Current Limitations for Predicting Liquid Dispersion in Continuous Flow Bubble Columns Using CFD

Abstract

1. Introduction

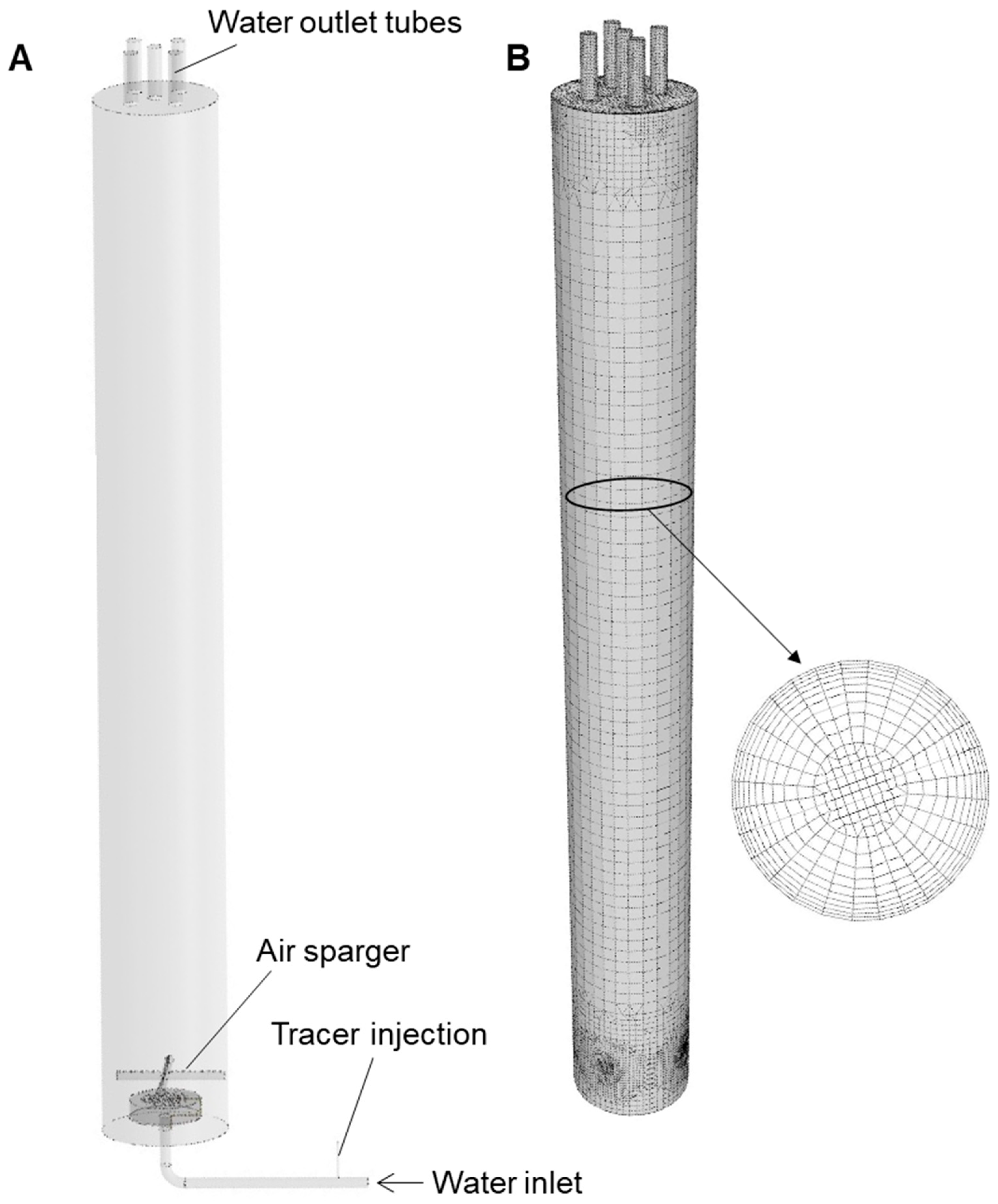

2. Materials and Methods

2.1. Validation Experiments

2.2. CFD Simulations

3. Results

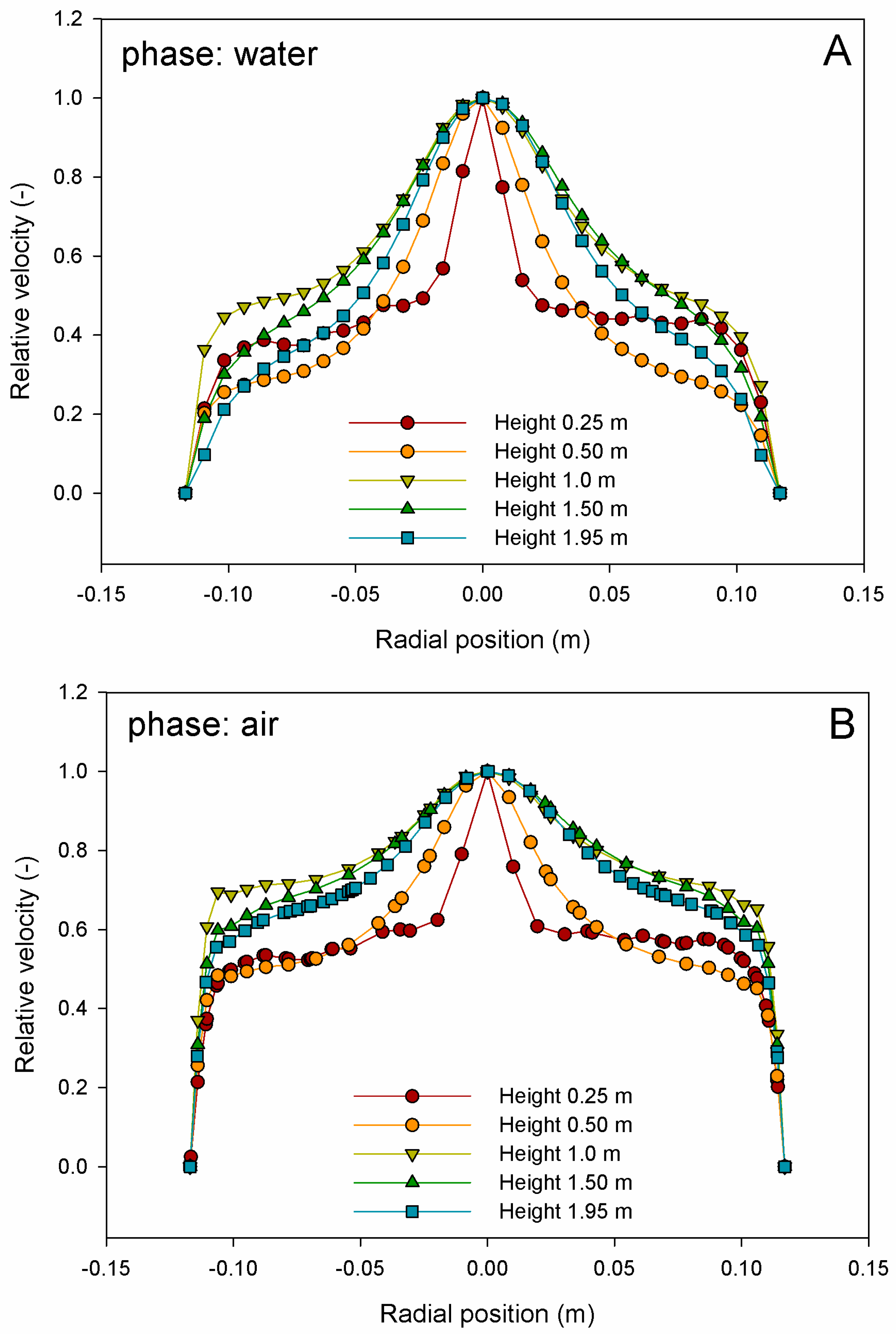

3.1. Velocity Profiles for Mono- and Biphasic Simulations

3.2. Liquid Phase Dispersion in Single-Phase Water Flow

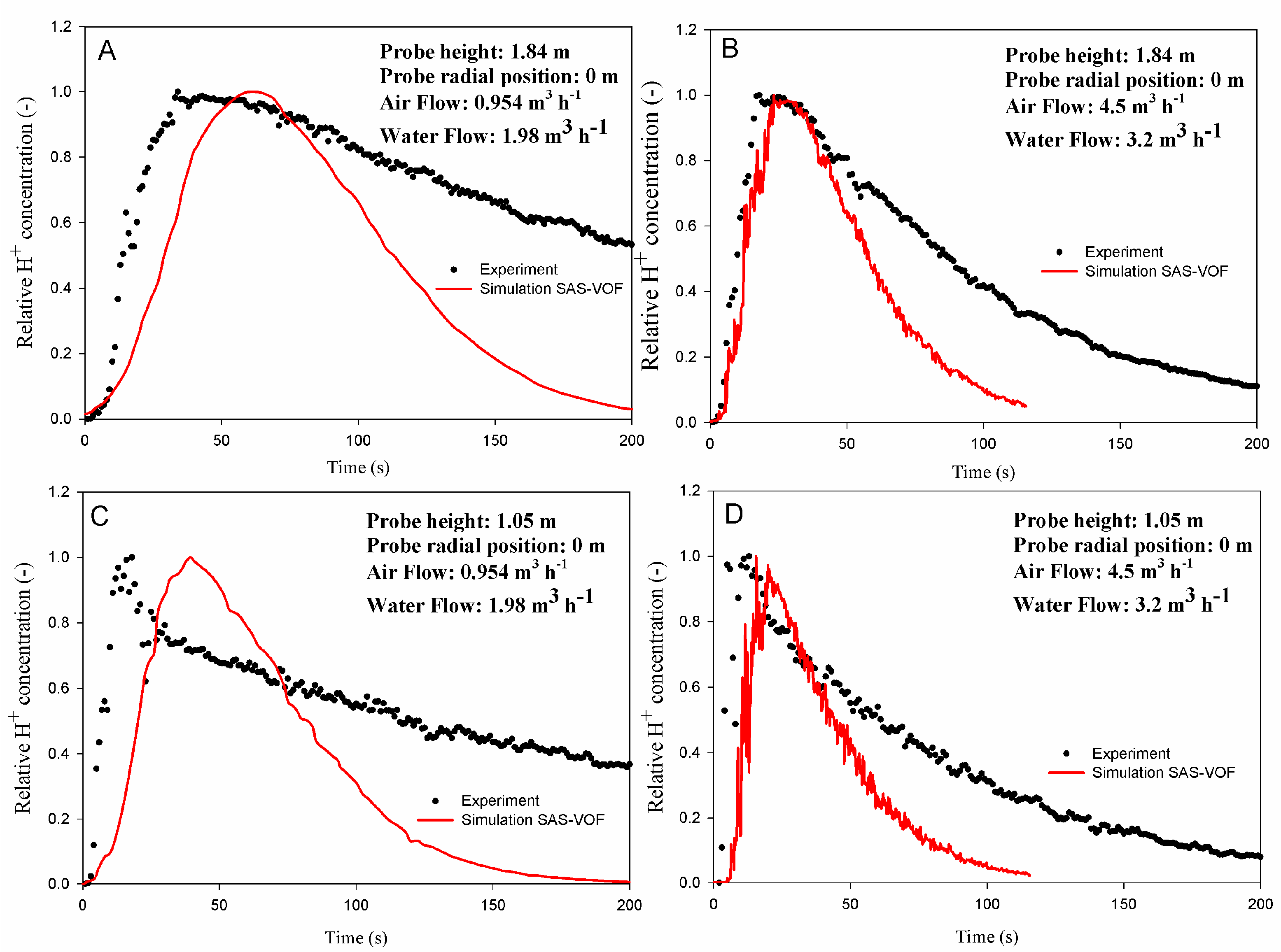

3.3. Liquid-Phase Dispersion in Air-Water Two-Phase System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CFD | Computational fluid dynamics |

| DES | Detached eddy simulation |

| DNS | Direct numerical simulation |

| EARSM | Explicit algebraic Reynolds stress model |

| E-E | Euler-Euler schemes |

| E-L | Euler-Lagrange approaches |

| k | Turbulent kinetic energy (J kg−1) |

| LES | Large eddy simulation |

| l | Length scale (m) |

| l0 | Length scale defined by Equation (1) (m) |

| MSD | Modeled stress depletion |

| ma | Mass flow rate (kg s−1) |

| Qa | Volume flow rate (m3 h−1) |

| RANS | Reynolds-averaged Navier-Stokes models |

| Re | Reynolds number |

| RNG | Renormalization group |

| RSM | Reynolds stress model |

| r | Radial position of sensor from central axis (m) |

| SAS | Scale-adaptive simulation |

| SST | Shear stress transport |

| SST-SAS | Shear stress transport scale-adaptive simulation |

| ti | Duration of tracer pulse (s) |

| trm | Residence time (s) |

| ua | Superficial velocity (m s−1) |

| VL | Volume of water in the bubble column (m3) |

| VOF | Volume-of-fluid model |

| xi | Mole fraction of H+ in tracer (-) |

| z | Axial location of a pH sensor above the column base (m) |

| Δ | Size of the cell (m) |

| ε | Rate of dissipation of turbulent kinetic energy (J kg−1 s−1) |

| μ | Viscosity (Pa s) |

| ρ | Density (kg m−3) |

| σt2 | Variance of the residence time (s2) |

| σθ2 | Variance of the relative residence time (-) |

| ω | Specific energy dissipation rate (J kg−1 s−1) |

References

- Chisti, Y. Mass Transfer. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 1–70. [Google Scholar]

- Deckwer, W.D. Bubble Column Reactors; Wiley: Chichester, UK, 1992. [Google Scholar]

- Shah, Y.T.; Kelkar, B.G.; Godbole, S.P.; Deckwer, W.-D. Design Parameters Estimations for Bubble Column Reactors. AIChE J. 1982, 28, 353–379. [Google Scholar] [CrossRef]

- Ho, D.; Kim, K.; Earmme, T.; Kim, C. Enhancing Gas–Liquid Volumetric Mass Transfer Coefficient. J. Ind. Eng. Chem. 2020, 87, 1–17. [Google Scholar] [CrossRef]

- Kantarci, N.; Borak, F.; Ulgen, K.O. Bubble Column Reactors. Process Biochem. 2005, 40, 2263–2283. [Google Scholar] [CrossRef]

- Chen, P.; Duduković, M.P.; Sanyal, J. Three-Dimensional Simulation of Bubble Column Flows with Bubble Coalescence and Breakup. AIChE J. 2005, 51, 696–712. [Google Scholar] [CrossRef]

- Ebadi Amooghin, A.; Jafari, S.; Sanaeepur, H.; Kargari, A. Computational Fluid Dynamics Simulation of Bubble Coalescence and Breakup in an Internal Airlift Reactor: Analysis of Effects of a Draft Tube on Hydrodynamics and Mass Transfer. Appl. Math. Model. 2015, 39, 1616–1642. [Google Scholar] [CrossRef]

- Zahradnik, J.; Fialova, M.; Ruzicka, M.; Drahos, J.; Kastanek, F.; Thomas, N.H. Duality of the Gas-Liquid Flow Regimes in Bubble-Column Reactors. Chem. Eng. Sci. 1997, 52, 3811–3826. [Google Scholar] [CrossRef]

- Shu, S.; Vidal, D.; Bertrand, F.; Chaouki, J. Multiscale Multiphase Phenomena in Bubble Column Reactors: A Review. Renew. Energy 2019, 141, 613–631. [Google Scholar] [CrossRef]

- Behkish, A.; Lemoine, R.; Sehabiague, L.; Oukaci, R.; Morsi, B.I. Gas Holdup and Bubble Size Behavior in a Large-Scale Slurry Bubble Column Reactor Operating with an Organic Liquid under Elevated Pressures and Temperatures. Chem. Eng. J. 2007, 128, 69–84. [Google Scholar] [CrossRef]

- Krishna, R.; Sie, S.T. Design and Scale-up of the Fischer–Tropsch Bubble Column Slurry Reactor. Fuel Process. Technol. 2000, 64, 73–105. [Google Scholar] [CrossRef]

- López-Rosales, L.; Sánchez-Mirón, A.; García-Camacho, F.; Place, A.R.; Chisti, Y.; Molina-Grima, E. Pilot-Scale Outdoor Photobioreactor Culture of the Marine Dinoflagellate Karlodinium Veneficum: Production of a Karlotoxins-Rich Extract. Bioresour. Technol. 2018, 253, 94–104. [Google Scholar] [CrossRef]

- Chisti, Y. Shear Sensitivity. In Encyclopedia of Industrial Biotechnology; John Wiley & Sons, Inc.: New York, NY, USA, 2009; pp. 1–40. [Google Scholar]

- Kim, J.Y.; Kim, B.; Nho, N.-S.; Go, K.-S.; Kim, W.; Bae, J.W.; Jeong, S.W.; Epstein, N.; Lee, D.H. Gas Holdup and Hydrodynamic Flow Regime Transition in Bubble Columns. J. Ind. Eng. Chem. 2017, 56, 450–462. [Google Scholar] [CrossRef]

- Camacho Rubio, F.; Sánchez Mirón, A.; Cerón García, M.C.; García Camacho, F.; Molina Grima,, E.; Chisti, Y. Mixing in Bubble Columns: A New Approach for Characterizing Dispersion Coefficients. Chem. Eng. Sci. 2004, 59, 4369–4376. [Google Scholar] [CrossRef]

- Kawase, Y.; Moo-Young, M. Mixing Time in Bioreactors. J. Chem. Technol. Biotechnol. 1989, 44, 63–75. [Google Scholar] [CrossRef]

- Levenspiel, O.; Lai, B.W.; Chatlynne, C.Y. Tracer Curves and the Residence Time Distribution. Chem. Eng. Sci. 1970, 25, 1611–1613. [Google Scholar] [CrossRef]

- Liu, Y.; Hinrichsen, O. Study on CFD–PBM Turbulence Closures Based on k–ε and Reynolds Stress Models for Heterogeneous Bubble Column Flows. Comput. Fluids 2014, 105, 91–100. [Google Scholar] [CrossRef]

- Khan, Z.; Bhusare, V.H.; Joshi, J.B. Comparison of Turbulence Models for Bubble Column Reactors. Chem. Eng. Sci. 2017, 164, 34–52. [Google Scholar] [CrossRef]

- Dhotre, M.T.; Deen, N.G.; Niceno, B.; Khan, Z.; Joshi, J.B. Large Eddy Simulation for Dispersed Bubbly Flows: A Review. Int. J. Chem. Eng. 2013, 2013, 343276. [Google Scholar] [CrossRef]

- Huang, Q.; Yang, C.; Yu, G.; Mao, Z.S. CFD Simulation of Hydrodynamics and Mass Transfer in an Internal Airlift Loop Reactor Using a Steady Two-Fluid Model. Chem. Eng. Sci. 2010, 65, 5527–5536. [Google Scholar] [CrossRef]

- Masood, R.M.A.; Rauh, C.; Delgado, A. CFD Simulation of Bubble Column Flows: An Explicit Algebraic Reynolds Stress Model Approach. Int. J. Multiph. Flow 2014, 66, 11–25. [Google Scholar] [CrossRef]

- López-Rosales, L.; Sánchez-Mirón, A.; Contreras-Gómez, A.; García-Camacho, F.; Battaglia, F.; Zhao, L.; Molina-Grima, E. Characterization of Bubble Column Photobioreactors for Shear-Sensitive Microalgae Culture. Bioresour. Technol. 2019, 275, 1–9. [Google Scholar] [CrossRef]

- Deen, N.G.; Solberg, T.; Hjertager, B.H. Large Eddy Simulation of the Gas–Liquid Flow in a Square Cross-Sectioned Bubble Column. Chem. Eng. Sci. 2001, 56, 6341–6349. [Google Scholar] [CrossRef]

- Laborde-Boutet, C.; Larachi, F.; Dromard, N.; Delsart, O.; Schweich, D. CFD Simulation of Bubble Column Flows: Investigations on Turbulence Models in RANS Approach. Chem. Eng. Sci. 2009, 64, 4399–4413. [Google Scholar] [CrossRef]

- Tabib, M.V.; Roy, S.A.; Joshi, J.B. CFD Simulation of Bubble Column—An Analysis of Interphase Forces and Turbulence Models. Chem. Eng. J. 2008, 139, 589–614. [Google Scholar] [CrossRef]

- Ekambara, K.; Dhotre, M.T. CFD Simulation of Bubble Column. Nucl. Eng. Des. 2010, 240, 963–969. [Google Scholar] [CrossRef]

- Ansari, M.R.; Azadi, R.; Salimi, E. Capturing of Interface Topological Changes in Two-Phase Gas–Liquid Flows Using a Coupled Volume-of-Fluid and Level-Set Method (VOSET). Comput. Fluids 2016, 125, 82–100. [Google Scholar] [CrossRef]

- McClure, D.D.; Norris, H.; Kavanagh, J.M.; Fletcher, D.F.; Barton, G.W. Validation of a Computationally Efficient Computational Fluid Dynamics (CFD) Model for Industrial Bubble Column Bioreactors. Ind. Eng. Chem. Res. 2014, 53, 14526–14543. [Google Scholar] [CrossRef]

- McClure, D.D.; Aboudha, N.; Kavanagh, J.M.; Fletcher, D.F.; Barton, G.W. Mixing in Bubble Column Reactors: Experimental Study and CFD Modeling. Chem. Eng. J. 2015, 264, 291–301. [Google Scholar] [CrossRef]

- Wei, C.N.; Ochiai, S. Tracer-Response Techniques in Evaluation of Mixing in Reactors. The Mixing Characteristics of an Industrial Liquid-Phase Reactor Are Evaluated from the Transient Response of the Tracer Concentration at the Outlet. Plant/Oper. Prog. 1983, 2, 123–126. [Google Scholar] [CrossRef]

- Sánchez Mirón, A.; Cerón García, M.C.; García Camacho, F.; Molina Grima, E.; Chisti, Y. Mixing in Bubble Column and Airlift Reactors. Chem. Eng. Res. Des. 2004, 82, 1367–1374. [Google Scholar] [CrossRef]

- Luo, H.-P.; Al-Dahhan, M.H. Verification and Validation of CFD Simulations for Local Flow Dynamics in a Draft Tube Airlift Bioreactor. Chem. Eng. Sci. 2011, 66, 907–923. [Google Scholar] [CrossRef]

- Wiora, J.; Wiora, A. Measurement Uncertainty Calculations for PH Value Obtained by an Ion-Selective Electrode. Sensors 2018, 18, 1915. [Google Scholar] [CrossRef] [PubMed]

- Ashton, N. Recalibrating Delayed Detached-Eddy Simulation to Eliminate Modelled-Stress Depletion. In Proceedings of the 23th AIAA Computational Fluid Dynamics Conference, Denver, CO, USA, 5–9 June 2017; AIAA AVIATION Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar]

- Sanchez-Forero, D.I.; Silva, J.L., Jr.; Silva, M.K.; Bastos, J.C.S.C.; Mori, M. Experimental and Numerical Investigation of Gas-Liquid Flow in a Rectangular Bubble Column with Centralized Aeration Flow Pattern. Chem. Eng. Trans. 2013, 32, 1561–1566. [Google Scholar] [CrossRef]

- Han, S.; Zhou, J.; Jin, Y.; Loh, K.C.; Wang, Z. Liquid Dispersion in Gas-Liquid-Solid Circulating Fluidized Beds. Chem. Eng. J. 1998, 70, 9–14. [Google Scholar] [CrossRef]

- Islam, M.T.; Ganesan, P.B.; Cheng, J.; Uddin, M.S. Single Bubble Rising Behaviors in Newtonian and Non-Newtonian Fluids with Validation of Empirical Correlations: A Computational Fluid Dynamics Study. Eng. Rep. 2020, 2, e12100. [Google Scholar] [CrossRef]

- Akhtar, M.A.; Tadé, M.; Pareek, V. Simulations of Bubble Column Reactors Using a Volume of Fluid Approach: Effect of Air Distributor. Can. J. Chem. Eng. 2007, 85, 290–301. [Google Scholar] [CrossRef]

- Xiao, F.; Dianat, M.; McGuirk, J.J. LES of Turbulent Liquid Jet Primary Breakup in Turbulent Coaxial Air Flow. Int. J. Multiph. Flow 2014, 60, 103–118. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Q. Prediction of Particle Deposition onto Indoor Surfaces by CFD with a Modified Lagrangian Method. Atmos. Environ. 2009, 43, 319–328. [Google Scholar] [CrossRef]

| Parameter | Setting |

|---|---|

| Pressure-velocity coupling | SIMPLE |

| Spatial discretization | Least squares cell based |

| Pressure | Standard |

| Momentum | 2nd Order upwind |

| Turbulent kinetic energy | 2nd Order upwind |

| Turbulent dissipation rate | 2nd Order upwind |

| Specific dissipation rate | 2nd Order upwind |

| Intermittency | 2nd Order upwind |

| Momentum thickness Re | 1st Order upwind |

| Tracer concentration | 2nd Order upwind |

| Transient state formulation | 1st Order implicit |

| Fluid | Water | Tracer (HCl, 37% w/w) | Air |

|---|---|---|---|

| Molar mass (kg kmol−1) | 18.152 | 36.460 | 28.996 |

| Density, ρ (kg m−3) | 998.2 | 1190.0 | 122.5 × 10−2 |

| Viscosity, μ (Pa s) | 10.03 × 10−4 | 2.0 × 10−5 | 178.94 × 10−7 |

| Surface tension (N m−1) | 72.75 × 10−3 | - | - |

| Flow | Low | High |

|---|---|---|

| ti (s) | 2.5 | 2.5 |

| xi | 0.2246 | 0.2246 |

| Qw (m3 h−1) | 1.98 | 3.2 |

| uw (m s−1) | 0.0128 | 0.0207 |

| mw (kg s−1) | 0.549 | 0.887 |

| Qa (m3 h−1) | 0.954 | 4.5 |

| ua (m s−1) | 0.0612 | 0.0291 |

| Qa/VL (vvm) | 0.185 | 0.872 |

| ma (kg s−1) | 32.46 × 10−5 | 153.13 × 10−5 |

| Flow Settings | z (m) | r (m) | Experiments | Simulations (SAS + VOF) | ||||

|---|---|---|---|---|---|---|---|---|

| trm (s) | σt2 (s2) | σθ2 (-) | trm (s) | σt2 (s2) | σθ2 (-) | |||

| Qw = 1.98 m3 h−1; Qa = 0.954 m3 h−1 | 1.05 | 0 | 221.8 | 36,843 | 0.75 | 59.2 | 1210 | 0.35 |

| 1.05 | 0.1 | 218.1 | 35,530 | 0.75 | 60.7 | 1209 | 0.33 | |

| 1.84 | 0 | 227.9 | 34,679 | 0.67 | 82.9 | 1603 | 0.23 | |

| 1.84 | 0.1 | 244.4 | 37,890 | 0.63 | 80.6 | 1600 | 0.25 | |

| Qw = 3.2 m3 h−1; Qa = 4.5 m3 h−1 | 1.05 | 0 | 77.0 | 4409 | 0.74 | 34.8 | 514 | 0.43 |

| 1.05 | 0.1 | 76.1 | 4193 | 0.72 | 35.8 | 523 | 0.41 | |

| 1.84 | 0 | 83.5 | 4078 | 0.59 | 44.6 | 540 | 0.28 | |

| 1.84 | 0.1 | 90.7 | 4444 | 0.54 | 44.0 | 538 | 0.28 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallardo-Rodríguez, J.J.; Velasco-Amate, J.; Lorenzo-Horcajo, E.; López-Rosales, L.; Chisti, Y.; Battaglia, F.; Sánchez-Mirón, A.; García-Camacho, F. Current Limitations for Predicting Liquid Dispersion in Continuous Flow Bubble Columns Using CFD. Appl. Sci. 2023, 13, 9250. https://doi.org/10.3390/app13169250

Gallardo-Rodríguez JJ, Velasco-Amate J, Lorenzo-Horcajo E, López-Rosales L, Chisti Y, Battaglia F, Sánchez-Mirón A, García-Camacho F. Current Limitations for Predicting Liquid Dispersion in Continuous Flow Bubble Columns Using CFD. Applied Sciences. 2023; 13(16):9250. https://doi.org/10.3390/app13169250

Chicago/Turabian StyleGallardo-Rodríguez, Juan José, Javier Velasco-Amate, Erika Lorenzo-Horcajo, Lorenzo López-Rosales, Yusuf Chisti, Francine Battaglia, Asterio Sánchez-Mirón, and Francisco García-Camacho. 2023. "Current Limitations for Predicting Liquid Dispersion in Continuous Flow Bubble Columns Using CFD" Applied Sciences 13, no. 16: 9250. https://doi.org/10.3390/app13169250

APA StyleGallardo-Rodríguez, J. J., Velasco-Amate, J., Lorenzo-Horcajo, E., López-Rosales, L., Chisti, Y., Battaglia, F., Sánchez-Mirón, A., & García-Camacho, F. (2023). Current Limitations for Predicting Liquid Dispersion in Continuous Flow Bubble Columns Using CFD. Applied Sciences, 13(16), 9250. https://doi.org/10.3390/app13169250