The Application of the Fuzzy Comprehensive Evaluation Method in the Sealing Evaluation of Caprocks in Underground Gas Storage

Abstract

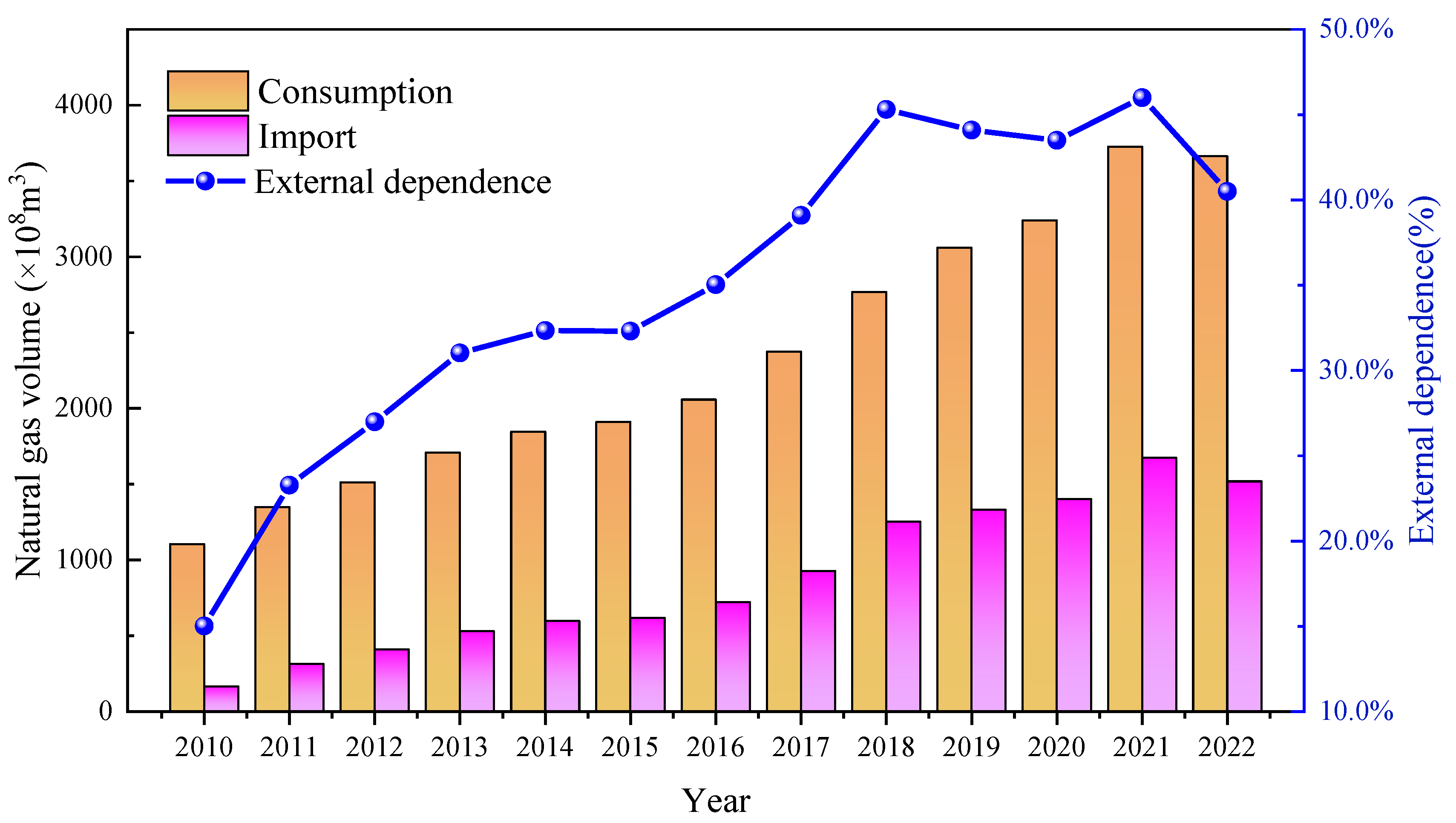

:1. Introduction

2. Selection of Parameters Affecting the Sealing Performance of Caprocks

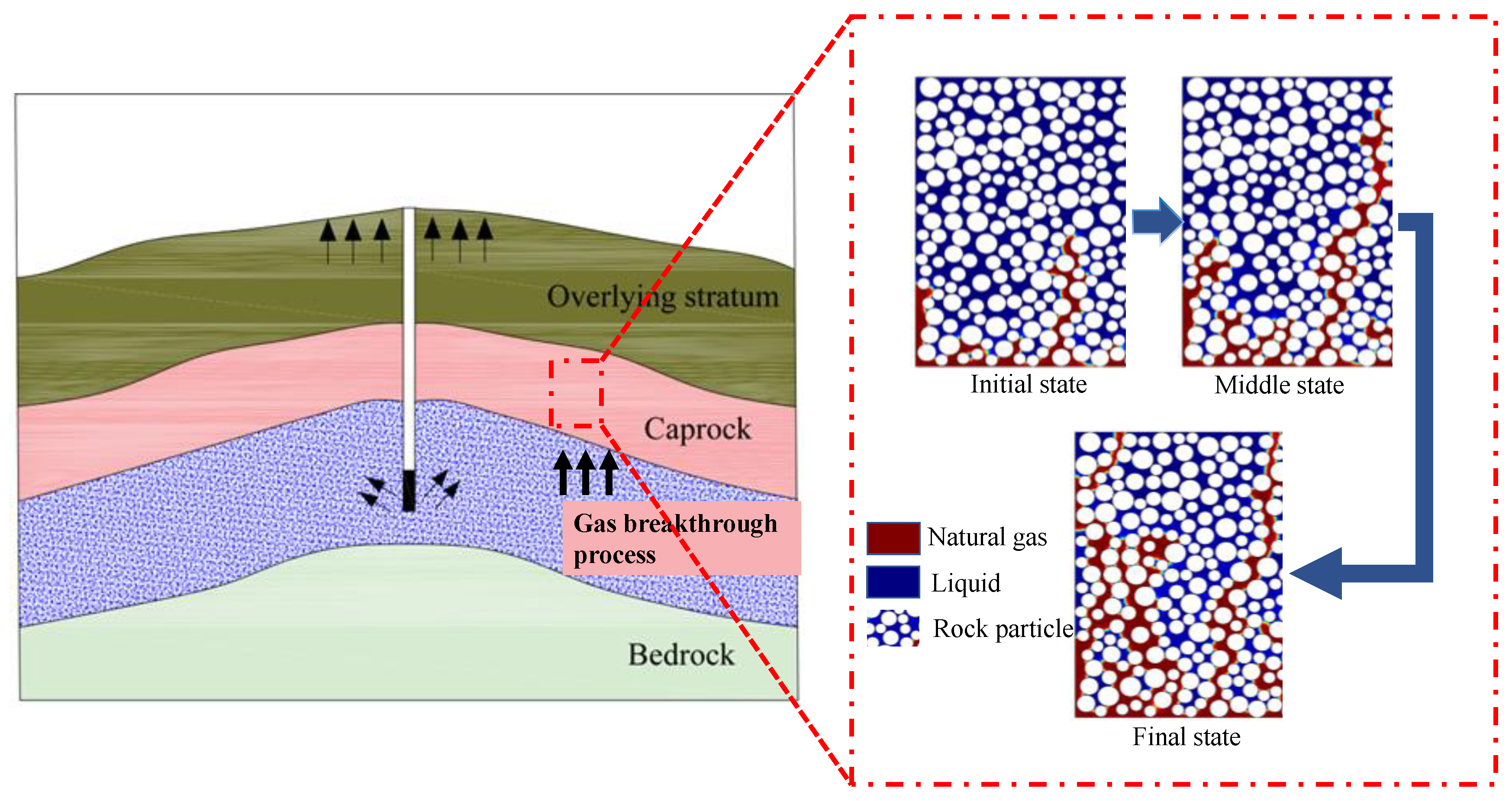

2.1. Sealing Mechanism of Caprocks

2.2. Indicator Screening of Caprock Sealing Evaluation

3. Comprehensive Fuzzy Evaluation Method

3.1. Comprehensive Fuzzy Evaluation Theory

3.2. Caprock Sealing Dynamic Evaluation

3.3. Classification of Parameters and Ranking Values

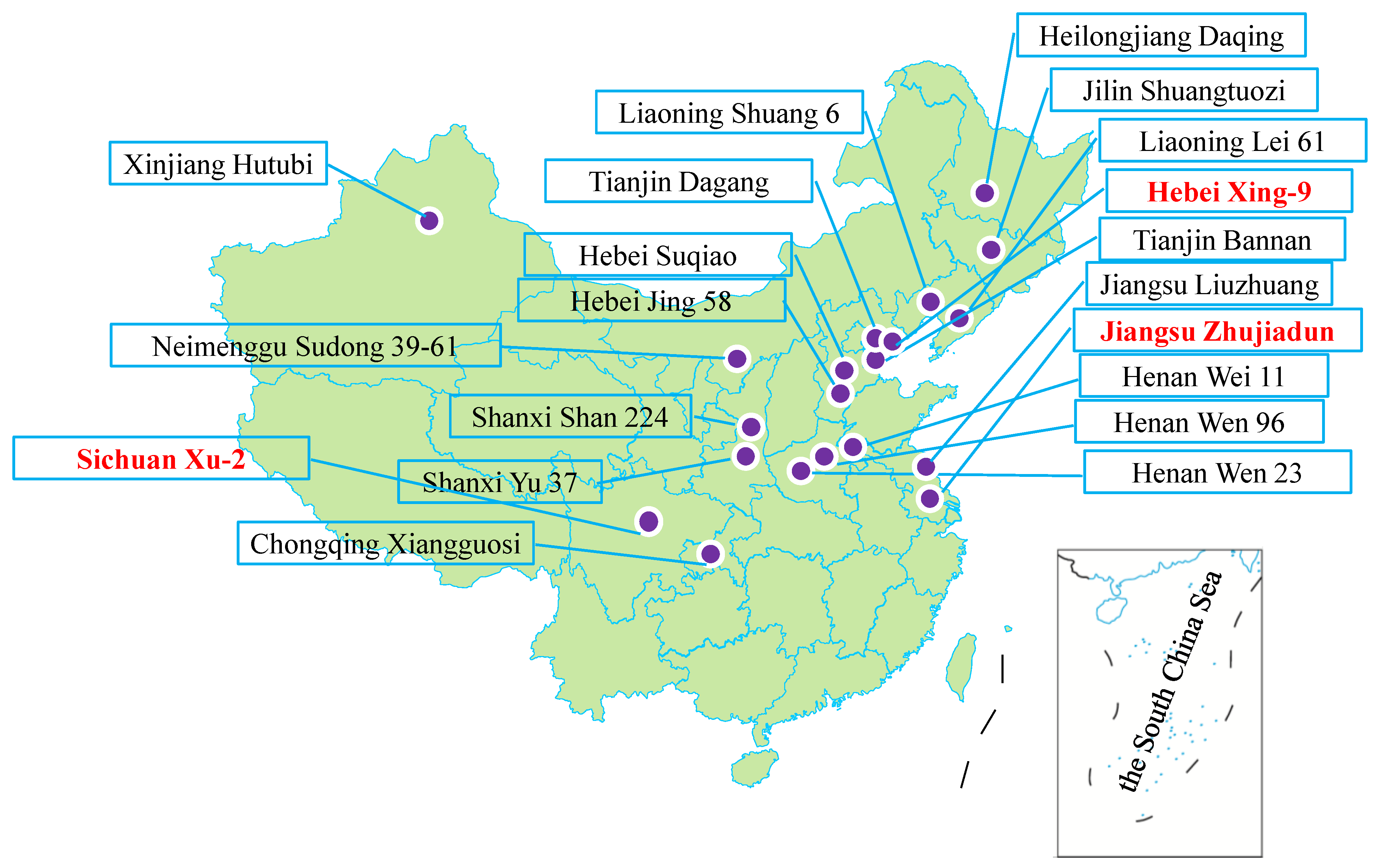

4. Sealing Evaluation of Caprocks in Three UGSs Planned or in Construction

4.1. Geological Characteristics

4.1.1. Xu-2 Gas Reservoir of Zhongba Gas Field

4.1.2. Xing-9 Gas Field

4.1.3. Zhujiadun Underground Gas Storage

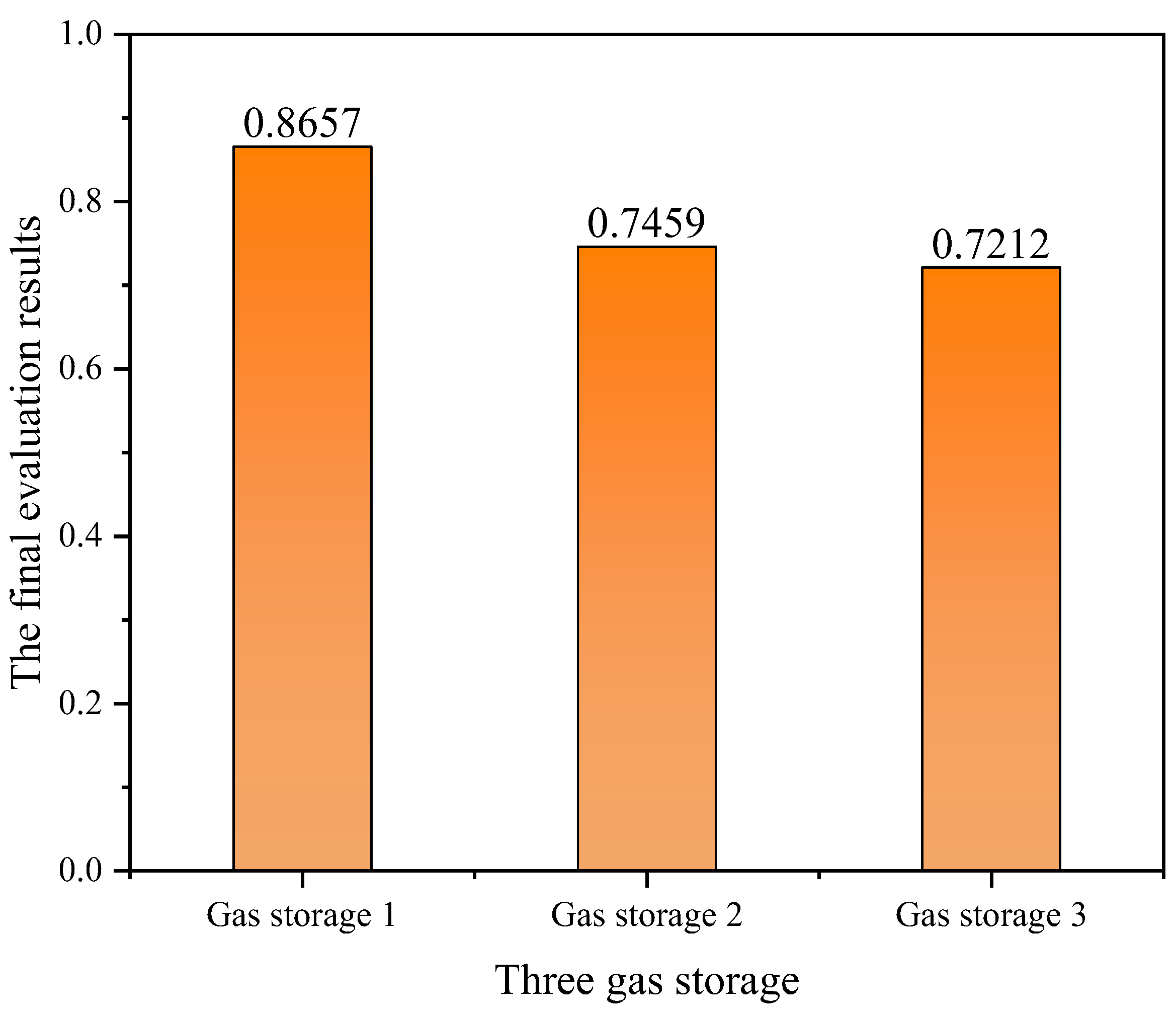

4.2. Weights Assignment of Parameters and Sealing Evaluation in Three UGSs Based on FCE

4.3. Verification of Evaluation Results

5. Conclusions

- (1)

- Two main factors affect the sealing performance of the caprock: the thickness and mechanical properties. Microscopically, the pore structure, permeability, and breakthrough pressure also affect the sealing performance of the caprock.

- (2)

- Using the AHP method, the weights of six parameters for caprock’s sealing is obtained. The breakthrough pressure of the caprock and permeability are the main factors with the weights of 0.4291 and 0.2157, respectively.

- (3)

- Using the fuzzy comprehensive evaluation method (FCEM), the sealing performance of the caprocks in three planned UGSs was evaluated. Zhujiadun gas storage, which has the relative evaluation score of 0.731, implies that the caprocks have good sealing performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. Analytical Hierarchy Process (AHP)

| Scale | Implication |

|---|---|

| 1 | Indicates that both factors are equally important compared to each other |

| 3 | Indicates that one factor is slightly more important than the other one when comparing the two factors |

| 5 | Indicates that one factor is significantly more important than the other when comparing the two factors |

| 7 | Indicates that one factor is strongly more important than the other when comparing the two factors |

| 9 | Indicates that one factor is extremely more important than the other when comparing the two factors |

| 2, 4, 6, 8 | Between two of the above two adjacent judgments |

- (1)

- AHP accuracy verification

| The Order of the Matrix | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

Appendix A.2. Fuzzy Comprehensive Evaluation Method (FCEM)

- (1)

- Determining the set of evaluation objectives V:

- (2)

- Determining the evaluation parameter W for the set of evaluation objectives V:

- (3)

- Various parameters are evaluated, and an evaluation matrix Z is obtained, where Z is a n × m matrix.

- (4)

- Normalizing the evaluation matrix Z using the membership function, the method of obtaining the membership function is given.

- (5)

- Use AHP to determine the weight of G, and each evaluation index W has its corresponding weight. The first step of AHP is to construct the judgment matrix H, and its equation is as follows:

- (6)

- Fuzzy calculation to obtain the evaluation score set P

References

- Wang, X.L.; Economides, M.J. Purposefully established underground natural gas storage. J. Nat. Gas Sci. Eng. 2012, 9, 130–137. [Google Scholar] [CrossRef]

- Lyu, X.; Yun, L.; Xu, J.; Liu, H.; Yu, X.; Peng, P.; Ouyang, M.; Luo, Y. Sealing capacity evolution of gypsum salt caprocks under multi-cycle alternating stress during operations of underground gas storage. J. Pet. Sci. Eng. 2023, 220, 111244. [Google Scholar] [CrossRef]

- Teatini, P.; Castelletto, N.; Ferronato, M.; Gambolati, G.; Janna, C.; Cairo, E.; Marzorati, D.; Colombo, D.; Ferretti, A.; Bagliani, A.; et al. Geomechanical response to seasonal gas storage in depleted reservoirs: A case study in the Po River basin, Italy. J. Geophys. Res. Earth Surf. 2011, 116. [Google Scholar] [CrossRef]

- Malakooti, R.; Azin, R. The optimization of underground gas storage in a partially depleted gas reservoir. Pet. Sci. Technol. 2011, 29, 824–836. [Google Scholar] [CrossRef]

- Jeanne, P.; Zhang, Y.; Rutqvist, J. Influence of hysteretic stress path behavior on seal integrity during gas storage operation in a depleted reservoir. J. Rock Mech. Geotech. Eng. 2020, 12, 886–899. [Google Scholar] [CrossRef]

- Zhang, N.; Shi, X.; Zhang, Y.; Shan, P. Tightness analysis of underground natural gas and oil storage caverns with limit pillar widths in bedded rock salt. IEEE Access 2020, 8, 12130–12145. [Google Scholar] [CrossRef]

- Zhechao, W.; Wei, L.; Jie, L. A review on state-of-the-art of underground gas storage and causes of typical accidents. Hazard Control Tunn. Undergr. Eng. 2019, 1, 49–58. [Google Scholar]

- Xu, Q.; Liu, H.; Song, Z.; Dong, S.; Zhang, L.; Zhang, X. Dynamic risk assessment for underground gas storage facilities based on Bayesian network. J. Loss Prev. Process Ind. 2023, 82, 104961. [Google Scholar] [CrossRef]

- Yu, H.; Yi, Y.; Romagnoli, A.; Tan, W.L. Cement soil stabilization for underground liquid natural gas storage. Cold Reg. Sci. Technol. 2022, 194, 103438. [Google Scholar] [CrossRef]

- Sadeghi, S.; Sedaee, B. Mechanistic simulation of cushion gas and working gas mixing during underground natural gas storage. J. Energy Storage 2022, 46, 103885. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Ren, Z. Modeling multiphase fluid flow and salt precipitation due to water vaporization in producing wells of underground gas storage. Gondwana Res. 2023. [Google Scholar] [CrossRef]

- Yousefi, S.H.; Groenenberg, R.; Koornneef, J.; Juez-Larré, J.; Shahi, M. Techno-economic analysis of developing an underground hydrogen storage facility in the depleted gas field: A Dutch case study. Int. J. Hydrogen Energy 2023, 48, 28824–28842. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Q.; Wang, G.; Zhu, L.; Li, Y. Investment strategy for underground gas storage facilities based on real option model considering gas market reform in China. Energy Econ. 2018, 70, 132–142. [Google Scholar] [CrossRef]

- Ding, G.; Li, C.; Wang, J.; Xu, H.; Zheng, Y.; Wanyan, Q.; Zhao, Y. The status quo and technical development direction of underground gas storages in China. Nat. Gas Ind. B 2015, 2, 535–541. [Google Scholar] [CrossRef]

- Zhang, G.; Li, B.; Zheng, D.; Ding, G.; Wei, H.; Qian, P.; Li, C. Challenges to and proposals for underground gas storage (UGS) business in China. Nat. Gas Ind. B 2017, 4, 231–237. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, Y.; Zhang, T.; Yu, K.; Wang, X.; Zhao, Q. Natural gas market and underground gas storage development in China. J. Energy Storage 2020, 29, 101338. [Google Scholar] [CrossRef]

- Zhao, X.; Al-Abdrabalnabi, R.; Wu, Y.-S.; Zhou, X. Evaluations of the feasibility of oil storage in depleted petroleum reservoirs through experimental modellling studies. Fuel 2021, 294, 120316. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, L.; Jia, D. An uncertainty quantitative model of wellbore failure risk for underground gas storage in depleted gas reservoir during the construction process. J. Energy Storage 2023, 57, 106144. [Google Scholar] [CrossRef]

- Liu, H.; Yang, C.; Liu, J.; Hou, Z.; Xie, Y.; Shi, X. An overview of underground energy storage in porous media and development in China. Gas Sci. Eng. 2023, 117, 205079. [Google Scholar] [CrossRef]

- Xie, L.; Zhang, H.; Li, H. Accident analysis and risk identification of underground gas storage with depleted oil and gas reservoirs. Nat. Gas Ind. 2009, 29, 116–119. [Google Scholar]

- Shen, X.; Liu, H.; Mu, L.; Lyu, X.; Zhang, Y.; Zhang, W. A semi-analytical model for multi-well leakage in a depleted gas reservoir with irregular boundaries. Gas Sci. Eng. 2023, 114, 204979. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Hu, W.; Ban, S.; Li, Y.; Ma, H.; Li, P.; Yang, C. Dynamic tightness evaluation of salt cavern energy storage. J. Energy Storage 2023, 57, 106313. [Google Scholar] [CrossRef]

- Sorai, M. Evaluation of Geochemical Impacts on Caprock’s Sealing Performance. Energy Procedia 2017, 114, 3578–3581. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Dang, F.; Liang, X.; Wang, S.; Ma, Z. Influence of CH4 adsorption diffusion and CH4-water two-phase flow on sealing efficiency of caprock in underground energy storage. Sustain. Energy Technol. Assess. 2020, 42, 100874. [Google Scholar] [CrossRef]

- Ouyang, S.; Lü, X.; Quan, H.; Awan, R.S.; Zhou, J.; Wang, R. Evolution process and factors influencing the tight carbonate caprock: Ordovician Yingshan Formation from the northern slope of the Tazhong uplift, Tarim Basin, China. Mar. Pet. Geol. 2023, 147, 105998. [Google Scholar] [CrossRef]

- Singh, H.; Dilmore, R.M. Stochastic prediction of fractured caprock by history matching pressure monitoring data. J. Pet. Sci. Eng. 2019, 179, 615–630. [Google Scholar] [CrossRef]

- Minardi, A.; Stavropoulou, E.; Kim, T.; Ferrari, A.; Laloui, L. Experimental assessment of the hydro-mechanical behavior of a shale caprock during CO2 injection. Int. J. Greenh. Gas Control 2021, 106, 103225. [Google Scholar] [CrossRef]

- Zhu, A.; Liu, J.; Ding, G.; Wu, Z.; Shi, X.; Zeng, Y. Experimental investigation on permeability, meso-damage and fractal characteristics of limestone caprock under THM coupling based on μCT technology. J. Pet. Sci. Eng. 2022, 212, 110197. [Google Scholar] [CrossRef]

- Jin, Z.; Yuan, Y.; Sun, D.; Liu, Q.; Li, S. Models for dynamic evaluation of mudstone/shale cap rocks and their applications in the Lower Paleozoic sequences, Sichuan Basin, SW China. Mar. Pet. Geol. 2014, 49, 121–128. [Google Scholar] [CrossRef]

- Hou, L.; Yu, Z.; Luo, X.; Wu, S. Self-sealing of caprocks during CO2 geological sequestration. Energy 2022, 252, 124064. [Google Scholar] [CrossRef]

- Wang, F.; Chen, D.; Wang, Q.; Du, W.; Chang, S.; Wang, C.; Tian, Z.; Cheng, M.; Yao, D. Quantitative evaluation of caprock sealing controlled by fault activity and hydrocarbon accumulation response: K gasfield in the Xihu Depression, East China Sea Basin. Mar. Pet. Geol. 2021, 134, 105352. [Google Scholar] [CrossRef]

- Blake, O.; Faulkner, D.; Worden, R.; Armitage, P.; Espie, A. Effect of thermal shock on the permeability and seismic wave velocity of the caprock and reservoir during CO2 injection. Int. J. Greenh. Gas Control 2022, 118, 103691. [Google Scholar] [CrossRef]

- Newell, P.; Martinez, M.J. Numerical assessment of fault impact on caprock seals during CO2 sequestration. Int. J. Greenh. Gas Control 2020, 94, 102890. [Google Scholar] [CrossRef]

- Zhou, X.; Lü, X.; Sui, F.; Wang, X.; Li, Y. The breakthrough pressure and sealing property of Lower Paleozoic carbonate rocks in the Gucheng area of the Tarim Basin. J. Pet. Sci. Eng. 2022, 208, 109289. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, Z.; Patrick, W.; Liu, J.; Lei, H.; Zhang, L. Pore-scale numerical simulation of supercritical CO2 migration in porous and fractured media saturated with water. Adv. Geo-Energy Res. 2020, 4, 419–434. [Google Scholar] [CrossRef]

- Iraji, S.; Soltanmohammadi, R.; Munoz, E.R.; Basso, M.; Vidal, A.C. Core scale investigation of fluid flow in the heterogeneous porous media based on X-ray computed tomography images: Upscaling and history matching approaches. Geoenergy Sci. Eng. 2023, 225, 211716. [Google Scholar] [CrossRef]

- Soltanmohammadi, R.; Iraji, S.; De Almeida, T.R.; Munoz, E.R.; Fioravanti, A.R.; Vidal, A.C. Insights into Multi-Phase Flow Pattern Characteristics and Petrophysical Properties in Heterogeneous Porous Media. In Conference Insights into Multi-Phase Flow Pattern Characteristics and Petrophysical Properties in Heterogeneous Porous Media; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2021; Volume 2021, pp. 1–5. [Google Scholar]

- Orlic, B.; Wassing, B. A study of stress change and fault slip in producing gas reservoirs overlain by elastic and viscoelastic caprocks. Rock Mech. Rock Eng. 2013, 46, 421–435. [Google Scholar] [CrossRef]

- Defoort, T.; Salimzadeh, S.; Paluszny, A.; Zimmerman, R. A finite element geomechanical study of the brittle failure of a caprock due to deflation. In Conference a Finite Element Geomechanical Study of the Brittle Failure of a Caprock due to Deflation; ARMA: Westfield, MA, USA, 2015; pp. 2015–2352. [Google Scholar]

- Ao, L.; Lin, B. Sealability evalution of Zhujiadun underground gas storage. Complex Oil Gas Reserv. 2021, 14, 86–90. (In Chinese) [Google Scholar]

- Shu, P.; Gao, T.; Wang, H.; Liang, H. Caprock sealing-property classifying standard and evalution of Shengping gas storage in Daqing Oilfiled. Daqing Pet. Geol. Dev. 2019, 38, 272–276. (In Chinese) [Google Scholar]

- Qin, Y. Study on Sealing Performance of Caprock in Exhausted Reservoir Gas Storage. Master’s Thesis, Jilin University, Changchun, China, 2022. (In Chinese). [Google Scholar]

- Teng, S.; Zhang, P.; Jia, S.; Xu, M.; Zhang, G.J. Study on dynamic sealing evalution of carbonate gas storage caprock. Nat. Gas Oil 2022, 40, 98–107. (In Chinese) [Google Scholar]

- Hou, Y.; Wu, Z.; Qi, H.; Wang, Y.; Ran, L. Assessment on cap rock tightness of the Gas storehouse of Anning salt cavern. China Well Miner. Salt 2013, 44, 16–19. (In Chinese) [Google Scholar]

- Li, Y.; Sun, Z.; Han, L.; Mei, N. Fuzzy comprehensive evaluation method for energy management systems based on an internet of things. IEEE Access 2017, 5, 21312–21322. [Google Scholar] [CrossRef]

- Jia, S.; Jin, S.; Zheng, D.; Meng, Q.; Zhang, H.; Lin, J. Evaluation indices and classification criterion of aquifer site for gas storage. Chin. J. Rock Mech. Eng. 2015, 34, 1628–1640. [Google Scholar]

- Hartenian, L.S.; Bobko, P.; Berger, P.K. An Empirical Validation of Bipolar Risk Perception Scaling Methods 1. J. Appl. Soc. Psychol. 1993, 23, 335–351. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, X.; Zhang, C.; Wang, X.; Sang, Q. Recognition of tight sandstone reservoir characteristics and development potential of the 2nd member of Xujiahe gas reservoir in Zhongba gas field. Eval. Dev. Oil Gas Reserv. 2019, 9, 10–15. (In Chinese) [Google Scholar]

- Zhu, X. Optimization demonstration of gas lift pipe network in Xu-2 gas reservoir of Zhongba gas field. Chem. Enterp. Manag. 2019, 1, 215–216. (In Chinese) [Google Scholar]

- Liu, L.; Sang, Q.; Cao, J.; Zhang, C.; Wang, X.; Deng, Q. Comprehensive evalution of sealing capacityof depleted gas reservoir reconstructed to gas storage: A case study of Xu-2 gas reservoir in Zhongba gas field, northwest Sichuan. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 42–50. (In Chinese) [Google Scholar]

- Zhan, M.; Wu, Y.; Wang, Y.; Wang, H.; Su, W.; He, Y. Study on the development characteristics and technology strategies for the Xing 9 condensate gas reservoir. Nat. Gas Geosci. 2013, 24, 1022–1026. [Google Scholar]

- Lin, J.; Jia, S.; Liu, T.; Yan, H.; Xi, Z. Comprehensive evalution of sealing ability of mudstone caprock for Xing 9 depleted gas reservoir in reconstrucyion underground gas storage. Chin. J. Rock Mech. Eng. 2015, 34, 4099–4107. (In Chinese) [Google Scholar]

- Wang, X.; Liu, M.; Wang, Y.; Zhang, Y.; Qiu, A. One-time up-return cementing in Xing-9 conglomerate gas storage. Spec. Oil Gas Reserv. 2017, 24, 153–156. (In Chinese) [Google Scholar]

- Wang, G.; Cheng, T.; Lu, L.; Ren, C.; Huang, X. Relationship between near-surface expressions of hydrocarbon microseepage and migration pathways pathways-A case study in the Zhujiadun gas field, the Yancheng sag, the northern Jiangsu Basin. Pet. Exp. Geol. 2008, 30, 302–306. (In Chinese) [Google Scholar]

| Lithology | Breakthrough Pressure | Porosity | Permeability | Thickness | Fracture Development Degree | Rock Brittleness | Continuity | Source |

|---|---|---|---|---|---|---|---|---|

| ✔ | ✔ | ✔ | ✔ | ✔ | × | × | × | Ao et al. [40] |

| ✔ | ✔ | ✔ | ✔ | ✔ | × | × | × | Shu et al. [41] |

| × | × | × | × | × | ✔ | × | × | Qin et al. [42] |

| ✔ | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | Teng et al. [43] |

| ✔ | ✔ | ✔ | ✔ | × | ✔ | × | × | Gou et al. [44] |

| Breakthrough Pressure (A) | Permeability (B) | Thickness (C) | Brittleness (D) | Fracture Development Degree (E) | Porosity (F) | |

|---|---|---|---|---|---|---|

| Breakthrough pressure (A) | 1 | 4 | 5 | 5 | 3 | 4 |

| Permeability (B) | 1/4 | 1 | 3 | 4 | 2 | 4 |

| Thickness (C) | 1/5 | 1/3 | 1 | 3 | 2 | 4 |

| Brittleness (D) | 1/5 | 1/4 | 1/3 | 1 | 2 | 2 |

| Fracture development degree (E) | 1/3 | 1/2 | 1/2 | 1/2 | 1 | 3 |

| Porosity (F) | 1/4 | 1/4 | 1/4 | 1/2 | 1/3 | 1 |

| A | B | C | D | E | F | |

|---|---|---|---|---|---|---|

| Weight | 0.4291 | 0.2157 | 0.1370 | 0.0816 | 0.0893 | 0.0473 |

| Parameters | Grading | |||

|---|---|---|---|---|

| Good | Generally Good | Medium | Bad | |

| A | >10 | 5~10 | 1~5 | <1 |

| B | <0.001 | 0.001~0.01 | 0.01~0.1 | >0.1 |

| C | >80 | 30~80 | 10~30 | <10 |

| D | Plasticity | Brittle plasticity | Fragility | Strong brittleness |

| E | Few fractures | A small number of cracks | Rich non-connected cracks | Rich connected cracks |

| F | <5 | 5~15 | 15~25 | >25 |

| Impact Factors | Attribute Classification | |

|---|---|---|

| 1 | A | Revenue |

| 2 | B | Cost |

| 3 | C | Revenue |

| 4 | D | Cost |

| 5 | E | Cost |

| 6 | F | Cost |

| 0 | 1 | 3 | 5 | 7 | 9 | 10 | |

|---|---|---|---|---|---|---|---|

| Cost element | highest | very high | high | average | low | very low | minimum |

| Revenue element | minimum | very low | low | average | high | very high | highest |

| Xu-2 [50] | Xing-9 [52] | Zhujiadun [40] | |

|---|---|---|---|

| A | 8–50 (26.4) | 20–32.11 (24) | (47.75) |

| B | 0.0001–0.001 (0.0005) | 0.0116–0.551 (0.0223) | (0.085) |

| C | 60–160 (137) | (400) | 400–600 (500) |

| D | Medium–low brittleness 7.0–30.0 | Fragility 48.49–57.85 | Fragility 45.44–48 |

| E | Small amount | Small amount | Small amount |

| F | 0.01–0.074 (0.04) | 0.0484–0.067 (0.059) | (0.33) |

| Xu-2 | Xing-9 | Zhujiadun | |

|---|---|---|---|

| A | 6 | 5 | 10 |

| B | 10 | 0.2 | 0.05 |

| C | 3 | 8 | 10 |

| D | 10 | 4 | 4 |

| E | 10 | 10 | 10 |

| F | 10 | 7 | 1 |

| Levels | Values | Sealing Performance |

|---|---|---|

| Good | The caprock has good sealing performance and is very suitable for building the gas storage. | |

| Generally good | The caprock has better sealing performance and is suitable for building the gas storage | |

| Medium | The caprock sealing property is general, which needs further demonstration. | |

| Bad | Not suitable for building the gas storage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ban, S.; Liu, H.; Wei, X.; Shi, X.; Mao, H.; Song, Y.; Tan, H. The Application of the Fuzzy Comprehensive Evaluation Method in the Sealing Evaluation of Caprocks in Underground Gas Storage. Appl. Sci. 2023, 13, 9753. https://doi.org/10.3390/app13179753

Ban S, Liu H, Wei X, Shi X, Mao H, Song Y, Tan H. The Application of the Fuzzy Comprehensive Evaluation Method in the Sealing Evaluation of Caprocks in Underground Gas Storage. Applied Sciences. 2023; 13(17):9753. https://doi.org/10.3390/app13179753

Chicago/Turabian StyleBan, Shengnan, Hejuan Liu, Xinxing Wei, Xilin Shi, Haijun Mao, Yujia Song, and Hongying Tan. 2023. "The Application of the Fuzzy Comprehensive Evaluation Method in the Sealing Evaluation of Caprocks in Underground Gas Storage" Applied Sciences 13, no. 17: 9753. https://doi.org/10.3390/app13179753

APA StyleBan, S., Liu, H., Wei, X., Shi, X., Mao, H., Song, Y., & Tan, H. (2023). The Application of the Fuzzy Comprehensive Evaluation Method in the Sealing Evaluation of Caprocks in Underground Gas Storage. Applied Sciences, 13(17), 9753. https://doi.org/10.3390/app13179753