Abstract

Teachers in workshops of vocational education training (VET) schools are at risk of exposure to occupational hazards, as are the rest of the teaching staff. However, due to the characteristics of these workshops, these teachers are exposed to a greater extent to other types of risks, such as noise or vibrations. Exposure to these risks for vocational training teachers has been little studied compared to other risks, such as voice disorders. In this study, exposure to noise and vibration was evaluated for teachers in a vocational training center in Cordoba (Spain), working in body shops. The values obtained from the measurements taken for different tasks and machine tools showed that the exposure limit values specified in the corresponding regulations were reached and even exceeded. This implies that these types of risks must be taken into consideration for these types of teachers, and that measures must be taken to mitigate their effects.

1. Introduction

In Spain, Law 31/1995, of 8 November 1995, on the prevention of occupational risks, establishes the guarantees and responsibilities necessary to establish an adequate level of protection for the health of workers against the risks derived from working conditions. This law is applicable to all workers, including teachers at all educational levels.

Not all teachers at different levels of education are subject to the same occupational risks during their work. Many of the occupational hazards are common to all teachers, such as the continuous use of their voice in teaching, regardless of the level of education to which they belong.

The published literature on the risks affecting the teaching community reveals widely known factors related to voice disorders and vocal cord nodules, the only occupational disease recognized for teachers at all levels of education in Spain [1]. The risks related to voice disorders have been widely studied and analyzed, both their causes and consequences and how to prevent them [2,3,4,5,6].

However, there are specific risks to which some teachers are exposed, depending on the subjects they teach and the educational level at which they work. Thus, for example, in vocational education training (VET), specific subjects or training modules are taught whose curriculum means that teachers are exposed to a greater number and types of risks than in infant or primary education. Therefore, specific and more relevant risks can be found in secondary and higher education depending on the specialty of the teaching staff.

In the case of noise, there are specialties in which exposure to noise is greater than in others. According to research conducted by Sachová et al. in 2009 [7], teachers belonging to a specialty with high noise exposure had twice as many hearing losses as those belonging to a specialty characterized by a lower noise level. In this sense, exposure to noise has until recently been considered a negligible risk for teachers [8,9], although it has been widely demonstrated that a high level of noise in classrooms causes teachers to strain their voices, which can lead to the development of chronic voice disorders when this strain is sustained over time [10] and with the level of stress suffered by teachers [11].

Research has been carried out in which noise-induced hearing loss has been considered as the main risk factor to consider in the development of occupational hearing loss for this group, a conclusion reached by Martins et al. in 2007 [12]. This risk has also been studied for performing arts teachers, mainly music and singing teachers, according to the work performed by Isaac et al. in 2017 [13], who concluded that hearing loss among singing teachers is severe and frequent. In the research conducted by Behar et al. in 2004 [14], equivalent continuous noise levels (Leqs) above the 85 dBA limit were measured for 78% of music teachers who participated in the research, and 39% of them worked with a noise exposure level (Lex), calculated for 8 h, also higher than 85 dBA; therefore, recommendations were proposed to limit and reduce noise exposure. The risk of noise-induced hearing loss was studied for physical education teachers by Maffei et al. in 2009 [15], Sá et al. in 2014 [16] and Strasse et al. in 2015 [17]. Their research concluded that teachers in this specialty could be affected by exposure to noise levels above acceptable limits due, among other factors, to poor acoustic conditions in gymnasiums and noisy sports activities carried out with large groups of students. Similarly, research has been conducted on the effect of noise on early childhood teachers on the development of hearing-related symptoms, such as hearing loss, tinnitus, difficulty perceiving speech, hyperacusis and induced auditory fatigue, such as that conducted by Fredriksson et al. in 2019 [18], who concluded that working as a preschool teacher increased the risk of self-reported hearing-related symptoms.

However, few studies have considered the risk of deafness among teachers working in vocational training workshops. In this line, there is the work carried out in 1975 by Rozema [19], who measured noise levels in carpentry workshops, obtaining values between 85 and 90 dBA during the working day. This study concluded that many conditions in workshops should be improved to minimize the risk of hearing damage. Additionally, noteworthy is the research work conducted by Summan et al. in 2020 [20], who analyzed the working conditions of teachers in carpentry, metalworking and automotive workshops in secondary schools in British Columbia (Canada), concluding that more than half of the teachers participating in the study were exposed to unacceptable levels of noise during teaching.

Exposure to hand–arm vibration is common in many industries where workers use vibrating tools. The association between vibration exposure and hand–arm vibration symptoms in a Swedish mechanical industry has been studied by Vilhborg et al. [21]. Additionally, hand–arm vibration syndrome in Swedish car mechanics has been studied by Barregard et al. [22]. However, to the authors’ knowledge, there are no known studies that address the vibration exposure of VET teachers.

In this context, there is little research on the specific occupational risks derived from the professional activity of VET teachers. Therefore, the objective of this research was to carry out a study to analyze whether the noise and vibration levels, to which teachers working in bodywork workshops of a vocational training center in Cordoba (Spain) are exposed, reached or exceeded the recommended limit values.

2. Materials and Methods

2.1. Context

The Spanish education system is divided into different levels or stages, from early childhood education (ECI) to university. The intermediate levels include compulsory secondary education (CSE), as well as the vocational education and training stages. Vocational education is organized into professional families, among which are the so-called intermediate-level training cycles and higher-level training cycles. Vocational education develops the sets of knowledge, skills, practical training, and attitudes that prepare students for the qualified exercise of various professions.

This study was carried out in a VET center located in Cordoba (Spain). The educational center has more than 1500 students. In this center, it is possible to study, among others, the training cycles of the professional families of mechanical manufacturing, installations and maintenance, and transport and the maintenance of vehicles. Within the latter is the bodywork cycle, the workshops and laboratories of which this study was carried out in. The department responsible for teaching in these workshops was composed of 10 teachers. These teachers taught the different practical modules in blocks of 2 or 3 h per day, with 2 teachers working on each module. The maximum number of teaching hours of the teaching staff was 5 h per day of their total teaching hours, which in the worst case was 18 h per week. Homogeneous groups were considered as the teachers present in the workshop during the same hour, in which activities corresponding to two different professional modules could be carried out simultaneously, so that up to 4 teachers could be present in a workshop or laboratory during the same class.

To determine whether the teachers of the bodywork cycle of this VET center were exposed to noise and vibration levels that posed a health risk, the sound pressure level, loudness and vibration were measured. The measurements were carried out in the workshops of the VET center in 2019.

2.2. Legislation

In Spain, the purpose of Law 31/1995, of 8 November 1995, on occupational risk prevention, is to determine the guarantees and responsibilities necessary to establish an adequate level of protection for the health of workers against risks arising from working conditions. Its scope of application includes both workers linked by an employment relationship in a strict sense and public employees in the public administration service. It includes teachers at all educational levels, including vocational training teachers.

According to UNE-EN-ISO 9612:2009 [23], three different strategies were proposed to assess the occupational daily noise exposure, including the task-based measurement (TBM), the job-based measurement (JBM) and the full-day measurement (FDM). For this case study, the TBM strategy was followed. In this context, the tasks that according to the teachers had the highest noise levels were identified.

Regarding noise exposure, the Spanish Royal Decree 286/2006 [24] on the protection of the health and safety of workers against risks related to noise exposure sets the daily equivalent exposure limit value at 87 dB(A) and the limit value for action at 85 dB(A).

The measurement and evaluation of human exposure to hand-transmitted vibration is regulated in UNE-EN-ISO 5349 [25]. Part 2 of ISO 5349 includes practical guidance for measurement at the workplace, which was followed in this study.

In relation to vibration exposure limit values, the Spanish Royal Decree 1311/2005 [26] on the protection of the health and safety of workers from the risks arising or likely to arise from exposure to mechanical vibration sets the normalized daily exposure limit value for an 8 h period to 5 m/s2 and the limit value for action to 2.5 m/s2.

2.3. Tasks

The main tasks performed in the body shop included the removal of dents from vehicle bodywork, bodywork shaping with stretching equipment and tools (hammer–dolly), bodywork fixing, surface preparation for dimensional equalization, repair of steel and aluminum elements using appropriate techniques and procedures (reworking welding spots), sanding of sheet metal filler coatings, bodywork painting, fixing of removable elements, replacement of elements of the suspension and steering systems, cooling system and intake and exhaust system, etc. Of all these tasks, the ones with the highest noise or vibration levels perceived by the teachers were selected for measurements, and these were detailed in the Section 2.4 and Section 2.5.

2.4. Noise Measurements

For the noise measurements, a multichannel data acquisition system LMS SCADA mobile, a 36-microphones array model TL-AHW 16.1 and Siemens LMS TestLab software v 180.2018.520.0 release 18 were used.

The microphones were placed 0.4 m from the entrance of the external auditory canal, on the side of the most exposed ear, and at a height of 1.5 m from the floor, with the worker performing the task standing up in all cases, in accordance with UNE-EN-ISO 9612 [23].

The sound pressure level (SPL) shows how loud a sound is expressed in numerical terms. This is the pressure level of a sound, and its unit is decibels (dB). The one third octave band was used to provide information about the noise spectrum into approximately 10 frequency bands called one-third octave bands. This parameter has been used to select the correct personal protective equipment (PPE) adapted to the most damaging bands for the ear.

Decibel values show the amplitude of a sound; however, it is not possible to know the perceived loudness of a sound. In fact, there is a sound quality metric called loudness, for which the unit is sone, which provides the correct human hearing equivalent sound perception. Loudness is related to annoyance. Taking into consideration accessible methodologies, only the one provided by Zwicker and Fastl [27] is effective when it comes to broadband excitation. Subsequently, this technique was selected, as it fulfilled the ISO 532B [28], DIN 45631 [29] and ISO/R 131 [30] requirements. The stationary loudness spectrum, called specific loudness, is useful in locating the frequency ranges that contribute the most to the perceived loudness of a sound. To calculate the specific loudness, a decomposition into its frequencies using a discrete Fourier transformation had to be performed. These frequencies were bundled according to the nonlinear critical-band rate scale (bark). Then, spectral masking effects were applied before the decibel values were calculated. The decibel values were transformed to equal loudness levels (phon) and, finally, from these, the specific loudness sensation was calculated (sone). The time windows to reduce the leakage problems used were Hanning and the block size was 2048. The algorithm for transforming a time-domain signal into a frequency-domain signal was internal to the measurement equipment’s software itself. The subsequent transformation into one-third octave bands followed a standardized UNE-EN-ISO 266:1998 [31] norm, which specifies the complete procedure, including the calculation of the frequency bands.

For this study, both SPL and loudness were measured. The measurements were taken in the work area of painting (paint booth) and in the workshop. The workshop was divided into different areas, such as the vehicle service and maintenance area, the structural recovery area, the welding area and the sheet metal forming and repair area. The measurements were taken during a 5 h working day of several of the practical modules taught in the body shop.

The main sources of noise present in the body shop occurred during the removal of dents from sheet metal using the multifunction tool, in the shaping of bodywork with the hammer–dolly, in the repair of metallic steel elements after welding operations, in which the welding points must be reworked so that the finish is uniform, the sanding operations of sheet metal fillers and the painting operations of vehicles or removable elements of these, carried out in a paint booth.

A task-based strategy was used for the noise study, in accordance with the UNE-EN-ISO 9612 standard. Following the TBM strategy, the tasks were classified as continuous noise tasks, when they had similar characteristics in terms of working conditions and noise exposure, and variable noise tasks, which were grouped by the average daily exposure time. The most important within the first group were vehicle painting tasks. During the working day, noise was measured in the paint booth during vehicle painting operations, when the extraction system and the compressor that sprayed the paint were in operation.

The tasks classified as variable noise were carried out in the vehicle repair, assembly and maintenance work area. Noise exposure was measured for the following tasks: sheet metal repair work with a hammer–dolly and a multifunction tool—pneumatic hammer; sheet metal cutting work with electric saw, spot welding reworking, sheet metal finishing work with an orbital sander, as well as repair work on plastic parts with a pneumatic sander.

The tasks whose noise level could increase because of the operation of the extraction system were the sheet metal sanding operations, so special attention was paid to the noise level of these tasks. Firstly, one noise measurement was carried out to the sanding machine without dust extraction. After this, the dust extraction was turned on and another noise measurement was obtained. The duration of the measurement was 30 s.

According to Spanish NTP 270 [32], noise is considered continuous noise when the difference between the maximum and minimum values of the A-weighted sound pressure level is less than 5 dB. Noise is considered to be a random variable when the difference between the maximum and minimum values of the A-weighted sound pressure level is greater than 5 dB.

As indicated in the UNE-EN-ISO 9612 standard, for tasks lasting more than 5 min, the duration of each measurement should be at least 5 min. However, the duration of each measurement could be reduced if the level was constant or repetitive, or if the noise produced by the task was considered as a minor contributor to the total noise exposure. For the noise measurement of the vehicle painting task, whose noise level was considered a minor contributor to the teacher’s noise exposure, 5 measurements of 2 min durations each were performed. The duration of the measurements could be even shorter for the case of stable noise, according to NTP 270, which established a minimum of 5 measurements with a minimum duration of 15 s each to obtain the A-weighted equivalent continuous sound pressure level (LAeq,T). To determine the noise level of the rest of the tasks performed in the body shop, classified within the random variable noise group, different measurements were obtained, with a minimum of 3 and a duration of 5 min each, randomly during the time interval considered for each task, as detailed in the UNE-EN-ISO 9612 standard.

For all measurements of the different tasks, the A-weighted equivalent continuous sound pressure level (LAeq,T) and peak sound pressure levels were obtained. The mean equivalent continuous sound pressure level from n measurements of a given task was obtained using Equation (1).

where LAeq,T,m is the A-weighted equivalent continuous sound pressure level of a task m, LAeq,T,mi is the A-weighted equivalent continuous sound pressure level of each sample, i is the number of a sample of task m and n is the total number of samples for task m.

The contribution of each task to the daily noise exposure level was obtained by using Equation (2).

where LAeq,D,m is the daily noise exposure level of task m, LAeq,T,m is the daily noise exposure level of task m and Tm is the duration of task m.

Equation (3) was used to obtain the daily noise exposure level, considering all the tasks carried out throughout the day.

where LAeq,D,T is the daily noise exposure level of all tasks, LAeq,T,m is the A-weighted equivalent continuous sound pressure level of a task m, Tm is the duration of task m, m is the task number and M is the total number of tasks.

The standard uncertainty of the noise level due to sampling for each of the tasks, the sensitivity coefficients and the combined standard uncertainty were calculated using the spreadsheet included in UNE-EN-ISO 9612 [23].

To determine the most damaging frequency bands for the hearing of teachers exposed to the most dangerous noise tasks in the body shop, the noise spectrum was obtained at one-third octave frequencies.

2.5. Vibration Measurements

In the vehicle repair process, there are many tasks in which workers are exposed to vibrations of the hand–arm system because of the use of machine tools necessary to carry out their work. These vibrations pose risks to the health and safety of workers, mainly vascular, bone, joint, nerve or muscular problems.

For the hand–arm vibration study, a SVANTEK type I vibrometer was used, specifically, the SVAN 948 model with reference number 9889, together with a triaxial accelerometer for measuring hand–arm vibrations, the latter located in the center of the gripping area with the tool by means of an auxiliary grip support.

There are different methods for attaching accelerometers to vibrating surfaces. In this case, a mounting adhesive adapted to the worker’s hands was used. To keep the adapter in a correct position between the work surface and the hand, an adhesive tape was used, following the indications of Annex D of the UNE-EN-ISO 5349-2 standard.

The measurements were taken in the work area of the structural recovery area, the welding area and the sheet metal forming and repair area.

Among the tasks carried out by the teachers, both in the repair of sheet metal and in its finishing, the ones with the highest level of vibrations were sanding sheet metal, reducing dents with the multifunction tool and reworking welding points with the radial saw. The task of polishing and cutting the car’s sheet metal using a disc grinder was also studied, as well as the removal of dents from the sheet metal using a dent puller.

To determine the vibration exposure of the teaching staff, the methodology described in the UNE-EN-ISO 5349-2 standard was followed, considering the magnitude of the vibrations (total vibration value) and the duration of daily exposure. The standard establishes four strategies for organizing the measurements. Of these, due to the nature of the tasks to be studied, the strategy of long-duration measurements of intermittent tool operations was employed for spot welding reworking tasks and for sanding tasks, using the roto-orbital sander and the flat sander. On the other hand, the strategy of fixed-duration measurements of single or multiple tool operation pulses or shocks was followed to obtain the vibration value when the multifunction tool was used for the task of removing dents from the sheet metal.

According to UNE-EN-ISO 5349, the minimum acceptable duration of measurements depends on the signal, instrumentation and characteristics of the operation. The total measurement time (number of samples multiplied by the duration for each measurement) had to be at least 1 min and, for each operation, at least 3 samples had to be taken.

Measurements were conducted for a time duration of 30 min for dent removal tasks with the multifunction spot welding reworking with the radial sander and for sanding operations using both the roto-orbital sander and the flat sander. For the long-duration measurements of intermittent tool operations, spot welding reworking and sanding operations, 3 measurements of 2 min durations each were performed. For the case of fixed-duration measurements of tool operation pulses or single or multiple shocks, when the worker used the multifunction tool, 10 measurements of 10 s durations each were performed during the task evaluation time.

The rms value of the frequency-weighted acceleration during the development of each of the tasks studied was obtained by means of Equation (4).

where A(8) is the daily vibration exposure (total equivalent vibration energy value for 8 h) in m/s2, ahw is the rms value of the frequency-weighted acceleration of hand-transmitted vibrations in m/s2, Texp is the total daily duration of vibration exposure and T0 is the reference duration of 8 h (28,800 s).

For the case of the dent removal task with the multifunction tool, the exposure time (Texp) was determined by means of Equation (5).

Since, in this case, the work in the body shop was such that the total daily vibration exposure consisted of several operations with different magnitudes of vibrations, the daily vibration exposure A(8) was obtained by applying Equation (6).

where ahvi is the total vibration value for operation i, n is the number of individual vibration exposures and Ti is the duration of operation i.

To determine the total vibration exposure to which teachers who performed these tasks on a daily basis during their workday were exposed, the weighted acceleration value for each task was taken into account and averaged to obtain a measure that was the most representative of the exposure.

3. Results

3.1. Noise Measurements

The results of the different measurements carried out in the workshop at the center were divided into continuous noise measurements and variable noise measurements, according to the classification discussed in the Section 2. These are shown in Table 1, Table 2 and Table 3.

Table 1.

Noise measurements carried out in the paint booth for continuous noise.

Table 2.

Noise measurements carried out in the body shop for variable noise.

Table 3.

Total noise exposure.

The results of the measurements showed that the machines and tasks carried out in this workshop generated noise levels ranging from 75.5 to 94.1 dBA. The lowest levels were obtained during sheet metal painting tasks in the paint booth (75.5 dBA), while the highest noise values were obtained during manual sheet metal dent repair tasks (hammer–dolly), which depended on the force with which the worker struck (94.1 dBA). Teachers with five hours in the workshop were exposed to a noise level of 89.1 dBA, with an associated uncertainty of 1.6 dBA for a one-sided coverage probability of 95% (K = 1.65).

The Spanish Royal Decree 286/2006 [24] sets the daily equivalent exposure limit value at 87 dB(A) and the limit value for action at 85 dB(A). From the results obtained, it was possible to observe that the variable noise measurements exceeded the limit value in all cases, except in the case of sheet metal finishing tasks with an orbital sander, which was very close to the limit value, so there was a hygiene risk and the company had to take immediate measures to reduce exposure below the limit values, as well as determine the reasons for overexposure.

The workshops of this VET center did not have noise control measures at the source level for machines, nor did they have acoustic treatment of walls and ceilings. The teachers present in the workshops did not use any hearing protection system during the working day, a necessary condition to perform noise measurements based on the UNE-EN-ISO 9612 standard.

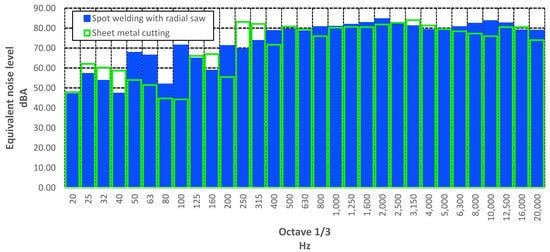

To determine the noise level for the most dangerous frequency bands of the different tasks, the two nonmanual tasks of sheet metal cutting and spot welding with the radial saw, whose noise level depends on the operation of a machine and not on the force with which the operator hits the sheet metal, stood out. For both tasks, which had an average sound pressure level of more than 93 dBA, the noise spectrum was obtained for the one-third octave frequency. Figure 1 shows the one-third octave noise spectrum of the most hazardous tasks.

Figure 1.

One-third octave noise spectrum of some of the most hazardous tasks in terms of average noise level.

In Figure 1, the highest equivalent noise level was found in the 2000 Hz frequency band, very close to 85 dBA, the upper exposure value according to the Spanish Royal Decree 286/2006 [24].

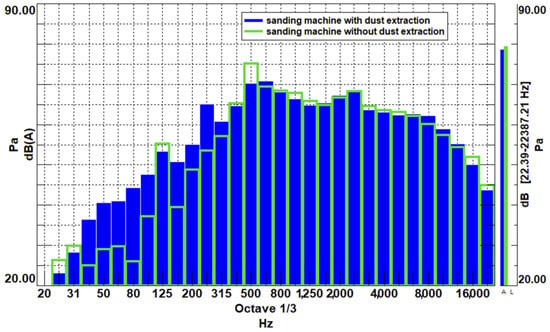

The noise level to which workers were exposed during sanding operations, with and without the operation of the dust extraction system, was also measured. Figure 2 shows the one-third octave bands of frequency. It was possible to see that the total sound pressure level (A) was almost 85 dBA. Moreover, the effect of the dust extraction could be appreciated as the SPL rose, specially at medium and high frequencies.

Figure 2.

One-third octave band of frequency, where A is the sum of the data values with the standard acoustic filtering and L is the sum of the linear unweighted data values in all octave bands.

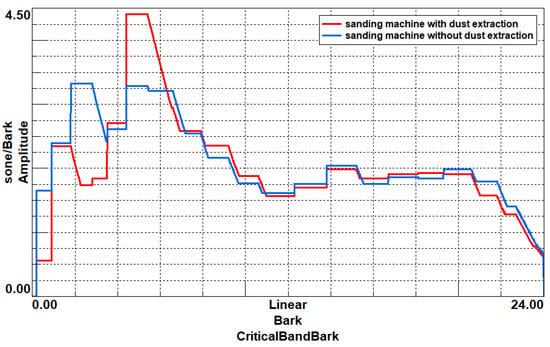

The stationary loudness spectrum called specific loudness was useful in locating the frequency ranges that contributed the most to the perceived loudness of a sound. Loudness is related to annoyance, with higher values implying a higher level of annoyance.

Figure 3 shows the specific loudness for the sanding machine with and without the dust extraction. The maximum pick was reached between four and six critical band of frequency, this having almost the same value for the other mid–high bark of frequency. The specific loudness graph over the critical band shown in Figure 3 clearly identified critical band five as the most annoying in terms of perceived noise level.

Figure 3.

Specific loudness for sanding machine with and without dust extraction.

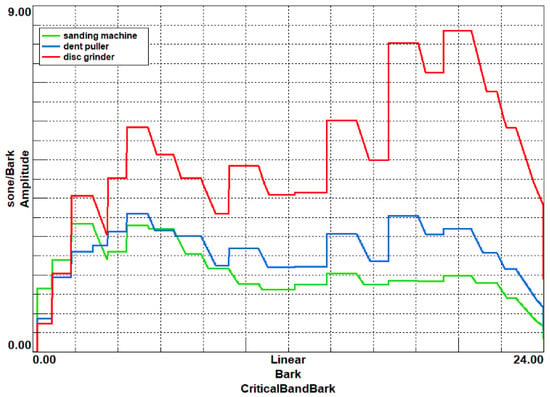

From Figure 4, it was possible to observe that the sanding machine, disc grinder and dent puller had a similar specific loudness for the low bark of frequency.

Figure 4.

Specific loudness for sanding machine, disc grinder and dent puller.

For the purposes of specific loudness with all three machines running, the disc grinder was the most annoying, as it had the highest levels for all frequency bands than the rest of the machines. It could also be seen for this machine that high frequencies were more annoying than low frequencies.

For the sanding machine and dent puller, both seemed to have similar tendencies as far as specific loudness was concerned. The most annoying band was 2 for the sanding machine and 15 and 17 bands for the dent puller.

3.2. Vibration Measurements

The results obtained for the vibration measurement of the analyzed tasks were as shown in Table 4.

Table 4.

Vibration measurements.

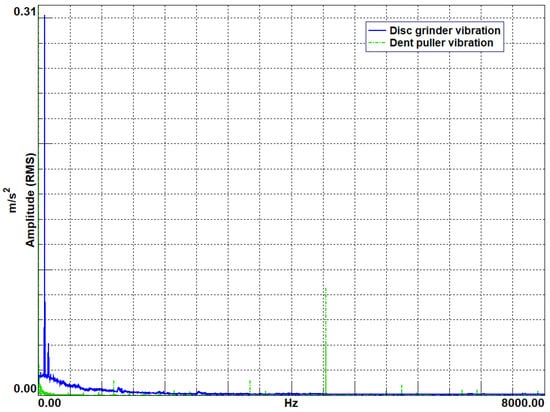

The hand–arm vibrations were evaluated for the disc grinder and dent puller. The disc grinder was used to polish and cut the sheet metal of the car. The dent of the sheet was removed using a dent puller. In the case of the dent puller, the sheet had a huge impact. This was measured with an accelerometer placed in the hand of the user. Figure 5 shows the acceleration level measured at the tool without a ponderation frequency given in the UNE-EN-ISO 5349 [25]. The impact of the disc grinder was three times higher than the dent puller. Applying the frequency ponderation stablished in UNE-EN-ISO 5349, the hand–arm vibration was 30.4 m/s2 for the disc grinder and 11.3 m/s2 for the dent puller.

Figure 5.

Hand–arm vibration for disc grinder and dent puller.

The results showed that the normalized daily exposure limit value for an 8 h period was exceeded, which was 5 m/s2, according to article three of the Spanish Royal Decree 1311/05 [26]; therefore, preventive measures should be taken immediately to reduce these levels.

4. Discussion

The exposure of teachers to noise and vibrations was measured in a VET school in Cordoba. This exposure was measured for various tasks and tools. The results obtained for the noise measurements in the VET school body shops exceeded the values that could be obtained in normal classrooms [9].

The results indicated that the highest noise exposure levels were found when using the disc grinder. The teachers could be involved in noisy tasks most of time in the laboratory and workshops and, on average, at levels higher than the action level. Moreover, they used different tools, like those that were described, including a sanding machine, disc grinder and dent puller, among others. The dust extraction system noise levels range almost reached 85 dB, that is according to values obtained by Summan et al. [20]. The average noise exposure level for teachers was approximately 89 dBA for a working day with 5 h of workshop, being this level higher than the maximum level stablished by the Spanish Royal Decree 286/2006 [24].

Few published studies were found that assessed the noise exposure of teachers in VET schools and centers. Among these, the study conducted in public TVET institutes in Malaysia stood out [33]. The results obtained in the Cordoba case study (ranging from 75.5 to 94.01 dBA, daily equivalent noise level) were in accordance with those obtained by Rahim et al. [33] in Malaysia, which ranged from 75.3 to 95 dB. These results exceeded the noise exposure levels allowed by legislation.

Regarding vibration exposure, Vihlborg et al. [21] studied the association between vibration exposure and hand–arm vibration symptoms in a Swedish mechanical industry. The association between occupational exposure to hand–arm vibration and hearing loss was reviewed by Weier in 2020 [34]. Barregard et al. [22] studied the occurrence of hand–arm vibration syndrome (HAVS) in Swedish car mechanics. The intensity of the vibrations estimated from a large survey on 286 nut-runners used at 26 garages in Sweden showed an average weighted acceleration level of 3.5 m/s2. Measurements taken in Cordoba showed even higher values than these.

The Spanish law on occupational risk prevention applies to all sectors, including vocational training teachers. However, it was observed that the VET center in this case study did not apply protective measures against the risks studied. The teachers present in the workshops did not use any hearing protection system during the working day, neither when carrying out the tasks nor when supervising the correct performance of the students. This agreed with what Summan et al. [20] observed in the technology educational shops in Canada that they analyzed. Therefore, further measures should be taken in this regard.

Recommendations

All the studies found suggested the need to adopt measures to mitigate the effects of exposure to both noise and vibrations to prevent the appearance of occupational diseases. Considering the results obtained for this case study in a VET center, these prevention measures should have also been applied to the teaching staff. The most suitable measures include the daily monitoring of the noise level of machines, equipment and tools in the workshops of the professional families whose workers are most exposed to this physical agent, the correct maintenance of machines and equipment, the use of personal protective equipment suitable for the tasks carried out in the workshops and specific and regular health surveillance for exposed workers.

5. Conclusions

Exposure of workers to noise or vibration has been extensively studied for multiple sectors. In fact, because exposure to high noise levels in classrooms can cause voice disorders in teachers in general, this has also been extensively studied. However, in vocational schools, where teachers work in laboratories and workshops, there are also risks related to high levels of noise and vibrations caused by the machines and tools used there. There is a lack of studies analyzing the exposure of teachers in VET centers and schools to these risks.

Therefore, this study analyzed the exposure to noise and vibrations of a VET bodywork training cycle teaching staff. The results of the noise measurements showed that the machines and tasks carried out in this workshop generated noise levels ranging from 75.5 to 94.1 dBA. Regarding hand–arm vibrations, a daily weighted acceleration value of 17.69 m/s2 was obtained. Measurements for both hazards showed that the limit values allowed by legislation were reached or exceeded.

The results obtained in this study contribute towards showing the existence of specific risks for VET teachers that have not been widely studied and that should lead to the adoption of measures that try to minimize their consequences to teachers’ health. This highlights the need for further studies in this sector of teaching staff, as well as for measures to minimize the consequences of such exposure, which can lead to occupational diseases. These measures include the provision of sufficient personal protective equipment appropriate to the tasks they carry out and regular medical examinations of the hearing function and audiometric monitoring of teachers working in these workshops.

Author Contributions

Conceptualization, L.S.-R., M.D.R.-M. and M.G.-R.; measurements, L.S.-R. and M.D.R.-M.; data analysis, L.S.-R., M.D.R.-M. and M.G.-R.; writing—original draft preparation, L.S.-R., M.D.R.-M. and M.G.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ministerio de Trabajo y Asuntos Sociales, Real Decreto 1299/2006, de 10 de noviembre, por el que se aprueba el cuadro de enfermedades profesionales en el sistema de la Seguridad Social y se establecen criterios para su notificación y registro. Boletín Of. Estado. 2006, 302, 44487–44546.

- Cantor Cutiva, L.C.; Vogel, I.; Burdorf, A. Voice disorders in teachers and their associations with work-related factors: A systematic review. J. Commun. Disord. 2013, 46, 143–155. [Google Scholar] [CrossRef] [PubMed]

- Byeon, H. The Risk Factors Related to Voice Disorder in Teachers: A Systematic Review and Meta-Analysis. Int. J. Environ. Res. Public Health 2019, 16, 3675. [Google Scholar] [CrossRef]

- Patjas, M.; Vertanen-Greis, H.; Pietarinen, P.; Geneid, A. Voice symptoms in teachers during distance teaching: A survey during the COVID-19 pandemic in Finland. Eur. Arch. Otorhinolaryngol. 2021, 278, 4383–4390. [Google Scholar] [CrossRef]

- Alves, L.A.; do Carmo Cruz Robazzi, M.L.; Marziale, M.H.P.; de Felippe, A.C.N.; da Conceição Romano, C. Health disorders and teachers’ voices: A workers’ health issue. Rev. Lat. Am. Enfermagem. 2009, 17, 566–572. [Google Scholar] [CrossRef][Green Version]

- Martins, R.H.G.; Pereira, E.R.B.N.; Hidalgo, C.B.; Tavares, E.L.M. Voice Disorders in Teachers. A Review. J. Voice. 2014, 28, 716–724. [Google Scholar] [CrossRef] [PubMed]

- Sachová, P.; Mrázková, E.; Menzlová, M.; Richterová, K.; Sachová, R.; Janout, V. Noise as a risk factor in school facilities. Occup. Med. (Chic. Ill) 2009, 4, 182–187. [Google Scholar]

- Maffei, L.; Iannace, G.; Masullo, M. Noise Exposure of Physical Education and Music Teachers. Noise Vib. Worldw. 2011, 42, 9–16. [Google Scholar] [CrossRef]

- Sala, E.; Holmqvist Jämsén, S.; Rantala, L.M.; Hakala, S.J.; Jónsdóttir, V. Activity noise in comprehensive school classrooms in Finland. In Proceedings of the 42nd International Congress and Exposition on Noise Control Engineering 2013, INTER-NOISE 2013: Noise Control for Quality of Life, Innsbruck, Austria, 15–18 September 2013. [Google Scholar]

- Augustyńska, D.; Kaczmarska, A.; Mikulski, W.; Radosz, J. Assessment of Teachers’ Exposure to Noise in Selected Primary Schools. Arch. Acoust. 2010, 35, 521–542. [Google Scholar] [CrossRef]

- Tomek, R.; Urhahne, D. Relating teachers’ coping styles to student noise and perceived stress. Educ. Psychol. 2022, 42, 375–395. [Google Scholar] [CrossRef]

- Garcia Martins, R.H.; Mendes Tavares, E.L.; Lima Neto, A.C.; Fioravanti, M.P. Occupational hearing loss in teachers: A probable diagnosis. Braz. J. Otorhinolaryngol. 2007, 73, 239–244. [Google Scholar] [CrossRef]

- Isaac, M.J.; McBroom, D.H.; Nguyen, S.A.; Halstead, L.A. Prevalence of Hearing Loss in Teachers of Singing and Voice Students. J. Voice. 2017, 31, 379.e21–379.e32. [Google Scholar] [CrossRef] [PubMed]

- Behar, A.; MacDonald, E.; Lee, J.; Cui, J.; Kunov, H.; Wong, W. Noise Exposure of Music Teachers. J. Occup. Environ. Hyg. 2004, 1, 243–247. [Google Scholar] [CrossRef] [PubMed]

- Maffei, L.; Iannace, G.; Masullo, M.; Nataletti, P. Noise exposure in school gymnasia and swimming pools. Noise Control Eng. J. 2009, 57, 603–612. [Google Scholar] [CrossRef]

- Sá, M.M.; Azevedo, R.; Martins, C.; Machado, O. Portuguese Physical Education Instructors’ Exposure to Noise and Perception of Associated Risk. Hum. Ecol. Risk Assess. Int. J. 2014, 20, 448–460. [Google Scholar] [CrossRef]

- Strasse, W.A.D.; Stadnik, A.M.W.; Ulbricht, L. Assessment of the level of noise in gyms for sports in a college in the city of Curitiba. In Occupational Safety and Hygiene III, 1st ed.; Arezes, P.M., Baptista, J.S., Barroso, M.P., Carneiro, P., Cordeiro, P., Costa, N., Melo, R.B., Miguel, A.S., Perestrelo, G., Eds.; CRC Press: London, UK, 2015; Volume 1, pp. 237–240. [Google Scholar]

- Fredriksson, S.; Kim, J.L.; Torén, K.; Magnusson, L.; Kähäri, K.; Söderberg, M.; Persson Waye, K. Working in preschool increases the risk of hearing-related symptoms: A cohort study among Swedish women. Int. Arch. Occup. Environ. Health. 2019, 92, 1179–1190. [Google Scholar] [CrossRef]

- Rozema, T. Investigation of noise level in lower occupational training school work rooms (Dutch). Veiligheid 1975, 51, 159–165. [Google Scholar]

- Summan, A.S.; Bartlett, K.; Davies, H.; Koehoorn, M. Noise exposure among teachers in technology educational shops in selected British Columbia, Canada, high schools. J. Occup. Environ. Hyg. 2020, 17, 457–463. [Google Scholar] [CrossRef]

- Vihlborg, P.; Bryngelsson, L.; Lindgren, B.; Gunnarsson, L.G.; Graff, P. Association between vibration exposure and hand-arm vibration symptoms in a Swedish mechanical industry. Int. J. Ind. Ergon. 2017, 62, 77–81. [Google Scholar] [CrossRef]

- Barregard, L.; Ehrenström, L.; Marcus, K. Hand-arm vibration syndrome in Swedish car mechanics. Occup. Environ. Med. 2003, 60, 287–294. [Google Scholar] [CrossRef]

- UNE-EN ISO 9612:2009; Acústica—Determinación de la Exposición al Ruido en el Trabajo—Método de Ingeniería. AENOR: Madrid, Spain, 2009.

- Ministerio de la Presidencia. Real Decreto 286/2006, de 10 de marzo, sobre la protección de la salud y la seguridad de los trabajadores contra los riesgos relacionados con la exposición al ruido. Boletín Of. Estado 2006, 60, 9842–9848. [Google Scholar]

- UNE-EN ISO 5349-2:2001; Vibraciones Mecánicas. Medición y Evaluación de la Exposición Humana a las Vibraciones Transmitidas por la Mano. Parte 2: Guía Práctica Para la Medición en el Lugar de Trabajo. AENOR: Madrid, Spain, 2001.

- Ministerio de Trabajo y Asuntos Sociales. Real Decreto 1311/2005, de 4 de noviembre, sobre la protección de la salud y la seguridad de los trabajadores frente a los riesgos derivados o que puedan derivarse de la exposición a vibraciones mecánicas. Boletín Of. Estado. 2005, 265, 36385–36390. [Google Scholar]

- Zwicker, E.; Fastl, H. Psychoacoustics; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- ISO 532B:1975; Acoustics—Method for Calculating Loudness Level—Part 1: Stationary Sounds. International Organization for Standardization: Geneva, Switzerland, 1975.

- DIN 45631:1991; Berechnung des Laustärkepegels und der Lautheit aus dem Geräuschspektrum. Verfahren nach E. Zwicker. Deutsches Institut für Normung: Berlin, Germany, 1991.

- ISO/R 131:1959; Expression of the Physical and Subjective Magnitudes of Sound or Noise. International Organization for Standardization: Geneva, Switzerland, 1959.

- UNE-EN ISO 266:1998; Acústica. Frecuencias Preferentes. (ISO 266:1997). AENOR: Madrid, Spain, 1998.

- Instituto Nacional de Seguridad e Higiene en el Trabajo. NTP 270: Evaluación de la exposición al ruido. In Determinación de Niveles Representativos; Ministerio de Trabajo y Asuntos Sociales de España: Madrid, Spain, 1991. [Google Scholar]

- Abdul Rahim, K.A.; Jewaratnam, J.; Che Hassan, C.R. Identification of Noise Levels for Skill Training Activities, Equipment, Machines and Power Tools at TVET Institutes in Malaysia. Int. J. Environ. Res. Public Health 2022, 19, 15783. [Google Scholar] [CrossRef] [PubMed]

- Weier, M.H. The Association Between Occupational Exposure to Hand–Arm Vibration and Hearing Loss: A Systematic Literature Review. Saf. Health Work. 2020, 11, 249–261. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).