Analysis of Vibration and Acoustic Radiation Characteristics of Reinforced Laminated Cylindrical Shell Structure

Abstract

:1. Introduction

2. Experimental Research

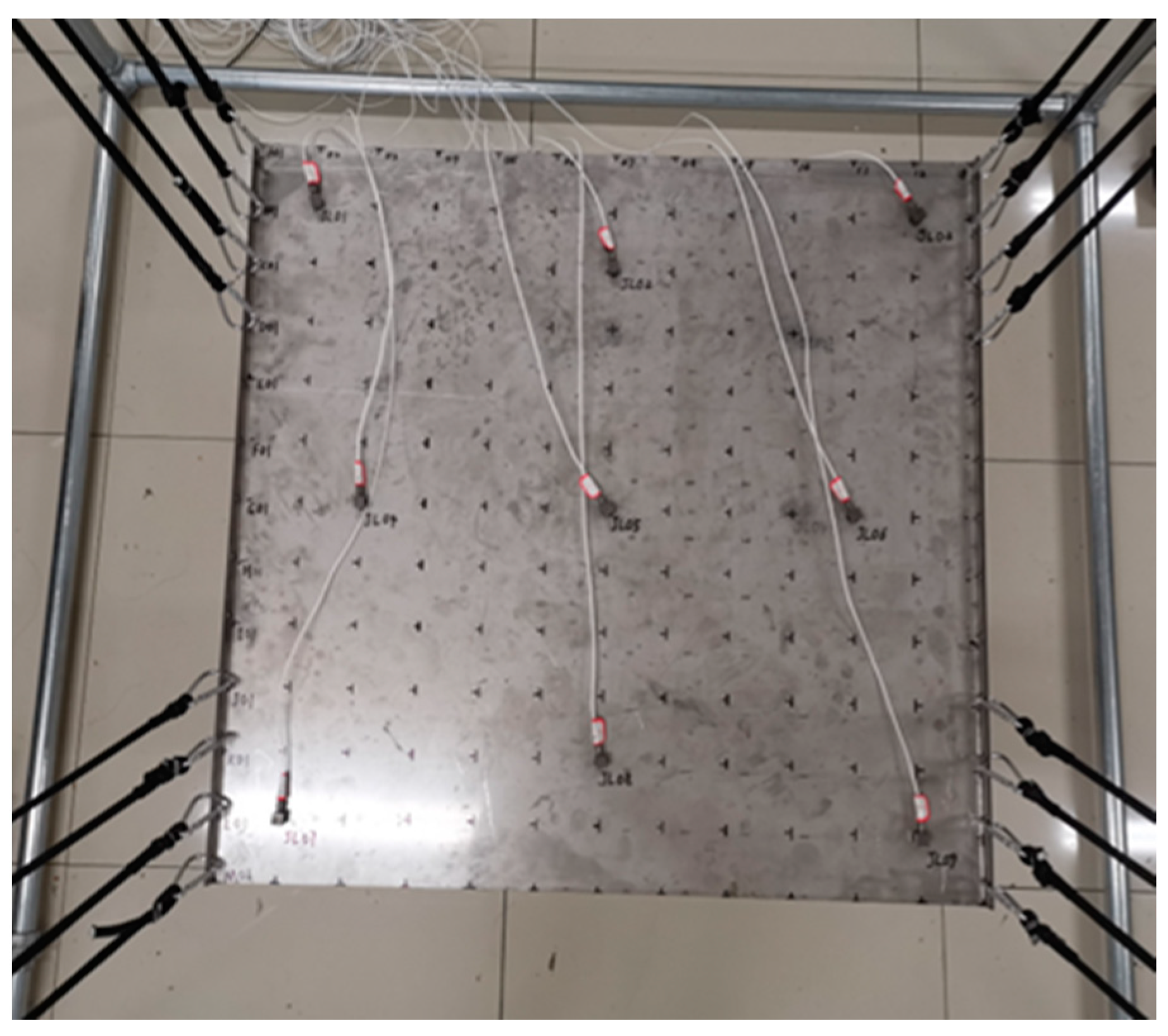

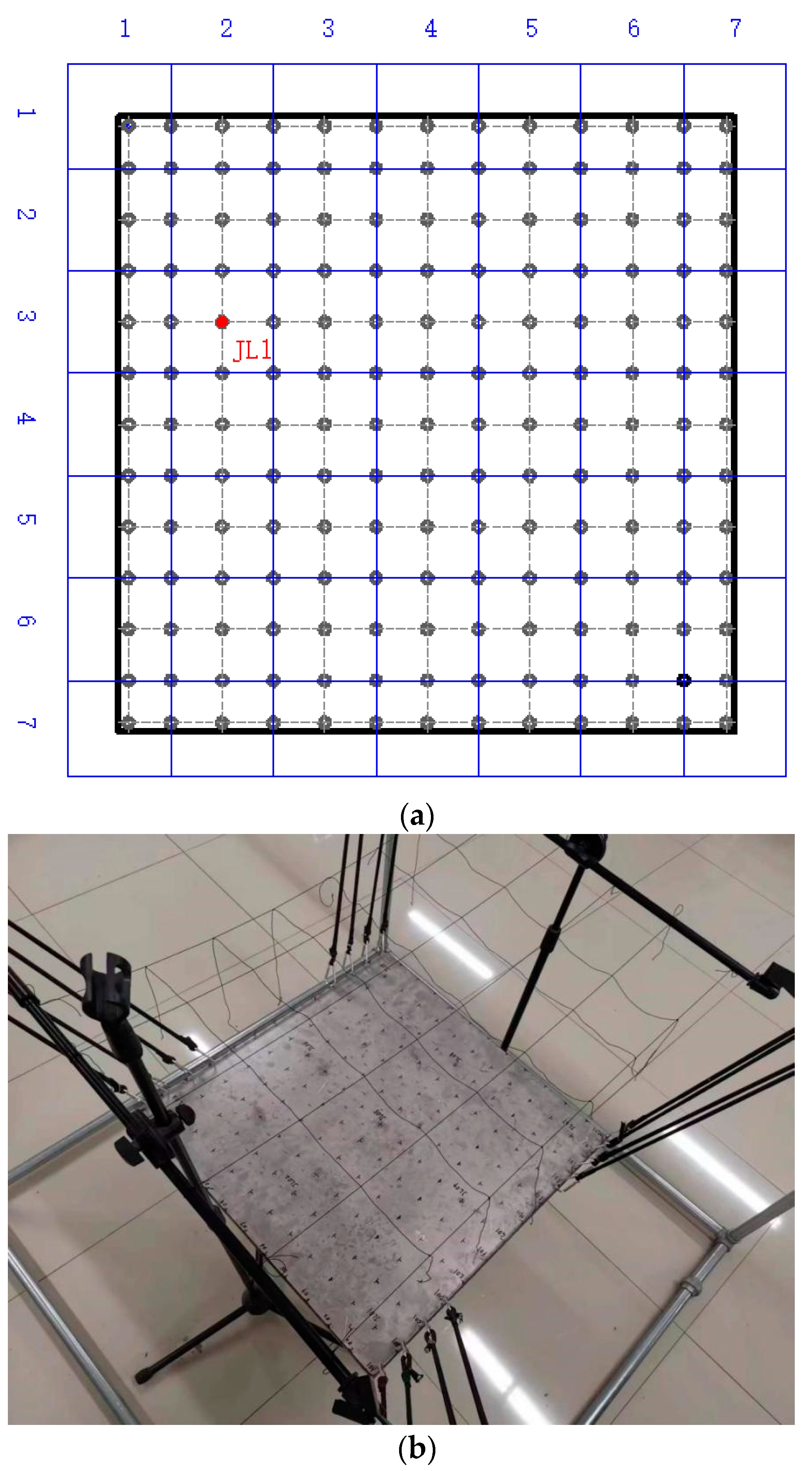

2.1. Experimental Setup Construction

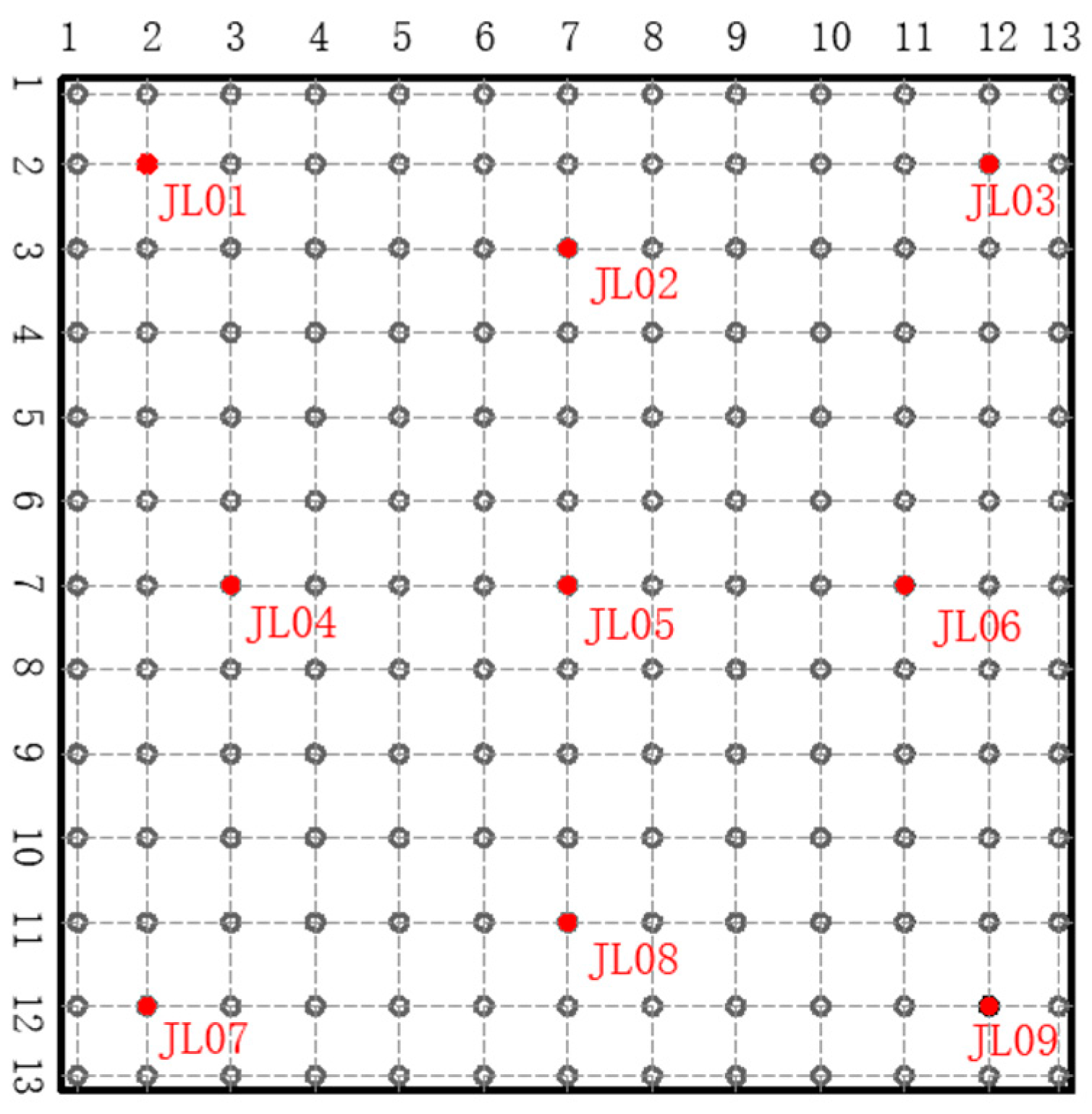

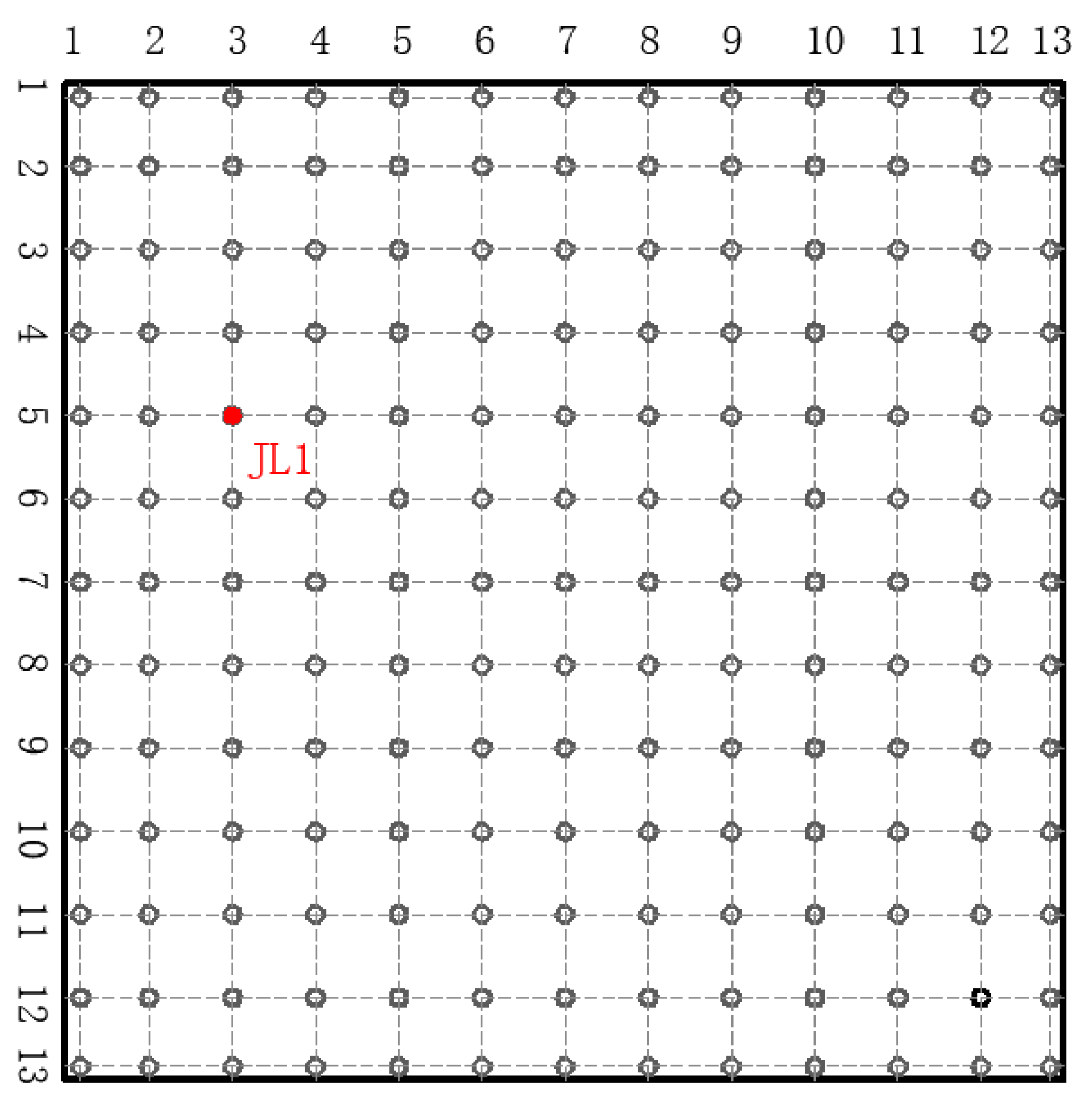

2.2. Modal Experimental Testing

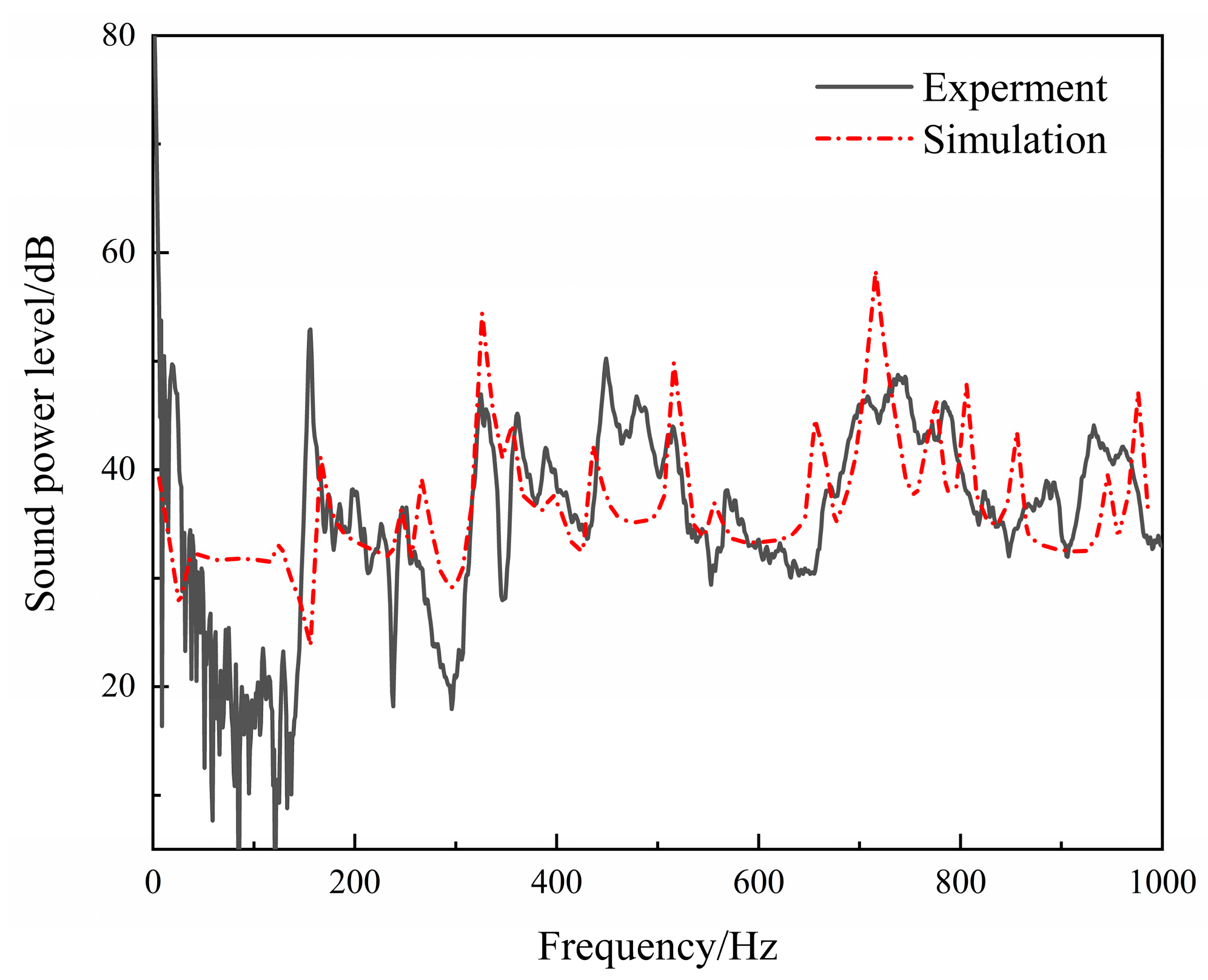

2.3. Acoustic Radiation Experiment

3. Finite Element Simulation Study

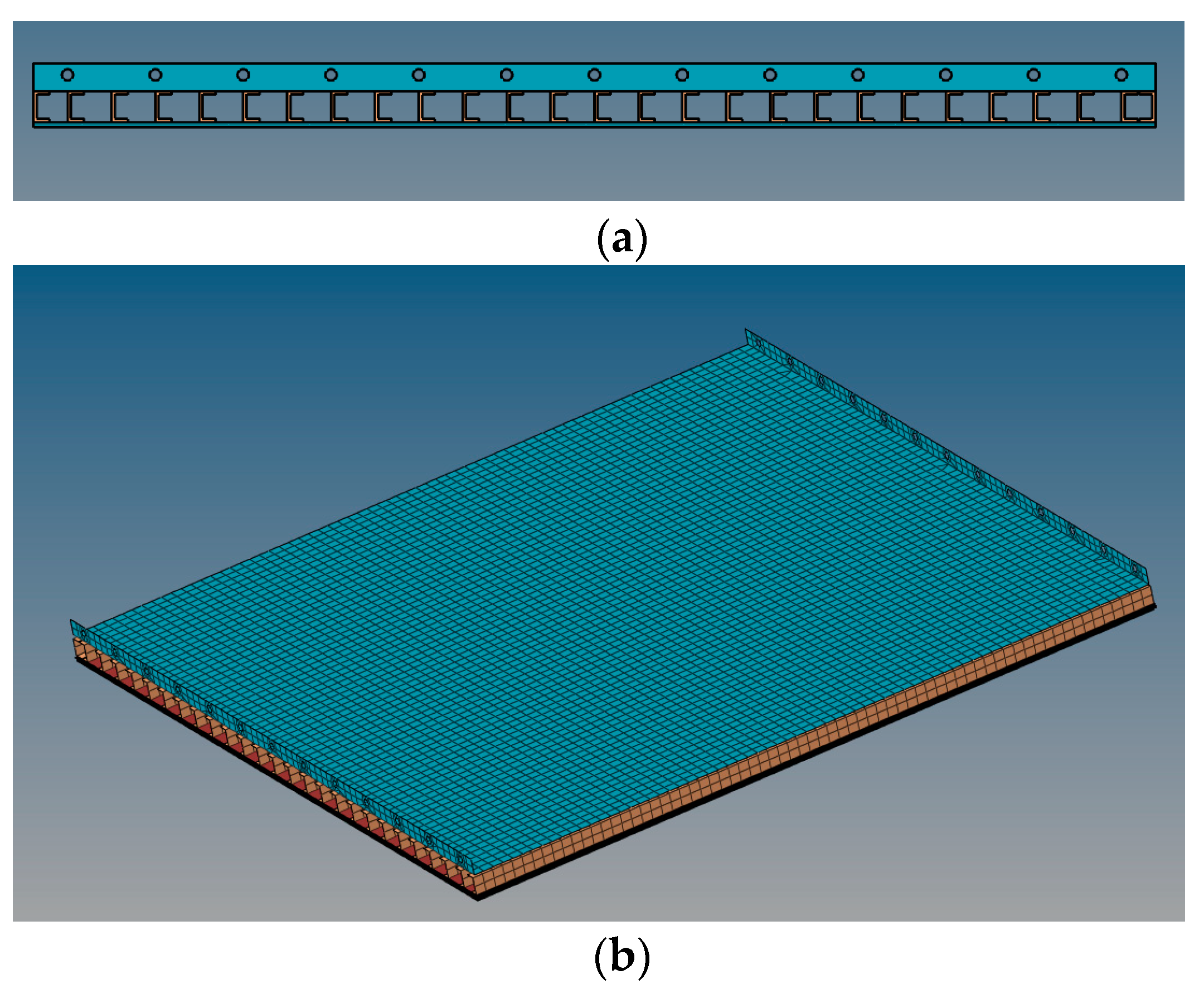

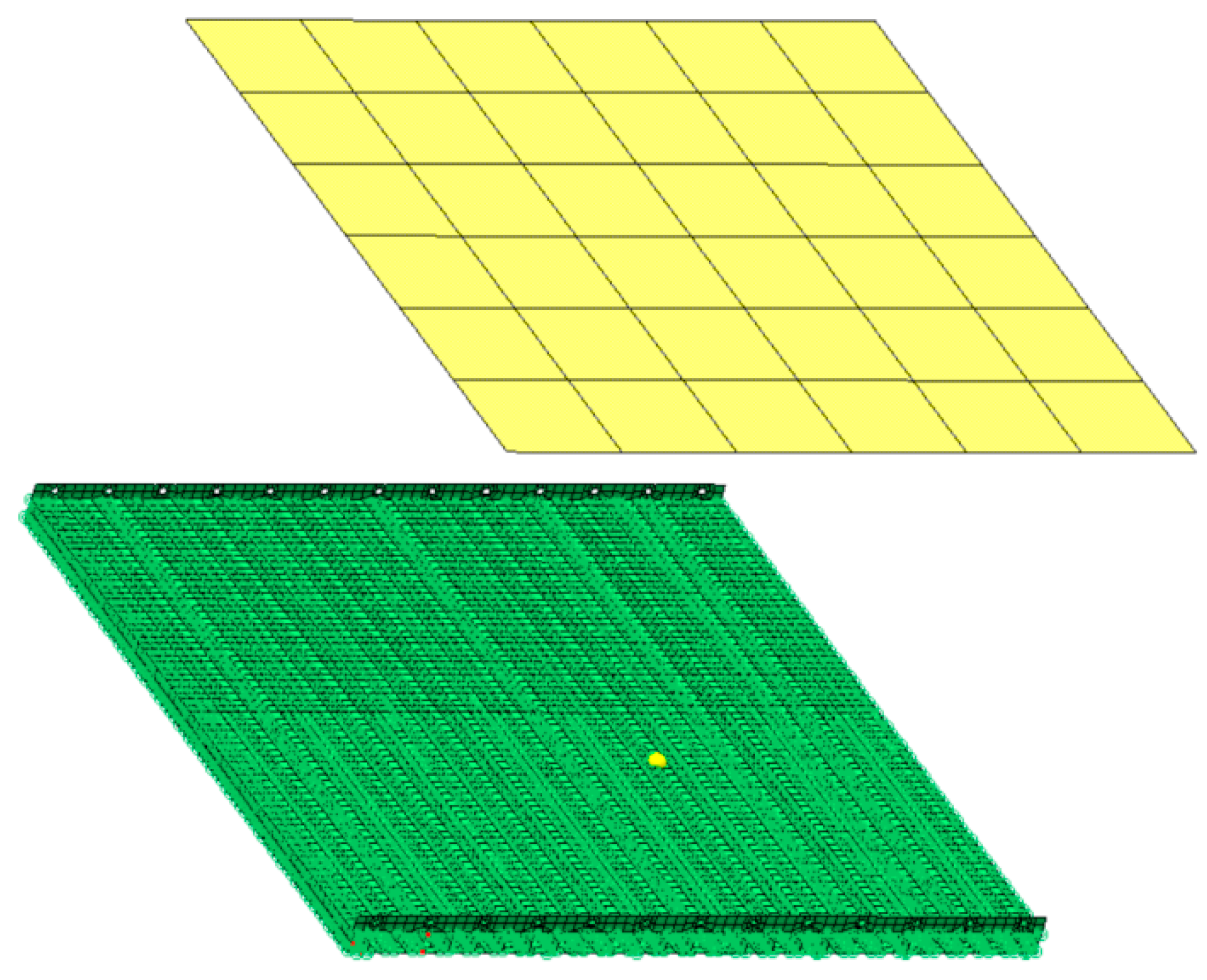

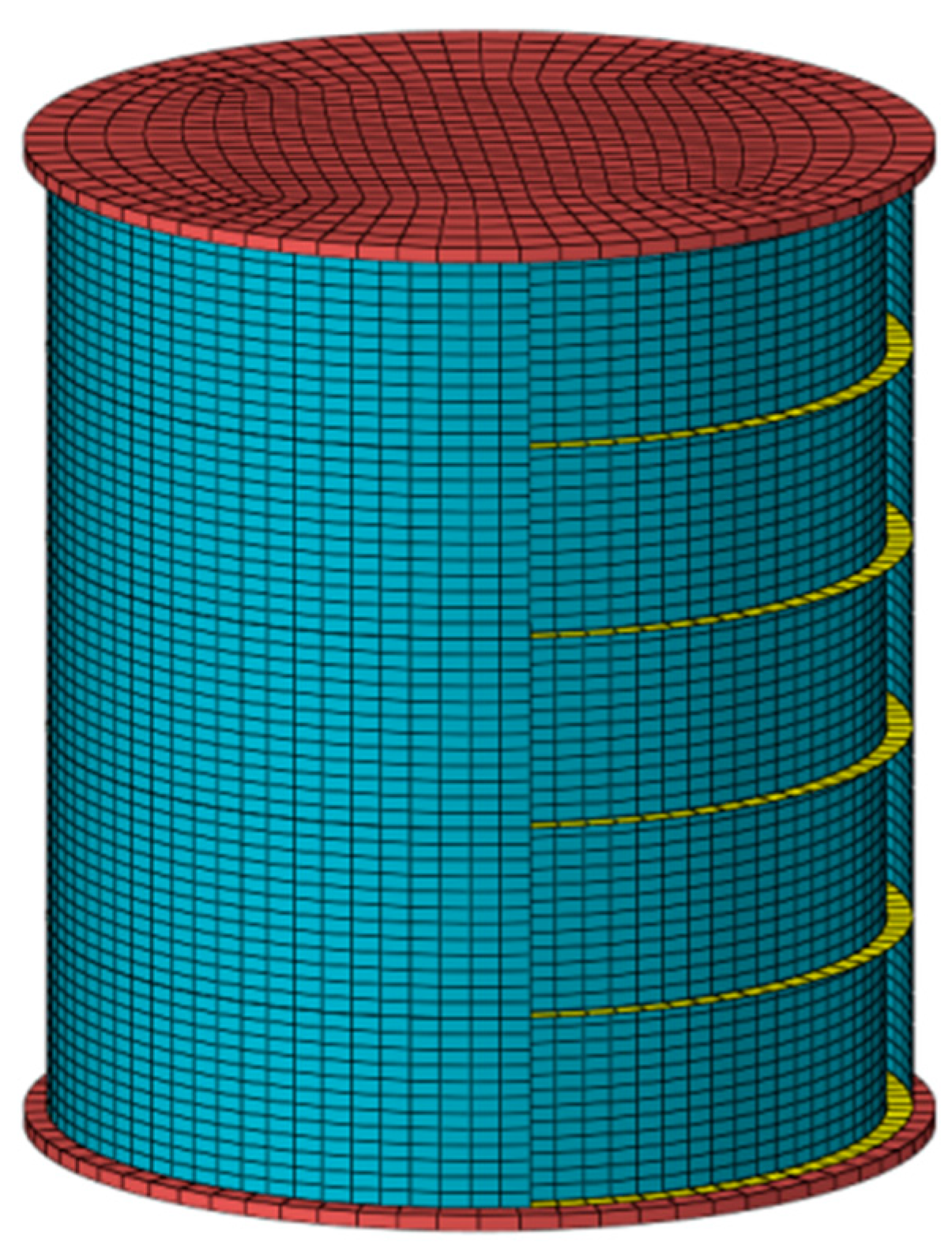

3.1. Finite Element Model

3.2. Finite Element Model Validation

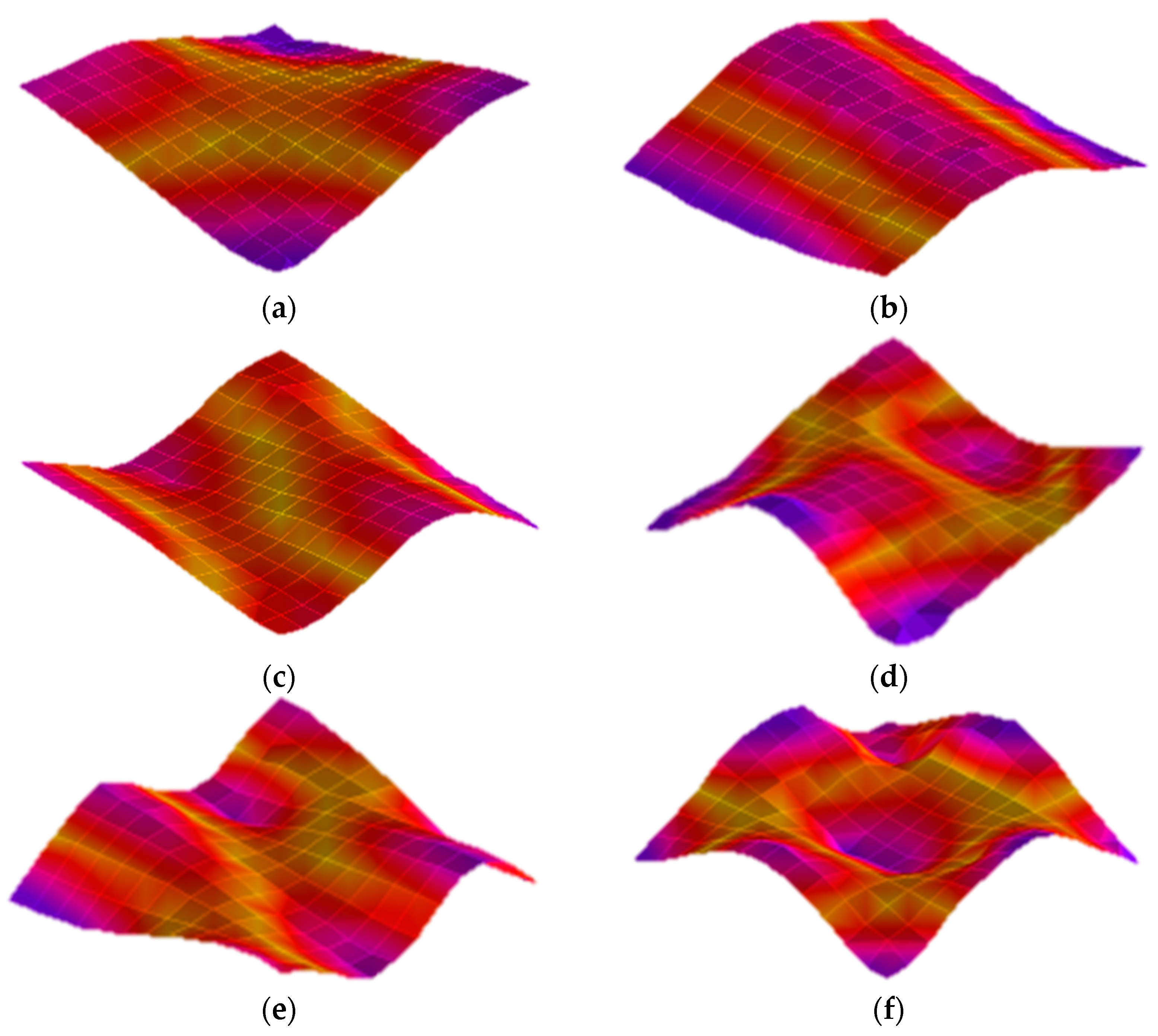

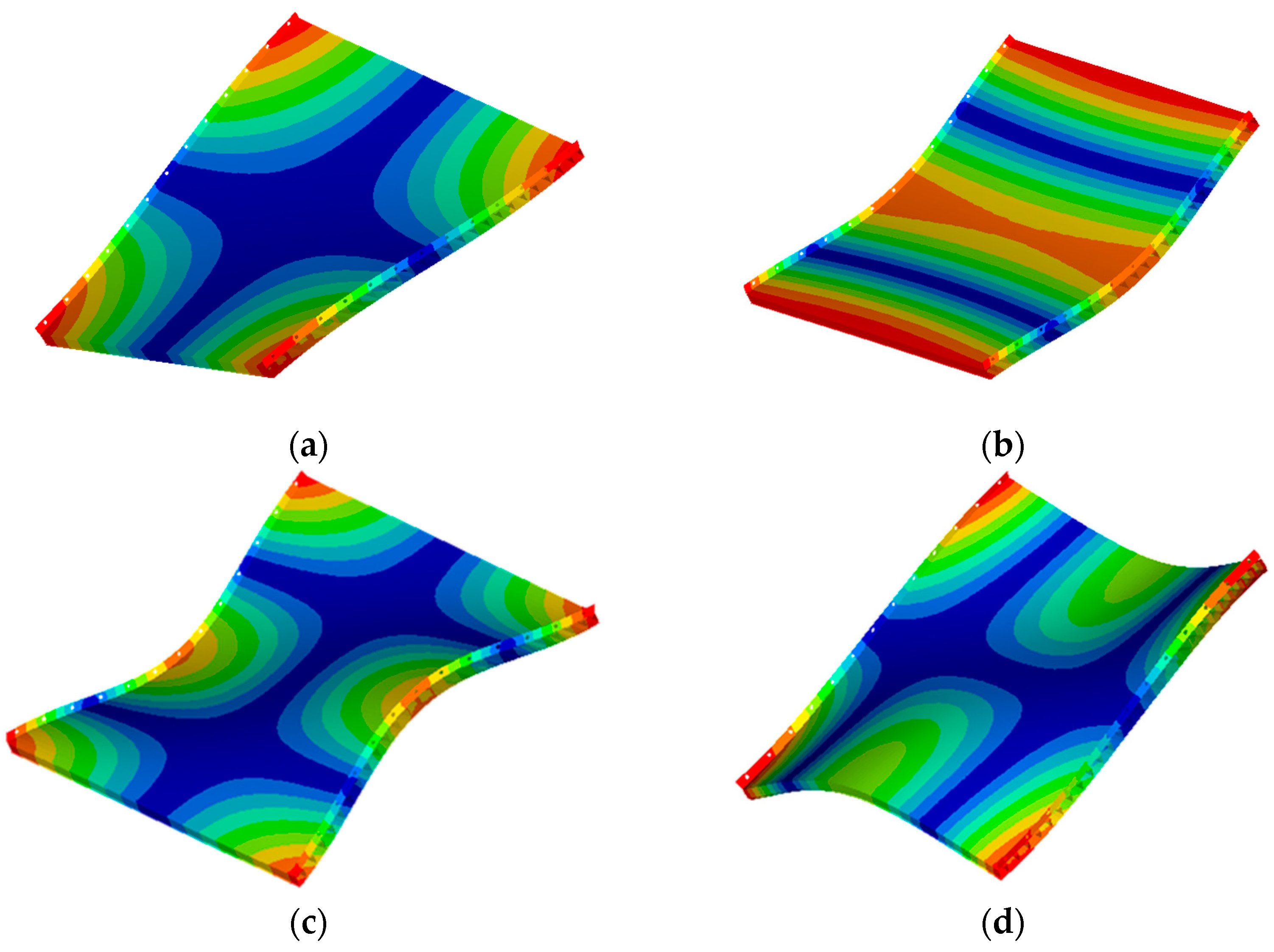

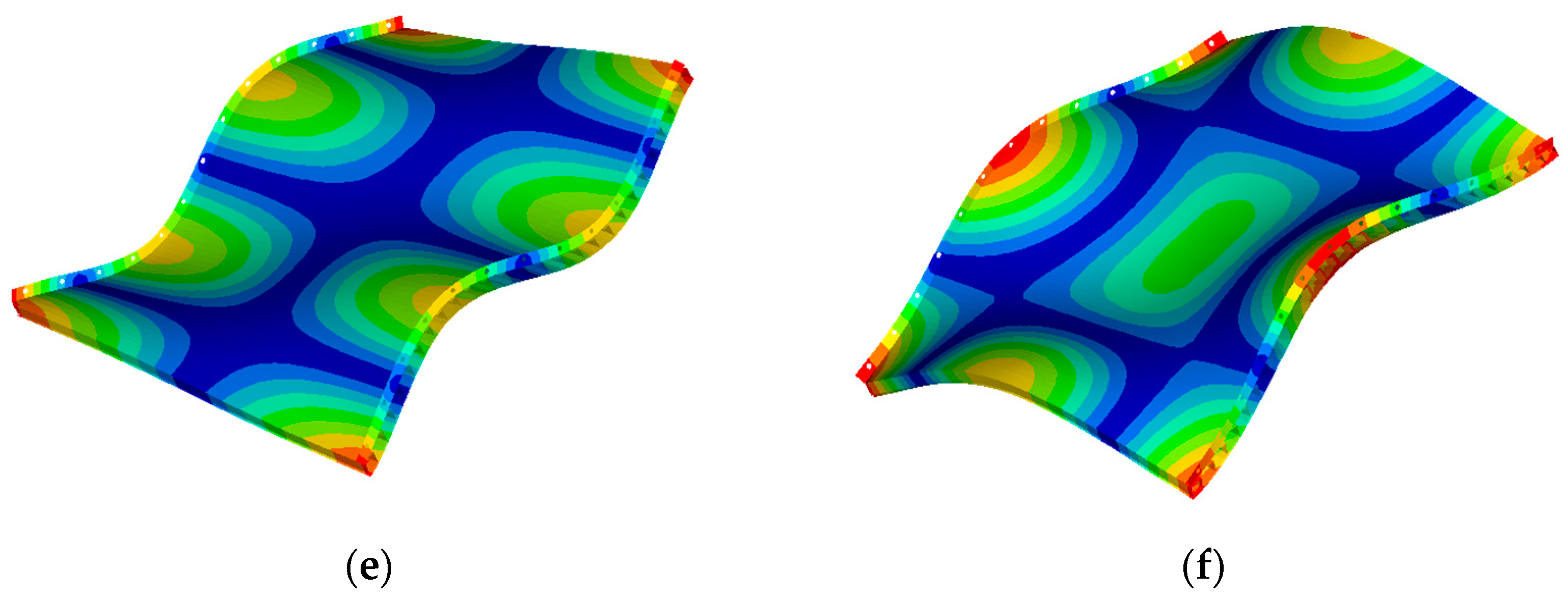

3.2.1. Structural Modes

3.2.2. Structural Sound Radiation

4. Analysis of Sound Radiation Characteristics for Reinforced Laminated Cylindrical Shell Structures

4.1. Finite Element Model

4.2. Effect of Reinforcement Method

4.2.1. Effects of Longitudinal Reinforcement

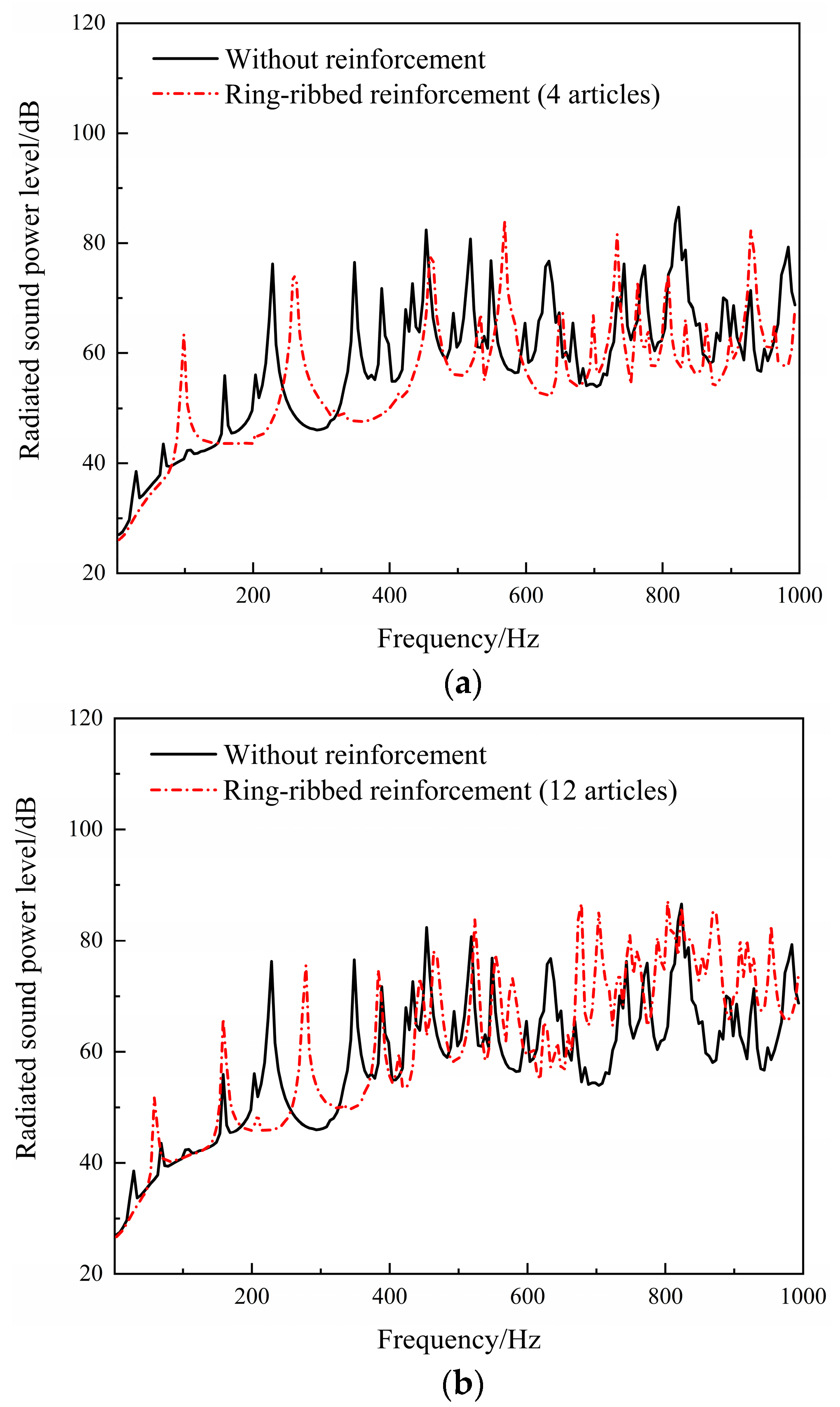

4.2.2. Effects of Ring Stiffening

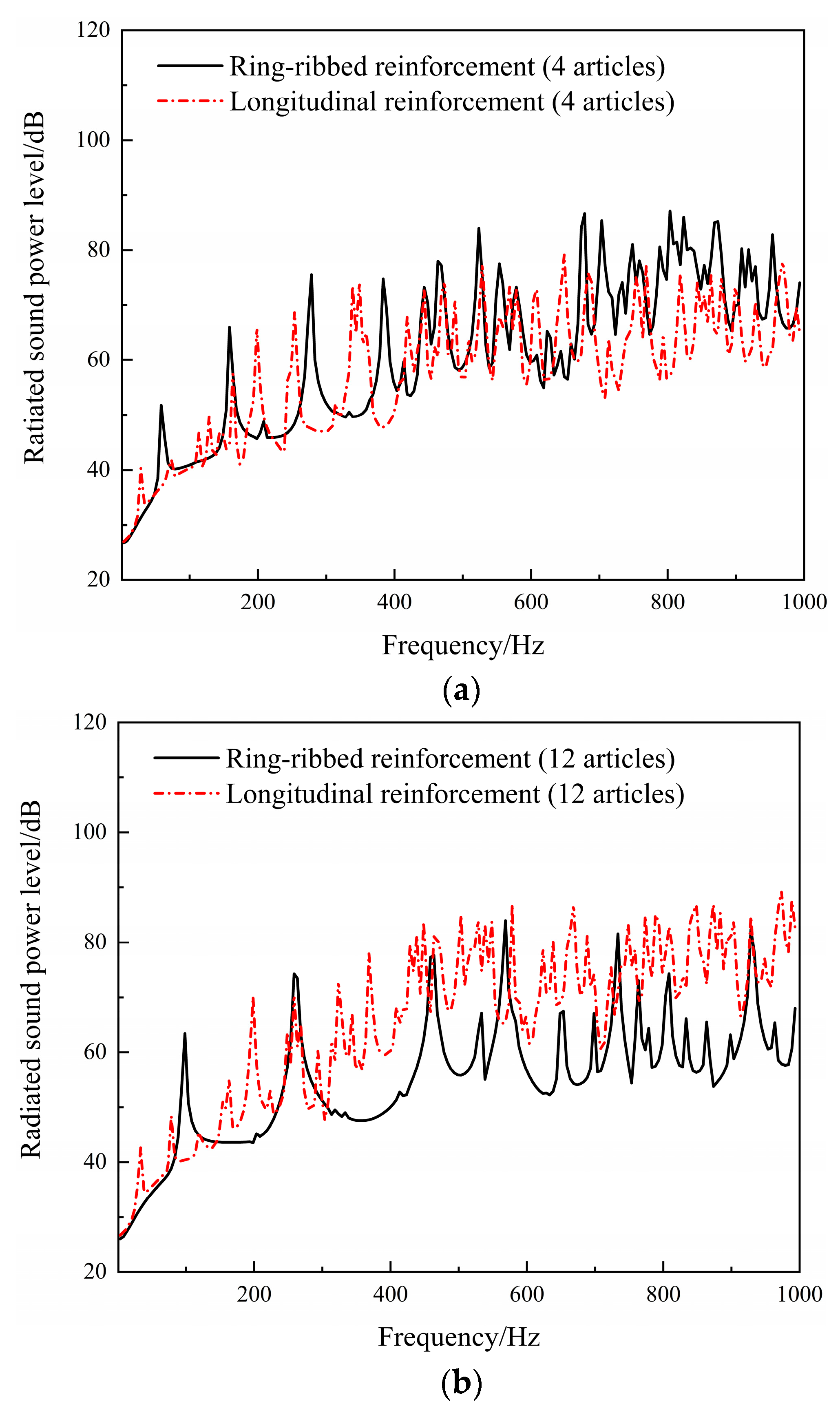

4.2.3. Effects of Different Reinforcement Forms on the Noise Radiation of Laminated Cylindrical Shell Structures

4.3. Effects of Reinforcement Quantity

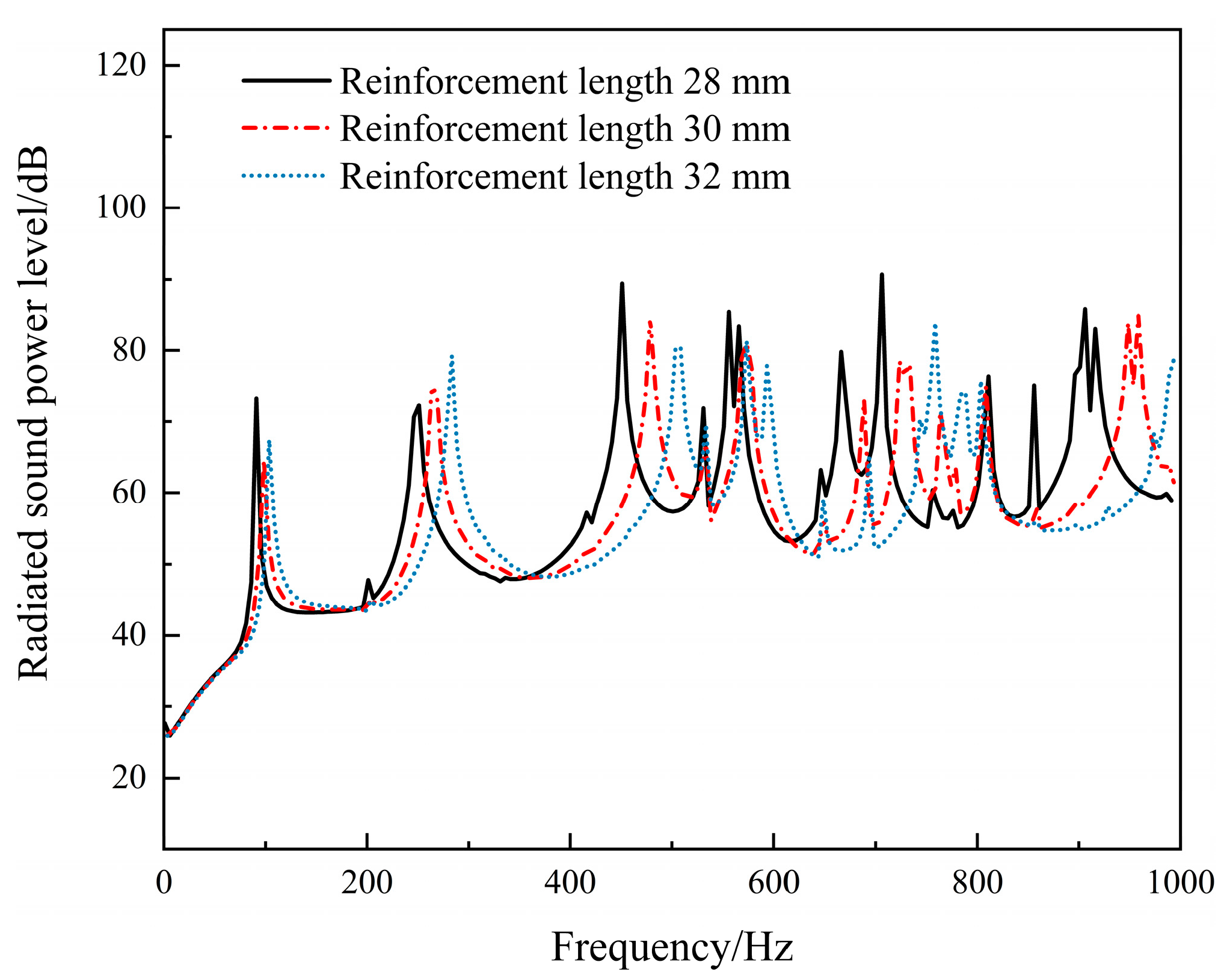

4.4. Effects of Reinforcement Length

4.5. Effects of Reinforcement Thickness

5. Conclusions

- In the frequency range of 1–1000 Hz, when comparing the cylindrical shells reinforced with ring ribs and longitudinal ribs, both having 12 ribs, the former has a 16.19 dB lower overall sound power level than the latter. This indicates that the ring rib reinforcement performs better in reducing the structural noise radiation.

- In the frequency range of 1–1000 Hz, when the number of ring ribs is 4, 10, and 16, the overall sound power level of the structure is 90.1 dB, 80.82 dB, and 80.28 dB, respectively. This indicates that as the number of ring ribs increases, the structure’s sound radiation decreases. Additionally, the number of radiation peaks also decreases, and the peak values shift towards higher frequencies. This is due to the increased number of ring ribs, which leads to stronger axial restraint on the cylindrical shell, resulting in a smoother structure sound power level curve and a reduction in radiation peak values.

- In the frequency range of 1–1000 Hz, the total sound power levels of the rib-reinforced cylindrical shell are 80.14 dB, 79.17 dB, and 80.28 dB, respectively, for rib lengths of 28 mm, 30 mm, and 32 mm. This indicates that with the increase in rib length, the overall sound power level shows a trend of an initial increase and then a decrease.

- In the frequency range of 1–1000 Hz, the total sound power levels of the rib-reinforced cylindrical shell are 82.4 dB, 80.28 dB, and 78.32 dB, respectively, for rib thicknesses of 1.4 mm, 2.0 mm, and 2.6 mm. This indicates that with the increase in rib thickness, the radiated noise of the cylindrical shell structure decreases. This suggests that increasing the rib thickness increases the contact area between the reinforcing ribs and the inner and outer shells to some extent, resulting in a more uniform distribution of excitation forces on the shell, effectively reducing the radiated noise of the structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, Q.Q.; Chen, Z.J. Vibro-acoustic characteristics of ring-stiffened cylindricalshells using structure reactance improvement. J. Huazhong Univ. Sci. Tech. 2012, 40, 90–94. [Google Scholar]

- Naghsh, A.; Saadatpour, M.; Azhari, M. Free vibration analysis of stringer stiffened general shells of revolution using a meridional finite strip method. Thin-Walled Struct. 2015, 94, 651–662. [Google Scholar]

- Maxit, L.; Guasch, O.; Meyer, V.; Karimi, M. Noise radiated from a periodically stiffened cylindrical shell excited by a turbulent boundary layer. J. Sound Vib. 2020, 466, 115016. [Google Scholar]

- Bae, S.; Lee, S. Acoustic Radiation from a Submerged Stiffened Cylindrical Shell Excited by Resiliently Mounted Machinery. Trans. Korean Soc. Noise Vib. Eng. 2015, 25, 33–39. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, H.; Li, H.C.; Pang, F.Z.; Wang, H.F. Numerical and experimental investigation of vibro-acoustic characteristics of a submerged stiffened cylindrical shell excited by a mechanical force. Ocean. Eng. 2022, 249, 110913. [Google Scholar]

- Zou, M.S.; Tang, H.C.; Liu, S.X. Modeling and calculation of acoustic radiation of underwater stiffened cylindrical shells treated with local damping. Mar. Struct. 2023, 88, 103366. [Google Scholar] [CrossRef]

- Wang, S.Y. Theories and Applications of Acoustic Radiation from Reinforced Thin-Wall Structures. Value Eng. 2018, 37, 95–97. [Google Scholar]

- Zhang, B.; Xiang, Y.; Li, F.; Guo, N.; Xiao, H.F. Research of Sound Radiation Characteristics of a Stiffened Cylindrical Shell and Its Acoustic Optimal Design. Noise Vib. Control 2017, 37, 31–36. [Google Scholar]

- Tong, Y.Z.; Pan, X.F.; Deng, H.C.; Wu, K. Acoustic scattering from an infinitely long cylindrical shell with lengthwise ribs. J. Ship Mech. 2022, 26, 750–760. [Google Scholar]

- Tong, Y.Z.; Fan, J.; Wang, B.; Tang, W.L. Acoustic radiation from an infinite cylindrical shell with internal periodic lengthwise ribs. J. Ship Mech. 2021, 25, 246–255. [Google Scholar]

- Wang, X.Z.; Jiang, C.M.; Ji, F.; Fang, Y.M. Acoustic radiation of submerged ring-stiffened cylindrical shells with Precise Transfer Matrix Method. J. Ship Mech. 2017, 21, 503–511. [Google Scholar]

- GB/T 16404.2-1999; Acoustics—Determination of Sound Power Levels of Noise Sources Using Sound Intensity—Part 2: Measurement by Scanning. State Administration for Market Regulation: Beijing, China, 1999; p. 24.

- Du, G.H.; Zhu, Z.M. Fundamentals of Acoustics, 2nd ed.; Nanjing University Press: Nanjing, China, 2001. [Google Scholar]

| Density/kg/m3 | Young’s Modulus/GPa | Poisson’s Ratio | Velocity/m/s | |

|---|---|---|---|---|

| Steel | 7700 | 210 | 0.3 | / |

| Structural glue | 900 | 1.5 | 0.41 | / |

| Atmosphere | 1.225 | / | / | 340 |

| Vibration Pattern | Experimental Value | Simulation Value | Inaccuracies | |

|---|---|---|---|---|

| 1st | (2, 2) | 126.2 Hz | 127.1 Hz | 0.7% |

| 2nd | (1, 2) | 154.0 Hz | 168.0 Hz | 9.1% |

| 3rd | (2, 3) | 259.9 Hz | 250.8 Hz | 3.5% |

| 4th | (3, 2) | 354.2 Hz | 355.3 Hz | 0.3% |

| 5th | (2, 4) | 378.8 Hz | 379.8 Hz | 0.3% |

| 6th | (3, 3) | 445.2 Hz | 442.0 Hz | 0.7% |

| 7th | (2, 5) | 516.1 Hz | 522.0 Hz | 1.1% |

| 8th | (3, 4) | 564.0 Hz | 567.5 Hz | 0.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Wang, N.; Tian, Y.; Kuang, W.; Wei, L.; Zheng, Z. Analysis of Vibration and Acoustic Radiation Characteristics of Reinforced Laminated Cylindrical Shell Structure. Appl. Sci. 2023, 13, 9617. https://doi.org/10.3390/app13179617

Li B, Wang N, Tian Y, Kuang W, Wei L, Zheng Z. Analysis of Vibration and Acoustic Radiation Characteristics of Reinforced Laminated Cylindrical Shell Structure. Applied Sciences. 2023; 13(17):9617. https://doi.org/10.3390/app13179617

Chicago/Turabian StyleLi, Bin, Ning Wang, Ying Tian, Wenjian Kuang, Langlang Wei, and Zilai Zheng. 2023. "Analysis of Vibration and Acoustic Radiation Characteristics of Reinforced Laminated Cylindrical Shell Structure" Applied Sciences 13, no. 17: 9617. https://doi.org/10.3390/app13179617

APA StyleLi, B., Wang, N., Tian, Y., Kuang, W., Wei, L., & Zheng, Z. (2023). Analysis of Vibration and Acoustic Radiation Characteristics of Reinforced Laminated Cylindrical Shell Structure. Applied Sciences, 13(17), 9617. https://doi.org/10.3390/app13179617