Study on the Rate of the Removal of Nano-Crystalline Diamond—Coated Materials by Femtosecond Laser Etching

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Diamond Coating

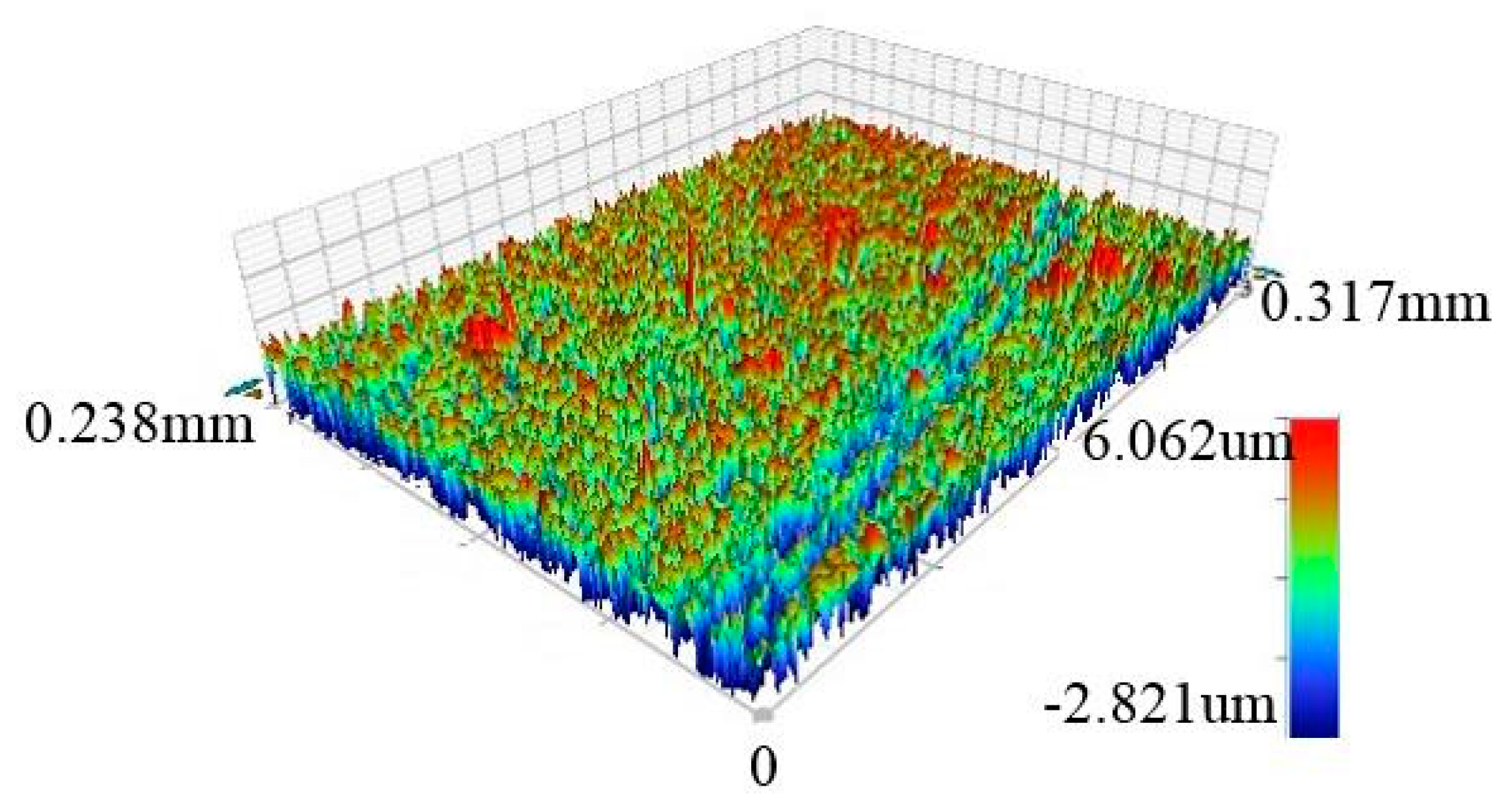

2.2. Surface Roughness of the Coating

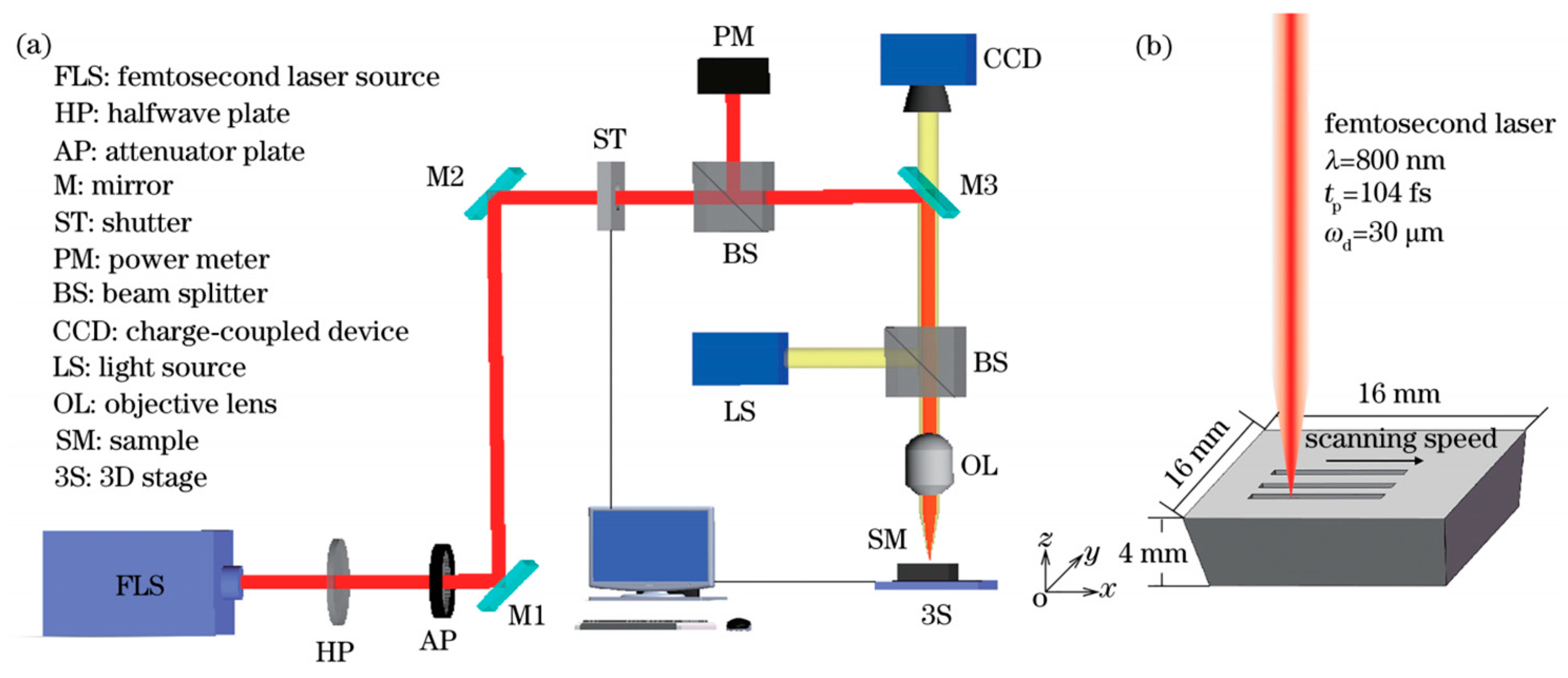

2.3. Processing Equipment and Process

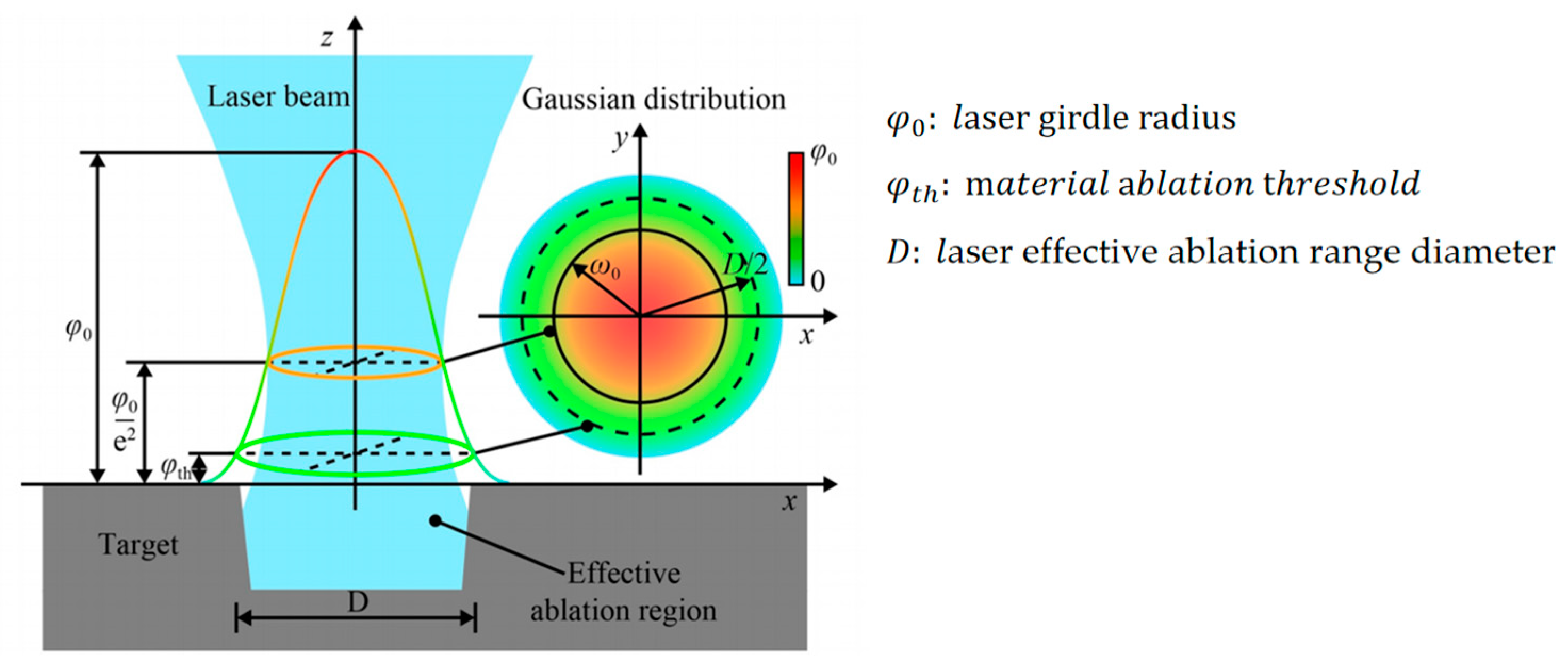

2.4. Modelling of Material Removal Rates and Research on Material Removal Methods

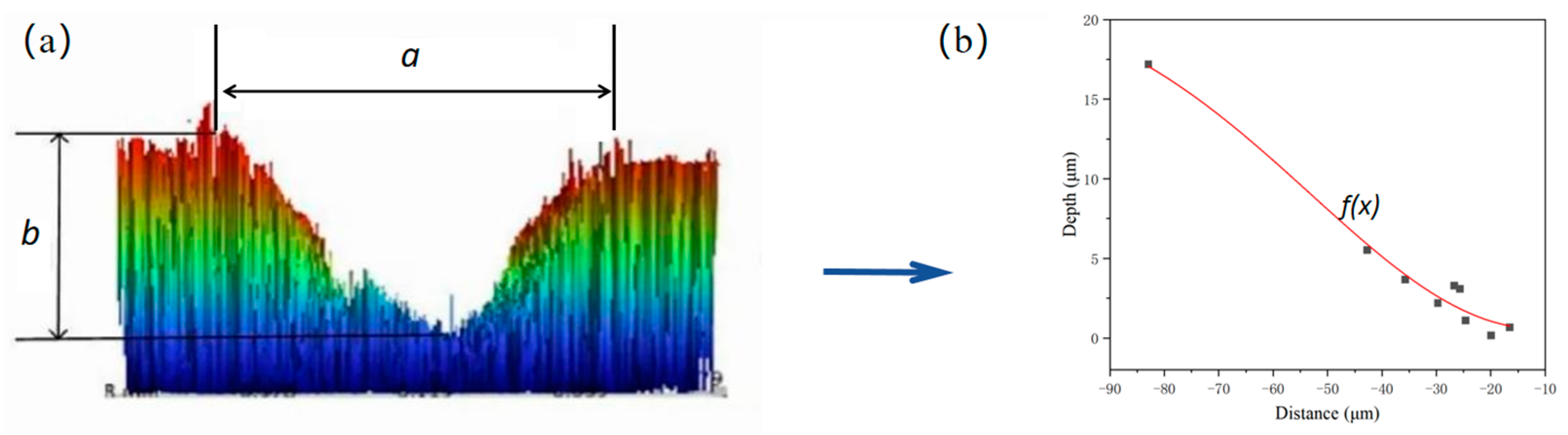

2.4.1. Investigation of the Material Removal Process

2.4.2. Material Removal Rate Modelling

3. Results

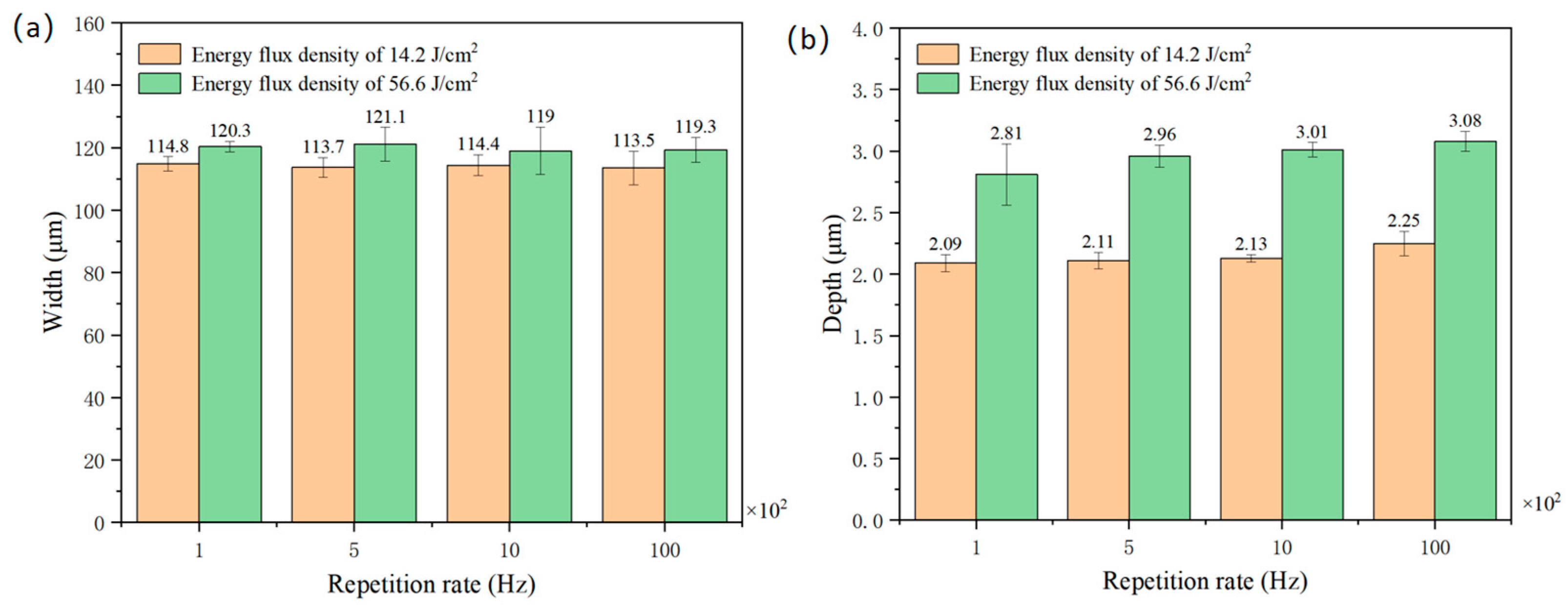

3.1. Effect of Laser Repetition Frequency on the Material Removal Rate

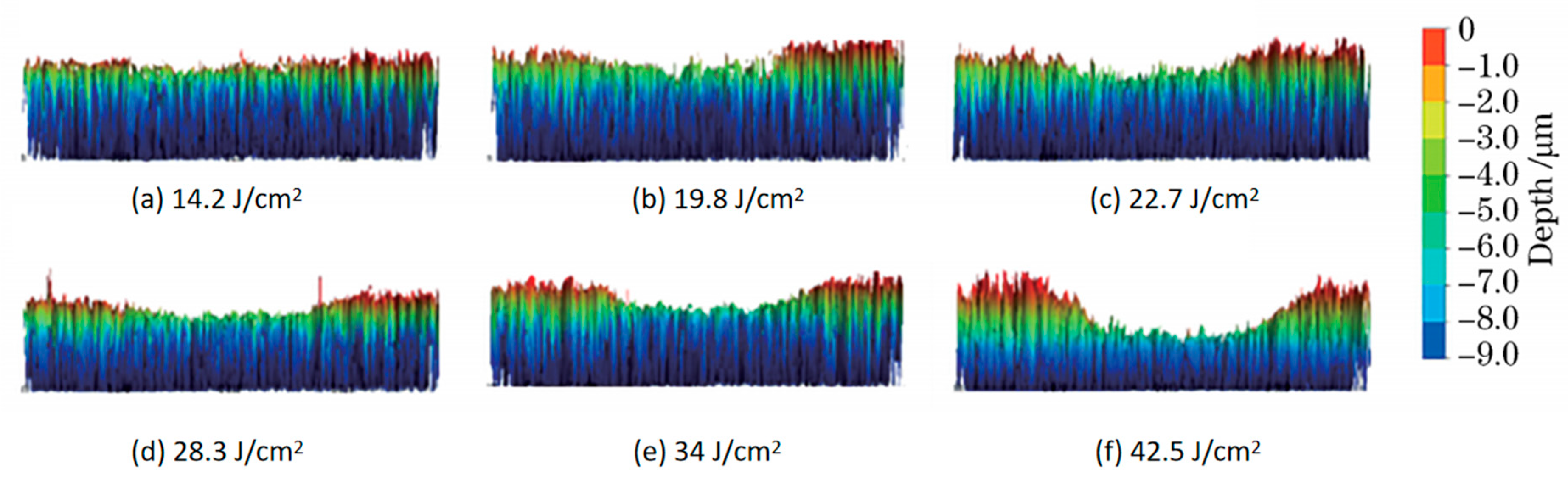

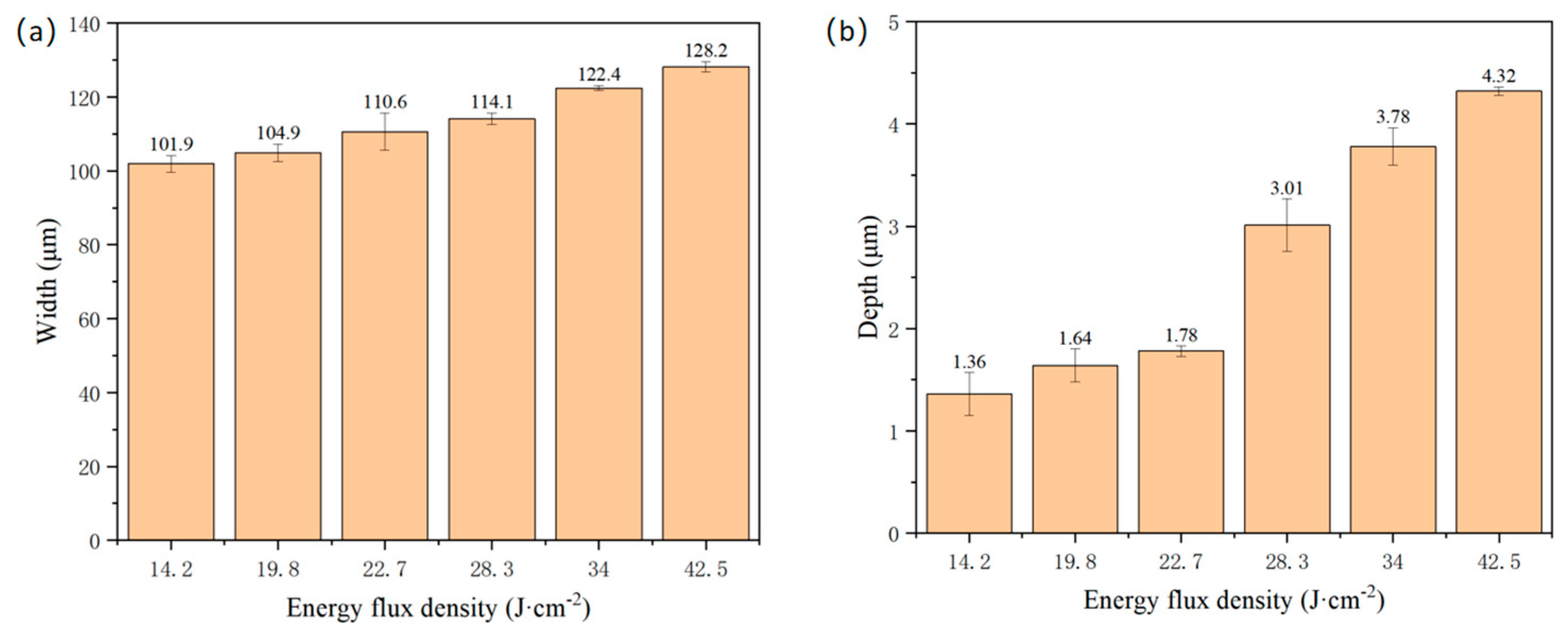

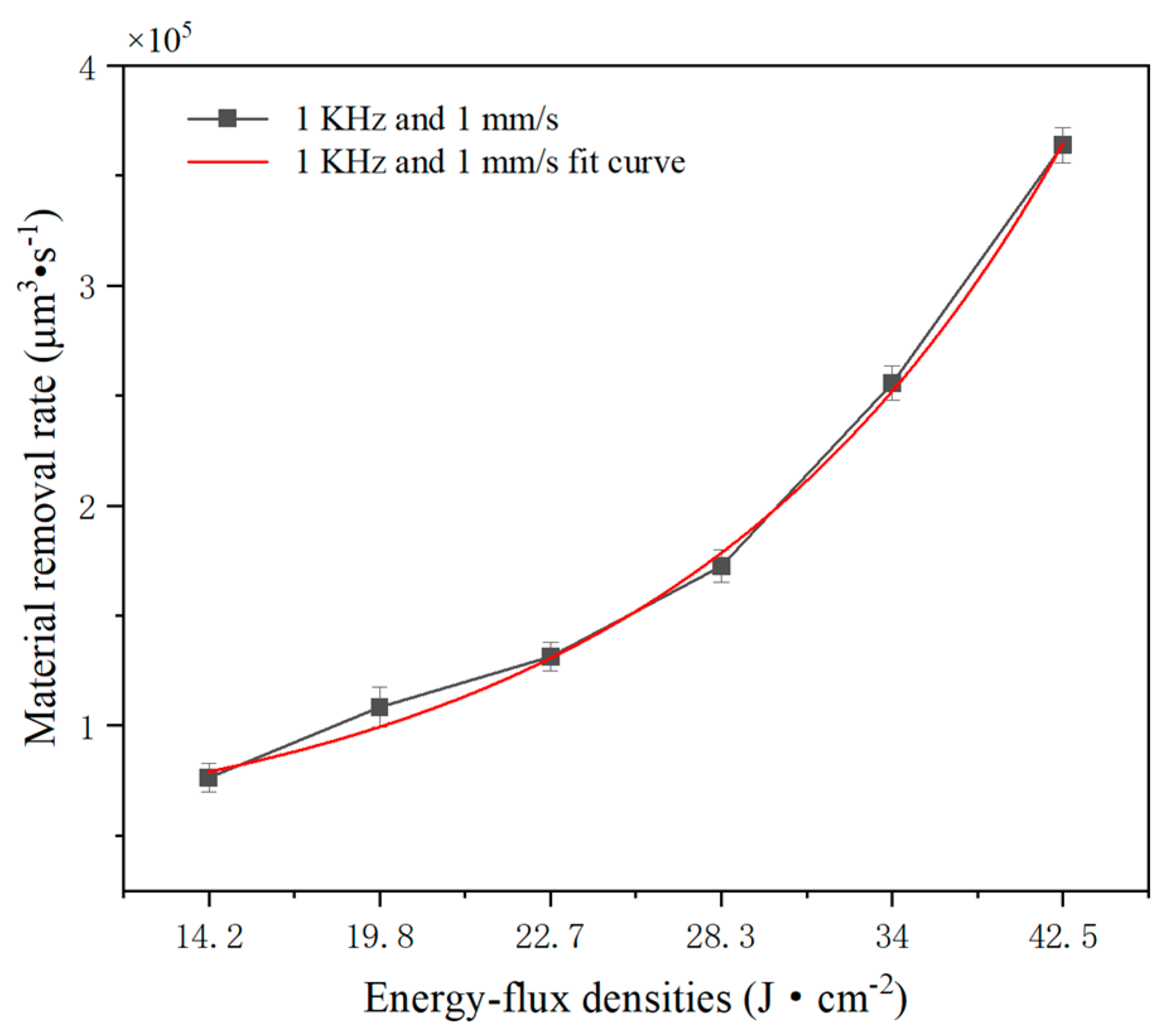

3.2. Effect of the Focused Spot’s Energy−Flux Density on the Pace of Material Removal

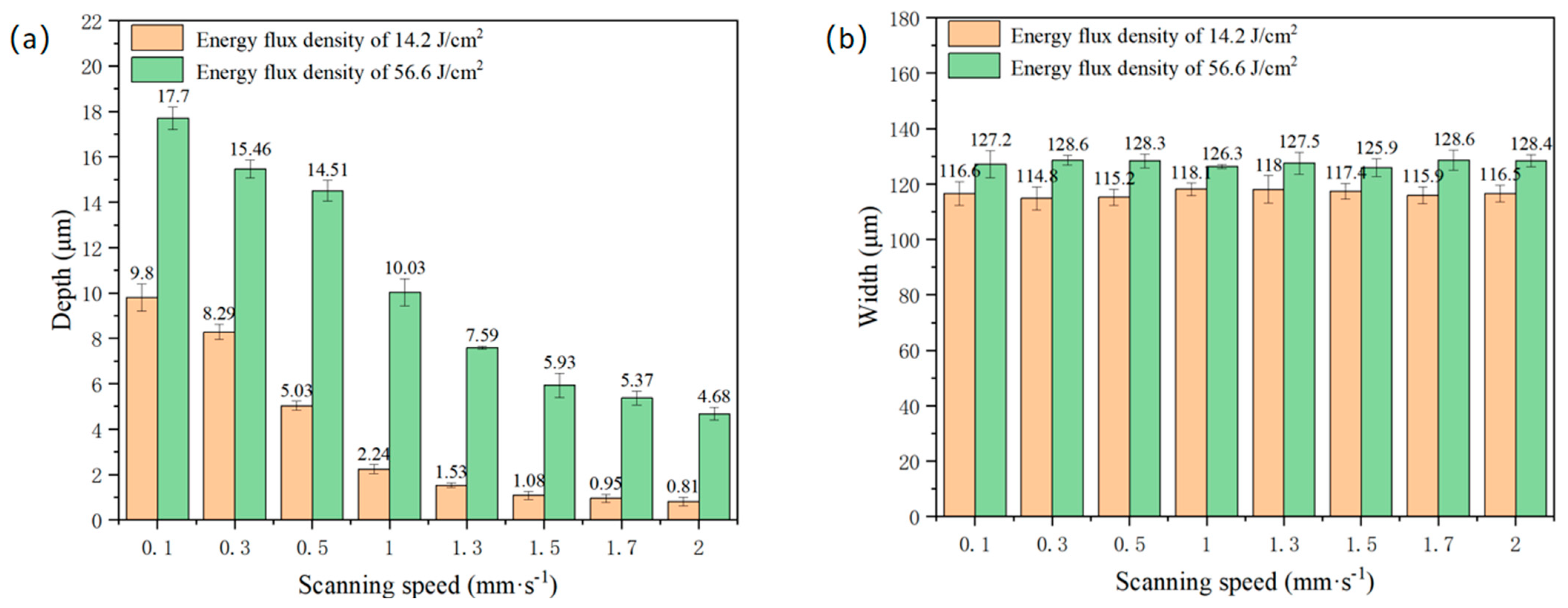

3.3. Effect of Laser Scanning Speed on Material Removal Rate

4. Conclusions

- (1)

- The diamond film’s ablation width and depth at various repetition frequencies do not fluctuate much due to the ablation equilibrium, and the material removal rate tends to be constant when the energy−flux density of the focused point and the scanning speed are known.

- (2)

- After determining the femtosecond laser repetition frequency and scanning speed, the focused spot energy−flux density increases, increasing the femtosecond laser’s etching intensity. This increases the etching width and ablation depth significantly, as well as the rate at which material is removed.

- (3)

- The spot overlap rate reduces as the scanning speed increases, but the laser energy density does not change; therefore, the etching width does not change significantly when the energy−flux density and repetition frequency of the focused spot are known. Due to the plasma shielding effect and the decreased spot overlap rate, the etching depth of the film is greatly lowered. The volume of material removed increases and subsequently falls as the scanning speed increases; the material removal rate is highest at 1 mm/s.

Author Contributions

Funding

Conflicts of Interest

References

- Li, G.; Zhang, B.; Sun, L.; Ren, Y.; Jia, Y.; Chen, F. Femtosecond Laser Micromachining of Cladding Waveguides in KTiOAsO4 Crystal for Second-Harmonic Generation. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2021, 15, 2100345. [Google Scholar] [CrossRef]

- Wu, M.; Guo, B.; Zhao, Q.; He, P.; Zeng, Z.; Zang, J. The influence of the ionization regime on femtosecond laser beam machining mono-crystalline diamond. Opt. Laser Technol. 2018, 106, 34–39. [Google Scholar] [CrossRef]

- Mouhamadali, F.; Equis, S.; Saeidi, F.; Best, J.P.; Cantoni, M.; Hoffmann, P.; Wasmer, K. Nanosecond pulsed laser-processing of CVD diamond. Opt. Lasers Eng. 2020, 126, 105917. [Google Scholar] [CrossRef]

- Xu, F.; Zuo, D.; Wang, M. Study on Mechanical Polishing for CVD Diamond Thick Film and Its Residual Stresses. J. Synth. Cryst. 2004, 33, 436–440. [Google Scholar]

- Ollison, C.D.; Brown, W.D.; Malshe, A.P.; Naseem, H.A.; Ang, S.S. A comparison of mechanical lapping versus chemical-assisted mechanical polishing and planarization of chemical vapor deposited (CVD) diamond. Diam. Relat. Mater. 1999, 8, 1083–1090. [Google Scholar] [CrossRef]

- Jun, R.; Kailiang, Z.; Fang, W.; Yujie, L.; Yujie, Y. Investigation of diamond films polished by thermal chemical mechanical polishing. ECS Trans. 2013, 52, 517. [Google Scholar] [CrossRef]

- Man, W.D.; Wang, J.H.; Wang, C.X.; Wang, S.G.; Xiong, L.W. Planarizing CVD diamond films by using hydrogen plasma etching enhanced carbon diffusion process. Diam. Relat. Mater. 2007, 16, 1455–1458. [Google Scholar] [CrossRef]

- Wang, W.T.; Hu, B.; Wang, M.W. Femtosecond laser fine processing of energetic materials. Acta Phys. Sin. 2013, 62, 69–74. [Google Scholar]

- Ranakoti, L.; Gangil, B.; Rajesh, P.K.; Singh, T.; Sharma, S.; Li, C.; Ilyas, R.A.; Mahmoud, O. Effect of surface treatment and fiber loading on the physical, mechanical, sliding wear, and morphological characteristics of tasar silk fiber waste-epoxy composites for multifaceted biomedical and engineering applications: Fabrication and characterizations. J. Mater. Res. Technol. 2022, 19, 2863–2876. [Google Scholar]

- Ntuli, L.M.; Mulopo, J.; Diale, P. Coupled go–mwcnt composite ink for enhanced dispersibility and synthesis of screen-printing electrodes. Chem. Afr. 2023, 6, 437–448. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Superhydrophobic surfaces fabricated by femtosecond laser with tunable water adhesion: From lotus leaf to rose petal. ACS Appl. Mater. Interfaces 2015, 7, 9858–9865. [Google Scholar] [CrossRef]

- Long, J.; Pan, L.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Cassie-state stability of metallic superhydrophobic surfaces with various micro/nanostructures produced by a femtosecond laser. Langmuir 2016, 32, 1065–1072. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Jin, L.; Yang, B.; Chen, Z.; Zhang, G. Influence of the Internal Structure Type of a Large-Area Lower Exhaust Workbench on Its Surface Air Distribution. Int. J. Environ. Res. Public Health 2022, 19, 11395. [Google Scholar] [CrossRef] [PubMed]

- Wu Mn, S.C.W.; Huang, Y.H. Cause of femtosecond laser ablation inducing defect of polystyrene. Laser Infrared 2017, 47, 1089–1095. [Google Scholar]

- Yasumaru, N.; Miyazaki, K.; Kiuchi, J.; Magara, H. Nanoscale modification of DLC film surfaces with femtosecond laser pulses. In Proceedings of the Fifth International Symposium on Laser Precision Microfabrication, Nara, Japan, 11–14 May 2004; Volume 5662, pp. 755–759. [Google Scholar]

- Jia, X.; Jia, T.; Zhang, S.; Sun, Z.; Qiu, J.; Xu, Z. Manipulation of cross-linked micro/nanopatterns on ZnO by adjusting the femtosecond-laser polarizations of four-beam interference. Appl. Phys. A 2014, 114, 1333–1338. [Google Scholar] [CrossRef]

- Wei, J.; Yuan, S.; Zhang, J.; Zhou, N.; Zhang, W.; Li, J.; An, W.; Fu, Y. Removal mechanism of SiC/SiC composites by underwater femtosecond laser ablation. J. Eur. Ceram. Soc. 2022, 42, 5380–5390. [Google Scholar] [CrossRef]

- Shrestha, R.; Zhan, Z.B.; He, N.; Li, L. Optimization of the grinding parameters for CVD diamond micro-tools. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2014; Volume 800, pp. 633–638. [Google Scholar]

- Lin, Y.; Gupta, M.C.; Taylor, R.E.; Lei, C.; Stone, W.; Spidel, T.; Yu, W.; Williams, R. Nanosecond pulsed laser micromachining for experimental fatigue life study of Ti–3Al–2.5 V tubes. Opt. Lasers Eng. 2009, 47, 118–122. [Google Scholar] [CrossRef]

- Yao, X. Switchable linear-cavity nanotube-mode-locking fiber laser emitting picosecond or femtosecond pulses. Opt. Commun. 2015, 335, 262–265. [Google Scholar] [CrossRef]

- Dong, Z.W.; Zhang, W.B.; Zheng, L.W.; Jiang, T.; Fan, G.X.; Zhao, X.; Zhao, Q.L.; Chen, D.Y.; Xia, Y.Q. Processing of diamond applying femtosecond and nanosecond laser pulses. Infrared Laser Eng. 2015, 44, 893–896. [Google Scholar]

- Ma, S.; Zheng, J.; Wang, S.; Xu, M.; Li, Y. All-Optical Bistability in Grating Coupling to Nonlinear Waveguide. Chin. J. Lasers B 1998, 7, 333. [Google Scholar]

- Xiong, B.; Chen, G.; Yin, J.; Zhou, C.; Hu, B. Experimental research on conical array of single crystal diamond based on femtosecond laser. Appl. Laser 2018, 38, 270. [Google Scholar]

- Aoki, T.; Gnatyuk, D.V.; Odarych, V.A.; Poperenko, L.V.; Yurgelevych, I.V.; Levytskyi, S.N. Influence of nanosecond laser irradiation on optical properties of surface layers of CdTe crystals. Thin Solid Films 2011, 519, 2834–2837. [Google Scholar] [CrossRef]

- Lu, F.; Zha, L.Q.; Liu, L.S. Research on preparation and cutting performance of diamond-coated cemented carbide tools used in hard brittle material machining. Rare Met. Cem. Carbides 2018, 46, 78–82. [Google Scholar]

- Dumpala, R.; Chandran, M.; Kumar, N.; Dash, S.; Ramamoorthy, B.; Rao, M.R. Growth and characterization of integrated nano-and microcrystalline dual layer composite diamond coatings on WC–Co substrates. Int. J. Refract. Met. Hard Mater. 2013, 37, 127–133. [Google Scholar] [CrossRef]

- Wang, X.C.; Wang, C.C.; Sun, F.H.; Shen, B. Fabrication, polishing and application of diamond coated compacting die with sector-shaped hole. Chin. Surf. Eng. 2016, 29, 75–82. [Google Scholar]

- Zhao, J.H.; Li, C.H.; Xu, J.J.; Hao, Y.W.; Li, X.B. Surface modification of nanostructured ZnS by femtosecond laser pulsing. Appl. Surf. Sci. 2014, 293, 332–335. [Google Scholar] [CrossRef]

- Peng, E.; Tsubaki, A.; Zuhlke, C.A.; Wang, M.; Bell, R.; Lucis, M.J.; Anderson, T.P.; Alexander, D.R.; Gogos, G.; Shield, J.E. Micro/nanostructures formation by femtosecond laser surface processing on amorphous and polycrystalline Ni60Nb40. Appl. Surf. Sci. 2017, 396, 1170–1176. [Google Scholar] [CrossRef]

- Yu, Z.; Cai, Q.; Wang, X.; Xu, J.; Yu, H. Preparation of micro-textured turning tools and high speed micro turning test of SUS304 steel. China Surf. Eng. 2016, 29, 1–7. [Google Scholar]

- Cunha, A.; Elie, A.M.; Plawinski, L.; Serro, A.P.; do Rego AM, B.; Almeida, A.; Urdaci, M.C.; Durrieu, M.-C.; Vilar, R. Femtosecond laser surface texturing of titanium as a method to reduce the adhesion of Staphylococcus aureus and biofilm formation. Appl. Surf. Sci. 2016, 360, 485–493. [Google Scholar] [CrossRef]

- Xiang, D.; Chen, Y.; Guo, Z.; Feng, H.; Wu, B.; Niu, X. Influence of textured diamond film on tribological properties of cemented carbide substrate. Int. J. Refract. Met. Hard Mater. 2019, 78, 303–309. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis. Eng. 2012, 36, 229–237. [Google Scholar] [CrossRef]

- Wang, X.C.; Lim, G.C.; Zheng, H.Y.; Ng, F.L.; Liu, W.; Chua, S.J. Femtosecond pulse laser ablation of sapphire in ambient air. Appl. Surf. Sci. 2004, 228, 221–226. [Google Scholar] [CrossRef]

- Corkum, P.B.; Brunel, F.; Sherman, N.K.; Srinivasan-Rao, T. Thermal response of metals to ultrashort-pulse laser excitation. Phys. Rev. Lett. 1988, 61, 2886–2889. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wei, C.; Zhang, Y.; Li, X.; Chen, X. Effects of Femtosecond Laser Ablation on Surface Micro-properties of Nano-crystalline Diamond Coating. China Surf. Eng. 2019, 32, 1–10. [Google Scholar]

- Bulgakova, N.M.; Burakov, I.M.; Meshcheryakov, Y.P.; Stoian, R.; Rosenfeld, A.; Hertel, I.V. Theoretical models and qualitative interpretations of fs laser material processing. J. Laser Micro/Nanoeng. 2007, 2, 76–86. [Google Scholar] [CrossRef]

- Chen, J.Y.; Li, Z.Y.; Wang, H.D. Femtosecond laser ablation of nano twinned diamond. Manuf. Technol. Mach. Tool 2019, 3, 78–82. [Google Scholar]

- Sugihara, T.; Singh, P.; Enomoto, T. Development of novel cutting tools with dimple textured surfaces for dry machining of aluminum alloys. Procedia Manuf. 2017, 14, 111–117. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ota, M.; Nakamoto, K.; Fukaya, T.; Russell, M.; Zohdi, T.I.; Yamazaki, K.; Aoyama, H. A study on machining of binder-less polycrystalline diamond by femtosecond pulsed laser for fabrication of micro milling tools. CIRP Ann. 2016, 65, 245–248. [Google Scholar] [CrossRef]

- Plech, A.; Kotaidis, V.; Lorenc, M.; Boneberg, J. Femtosecond laser near-field ablation from gold nanoparticles. Nat. Phys. 2006, 2, 44–47. [Google Scholar] [CrossRef]

- Pecholt, B.; Vendan, M.; Dong, Y.; Molian, P. Ultrafast laser micromachining of 3C-SiC thin films for MEMS device fabrication. Int. J. Adv. Manuf. Technol. 2008, 39, 239–250. [Google Scholar] [CrossRef]

- von der Linde, D.; Tinten, K.S. The physical mechanisms of short-pulse laser ablation. Appl. Surf. Sci. 2000, 154, 1–10. [Google Scholar] [CrossRef]

- Kim, B.; Iida, R.; Doan, H.D.; Fushinobu, K. Mechanism of TCO thin film removal process using near-infrared ns pulse laser: Plasma shielding effect on irradiation direction. Int. J. Heat Mass Transf. 2016, 102, 77–85. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, V. Laser beam micromachining (LBMM)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

| Index | Deposition Parameters |

|---|---|

| Deposition pressure of chemical vapor (KPa) Acetone/hydrogen/argon (nmL · min−1) | 1.8 50/250/250 |

| Applied voltage of tantalum wire (V) Additional bias current (A) Tantalum wire–substrate spacing (mm) Temperature of vapor deposition (°C) Substrate temperature (°C) Time of vapor deposition (h) | 20 2 10 450 700 7 |

| Power (mW) | 50 | 70 | 80 | 100 | 120 | 150 |

| Energy−flux density (J·cm−2) | 14.2 | 19.8 | 22.7 | 28.3 | 34.0 | 42.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, L.; Ma, Y.; Cao, H.; Zhang, X.; Han, Y.; Wei, C. Study on the Rate of the Removal of Nano-Crystalline Diamond—Coated Materials by Femtosecond Laser Etching. Appl. Sci. 2023, 13, 9864. https://doi.org/10.3390/app13179864

Ren L, Ma Y, Cao H, Zhang X, Han Y, Wei C. Study on the Rate of the Removal of Nano-Crystalline Diamond—Coated Materials by Femtosecond Laser Etching. Applied Sciences. 2023; 13(17):9864. https://doi.org/10.3390/app13179864

Chicago/Turabian StyleRen, Lujun, Yuping Ma, Haisong Cao, Xingxing Zhang, Yuan Han, and Chao Wei. 2023. "Study on the Rate of the Removal of Nano-Crystalline Diamond—Coated Materials by Femtosecond Laser Etching" Applied Sciences 13, no. 17: 9864. https://doi.org/10.3390/app13179864

APA StyleRen, L., Ma, Y., Cao, H., Zhang, X., Han, Y., & Wei, C. (2023). Study on the Rate of the Removal of Nano-Crystalline Diamond—Coated Materials by Femtosecond Laser Etching. Applied Sciences, 13(17), 9864. https://doi.org/10.3390/app13179864