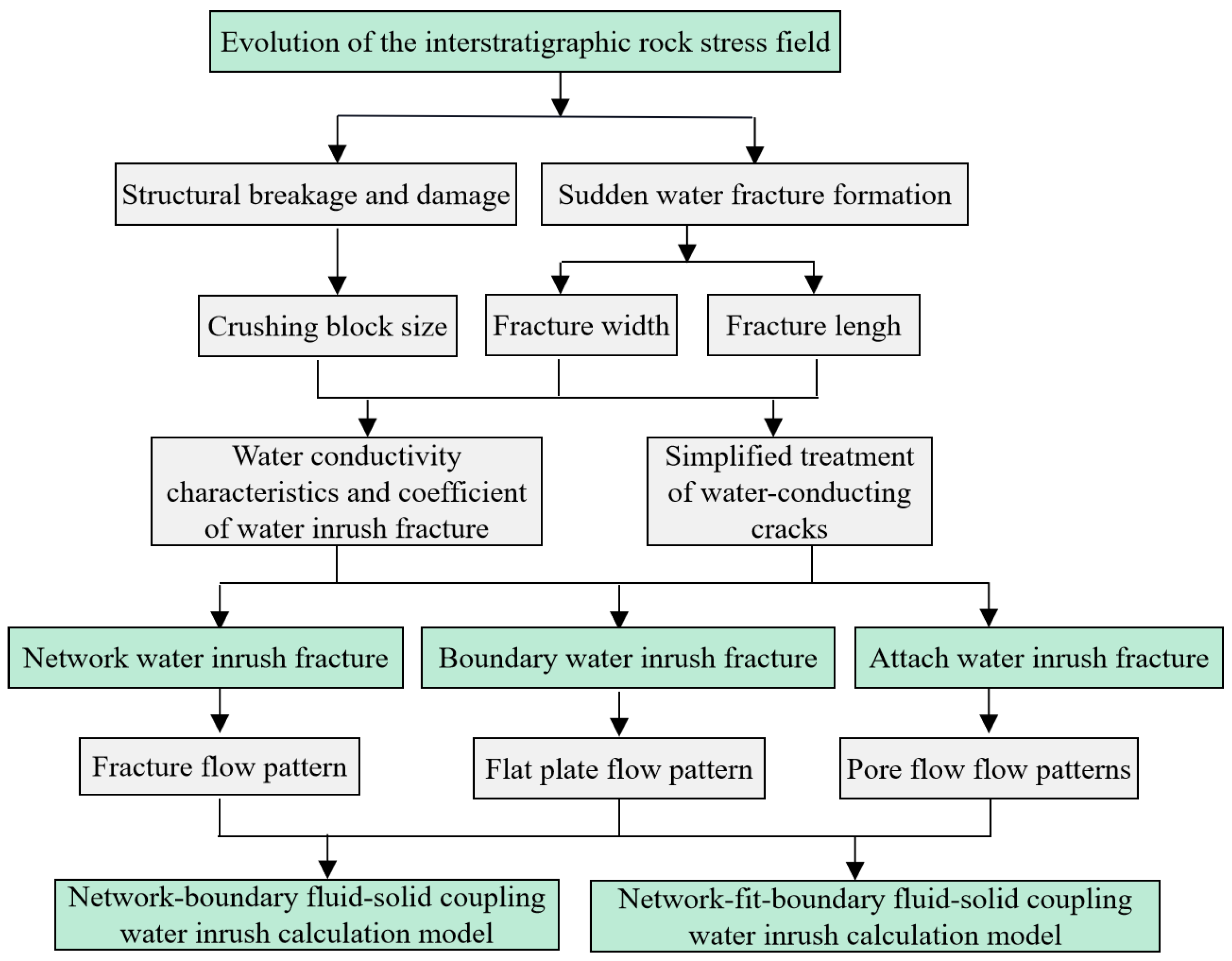

5.1.1. Solution of Flat Plate Flows Water Inrush Model

The unidirectional flow of incompressible fluid water in the boundary waters inrush fracture can be expressed by mass conservation and the N-S equation. The N-S equation includes fluid pressure, viscous force, body force, unsteady inertia force, and convective inertia force. It is generally believed that the flow of common fluid in the fracture is approximately steady motion. The body force is equivalent to the pressure on calculation, and the unsteady inertia force is neglected. The equation is simplified as:

In the formula,

is the flow velocity of water in the

direction of the fracture;

is the viscosity of fluid water;

is the density of water;

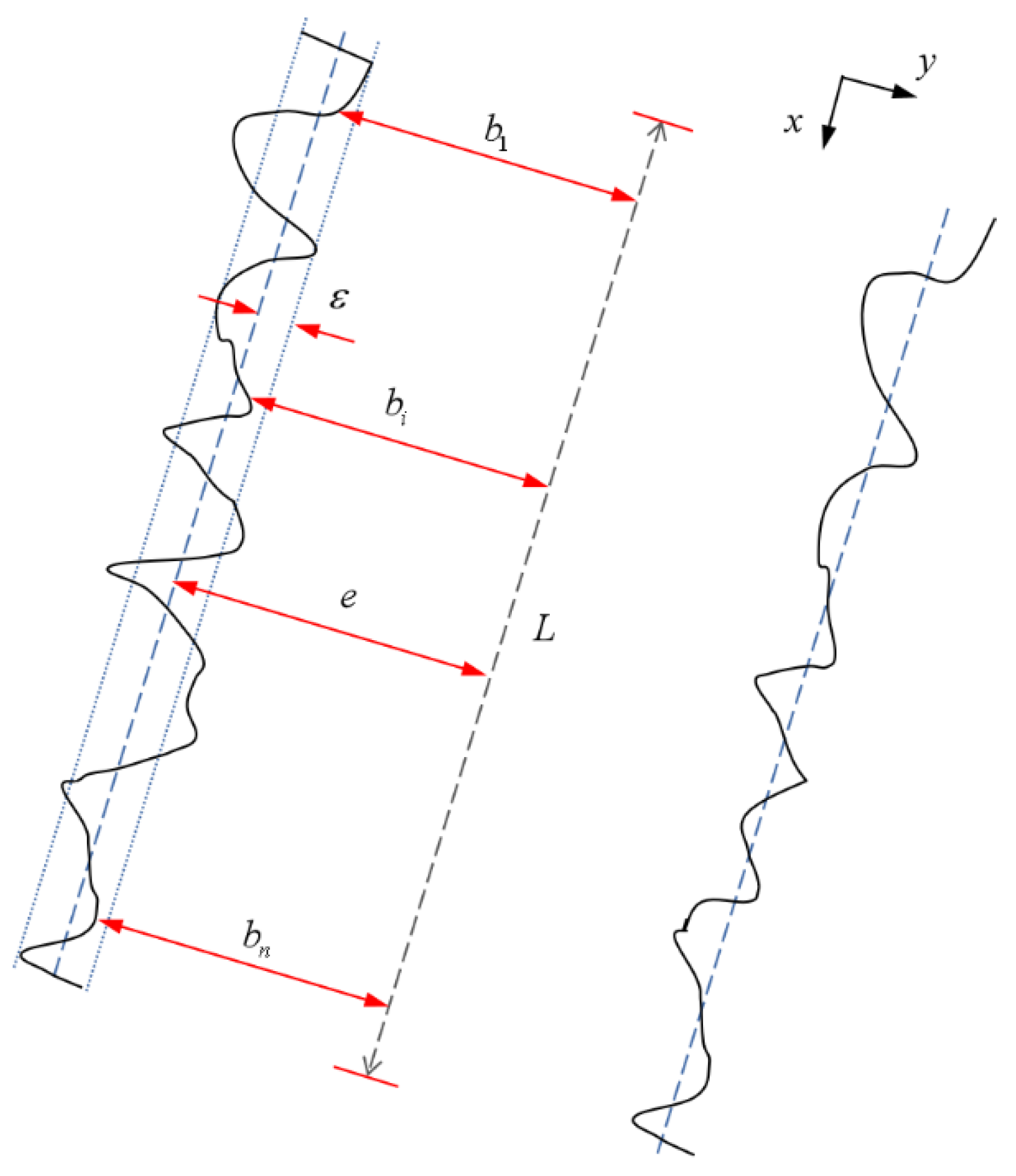

is pressure. Taking the water-inrush fracture boundary in

Figure 17, the fracture surface of the water-inrush fracture is a rough surface, so it is approximately regarded as symmetrical distribution; only half of the water-inrush fracture surface is discussed.

In

Figure 17,

is the distance from any point on the boundary water inrush fracture surface to the middle line of the fracture,

. If the water inrush fracture width

can be regarded as the mean of all fracture widths, the roughness fluctuation of the water inrush fracture surface

is much smaller than the width of the water inrush fracture; that is,

In the formula,

is the infinitesimal function of

, i.e.,

≪

. If available,

≪

. If it is expressed by the roughness of the water inrush fracture surface,

In the formula, is the standard deviation of the rough fluctuation height of the left and the surface of the water inrush fracture and its average ; is the dimensionless roughness coefficient.

Based on the roughness of the water inrush fracture surface in Equation (27), the characteristic flow velocity of water in the

direction of the fracture surface is set as

, and the velocity

perpendicular to the water inrush fracture surface can be obtained from Equation (23):

Through the order of magnitude analysis, it can be seen that the order of magnitude of the flow velocity

in the

direction is

and the order of magnitude of the flow velocity

in the

direction is

, so it is assumed that

The flow velocity

of water in the

direction of the boundary water inrush fracture is much smaller than the flow velocity

in the

direction; that is,

≪

, so the flow velocity

in the

direction can be ignored. Equation (25) can be transformed into

Based on the ratio of inertial force and viscous force in the analysis Formula (25) of the N-S mass conservation equation, we have

where

is the Reynolds coefficient. When water flows in the boundary water inrush fracture,

. If Equation (30) meets the condition

≪ 1, the inertia force of water flow can be ignored, and Equation (25) can be transformed into

The cubic law of water flow in the boundary water-inrush fracture can be obtained by integrating the cross-sectional area along the

direction of the boundary water-inrush fracture and combining the Formula (30):

In the formula, is the pressure difference at both ends of the boundary water inrush fracture. is the distance from the flat approximate plate surface to the fracture center line.

The conditions of whether the water flow in the boundary water inrush fracture is suitable for the flat plate cubic law can be obtained by combining the Formula (27), Formula (29), and formula (

≪ 1).

Based on the above analysis, according to the cubic law of plate flow in Formula (34), it can be seen that the Reynolds coefficient and the fracture roughness affect each other. When is smaller, the cubic law is established under the higher Reynolds coefficient. Similarly, when the Reynolds coefficient is smaller, the cubic law has stronger adaptability in rough fractures. Therefore, for the smooth plate , the flow of the fracture is long enough; that is, the cubic law of is fully established in the laminar flow range ().

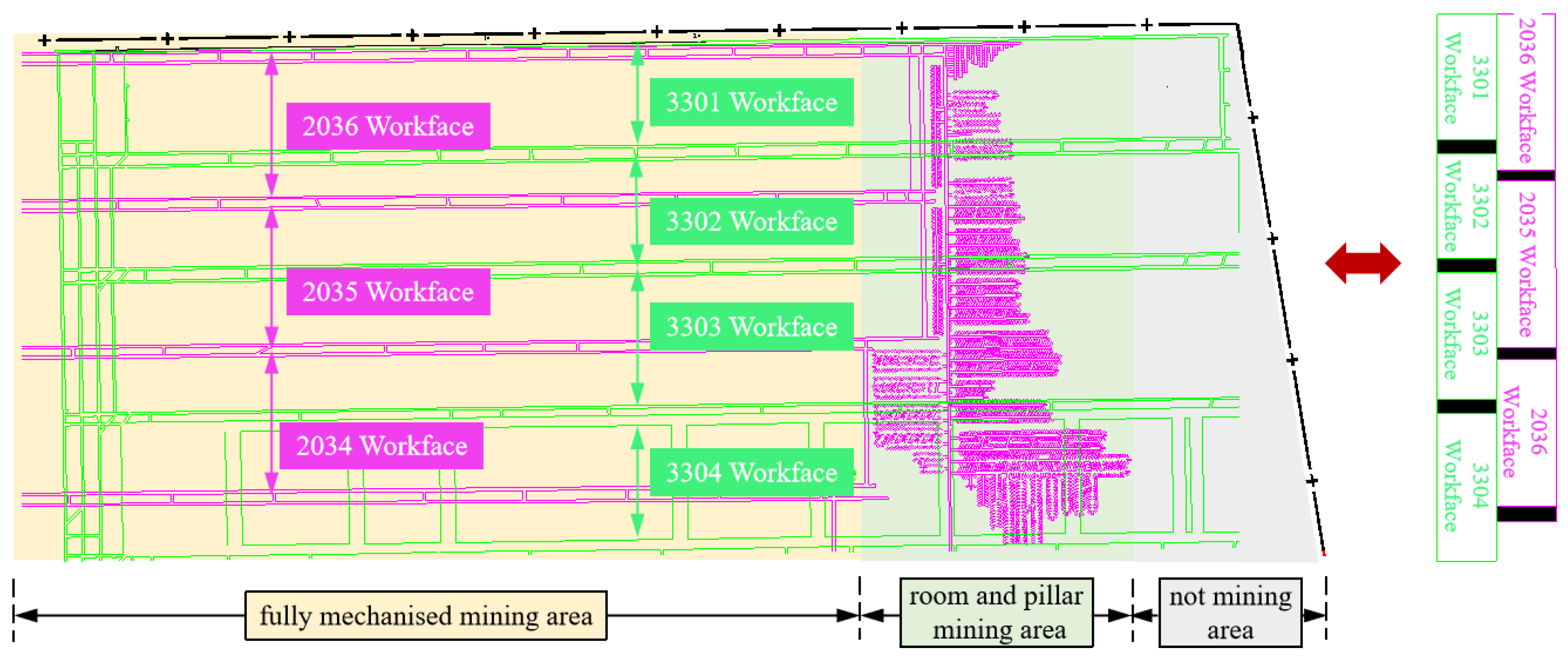

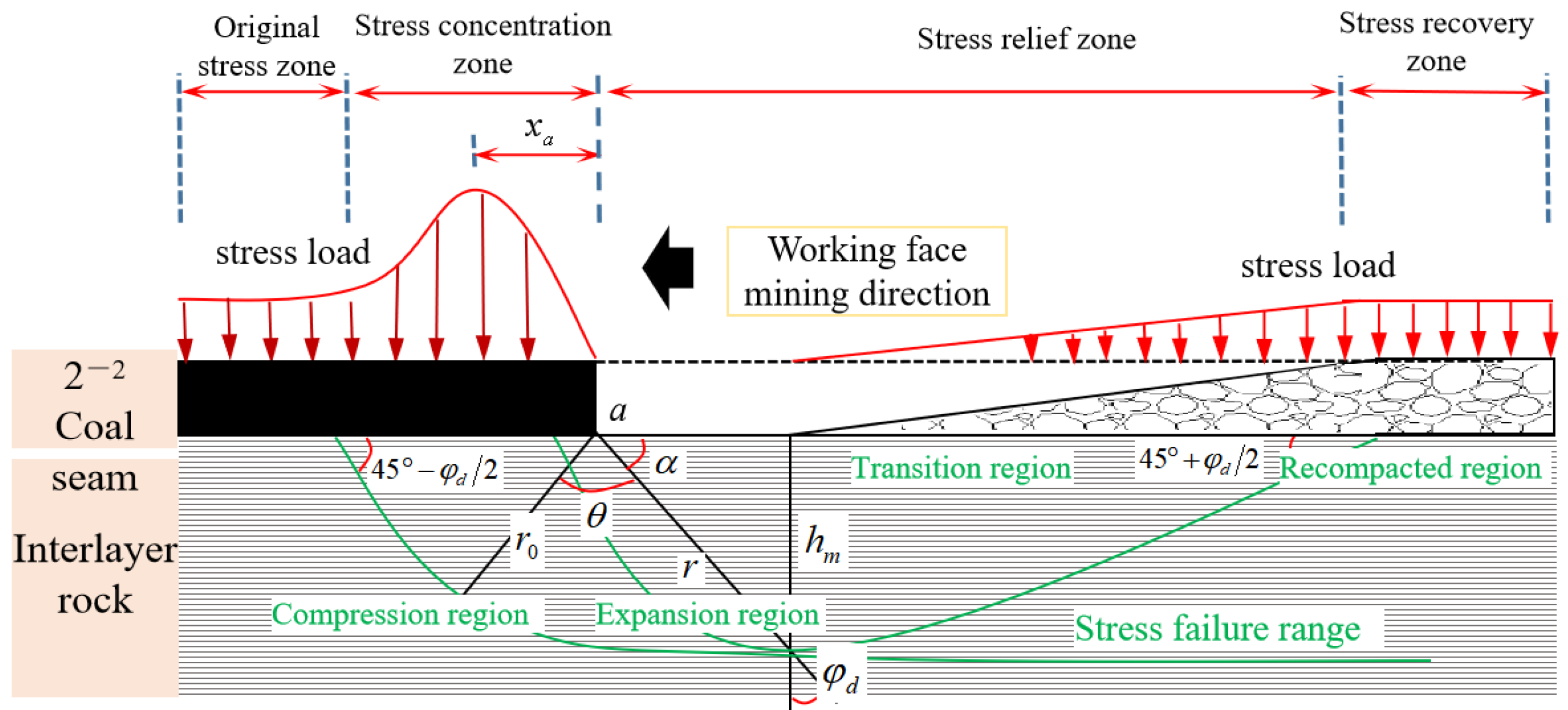

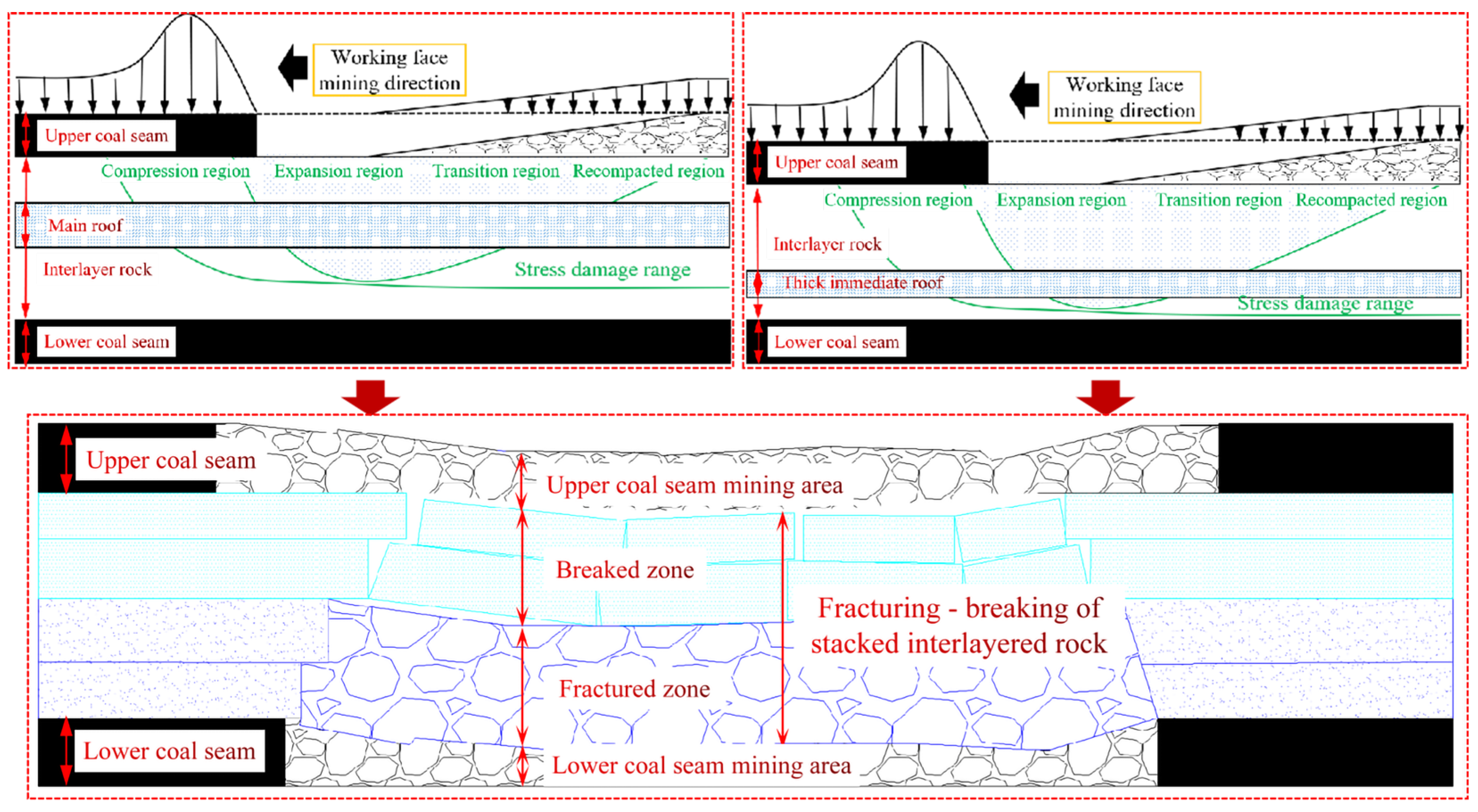

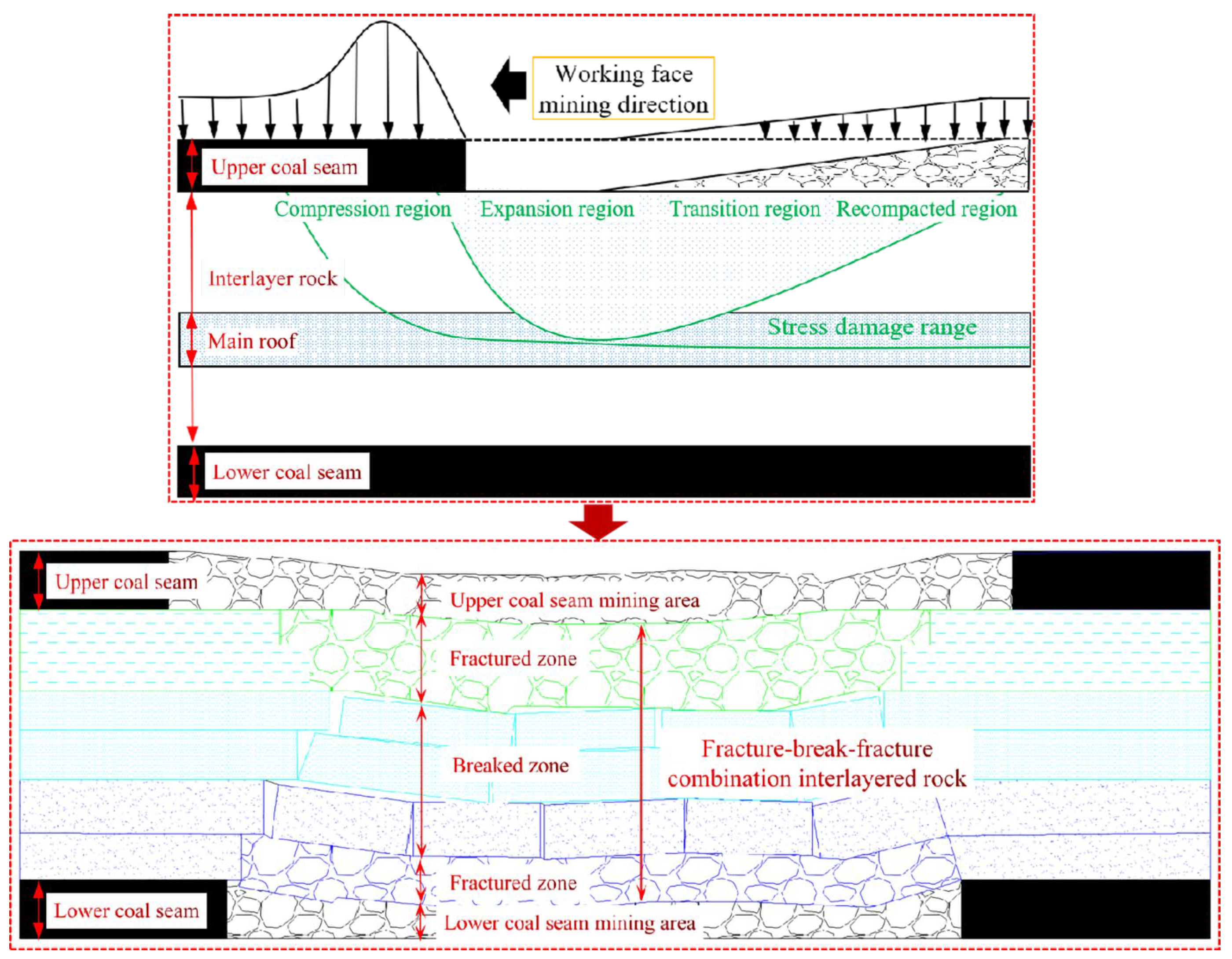

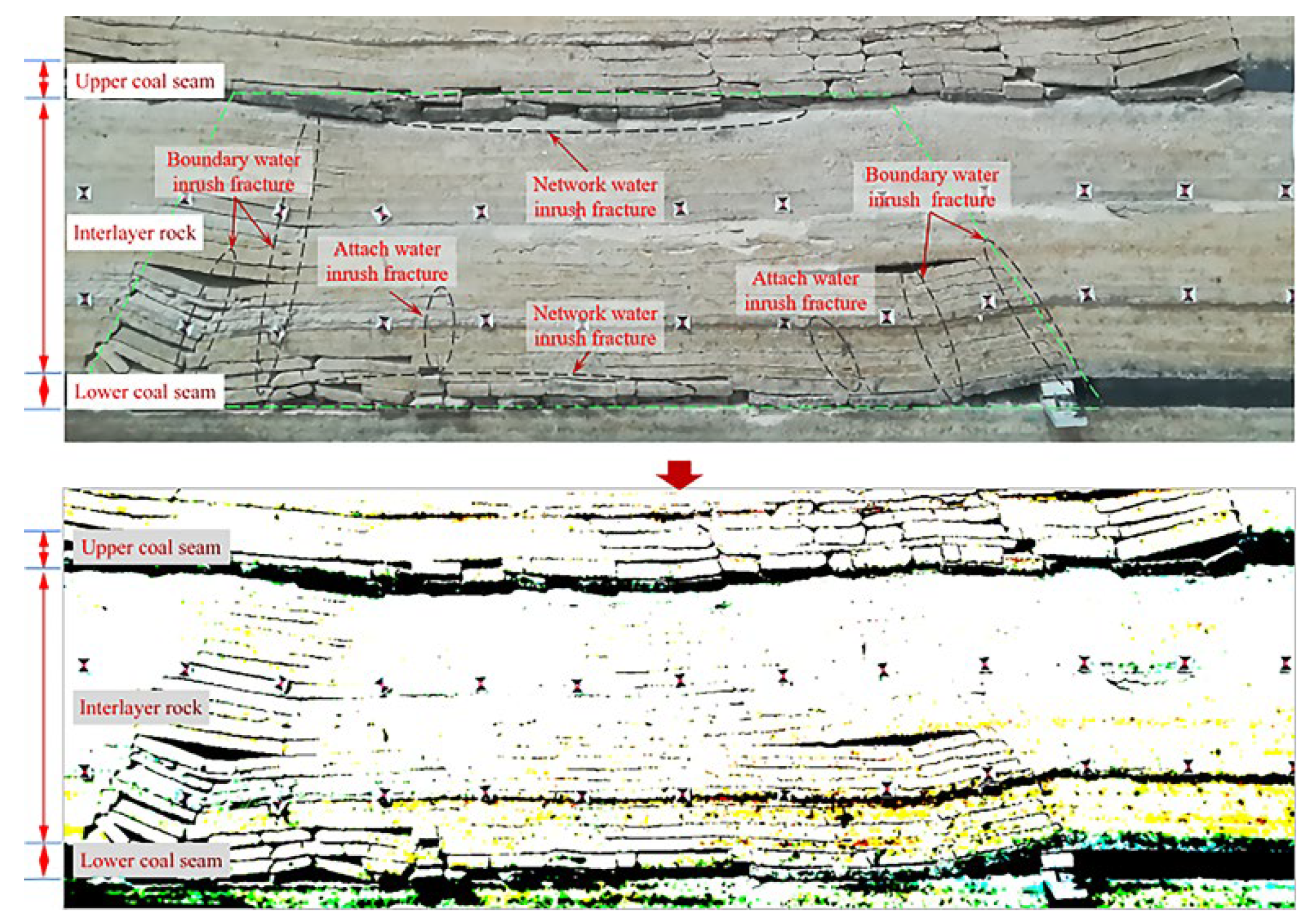

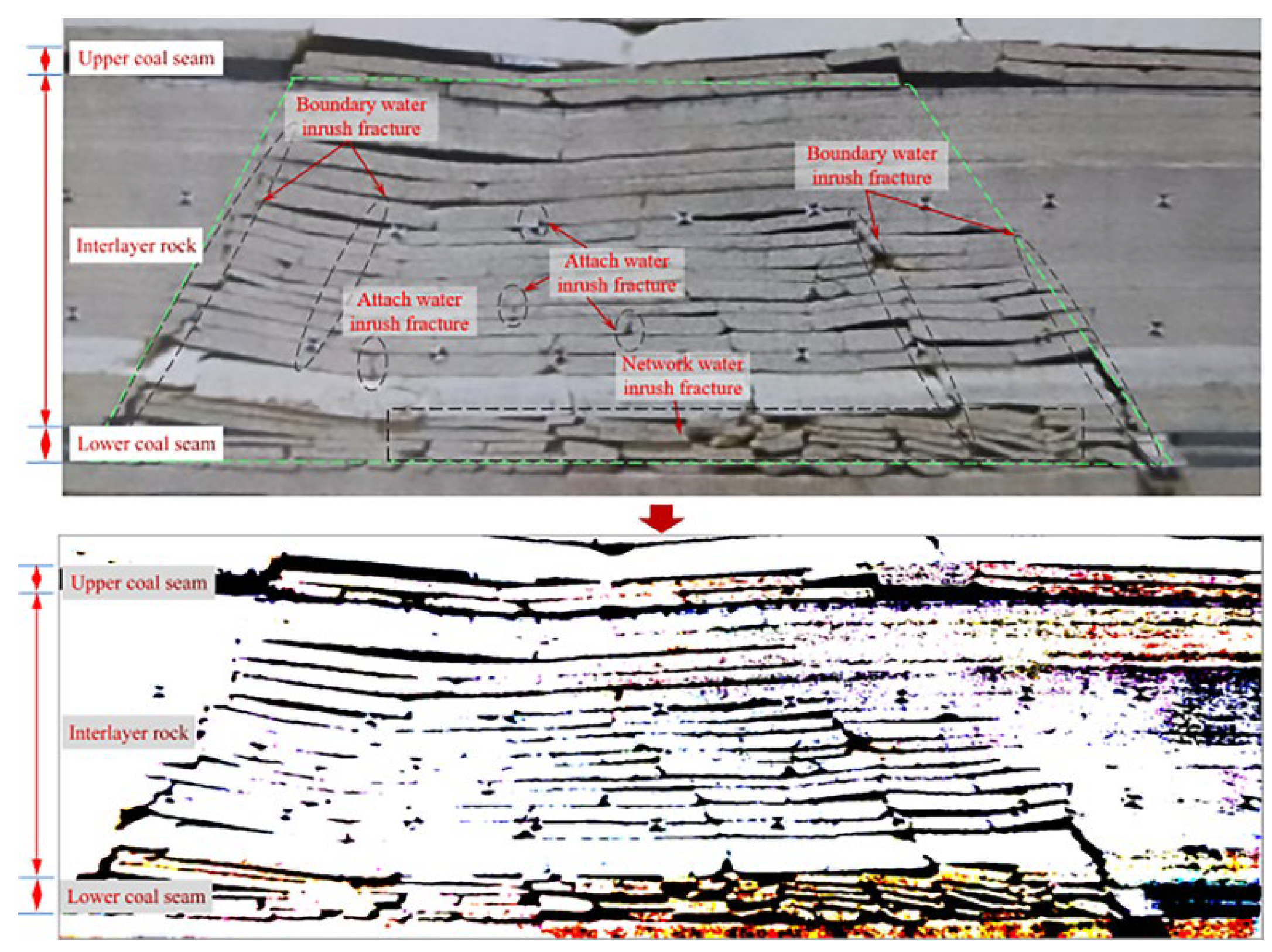

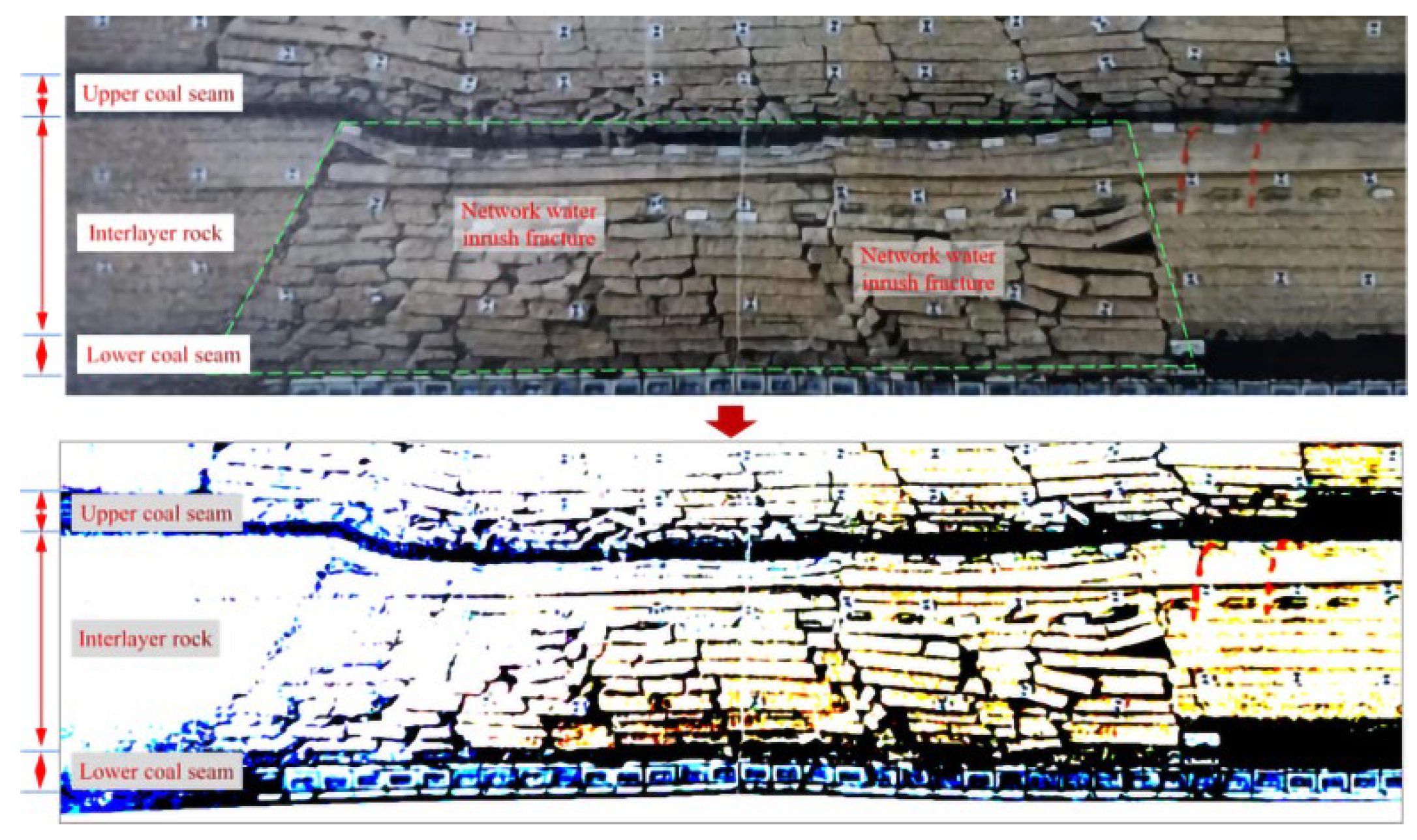

Based on the analysis of the similar simulation results from the distribution and evolution characteristics of the boundary water inrush fractures in the inter-layer rock, it can be seen that the boundary waters inrush fractures are affected by the mining of the upper and lower coal seams throughout the inter-layer rock, and the water accumulation in the upper coal seam gob is in the inter-layer rock boundary water inrush fractures. The flow rate is fast, and the water inflow is large. Therefore, based on the above comprehensive analysis, the boundary waters inrush fractures in the inter-layer rock in the three-dimensional space are regarded as flat fractures, and the flow of water in the gob in the boundary waters inrush fractures are regarded as a flat fracture flow water inrush model. As shown in

Figure 18.

According to the cubic law of plate fracture flow, the velocity of water in the boundary water inrush fracture can be expressed as

In the formula, is the direction of water flow; is perpendicular to the direction of water inrush fracture surface; is the velocity of water flow in direction, ; is the width of water inrush fracture, ; is the dynamic viscosity of water, ; is the pressure gradient in the direction, .

It can be seen from Equation (35) that the velocity profile presents a parabolic surface when water flows in the plate fracture. The calculation formula for the fracture flow per unit cross-section length of the plate waters inrush fracture can be obtained by integrating Equation (23); therefore, the cubic law is

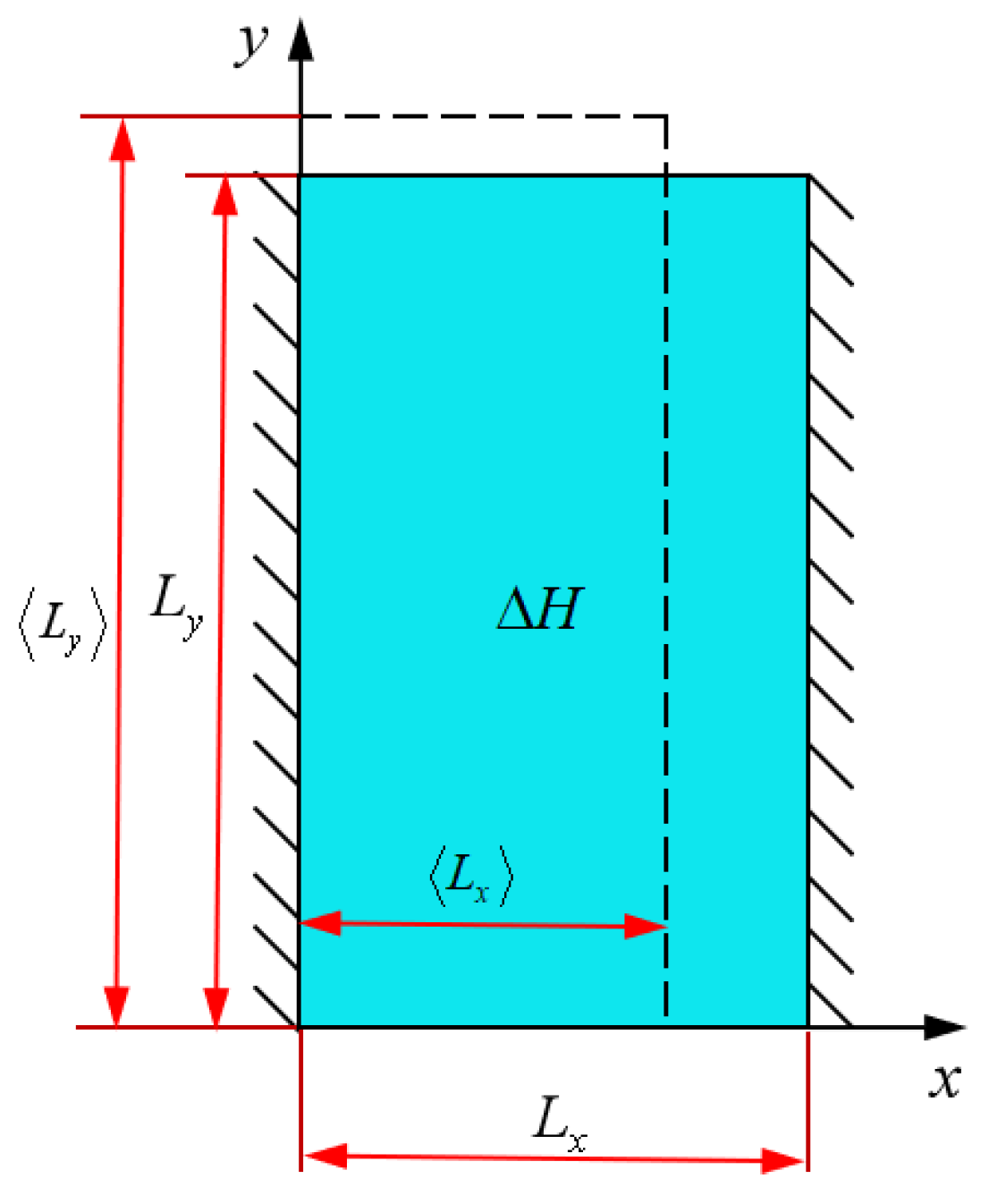

In order to solve the water flow in the fracture of the inter-layer rocks boundary more accurately, based on the parallel plate cubic law, the generalized cubic theorem is used to solve the water inrush model of the plate flow state under the influence of the roughness and opening degree of the plate composed of the rock strata between the broken faults. It is assumed that the area of the water inrush fracture on the plate is a rectangular plane of

, and

and

are the length and width of the water inrush fracture plane, respectively. The upper and lower boundaries of the water inrush fracture plane are fixed head boundaries, the water head difference is

, and the left and right boundaries are impermeable boundaries. The plane flow model of rectangular water inrush fracture is shown in

Figure 19. It is assumed that the average initial opening of the two planes of the water inrush fracture is

, and the initial area contact rate of the two planes is

. Under the action of the fracture pressure and shear load of the inter-layer rock stratum, the water inrush fracture plane produces the normal total deformation

under the combined action of compression closure deformation and share opening deformation. The instantaneous mechanical opening is

, and the area contact rate is

. In order to facilitate the subsequent solution, the normalized opening

is defined.

The normal total deformation of the water inrush fracture plane is produced under the combined action of compression closure deformation and shear opening deformation, which can be expressed as

In the formula, is the total normal deformation of the fracture plane; is the elastic component of the normal deformation of the fracture plane; is the normal deformation plastic component of the fracture plane; is the normal stiffness of the fracture plane. The first item on the right side of Formula (37) is the nonlinear elastic closure deformation of water inrush fracture plane normal compression; the second term is the plane opening deformation caused by shear.

During the break process of inter-layer rock, the contact area and the opening degree of the boundary water inrush fracture surface will change into the action of compression-shear load. When the normal compression deformation of the fracture surface occurs, the mechanical opening of the fracture surface decreases, and the contact area increases. When the shear expansion occurs on the fracture surface, the mechanical opening of the fracture surface increases and the area contact rates decreases. When the fracture surfaces reach a certain amount of closure of the action of normal load, the bulge formed by the fracture of the water inrush fracture surface will be flattened or crushed, and the area contact rate reaches a certain value and has nothing to do with the opening. Therefore, the evolution law of the area contact rate of the fracture plane under compression–shear loads is as follows.

In the formula, is the area contact rate under the compression-shear action of the fracture surface; is the area contact rate when the fracture surface is closed; is the normalized opening of the structure; is the fitting parameter. Under the initial conditions, the normalized opening and the contact rate of the fracture surface are . If is known, then computes . Obviously, when the water inrush fracture surface is completely closed, ; when the compression deformation occurs on the water inrush fracture surface, ; when the water inrush fracture surface occurs shear deformation, . During the deformation process of the water inrush fracture surface, when the mechanical opening reaches a stable value, the contact rate of the fracture area also reaches a certain value. Equation (38) shows that the area contact rate and shear angle of water inrush fracture surface have the same variation law, and the area contact rate of the fracture surface is mainly controlled by shear characteristics.

When the area contact rate of the water inrush fracture surface is

, the effective water inrush area does not exceed

. Therefore, when the effective contact area of the fracture surface decreases, the effective flow width of the water inrush fracture surface decreases, resulting in the transformation of the groove to the pipe flow on the flat fracture surface to increase the water inrush diameter. It is assumed that the effective flow width of the water inrush fracture surface is reduced from

to

, and the effective flow length is increased from

to

, as shown in

Figure 19. In order to define the equivalent hydraulic opening of water inrush fractures surface, there is

Under the condition of considering the change in contact rate of water inrush fracture area, it is assumed that the decrease of effective flow width of water inrush fractures surface and the effective flow length had the same ratio, then

By introducing the equivalent hydraulic aperture

of the water inrush fracture surface, the loss of water flows energy in the water inrush fracture surface can be well solved; that is, the water inrush fracture surface and the smooth, ideal water inrush fracture surface are lost, respectively. When considering the field water inrush fracture surface with mechanical opening

, effective flow width

, and effective flow length

, the flow diffusion energy of water inrush fracture surface can be expressed as Equation (42). When considering the water inrush fracture surface of the equivalent hydraulic opening

, ideal flows width

, and ideal flows length

, the flow diffusion energy of the water inrush fracture surface can be expressed as Equation (43).

In the formula, is the total energy of water flow and diffusion in the water inrush fracture surface.

According to the equivalent principle of water flow diffusion energy, the water flow energy of the field waters inrush fracture surface is equal to that of the smooth, ideal water inrush fracture surface. Combined with Formulas (40) and (41), the equivalent hydraulic opening of the water inrush fracture surface can be expressed as

Because it is impossible to reach complete waterless flow when the water inrush fracture surface is completely closed, the total flow of the water inrush fracture surface is

In the formula,

is the water flow related to the change in opening degree under the compression–shear load of water inrush fracture surface.

In Formulas (44) and (45),

is combined, in which

is the water inrush coefficient related to the lithology and fracture structure of the rock layer between the faults. Equation (46) can be converted to

In the formula, is a dimensionless parameter; is the flow of water through a smooth plane with an opening degree of and a water inrush coefficient of .

According to Equation (48), the dimensionless parameter is related to the change in the opening degree of the water inrush fracture surface, the contact rate of the fracture surface, and the ratio . At that time, and indicate that the water inrush characteristics of the fracture surface after the fracture surface have a large closure; with the increase in , shows the water inrush characteristics under the coupling effect of shear expansion, profit softening, and the change in contact rate of fracture surface area. When , it represents the change in water inrush quantity of water inrush fracture on the smooth plate fracture surface without stress, with an initial contact area of zero and tending to zero.

In summary, by solving the three-dimensional flat plate flow model and analyzing the rectangular planar model of the boundary water-inrush channel of the interlayer rock, it can be obtained that the water movement toward the boundary water-inrush channel can be completely transformed into the solution to the flat plate flow model mentioned above; by considering the roughness of the boundary water-inrush channel and the change in the width and length of the fractures, it can truly respond to the mechanism of the boundary water-inrush of the interlayer rock under the influence of the quarrying. This can also provide the theoretical basis for the control and prediction of water-inrush disasters.

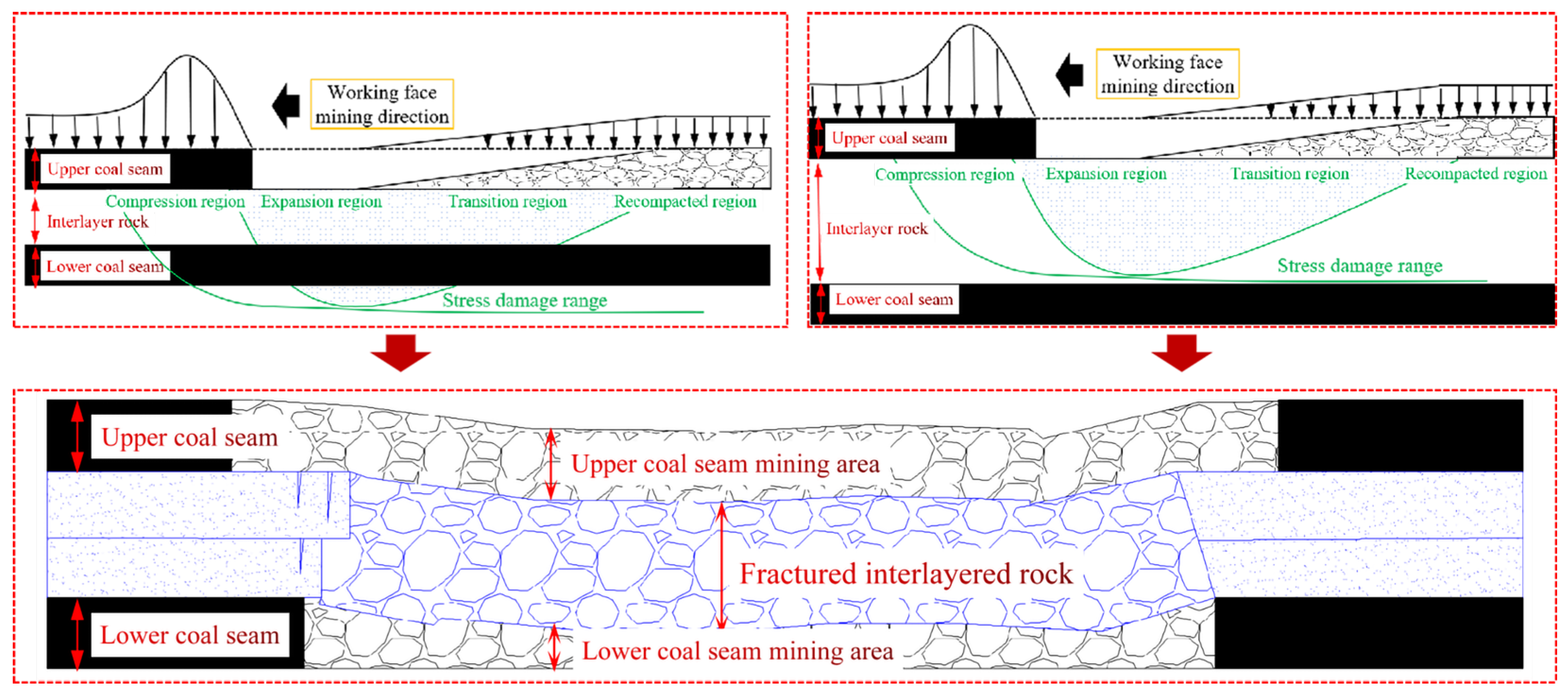

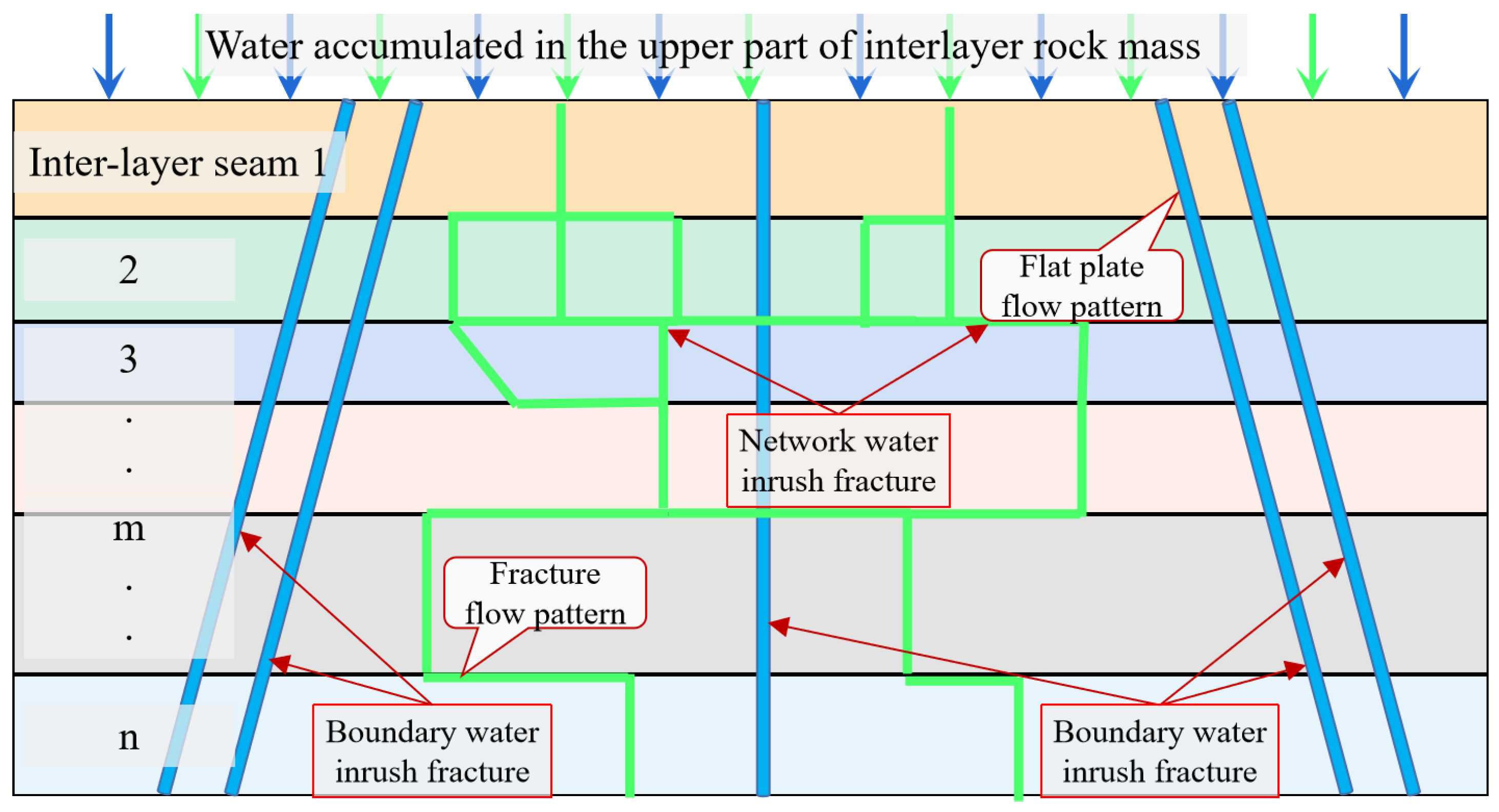

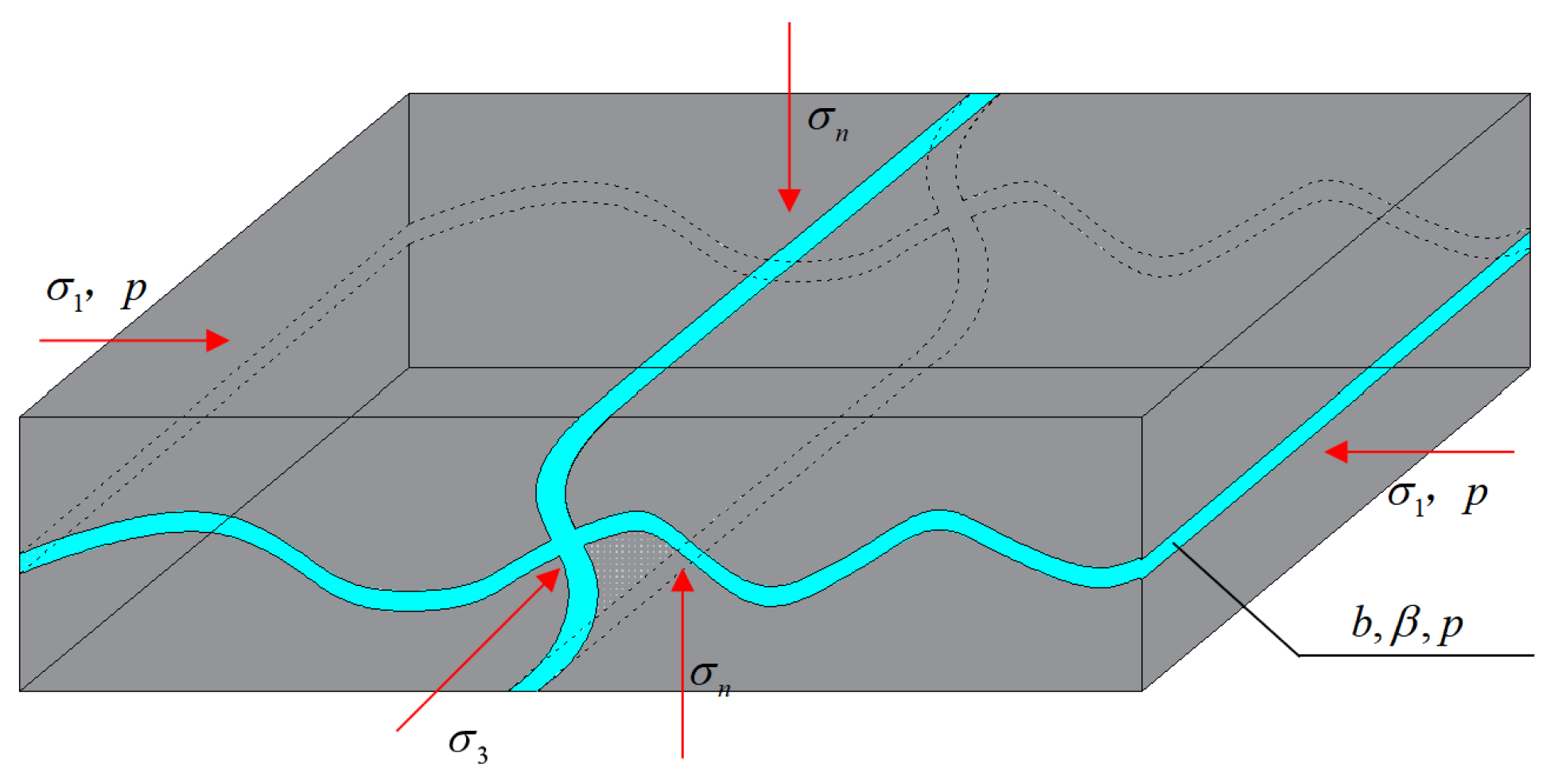

5.1.2. Solution of Fracture Flow Water Inrush Model

For the solution of the fracture flow water model when the gob water flows in the network water inrush fractures of the inter-layer rock, only the coupling effect of the water flow field in the network water inrush fractures and the rock layer between the broken faults are considered; the pore flow inside the inter-layer rock layer is not considered. Therefore, the flow process of gob water in the network waters inrush fractures is different from the plate flow boundary water inrush fractures. The rock strata of the network water inrush fractures medium do not exist

(rock mass characterization unit volume), or the scale

is equivalent to the macroscopic engineering scale of the inter-layer rock strata fracture. Therefore, the research on the water inrush of this part of the inter-layer rock strata can only be solved by the research method of rock structure mechanics; that is, the whole inter-layer rock is regarded as composed of several matrix inter-layer rock blocks and network water inrush fracture structures. The water accumulation in the gob is solved in the form of fracture flow in the inter-layer rock strata. The three-dimensional stress inter-layer rock fracture flow model is shown in

Figure 20.

In order to build the water inrush model research closer to the actual project site, the following assumptions are made for the construction model:

- ①

The inter-layer rock of the network water inrush fracture part is a structure composed of the inter-layer broken rock layer, and the network water inrush fracture, the rock layer between the broken faults, is a homogeneous and isotropic elastomer.

- ②

Compared with the network water inrush fractures, the water storage capacity and permeability of the rock strata between the broken faults are particularly weak, so the water storage capacity and permeability of the rock strata between the broken faults are not considered or ignored.

- ③

The flow of water in the network waters inrush fractures to obey Darcy’s law .

- ④

The deformation law of network waters inrush fractures to obey the joint model.

- ⑤

The effective stress law of the network water inrush fracture is , and the rock layer between the fault is only affected by the solid stress.

The inter-layer rock is broken to form structural planes with different sizes and occurrences, inter-layer rock strata with different blocks and shapes divided by different structural planes. Therefore, the deformation of the fractured rock under external load depends on the deformation of the fractured rock block and the deformation of its structural plane. The deformation of the broken block of the inter-layer rock stratum is not considered; only the deformation of the structural plane is considered. Therefore, the deformation of the broken block of the inter-layer rock stratum adopts the stress–strain linear elastic relationship to elastic mechanics, and its elastic–plastic deformation is not considered.

Mathematic model of elastic deformation of inter-layer rocks fracture block. The deformation problem of rock strata between broken faults is analyzed. Firstly, an arbitrary parallel hexahedron is taken in the broken block of inter-layer rock strata. The parallel hexahedron is located in the rectangular coordinate system, and the position is the independent variable. The stress component is its function; the stress balance equation in tensor form is constructed based on the force and moment balance Equation (37).

Considering the geometric shape of the rock fracture block of the water inrush fractures, the relationship between the deformation component and the displacement can be derived, and the geometric equation in tensor forms is obtained [

37].

Considering the geometric shape of the fracture block of the water inrush fractures, the relationship between the stress variation component and the deformation component is determined. The generalized Hu’s law can be used to obtain the constitutive equation:

In the formula, is the elastic modulus of inter-layer rock, ; is the Poisson’s ratio of inter-layer rock; is the volume strain; is the bulk modulus of elasticity of the broken block, ; is the shear elastic modulus of the fracture block, ; is Kroneker symbol: .

Equations (51) and (52) are constitutive relations expressed by stress and strain, respectively. When the deformation of rock strata between faults is expressed by displacement component, Equations (50) and (52) are substituted for Equation (49), and the linear combination of displacement or the linear combination of the first derivative is used to express stress. Finally, the tensor form equilibrium equation expressed by the displacement component is obtained; that is, the deformation model of inter-layer rocks fracture block.

In the formula, .

It is assumed that the deformation of the strata between the broken faults and the spatial structure surface formed by the network waters inrush fractures is continuous during the deformation process. Based on the study of the interaction between water and soil saturation, Terzaghi proposed the famous effective stress principle. Under the action of three-dimensional stress, it can be expressed as

where

is the effective stress tensor,

;

is the total stress tensor,

;

is pore pressure,

.

In [

38], based on the research of Terzaghi, the effective stress law in three-dimensional case is proposed; that is,

In the formula, is the effective stress coefficient, also known as the Biot coefficient. It mainly depends on the volume stress, fracture connectivity, pore pressure, and volume model of inter-layer broken rock blocks. is not a constant but a linear function composed of the volumetric force and the pore force of the fractured rock mass. When the volumetric stress increases, the effective stress coefficient decreases.

The effective stress equation of network water inrush fracture is

Coefficient reflects the contact condition of the structural plane of the water inrush fracture. When , the water inrush fracture surface is completely closed; when , the water inrush fracture surface has no contact.

The deformation characteristics of network water inrush fractures are mainly affected by the overburden load and horizontal extrusion stress during the mining process of the upper and lower working faces, which causes the contact state, roughness, strength, deformation, and filling state of the inter-layer rock fracture surface. It is assumed that the normal deformation of the water inrush fracture surface is elastic deformation; the fracture is closed when the normal stress increases, but it is less than the initial fracture opening. When the normal stress decreases, the fracture surface completely recovers deformation, and there are no changes in the plastic zone. Because the width of the water inrush fracture unit is small, it is assumed that the fracture deformation obeys the spatial eight-node Goodman model, so the deformation of the network water inrush fracture is actually plane deformation, which is controlled by both tangential stress and normal stress. The governing equation is

In the formula, and are the normal stress and tangential stress of the network water inrush fracture, ; and are the normal stiffness and tangential stiffness of the network water inrush fracture, ; and are normal strain and tangential strain.

Fracture waters flow and stress coupling model. The fracture width of the network waters inrush fracture changes obviously under the action of normal stress, so the fracture width is used as an intermediate variable to construct the relationship between the fracture stress change and the water flow. Because the physical meaning of the width change in the rough fracture and the smooth fracture is different, the ideal fracture model with the same mechanical width and hydraulic width is constructed here. The specific ideal fracture hydraulic model fractures width is

, the fracture surface is smooth and extends outward, the fracture length is greater than the fracture width, the fracture is regarded as a local plate fracture, and the water flow law is

In the formula, is the average velocity of water in the fracture, ; is the water inrush coefficient, .

The flow of water in the network waters inrush fracture is laminar flow, so the water inrush coefficient is

The unit width flow of water in water inrush fracture is

where

is the acceleration of gravity,

;

is the water year,

. In Equation (62), the flow rate

is proportional to the cubic of the fracture width

; that is, the cubic law of fracture seepage.

Based on the cubic law of fracture seepage, Barton [

38] improved the coupling model of fracture water flow and stress on the basis of experimental research and theoretical analysis.

In the formula, is the uniaxial compressive strength of rock strata between broken faults, ; is the roughness coefficient of network water inrush fracture surface; is the compressive strength of the network water inrush fracture surface, .

When the single water inrush fracture surface is taken as the research object, the normal stress is

, the mechanical width of the fracture surface is

, and the elastic constants of the fracture are

and

. Assuming that the width of the water inrush fracture in the inter-layer rock network is much smaller than the inter-layer rock scale, it is considered that

,

; its generalized Hooke’s law can be written as

Suppose that the relative displacements in the direction

are

respectively, then the Expression (65) can be expressed as

Among, .

When the water inrush fracture only considers the normal stress, Equation (66) can be transformed into

The integral of Equation (67) can be obtained.

The instantaneous mechanical width of single network waters inrush fracture is

Substituting Equations (63), (64), and (69) into Equation (68), the deformation width of network waters inrush fractures under normal stress is obtained.

Fracture water coupling water inrush model. The continuity equation of network waters inrush fracture is

where

is the density of water,

;

is the porosity of inter-layer rock, %;

is the water inrush rate of fracture,

;

is the sink-source term.

Taking pressure as a variable of density

and porosity

of inter-layer rock, then Equation (73) can be transformed into

Assuming the compressibility factor

of the fluid, the above equation can be obtained.

In formula (75),

is the water storage coefficient, which is generally considered to be caused by the change in inter-layer rock strata. Substituting Equation (75) into Equations (71) and (72), there is

Equation (76) is the fluid–solid coupling water inrush model of water inrush fracture and water formed by inter-layer rock fracture.

Based on the above coupling model of fracture deformation and stress of inter-layer rock, the fracture state model of water accumulation in the upper part of inter-layer rock in network water inrush fractures is obtained, and the equation of fracture flow water inrush model is solved.

Initial conditions: assuming that the initial pressure and effective pressure are and respectively, the gob water and inter-layer rock density is and , respectively.

Boundary conditions: constant pressure or constant flow on the interface

of the inter-layer rock mass.

The boundary displacement is quantified as:

According to the above solution conditions, the variables and of the above fluid–solid coupling model are solved. The key parameters such as water inrush velocity, flow rate, strain, and stress are further solved to solve the fracture flow water inrush model. According to the model built above, it can be embedded in the numerical simulation software Comsol Multiphysics to calculate the flow process and results of water in the network water inrush fracture and make full use of the advantages of numerical calculation software to reflect the water inrush process in the real inter-layer rock mass network water inrush fracture to the greatest extent.

Through the above analysis, combined with the interlayer rock network water-inrush fracture characteristics and the adoption of stress effects, in addition to the interlayer rock breakage block elastic deformation mathematical model, fracture water flow and stress coupling model, and fracture water coupling water-inrush model to optimize, as well as the more prominent on-site network water-inrush channel and constructed fracture flows solving model, a better description of the mechanism of the interlayer rock network water-inrush can be obtained.

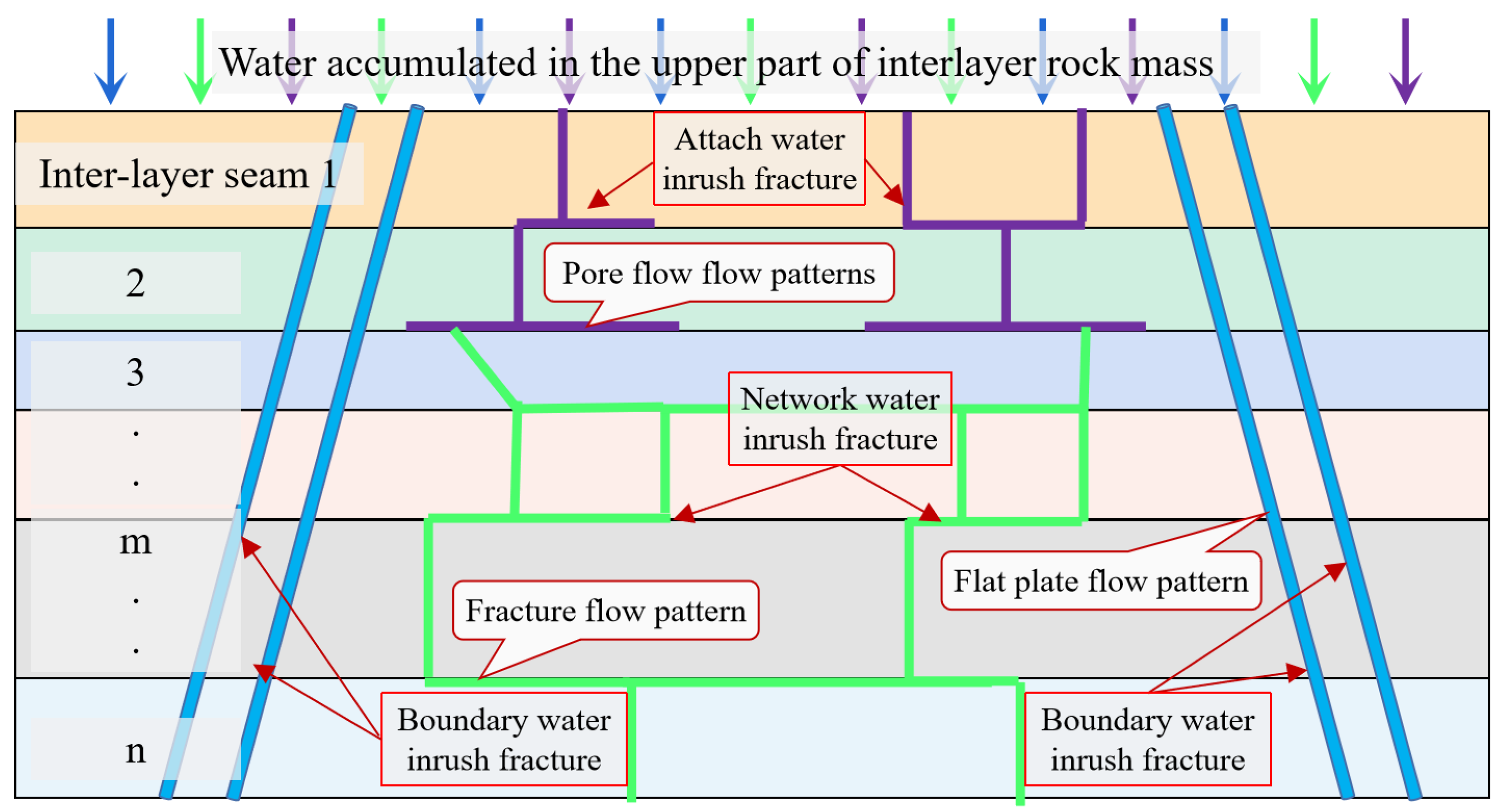

5.1.3. Solution of Water Inrush Model of Pore Fracture Flow Pattern

When the upper water flows in the water inrush fracture of the inter-layer rock, due to its long flow time and slow flow speed, there is both the flow in the transverse water inrush fracture and the flow in the longitudinal water inrush fracture, so the water inrush solution process of the pore fracture flow state can be solved according to the fracture network seepage theory. The water flow in the water inrush fractures formed by the inter-layer rock strata is regarded as the movement toward the “double medium” seepage channels composed of fractures and pores. It is considered that the water inrush in the fractures formed by the inter-layer rock strata is strong, and the permeability between the pores is weak. The fracture system and the pore system are regarded as continuous; the water exchange of the fracture system and the pore system is considered separately. It is proposed and solved. Model assumptions:

- ①

On the basis of primary pores, the inter-layer rock fracture blocks are cut into rock blocks of different shapes and sizes by widely distributed water inrush fractures; the primary pores and fractures are evenly distributed in the rock strata between the broken faults, thus forming two overlapping continua. The water inrush capacity of inter-layer rock strata is much larger than that of pores; the water inrush capacity of pores in other parts of inter-layer rock strata is neglected. There are two fluid pressures at each point in the seepage field, namely pore pressure and fracture pressure. The seepage of fluid in the water inrush fracture shows the pressure difference and violent mass exchange between the two systems.

- ②

According to the principle of dimensional analysis, the mass exchange of the two systems is derived as

In the formula,

is the characteristic coefficient of fractured rock mass which is proportional to the avoidance of rock blocks.

is the dynamic viscosity of water;

is fluid density;

is the fracture water inrush coefficient;

is the pore system water pressure;

is the water pressure of fracture system;

is the flow rate of pores to fractures per unit volume of fractured rock blocks in unit time.

- ③

Assuming that the fractured rock layer is still homogeneous and isotropic for fracture and pore media, both fracture flow and pore to flow to obey Darcy’s law, the constitutive equation of water flow is

In the formula, is the flow velocity; is permeability.

The mass conservation equation is

In the formula, is porosity.

Considering the compressibility of fluid and medium (broken rock and fracture), the method of compression coefficient can be used to deal with it. Suppose that the compression coefficient of water is

The compression coefficient of inter-layer rock is , the compression coefficient of water inrush fracture is . According to the principle of effective stress, the pressure acting on inter-layer rock and water inrush fracture is and , respectively.

Substitution (84) is available.

The Formulas (80)–(82) and (87) are brought into Formulas (83) and (84), respectively.

Equations (88) and (89) can also use the water storage coefficient A to represent the compression coefficient of inter-layer rock and water. Ignoring the compression effect of the pressure of the two medium systems on the inter-layer rock, there is

Although the Barenblantt-hole fracture water inrush model considers the flow difference between the fracture and the pore system, it assumes that the two are isotropic and homogeneous, which is quite different from the actual situation, especially the fracture system. Therefore, based on this improvement, the random distribution of water inrush fractures in the inter-layer rock strata is expressed as an ideal model of the same cuboid composed of orthogonal fracture network segmentation. It is assumed that the direction of water flows is parallel to the water inrush fractures in each direction, the water inrush fracture groups perpendicular to each principal axis are equally spaced, and the fracture width is constant, but the spacing and width of the water inrush fracture groups along each principal axis can be different, so a homogeneous anisotropic calculation model is formed and the flow of water in the inter-layer rock layer is ignored. The model equation proposed as the basis of Equation (91) is

When the gob water flows in the inter-layer rock mass, Equations (92) and (93) can be simplified as

In order to more accurately describe the fracture of inter-layer rock mass and the flow of water in inter-layer rocks strata, considering the elastic effect of rock strata between broken faults, this paper puts forward a calculation model of the water flow field and pore fracture field formed by water accumulation in gob in the attach water inrush fracture and inter-layer rock strata. The model assumes that the flow space of water is in the attach water inrush fracture, the contact area between fracture and inter-layer rock strata, and the non-flow area. According to the conservation equation, the equation of gob water flowing in the above area is determined, and the flow equation under the following three special conditions is mainly considered.

At the intersection of water inrush fractures, the algebraic sum of water flow at the intersection of water inflow and outflow is zero.

In the formula, is the total number of intersecting water inrush fractures in the rock strata between the nodes.

The attach water inrush fracture divides the inter-layer rock layer into

blocks; the attach water inrush fracture of each inter-layer rock layer can be regarded as a closed polygonal loop, and the algebraic sum of the pressure difference in the two closed loops is zero.

In the formula, is the length of the first water inrush fracture loop; is the pressure gradient of the water inrush fracture circuit; is the total number of basic units surrounding the polygon.

The longitudinal joint waters inrush fractures divide the inter-layer rock strata into irregular basic units, and only one fracture in each unit forms a curved channel.

In the formula, is the total pressure difference from the inflow boundary of the outflow boundary, is the total number of the basic units of the polygon, and is the code of the unit path.

Equations (96)–(98) are available.

There are

equations in the formula, which constitute the control equation of this model. In the calculation process, the loop pressures gradient and node flow are used as the basic variables, which increases the number of unknowns to be solved. If the node pressure

is used as the basic variable, the fracture unit diversion coefficient and the pressure gradient are used to represent the node flow, and any joint water inrush fracture unit

is studied. The node number of the two endpoints is

. The width of the fracture is

, the length is

, the porosity is

, and

is the water density. The flow rate of the inter-layer rock stratum unit

is

The node with

fracture unit convergence is

, it is connected with another

node

through

units. The flow balance of node

is studied. Because the node itself does not have the ability to store water, according to the mass conservation equation, the algebraic sum of the total flow at the node is zero; that is,

In the formula,

denotes the water pressure of node

;

denotes the water pressure of another node in the

unit of the contact node

. If considering the performance of the stored water of each joint water inrush fracture unit, the node has a sink or source, expressed by

; the above equation can be written as

All the nodes studied constitute equations for solving the water head of nodes; not only the storage capacity of fractures is considered, but also the flow control equation of the fracture network is directly expressed by node pressure. It is convenient to solve by modern calculation methods such as finite element method.

In summary, by analyzing the characteristics of the water-surge channels in the inter-layer rock, the boundary water-inrush fractures, network water-inrush fractures, and attach water-inrush fractures can be transformed into the optimized flat plate flow model, fracture flow model, and pore-fracture flow model for the solution, and the analysis of water-inrush mechanism in the inter-layer rock can be carried out through the analysis of the water movement in the water conduction channel in different flow modes, and the constructed coupled flow-consolidation model can realistically respond to the mechanism of the disaster caused by the water surge in the interlayer rock.