The Characteristics of Acoustic Emissions Due to Gas Leaks in Circular Cylinders: A Theoretical and Experimental Investigation

Abstract

:1. Introduction

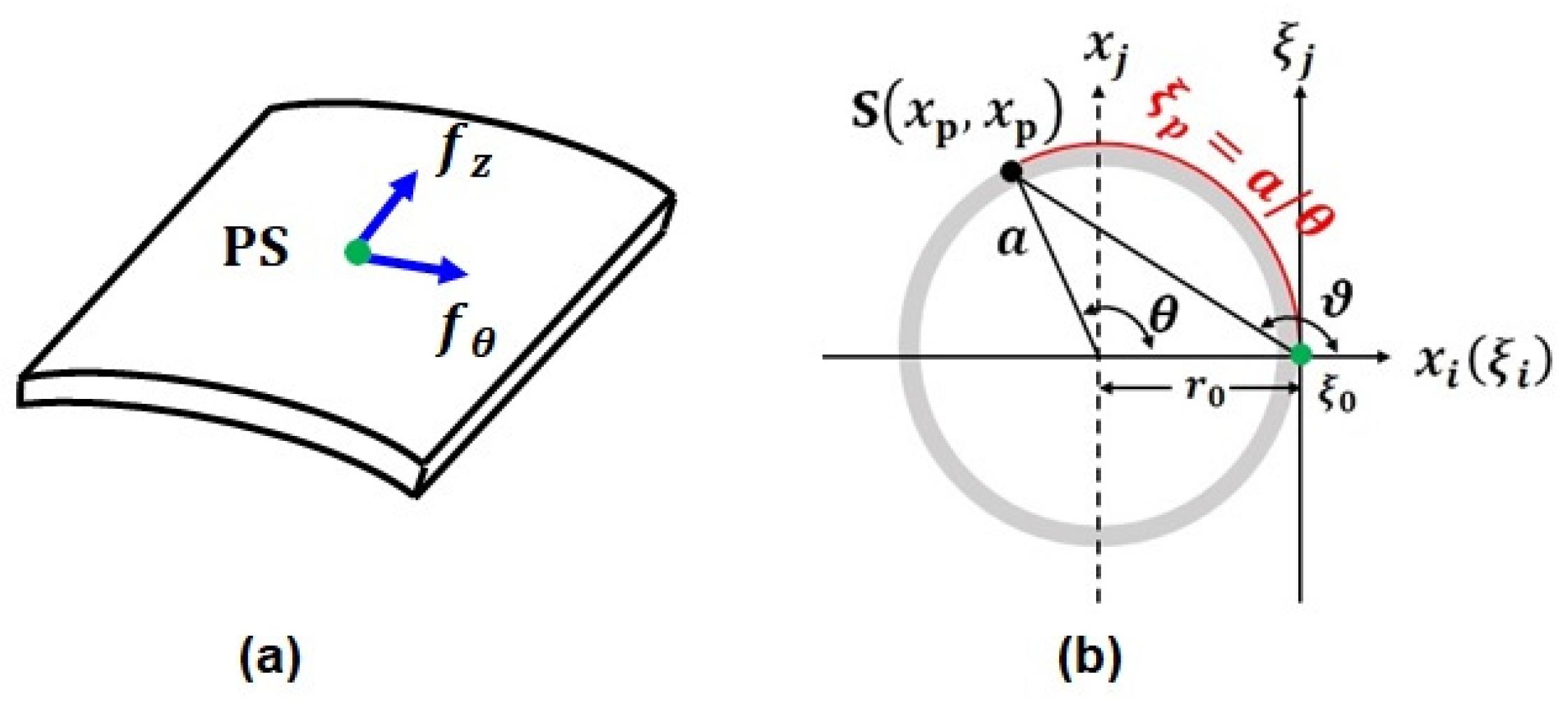

2. Analytical Model

2.1. Fluctuating Reynolds Stress as Point Source

2.2. Displacement Fields

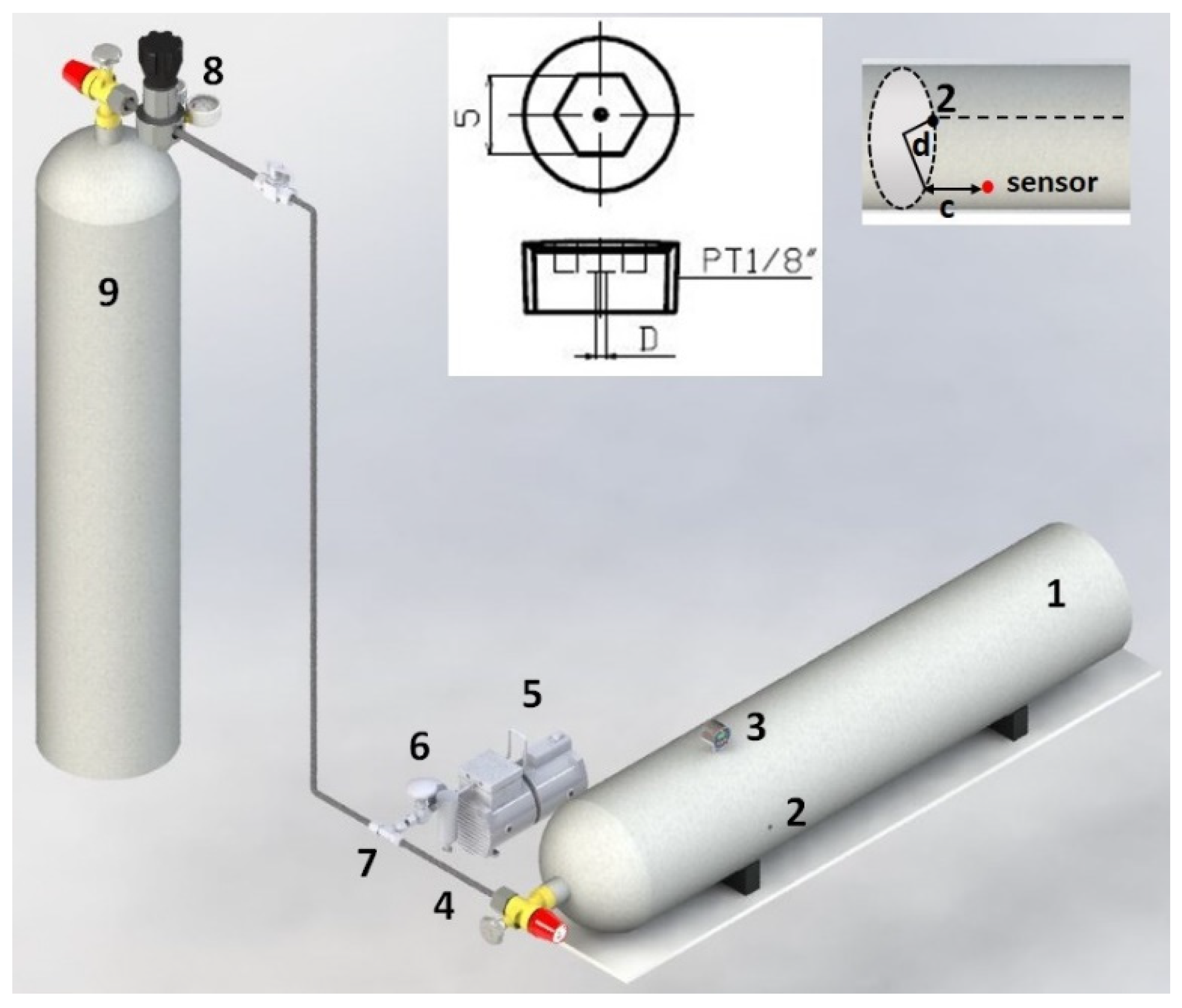

3. Experiment

4. Results and Discussion

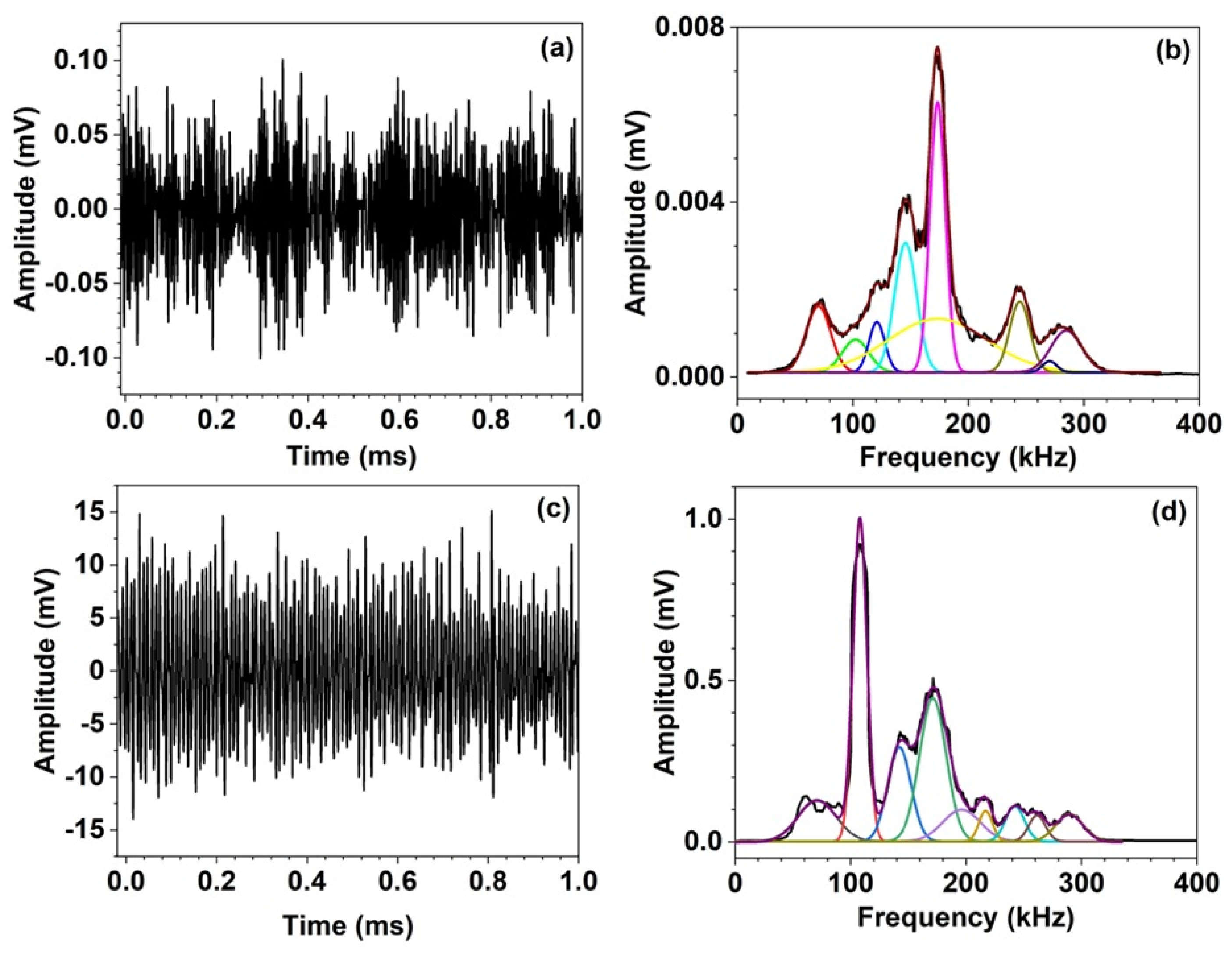

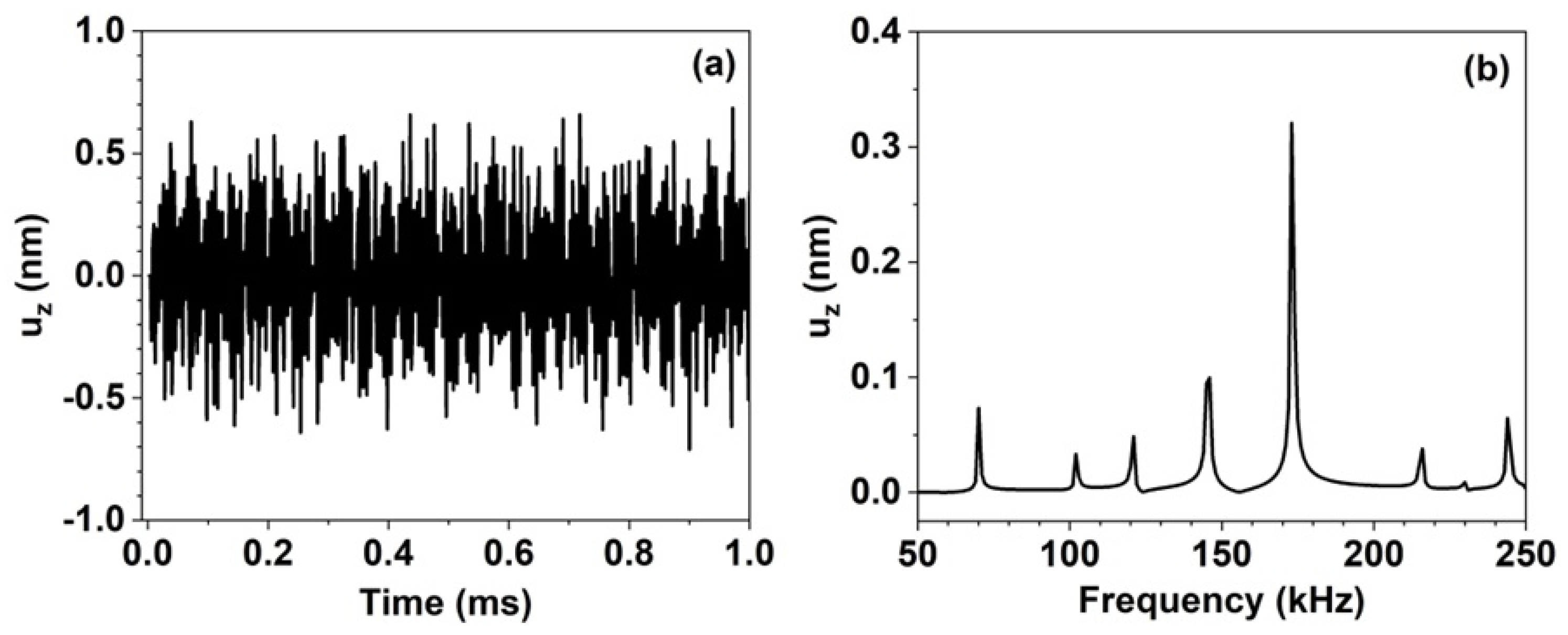

4.1. AE Properties

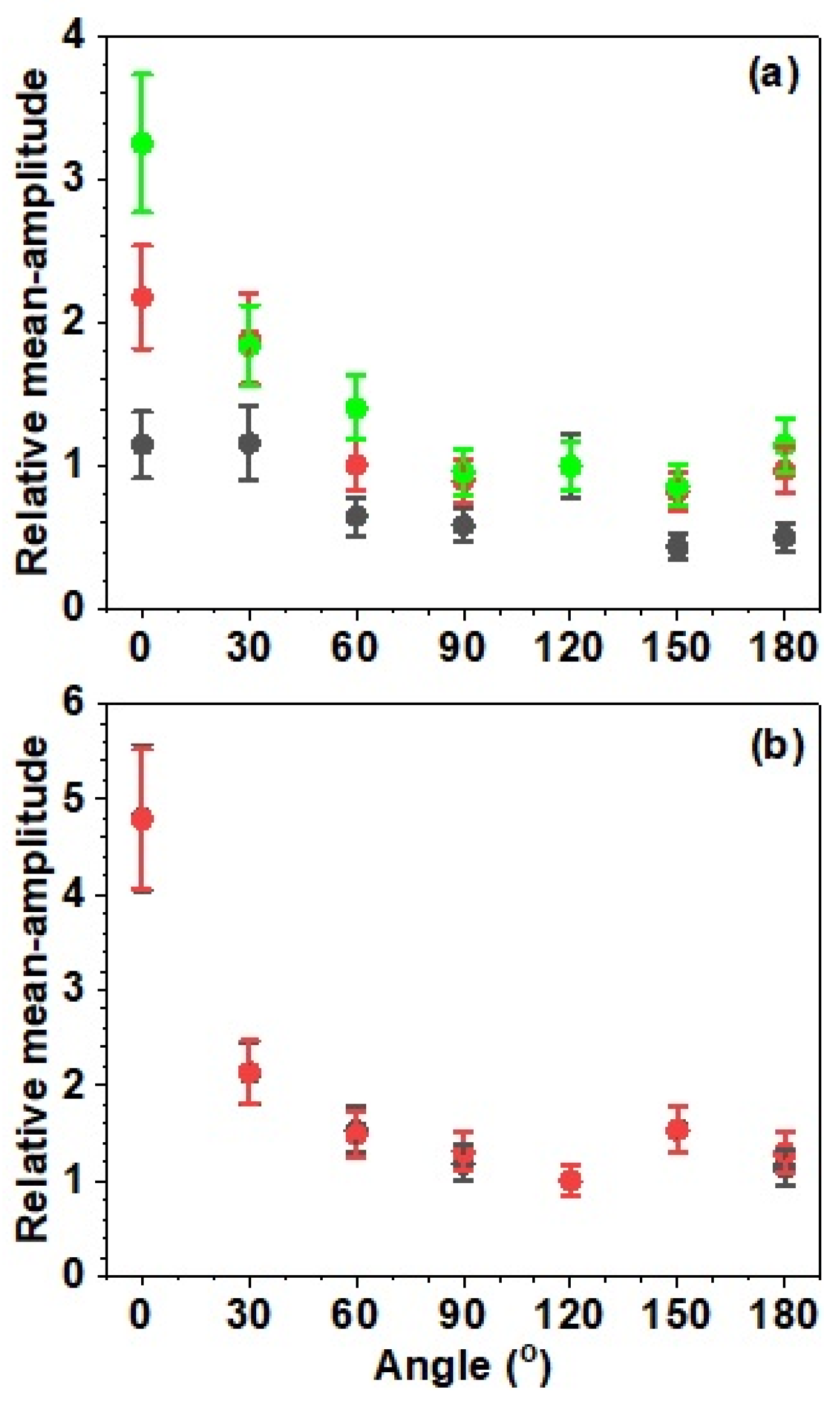

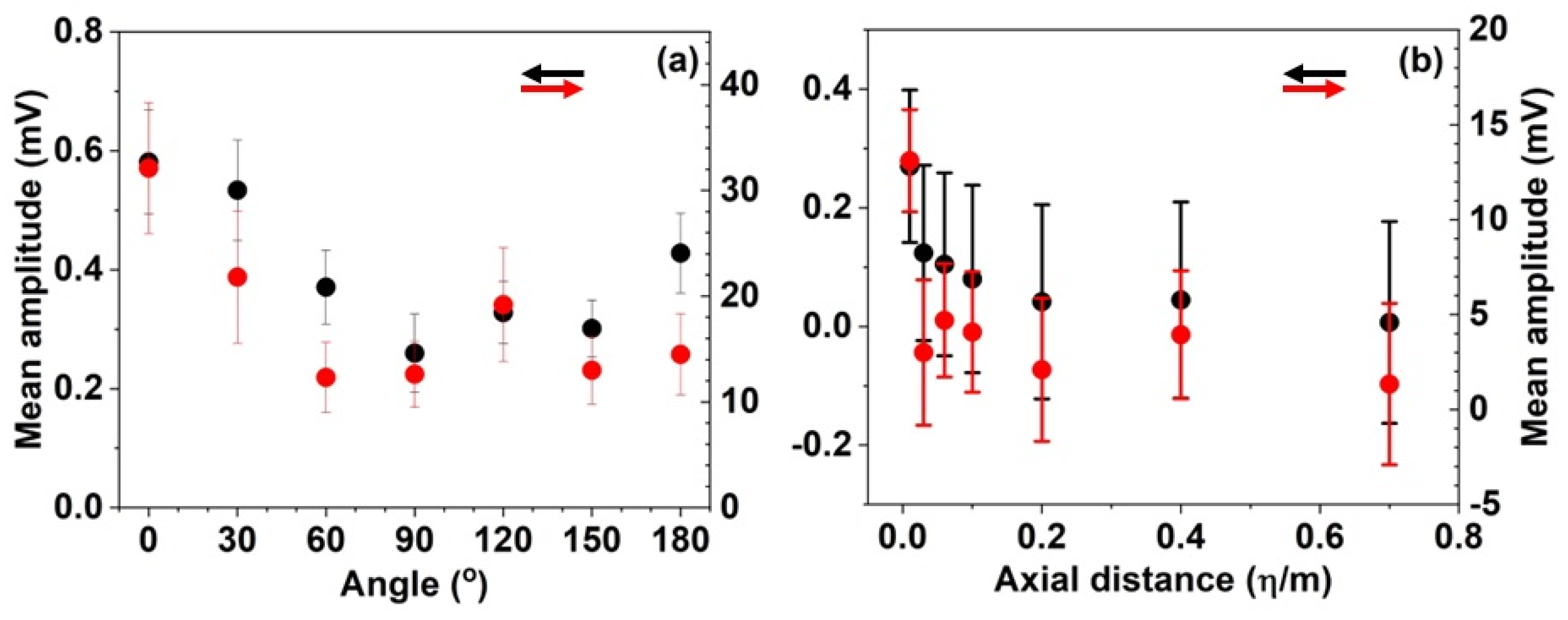

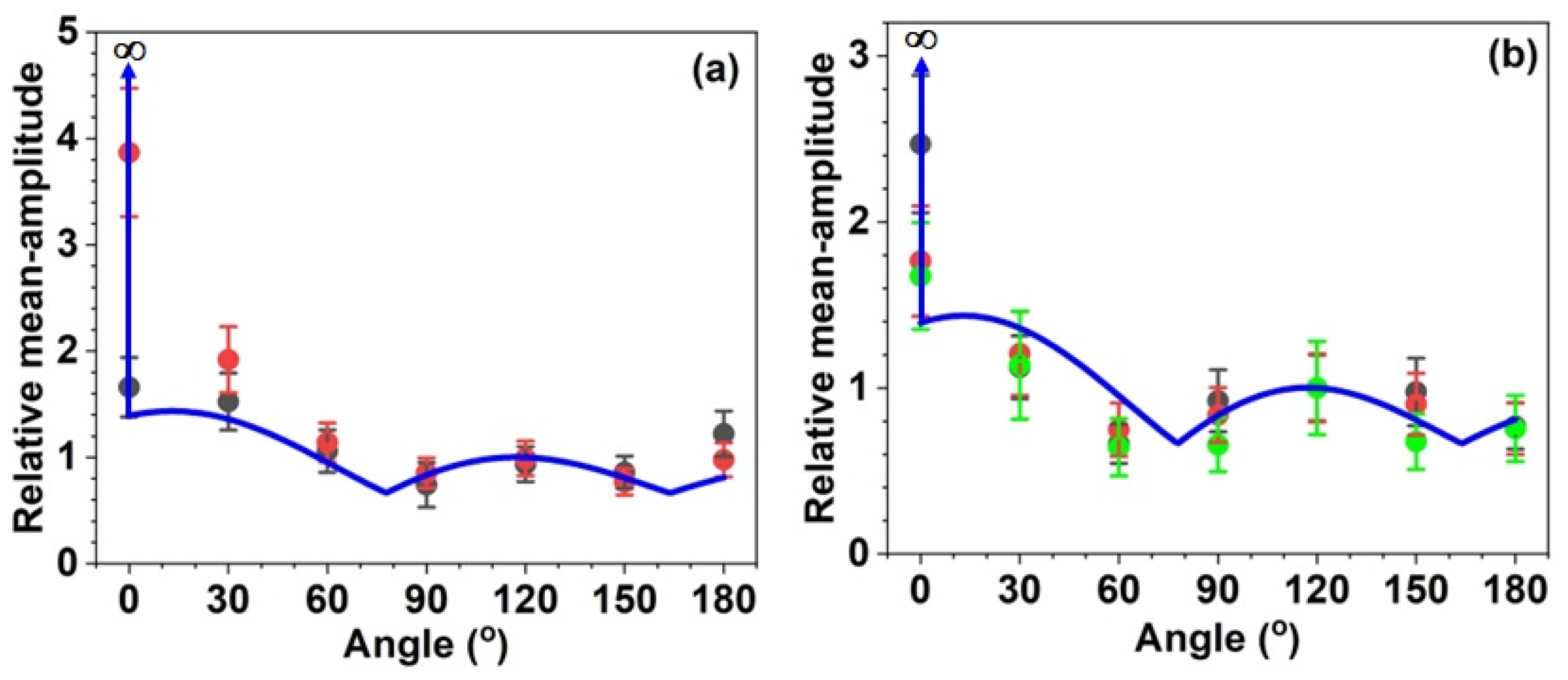

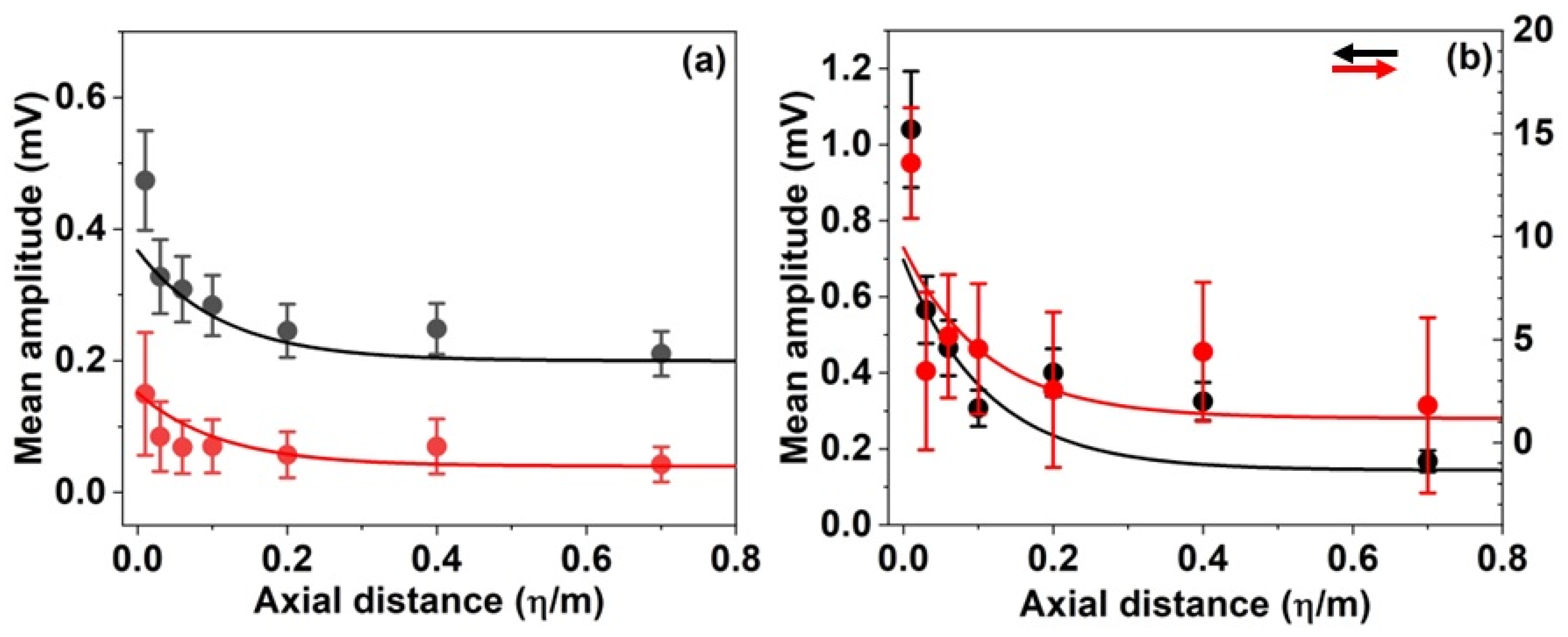

4.2. Angular and Axial Dependence

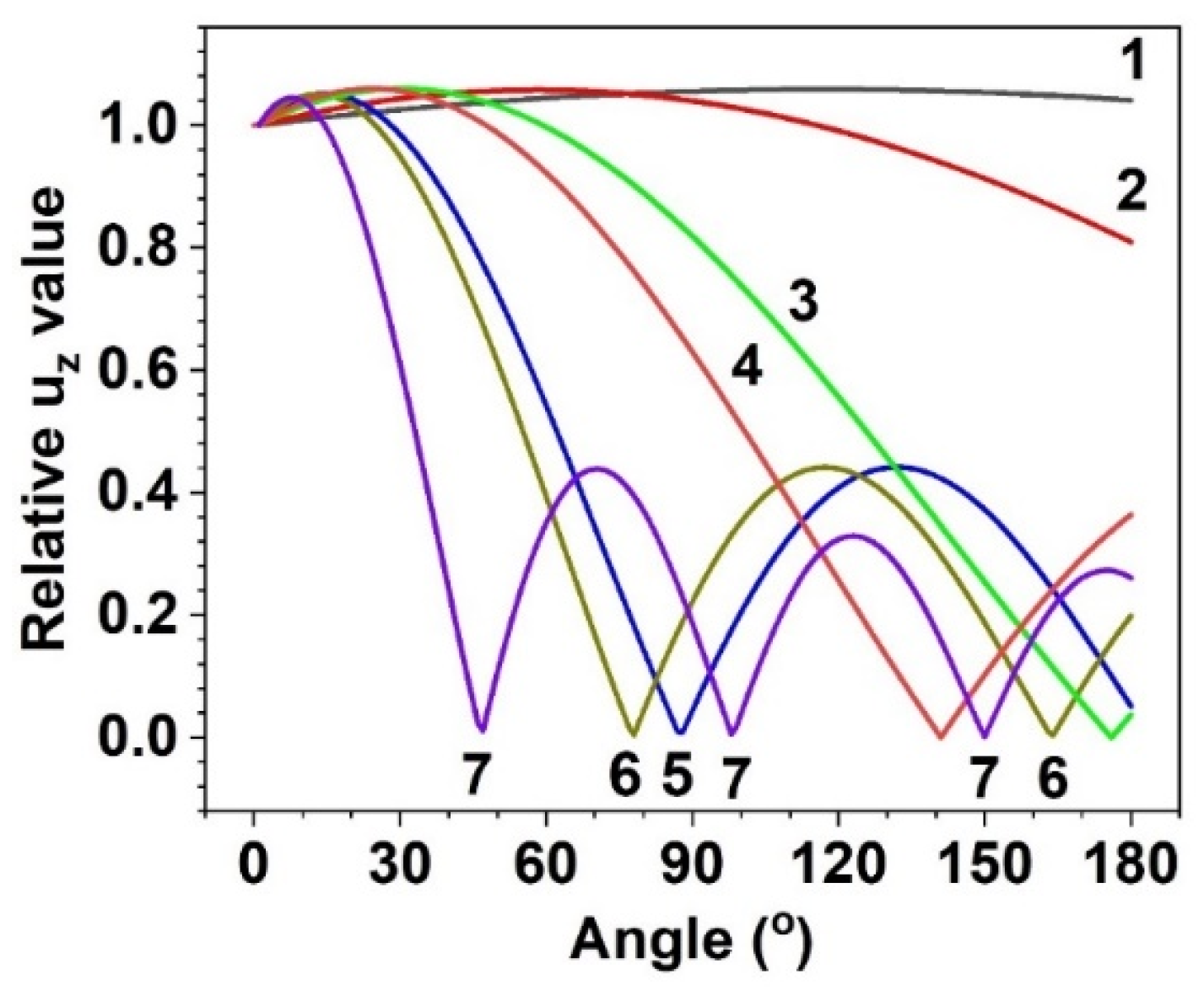

4.3. Verification of CFIP Model

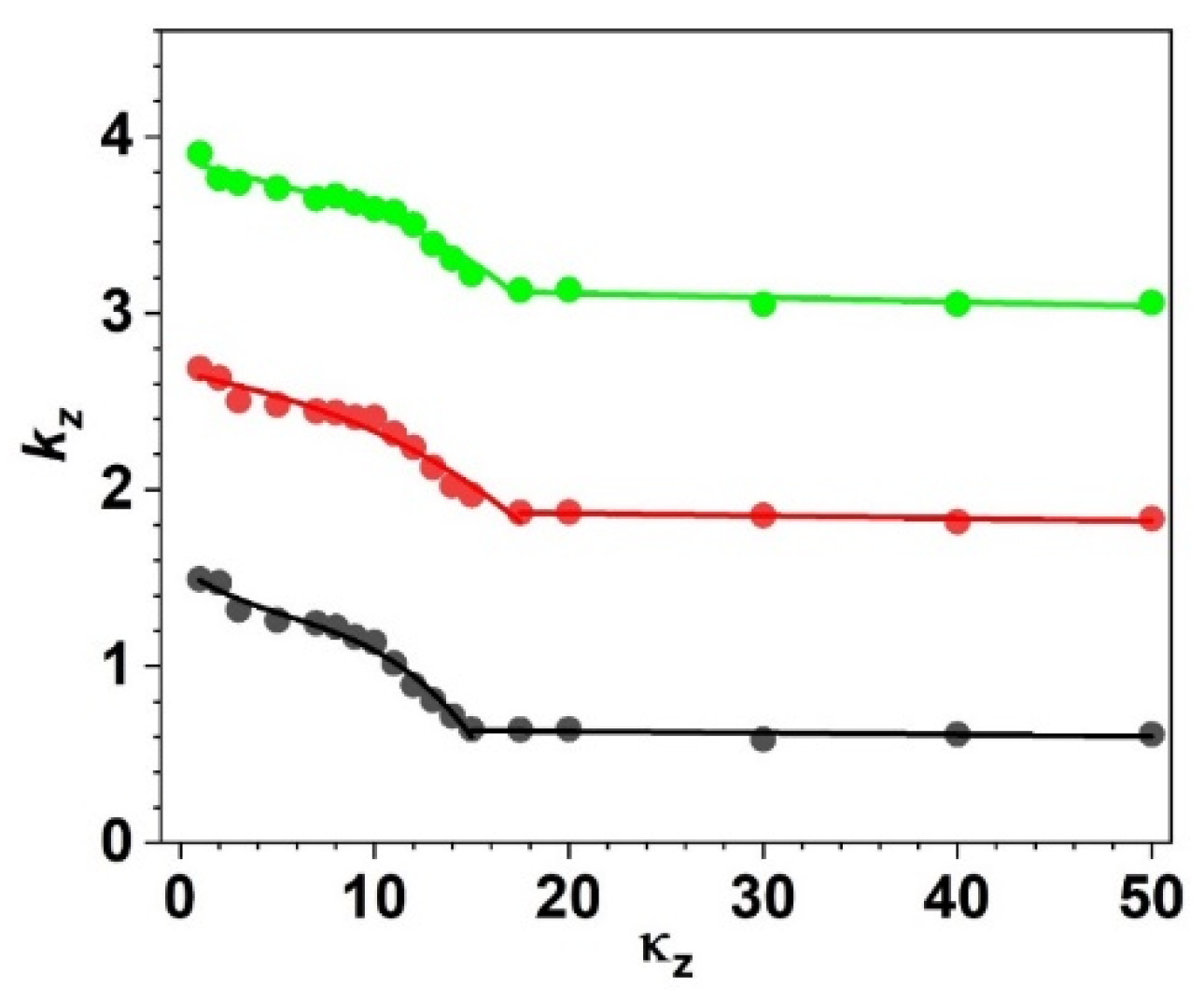

4.3.1. Determination of

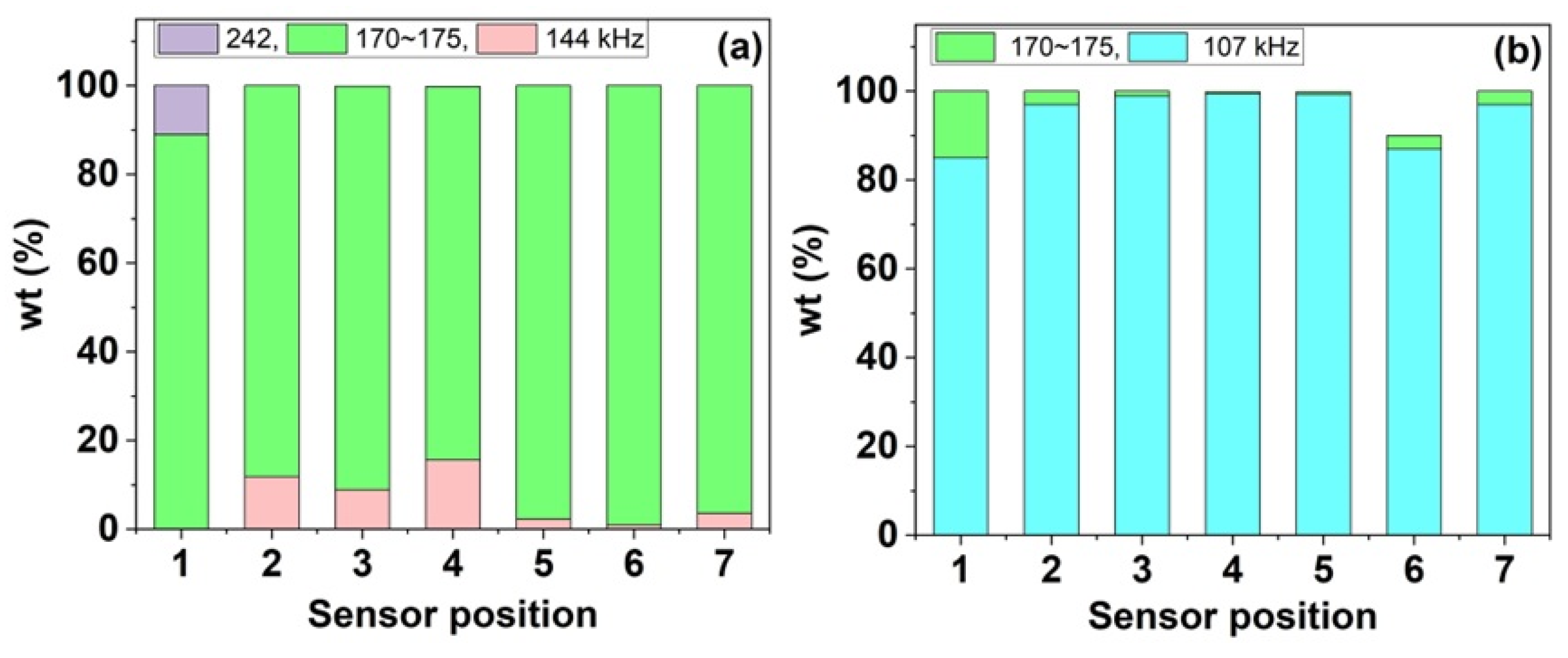

4.3.2. Multi-Frequency AE

4.3.3. Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Korlapatia, N.V.S.; Khana, F.; Noora, Q.; Mirza, S.; Vaddiraju, S. Review and Analysis of Pipeline Leak Detection Methods. J. Pipeline Sci. Eng. 2022, 2, 100074. [Google Scholar] [CrossRef]

- Reddy, R.S.; Payal, G.; Karkulali, P.; Himanshu, M.; Ukil, A.; Dauwels, J. Pressure and Flow Variation in Gas Distribution PipeLine for Leak Detection. In Proceedings of the IEEE International Conference on Industrial Technology, Taipei, Taiwan, 14–17 March 2016. [Google Scholar]

- Tian, X.; Jiao, W.; Liu, T. Intelligent Leak Detection Method for Low-pressure Gas Pipeline inside Buildings Based on Pressure Fluctuation Identification. J. Civ. Struct. Health Monit. 2022, 12, 1191–1208. [Google Scholar] [CrossRef]

- Huang, S.C.; Lin, W.W.; Tsai, M.T.; Chen, M.H. Fiber Optic In-Line Distributed Sensor for Detection and Localization of the Pipeline Leaks. Sens. Actuators A Phys. 2007, 135, 570–579. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.-M. Pipeline Leak Detection Using Acoustic Emission and State Estimate in Feature Space. IEEE Trans. Inst. Meas. 2022, 71, 2518709. [Google Scholar] [CrossRef]

- Brunner, A.J.; Barbezat, M. Acoustic Emission Leak Testing of Pipes for Pressurized Gas Using Active Fiber Composite Elements as Sensors. J. Acoust. Emiss. 2007, 25, 42–50. [Google Scholar]

- Xiao, R.; Joseph, P.; Li, J. The Leak Noise Spectrum in Gas Pipeline Systems: Theoretical and Experimental Investigation. J. Sound Vib. 2020, 488, 115646. [Google Scholar] [CrossRef]

- Putra, I.B.A.; Prasetiyo, I.; Sari, D.P. The Use of Acoustic Emission for Leak Detection in Steel Pipes. Appl. Mech. Mater. 2015, 771, 88–91. [Google Scholar] [CrossRef]

- Meribout, M. Gas Leak-Detection and Measurement Systems: Prospects and Future Trends. IEEE Trans. Inst. Meas. 2021, 70, 4505813. [Google Scholar] [CrossRef]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental Study on Leak Detection and Location for Gas Pipeline Based on Acoustic Method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Ullah, N.; Ahmed, Z.; Kim, J.-M. Pipeline Leakage Detection Using Acoustic Emission and Machine Learning Algorithms. Sensors 2023, 23, 3226. [Google Scholar] [CrossRef] [PubMed]

- Quy, T.B.; Kim, J.-M. Real-Time Leak Detection for a Gas Pipeline Using a k-NN Classifier and Hybrid AE Features. Sensors 2021, 21, 367. [Google Scholar] [CrossRef] [PubMed]

- Lighthill, M.J. On Sound Generated Aerodynamically. I. General Theory. Proc. R. Soc. A 1952, 211, 564–587. [Google Scholar]

- Pollock, A.A.; Pepper, C.E. Quantitative Analysis of Acoustic Emission from Gas Leaks in a Model Piping System. Rev. Prog. Quant. Nondestruct. Eval. 1999, 18, 427–434. [Google Scholar]

- Yoshida, K.; Akematsu, Y.; Sakamaki, K.; Horikawa, K. Effect of Pinhole Shape with Divergent Exit on AE Characteristics during Gas Leak. J. Acoust. Emiss. 2003, 21, 223–229. [Google Scholar]

- Laodeno, R.N.; Nishino, H.; Yoshida, K. Characterization of AE Signals Generated by Gas Leak on Pipe with Artificial Defect at Different Wall Thickness. Mater. Trans. 2008, 49, 2341–2346. [Google Scholar] [CrossRef]

- Mostafapour, A.; Davoudi, S. Analysis of Leakage in High Pressure Pipe Using Acoustic Emission Method. Appl. Acoust. 2013, 74, 335–342. [Google Scholar] [CrossRef]

- Kim, K.B.; Kim, B.K.; Kang, J.-G. Modeling Acoustic Emission Due to an Internal Point Source in Circular Cylindrical Structures. Appl. Sci. 2022, 12, 12032. [Google Scholar] [CrossRef]

- Morse, P.M.; Feshbach, H. Methods of Theoretical Physics; McGraw-Hill: New York, NY, USA, 1953; pp. 1764–1767. [Google Scholar]

- Brennen, C.E. An Internet Book on Fluid Dynamics. 2006. Available online: http://brennen.caltech.edu/fluidbook/basicfluiddynamics/turbulence.htm (accessed on 20 August 2023).

- Bomelburg, H.J. Estimation of Gas Leak Rates Through Very Small Orifices and Channels; BNWL-2223-77; Pacific Northwest Laboratory: Richland, WA, USA, 1977. [Google Scholar]

- Bariha, N.; Mishra, I.M.; Srivastava, V.C. Harzard Analysis of Failure of Natural Gas and Petroleum Gas Pipelines. J. Loss Prev. Process Ind. 2016, 40, 217–226. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, P.; Zhuang, Y.; Wu, X.; Liu, Y.; Han, X.; Chen, G. An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space. Appl. Sci. 2022, 12, 5657. [Google Scholar] [CrossRef]

- Eringen, A.C.; Suhubi, E.S. Fundamentals of Linear Elastodynamics. In Elastodynamics; Academic Press: New York, NY, USA, 1975; Volume II, pp. 343–366. [Google Scholar]

- Korea Gas Safety Code, Korea Gas Safety Corporation. Available online: https://cyber.kgs.or.kr/kgscode.eng.index.do (accessed on 20 August 2023).

| /kHz | 70.2 | 102.3 | 120.8 | 145.6 | 173.4 | 244.5 | 270.3 | 284.5 |

| 0.091 | 0.045 | 0.069 | 0.18 | 0.45 | 0.097 | 0.015 | 0.058 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.B.; Kim, J.-H.; Jin, J.-E.; Kim, H.-J.; Kim, C.-I.; Kim, B.K.; Kang, J.-G. The Characteristics of Acoustic Emissions Due to Gas Leaks in Circular Cylinders: A Theoretical and Experimental Investigation. Appl. Sci. 2023, 13, 9814. https://doi.org/10.3390/app13179814

Kim KB, Kim J-H, Jin J-E, Kim H-J, Kim C-I, Kim BK, Kang J-G. The Characteristics of Acoustic Emissions Due to Gas Leaks in Circular Cylinders: A Theoretical and Experimental Investigation. Applied Sciences. 2023; 13(17):9814. https://doi.org/10.3390/app13179814

Chicago/Turabian StyleKim, Kwang Bok, Jun-Hee Kim, Je-Eon Jin, Hae-Jin Kim, Chang-Il Kim, Bong Ki Kim, and Jun-Gill Kang. 2023. "The Characteristics of Acoustic Emissions Due to Gas Leaks in Circular Cylinders: A Theoretical and Experimental Investigation" Applied Sciences 13, no. 17: 9814. https://doi.org/10.3390/app13179814

APA StyleKim, K. B., Kim, J.-H., Jin, J.-E., Kim, H.-J., Kim, C.-I., Kim, B. K., & Kang, J.-G. (2023). The Characteristics of Acoustic Emissions Due to Gas Leaks in Circular Cylinders: A Theoretical and Experimental Investigation. Applied Sciences, 13(17), 9814. https://doi.org/10.3390/app13179814