Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review

Abstract

1. Introduction

2. Computational Fluid Dynamics

2.1. Governing Equations and Turbulence Models

- ▪

- Conservation of Mass (Continuity Equation) establishes that the rate of mass accumulation must balance with the mass flows into and out (Equation (1)).

- ▪

- Conservation of Momentum (Newton’s Second Law or Navier–Stokes Equations) establishes that the sum of external forces acting on a fluid particle is equal to its rate of linear momentum change (Equation (2)).

- ▪

- Conservation of Energy (First Law of Thermodynamics) establishes that the change in internal energy of a fluid particle is equal to the sum of the heat exchanged and the work carried out on the particle (Equation (3)).

2.2. Software Used

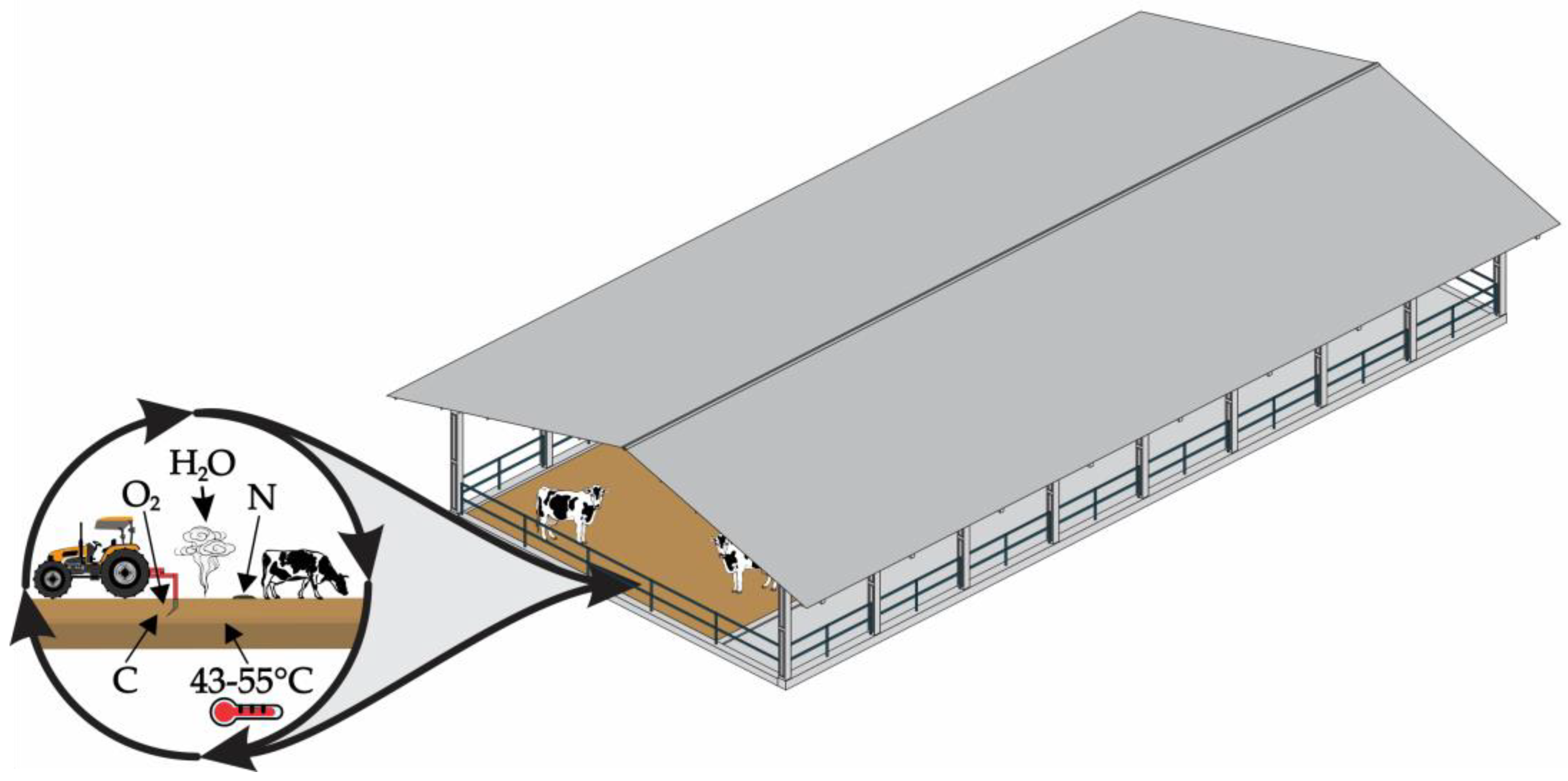

3. CFD Applied to Compost-Bedded Pack Barn Systems

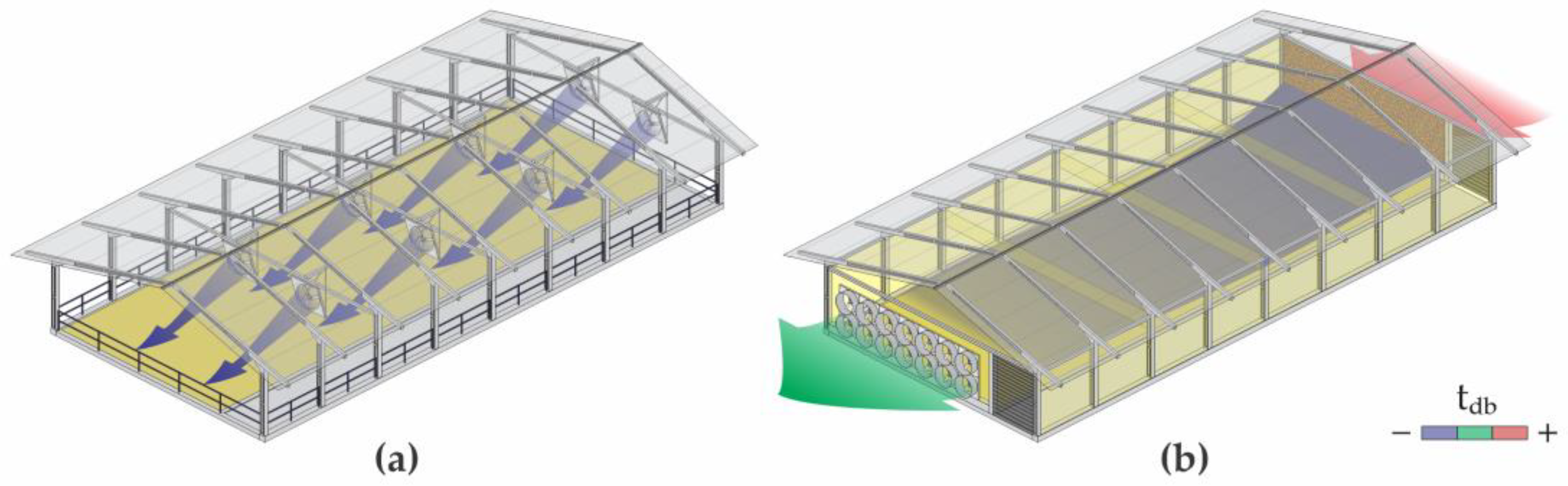

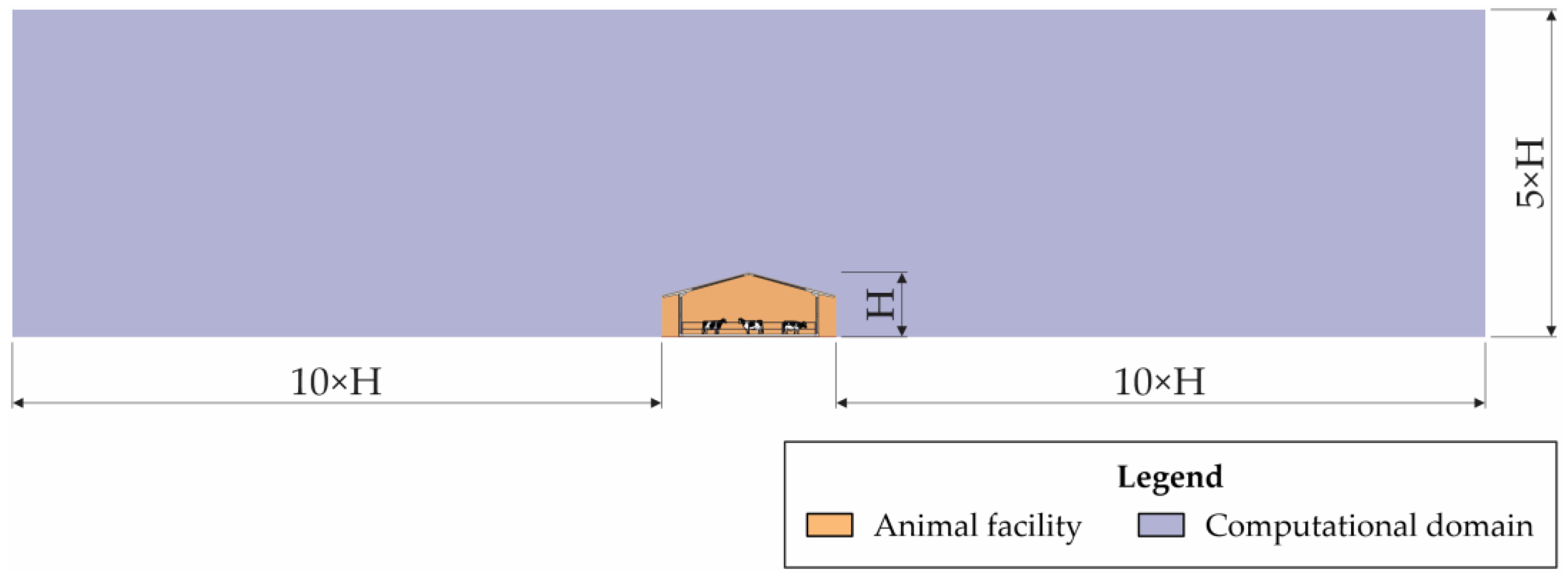

3.1. CBPs Typology and Computational Domain

- ▪

- For facilities of big length, where there are flow conditions repeatability, it is possible to model and collect data for validation only in a smaller facility region, if it is representative. This strategy has already been used by some authors for modeling animal facilities using CFD, such as Saraz et al. [41].

- ▪

- ▪

- Facilities for cattle usually have a high height (>3.0 m). Therefore, the internal computational domain can be divided into two subdomains: animal-occupied zone (AOZ, height ≤ 1.5 m) comprising the region occupied by animals, in which there is greater interest in this study, and there is a need for refinement and structuring to ensure consistent and regular sampling; and headspace (HS, height > 1.5 m), a region of free air movement of less interest in research, may be less refined (mesh with fewer divisions) and unstructured, with refinement only at ends and openings. In this case, the plane between the subdomains must be configured as an interface to ensure the continuity of the flow in this region (between both meshes) [14,77].

- ▪

- When choosing to model the animals distributed along the AOZ, they can be represented by ellipsoids with body length and diameter obtained from animals’ linear measurements of the same size and age. Simply put, laying down animals can be represented by half an ellipsoid and those standing up by a whole ellipsoid, as already applied satisfactorily in some studies [47,76]. The animals can also be represented by a set of cylinders (representing the trunk, paws, and head), ensuring adequate results, as observed in some studies [43,79].

- ▪

- AOZ can be assumed to be a porous medium with resistance to air flow rather than simulating animals, flooring, and small partition structures in detail, which would require complex meshes, a lot of time to calculate, and might not achieve convergence. This strategy has been adopted by several researchers in studies of animal facilities, such as Wu et al. [31], Mondaca et al. [14], and Wang et al. [77].

- ▪

- If the facility has a lining under the roof, the computational model can be generated without the roof presence [41], simplifying the computational domain. However, when the facility has pillars and/or walls inside, whenever possible, these constructive components should also be included in the computational model, and their effects should be considered in the heat and mass transfer processes [36].

- ▪

- Due to the high computational cost, the fan’s complete geometry can be suppressed, which are represented only by circles/ellipses of the same diameter, only informing the speed and/or air flow values [42,80]. Whenever possible, performance data (air speed and flow, pressure, etc.) of the fans should be obtained using field tests [14].

3.2. Mesh Generation and Independence Testing

3.3. Boundary Conditions and Simulation Schemes

3.4. Post-Processing and Model Validation

3.5. CFD Studies Performed on CBPs

3.6. Considerations for Future Studies

- ▪

- If the facility has pillars and/or walls inside, these constructive elements must be considered in the computational domain. Normally, there is a reduction in air velocity in the regions where these elements are located, and, consequently, there is a tendency for the concentration of temperature, humidity, and gases, which is not going to be predicted in the CFD model if they are not considered in the computational domain [36].

- ▪

- In the case of CBP systems with open sides, if there are other buildings nearby, these must be included in the computational model since they can influence the air flow and the environmental conditions inside the facility [31]. The same is valid for variations in topography in the external region of the facility, which can influence the air flow when they are large scale [48]. If there is variation in the speed and direction of natural air flow through the inlet side of the facility due to variations in terrain and other obstacles, whenever possible, these variations should be included in the computational model, using relevant approaches, so that divergences do not occur in relation to the real situation [36].

- ▪

- Whenever possible, it is recommended that housed animals be included in the computational domain with uneven distribution according to the places where there is a tendency for their concentration [29]. In this way, the simulation can return results closer to those of the physical (real) system, unlike the cases in which the AOZ is assumed to be a uniform porous medium [14,31], which disregards the fact that the animals tend to concentrate in certain facility regions, such as near feeders, drinkers, salt troughs, sprinkler lines, etc. Additionally, it is important to highlight that when the animal’s presence is not represented in the computational domain, as observed in some CFD studies carried out in animal facilities [16,30,44], the results achieved will not represent a typical production situation.

- ▪

- It is important to include momentum source terms due to the animal’s presence and building elements, as well as heat source terms due to animal metabolism and the bedding composting process. These terms must be calculated considering adequate approaches, according to the pressure, energy, and metabolic loss mechanisms that occur in each case and included together with the momentum and energy conservation equations [36,48].

- ▪

- As there is variation in the spatial distribution of bedding temperature, as reported in some studies [17,18], due to ventilation conditions and bedding management, it is of interest to establish distribution models of the bedding surface temperature, as performed by Vega et al. [29]. If the bedding surface temperature is considered constant throughout the area, deviations from real situations may occur.

- ▪

- As there is the transfer of chemical species, such as moisture and water vapor due to the accumulation of animal feces/urine and bedding composting, it is also important to include transport models for these and other chemical species present in CBP systems. If this is not considered in the CFD modeling, the results achieved may differ from the physical systems, given that the mass balance will not faithfully represent the real situation.

4. Conclusions

- ▪

- The computational domain must be defined considering the constructive typology of the facility and other aspects that influence the phenomena of heat, mass, and energy transfer. For open facilities, the indoor and outdoor environments are usually represented in a single computational domain, while for closed facilities, only the indoor environment is represented. In both cases, refinements must be performed in the interest regions, as well as mesh independence tests.

- ▪

- Numerical schemes and turbulence models, specifically Semi-Implicit Method for Pressure-Linked Equations (SIMPLE) and second-order upwind schemes, are usually used for pressure-velocity coupling and for spatial discretization, respectively. The commonly used turbulence models are the standard k-ε and k-ε RNG, selected based on the desired accuracy and computational cost.

- ▪

- Post-processing and validation: The results obtained are usually visualized using contour planes, vector graphics, and air current lines. To verify that the CFD model is satisfactory in adequately representing the real facility environment, it is important that validation studies are conducted using experimental data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Acronym | Search String |

|---|---|

| CFD | CFD OR “Computational Fluid Dynamics” OR “Computational Fluid Dynamic” |

| Cattle facilities | “dairy cattle houses” OR “dairy cattle house” OR “dairy cattle housings” OR “dairy cattle housing” OR “dairy cattle buildings” OR “dairy cattle building” OR “dairy cattle facilities” OR “dairy cattle facility” OR “dairy cattle barns” OR “dairy cattle barn” OR “dairy cows houses” OR “dairy cows house” OR “dairy cows housings” OR “dairy cows housing” OR “dairy cows buildings” OR “dairy cows building” OR “dairy cows facilities” OR “dairy cows facility” OR “dairy cows barns” OR “dairy cows barn” OR “dairy houses” OR “dairy house” OR “dairy housings” OR “dairy housing” OR “dairy buildings” OR “dairy building” OR “dairy facilities” OR “dairy facility” OR “dairy barns” OR “dairy barn” OR “cattle houses” OR “cattle house” OR “cattle housings” OR “cattle housing” OR “cattle buildings” OR “cattle building” OR “cattle facilities” OR “cattle facility” OR “cattle barns” OR “cattle barn” OR “livestock houses” OR “livestock house” OR “livestock housings” OR “livestock housing” OR “livestock buildings” OR “livestock building” OR “livestock facilities” OR “livestock facility” OR “livestock barns” OR “livestock barn” OR “compost barn” OR “compost bedded” OR “compost-bedded pack” OR “compost-bedded barn” OR “compost-bedded pack barn” OR “compost-bedded pack barn system” OR “free-stall” OR “free stall” OR “freestall” OR “free-stall barns” OR “freestall facilities” OR “freestall facility” OR “tie-stall” OR “tie stall” OR “tiestall” OR “tie-stall barns” OR “tiestall facilities” OR “tiestall facility” |

| Poultry facilities | “broiler houses” OR “broiler house” OR “broiler housings” OR “broiler housing” OR “broiler buildings” OR “broiler building” OR “broiler facilities” OR “broiler facility” OR “broiler barns” OR “broiler barn” OR “poultry houses” OR “poultry house” OR “poultry housings” OR “poultry housing” OR “poultry buildings” OR “poultry building” OR “poultry facilities” OR “poultry facility” OR “poultry barns” OR “poultry barn” OR “broiler chickens houses” OR “broiler chickens house” OR “broiler chickens housings” OR “broiler chickens housing” OR “broiler chickens buildings” OR “broiler chickens building” OR “broiler chickens facilities” OR “broiler chickens facility” OR “broiler chickens barns” OR “broiler chickens barn” OR “chickens houses” OR “chickens house” OR “chickens housings” OR “chickens housing” OR “chickens buildings” OR “chickens building” OR “chickens facilities” OR “chickens facility” OR “chickens barns” OR “chickens barn” OR “hen houses” OR “hen house” OR “hen housings” OR “hen housing” OR “hen buildings” OR “hen building” OR “hen facilities” OR “hen facility” OR “hen barns” OR “hen barn” OR “layer hen houses” OR “layer hen house” OR “layer hen housings” OR “layer hen housing” OR “layer hen buildings” OR “layer hen building” OR “layer hen facilities” OR “layer hen facility” OR “layer hen barns” OR “layer hen barn” |

| Swine facilities | “piglet houses” OR “piglet house” OR “piglet housings” OR “piglet housing” OR “piglet buildings” OR “piglet building” OR “piglet facilities” OR “piglet facility” OR “piglet barns” OR “piglet barn” OR “pig houses” OR “pig house” OR “pig housings” OR “pig housing” OR “pig buildings” OR “pig building” OR “pig facilities” OR “pig facility” OR “pig barns” OR “pig barn” OR “swine houses” OR “swine house” OR “swine housings” OR “swine housing” OR “swine buildings” OR “swine building” OR “swine facilities” OR “swine facility” OR “swine barns” OR “swine barn” OR “swine nursery houses” OR “swine nursery house” OR “swine nursery housings” OR “swine nursery housing” OR “swine nursery buildings” OR “swine nursery building” OR “swine nursery facilities” OR “swine nursery facility” OR “swine nursery barns” OR “swine nursery barn” OR “farrowing houses” OR “farrowing house” OR “farrowing housings” OR “farrowing housing” OR “farrowing buildings” OR “farrowing building” OR “farrowing facilities” OR “farrowing facility” OR “farrowing barns” OR “farrowing barn” |

| Only CBP facilities | “compost barn” OR “compost bedded” OR “compost-bedded pack” OR “compost-bedded barn” OR “compost-bedded pack barn” OR “compost-bedded pack barn system” |

References

- United Nations. Department of Economic and Social Affairs. Population Division World Population Prospects 2022: Summary of Results 2022; United Nations, Department of Economic and Social Affairs: New York, NY, USA, 2022. [Google Scholar]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global Food Demand and the Sustainable Intensification of Agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef]

- Food and Agriculture Organization—FAO. The Future of Food and Agriculture: Trends and Challenges. Annu. Rep. 2017, 296, 1–163. [Google Scholar]

- Symeonaki, E.; Arvanitis, K.G.; Piromalis, D.; Tseles, D.; Balafoutis, A.T. Ontology-Based IoT Middleware Approach for Smart Vivestock Farming toward Agriculture 4.0: A Case Study for Controlling Thermal Environment in a Pig Facility. Agronomy 2022, 12, 750. [Google Scholar] [CrossRef]

- Saitone, T.L.; Sexton, R.J. Agri-Food Supply Chain: Evolution and Performance with Conflicting Consumer and Societal Demands. Eur. Rev. Agric. Econ. 2017, 44, 634–657. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass Energy Technologies from Innovative Dairy Farming Systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Bournet, P.E.; Rojano, F. Advances of Computational Fluid Dynamics (CFD) Applications in Agricultural Building Modelling: Research, Applications and Challenges. Comput. Electron. Agric. 2022, 201, 107277. [Google Scholar] [CrossRef]

- Arshad, J.; Rehman, A.U.; Ben Othman, M.T.; Ahmad, M.; Tariq, H.B.; Khalid, M.A.; Moosa, M.A.R.; Shafiq, M.; Hamam, H. Deployment of Wireless Sensor Network and IoT Platform to Implement an Intelligent Animal Monitoring System. Sustainability 2022, 14, 6249. [Google Scholar] [CrossRef]

- Ramirez, B.C.; Gao, Y.; Hoff, S.J.; Harmon, J.D. Thermal Environment Sensor Array: Part 1 Development and Field Performance Assessment. Biosyst. Eng. 2018, 174, 329–340. [Google Scholar] [CrossRef]

- Eckelkamp, E.A.; Taraba, J.L.; Akers, K.A.; Harmon, R.J.; Bewley, J.M. Understanding Compost Bedded Pack Barns: Interactions among Environmental Factors, Bedding Characteristics, and Udder Health. Livest. Sci. 2016, 190, 35–42. [Google Scholar] [CrossRef]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited Review: Compost-Bedded Pack Barns for Dairy Cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef]

- Pilatti, J.A.; Vieira, F.M.C. Environment, Behavior and Welfare Aspects of Dairy Cows Reared in Compost Bedded Pack Barns System. J. Anim. Behav. Biometeorol. 2017, 5, 97–105. [Google Scholar] [CrossRef]

- Norton, T.; Grant, J.; Fallon, R.; Sun, D.-W. Assessing the Ventilation Effectiveness of Naturally Ventilated Livestock Buildings under Wind Dominated Conditions Using Computational Fluid Dynamics. Biosyst. Eng. 2009, 103, 78–99. [Google Scholar] [CrossRef]

- Mondaca, M.R.; Choi, C.Y.; Cook, N.B. Understanding Microenvironments within Tunnel-Ventilated Dairy Cow Freestall Facilities: Examination Using Computational Fluid Dynamics and Experimental Validation. Biosyst. Eng. 2019, 183, 70–84. [Google Scholar] [CrossRef]

- Cao, M.; Yi, Q.; Wang, K.; Li, J.; Wang, X. Predicting Ventilation Rate in a Naturally Ventilated Dairy Barn in Wind-Forced Conditions Using Machine Learning Techniques. Agriculture 2023, 13, 837. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Comparison of Different Mechanical Ventilation Systems for Dairy Cow Barns: CFD Simulations and Field Measurements. Comput. Electron. Agric. 2021, 186, 106207. [Google Scholar] [CrossRef]

- Andrade, R.R.; Tinôco, I.F.F.; Damasceno, F.A.; Ferraz, G.A.S.; Freitas, L.C.S.R.; Ferreira, C.F.S.; Barbari, M.; Baptista, F.J.F.; Coelho, D.J.R. Spatial Distribution of Bed Variables, Animal Welfare Indicators, and Milk Production in a Closed Compost-Bedded Pack Barn with a Negative Tunnel Ventilation System. J. Therm. Biol. 2022, 105, 103111. [Google Scholar] [CrossRef]

- Oliveira, C.E.A.; Tinôco, I.F.F.; Oliveira, V.C.; Rodrigues, P.H.M.; Silva, L.F.; Damasceno, F.A.; Andrade, R.R.; Sousa, F.C.; Barbari, M.; Bambi, G. Spatial Distribution of Bedding Attributes in an Open Compost-Bedded Pack Barn System with Positive Pressure Ventilation in Brazilian Winter Conditions. Animals 2023, 13, 786. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, X.; Mondaca, M.R.; Rong, L.; Choi, C.Y. Assessment of Optimal Airflow Baffle Locations and Angles in Mechanically-Ventilated Dairy Houses Using Computational Fluid Dynamics. Comput. Electron. Agric. 2019, 165, 104930. [Google Scholar] [CrossRef]

- Jung, S.; Chung, H.; Mondaca, M.R.; Nordlund, K.V.; Choi, C.Y. Using Computational Fluid Dynamics to Develop Positive-Pressure Precision Ventilation Systems for Large-Scale Dairy Houses. Biosyst. Eng. 2023, 227, 182–194. [Google Scholar] [CrossRef]

- Ding, C.; Lam, K.P.; Wong, N.H. Coupled Natural Ventilation Modeling for Contextual Parametric Design Decision Support. Procedia Eng. 2016, 169, 264–271. [Google Scholar] [CrossRef]

- Lv, Y.; Yao, H.; Li, A.; Yi, Q.; Janke, D.; Amon, T.; DS Quoie, G.; Shen, X.; Long, Z. Comparison of Simulation Methods for Dynamic Internal Air Distribution in Naturally Ventilated Livestock Buildings. Comput. Electron. Agric. 2022, 202, 107427. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.-W.; Grant, J.; Fallon, R.; Dodd, V. Applications of Computational Fluid Dynamics (CFD) in the Modelling and Design of Ventilation Systems in the Agricultural Industry: A Review. Bioresour. Technol. 2007, 98, 2386–2414. [Google Scholar] [CrossRef]

- Tu, J.; Yeoh, G.-H.; Liu, C. Computational Fluid Dynamics: A Practical Approach, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Kim, J.G.; Lee, I.B.; Lee, S.Y.; Park, S.J.; Jeong, D.Y.; Choi, Y.B.; Decano-Valentin, C.; Yeo, U.H. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture 2022, 12, 1139. [Google Scholar] [CrossRef]

- Drewry, J.L.; Choi, C.Y.; Powell, J.M.; Luck, B.D. Computational Model of Methane and Ammonia Emissions from Dairy Barns: Development and Validation. Comput. Electron. Agric. 2018, 149, 80–89. [Google Scholar] [CrossRef]

- Doumbia, E.M.; Janke, D.; Yi, Q.; Amon, T.; Kriegel, M.; Hempel, S. CFD Modelling of an Animal Occupied Zone Using an Anisotropic Porous Medium Model with Velocity Depended Resistance Parameters. Comput. Electron. Agric. 2021, 181, 105950. [Google Scholar] [CrossRef]

- Damasceno, F.A.; Taraba, J.L.; Day, G.B.; Vega, F.A.O.; Rocha, K.S.O.; Black, R.A.; Bewley, J.M.; Oliveira, C.E.A.; Barbari, M. 3D CFD Analysis of Natural Ventilation in Reduced Scale Model of Compost Bedded Pack Barn for Dairy Cows. Appl. Sci. 2020, 10, 8112. [Google Scholar] [CrossRef]

- Vega, F.A.O.; Ríos, A.P.M.; Saraz, J.A.O.; Andrade, R.R.; Damasceno, F.A.; Barbari, M. CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System. Animals 2022, 12, 1776. [Google Scholar] [CrossRef]

- Tomasello, N.; Valenti, F.; Cascone, G.; Porto, S.M.C. Development of a CFD Model to Simulate Natural Ventilation in a Semi-Open Free-Stall Barn for Dairy Cows. Buildings 2019, 9, 183. [Google Scholar] [CrossRef]

- Wu, W.; Zhai, J.; Zhang, G.; Nielsen, P.V. Evaluation of Methods for Determining Air Exchange Rate in a Naturally Ventilated Dairy Cattle Building with Large Openings Using Computational Fluid Dynamics (CFD). Atmos. Environ. 2012, 63, 179–188. [Google Scholar] [CrossRef]

- Nielsen, P.V. Berechnung Der Luftbewegung in Einem Zwangsbelufteten Raum. GI-Gesundh. Ing. 1973, 94, 299–302. [Google Scholar]

- Rong, L.; Nielsen, P.V.; Bjerg, B.; Zhang, G. Summary of Best Guidelines and Validation of CFD Modeling in Livestock Buildings to Ensure Prediction Quality. Comput. Electron. Agric. 2016, 121, 180–190. [Google Scholar] [CrossRef]

- Nielsen, P.V. Fifty Years of CFD for Room Air Distribution. Build. Environ. 2015, 91, 78–90. [Google Scholar] [CrossRef]

- Kwon, K.; Lee, I.; Zhang, G.Q.; Ha, T. Computational Fluid Dynamics Analysis of the Thermal Distribution of Animal Occupied Zones Using the Jet-Drop-Distance Concept in a Mechanically Ventilated Broiler House. Biosyst. Eng. 2015, 136, 51–68. [Google Scholar] [CrossRef]

- Saraz, J.A.O.; Tinôco, I.F.F.; Rocha, K.S.O.; Norton, K.S. A CFD Based Approach for Determination of Ammonia Concentration Profile and Flux from Poultry Houses with Natural Ventilation. Rev. Fac. Nac. Agron. Medellín 2016, 69, 7825–7834. [Google Scholar] [CrossRef]

- Damasceno, F.A.; Baêta, F.C.; Martins, M.A.; Saraz, J.A.O.; Tinôco, I.F.F. Computational Fluid Dynamics (CFD) and It’s Use for Analysis of Gas Distribution inside Animal Production Facilities: A Literature Review. Rev. UDCA Actual. Divulg. Cient. 2011, 14, 83–93. [Google Scholar]

- Saraz, J.A.O.; Martins, M.A.; Marín, O.L.Z.; Damasceno, F.A.; Velasquez, H.J.C. Una Revisión Acerca de la Dinamica de Fluidos Computacionales (CFD) En Instalaciones Avícolas. DYNA 2012, 79, 142–149. [Google Scholar]

- Bustamante, E.; García-Diego, F.J.; Calvet, S.; Estellés, F.; Beltrán, P.; Hospitaler, A.; Torres, A.G. Exploring Ventilation Efficiency in Poultry Buildings: The Validation of Computational Fluid Dynamics (CFD) in a Cross-Mechanically Ventilated Broiler Farm. Energies 2013, 6, 2605–2623. [Google Scholar] [CrossRef]

- Curi, T.M.R.C.; Moura, D.J.; Massari, J.M.; Mesquita, M.; Pereira, D.F. Computational Fluid Dynamics (CFD) Application for Ventilation Studies in Broiler Houses. Eng. Agric. 2017, 37, 1–12. [Google Scholar] [CrossRef]

- Saraz, J.A.O.; Rocha, K.S.O.; Damasceno, F.A.; Tinoco, I.F.F.; Osorio, R.; Tobón, J.C.A. A CFD Approach to Assess the Effects of Different Opening Combinations in Poultry Houses. Rev. Bras. Eng. Agric. Ambient. 2017, 21, 852–857. [Google Scholar] [CrossRef]

- Fagundes, B.; Damasceno, F.A.; Andrade, R.R.; Saraz, J.A.O.; Barbari, M.; Vega, F.A.O.; Nascimento, J.A.C. Comparison of Airflow Homogeneity in Compost Dairy Barns with Different Ventilation Systems Using the CFD Model. Agron. Res. 2020, 18, 788–796. [Google Scholar] [CrossRef]

- Bustos-Vanegas, J.D.; Hempel, S.; Janke, D.; Doumbia, M.; Streng, J.; Amon, T. Numerical Simulation of Airflow in Animal Occupied Zones in a Dairy Cattle Building. Biosyst. Eng. 2019, 186, 100–105. [Google Scholar] [CrossRef]

- Bustamante, E.; García-Diego, F.J.; Calvet, S.; Torres, A.G.; Hospitaler, A. Measurement and Numerical Simulation of Air Velocity in a Tunnel-Ventilated Broiler House. Sustainability 2015, 7, 2066–2085. [Google Scholar] [CrossRef]

- Vega, F.A.O.; Rios, A.P.M.; Damasceno, F.A.; Saraz, J.A.O.; Nascimento, J.A.C. Airflow Profile Study of a Compost Dairy Barn Using a Low-Cost 3d-Printed Anemometer Network. Agron. Res. 2020, 18, 931–944. [Google Scholar] [CrossRef]

- Tomasello, N.; Valenti, F.; Cascone, G.; Porto, S.M.C. Improving Natural Ventilation in Renovated Free-Stall Barns for Dairy Cows: Optimized Building Solutions by Using a Validated Computational Fluid Dynamics Model. J. Agric. Eng. 2021, 52, 1135. [Google Scholar] [CrossRef]

- Norton, T.; Grant, J.; Fallon, R.; Sun, D.-W. Optimising the Ventilation Configuration of Naturally Ventilated Livestock Buildings for Improved Indoor Environmental Homogeneity. Build. Environ. 2010, 45, 983–995. [Google Scholar] [CrossRef]

- Kim, R.-W.; Hong, S.-W.; Norton, T.; Amon, T.; Youssef, A.; Berckmans, D.; Lee, I.-B. Computational Fluid Dynamics for Non-Experts: Development of a User-Friendly CFD Simulator (HNVR-SYS) for Natural Ventilation Design Applications. Biosyst. Eng. 2020, 193, 232–246. [Google Scholar] [CrossRef]

- Janke, D.; Caiazzo, A.; Ahmed, N.; Alia, N.; Knoth, O.; Moreau, B.; Wilbrandt, U.; Willink, D.; Amon, T.; John, V. On the Feasibility of Using Open Source Solvers for the Simulation of a Turbulent Air Flow in a Dairy Barn. Comput. Electron. Agric. 2020, 175, 105546. [Google Scholar] [CrossRef]

- Hong, S.W.; Exadaktylos, V.; Lee, I.B.; Amon, T.; Youssef, A.; Norton, T.; Berckmans, D. Validation of an Open Source CFD Code to Simulate Natural Ventilation for Agricultural Buildings. Comput. Electron. Agric. 2017, 138, 80–91. [Google Scholar] [CrossRef]

- Wagner, P.E. Bedded Pack Shelters. Lanc. Farming 2002, 47, 36. [Google Scholar]

- Lazzarini, B.; Baudracco, J.; Tuñon, G.; Gastaldi, L.; Lyons, N.; Quattrochi, H.; Lopez-Villalobos, N. Review: Milk Production from Dairy Cows in Argentina: Current State and Perspectives for the Future. Appl. Anim. Sci. 2019, 35, 426–432. [Google Scholar] [CrossRef]

- Fávero, S.; Portilho, F.V.R.; Oliveira, A.C.R.; Langoni, H.; Pantoja, J.C.F. Factors Associated with Mastitis Epidemiologic Indexes, Animal Hygiene, and Bulk Milk Bacterial Concentrations in Dairy Herds Housed on Compost Bedding. Livest. Sci. 2015, 181, 220–230. [Google Scholar] [CrossRef]

- Bran, J.A.; Costa, J.H.C.; von-Keyserlingk, M.A.G.; Hötzel, M.J. Factors Associated with Lameness Prevalence in Lactating Cows Housed in Freestall and Compost-Bedded Pack Dairy Farms in Southern Brazil. Prev. Vet. Med. 2019, 172, 104773. [Google Scholar] [CrossRef] [PubMed]

- Vieira, F.M.C.; Soares, A.A.; Herbut, P.; Vismara, E.S.; Godyń, D.; dos Santos, A.C.Z.; Lambertes, T.S.; Caetano, W.F. Spatio-Thermal Variability and Behaviour as Bio-Thermal Indicators of Heat Stress in Dairy Cows in a Compost Barn: A Case Study. Animals 2021, 11, 1197. [Google Scholar] [CrossRef] [PubMed]

- Méndez, M.N.; Grille, L.; Mendina, G.R.; Robinson, P.H.; de Lourdes Adrien, M.; Meikle, A.; Chilibroste, P. Performance of Autumn and Spring Calving Holstein Dairy Cows with Different Levels of Environmental Exposure and Feeding Strategies. Animals 2023, 13, 1211. [Google Scholar] [CrossRef]

- Kim, E.; Lee, S.; Jo, H.; Jeong, J.; Mulbry, W.; Rahman, S.; Ahn, H. Solid-State Anaerobic Digestion of Dairy Manure from a Sawdust-Bedded Pack Barn: Moisture Responses. Energies 2018, 11, 484. [Google Scholar] [CrossRef]

- Sun, L.; Han, X.; Li, J.; Zhao, Z.; Liu, Y.; Xi, Q.; Guo, X.; Gun, S. Microbial Community and Its Association with Physicochemical Factors during Compost Bedding for Dairy Cows. Front. Microbiol. 2020, 11, 254. [Google Scholar] [CrossRef]

- Akbarian-Tefaghi, M.; Ahmadi, F.; Nasrollahi, S.M.; Khanaki, H.; Khan, A.; Ghaffari, M.H. Effects of Freestall vs. Bedded Pack Housing on Growth Performance, Health Status, and Behavioral Responses of Weaned Heifers. Res. Vet. Sci. 2022, 152, 175–180. [Google Scholar] [CrossRef]

- Niu, K.; An, Z.; Yao, Z.; Chen, C.; Yang, L.; Xiong, J. Effects of Different Bedding Materials on Production Performance, Lying Behavior and Welfare of Dairy Buffaloes. Animals 2023, 13, 842. [Google Scholar] [CrossRef]

- Ofner-Schröck, E.; Zähner, M.; Huber, G.; Guldimann, K.; Guggenberger, T.; Gasteiner, J. Compost Barns for Dairy Cows-Aspects of Animal Welfare. Open J. Anim. Sci. 2015, 5, 124–131. [Google Scholar] [CrossRef][Green Version]

- Burgstaller, J.; Raith, J.; Kuchling, S.; Mandl, V.; Hund, A.; Kofler, J. Claw Health and Prevalence of Lameness in Cows from Compost Bedded and Cubicle Freestall Dairy Barns in Austria. Vet. J. 2016, 216, 81–86. [Google Scholar] [CrossRef]

- Biasato, I.; D’Angelo, A.; Bertone, I.; Odore, R.; Bellino, C. Compost Bedded-Pack Barn as an Alternative Housing System for Dairy Cattle in Italy: Effects on Animal Health and Welfare and Milk and Milk Product Quality. Ital. J. Anim. Sci. 2019, 18, 1142–1153. [Google Scholar] [CrossRef]

- Odore, R.; Biasato, I.; Gardini, G.; D’angelo, A.; Bellino, C. Effects of Compost-Bedded Pack Barn on Circulating Cortisol and Beta-Endorphins in Dairy Cows: A Case Study. Animals 2021, 11, 3318. [Google Scholar] [CrossRef] [PubMed]

- Stentiford, E.I. Composting Control: Principles and Practice. In The Science of Composting; Springer: Dordrecht, Germany, 1996; pp. 49–59. [Google Scholar]

- Damasceno, F.A. Processo de Compostagem. In Compost Barn Como uma Alternativa Para a Pecuária Leiteira; Gulliver: Divinópolis, Brazil, 2020; pp. 127–147. [Google Scholar]

- Janni, K.A.; Endres, M.I.; Reneau, J.K.; Schoper, W.W. Compost Dairy Barn Layout and Management Recommendations. Appl. Eng. Agric. 2007, 23, 97–102. [Google Scholar] [CrossRef]

- Lobeck, K.M.; Endres, M.I.; Janni, K.A.; Godden, S.M.; Fetrow, J. Environmental Characteristics and Bacterial Counts in Bedding and Milk Bulk Tank of Low Profile Cross-Ventilated, Naturally Ventilated, and Compost Bedded Pack Dairy Barns. Appl. Eng. Agric. 2012, 28, 117–128. [Google Scholar] [CrossRef]

- Guerra-Galdo, E.H.; Sanz, S.C.; Barber, F.E.; López-Jiménez, P.A. CFD Model for Ventilation Assessment in Poultry Houses with Different Distribution of Windows. Int. J. Energy Environ. 2015, 6, 411–424. [Google Scholar]

- Mrema, G.C.; Gumbe, L.O.; Chapete, H.J.; Agullo, J.O. Rural Structures in the Tropics: Design and Development, 1st ed.; FAO: Roma, Italy, 2011; ISBN 9789251070475. [Google Scholar]

- Abu-Zidan, Y.; Mendis, P.; Gunawardena, T. Optimising the Computational Domain Size in CFD Simulations of Tall Buildings. Heliyon 2021, 7, e06723. [Google Scholar] [CrossRef] [PubMed]

- Lee, I.B.; Sase, S.; Sung, S.H. Evaluation of CFD Accuracy for the Ventilation Study of a Naturally Ventilated Broiler House. Jpn. Agric. Res. Q. 2007, 41, 53–64. [Google Scholar] [CrossRef]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ Guidelines for Practical Applications of CFD to Pedestrian Wind Environment around Buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Blocken, B. Computational Fluid Dynamics for Urban Physics: Importance, Scales, Possibilities, Limitations and Ten Tips and Tricks towards Accurate and Reliable Simulations. Build. Environ. 2015, 91, 219–245. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Q. Effect of Fluctuating Wind Direction on Cross Natural Ventilation in Buildings from Large Eddy Simulation. Build. Environ. 2002, 37, 379–386. [Google Scholar] [CrossRef]

- Norton, T.; Kettlewell, P.; Mitchell, M. A Computational Analysis of a Fully-Stocked Dual-Mode Ventilated Livestock Vehicle during Ferry Transportation. Comput. Electron. Agric. 2013, 93, 217–228. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Yi, Q.; Zhang, G.; Amon, T.; Janke, D.; Li, X.; Chen, B.; He, Y.; Wang, K. Numerical Evaluation on Ventilation Rates of a Novel Multi-Floor Pig Building Using Computational Fluid Dynamics. Comput. Electron. Agric. 2021, 182, 106050. [Google Scholar] [CrossRef]

- Seo, I.H.; Lee, I.B.; Moon, O.K.; Kim, H.T.; Hwang, H.S.; Hong, S.W.; Bitog, J.P.; Yoo, J.I.; Kwon, K.S.; Kim, Y.H.; et al. Improvement of the Ventilation System of a Naturally Ventilated Broiler House in the Cold Season Using Computational Simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Mondaca, M.; Choi, C.Y. Assessment of Dairy Cow Geometries in Computational Modeling. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting 2015, New Orleans, LA, USA, 26–29 July 2015; ASABE: St. Joseph, MI, USA, 2015; Volume 5. [Google Scholar]

- Blanes-Vidal, V.; Guijarro, E.; Balasch, S.; Torres, A.G. Application of Computational Fluid Dynamics to the Prediction of Airflow in a Mechanically Ventilated Commercial Poultry Building. Biosyst. Eng. 2008, 100, 105–116. [Google Scholar] [CrossRef]

- Yeo, U.-H.; Decano-Valentin, C.; Ha, T.; Lee, I.-B.; Kim, R.-W.; Lee, S.-Y.; Kim, J.-G. Impact Analysis of Environmental Conditions on Odour Dispersion Emitted from Pig House with Complex Terrain Using CFD. Agronomy 2020, 10, 1828. [Google Scholar] [CrossRef]

- Seo, I.-H.; Lee, I.-B.; Moon, O.-K.; Hong, S.-W.; Hwang, H.-S.; Bitog, J.P.; Kwon, K.-S.; Ye, Z.; Lee, J.-W. Modelling of Internal Environmental Conditions in a Full-Scale Commercial Pig House Containing Animals. Biosyst. Eng. 2012, 111, 91–106. [Google Scholar] [CrossRef]

- Li, Y.; Nielsen, P.V. CFD and Ventilation Research. Indoor Air 2011, 21, 442–453. [Google Scholar] [CrossRef]

- Das, B.; Dutta, P.P.; Bardalai, M.; Dutta, P.P. Comparative Study on Performance of High Volume Low Speed (HVLS) Fans with High-Speed Fans for the Use in Dairy Barns. Mater. Today Proc. 2021, 47, 4606–4610. [Google Scholar] [CrossRef]

- Mylostyvyi, R.; Izhboldina, O.; Chernenko, O.; Khramkova, O.; Kapshuk, N.; Hoffmann, G. Microclimate Modeling in Naturally Ventilated Dairy Barns during the Hot Season: Checking the Accuracy of Forecasts. J. Therm. Biol. 2020, 93, 102720. [Google Scholar] [CrossRef]

- Kaufman, J.D.; Saxton, A.M.; Ríus, A.G. Short Communication: Relationships among Temperature-Humidity Index with Rectal, Udder Surface, and Vaginal Temperatures in Lactating Dairy Cows Experiencing Heat Stress. J. Dairy Sci. 2018, 101, 6424–6429. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H.; Gebremedhin, K.G.; Bjerg, B.S.; Van Os, J.; Tucker, C.B.; Zhang, G. A Predictive Model of Equivalent Temperature Index for Dairy Cattle (ETIC). J. Therm. Biol. 2018, 76, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.G.B.S.; Ferraz, P.F.P.; Damasceno, F.A.; Zotti, M.L.A.N.; Barbari, M. Compost Barns: A Bibliometric Analysis. Animals 2022, 12, 2492. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Vitorino Filho, V.A.; Goi, M.Y.O. Supply Chain Management 4.0: Content Analysis in the Most Relevant Articles from Scopus and Web of Science Databases. Braz. J. Dev. 2021, 7, 117868–117889. [Google Scholar] [CrossRef]

| No. | Location | Type | Specifications | References |

|---|---|---|---|---|

| Compost-Bedded Pack Barn Systems with Open Sides | ||||

| 1 | Fans | Inlet | Establish air velocity and turbulent intensity in air flow directions | Das et al. [84] |

| 2 | Roof, pillars, floors of food and service alleys, walls, etc. | Wall | Non-slip condition, isothermal, with temperatures specified per experimental conditions | Mondaca et al. [14] Vega et al. [29] Cao et al. [15] |

| 3 | Bedding surface | Wall | Non-slip condition, with variable temperature according to experimental measurements | Vega et al. [29] |

| 4 | Inlet region of natural air currents | Inlet | Air speed established according to experimental measurements | Pakari and Ghani [16] |

| 5 | Region opposite to the entry of natural air currents | Outlet | Static pressure set to zero | Pakari and Ghani [16] Cao et al. [15] |

| 6 | Side openings | Opening | Entrainment, with relative pressure established according to experimental conditions | Pakari and Ghani [16] |

| Closed Compost-Bedded Pack Barns systems | ||||

| 1 | Evaporative pad cooling inlet | Opening | Entrainment, with relative pressure established according to experimental conditions | Wang et al. [77] Vega et al. [29] |

| 2 | Evaporative pad cooling output | Outlet | Air speed established according to experimental measurements | Vega et al. [29] |

| 3 | Roof, side curtains, deflectors, pillars, doors, floors of food and service alleys, walls, etc. | Wall | Non-slip condition, isothermal, with temperatures specified per experimental conditions | Mondaca et al. [14] Wang et al. [77] Vega et al. [29] Cao et al. [15] |

| 4 | Bedding surface | Wall | Non-slip condition, with variable temperature depending on the distance from the pad cooling | Vega et al. [29] |

| 5 | Side curtains | Symmetry | Vega et al. [29] | |

| 6 | Exhaust fans | Outlet | Establish air velocity and turbulent intensity in air flow directions | Mondaca et al. [14] Das et al. [84] Vega et al. [29] |

| Reference | FCT | Dim. | Code | Grid | SD | Turb. | EV | Comments |

|---|---|---|---|---|---|---|---|---|

| Fagundes et al. [42] | CBP with open sides | 3D | Ansys® CFX | GCSP | 2nd order upwind | Std. k–e | Yes | Bedding surface temperature is considered constant and equal to 25 °C |

| Vega et al. [45] | CBP with open sides | 3D | Ansys® Fluent | NGCS | NS | RNG k-ε | Yes | Only the validation of the developed propeller anemometers was carried out in CBP systems |

| Damasceno et al. [28] | CBP with open sides | 3D | Ansys® CFX | GCSP | NS | Std. k–e | Yes | Validation carried out in a wind tunnel, using reduced models of naturally ventilated CBP systems |

| Vega et al. [29] | CBP fully closed | 3D | Ansys® CFX | GCSP | 2nd order upwind | k-ε with SWF | Yes | Modeling performed considering the animal’s presence, represented by spheres |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, C.E.A.; Tinôco, I.d.F.F.; Sousa, F.C.d.; Damasceno, F.A.; Andrade, R.R.; Maciel, F.d.F.; Barbari, M.; Martins, M.A. Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review. Appl. Sci. 2023, 13, 9331. https://doi.org/10.3390/app13169331

Oliveira CEA, Tinôco IdFF, Sousa FCd, Damasceno FA, Andrade RR, Maciel FdF, Barbari M, Martins MA. Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review. Applied Sciences. 2023; 13(16):9331. https://doi.org/10.3390/app13169331

Chicago/Turabian StyleOliveira, Carlos Eduardo Alves, Ilda de Fátima Ferreira Tinôco, Fernanda Campos de Sousa, Flávio Alves Damasceno, Rafaella Resende Andrade, Fabiane de Fátima Maciel, Matteo Barbari, and Márcio Arêdes Martins. 2023. "Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review" Applied Sciences 13, no. 16: 9331. https://doi.org/10.3390/app13169331

APA StyleOliveira, C. E. A., Tinôco, I. d. F. F., Sousa, F. C. d., Damasceno, F. A., Andrade, R. R., Maciel, F. d. F., Barbari, M., & Martins, M. A. (2023). Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review. Applied Sciences, 13(16), 9331. https://doi.org/10.3390/app13169331