Abstract

The aim of this study is to use the response surface methodology (RSM) to mathematically model the response parameters and emission of greenhouse gases (GHG) and optimize the drying variables for a carrot dried with the microwave method using various pretreatments. To this end, the influence of the drying parameters (independent), such as microwave power and slice thickness dried by two pretreatments of ultrasonication at 30 °C for 10 min and blanching at 70 for 2 min, was explored on the dependent (response) parameters including the thermal properties (drying time, effective moisture diffusion coefficient (Deff), specific energy consumption, energy efficiency, quality features (color changes and shrinkage), and GHG emission (including CO2 and NOx). It should be mentioned that the emission of GHG was determined based on the energy consumption of various types of power plants such as the gas turbine steam power turbine, and combined cycle turbines using various fuels such as natural gas, heavy oil, and gas oil. The results indicated that the ultrasonication and blanching pretreatments can decrement the drying time (linearly), energy consumption (linearly or quadratically), shrinkage(quadratically), and color changes(quadratically) and enhance the Deff (linearly) and energy efficiency (linearly or quadratically) in all samples with R2 > 0.86. Moreover, the shortest drying time (42 min), lowest SEC (9.51 MJ/kg), and GHG emission ((4279.74 g CO2 in the combined cycle turbines plant, and 18.16 g NOX in the gas turbine plant) with natural gas for both plants) were recorded for the samples pretreated with blanching while the lowest color changes (13.69) and shrinkage (21.29) were observed in the ultrasonicated samples. Based on the optimization results, a microwave power of 300 W and steam power turbine of 2 mm were the best variables with a desirability of about 80% which resulted in the highest-quality products at the lowest GHG emission.

1. Introduction

A carrot is one of the vegetables belonging to the group of apiaceae with the scientific name of Daucus carrot L. [1]. The root of this plant contains various minerals such as iron, copper, magnesium, and phosphorous, as well as vitamins such as group B vitamins, and C [2]. A carrot is a rich source of beta-carotene, i.e., a precursor of vitamin A, such that the daily use of 100 g of this product can supply 17% of the total recommended daily intake of vitamin A [3]. These benefits, along with the desirable taste of this vegetable, have resulted in the application of carrots in various foods [4].

As most of the vegetables are seasonal (i.e., available only at a specific time of the year), their abundance in the harvesting seasons and thus their low price may result in their spoilage [5]. In this regard, the use of processing and preservation can prevent this spoilage, making them available at the other times of the year at profitable prices [6]. Drying is one of these methods in which the moisture content (MC) of the sample is decreased to a constant level [7]. One of the most common drying techniques in food processing is microwave drying. The superiority of this method over the others lies in the uniform drying of the products which improves their quality [8]. With the increasing demand for pre-cooked foods, the development of the microwave drying method is of crucial importance for agricultural products.

Various methods have been proposed for preserving the quality of dried agricultural products, among them being pretreatments with edible coatings [9], osmotic dewatering [10], microwaving [11], ultrasonication [12], blanching [13], ethanol and citric acid [14], and electric pulsing [15] before and after drying. The results have shown that the application of different pretreatments can improve the thermal properties while preserving the product quality.

As the drying process accounts for 12–20% of the energy use of the processing industry, optimization of this process in terms of energy use is of crucial significance [16]. Diverse methods have been developed for optimization, among which is the response surface method (RSM). In the RSM, the relationship between the response and independent variables can be determined through mathematical modeling [17]. Numerous studies have optimized and modeled the impact of the drying variables (such as air speed and temperature, microwave power (MP), and slice thickness (ST)) on the response parameters including mechanical and thermal qualities as well as the quality of the agricultural products such as cumin seeds [18], sweet potato slices [8], and Cornus mas [10]. In all the mentioned studies, the researchers have reported the best drying variables and pretreatments to achieve the best parameters; however, no similar study was found for carrot slices.

Iran is one of the richest countries in terms of energy sources including fossil fuels. Natural gas (NG), heavy oil (HO), and gas oil (GO) are among the main sources of energy applied for electricity generation. High energy consumption of agricultural product dryers will result in greenhouse gas (GHG) emissions such as CO2 and NOx which will result in serious environmental consequences. Such a high GHG emission can be one of the major sources of global warming. Global estimates have suggested that 80% of the raw energy in the world is supplied from fossil fuels. In 2013, 76 million barrels of oil were consumed, which is expected to grow to 123 million barrels by 2025 [11]. Therefore, any decline in energy consumption will lead to lowering GHG emission. The emission of GHG arisen from overconsumption of fossil fuels has led to environmental consequences such as ozone layer depletion, global warming, climate change, flooding and acidic rainfalls, and the rising level of sea water, which will have a serious negative impact on human lives. As the energy use of dryers is based on fossil or electricity fuels, the consumption of energy, and hence, GHG emission of the drying process, should be decremented. So far, several researchers have addressed the effect of the drying methods combined with various pretreatments on GHG emission from drying agricultural products [19,20,21,22].

Previous reports have shown that no study has addressed the optimization and modeling of the effects of the drying variables and pretreatments on the thermal and quality properties, as well as the GHG emission of the drying process of carrot slices. In this regard, the present research is highly necessary. The aim of this study is, thus, the establishment of the best mathematical model for the optimization of quality (color and shrinkage) and thermal (drying time (Dt) properties, effective moisture diffusivity (Deff), specific energy consumption (SEC), energy efficiency (Eef), and GHG emission (including NOx and CO2), which were determined for six different plants (including steam power-natural gas (SP-NG), steam power-heavy oil (SP-HO), gas turbine-natural gas (GT-NG), gas turbine-gas oil (GT-GO), combined cycle turbines-natural gas (CC-NG), and combined cycle turbines-natural gas (CC-GO)). The drying variables (independent) included MP (including 100, 200, and 300 W) and ST (including 2, 4, and 6 mm). Two pretreatments of ultrasonication and blanching at 30 °C and 70 °C for 10 and 2 min were also considered, respectively.

2. Materials and Methods

2.1. Carrot Sample

Fresh medium-sized carrots (length: 0.17 m and diameter: 0.03 m) were bought from a local market in Parsabad (Ardabil, Iran). The carrots were transferred to the agricultural science and natural resource faculty of Moghan. The samples were then washed, and their MC was measured using an oven (Memmert company, UFB500, Schwabach, Germany) at 105 °C for 24 h [23] and the MC was evaluated based on the standards [24]. The experiments were carried out in triplicates to ensure the validity of the results. Then, Equation (1) was employed to calculate the moisture content (MC) of the carrot which was 11.95 ± 0.55 (d.b.) [14].

In Equation (1), MCd.b. shows the initial MC while Mf and Mi are the final and initial weight of the sample in kg, respectively.

2.2. Ultrasonication and Blanching Pretreatments

The samples were classified into three groups before drying: (I) controls (with no pretreatment), (II) ultrasonicated samples, and (III) blanched samples. Ultrasonication was carried out under laboratory conditions using an ultrasonic bath (Parsonic company, 750S model, Iran, Tehran) at 30 °C and 28 kHZ frequency with ratio of 1:4 for sample-to-water [15]. For blanching, the samples were put in hot water at constant temperature of 70 °C for 2 min [14]. After the pretreatment, the slices were withdrawn from the water and their surface-adsorbed water was cleaned by a towel tissue. All the samples were then transferred to the microwave dryer until reaching a constant weight.

2.3. Microwave Dryer

The samples were transferred into a domestic microwave oven (Sharp R-861SLM) for drying. All the experiments were carried out for three different ST (2, 4, and 6 mm) and MP (100, 200, and 300 W) in triplicate. The tray with the samples was put on a balance scale to measure the weight of the slices at regular 2-min intervals using a digital balance (AND company, GF-6000 model, Tokyo, Japan). About 0.01 kg of the carrot slices were put in the microwave chamber. The process of drying continued from the initial MC of 11.95 ± 0.55 until the final MC of 0.11 ± 0.1 (d.b.) [25]. The time taken by this process is called Dt.

2.4. Effective Moisture Diffusivity

To measure the Deff, the diagram of the drying kinetics and the Crank equation based on the second Fick’s law were applied. To this end, the MC was plotted versus the time of the drying process. Then, the moisture ratio was determined, and its logarithmic diagram was drawn versus time and fitted with a straight line. The second Fick’s law deals with the mass diffusivity during the drying process’s descending phase, and it may be solved for a variety of geometries by employing the right boundary conditions. Equation (2) can be used to calculate the Fick equation for a thin layer:

In which L denotes the sample thickness (m); n shows the number of the drying terms (1, 2, 3, 4, …). Mt, Me, and Mb represent the sample moisture at time of t, equilibrium, and initial MC (d.b.), respectively. MR shows the moisture ratio, while t stands for the Dt. Deff is also expressed in m2/s.

If both sides of the equation are considered a natural logarithm, Equation (3) is obtained which is a straight line [26]. Putting the slope of this line equal with the slope of the fitted line of the natural logarithm, the value of Deff can be determined (Equation (4)) [27].

2.5. Specific Energy Consumption

SEC shows the ratio of the total energy use to the water lost during the drying process. Based on the experiments, the total energy use was obtained by measuring the energy consumption of the microwave, ultrasonic wave generator, and blanching heat according to the reported equation (Taghinezhad et al., 2020 [11]). The SEC was obtained by Equation (5) [28].

In Equation (5), SEC shows the specific energy consumption (MJ/kg−1 water), while TEC denotes the total energy use (MJ). Mw also represents the value of water leaving the sample during the process of drying (kg).

The Eef () of the microwave dryer for drying carrot slices can be obtained by Equation (6) [29].

where P (W), λw and t are the microwave power (W), the latent heat for water vaporization (2257 kJ/kg), and Dt (min), respectively.

2.6. Greenhouse Gas Emission

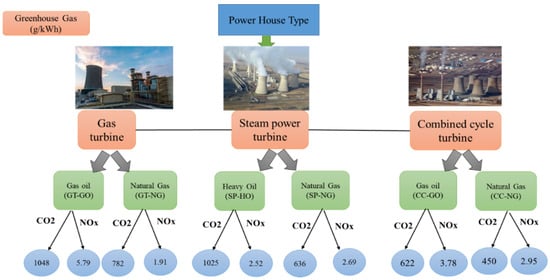

Consumption of the dryer energy is based on the fossil or electricity fuels (NG, HO, and GO). Therefore, various methods have to be explored to reduce energy use, and hence the emission of GHG. Regarding the climate of Iran, electricity is mainly produced in the PP using fossil fuels. Regarding the fact that Iran is one of the countries with the highest NG and HO resources, it is also one of the biggest producers of GHG. As all the PP of Iran are GT-GO, GT-NG, SP-HO, SP-NG, and CC-NG, the mean GHG emission (NOx and CO2) was determined for various types of plants with different fuels for the production of 1 kWh energy as depicted in Figure 1 [30].

Figure 1.

Mean pollution rate of power plants by fuel type.

2.7. Color

Color is one of the major features of agricultural products. Color and its variations are directly related to the chemical and physical characteristics of the sample [31]. Portable colorimeter (HP company–200 model, Guangdong, China) was employed to obtain the index of the sample color. For each test, 10 carrots were evaluated, and their mean values were considered and compared with the fresh samples. Parameters of L* (varying from 0–100), a* (varying from −60 to 60), and b* (altering from −60 to 60), respectively, indicate the white to black, green to red, and blue to yellow colors [32]. The total color variations of the carrot slices can be calculated by Equation (7) [25].

In which , , and show the color values of the dried carrot using a microwave dryer with various pretreatments under different experimental conditions. Variables , , and also represent the initial color of the slices.

2.8. Shrinkage

For determination of carrot shrinkage, first the initial volume of the carrot sample before and after the drying process with toluene were measured using a pycnometer. Then the shrinkage was determined from the ratio of the difference between the initial and dried samples to the initial volume as expressed in Equation (8) [4].

In which Vi and V, respectively, denote the sample volume before and after drying (cm3). Sv also represents the shrinkage (%).

2.9. RSM

In this research, RSM was used in the form of Historical data design as implemented in Design Expert 10 software to analyze the data and optimize the drying process of carrots with a microwave dryer under different pretreatments. The independent variables (input) of the Design Expert software in the microwave dryer included the MP (at three levels of 100, 200, and 300 W) and the ST (2, 4, and 6 mm). The experiments were performed in the form of factorial design on a completely random basis in 3 repetitions. The dependent variables are Dt, Deff, SEC, Eef, GHG emissions (CO2, NOx), color, and shrinkage. They were used to model the behavior of two-line operating systems and investigate their interaction effects [10].

where yk is the response variable, xi shows the independent variable value, xj is the actual value of each parameter, β0 and βi denote the intercept and the coefficients of the variables, respectively, while βji is the coefficients of the interaction effects of the variables. Drying variables (independent) are shown in Table 1 with their coded levels.

Table 1.

The coded levels of the independent variables studied and their levels.

Three important steps in the process optimization with RSM include a statistical design of experiments, a prediction of coefficients in a mathematical model, and an estimation of response parameters and a study of model accuracy in the experimental designs [18]. Optimum operating conditions were achieved using optimization with RSM. For this purpose, optimization objectives, response levels, and independent variables were first set. Then, the best answers were obtained using the desirability function technique. In this study, achieving the shortest Dt, lowest SEC, GHG emission, color, and shrinkage, and the highest Deff and Eef were considered as the objectives of experiments in statistical analyses for optimization.

3. Results and Discussion

3.1. Drying Time (Dt)

The results of the variance analysis and modeling of different drying parameters to predict the response variables are listed in Table 2 along with the statistical coefficients. Accordingly, the effect of MP and ST in different pretreatments is significant on Dt (p < 0.0001), while the interaction effect of temperature × moisture on Dt was not significant for any of the pretreatments. Equations (10), (16), and (22) in Table 2 show the model of the changes in carrot Dt in relation to the independent parameters of the microwave dryer for untreated samples, ultrasonicated, and blanched samples, respectively.

Table 2.

Coefficients of the models fitted to the regression equation of response variables (A: Thickness and B: microwave power).

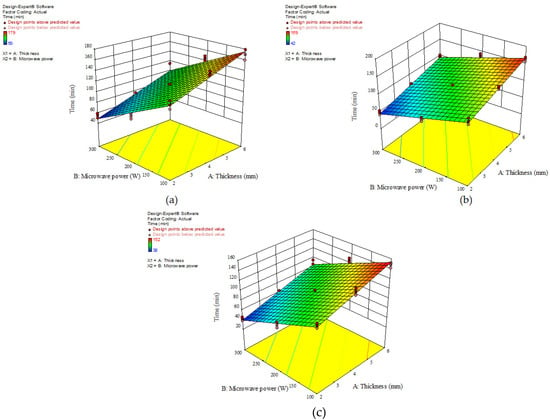

Changes in the Dt of sample slices for the control sample are depicted in Figure 2 for (a) controls, (b) ultrasonicated, and (c) blanched samples. The longest Dt (170 min) was observed for control samples with 6 mm thickness dried at the 100 W power, while the shortest Dt (42 min) was achieved at the MP of 300 W and 2 mm thickness in the samples pre-treated with blanching. According to Figure 2, the Dt has decreased linearly and significantly (p < 0.0001) by reducing the ST and increasing the MP. The microwave-induced power raises the temperature within the plant due to the collision of the ions placed in the electric field. The placement of water molecules along the field direction leads to friction, and hence, to heat production in the product. Subsequently, thermal energy is transferred to all different parts of the carrot through convection and conduction; therefore, the heat diffusion mechanism at higher MPs will shorten the Dt [33]. Similar findings were published by other researchers for different products such as kiwi [34], dragon fruit [35], and mushrooms [36]. Moreover, thicker slices of carrot samples dried slower than thinner ones for all experimental treatments, indicating that thinner materials approached equilibrium MC in a shorter time. Compared to the thicker slices, the moisture can be easily removed from the surface of the thinner products [34]. A study on drying yam slices under a hot air dryer stated that the Dt decreases by reducing the ST [26].

Figure 2.

Response surface plots showing the effect of slice thickness (A) and microwave power (B) on drying time: (a) control, (b) ultrasonicated, and (c) blanched samples.

Comparison of the Dt of ultrasound pretreated carrot slices with control samples shows that ultrasound pretreatment can accelerate the drying process. Ultrasound waves can open the micropores of carrot cells (due to the cavitation phenomenon), facilitating the moisture diffusion and significantly shortening the Dt. These results were confirmed for different products [37,38,39]. Abbaspour et al. [40] revealed a significant difference in the decrease in the Dt of ultrasound-treated terebinth dried by hot air and infrared dryers compared to untreated samples at all temperatures and powers, which is in agreement with the results of this study. According to Figure 2, blanching-pretreated samples had the shortest Dt. The reduction of Dt by blanching is probably attributable to the great damage of the cell structure and the reduction of the resistance of the cell wall and cell membrane against the movement of water [38,41]. Rybak et al. [12] reported that the Dt of blanched bell peppers was approximately 72% shorter than the samples pretreated with ultrasound and electric pulses.

3.2. Effective Moisture Diffusivity

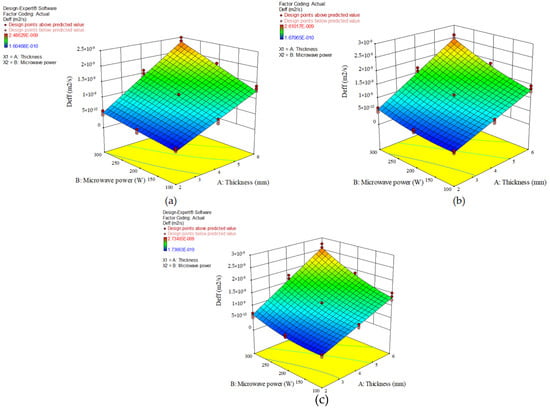

Based on Table 2, the independent effect of the MP and ST, as well as the interaction effects of ST × MP, were significant on the Deff for different pretreatments. The quadratic effect of the MP on the Deff of blanched and ultrasonicated samples was significant (p < 0.0001), while it was not significant in the controls. Equations (11), (17), and (23) in Table 2 show the model of the Deff variations in relation with the independent parameters. According to the model coefficients, the influence of the MP was higher than the effect of the ST on the Deff value of the pretreated samples. Figure 3 also reveals the interaction effects of the MP and ST on the Deff value of (a) untreated, (b) ultrasonicated, and (c) blanched carrots. The Deff value showed a significant (p < 0.0001) rise by enhancing the MP and ST. In general, a higher MP leads to higher temperatures and, hence, lower water viscosity and higher water activities. This phenomenon can result in easier diffusion of water within the product [33]. The same observations were reported in drying lemon [29] and tomato [6] slices. The impact of the ST on moisture diffusion can be discussed by the surface hardening of the samples. Due to the higher rate of moisture evaporation during the drying process, the surface of the thin slices is generally hardened faster than the thicker ones, which will inhibit the diffusion of moisture from the center to the surface of the samples [42]. The results of the current research are well in line with the reports on aloe vera gel [26], apple slices [43], and potatoes [44]. Based on the results, the use of ultrasonication and blanching pretreatments can quadratically increase the value of the Deff compared to the control samples. The influence of the blanching was more profound on the increase in the Deff as compared with ultrasonication. These results are consistent with the drying kinetic data, which imply that the stronger the mobility of internal water molecules, the shorter the Dt [45]. The formation of more pores and microchannels due to the ultrasound-induced cavitation and more enzyme degradation and tissue loosening due to blanching led to higher permeability [14]. The results of this research are in agreement with the researchers from other reports for cranberry snacks [46] and pumpkin products [47] that were pre-treated with ultrasound and blanching. Furthermore, when ultrasound waves pass through an environment, they cause successive expansion and contractions, leading to the cavitation phenomenon [39,48]. As a result, ultrasonic waves increased the Deff due to the small channels created inside the food which facilitated the moisture removal [49].

Figure 3.

Three-dimensional counterplots for Deff against microwave power and thickness: (a) control, (b) ultrasonicated, and (c) blanched samples.

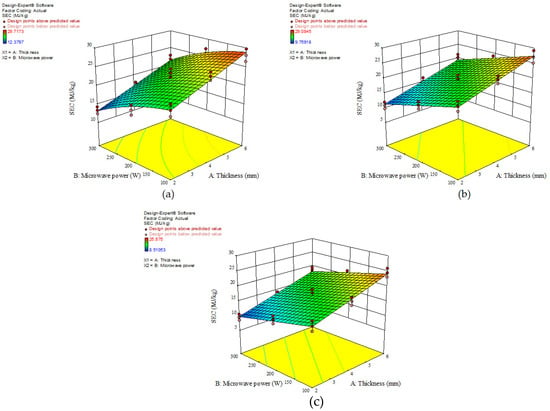

3.3. SEC

Table 2 lists the results of the influence of different parameters (MP and ST) in different pretreatments on the SEC of the microwave drying process. As can be seen, the MP and the ST have a significant effect (p < 0.0001) on the SEC value of carrot slices, while the interaction effect of the MP and the ST had no significant effect on the SEC value. Figure 4 also depicts the variations of the SEC for (a) control, (b) ultrasonicated, and (c) blanched samples. The value of the SEC decreases linearly or quadratically by increasing the MP and decreasing the ST. The use of the MP can accelerate the drying due to changes in the cell structure and faster moisture diffusion. Such a reduction in the Dt can decrement the SEC. In other words, the thermal gradient and the acceleration of moisture extraction from the samples are improved by increasing the MP [50]. Additionally, in thicker samples, the transfer of product moisture to the surface for final evaporation is associated with a slower movement, hence, the Dt is prolonged, leading to a higher SEC [51]. Similar findings were shown for drying potato [8], banana [52], and kiwi [34] slices.

Figure 4.

Response surface for the effects of variables (microwave power and thickness) on the SEC value of carrot slices: (a) control, (b) ultrasonicated, and (c) blanched samples.

According to Figure 4, the application of a pretreatment reduced energy consumption as compared to the untreated samples. It is worth mentioning that sonication (damaging carrot tissue due to creation of microscopic channels and cavitation) before drying is effective in reducing the Dt and the SEC [37]. Additionally, the use of the blanching pretreatment had a greater effect on the SEC reduction compared to the ultrasound pretreatment. This phenomenon may be assigned to the pressure difference between the surrounding environment and the sample tissue during the blanching stage. The blanching process leads to the formation of a porous structure, resulting in a better and faster moisture transfer during the microwave drying [53]. The highest SEC value (28.06 MJ/kg) was achieved at the MP of 100 W for control samples with the thickness of 6 mm, while the lowest SEC value (9.51 MJ/kg) was observed at a power of 300 W in the blanching-pretreated samples with the thickness of 2 mm. Similar findings were reported on the reduction of the SEC by using blanching and ultrasound pretreatment for different products, such as mushroom slices [15], parsley leaves [37], and blackberry [54].

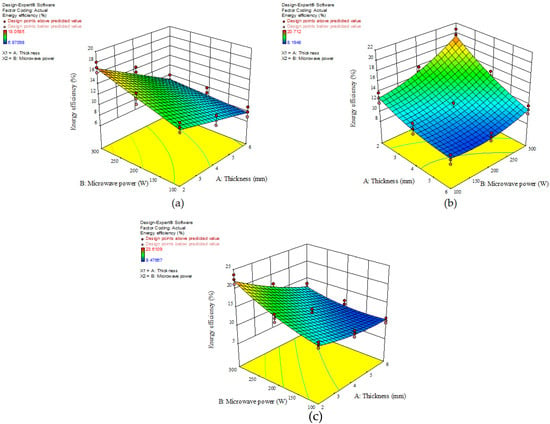

3.4. Energy Efficiency (Eef)

As suggested by Table 2, the influence of the drying parameters (MP and ST) and the interaction effect of MP–ST were significant (p < 0.00001) on the Eef of the samples pretreated by blanching and ultrasound. Figure 5 also represents the interaction effect of MP–ST on the Eef of (a) controls, (b) ultrasonicated, and (c) blanched carrots. As observed, the Eef rose linearly or quadratically by increasing the MP and ST. The highest Eef (22.39%) was achieved at the power of 300 W in the ultrasonicated samples with 2 mm thickness; the lowest Eef (7.78%) was also related to the power of 100 W and 6 mm thickness in the control samples. The simultaneous use of higher MP and thinner samples led to a faster removal of the surface moisture. A rise in the MC gradient also increased the microcracks within the samples. These cracks caused a volume change, further accelerating the removal of moisture and declining the Dt, which in turn enhanced the Eef [6]. The increment in the Eef by raising the MP and reducing the ST was reported before [8,55]. On the other hand, a comparison of the various pretreatments showed that the highest Eef was achieved in the blanching pretreatments while the untreated samples exhibited the lowest Eef. Pretreatments improved the Eef as they increased the destruction and accelerated the removal of moisture. These results coincided with the previous reports [18,28].

Figure 5.

Response surface plots showing combined effect of microwave power and thickness on energy efficiency: (a) control, (b) ultrasonicated, and (c) blanched samples.

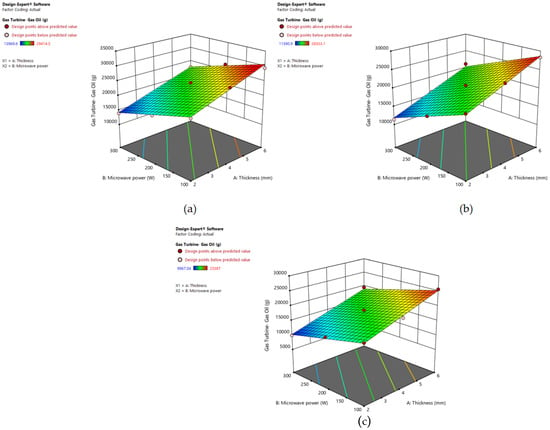

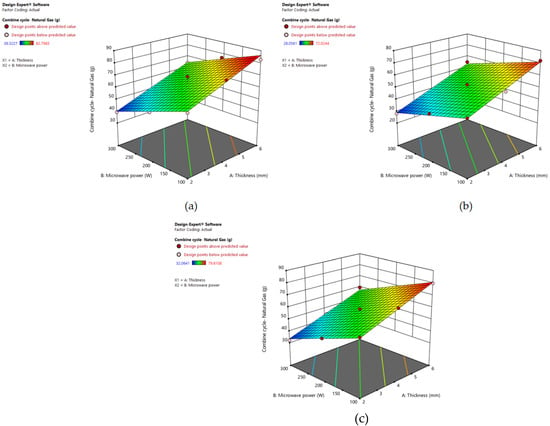

3.5. GHG

Table 3 lists the results of GHG modeling including CO2 and NOx for various MP and ST, as well as ultrasonication and blanching pretreatments using electricity from plants operating on diverse fuels. The R2 values were above 0.96. According to Table 3, the influence of the independent parameters was significant (p < 0.0001) on the emission of CO2 and NOx for all plants and their corresponding fuels. The second power of the independent parameters was only significant (p < 0.0001) on the emission of CO2 and NOx due to drying the control samples. Figure 6 and Figure 7, respectively, represent the interaction influences of MP–ST on the response variables of CO2 emission from a GT-GO plant and NOx emission of a CC-NG plant obtained based on the response surface diagrams for untreated and ultrasonicated and blanched samples. The highest CO2 and NOx emissions (29,414.5 and 162.5 g, respectively) were observed in the untreated samples with a thickness of 6 mm at the MP of 100 W dried by the electricity supplied from a GT-GO plant. However, the lowest CO2 (4279.7 g) was from a CC-NG plant in the drying of the blanched samples with the thickness of 2 mm at the MP of 300 W, while the lowest NOx emission (18.16 g) was related to the blanched samples with a thickness of 2 mm which were dried at the MP of 300 W of which electricity supply was a GT-NG plant. Regarding the obtained results, a rise in the MP and a decline in the ST decreased the GHG emission. Such a descending trend in the GHG emission can be assigned to the reduction in the SEC during drying at a high MP and thin thicknesses [56]. These findings are in line with the previous reports on the reduction of the GHG emission by increasing the MP for drying green pea [57], aloe vera [58], and Pistacia Atlantica [20].

Table 3.

Fitting the effect of different levels of microwave power and sample thickness on independent parameters in a microwave dryer without a pretreatment.

Figure 6.

Response surface plots showing combined effect of microwave power and thickness on CO2 in GT-GO: (a) control, (b) ultrasonicated, and (c) blanched samples.

Figure 7.

Three-dimensional plots of NOX in CC-NG for carrot drying (effect of microwave power and thickness): (a) control, (b) ultrasonicated, and (c) blanched samples.

The results suggested a significant reduction in GHG production upon a pretreatment of the samples. The reason could be the prevention from the formation of the hard layer upon a pretreatment, which can help in the fast removal of moisture, hence, declining the drying duration and the energy required for the drying process. Upon a decrement in the energy consumption, the amount of the required fuel and hence the GHG emission due to the combustion of the fossil fuels in the plants will be decremented [59]. In line with this research, the results of other studies on drying blackberries [60] and goldenberries [21] also indicated a decline in GHG emission upon a pretreatment of the samples.

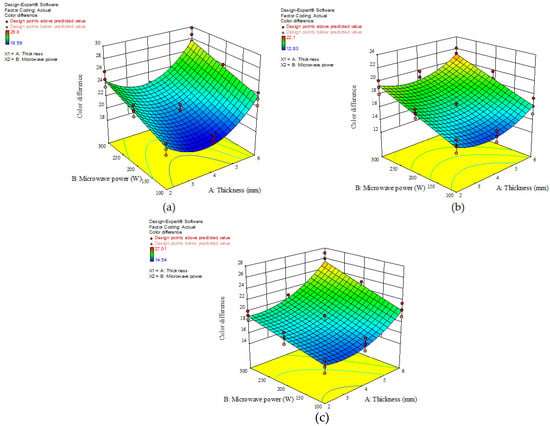

3.6. Color Changes

One of the prominent parameters in the quality of the dried agricultural products is color. Based on Table 2, the influence of the independent parameters of the MP and ST, as well as the quadratic effect of the thickness, were significant (p < 0.0001) on the color changes of the carrot slices. For blanched samples, the interaction effect of the MP–ST was also significant (p < 0.0001) on the color changes of the samples. Figure 8 presents the interaction effects of the MP and ST on the color changes during the process of the carrot sample drying. Accordingly, the color variation range of the untreated samples was 19.29–28.68 which altered to 13.69–21.22 and 15.59–25.94 in the samples pretreated by ultrasound waves and blanching, respectively. The lowest color change (13.69) was observed in the ultrasonicated samples with a thickness of 4 mm dried at the MP of 100 W, whereas the controls with thickness of 6 mm dried at the MP of 300 W experienced the highest color changes. At constant thickness, an increase in the MP increased the difference between the color of the dried and fresh samples in all pretreatments. This observation can be assigned to oxidation, non-enzymic browning reactions, and changes in the surface structure of the carrot samples during the drying process [18]. In drying red bell pepper [61] and okra pods [62], researchers found similar trends in which the increasing in the MP enhanced the color difference. As shown in Figure 8, the color change declined by increasing the ST from 2 to 4 mm in the untreated and sonicated samples, whereas an increase in the ST from 4 to 6 mm led to an ascending trend in the color change. In the case of the blanching pretreatment, a rise in the ST from 2 to 6 mm increased the color changes which was in line with the findings of other researchers who dried pumpkin [7] and potato [63]. For all the samples, big color changes were observed in the thickness of 6 mm as these samples required a longer time for drying. Therefore, they were exposed to oxidation and thermal degradation for a longer period of time, which enhanced the color changes in the final product [7].

Figure 8.

Relationships between microwave power and thickness with color-dependent variable: (a) control, (b) ultrasonicated, and (c) blanched samples.

After the ultrasonication and blanching pretreatments, the range of the color changes was maintained at an acceptable level. In other words, the application of the pretreatments better preserved the color features of the samples, suggesting that these pretreatments managed to prevent the browning of the carrot slices. High-temperature blanching also deactivates the enzymes such as polyphenol oxidase and peroxidase, hence decrementing the enzymic browning reactions during the drying process [32,64]. On the other hand, ultrasonication decreased the oxygen content of the carrot samples, hence inhibiting the browning reaction [47]. This is why the least color changes occurred in the samples pretreated by ultrasound waves. The results of this research on the effect of the ultrasound waves and blanching on a better color preservation are in line with previous studies such as studies on drying apples in a hot-air dryer (Bai et al., 2023 [32]), pumpkin samples dried in an IR dryer [47], and cranberry snacks dried in a microwave-vacuum dryer [65].

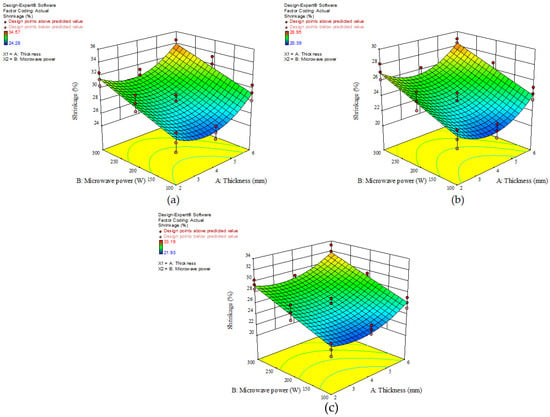

3.7. Shrinkage

As listed in Table 2, the influences of the MP and ST, as well as the quadratic effect of sample thickness, were significant (p < 0.0001) on the shrinkage of the dried samples. The interaction effect of the MP–ST was not significant. Based on Figure 9, the highest shrinkage (33.39%) was recorded in the untreated samples with 6 mm thickness dried at the MP of 300 W, while the ultrasonicated samples with a thickness of 4 mm dried at the MP of 100 W showed the lowest shrinkage (21.29%); as expected, a rise in the MP increased the shrinkage due to the contraction stress at higher powers, which led to the cellular collapse (deformation of the product and its cracking), and these results are in line with previous works [11,66]. An increase in the ST from 2 to 4 mm decremented the shrinkage followed by an increment in the shrinkage by further thickness enhancement from 4 to 6 mm. The highest shrinkage was generally observed in the thickest samples (6 mm) for all treatments. Drying will result in deformation and volume reduction, hence the shrinkage of the product. Heating and water removal from the matrix of the food products will lead to cellular stress, decrementing the dimensions of the product and contraction of its capillary structure. At higher thicknesses, these changes are more profound [67]. These findings coincided with the reports by other researchers on drying apple [68] and Persian shallot [69] of different thicknesses.

Figure 9.

The effects of microwave power and sample thickness on response surface plots of the shrinkage: (a) control, (b) ultrasonicated, and (c) blanched samples.

According to Figure 9, the use of an ultrasonic pretreatment and blanching led to a lower shrinkage compared to the untreated samples. The carrot slices pre-treated with ultrasound waves showed the lowest shrinkage at all MPs and ST followed by the blanched samples and controls, respectively. Tissue hydration and damage during pretreatment increased the MC of the blanched samples which led to more shrinkage in the blanched samples than in sonicated samples [70].

3.8. Optimization

A vital step in food process engineering to achieve an effective performance in different operations and high-quality food products is optimization. Selecting the proper drying parameters to achieve the desired response surfaces is the key challenge in the optimization process using RSM and its desirability function [61]. In this study, the MP and the ST were selected. The results of optimal drying conditions for carrots are listed in Table 4. The desirability obtained at optimal conditions for the investigated variables and responses were 0.776, 0.807, and 0.82 for untreated, ultrasonicated, and blanched samples, respectively. According to Table 4, the optimal conditions for carrot slices dried by the microwave method are as follows.

Table 4.

Results of optimization using a desirability method.

For samples without pretreatment, the MP (300 W) and the ST (2 mm) resulted in the following response values: Dt (48.96 min), SEC (13.22 MJ/kg)), Eef (16.92%), Deff (5.087 × 10−10), CO2 (14,220.6 g, in the GT-GO power plant), NOx (40.02 g, in the CC-NG power plant), color (24.54), and shrinkage (31.48%).

In the case of samples pretreated with ultrasound waves, the MP of 300 W and the ST of 2 mm led to the following response values: Dt (44.46) min, SEC (11.35 MJ/kg)), Eef (19.42%), Deff (5.90 × 10−10), CO2 (11,895.4 g, in the GT-GO power plant), NOx (33.48 g; in the CC-NG power plant), color (19.36), and shrinkage (26.95%).

For the samples with blanching pretreatment, the MP of 300 W and the ST of 2 mm resulted in the following response values: Dt (39.31 min), SEC (9.79 MJ/kg), Deff (6.5 × 10−10), CO2 (10,258.4 g; in a GT-GO plat), NOx (28.87 g; in a CC-NG plant), color (19.08), and shrinkage (29.13%).

4. Conclusions

In this research, microwave drying was utilized to dry carrot slices of different thicknesses. The RSM was employed to explore the effects of the MP (100, 200, and 300 W) and the ST (2, 4, and 6 mm) on Dt, Deff, SEC, Eef, GHG (CO2 and NOx), and qualitative characteristics (color and shrinkage) of carrot slices considering the ultrasonication and blanching pretreatments. The results showed a reduction in the Dt (linearly), SEC (linearly or quadratically), and GHG (linearly and quadratically) by increasing the MP and decreasing the ST, while causing an ascending trend in the Eef (linearly or quadratically) and the Deff (linearly). A statistical and graphical analysis indicated a significant effect of drying parameters (MP and ST) on the response parameters of drying carrot slices in all pretreatments (p < 0.0001). The optimization results showed that the MP of 300 W and the ST of 2 mm are the best independent variables for drying carrot slices. Different pretreatments reduced the GHG emission, while the lowest CO2 (4279.7 g in a CC power plant) and NOx (18.16 g in a GT power plant) emissions with NG were obtained for the blanched samples with a ST of 2 mm dried at a MP of 300 W. Regarding the serious global warming crisis, knowing that the increasing population results in an ever-increasing demand for agricultural products, and considering the high energy consumption in the drying process of agricultural products, the application of different pretreatments seems to be a practical and important approach to reduce the SEC and GHG emission, hence reducing climate change.

Author Contributions

Conceptualization, E.T. and M.K.; methodology, E.T. and M.K.; validation, E.T. and M.K.; formal analysis, E.T.; investigation, E.T. and M.K.; resources, E.T. and A.S.; data curation, E.T. and M.K.; writing—original draft preparation, E.T. and A.S.; writing—review and editing, E.T., A.S., A.F. and M.K.; visualization, E.T. and A.S.; funding acquisition, E.T. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the vice chancellor for research and technology of the University of Mohaghegh Ardabili (by a research project with Number: 1400.d.9.8779 and date 2021.07.24). Additionally, language editing was co-financed by Wroclaw University of Environmental and Life Sciences (UPWr), which is gratefully acknowledged for providing the necessary infrastructure and experimental facilities throughout the project duration.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research has been financially supported by the vice chancellor for research and technology of the University of Mohaghegh Ardabili in Iran, by the contract number 1400.d.9.8779 and date 2021.07.24. This project was also financed by the NAWA—Polish National Agency for Academic Exchange under the Ulam NAWA Program (Project No. BPN/ULM/2021/1/00231) at UPWr. The authors are highly thankful to the University of Mohaghegh Ardabili and NAWA—Polish National Agency with UPWr as well as Vali Rasooli Sharabiani (V.R.S.), Department of Biosystem Engineering, Faculty of Agriculture and Natural Resources, University of Mohaghegh Ardabili, Ardabil, Iran, and Ali Mirzazadeh (A. M.), Department of Agricultural Technology Engineering, Moghan College of Agriculture and Natural Resources, University of Mohaghegh Ardabili, Ardebili, Ardabil 5619911367, Iran.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| CC | Combined cycle turbines |

| Deff | Effective moisture diffusion coefficient |

| Dt | Drying time (min) |

| Eef | Energy efficiency (%) |

| GHG | Greenhouse gas |

| GO | Gas oil |

| GT | Gas turbine |

| HO | Heavy oil |

| L | Sample thickness (m) |

| M0 | Initial moisture content (d.b.) |

| MC | Moisture content (d.b.) |

| MCd.b. | Initial moisture content (d.b.) |

| Me | Equilibrium moisture content (d.b.) |

| Mf | Final weight of the sample (g) |

| Mi | Initial weight of the sample (g) |

| MP | Microwave power (W) |

| Mt | Sample moisture at time of t (d.b.) |

| Mw | Value of water leaving the sample during the process of drying (kg) |

| n | Number of the drying terms |

| NG | Natural gas |

| PP | Power plants (w) |

| RSM | Response surface methodology |

| SEC | Specific energy consumption (Mj/kg) |

| SP | Power turbine |

| ST | Slice thickness (mm) |

| Sv | Shrinkage (%) |

| t | Drying time (min) |

| TEC | Total energy use (MJ) |

| V | Sample volume after drying (cm3) |

| Vi | Sample volume before drying (cm3) |

| xi | Independent variable value |

| xj | Actual value of each parameter |

| yk | Response variable |

| β1 | Intercept of the variables |

| βi | Coefficients of the variables |

| λw | Latent heat for water vaporization (2257 kJ.kg−1) |

References

- Lyu, Y.; Bi, J.; Chen, Q.; Wu, X.; Gou, M.; Yang, X. Color enhancement mechanisms analysis of freeze-dried carrots treated by ultrasound-assisted osmosis (ascorbic acid-CaCl2) dehydration. Food Chem. 2022, 381, 132255. [Google Scholar] [CrossRef] [PubMed]

- de Souza, A.U.; Corrêa, J.L.G.; Tanikawa, D.H.; Abrahão, F.R.; de Jesus Junqueira, J.R.; Jiménez, E.C. Hybrid microwave-hot air drying of the osmotically treated carrots. LWT 2022, 156, 113046. [Google Scholar] [CrossRef]

- Fan, L.P.; Zhang, M.; Xiao, G.n.; Sun, J.c.; Tao, Q. The optimization of vacuum frying to dehydrate carrot chips. Int. J. Food Sci. Technol. 2005, 40, 911–919. [Google Scholar] [CrossRef]

- Dehghannya, J.; Seyed-Tabatabaei, S.-R.; Khakbaz Heshmati, M.; Ghanbarzadeh, B. Influence of three stage ultrasound—Intermittent microwave—Hot air drying of carrot on physical properties and energy consumption. Heat Mass Transf. 2021, 57, 1893–1907. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Ebadollahi, A. Potential application of chitosan-clay coating on some quality properties of agricultural product during storage. Agric. Eng. Int. CIGR J. 2017, 19, 189–194. [Google Scholar]

- Guemouni, S.; Mouhoubi, K.; Brahmi, F.; Dahmoune, F.; Belbahi, A.; Benyoub, C.; Adjeroud-Abdellatif, N.; Atmani, K.; Bakhouche, H.; Boulekbache-Makhlouf, L. Convective and microwave drying kinetics and modeling of tomato slices, energy consumption, and efficiency. J. Food Process Eng. 2022, 45, e14113. [Google Scholar] [CrossRef]

- Chikpah, S.K.; Korese, J.K.; Sturm, B.; Hensel, O. Colour change kinetics of pumpkin (Cucurbita moschata) slices during convective air drying and bioactive compounds of the dried products. J. Agric. Food Res. 2022, 10, 100409. [Google Scholar] [CrossRef]

- Sobowale, S.S.; Agbawodike, J.I.; Kewuyemi, Y.O.; Adebo, O.A. Response surface methodology approach for predicting microwave-convective drying characteristics of sweet potato slices. J. Food Process. Preserv. 2022, 46, e16683. [Google Scholar] [CrossRef]

- Salehi, F.; Satorabi, M. Influence of infrared drying on drying kinetics of apple slices coated with basil seed and xanthan gums. Int. J. Fruit Sci. 2021, 21, 519–527. [Google Scholar] [CrossRef]

- Hosseinzadeh Samani, B.; Khodadadi, A.; Rostami, S.; Lorigooini, Z. Investigation and optimization of the effect of osmotic-ultrasound drying pretreatment on qualitative properties and process energy consumption of Cornus mas. J. Food Process. Preserv. 2021, 45, e15377. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Kaveh, M.; Jahanbakhshi, A.; Golpour, I. Use of artificial intelligence for the estimation of effective moisture diffusivity, specific energy consumption, color and shrinkage in quince drying. J. Food Process Eng. 2020, 43, e13358. [Google Scholar] [CrossRef]

- Rybak, K.; Parniakov, O.; Samborska, K.; Wiktor, A.; Witrowa-Rajchert, D.; Nowacka, M. Energy and quality aspects of freeze-drying preceded by traditional and novel pre-treatment methods as exemplified by red bell pepper. Sustainability 2021, 13, 2035. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Kaveh, M.; Szumny, A. Optimization and prediction of the drying and quality of turnip slices by convective-infrared dryer under various pretreatments by RSM and ANFIS methods. Foods 2021, 10, 284. [Google Scholar] [CrossRef] [PubMed]

- Tepe, T.K.; Kadakal, Ç. Determination of drying characteristics, rehydration properties, and shrinkage ratio of convective dried melon slice with some pretreatments. J. Food Process. Preserv. 2022, 46, e16544. [Google Scholar] [CrossRef]

- Mirzaei-Baktash, H.; Hamdami, N.; Torabi, P.; Fallah-Joshaqani, S.; Dalvi-Isfahan, M. Impact of different pretreatments on drying kinetics and quality of button mushroom slices dried by hot-air or electrohydrodynamic drying. LWT 2022, 155, 112894. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Rasooli Sharabiani, V. The effect of combination dryer of hot air—Infrared and microwave on some quality properties of parboiled rice. Innov. Food Technol. 2017, 5, 25–38. [Google Scholar] [CrossRef]

- Rostami Gharkhloo, Z.; Sharifian, F.; Rahimi, A.; Akhoundzadeh Yamchi, A. Influence of high wave sound pretreatment on drying quality parameters of echinacea root with infrared drying. J. Sci. Food Agric. 2022, 102, 2153–2164. [Google Scholar] [CrossRef]

- Namjoo, M.; Moradi, M.; Niakousari, M. Evaluation of the effect of high-power ultrasound waves on conventional air drying of cumin seeds. Sustain. Energy Technol. Assess. 2022, 52, 102262. [Google Scholar] [CrossRef]

- Karimi, M.; Moradi, M.; Niakousari, M.; Karparvarfard, S.H. Application of heat carrier particles in a fluidized bed dryer: Dimensionless modeling and GHG emissions. J. Food Process Eng. 2022, 45, e14071. [Google Scholar] [CrossRef]

- Kaveh, M.; Chayjan, R.A.; Taghinezhad, E.; Sharabiani, V.R.; Motevali, A. Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J. Clean. Prod. 2020, 259, 120963. [Google Scholar] [CrossRef]

- Miraei Ashtiani, S.-H.; Rafiee, M.; Mohebi Morad, M.; Martynenko, A. Cold plasma pretreatment improves the quality and nutritional value of ultrasound-assisted convective drying: The case of goldenberry. Dry. Technol. 2022, 40, 1639–1657. [Google Scholar]

- Seyfi, A.; Asl, A.R.; Motevali, A. Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Sol. Energy 2021, 229, 162–173. [Google Scholar] [CrossRef]

- Wang, L.; Xu, B.; Wei, B.; Zeng, R. Low frequency ultrasound pretreatment of carrot slices: Effect on the moisture migration and quality attributes by intermediate-wave infrared radiation drying. Ultrason. Sonochem. 2018, 40, 619–628. [Google Scholar]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2010. [Google Scholar]

- Geng, Z.; Torki, M.; Kaveh, M.; Beigi, M.; Yang, X. Characteristics and multi-objective optimization of carrot dehydration in a hybrid infrared/hot air dryer. LWT 2022, 172, 114229. [Google Scholar] [CrossRef]

- Ononogbo, C.; Nwakuba, N.; Nwaji, G.; Nwufo, O.; Nwosu, E.; Okoronkwo, C.; Igbokwe, J.; Anyanwu, E. Thermal efficiency and drying Behaviour of Yam slices in a dryer driven by the waste heat of exhaust gases. Sci. Afr. 2022, 17, e01310. [Google Scholar] [CrossRef]

- Namjoo, M.; Moradi, M.; Niakousari, M.; Karparvarfard, S.H. Ultrasound-assisted air drying of cumin seeds: Modeling and optimization by response surface method. Heat Mass Transf. 2022, 59, 1073–1091. [Google Scholar] [CrossRef]

- Ghanbarian, D.; Torki-Harchegani, M.; Sadeghi, M.; Pirbalouti, A.G. Ultrasonically improved convective drying of peppermint leaves: Influence on the process time and energetic indices. Renew. Energy 2020, 153, 67–73. [Google Scholar]

- Tepe, F.B.; Tepe, T.K.; Ekinci, A. Drying kinetics and energy efficiency of microwave-dried lemon slices. Chem. Ind. Chem. Eng. Q. 2022, 28, 297–304. [Google Scholar] [CrossRef]

- Nazari, S.; Shahhoseini, O.; Sohrabi-Kashani, A.; Davari, S.; Paydar, R.; Delavar-Moghadam, Z. Experimental determination and analysis of CO2, SO2 and NOx emission factors in Iran’s thermal power plants. Energy 2010, 35, 2992–2998. [Google Scholar] [CrossRef]

- Koca, N.; Burdurlu, H.S.; Karadeniz, F. Kinetics of colour changes in dehydrated carrots. J. Food Eng. 2007, 78, 449–455. [Google Scholar] [CrossRef]

- Bai, J.-W.; Zhang, L.; Aheto, J.H.; Cai, J.-R.; Wang, Y.-C.; Sun, L.; Tian, X.-Y. Effects of different pretreatment methods on drying kinetics, three-dimensional deformation, quality characteristics and microstructure of dried apple slices. Innov. Food Sci. Emerg. Technol. 2023, 83, 103216. [Google Scholar]

- Beigi, M.; Torki, M. Experimental and ANN modeling study on microwave dried onion slices. Heat Mass Transf. 2021, 57, 787–796. [Google Scholar] [CrossRef]

- Darvishi, H.; Zarein, M.; Farhudi, Z. Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J. Food Sci. Technol. 2016, 53, 2317–2333. [Google Scholar] [PubMed]

- Raj, G.; Dash, K.K. Effect of intermittent microwave convective drying on physicochemical properties of dragon fruit. Food Sci. Biotechnol. 2022, 31, 549–560. [Google Scholar] [CrossRef]

- Szadzińska, J.; Mierzwa, D. The influence of hybrid drying (microwave-convective) on drying kinetics and quality of white mushrooms. Chem. Eng. Process. Process Intensif. 2021, 167, 108532. [Google Scholar]

- Sledz, M.; Wiktor, A.; Rybak, K.; Nowacka, M.; Witrowa-Rajchert, D. The impact of ultrasound and steam blanching pre-treatments on the drying kinetics, energy consumption and selected properties of parsley leaves. Appl. Acoust. 2016, 103, 148–156. [Google Scholar]

- Tao, Y.; Han, M.; Gao, X.; Han, Y.; Show, P.-L.; Liu, C.; Ye, X.; Xie, G. Applications of water blanching, surface contacting ultrasound-assisted air drying, and their combination for dehydration of white cabbage: Drying mechanism, bioactive profile, color and rehydration property. Ultrason. Sonochem. 2019, 53, 192–201. [Google Scholar]

- Wu, B.; Guo, X.; Guo, Y.; Ma, H.; Zhou, C. Enhancing jackfruit infrared drying by combining ultrasound treatments: Effect on drying characteristics, quality properties and microstructure. Food Chem. 2021, 358, 129845. [Google Scholar]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Khalife, E.; Witrowa-Rajchert, D.; Nowacka, M. Effect of pretreatments on convective and infrared drying kinetics, energy consumption and quality of terebinth. Appl. Sci. 2021, 11, 7672. [Google Scholar] [CrossRef]

- Castro, S.M.; Saraiva, J.A.; Domingues, F.M.; Delgadillo, I. Effect of mild pressure treatments and thermal blanching on yellow bell peppers (Capsicum annuum L.). LWT Food Sci. Technol. 2011, 44, 363–369. [Google Scholar] [CrossRef]

- Beigi, M. Infrared dehydration of blanched quince slices: Study on process and mass transfer characteristics: Drying of quince slices . Lat. Am. Appl. Res. Int. J. 2021, 51, 241–247. [Google Scholar]

- Royen, M.J.; Noori, A.W.; Haydary, J. Experimental study and mathematical modeling of convective thin-layer drying of apple slices. Processes 2020, 8, 1562. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. Investigating the influence of novel drying methods on sweet potato (Ipomoea batatas L.): Kinetics, energy consumption, color, and microstructure. J. Food Process Eng. 2018, 41, e12686. [Google Scholar]

- Zhu, R.; Shen, J.; Law, C.L.; Ma, X.; Li, D.; Han, Y.; Kiani, H.; Manickam, S.; Tao, Y. Combined calcium pretreatment and ultrasonic/microwave drying to dehydrate black chokeberry: Novel mass transfer modeling and metabolic pathways of polyphenols. Innov. Food Sci. Emerg. Technol. 2022, 83, 103215. [Google Scholar]

- Nowacka, M.; Wiktor, A.; Anuszewska, A.; Dadan, M.; Rybak, K.; Witrowa-Rajchert, D. The application of unconventional technologies as pulsed electric field, ultrasound and microwave-vacuum drying in the production of dried cranberry snacks. Ultrason. Sonochem. 2019, 56, 1–13. [Google Scholar]

- Chao, E.; Li, J.; Fan, L. Enhancing drying efficiency and quality of seed-used pumpkin using ultrasound, freeze-thawing and blanching pretreatments. Food Chem. 2022, 384, 132496. [Google Scholar] [CrossRef] [PubMed]

- Pandiselvam, R.; Aydar, A.Y.; Kutlu, N.; Aslam, R.; Sahni, P.; Mitharwal, S.; Gavahian, M.; Kumar, M.; Raposo, A.; Yoo, S. Individual and interactive effect of ultrasound pre-treatment on drying kinetics and biochemical qualities of food: A critical review. Ultrason. Sonochem. 2022, 92, 106261. [Google Scholar]

- Taghinezhad, E.; Kaveh, M.; Szumny, A. Thermodynamic and quality performance studies for drying kiwi in hybrid hot air-infrared drying with ultrasound pretreatment. Appl. Sci. 2021, 11, 1297. [Google Scholar] [CrossRef]

- Mouhoubi, K.; Boulekbache-Makhlouf, L.; Mehaba, W.; Himed-Idir, H.; Madani, K. Convective and microwave drying of coriander leaves: Kinetics characteristics and modeling, phenolic contents, antioxidant activity, and principal component analysis. J. Food Process Eng. 2022, 45, e13932. [Google Scholar]

- Nwakuba, N.; Chukwuezie, O.; Asonye, G.; Asoegwu, S. Energy analysis and optimization of thin layer drying conditions of okra. Arid Zone J. Eng. Technol. Environ. 2018, 14, 129–148. [Google Scholar]

- Samadi, S.H.; Ghobadian, B.; Najafi, G.; Motevali, A. Potential saving in energy using combined heat and power technology for drying agricultural products (banana slices). J. Saudi Soc. Agric. Sci. 2014, 13, 174–182. [Google Scholar] [CrossRef]

- Xu, J.; Wang, D.; Lei, Y.; Cheng, L.; Zhuang, W.; Tian, Y. Effects of combined ultrasonic and microwave vacuum drying on drying characteristics and physicochemical properties of Tremella fuciformis. Ultrason. Sonochem. 2022, 84, 105963. [Google Scholar] [CrossRef] [PubMed]

- Kaveh, M.; Taghinezhad, E.; Aziz, M. Effects of physical and chemical pretreatments on drying and quality properties of blackberry (Rubus spp.) in hot air dryer. Food Sci. Nutr. 2020, 8, 3843–3856. [Google Scholar] [CrossRef] [PubMed]

- Beigi, M.; Harchegani, H.B.; Torki, M.; Kaveh, M.; Szymanek, M.; Khalife, E.; Dziwulska-Hunek, A. Experimental and numerical analysis of thermodynamic performance of microwave dryer of onion. J. Food Process Eng. 2022, 45, e14116. [Google Scholar] [CrossRef]

- Motevali, A.; Koloor, R.T. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 2017, 154, 445–461. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Nowacka, M. Comparison of different drying techniques and their carbon emissions in green peas. Chem. Eng. Process. Process Intensif. 2021, 160, 108274. [Google Scholar] [CrossRef]

- Motevali, A.; Jafari, H.; Molkabadi, E.Z.; Zhu, S.; Koloor, R.T.; Taghizadeh-Alisaraei, A. Comparison of environmental pollution and social cost analyses in different drying technologies. Int. J. Glob. Warm. 2020, 22, 1–29. [Google Scholar]

- Motevali, A.; Hashemi, S.J.; Taghinejad, E. Investigation of energy parameters, environment and social costs for drying process (Case study: Apple slices). Agric. Mech. Syst. Res. 2019, 20, 37–54. [Google Scholar]

- Taghinezhad, E.; Kaveh, M.; Khalife, E.; Chen, G. Drying of organic blackberry in combined hot air-infrared dryer with ultrasound pretreatment. Dry. Technol. 2021, 39, 2075–2091. [Google Scholar] [CrossRef]

- Zahoor, I.; Khan, M.A. Microwave assisted fluidized bed drying of red bell pepper: Drying kinetics and optimization of process conditions using statistical models and response surface methodology. Sci. Hortic. 2021, 286, 110209. [Google Scholar]

- EL-Mesery, H.S.; Elabd, M.A. Effect of microwave, infrared, and convection hot-air on drying kinetics and quality properties of okra pods. Int. J. Food Eng. 2021, 17, 909–926. [Google Scholar]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. Modelling the mid-infrared drying of sweet potato: Kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transf. 2018, 54, 2917–2933. [Google Scholar]

- Li, Y.; Zhang, Y.; Liu, H.; Jin, X.; Liu, X. Impacts of different blanching pretreatments on the quality of dried potato chips and fried potato crisps undergoing heat pump drying. Int. J. Food Eng. 2021, 17, 517–527. [Google Scholar] [CrossRef]

- Nowacka, M.; Dadan, M.; Tylewicz, U. Current applications of ultrasound in fruit and vegetables osmotic dehydration processes. Appl. Sci. 2021, 11, 1269. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Chen, X.; Li, B.; Mao, X.; Miao, J.; Zhao, C.; Huang, L.; Gao, W. Effects of hot air and microwave-assisted drying on drying kinetics, physicochemical properties, and energy consumption of chrysanthemum. Chem. Eng. Process. Process Intensif. 2018, 129, 84–94. [Google Scholar] [CrossRef]

- Mayor, L.; Sereno, A. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Paul, A.; Astatkie, E.; Martynenko, A. Electrohydrodynamic drying of fruit slices: Effect on drying kinetics, energy consumption, and product quality. J. Food Process. Preserv. 2022, 46, e16812. [Google Scholar]

- Chayjan, R.A.; Fealekari, M. Optimization of convective drying process for Persian shallot using response surface method (RSM). Agric. Eng. Int. CIGR J. 2014, 16, 157–166. [Google Scholar]

- Buvaneswaran, M.; Natarajan, V.; Sunil, C.K.; Rawson, A. Effect of pretreatments and drying on shrinkage and rehydration kinetics of ginger (Zingiber officinale). J. Food Process Eng. 2022, 45, e13972. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).