Comfort Study of General Aviation Pilot Seats Based on Improved Particle Swam Algorithm (IPSO) and Support Vector Machine Regression (SVR)

Abstract

1. Introduction

2. Methods

2.1. Support Vector Machine Regression

2.2. Principles of the Particle Swarm Algorithm

2.3. Improved Particle Swarm Algorithm to Optimize Support Vector Machines

2.4. Experimental Subjects

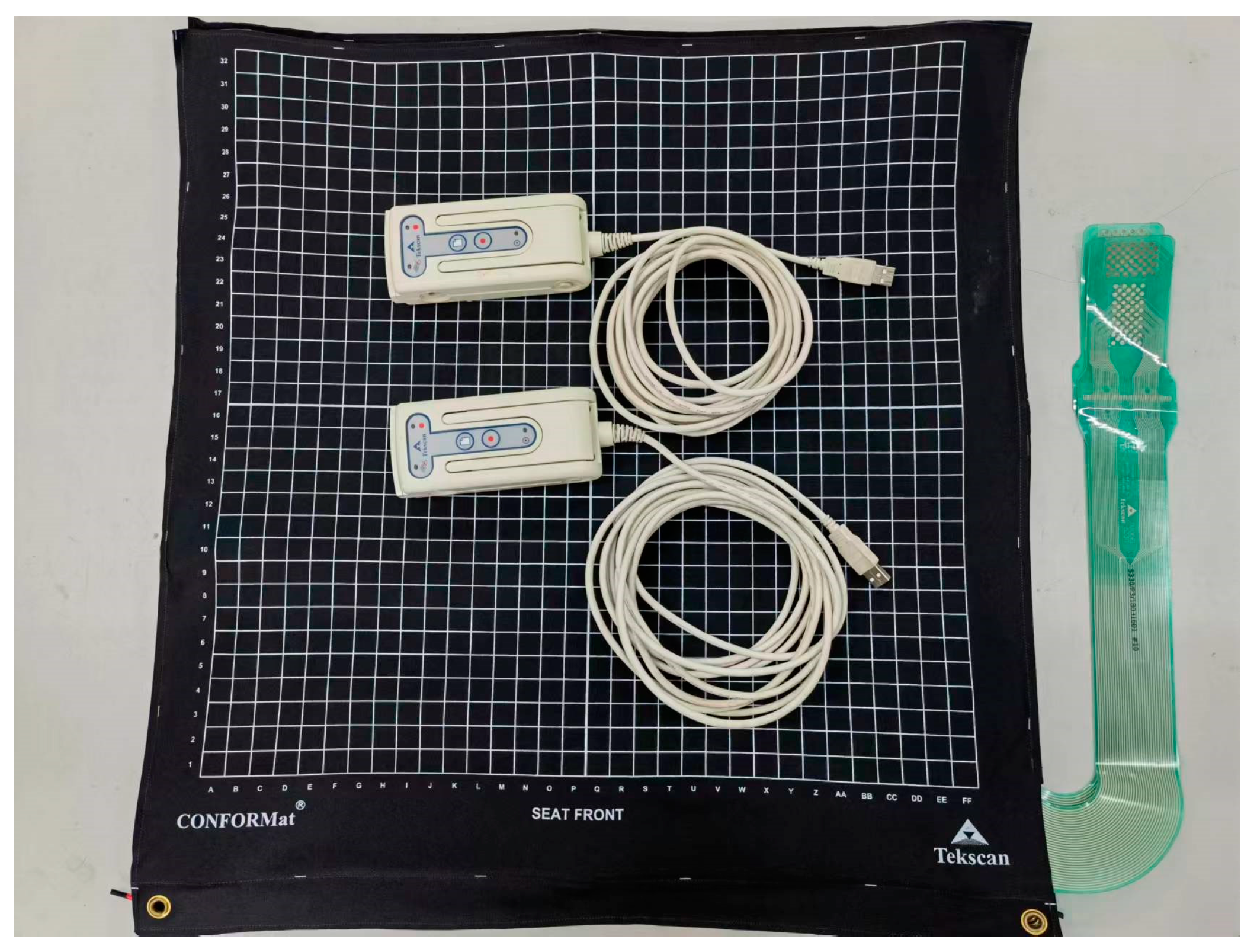

2.5. Experimental Equipment

2.6. Experimental Procedure

- (1)

- Thirty minutes before the experiment, the subjects had not undergone any strenuous exercise and were in good physical condition. Before the start of the experiment, the subjects were introduced to the experiment-related procedures and requirements, and their basic information was noted.

- (2)

- Preparation before the experiment. The pressure pad was laid flat on the chair surface and backrest, and the backrest tilt was adjusted to 140° (backrest tilt refers to the angle of presentation of the backrest and the ground); the seat pitch was adjusted to 60 cm (seat pitch refers to the frontmost of the seat and the frontmost of the footrest pitch). Proceed to the pre-experiment, as shown in Figure 4.

- (3)

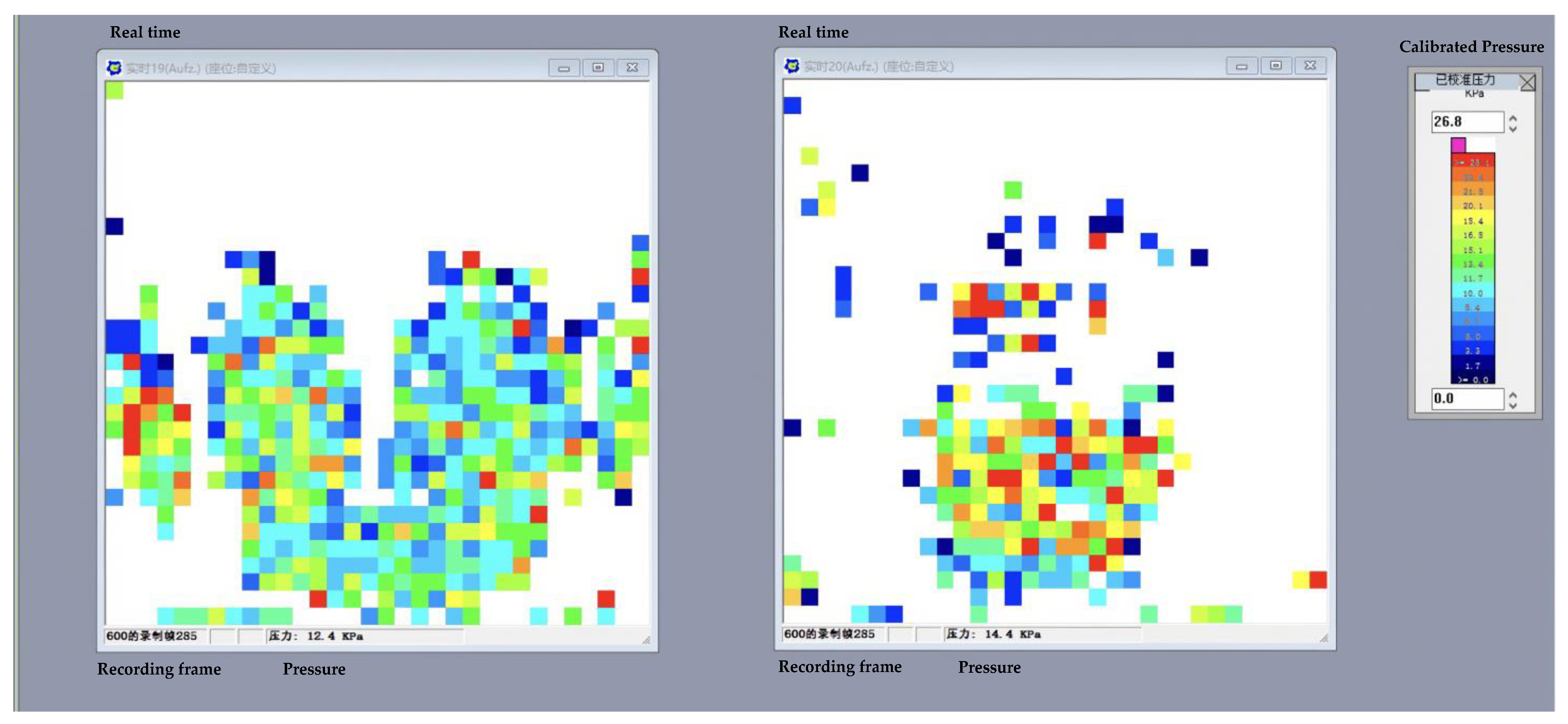

- The subjects wore tight-fitting clothing, sat on the chair in a standard driving position with their back against the back, placed their feet on the two footrests, tried to ensure that the pressure pads were wrinkle-free, and placed their left and right hands on the handles on both sides to maintain a stable sitting position for 2 min while using BPMS Research 7.0 software to collect the data in real time and form 2D cloud maps to ensure accuracy. The data were collected in real time using BPMS Research 7.0 software to form 2D cloud maps to ensure accuracy.

- (4)

- The results of the pre-experiment to determine comfort suggested that there were more obvious differences between the two seat pitches and three backrest tilts, so the seat pitches were adjusted to 63 cm and 68 cm, and the backrest tilts were adjusted to 100°, 110°, and 120°. After more than 15 min of rest, the personnel performed the next experiment, until the different distance and tilt angle experiments were tested and completed. Each person participated in a total of six experiments.

- (5)

- Subjective comfort was scored on a 7-point Likert scale for different seat pitches and backrest inclination angles, respectively.

3. Model Development and Validation

3.1. Data Collection and Analysis

3.2. Indicator Screening Based on LASSO Regression

3.3. Data Analysis

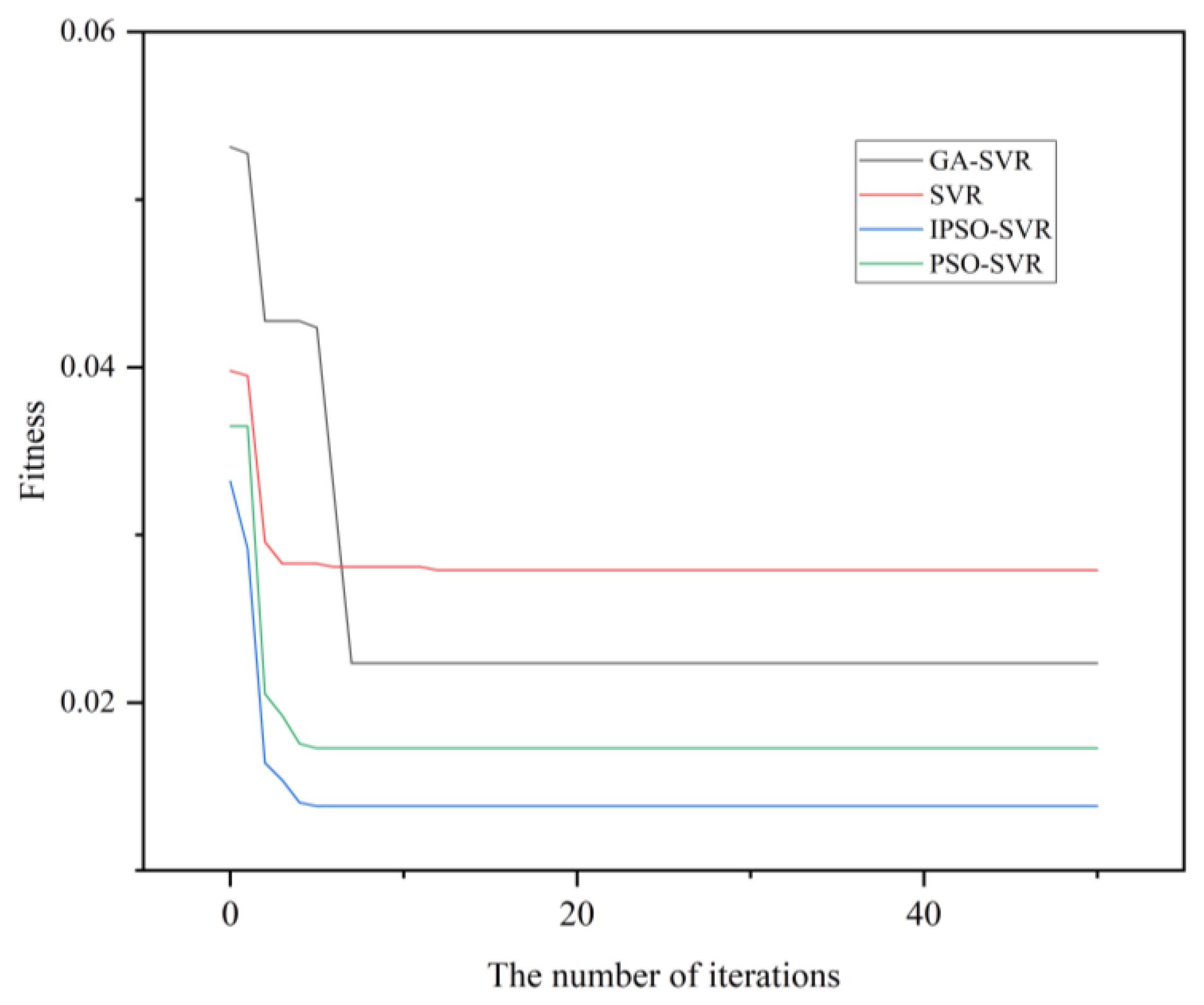

3.4. Establish the IPSO-SVR Prediction Model

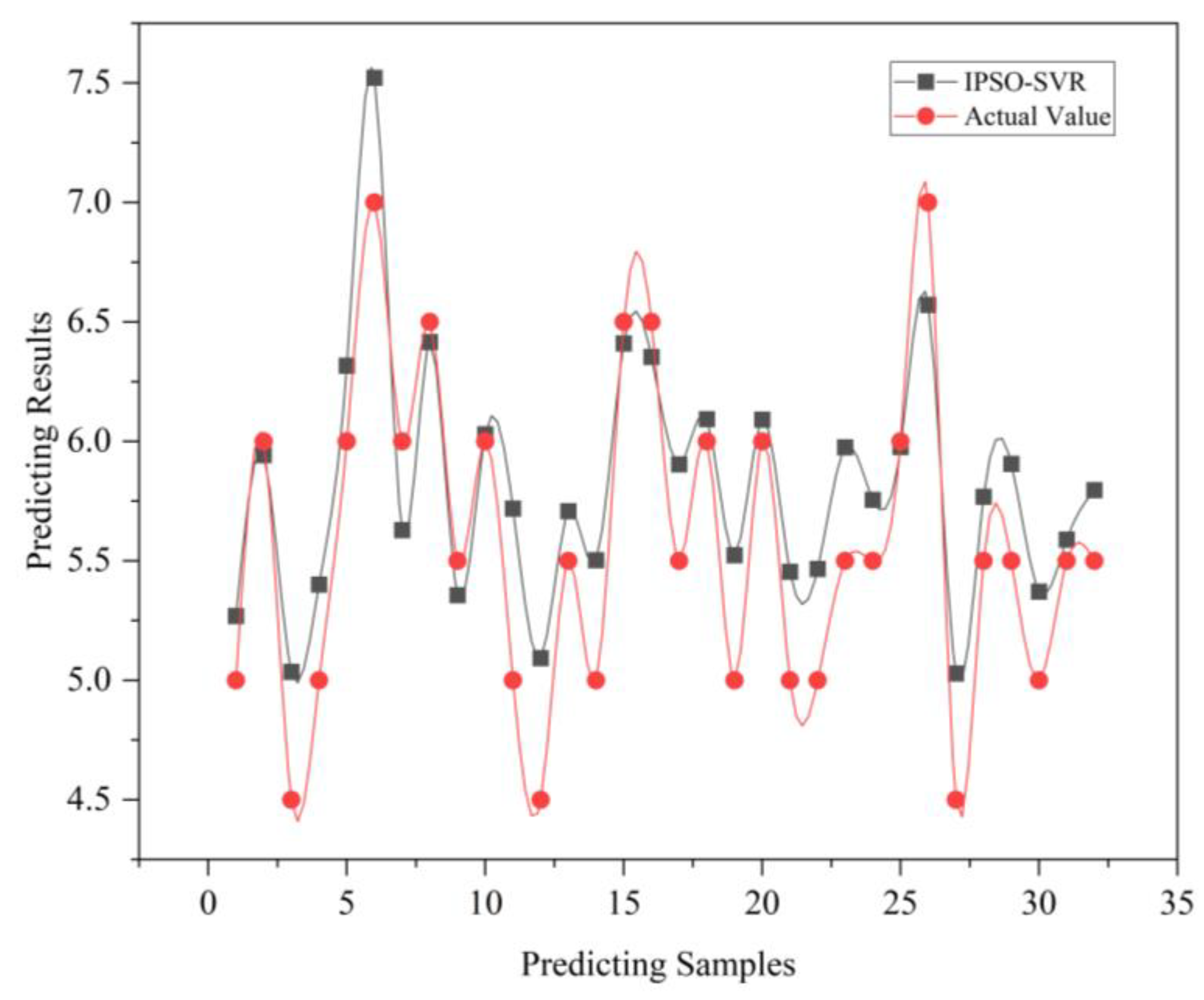

3.5. Model Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiong, K.W.; Xu, L.; Sun, J.C.; Chen, S.; Ma, J.; Hu, W.D. The role of lumbar support on lumbar muscles during simulated pilot sitting. Occup. Health 2019, 35, 743–747. [Google Scholar]

- Vanacore, A.; Lanzotti, A.; Percuoco, C.; Capasso, A.; Vitolo, B. A model-based approach for the analysis of aircraft seating comfort. Work 2020, 68, S251–S255. [Google Scholar] [CrossRef] [PubMed]

- Li, X.X.; Ding, L.; Wang, X.W.; Wei, S.H.; Zhou, Q.X.; Hu, H.M. Simulation of pilot seat cushion comfort based on Ansys. J. Beijing Univ. Aeronaut. Astronaut. 2015, 41, 241–245. [Google Scholar]

- Lapa, V.V.; Neverov, G.I.; Poliakov, V.V.; Solov’ev, N.N. Effect of inclination angles of supporting surfaces og aircraft seat on pilot’s working capacity in long-duration flight. Aerosp. Environ. Med. 2000, 34, 17–21. [Google Scholar]

- Vancampfort, D.; Firth, J.; Schuch, F.B.; Rosenbaum, S.; Mugisha, J.; Hallgren, M.; Probst, M.; Ward, P.B.; Gaughran, F.; Hert, M.D.; et al. Sedentary Behavior and Physical Activity Levels in People with Schizophrenia, Bipolar Disorder and Major Depressive Disorder: A Global Systematic Review and Meta-Analysis. World Psychiatry 2017, 16, 308–315. [Google Scholar] [CrossRef] [PubMed]

- Vancampfort, D.; Hallgren, M.; Firth, J.; Rosenbaum, S.; Schuch, F.B.; Mugisha, J.; Probst, M.; Damme, T.V.; Carvalho, A.F.; Stubbs, B. Physical Activity and Suicidal Ideation: A Systematic Review and Meta-Analysis. J. Affect. Disord. 2018, 225, 438–448. [Google Scholar] [CrossRef]

- Huo, X.; Sun, W.L.; Tao, Q.; Kang, J.S.; Li, Z.B.; Wang, S.D. Seat comfort testing and evaluation based on sitting posture analysis. J. Eng. Des. 2017, 24, 286–294. [Google Scholar]

- Wang, M.Y.; Lin, Q.X.; Sun, S.Y. Development and evaluation of the office computer seating comfort questionnaire. In Proceedings of the Fifteenth Annual Conference of the Ergonomics Society of Taiwan, Taiwan, China, 15 March 2008. [Google Scholar]

- Smith, D.R.; Andrews, D.M.; Wawrow, P.T. Development and evaluation of the automotive seating discomfort questionnaire. Int. J. Ind. Ergon. 2006, 36, 141–149. [Google Scholar] [CrossRef]

- Liu, Z.P.; Wang, J. Seat comfort and its evaluation theory and method. Aerosp. Med. Med. Eng. 2010, 23, 292–298. [Google Scholar]

- De Looze, M.P.; Kuijt-Evers, L.F.M.; Van Dieen, J.A.A.P. Sitting Comfort and Discomfort and the Relationships with Objective Measures. Ergonomics 2003, 46, 985–997. [Google Scholar] [CrossRef]

- Pei, H.N.; Li, Y.M.; Huang, X.G.; Yang, Y.Y.; Lou, Z.H.; Zhang, S.Y. Optimization study of seat surface material comfort based on pressure distribution measurement system. Aerosp. Med. Med. Eng. 2020, 33, 432–439. [Google Scholar]

- Gao, K.Z.; Luo, Q.; Zhang, Z.F.; Xu, Z.M. Evaluation of vibration comfort of automotive seats based on body pressure distribution. Automot. Eng. 2022, 44, 1936–1943, 1963. [Google Scholar]

- Deng, L.; Wang, G.; Chen, B. Operating Comfort Prediction Model of Human-Machine Interface Layout for Cabin Based on GEP. Comput. Intell. Neurosci. 2015, 2015, 92. [Google Scholar] [CrossRef]

- Rysanek, A.; Nuttall, R.; McCarty, J. Forecasting the impact of climate change on thermal comfort using a weighted ensemble of supervised learning models. Build. Environ. 2020, 190, 107522. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, Z.; Zhang, M.; Zhu, X.; Zhang, X. Comfort Prediction of Office Chair Surface Material Based on the Issa-Lssvm. Sensors 2022, 22, 9822. [Google Scholar] [CrossRef]

- Mariano-Hernández, D.; Hernández-Callejo, L.; Solís, M.; Zorita-Lamadrid, A.; Duque-Perez, O.; Gonzalez-Morales, L.; Santos-García, F. A Data-Driven Forecasting Strategy to Predict Continuous Hourly Energy Demand in Smart Buildings. Appl. Sci. 2021, 11, 7886. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.; Bründlinger, R. Improved Elman Neural Network Short-Term Residents Load Forecasting Considering Human Comfort Index. J. Electr. Eng. Technol. 2019, 14, 2315–2322. [Google Scholar] [CrossRef]

- Zhao, C.; Yu, S.H.; Miller, C.; Ghulam, M.; Li, W.H.; Wang, L. Predicting Aircraft Seat Comfort Using an Artificial Neural Network. Hum. Factors Ergon. Manuf. Serv. Ind. 2019, 29, 154–162. [Google Scholar] [CrossRef]

- Zhang, W.L.; Li, Y.L.; Yang, D.Z.; Xie, Q.H.; Yin, Y.Y.; Chen, D. SVR-based gasoline engine transition air flow prediction study. Automot. Engines 2023, 1, 44–51. [Google Scholar]

- Li, Z.D.; Zeng, J.; Wu, H.Q. A construction safety accident prediction model integrating GWO and SVR. J. Saf. Environ. 1–10.

- Wang, M.; Miao, W.; Tan, Y.; Wu, K.; Li, X.; Gu, Y.; Chen, L. Evaluation and Prediction Method of Automotive Electronic Accelerator Pedal Based on Support Vector Regression. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, in press. [Google Scholar] [CrossRef]

- Chen, P.; Xu, L.; Tang, Q.; Shang, L.; Liu, W. Research on Prediction Model of Tractor Sound Quality Based on Genetic Algorithm. Appl. Acoust. 2022, 185, 108411. [Google Scholar] [CrossRef]

- Sha, Y.D.; Guan, S.X.; Zhao, H.; Liu, Y.; Liu, G.E. Prediction of internal helical groove cutting force by support vector regression machine based on simulated annealing algorithm optimization. Tool Technol. 2023, 57, 100–105. [Google Scholar]

- Xiong, Q.; Zhang, X.; Xu, X.; He, S. A modified chaotic binary particle swarm optimization scheme and its application in face-iris multimodal biometric identification. Electronics 2021, 10, 217. [Google Scholar] [CrossRef]

- He, Y.Q.; Liu, G.S.; Xiao, Y.Y.; Zhang, Z. Optimization of substation siting based on improved GA-PSO hybrid algorithm. Power Syst. Prot. Control. 2017, 45, 143–150. [Google Scholar]

- Koboyashi, T.; Simon, D.L. Hybrid neural network genetic-algorithm technique for aircraft engine performance diagnostics. J. Propuls. Power 2005, 21, 751–758. [Google Scholar] [CrossRef]

- Zhu, B.H.; Zheng, B.Y.; Dai, Y.J.; Liu, C. Prediction of coal and gas protrusion hazard in tunnel based on nonlinear support vector machine. Mod. Tunn. Technol. 2020, 57, 20–25. [Google Scholar]

- Zhao, X.; Gu, W.H. Tunnel collapse risk prediction based on artificial swarm optimization support vector machine regression. Sci. Technol. Eng. 2023, 23, 3997–4003. [Google Scholar]

- Peng, S.W.; Liang, K.; Pan, L.; Zhao, J.; Feng, Q.; Ding, S. Time-optimal trajectory planning of robotic arm based on improved particle swarm algorithm. Comb. Mach. Tools Autom. Mach. Technol. 2023, 6, 31–34. [Google Scholar]

- Zhou, Y.J.; Zhao, M.; Fu, J.W.; Long, Z.Q. Design of rocket anti-lightning reinforcement based on particle swarm algorithm. J. Arms Equip. Eng. 2023, 44, 281–287. [Google Scholar]

- Miao, J.J.; Li, D.B.; Li, H.J.; Jue, Z.B.; Chen, Z.H.; Chen, Z.L.; Feng, Y.X. Status and prospect of improved particle swarm algorithm in coal-fired power plants. Environ. Eng. 2023, 41, 354–362. [Google Scholar]

- Feng, Y.M.; Li, C.J.; Zhang, M. Research on medium and long-term reservoir scheduling function based on improved particle swarm algorithm. Hydropower 2008, 34, 94–97. [Google Scholar]

- Tong, Q.J.; Li, M.; Zhao, Q. An improved particle swarm optimization algorithm based on classification idea. Mod. Electron. Technol. 2019, 42, 11–14. [Google Scholar]

- Pei, H.N. Study on Evaluation Method of Comfort for Civil Aircraft Cabin Based on Ergonomic Exposure. Ph.D. Thesis, North-Western Polytechnical University, Xi’an, China, 2017. [Google Scholar]

- Zhang, F.; Li, K.X.; Zhou, J.B. Research on the evaluation of human vibration comfort of cabin seat of a certain type of airplane. Strength Environ. 2019, 46, 59–63. [Google Scholar]

- Kokorikou, A.; Vinka, P.; de Pauw, I.C.; Braca, A. Exploring the design of a lightweight, sustainable and comfortable aircraft seat. Work J. Prev. Assess. Rehabil. 2016, 64, 941–954. [Google Scholar] [CrossRef]

- Zhong, Q.; Guo, G.; Pei, X.S.; Xu, N. An improved BP neural network-based office seating comfort evaluation method. Packag. Eng. 2018, 39, 155–158. [Google Scholar]

- Zhao, C.; Yu, S.H.; Wang, L.; Li, W.H. Characteristics of body pressure distribution under different sampling densities. J. Zhejiang Univ. (Eng. Ed.) 2019, 53, 268–274. [Google Scholar]

- Yu, S.H.; Gong, S.H. Grain price forecasting based on Lasso and support vector machine. J. Hunan Univ. (Soc. Sci. Ed.) 2016, 30, 71–75. [Google Scholar]

- Li, G.N.; Shi, J.K.; Chen, X.M.; Gao, C.; Jiang, X.J.; Cui, C.J.; Zhu, Q.; Hou, S.C.; Zhou, W.H. Research on overfocus scanning microscopy measurement method based on machine learning. Chin. Opt. 2022, 15, 703–711. [Google Scholar]

| Age | Height (cm) | Weight (kg) | Number | |

|---|---|---|---|---|

| Male | 26.67 ± 8.8 | 178.44 ± 4.86 | 74.38 ± 8.77 | 16 |

| Female | 25.55 ± 7.4 | 164.82 ± 5.20 | 55.36 ± 8.88 | 11 |

| Sum | 26.08 ± 8.2 | 172.89 ± 8.35 | 66.63 ± 12.84 | 27 |

| Variables | Regression Coefficient | Variables | Regression Coefficient |

|---|---|---|---|

| Gender | −0.107988 | Hip object pressure | 0 |

| Height | 0.087529 | Hip peak object pressure | 0 |

| Weight | 0.0647327 | Hip peak contact pressure | 0 |

| Back object pressure | 0 | Hip peak strength | 0 |

| Back peak object pressure | −0.0054094 | Hip contact area | 0.0211677 |

| Back peak contact pressure | −0.0058324 | Hip contact pressure | 0 |

| Back peak strength | 0 | Hip strength | 0.8117908 |

| Back contact area | 0.0042048 | ||

| Back contact pressure | 0.3892448 | ||

| Back strength | 0 |

| Parameters | Different Backrest Angles | Cardinal Values | Significance (p) | ||

|---|---|---|---|---|---|

| 100° | 110° | 120° | |||

| Back peak object pressure | 30.71 ± 2.15 | 32.81 ± 1.67 | 32.03 ± 2.16 | 588.203 | <0.01 ** |

| Back peak contact pressure | 31.13 ± 2.13 | 33.98 ± 2.14 | 34.55 ± 2.05 | 798.623 | <0.01 ** |

| Back contact area | 382.03 ± 7.98 | 411.99 ± 11.26 | 463.28 ± 10.87 | 1200 | <0.01 ** |

| Back contact pressure | 13.82 ± 0.35 | 13.59 ± 0.23 | 13.29 ± 0.29 | 1014.514 | <0.01 ** |

| Hip contact area | 741.99 ± 7.76 | 718.98 ± 6.48 | 679.19 ± 5.52 | 1200 | <0.01 ** |

| Hip strength | 977.39 ± 20.96 | 934.55 ± 17.67 | 902.32 ± 18.01 | 1200 | <0.01 ** |

| Parameters | Different Backrest Angles | |||||

|---|---|---|---|---|---|---|

| 100–110° | 100–120° | 110–120° | ||||

| Z | Sig | Z | Sig | Z | Sig | |

| Back peak object pressure | −20.654 | <0.01 ** | −18.423 | <0.01 ** | −11.139 | <0.01 ** |

| Back peak contact pressure | −21.092 | <0.01 ** | −21.039 | <0.01 ** | −5.643 | <0.01 ** |

| Back contact area | −21.222 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Back contact pressure | −19.327 | <0.01 ** | −21.222 | <0.01 ** | −20.654 | <0.01 ** |

| Hip contact area | −21.222 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Hip strength | −21.222 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Parameters | Different Backrest Angles | Cardinal Values | Significance (p) | ||

|---|---|---|---|---|---|

| 100° | 110° | 120° | |||

| Back peak object pressure | 36.66 ± 1.89 | 36.17 ± 1.93 | 31.23 ± 1.48 | 920.28 | <0.01 ** |

| Back peak contact pressure | 38.82 ± 2.01 | 37.75 ± 1.52 | 32.31 ± 1.52 | 924.753 | <0.01 ** |

| Back contact area | 392.11 ± 8.76 | 410.83 ± 11.04 | 479.41 ± 13.29 | 1188.12 | <0.01 ** |

| Back contact pressure | 14.58 ± 0.47 | 13.85 ± 0.29 | 13.53 ± 0.21 | 1088.813 | <0.01 ** |

| Hip contact area | 745.07 ± 10.23 | 730.21 ± 6.32 | 679.49 ± 8.32 | 1178.403 | <0.01 ** |

| Hip strength | 977.24 ± 29.26 | 982.31 ± 20.22 | 926.33 ± 19.46 | 911.213 | <0.01 ** |

| Parameters | Different Backrest Angles | |||||

|---|---|---|---|---|---|---|

| 100–110° | 100–120° | 110–120° | ||||

| Z | Sig | Z | Sig | Z | Sig | |

| Back peak object pressure | −6.159 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Back peak contact pressure | −11.06 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Back contact area | −21.21 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Back contact pressure | −21.222 | <0.01 ** | −21.222 | <0.01 ** | −20.215 | <0.01 ** |

| Hip contact area | −21.181 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Hip strength | −7.675 | <0.01 ** | −21.222 | <0.01 ** | −21.222 | <0.01 ** |

| Sample | Predicted Value | True Value | Relative Error |

|---|---|---|---|

| 1 | 5.268905 | 5 | 0.053781 |

| 2 | 5.942431 | 6 | 0.009595 |

| 3 | 5.035716 | 4.5 | 0.119048 |

| 4 | 5.400769 | 5 | 0.080154 |

| 5 | 6.316997 | 6 | 0.052833 |

| 6 | 7.522472 | 7 | 0.074639 |

| 7 | 5.628436 | 6 | 0.061927 |

| … | … | … | … |

| 30 | 5.37114 | 5 | 0.074228 |

| 31 | 5.588755 | 5.5 | 0.016137 |

| 32 | 5.795578 | 5.5 | 0.053742 |

| Prediction Model | RMSE | MAE | R2 | RSD | Prediction Accuracy |

|---|---|---|---|---|---|

| IPSO-SVR | 0.37 | 0.32 | 0.92 | 8.71% | 94.00% |

| PSO-SVR | 0.41 | 0.55 | 0.88 | 10.33% | 90.39% |

| SVR | 0.52 | 0.72 | 0.73 | 16.56% | 71.17% |

| GA-SVR | 0.48 | 0.59 | 0.84 | 13.91% | 84.63% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Zhang, X.; Gao, S.; Zhu, Y. Comfort Study of General Aviation Pilot Seats Based on Improved Particle Swam Algorithm (IPSO) and Support Vector Machine Regression (SVR). Appl. Sci. 2023, 13, 9038. https://doi.org/10.3390/app13159038

Zhang M, Zhang X, Gao S, Zhu Y. Comfort Study of General Aviation Pilot Seats Based on Improved Particle Swam Algorithm (IPSO) and Support Vector Machine Regression (SVR). Applied Sciences. 2023; 13(15):9038. https://doi.org/10.3390/app13159038

Chicago/Turabian StyleZhang, Mengyang, Xuyinglong Zhang, Shan Gao, and Yujie Zhu. 2023. "Comfort Study of General Aviation Pilot Seats Based on Improved Particle Swam Algorithm (IPSO) and Support Vector Machine Regression (SVR)" Applied Sciences 13, no. 15: 9038. https://doi.org/10.3390/app13159038

APA StyleZhang, M., Zhang, X., Gao, S., & Zhu, Y. (2023). Comfort Study of General Aviation Pilot Seats Based on Improved Particle Swam Algorithm (IPSO) and Support Vector Machine Regression (SVR). Applied Sciences, 13(15), 9038. https://doi.org/10.3390/app13159038