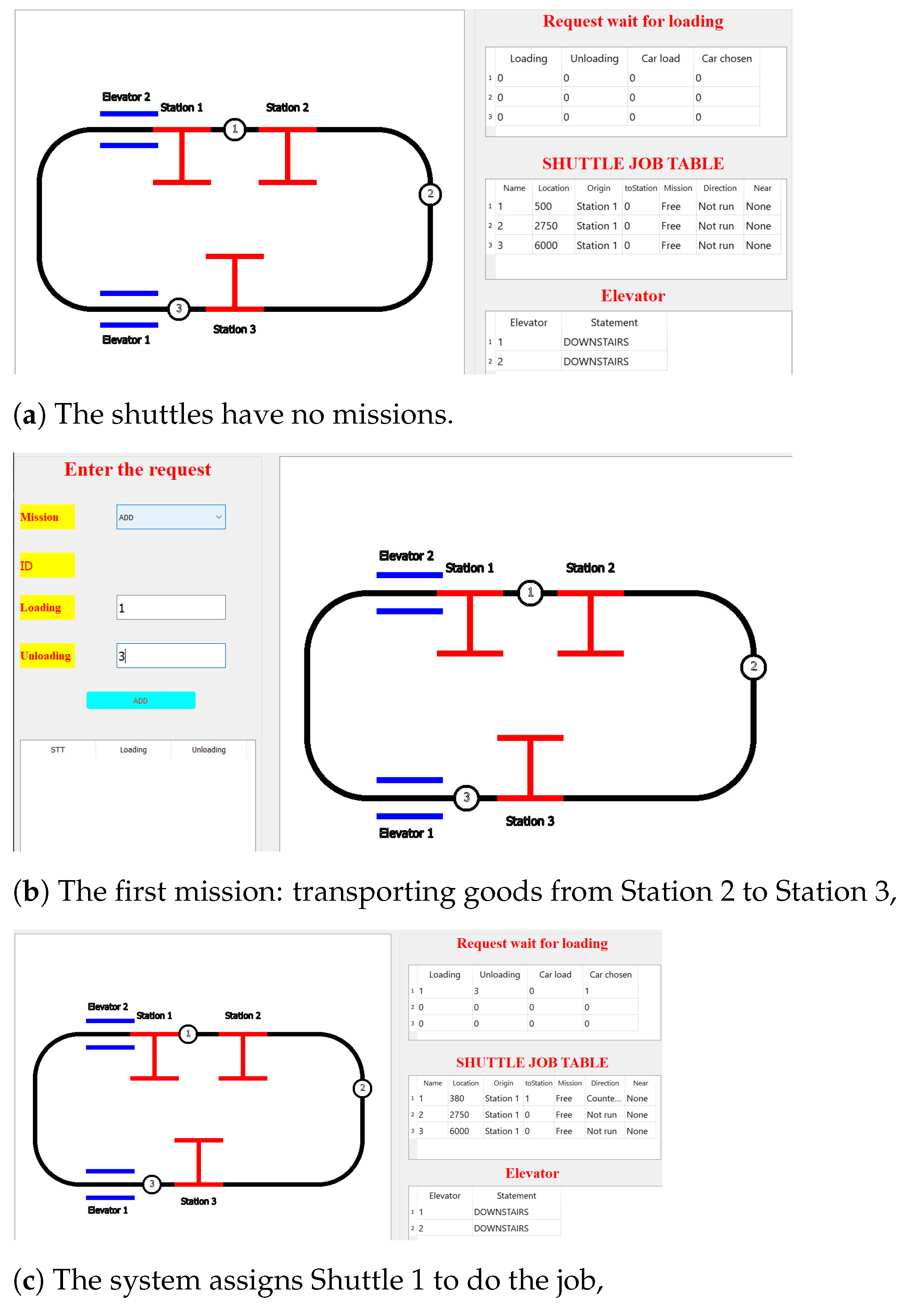

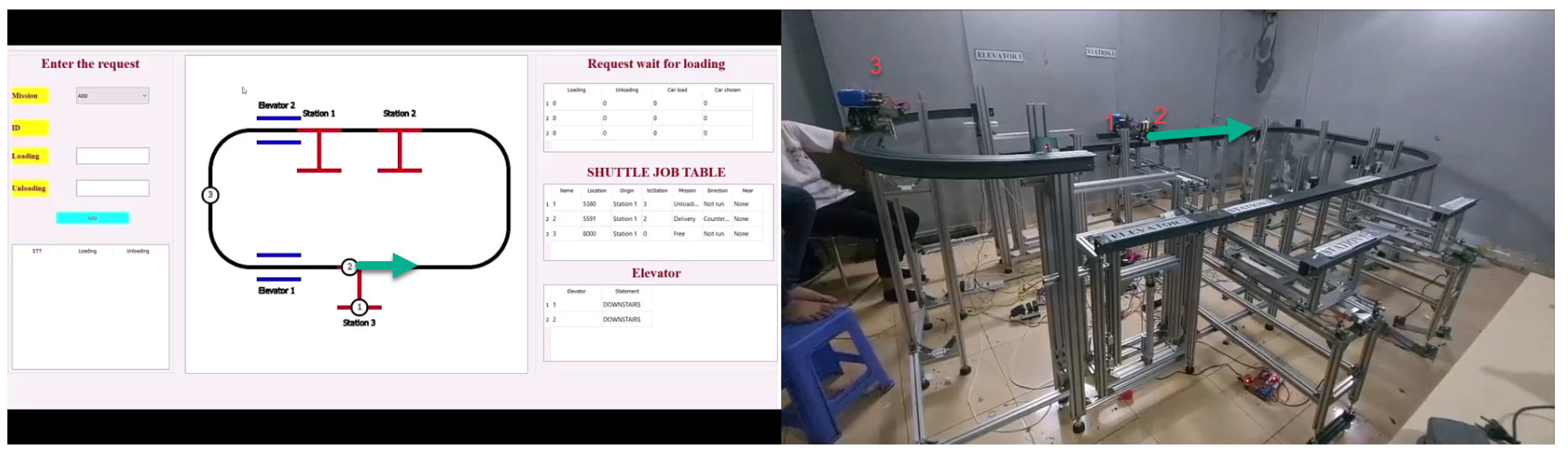

Figure 22.

Case 1—The system has just started to operate.

Figure 22.

Case 1—The system has just started to operate.

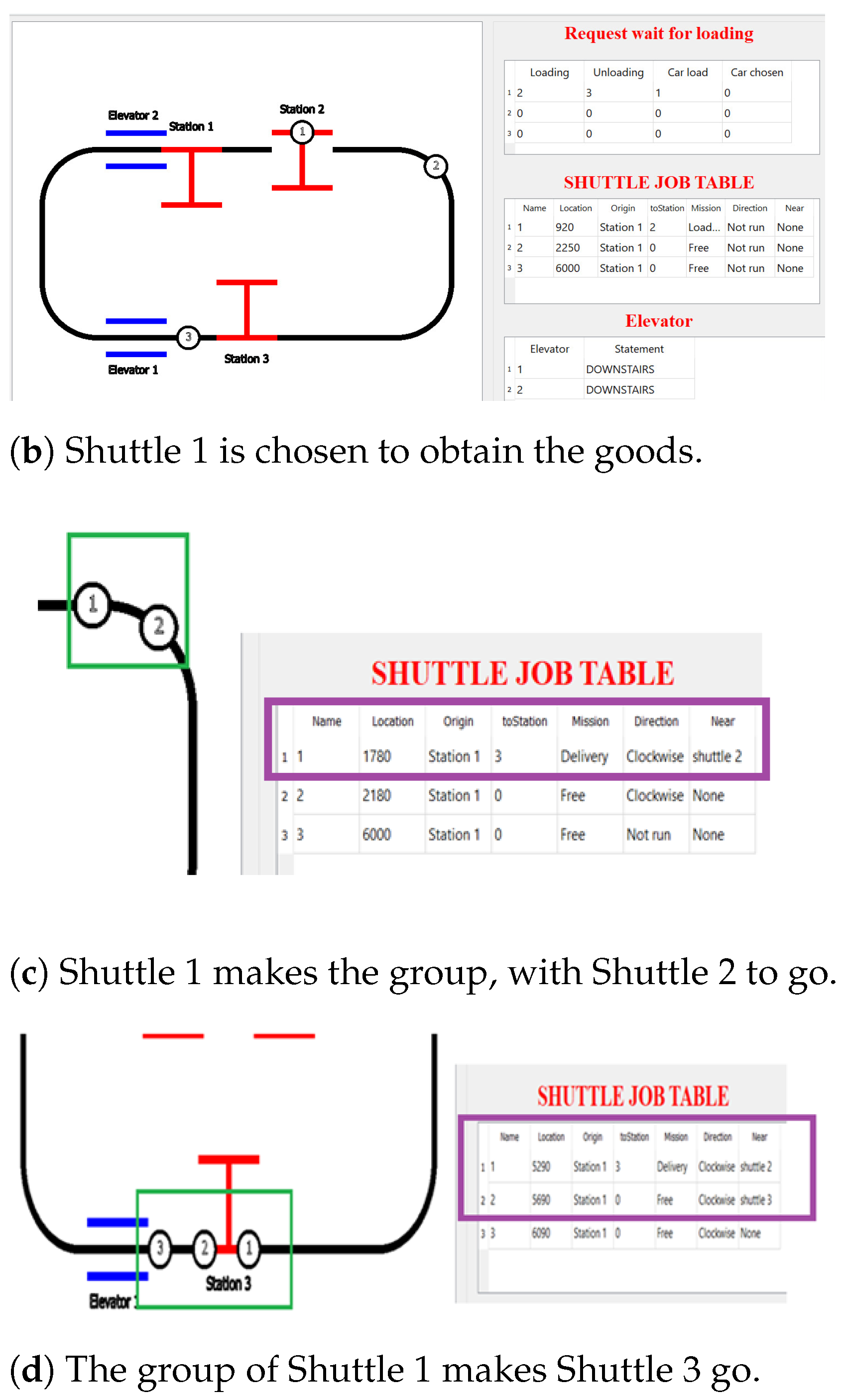

Figure 23.

Case 2—The shuttle doing its job must make another shuttle run away.

Figure 23.

Case 2—The shuttle doing its job must make another shuttle run away.

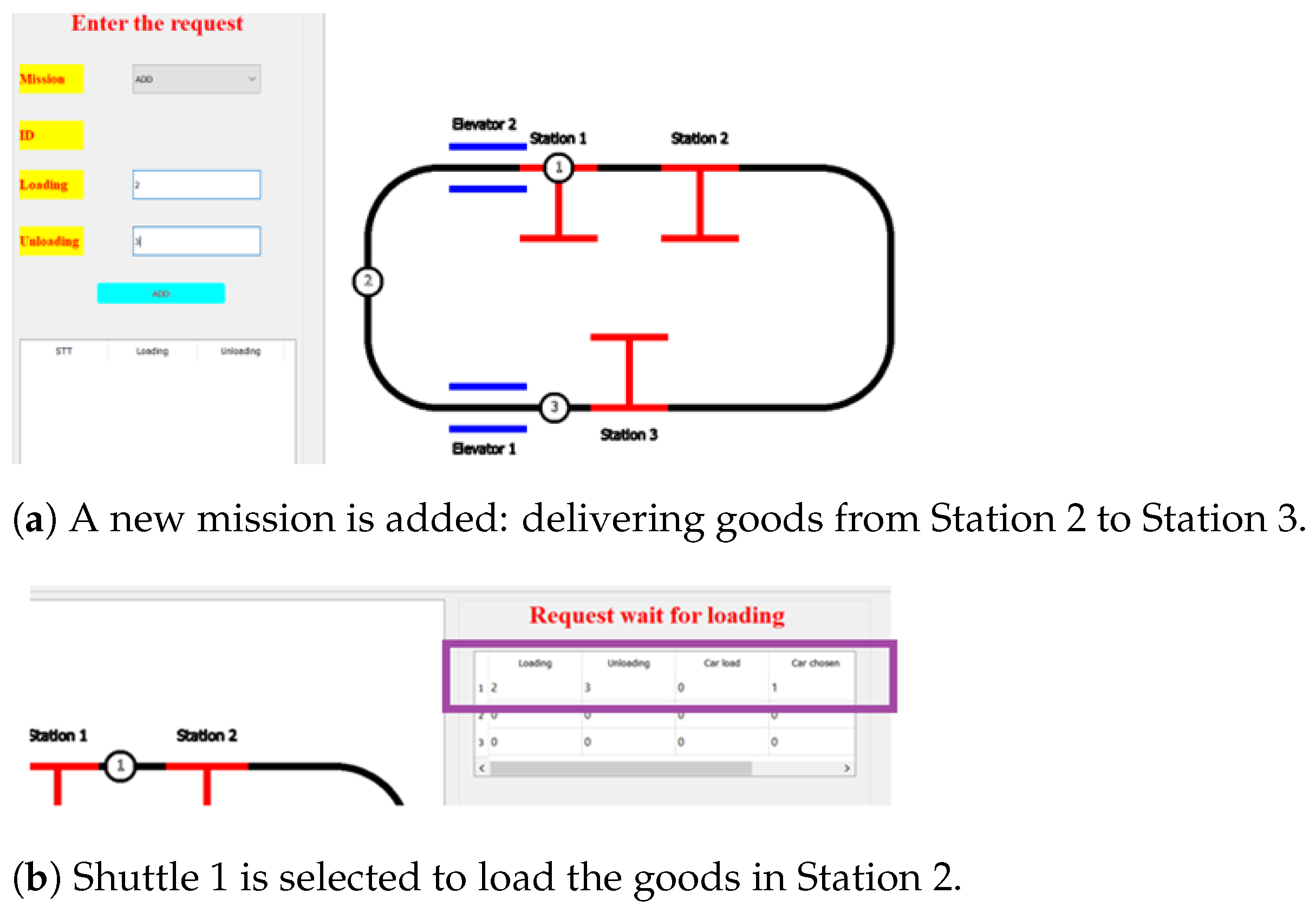

Figure 24.

Case 3—There is more than one shuttle operating to carry out the mission.

Figure 24.

Case 3—There is more than one shuttle operating to carry out the mission.

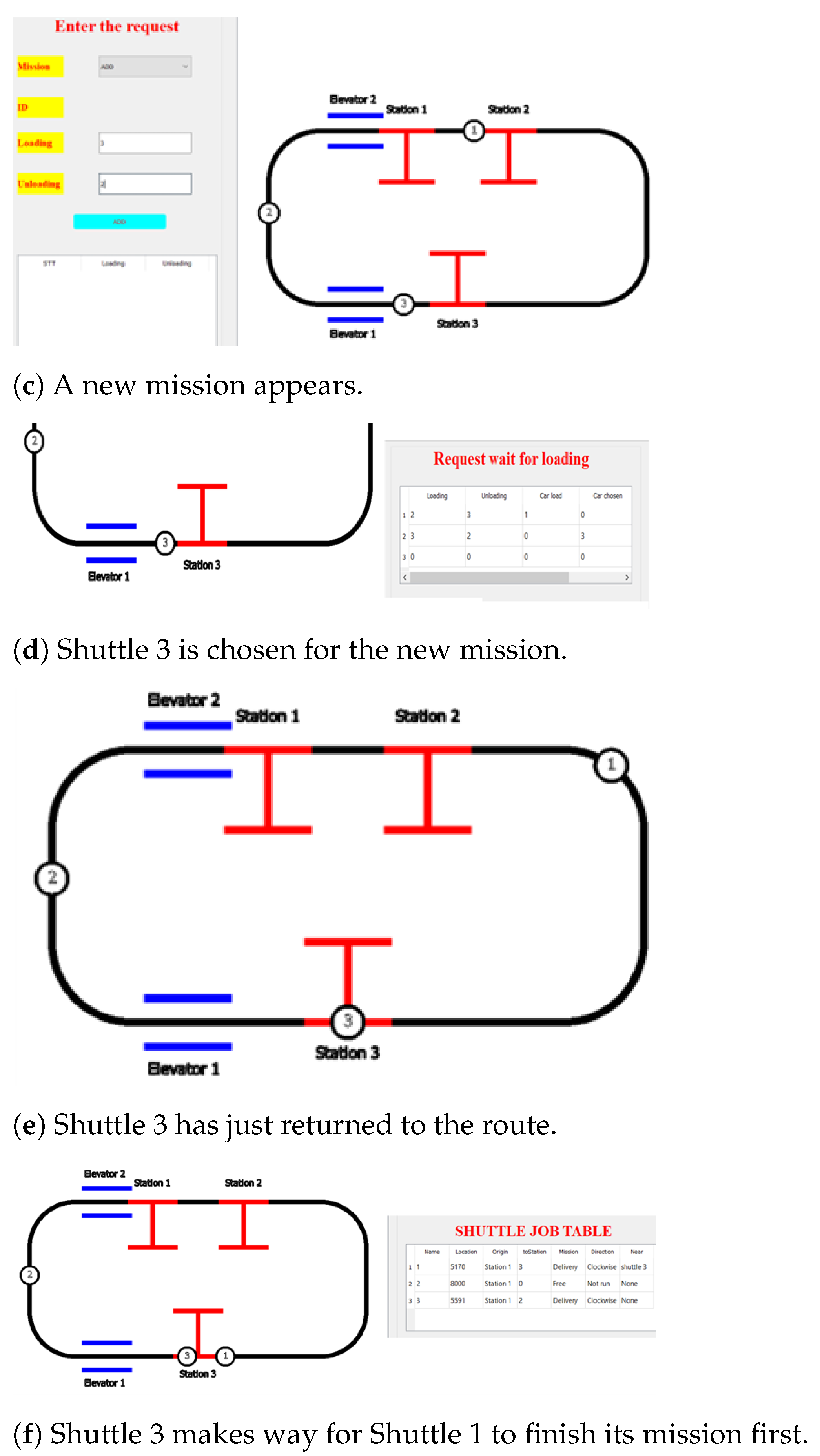

Figure 25.

Case 4—The low priority shuttle should find a station to avoid a high priority.

Figure 25.

Case 4—The low priority shuttle should find a station to avoid a high priority.

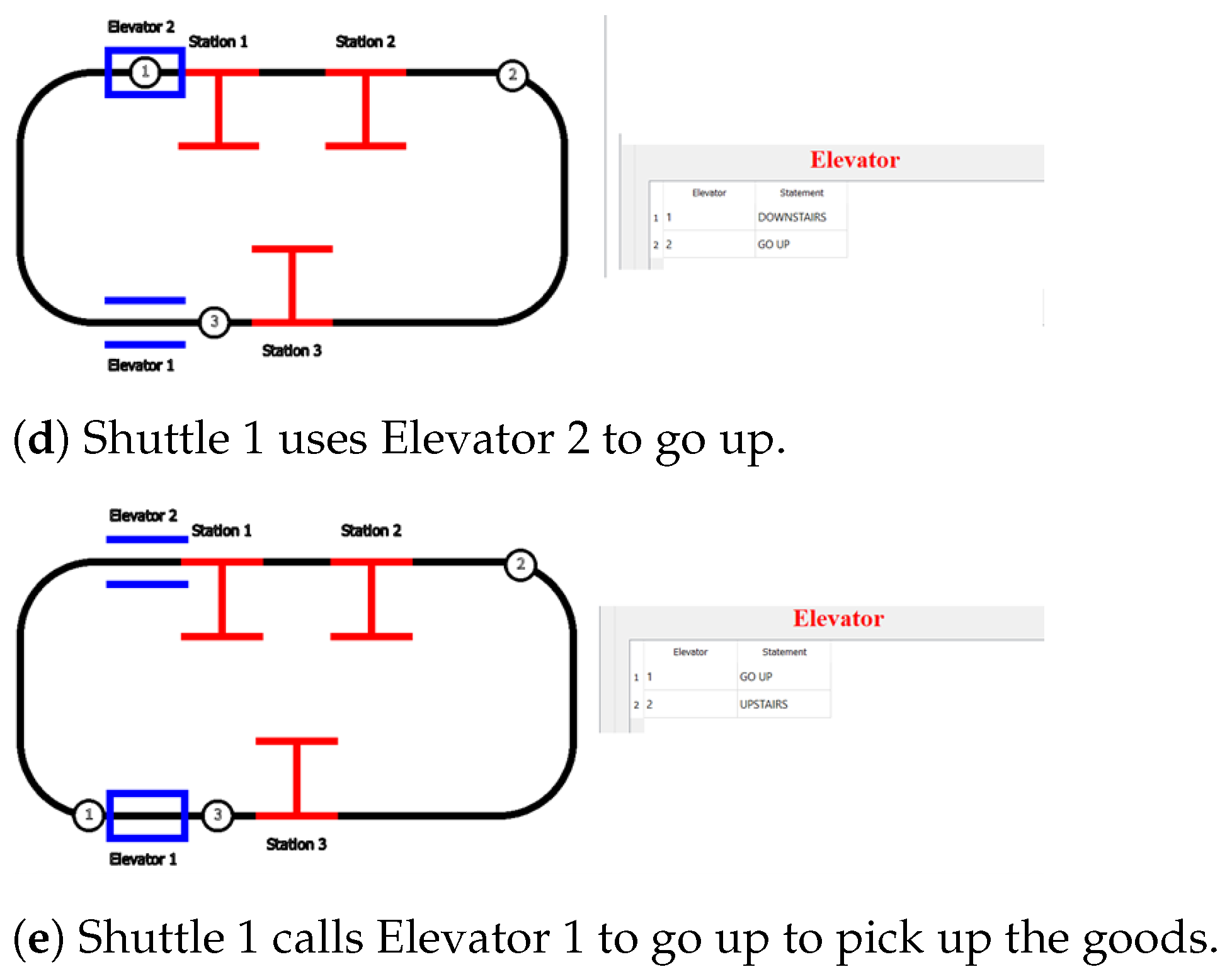

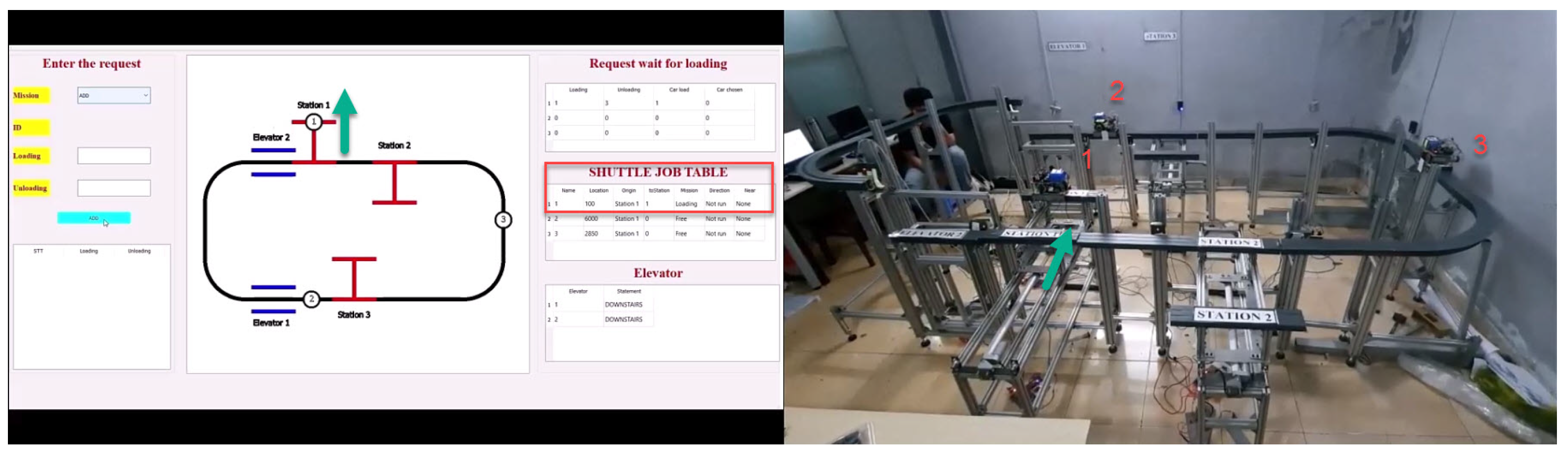

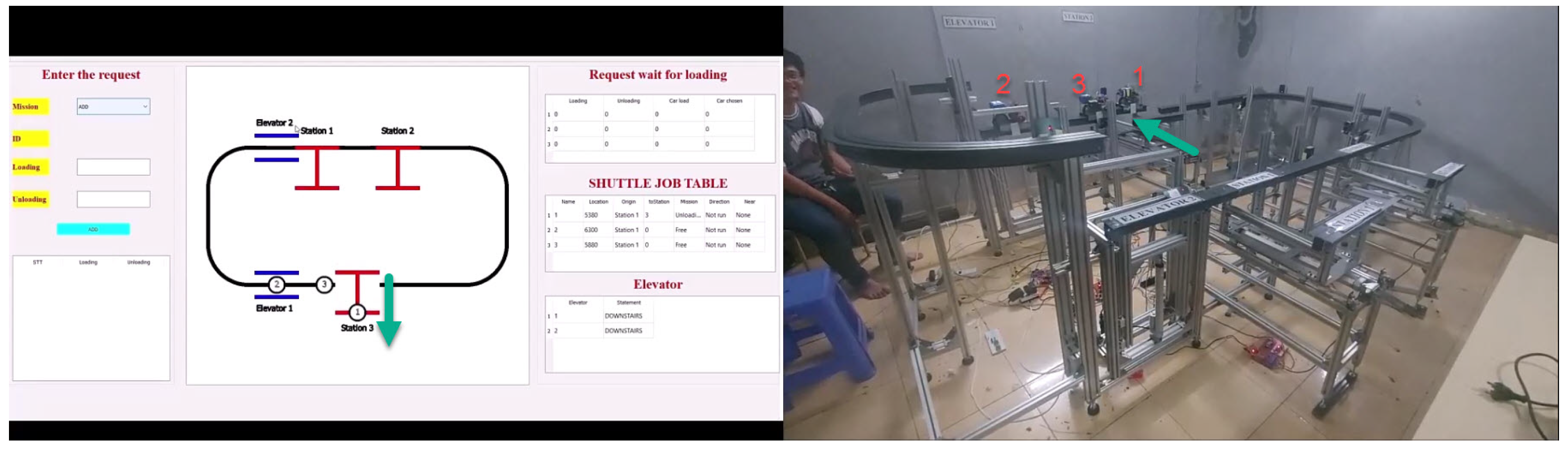

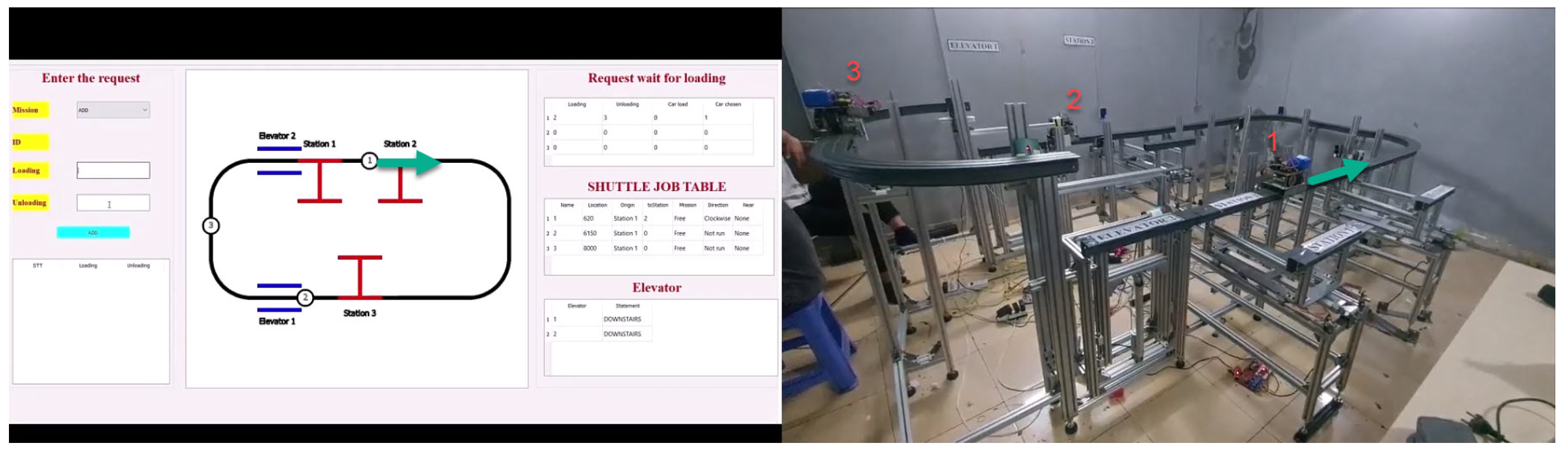

Figure 26.

The new mission is added from Station 1 to Station 3.

Figure 26.

The new mission is added from Station 1 to Station 3.

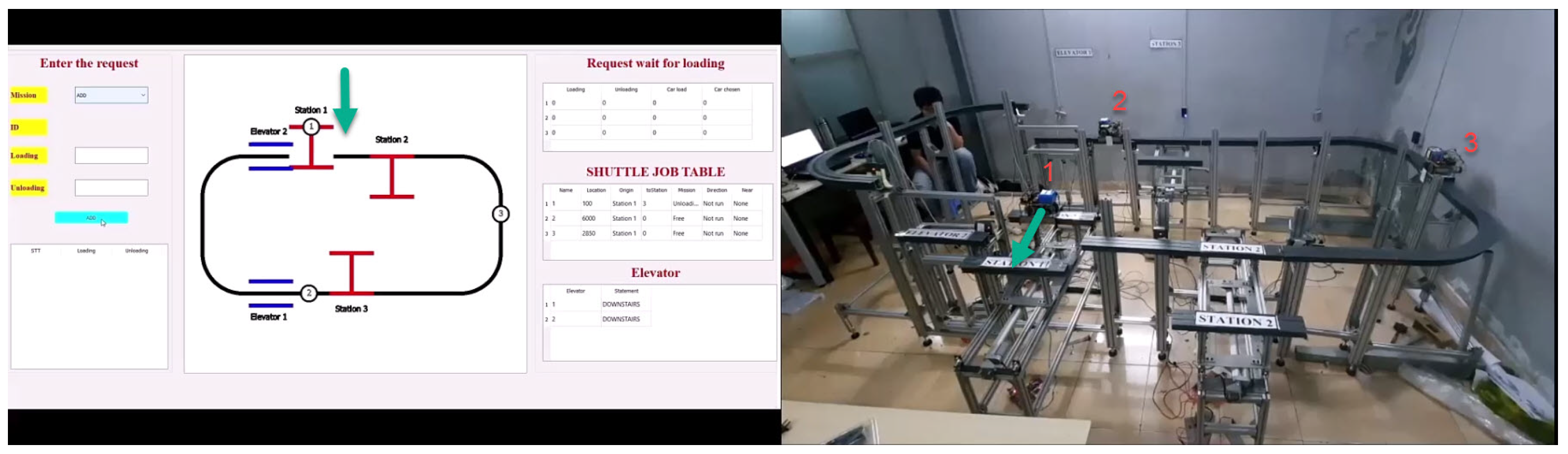

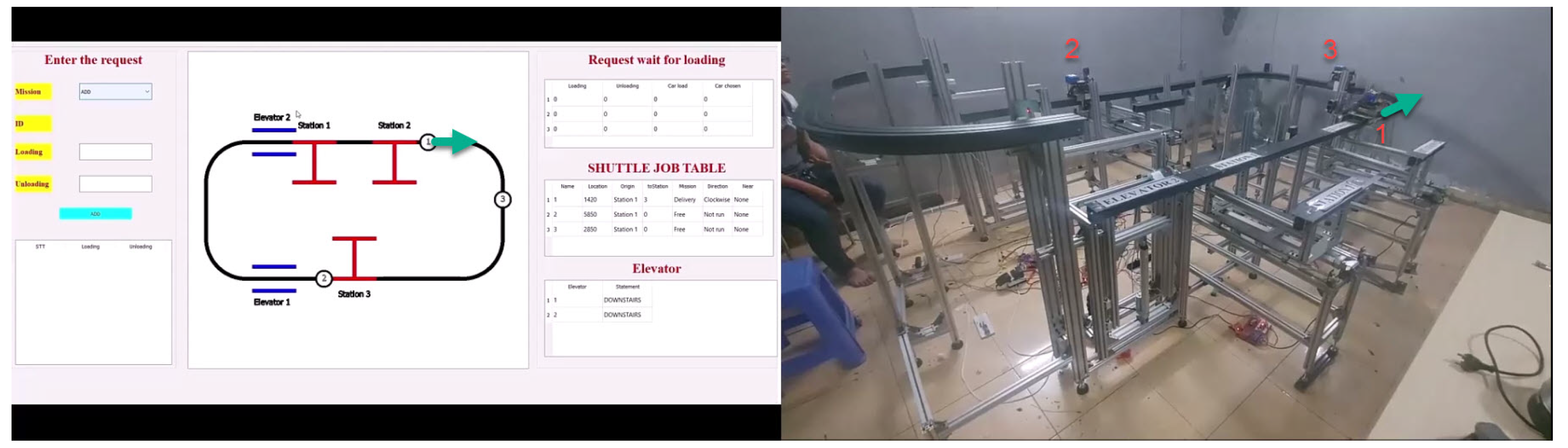

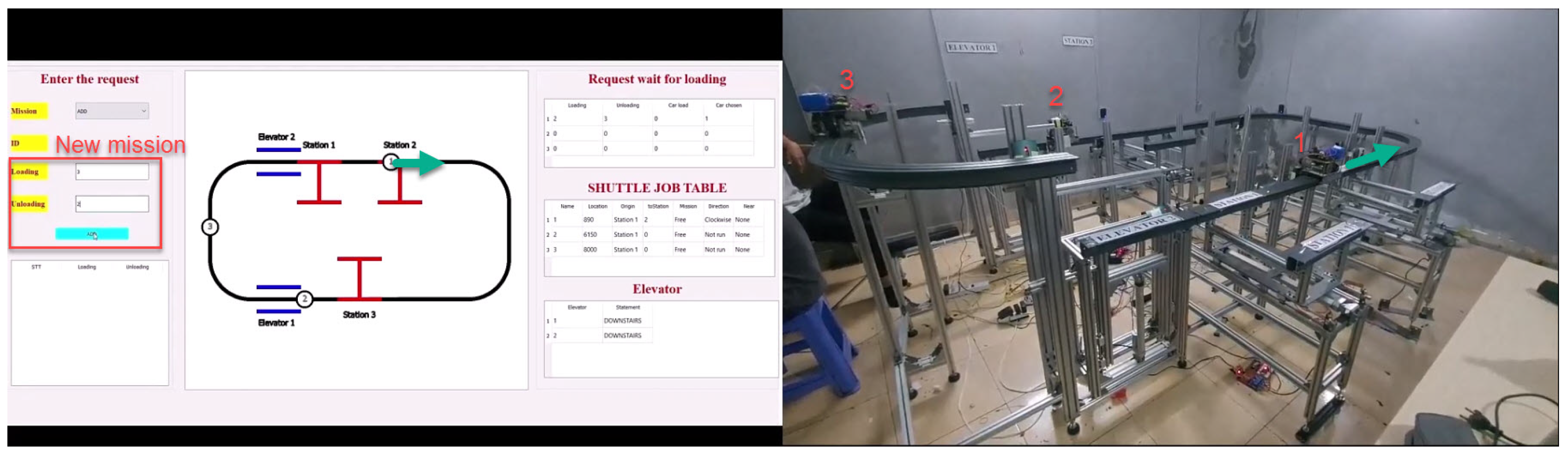

Figure 27.

The system chooses Shuttle 1 for the mission.

Figure 27.

The system chooses Shuttle 1 for the mission.

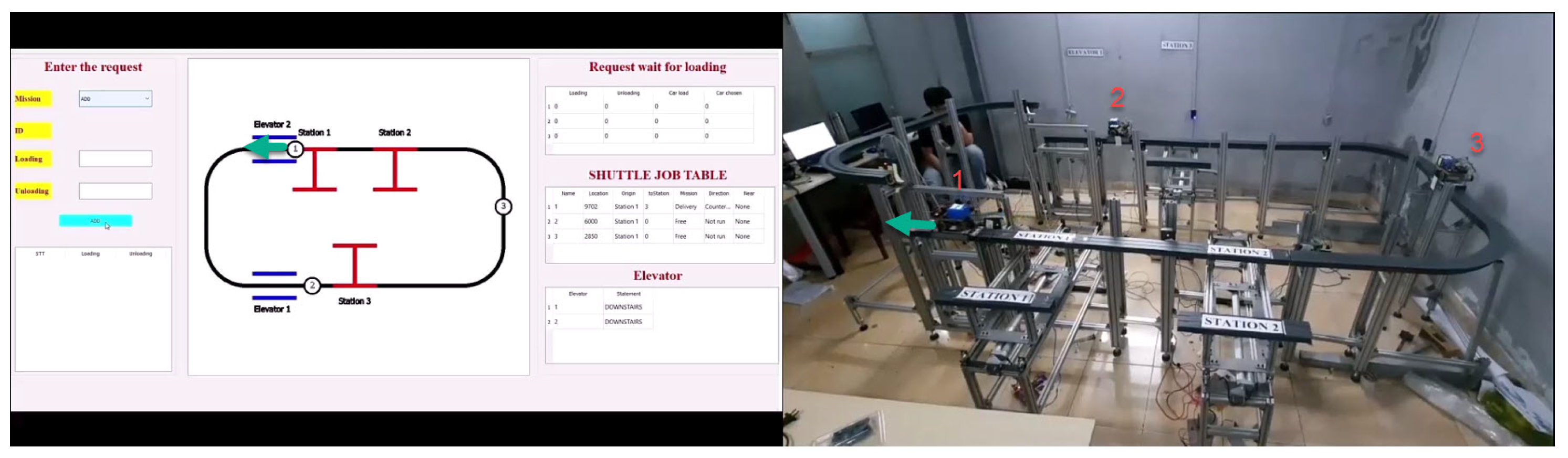

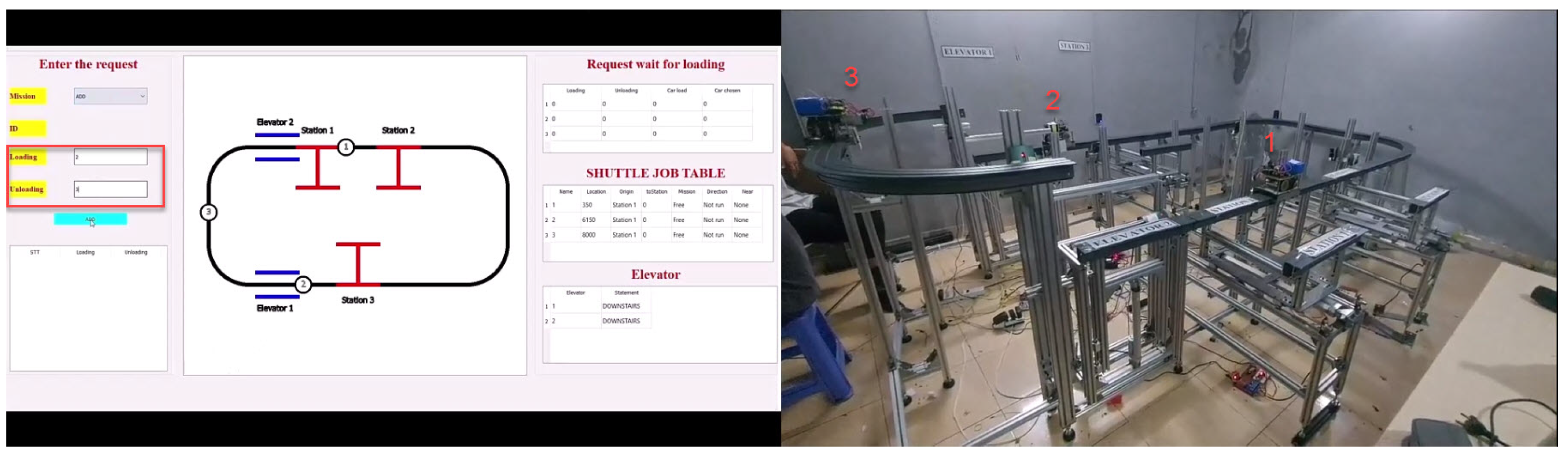

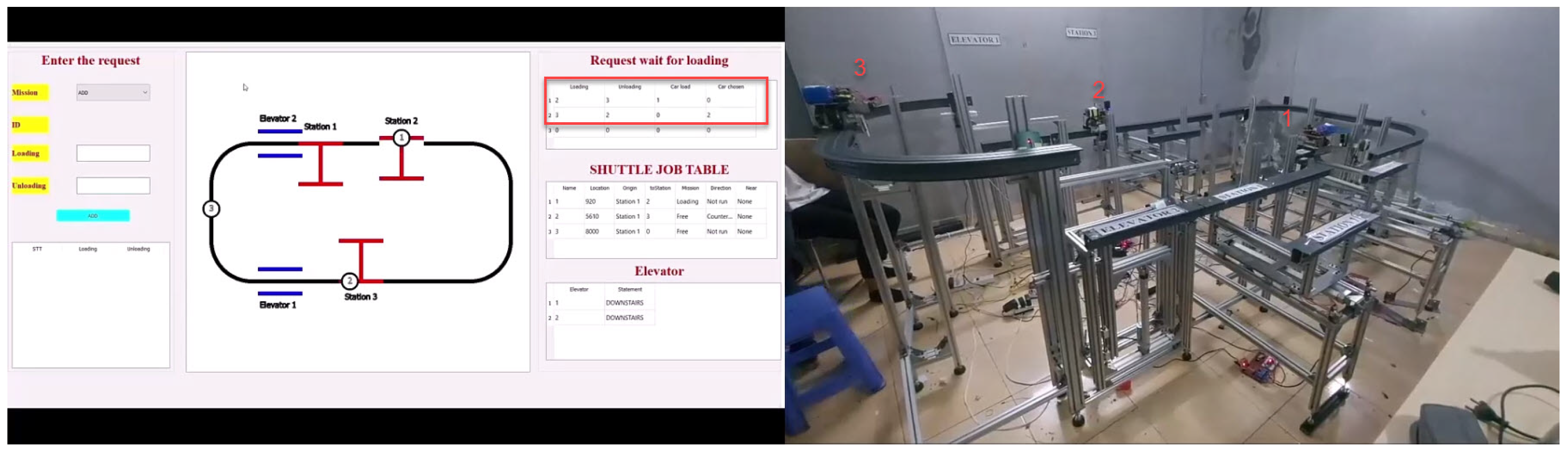

Figure 28.

The Shuttle 1 is running to Station 1 to get the goods.

Figure 28.

The Shuttle 1 is running to Station 1 to get the goods.

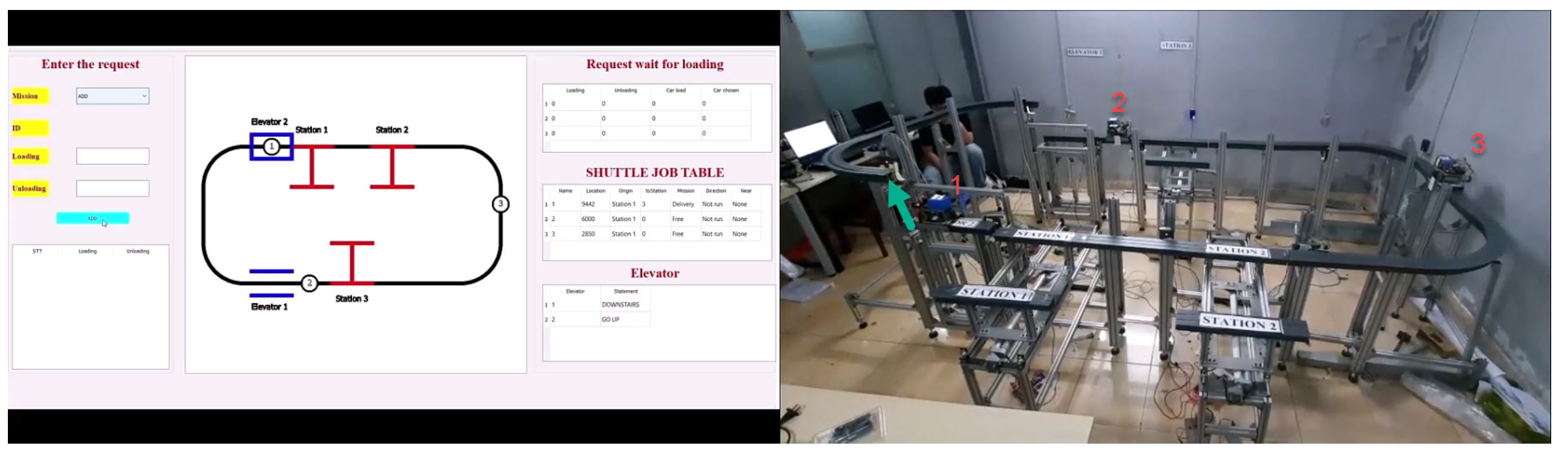

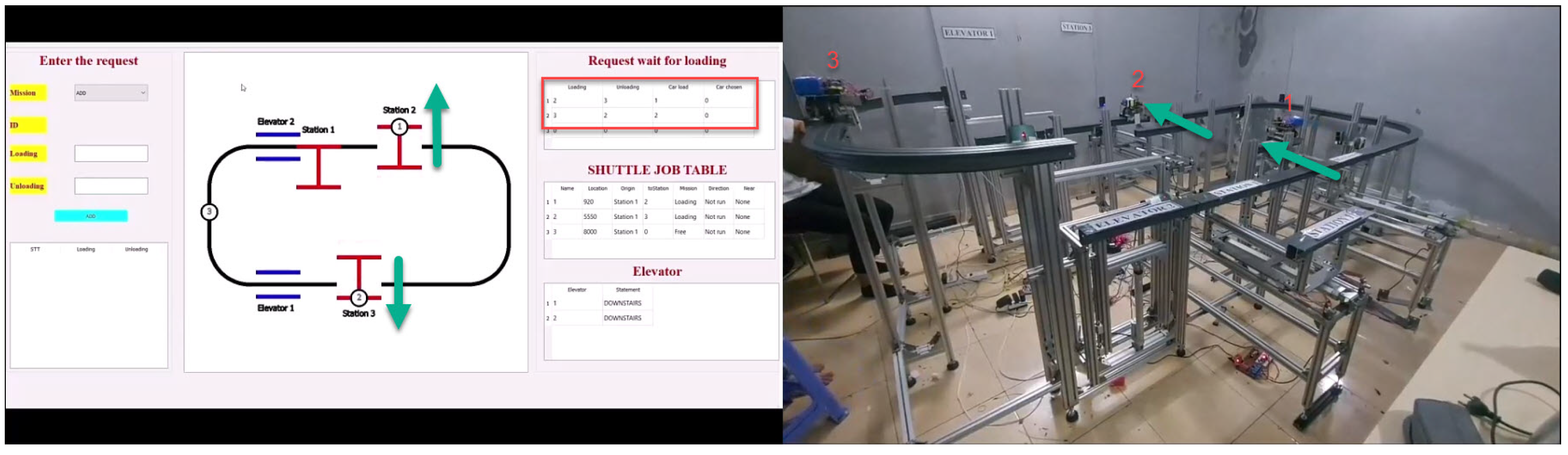

Figure 29.

Shuttle 1 is going into Station 1 to get the goods.

Figure 29.

Shuttle 1 is going into Station 1 to get the goods.

Figure 30.

The shuttle is loading the goods.

Figure 30.

The shuttle is loading the goods.

Figure 31.

The shuttle returns to the route.

Figure 31.

The shuttle returns to the route.

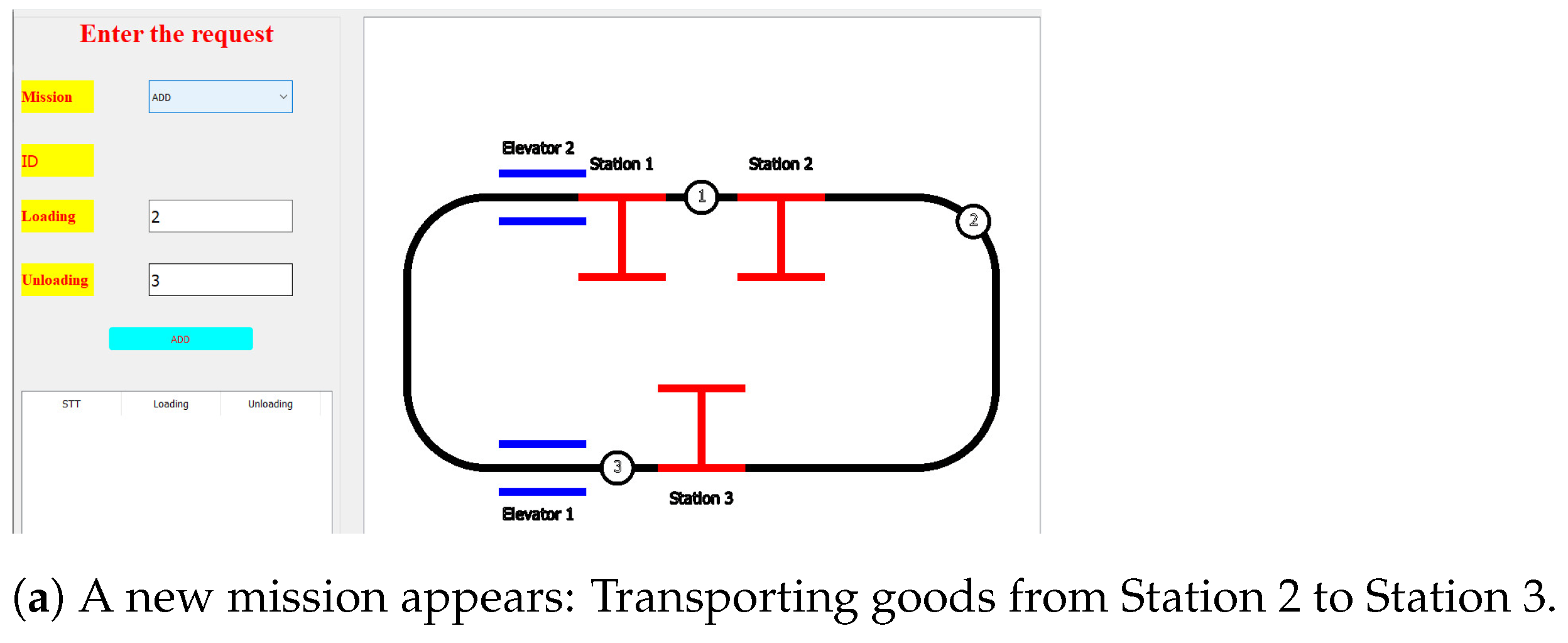

Figure 32.

Shuttle 1 runs into Elevator 2.

Figure 32.

Shuttle 1 runs into Elevator 2.

Figure 33.

Elevator 2 goes upstairs with Shuttle 1.

Figure 33.

Elevator 2 goes upstairs with Shuttle 1.

Figure 34.

Shuttle 1 goes upstairs successfully.

Figure 34.

Shuttle 1 goes upstairs successfully.

Figure 35.

Shuttle 1 continues running.

Figure 35.

Shuttle 1 continues running.

Figure 36.

Elevator 1 goes up to take Shuttle 1.

Figure 36.

Elevator 1 goes up to take Shuttle 1.

Figure 37.

Shuttle 1 goes into Elevator 1 to go down.

Figure 37.

Shuttle 1 goes into Elevator 1 to go down.

Figure 38.

Elevator 1 brings Shuttle 1 go down.

Figure 38.

Elevator 1 brings Shuttle 1 go down.

Figure 39.

Shuttle 1 successfully goes down.

Figure 39.

Shuttle 1 successfully goes down.

Figure 40.

System orders Shuttle 2 to run with Shuttle 1.

Figure 40.

System orders Shuttle 2 to run with Shuttle 1.

Figure 41.

Shuttle 2 runs with Shuttle 1.

Figure 41.

Shuttle 2 runs with Shuttle 1.

Figure 42.

Shuttle 2 keeps running.

Figure 42.

Shuttle 2 keeps running.

Figure 43.

Shuttle 1 goes into Station 3.

Figure 43.

Shuttle 1 goes into Station 3.

Figure 44.

After unloading, Shuttle 1 returns to the route.

Figure 44.

After unloading, Shuttle 1 returns to the route.

Figure 45.

The new mission is added.

Figure 45.

The new mission is added.

Figure 46.

Shuttle 1 goes to Station 2 to acquire the goods.

Figure 46.

Shuttle 1 goes to Station 2 to acquire the goods.

Figure 47.

Station 2 receives Shuttle 1.

Figure 47.

Station 2 receives Shuttle 1.

Figure 48.

Shuttle 1 returns to the route for delivering.

Figure 48.

Shuttle 1 returns to the route for delivering.

Figure 49.

Shuttle 1 begins running to Station 3 for delivering.

Figure 49.

Shuttle 1 begins running to Station 3 for delivering.

Figure 50.

Shuttle 3 is forced to run by Shuttle 1.

Figure 50.

Shuttle 3 is forced to run by Shuttle 1.

Figure 51.

Shuttle 2 is forced to run by the Shuttle 1 group.

Figure 51.

Shuttle 2 is forced to run by the Shuttle 1 group.

Figure 52.

Shuttle 1 gets into Station 3.

Figure 52.

Shuttle 1 gets into Station 3.

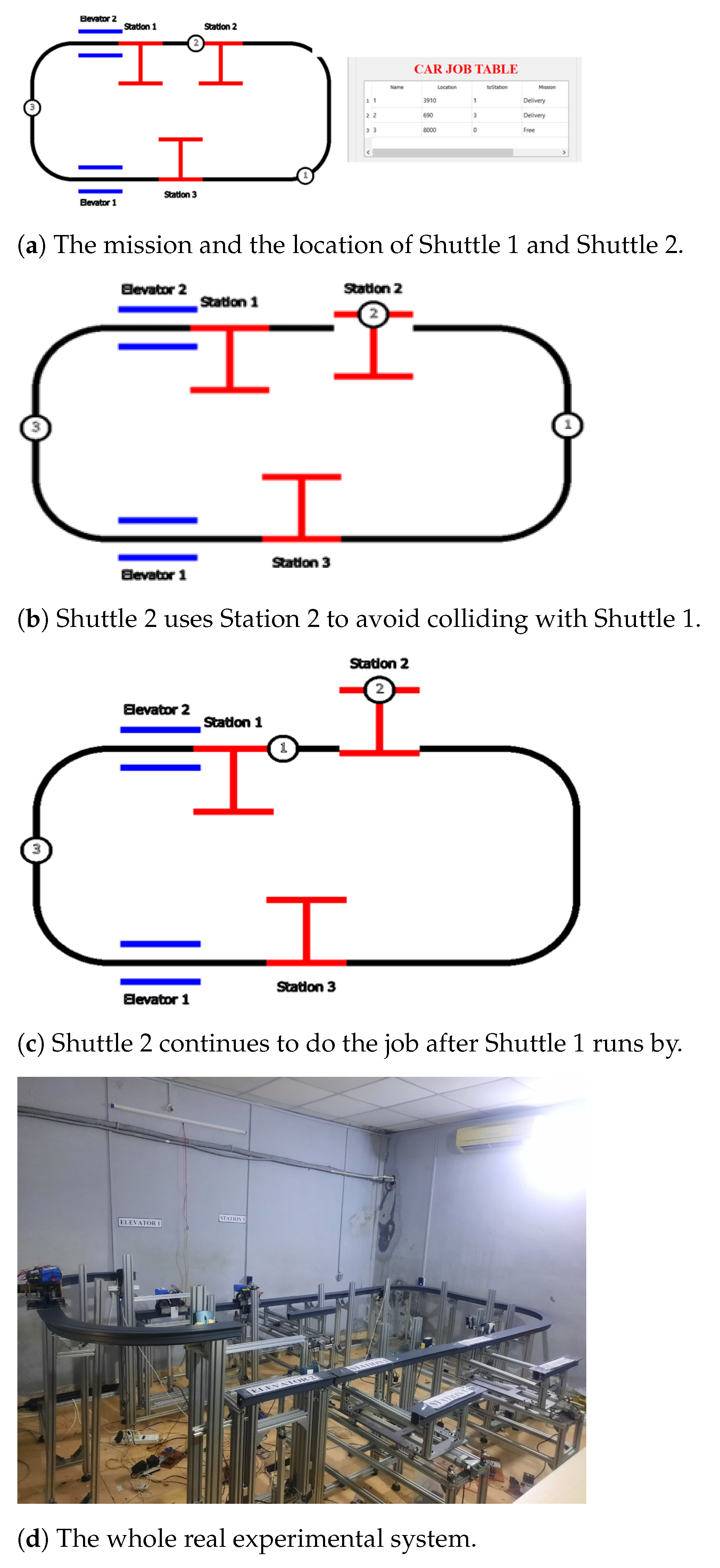

Figure 53.

The mission from Station 2 to Station 3 is added.

Figure 53.

The mission from Station 2 to Station 3 is added.

Figure 54.

Shuttle 1 is chosen for the first mission.

Figure 54.

Shuttle 1 is chosen for the first mission.

Figure 55.

The second mission is added.

Figure 55.

The second mission is added.

Figure 56.

The system selects the shuttle for second mission.

Figure 56.

The system selects the shuttle for second mission.

Figure 57.

Shuttle 1 and Shuttle 2 are loading.

Figure 57.

Shuttle 1 and Shuttle 2 are loading.

Figure 58.

Shuttle 1 is coming to Station 3.

Figure 58.

Shuttle 1 is coming to Station 3.

Figure 59.

The decision of system after Shuttle 2 has returned the route.

Figure 59.

The decision of system after Shuttle 2 has returned the route.

Figure 60.

Shuttle 2 exists the path of Shuttle 1.

Figure 60.

Shuttle 2 exists the path of Shuttle 1.

Figure 61.

Shuttle 2 runs after waiting for Shuttle 1 to enter Station 3.

Figure 61.

Shuttle 2 runs after waiting for Shuttle 1 to enter Station 3.

Figure 62.

Shuttle 2 arrives in the unloading station.

Figure 62.

Shuttle 2 arrives in the unloading station.

Table 1.

Four stages of the processing mission.

Table 1.

Four stages of the processing mission.

| Processing Steps | Details |

|---|

| 1 | Take the goods at load Station |

| 2 | Load the goods |

| 3 | Delivere the goods |

| 4 | Unload the goods |

Table 2.

Status breakdown table of shuttles.

Table 2.

Status breakdown table of shuttles.

| Priority | Status of Shuttles | Operation |

|---|

| 1 | The changing battery shuttle | The shuttle is changing the battery |

| 2 | The stopping shuttle | The shuttle is loading or unloading in the station |

| 3 | The nearing shuttle | The shuttle had just gone to its station but could not get into |

| 4 | The needed-changing battery shuttle | The shuttle has a battery which is lower than the “safe battery” level (the amount of energy the shuttle needs to require a battery change) |

| 6 | The delivery shuttle | The shuttle has goods on it and is delivering the goods |

| 7 | The free shuttle | The shuttle does not have goods on it and is ready for delivery |

Table 3.

Data at 0 s.

| Priority | Shuttle | Time to End Mission | State of Shuttles | Mission |

|---|

| 1 | B | 5 s | Delivery shuttle | Delivery in Station 2 |

| 2 | A | 80 s | Free shuttle | Take goods at Station 1 |

Table 4.

Data at 5 s.

| Priority | Shuttle | Time to End Mission | State of Shuttles | Mission |

|---|

| 1 | B | 40 s | Stopping shuttle | Unload in Station 2 and return |

| 2 | A | 75 s | Free shuttle | Take goods at Station 1 |

Table 5.

Data at 45 s.

| Priority | Shuttle | Time to End Mission | State of Shuttles | Mission |

|---|

| 1 | B | 20 s | Free shuttle | Take the goods at Station 1 |

| 2 | A | 0 s | Free shuttle | Does not have mission |

Table 6.

The details of two shuttles.

Table 6.

The details of two shuttles.

| Priority | Shuttle | State of Shuttles | Mission |

|---|

| 1 | 1 | Delivery shuttle | Delivery at Station 1 |

| 2 | 2 | Free shuttle | Get good at Station 2 |

Table 7.

The mission and priority of shuttles I, II, and III.

Table 7.

The mission and priority of shuttles I, II, and III.

| Priority | Status of Shuttles | Operation |

|---|

| 1 | I | To deliver at Staion 1 |

| 2 | II | To deliver at Station 2 |

| 3 | III | To acquire goods at Station 3 |

Table 8.

The details of all shuttles after “Make the shuttle stand in front of the Station”.

Table 8.

The details of all shuttles after “Make the shuttle stand in front of the Station”.

| Shuttles | Priority | Direction |

|---|

| B | 1 | Counter-clockwise |

| C | 1 | Clockwise |

| D | 1 | Clockwise |

Table 9.

Details of the system before changing status to “Find the direction of the system” at the time .

Table 9.

Details of the system before changing status to “Find the direction of the system” at the time .

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Not set |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Not set |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Not set |

| 4 | 4 | Free shuttle | Get good at Station E | Not set |

| 5 | 5 | Free shuttle | Get good at Station B | Not set |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

| 7 | 7 | Free shuttle | Don’t have mission | Not set |

Table 10.

Details of all the shuttles after the first turn.

Table 10.

Details of all the shuttles after the first turn.

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Clockwise |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Not set |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Not set |

| 4 | 4 | Free shuttle | Get good at Station E | Not set |

| 5 | 5 | Free shuttle | Get good at Station B | Not set |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

| 7 | 7 | Free shuttle | Don’t have mission | Not set |

Table 11.

Details of all the shuttles after the second turn.

Table 11.

Details of all the shuttles after the second turn.

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Clockwise |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Counter-clockwise |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Not set |

| 4 | 4 | Free shuttle | Get good at Station E | Not set |

| 5 | 5 | Free shuttle | Get good at Station B | Not set |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

| 7 | 7 | Free shuttle | Don’t have mission | Not set |

Table 12.

Details of all the shuttles after the third turn.

Table 12.

Details of all the shuttles after the third turn.

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Clockwise |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Counter-clockwise |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Counter-clockwise |

| 3 | 4 | Free shuttle | Get good at Station E | Counter-clockwise |

| 3 | 7 | Free shuttle | Don’t have mission | Counter-clockwise |

| 5 | 5 | Free shuttle | Get goods at Station B | Not set |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

Table 13.

Details of all the shuttles after the fourth turn.

Table 13.

Details of all the shuttles after the fourth turn.

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Clockwise |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Counter-clockwise |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Counter-clockwise |

| 3 | 4 | Free shuttle | Get good at Station E | Counter-clockwise |

| 3 | 7 | Free shuttle | Don’t have mission | Counter-clockwise |

| 5 | 5 | Free shuttle | Get goods at Station B | Non-run |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

Table 14.

Details of all the shuttles after the fifth turn.

Table 14.

Details of all the shuttles after the fifth turn.

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Clockwise |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Counter-clockwise |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Counter-clockwise |

| 3 | 4 | Free shuttle | Get good at Station E | Counter-clockwise |

| 3 | 7 | Free shuttle | Don’t have mission | Counter-clockwise |

| 5 | 5 | Free shuttle | Get goods at Station B | Non-run |

| 6 | 6 | Free shuttle | Don’t have mission | Non-run |

Table 15.

Details of the system before having to “find the direction of system” at the time .

Table 15.

Details of the system before having to “find the direction of system” at the time .

| Priority | Shuttle | State of Shuttle | Mission | Direction |

|---|

| 1 | 1 | Need charge shuttle | Go charge at Station A | Not set |

| 2 | 2 | Delivery shuttle | Delivery at Station D | Not set |

| 3 | 3 | Delivery shuttle | Delivery at Station F | Not set |

| 4 | 4 | Free shuttle | Get good at Station E | Not set |

| 5 | 5 | Free shuttle | Get goods at Station B | Not set |

| 6 | 6 | Free shuttle | Don’t have mission | Not set |

| 7 | 7 | Free shuttle | Don’t have mission | Not set |

Table 16.

Information on the shuttles.

Table 16.

Information on the shuttles.

| Shuttle’s Information | Value | Unit |

|---|

| Quantity of shuttles | 3 | pieces |

| Speed of shuttle | 0.3 | m/s |

| Length of shuttle | 0.3 | m |

| Unloading time | 10 | s |

| Loading time | 10 | s |

| Distance minimum between two shuttles | 0.4 | m |

| Battery consumption when moving continuously | 1.39 | %/s |

| Sample time | 0.1 | s |

Table 17.

Informations on the stations.

Table 17.

Informations on the stations.

| Station’s Information | Value | Unit |

|---|

| Quantity of stations | 3 | pieces |

| Changing time of Station | 12 | s |

| Length of station | 0.5 | m |

| Distance between 2 rails in station | 0.5 | m |

Table 18.

Information on the elevators.

Table 18.

Information on the elevators.

| Elevator’s Information | Value | Unit |

|---|

| Quantity of elevator | 2 | pieces |

| Changing time of elevator | 7 | s |

| Length of elevator | 0.5 | m |

| Height between 2 floors | 0.3 | m |

Table 19.

Summary of studies on dynamic routing of OHT vehicles in semiconductor fabs [

26].

Table 19.

Summary of studies on dynamic routing of OHT vehicles in semiconductor fabs [

26].

| Reference | Track Layout | Methodology | Number of OHT |

|---|

| Liao, Jeng, and Zhou [23] | Segregated | Petri nets and integer programming | 20 |

| Huang, Lu, and Fu [25] | Segregated | Markov decision model | 10 |

| Yang et al. [27] | Unified | K-shortest path algorithm | 20 |

| Bartlett et al. [28] | Dijkstra with dynamic edge weight | 250 programming | 6 |