Recent Case Histories of Carbon-Neutral Activity Using Ground Improvement Technology in Japan

Abstract

1. Introduction

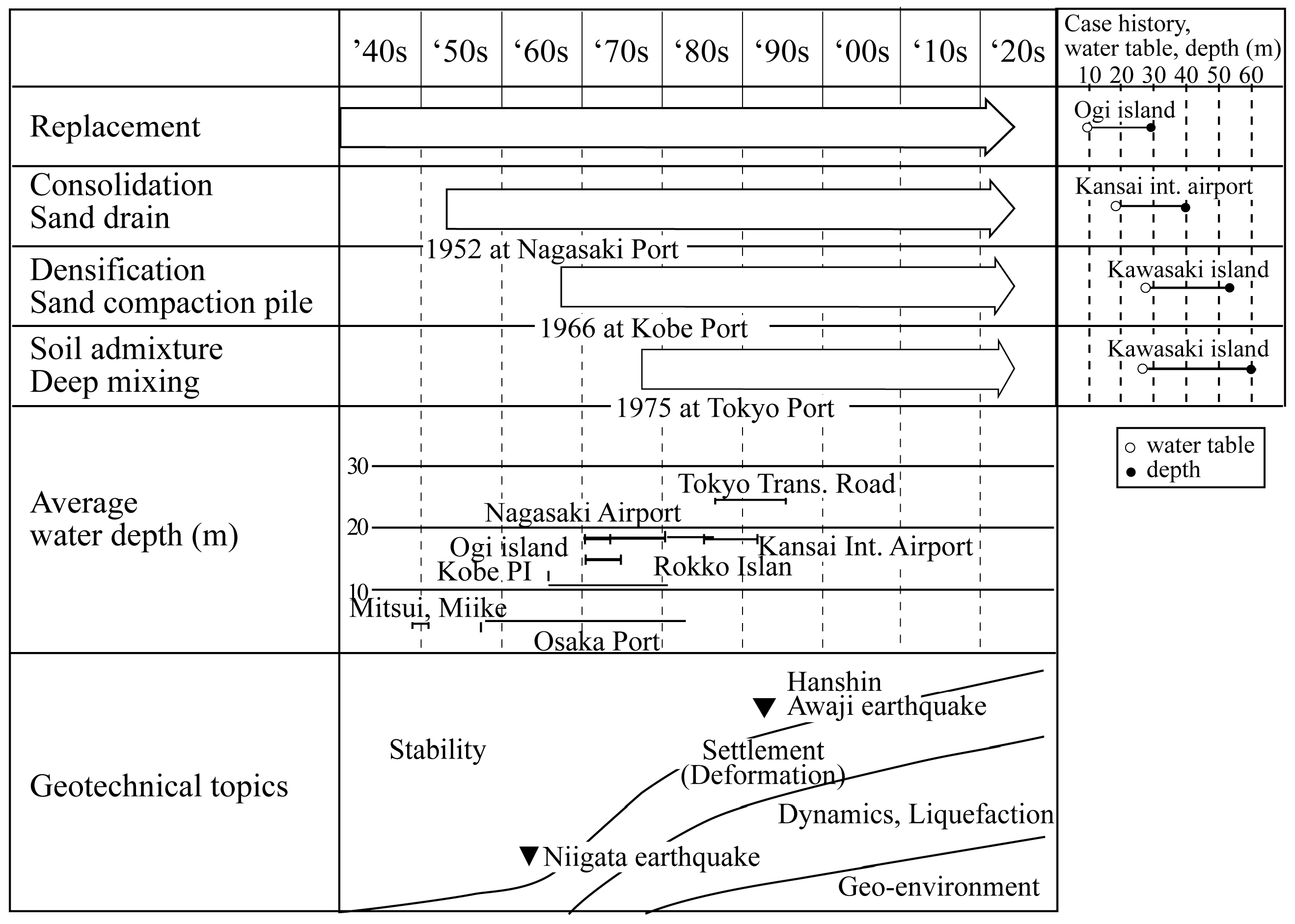

2. The Classification and Historical Development of Ground Improvement Techniques

3. Recent Developments in and Application of Environmentally Friendly Ground Improvement Techniques

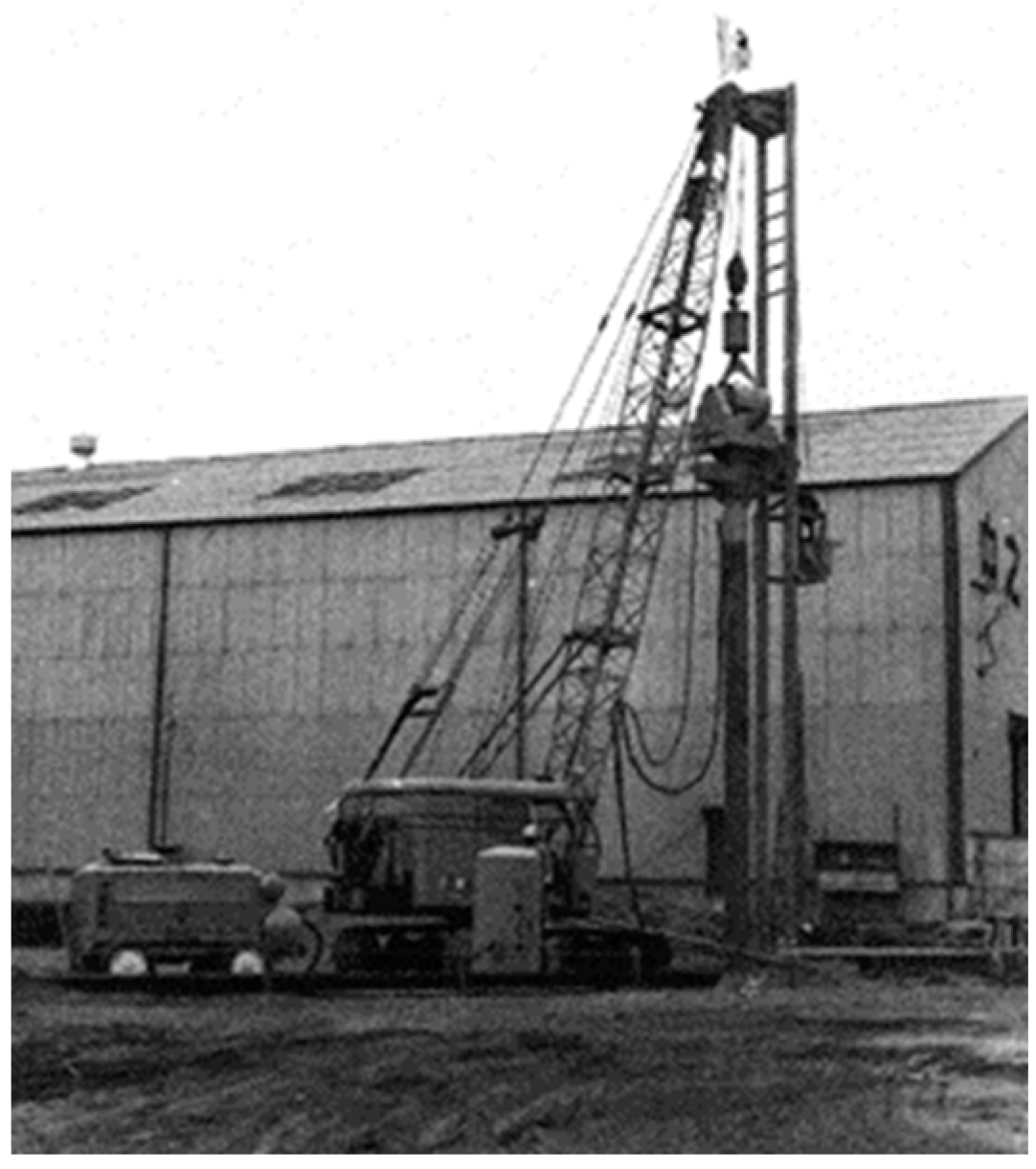

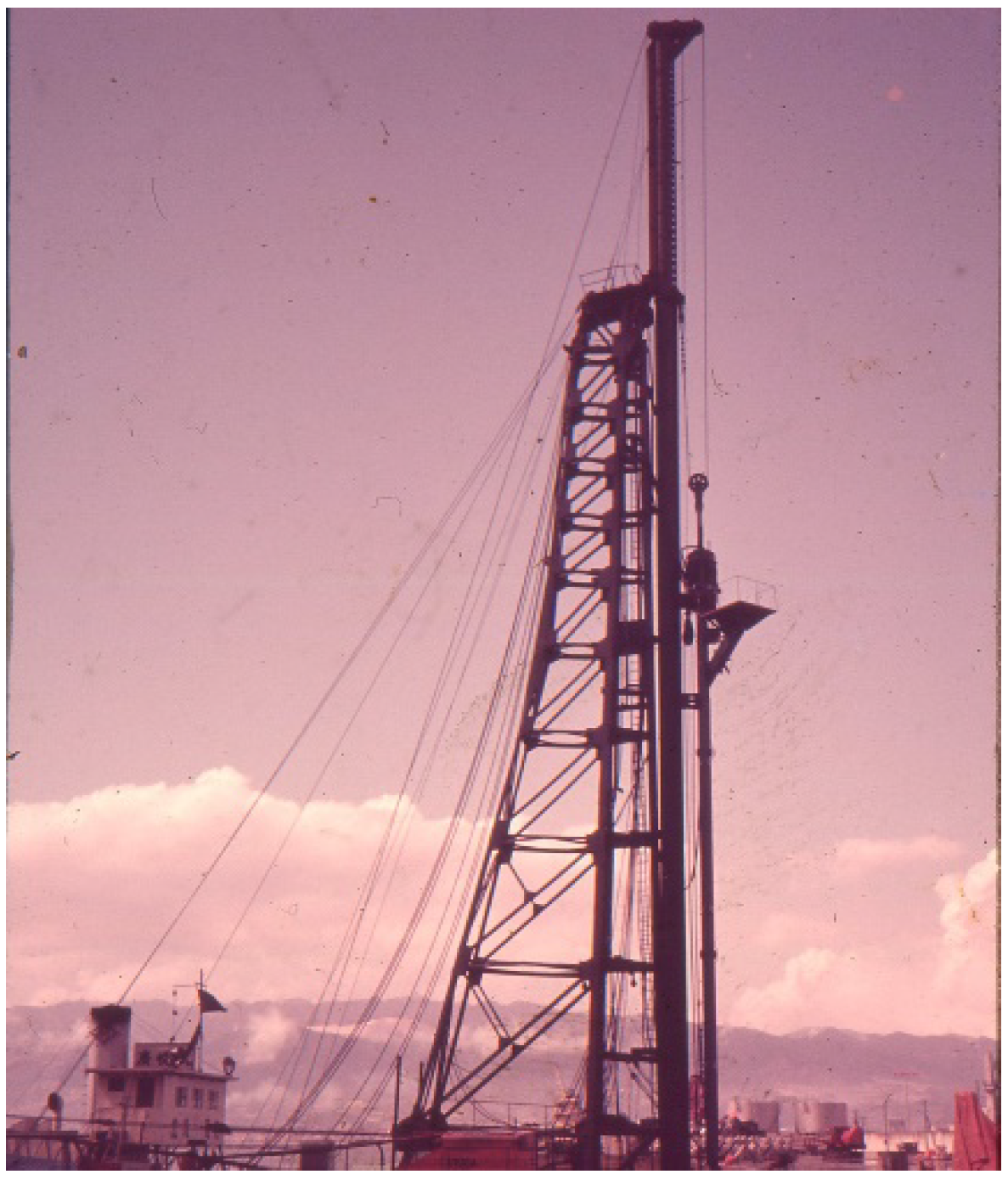

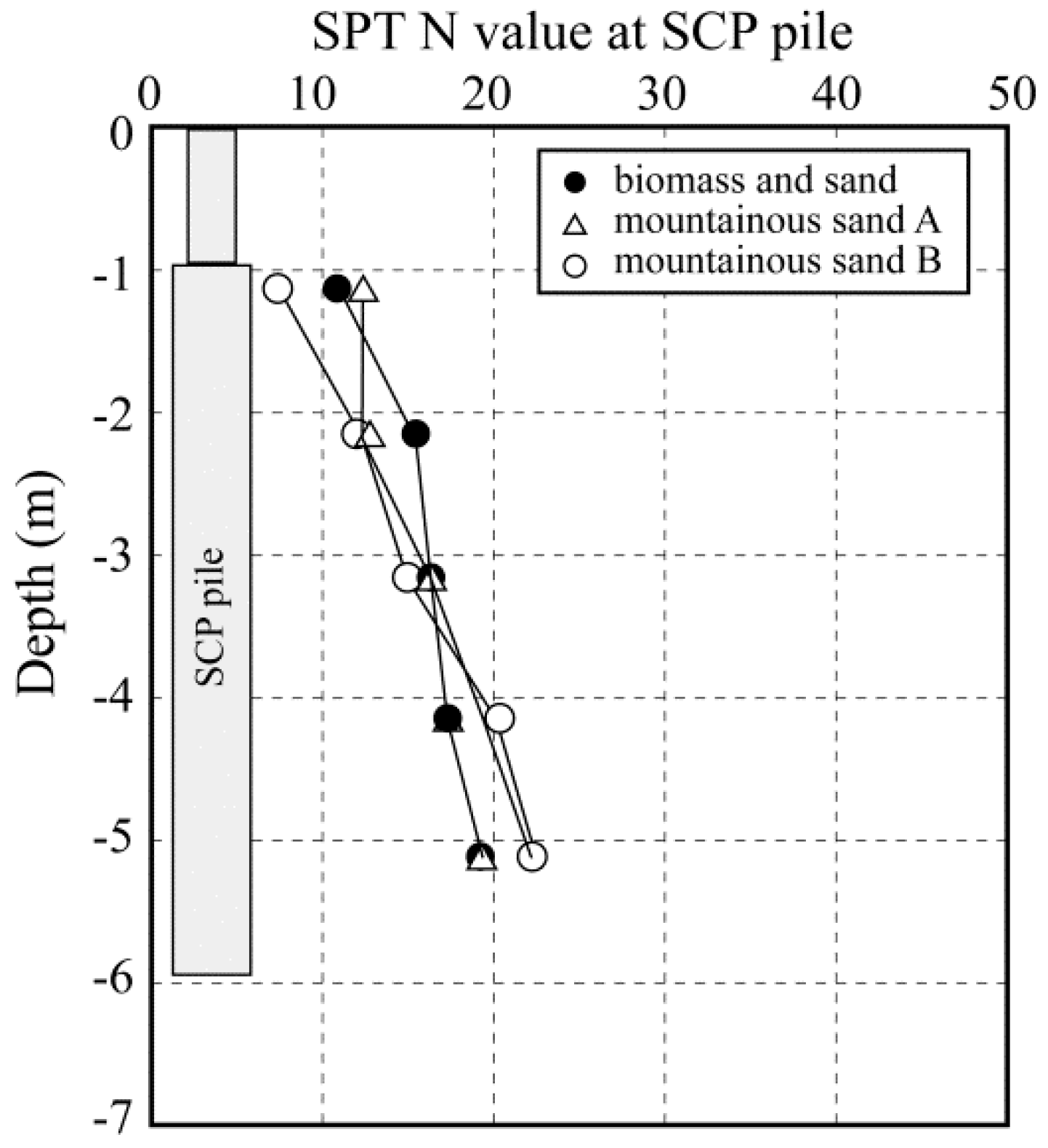

3.1. Soil Densification Techniques

- (1)

- Use of industry waste

- (2)

- Discharge of biochar into the ground together with granular material

3.2. Soil Admixture Stabilization Techniques

- (1)

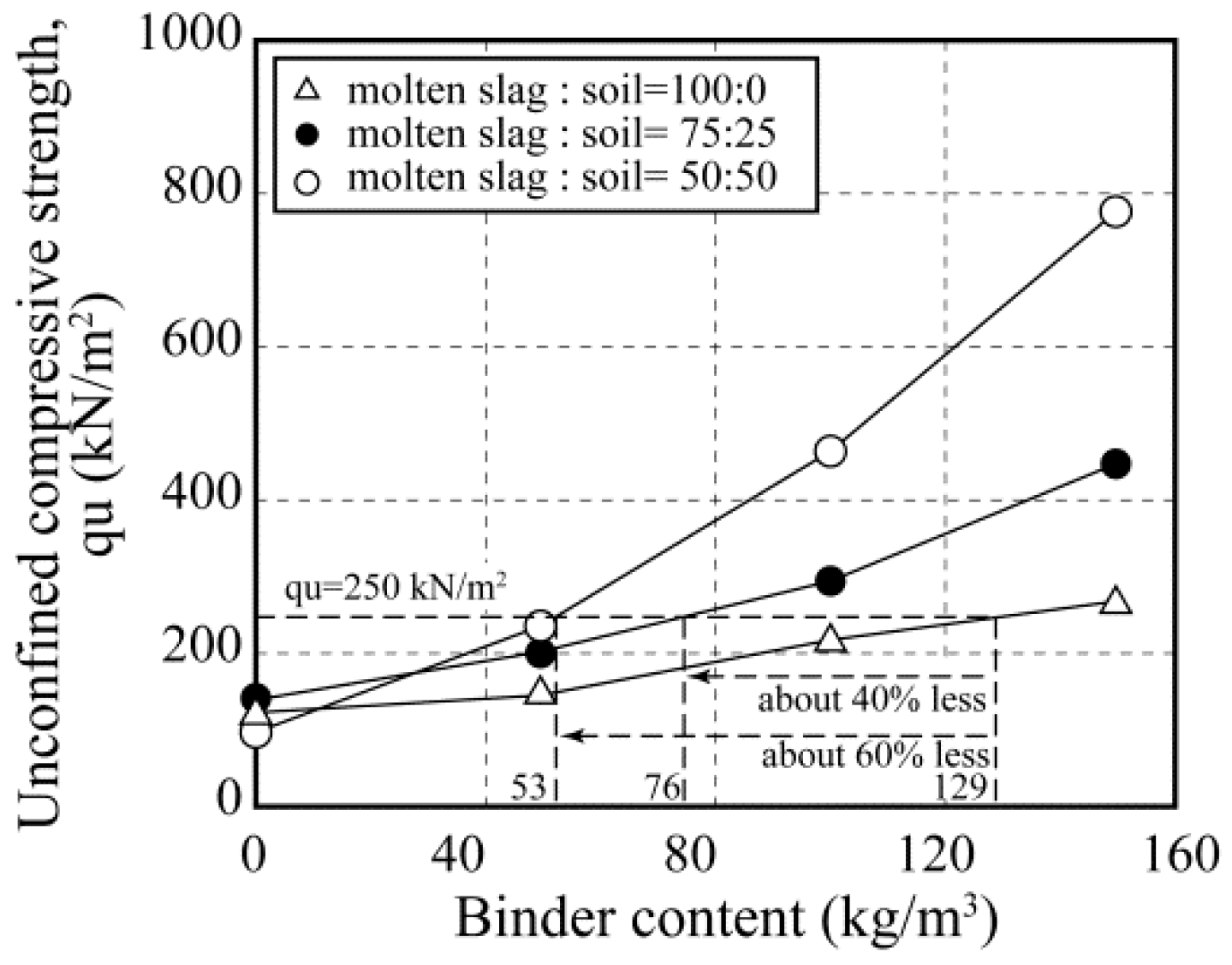

- Use of materials with a low carbon footprint

- (2)

- Mixing of biochar in the ground together with chemical binder

- (3)

- Beneficial use of spoil

- (4)

- Reduction in stabilized soil volume

- (5)

- Reduction in CO2 emission during execution

4. Concluding Remarks

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Ministry of the Environment, Japan, Greenhouse Gas Inventory Office of Japan (GIO), CGER, NIES: National Greenhouse Gas Inventory Report of Japan. 2013, p. 782. Available online: https://www.enecho.meti.go.jp/en/category/special/article/detail_164.html (accessed on 31 July 2023).

- Tsuboi, H. Ground Improvement Techniques for Marine Ground. In Proceedings of the 39th National Symposium on Geotechnical Engineering, Niigata, Japan, 7–9 July 1994; Japanese Society of Soil Mechanics and Foundation Engineering: Tokyo, Japan, 1994; pp. 13–18. (In Japanese). [Google Scholar]

- Kitazume, M. The Sand Compaction Pile Method; CRC Press, Taylor & Francis: Boca Raton, FL, USA, 2005; 232p. [Google Scholar]

- Kitazume, M.; Terashi, M. The Deep Mixing Method; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2013; 410p. [Google Scholar]

- Tsuchida, T.; Egashira, K. The Lightweight Treated Soil Method-New Geomaterials for Soft Ground Engineering in Coastal Areas; CRC Press: Boca Raton, FL, USA, 2004; 136p. [Google Scholar]

- Kitazume, M. The Pneumatic Flow Mixing Method; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2016; 233p. [Google Scholar]

- Kitazume, M.; Minami, K.; Matsui, H.; Naruse, E. Field test on applicability of copper slag sand to sand compaction pile method. In Proceedings of the 3rd International Congress on Environmental Geotechnics, Lisboa, Portugal, 7–11 September 1988; Volume 2, pp. 643–648. [Google Scholar]

- Okeno, K.; Saito, N.; Hyoudo, M.; Nakata, S.; Murata, M. Improved characteristics of granulated coal fly ash in marine SCP field test, Improvement effect. In Proceedings of the 60th Annual Conference of the Japan Society of Civil Engineers, Kyoto, Japan, 21–24 October 2001; pp. 400–401. (In Japanese). [Google Scholar]

- Fujiwara, T.; Tanaka, H.; Kadota, M.; Ohiso, Y.; Kurata, T. Field test of static compaction improved method by granulated excavated-soil. In Proceedings of the 35th Annual Conference of the Japanese Society of Soil Mechanics and Foundation Engineering, Sapporo, Japan, 13–15 September 2000; pp. 1425–1426. (In Japanese). [Google Scholar]

- Yamamoto, K.; Satou, K.; Watanabe, E.; Fijikawa, T.; Nunokawa, H.; Koga, C. Compaction and mechanical properties of bamboo chip and RC mixed material for SCP method. In Proceedings of the Annual Conference of Japan Society of Civil Engineers, Hiroshima, Japan, 14–15 September 2023; pp. 369–370. (In Japanese). [Google Scholar]

- Home Page of Fudo Tetra Corporation. 2023. Available online: https://www.fudotetra.co.jp/news/ (accessed on 31 July 2023).

- Yonezawa, T.; Sakai, E.; Koibuchi, K.; Kanda, T.; Dan, Y.; Sagawa, T. High-Slag Cement and Structures for Substantial Reduction of Energy and CO2. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013; pp. 1–10. [Google Scholar]

- Kono, T.; Tsugawa, S.; Yoshida, T.; Sato, E.; Yonezawa, T.; Taki, S.; Kinoshita, M.; Nito, N. Characteristics of soil improvement using high-volume blast furnace slag cement (part 1). In Proceedings of the 45th Annual Conference of the Japanese Geotechnical Society, Matsuyama, Japan, 8–10 August 2010; pp. 565–566. (In Japanese). [Google Scholar]

- Tanaka, Y.; Yamada, K.; Ookubo, Y.; Shibuya, T.; Nakagawa, M.; Akashi, Y.; Ichimura, M.; Yamagoshi, Y. Reclamation and evaluation of dredged soil with converter slag. J. Geotech. Eng. Jpn. Soc. Civ. Eng. 2021, 68, 486–491. (In Japanese) [Google Scholar]

- Yamagoshi, Y.; Akashi, Y.; Nakagawa, M.; Kanno, H.; Tanaka, Y.; Tsuji, T.; Imamura, T.; Shibuya, T. Reclamation of the artificial ground made of dredged soil and converter slag by using pipe mixing method. J. Geotech. Eng. Jpn. Soc. Civ. Eng. 2013, 69, 952–957. (In Japanese) [Google Scholar]

- Furuta, S.; Kinugawa, Y.; Takagi, S.; Tamura, S.; Nishida, M.; Nagasawa, M.; Tsuchiya, H.; Maeda, T. A decarbonizing soil improvement method using molten slag and biochar (No.1): Laboratory test. In Proceedings of the 78th Annual Conference of the Japan Society of Civil Engineers, Hiroshima, Japan, 11–15 September 2023. submitted (In Japanese). [Google Scholar]

- Nishida, M.; Nagasawa, M.; Tsuchiya, H.; Maeda, T.; Furuta, S.; Kinugawa, Y.; Takagi, S.; Tamura, S. A decarbonizing soil improvement method using molten slag and biochar (No.2): In-situ test. In Proceedings of the 78th Annual Conference of the Japan Society of Civil Engineers, Hiroshima, Japan, 11–15 September 2023. submitted (In Japanese). [Google Scholar]

- Home Page of Shimizu Corporation. Available online: https://www.shimz.co.jp/company/about/news-release/2023/2022061.html (accessed on 31 July 2023).

- Hirano, S.; Mizutani, Y.; Nakamura, H.; Shimomura, S.; Sasada, H. Quality improvement of deep mixing method by dispersant additives. In Proceedings of the 50th Annual Conference of the Japanese Society of Soil Mechanics and Foundation Engineering, Matsuyama, Japan, 19–21 September 2015; pp. 881–882. (In Japanese). [Google Scholar]

- Okabe, M.; Kawamura, K.; Masuda, K.; Seki, T. Ingenious device of site management in ground improvement work by CI-CMC method. J. Jpn. Soc. Soil Mech. Found. Eng. 2011, 59, 16–19. (In Japanese) [Google Scholar]

- Kenbo, H. Current Status, Issues and Prospects of Jet Grouting Method; Kisoko, Sougou Doboku Kenkyusho. Co., Ltd.: Tokyo, Japan, 2017; pp. 7–10. (In Japanese) [Google Scholar]

- Tokimatsu, K.; Mizuno, H.; Kakurai, M. Building damage associated with geotechnical problems. Soils Found. 1996, 36, 219–234. [Google Scholar] [CrossRef] [PubMed]

- Shinsaka, T.; Yamazaki, J.; Nakanishi, Y.; Komiya, K. Quality Control and Shape Control Techniques in Jet Grouting. In Proceedings of the International Foundations Congress & Equipment Expo, IFCEE 2018, Orlando, FL, USA, 5–10 March 2018. [Google Scholar]

- Shinsaka, T.; Yamazaki, J. Development of high-speed type jet grouting method. In Proceedings of the Geotechnics for Sustainable Development–Geotec Hanoi 2013, Hanoi, Vietnam, 28–30 November 2013. [Google Scholar]

- Tsuchiya, T.; Abe, H.; Komatsu, K. A study on altering the cross-sectional shape and altering the quality of the jet grout column. In Proceedings of the Grouting 2017: Jet Grouting, Diaphragm Walls, and Deep Mixing, Honolulu, HI, USA, 9–12 July 2017; pp. 21–30. [Google Scholar]

- Harada, K.; Ohbayashi, J.; Matsumoto, J.; Kubo, Y.; Akima, T. New ground improvement technologies under restricted conditions in Japan. In Proceedings of the 15th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, Fukuoka, Japan, 9–13 November 2015; pp. 1165–1170. [Google Scholar]

- Imamura, K.; Ishiguro, K. Environmentally friendly deep mixing vessel, Kokaku. Constr. Mech. 2010, 37–41. (In Japanese) [Google Scholar]

- Saegusa, H.; Asada, H.; Taguchi, H.; Fukawa, H.; Hirota, S. Case study on application of deep mixing method in Kinjo area of Nagoya port. In Proceedings of the DFI Deep Mixing Conference 2021, Online, 1–17 June 2021; pp. 225–232. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kitazume, M. Recent Case Histories of Carbon-Neutral Activity Using Ground Improvement Technology in Japan. Appl. Sci. 2023, 13, 8985. https://doi.org/10.3390/app13158985

Kitazume M. Recent Case Histories of Carbon-Neutral Activity Using Ground Improvement Technology in Japan. Applied Sciences. 2023; 13(15):8985. https://doi.org/10.3390/app13158985

Chicago/Turabian StyleKitazume, Masaki. 2023. "Recent Case Histories of Carbon-Neutral Activity Using Ground Improvement Technology in Japan" Applied Sciences 13, no. 15: 8985. https://doi.org/10.3390/app13158985

APA StyleKitazume, M. (2023). Recent Case Histories of Carbon-Neutral Activity Using Ground Improvement Technology in Japan. Applied Sciences, 13(15), 8985. https://doi.org/10.3390/app13158985