A Synergic Application of High-Oxygenated E-Fuels and New Bowl Designs for Low Soot Emissions: An Optical Analysis

Abstract

1. Introduction

2. Experimental Methodology

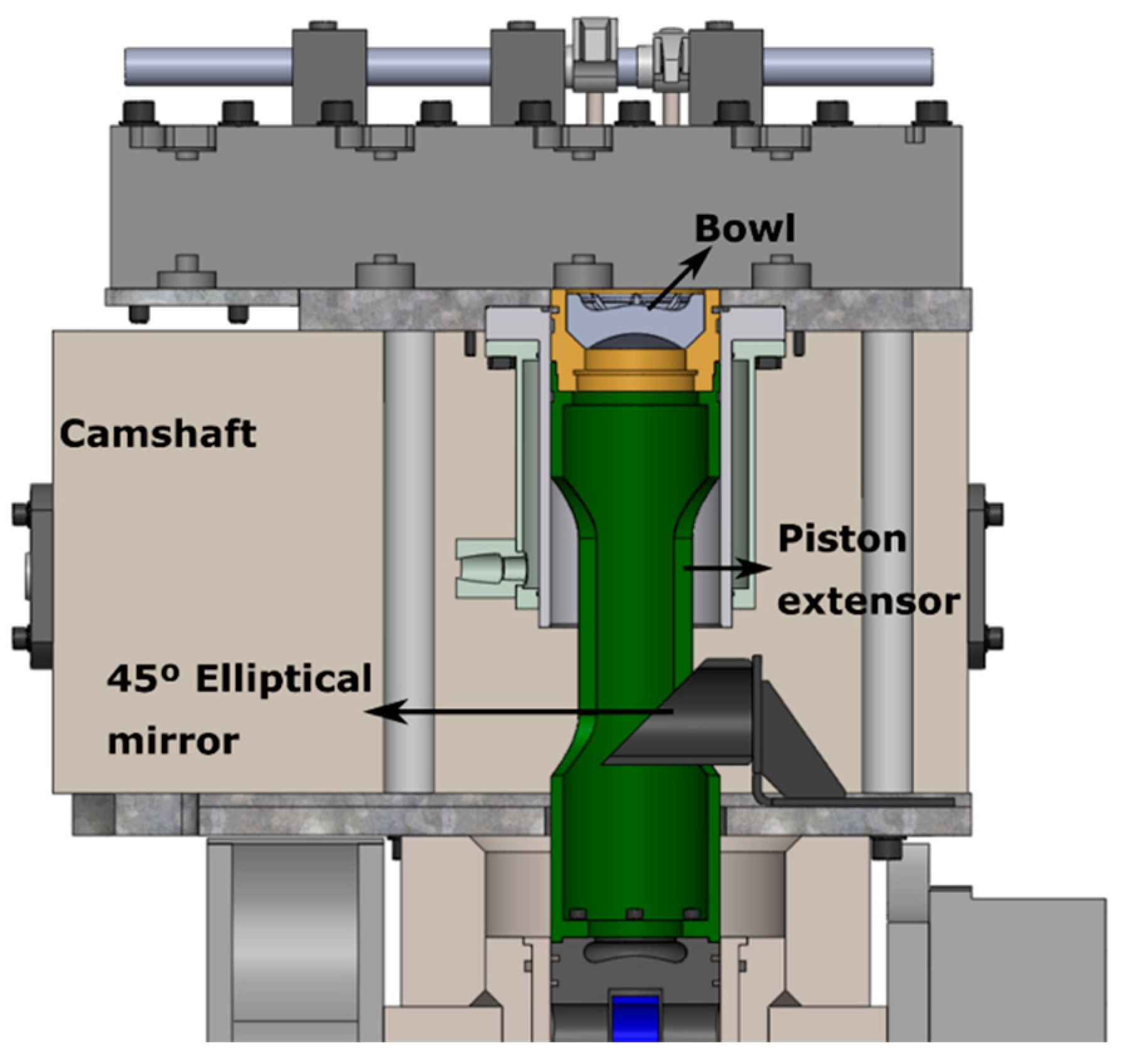

2.1. Optical Engine Facility

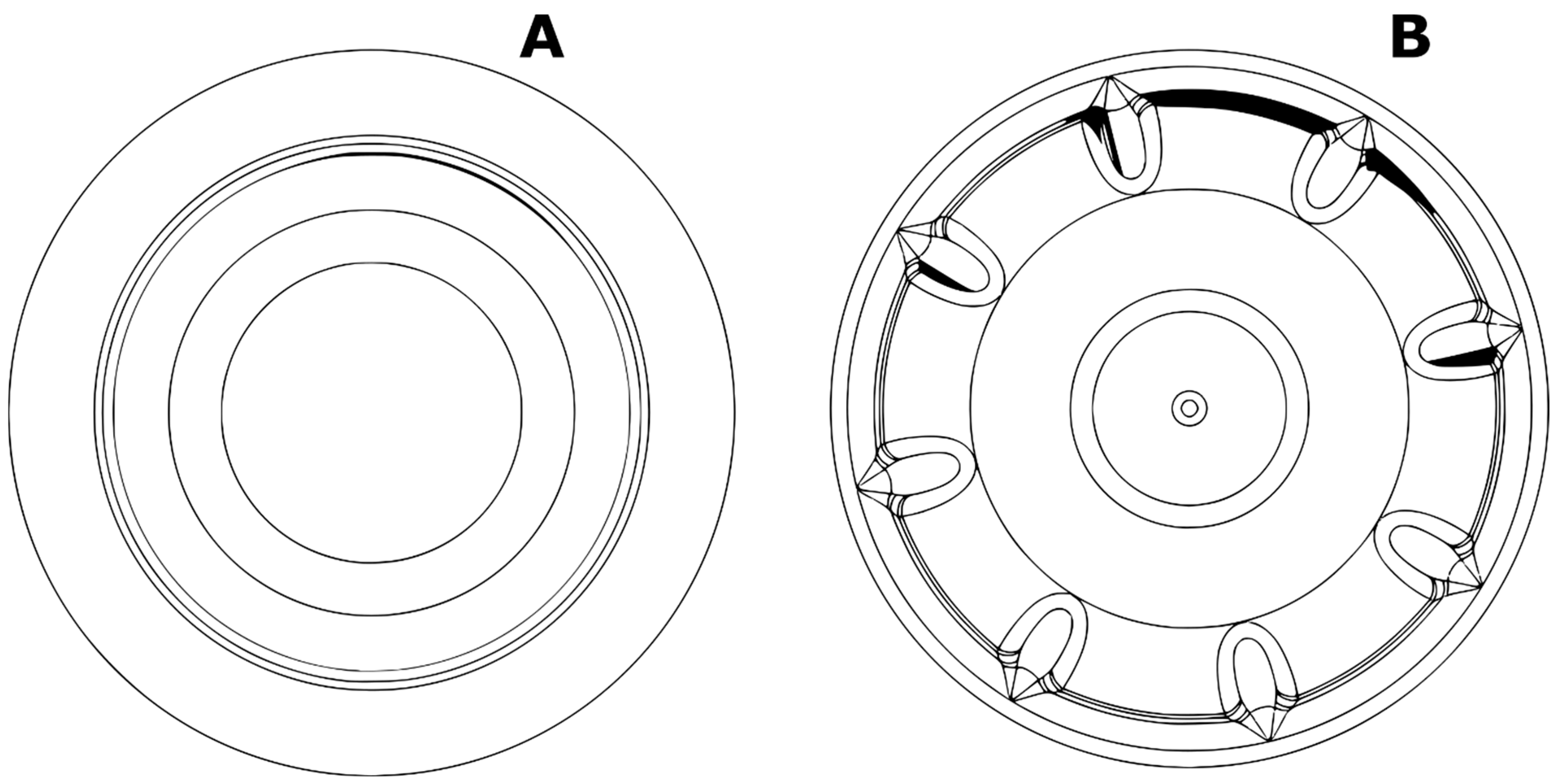

2.2. Piston Geometries

2.3. Optical Techniques and Methodology

2.3.1. OH* Chemiluminescence Radiation

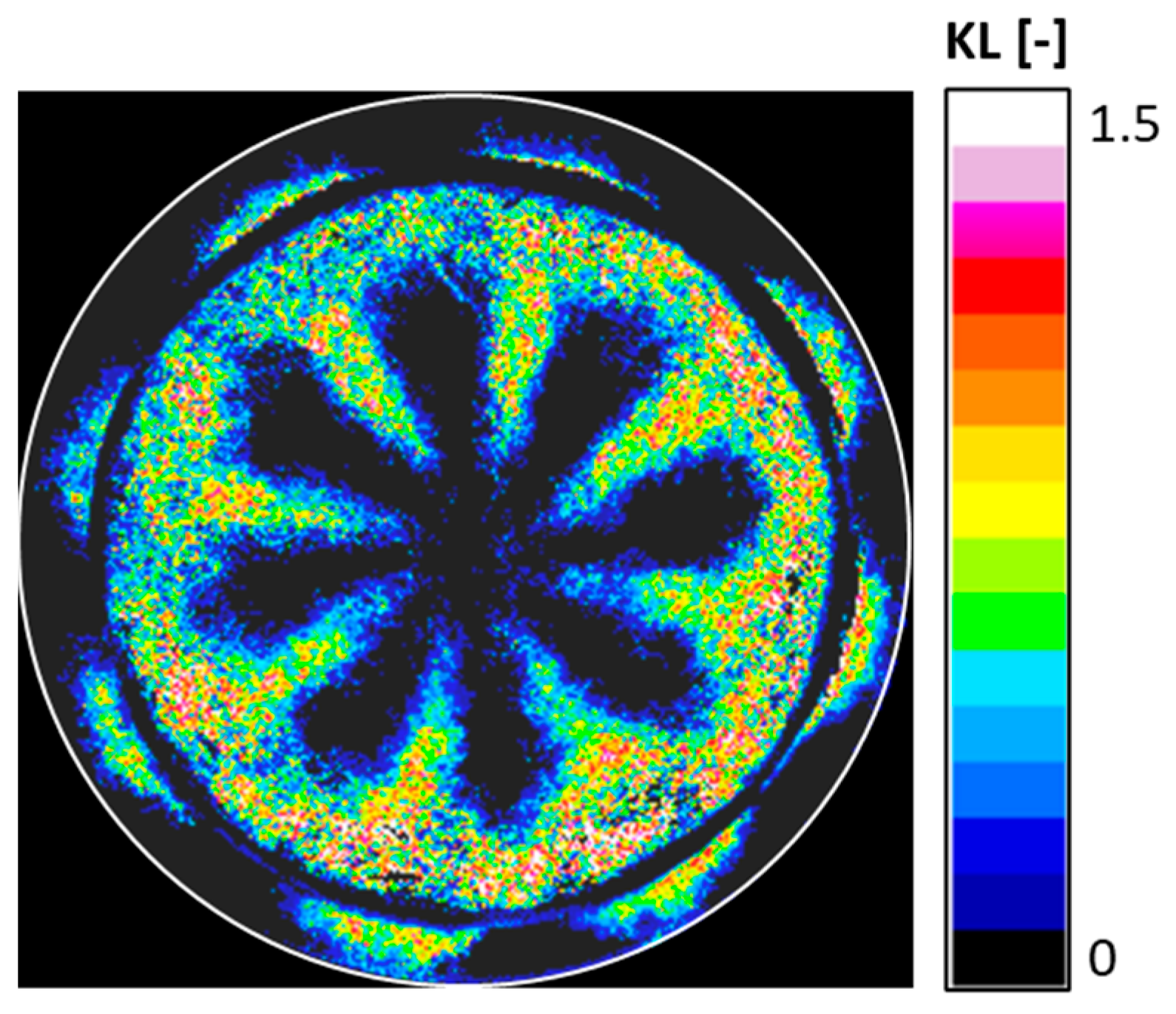

2.3.2. 2-Color Pyrometry Technique

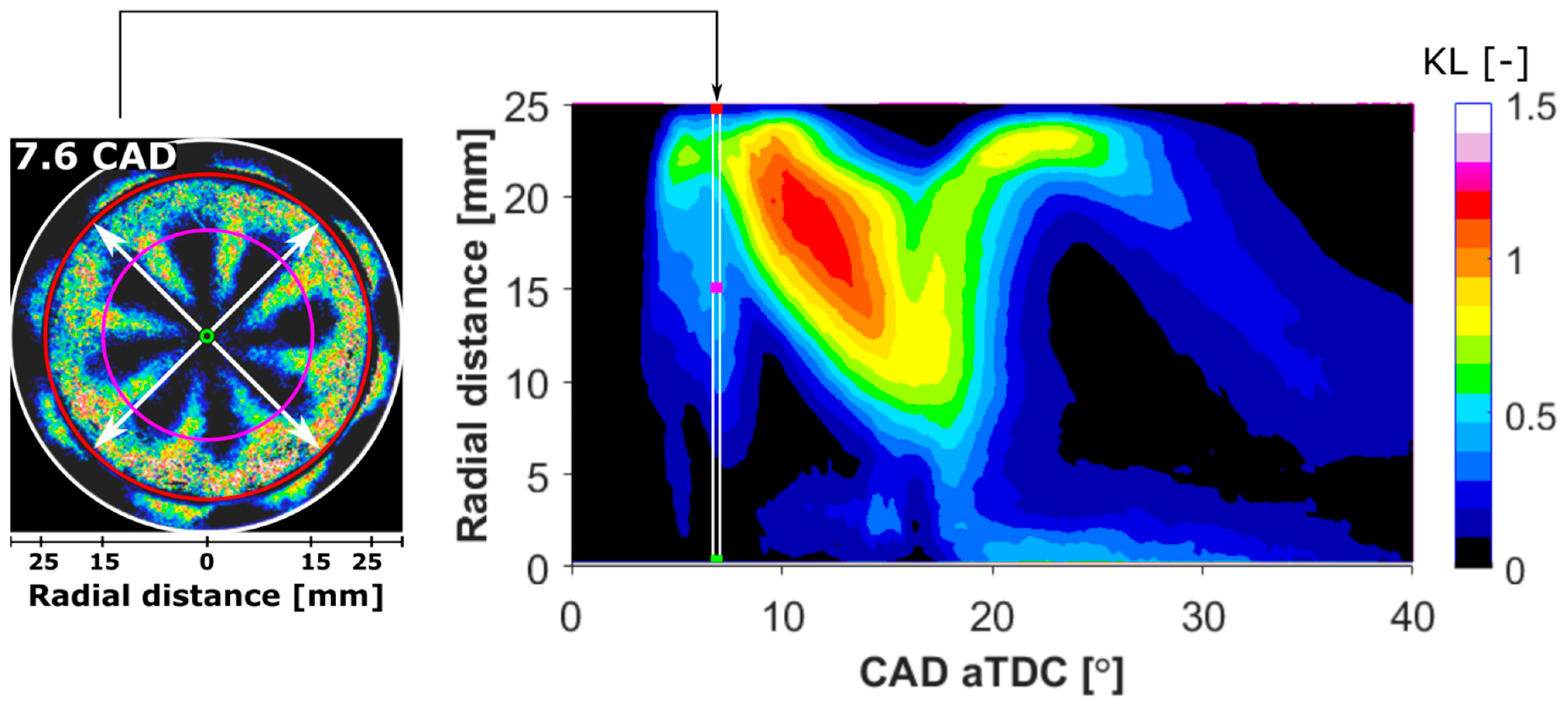

2.3.3. Post-Processing: Evolution Maps

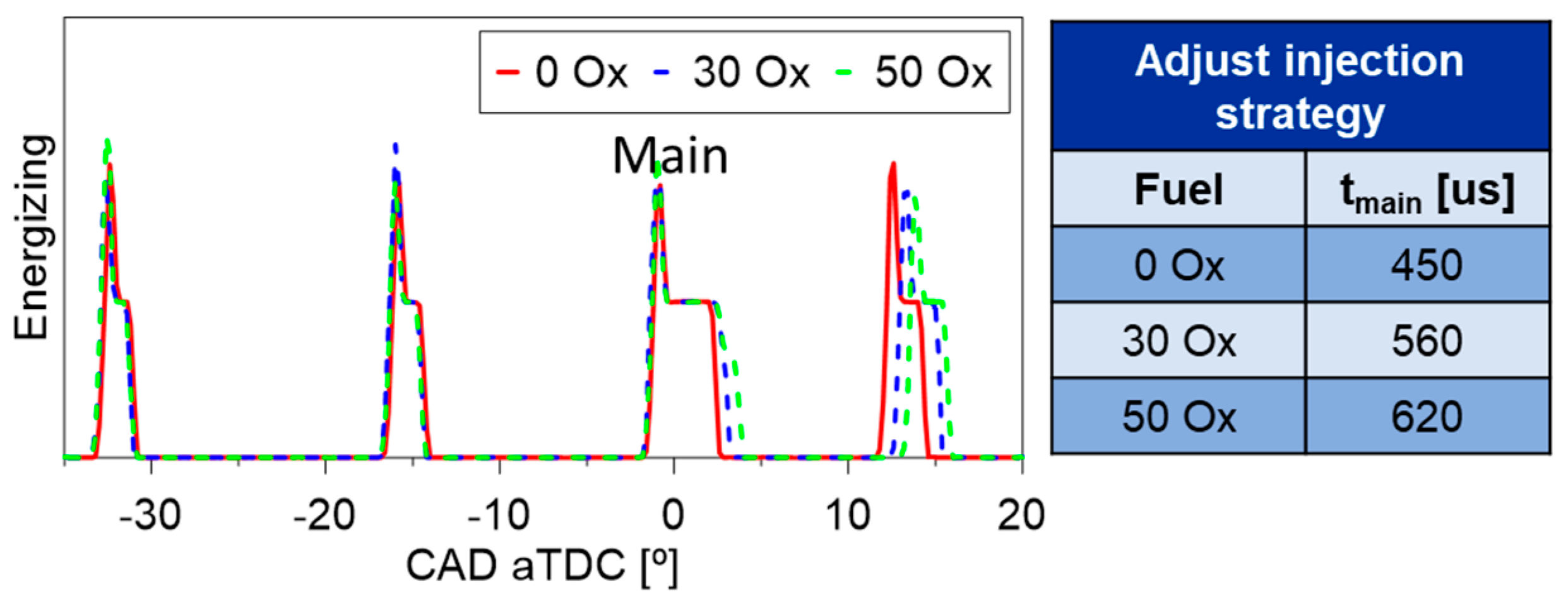

2.4. Operating Conditions

3. Results and Discussion

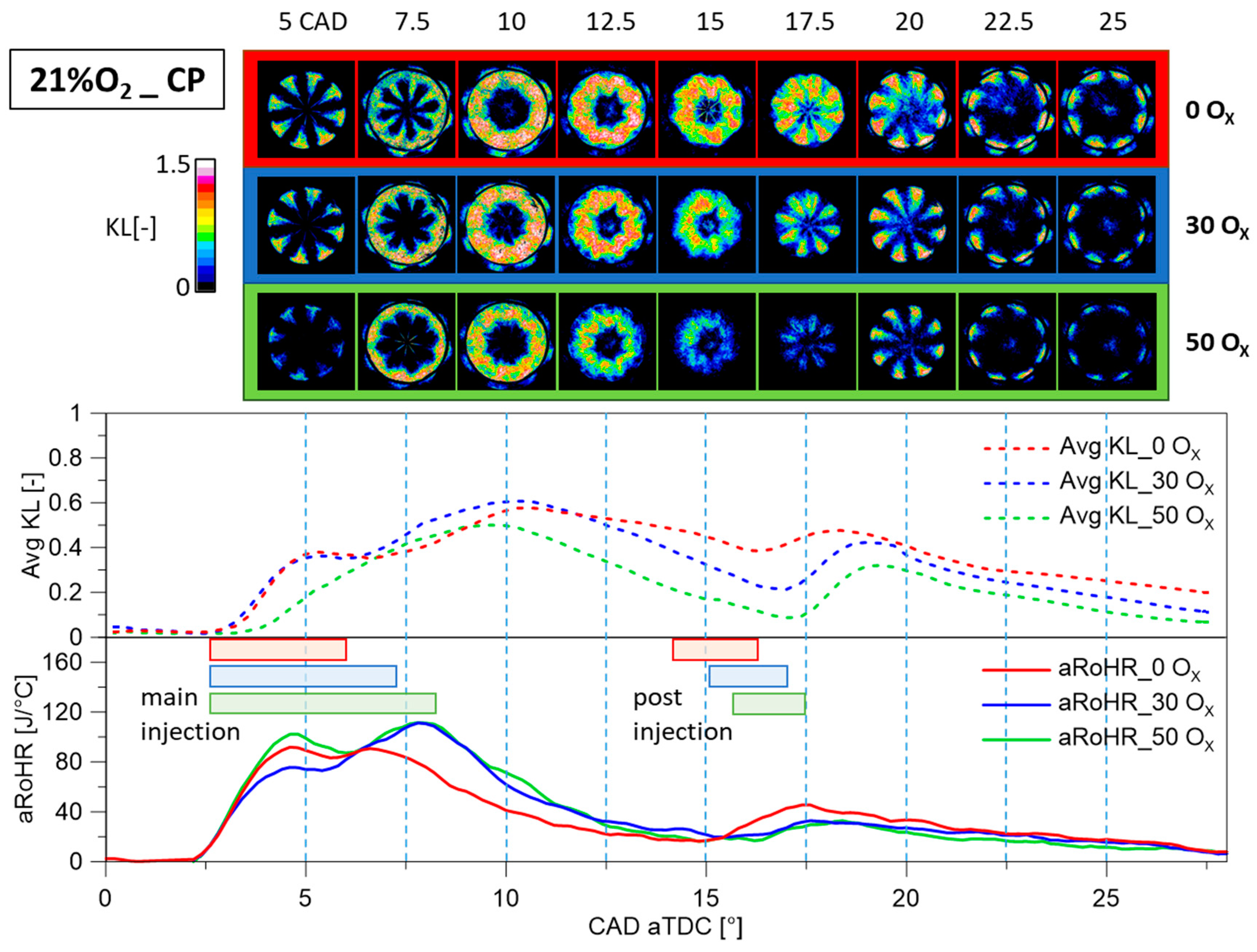

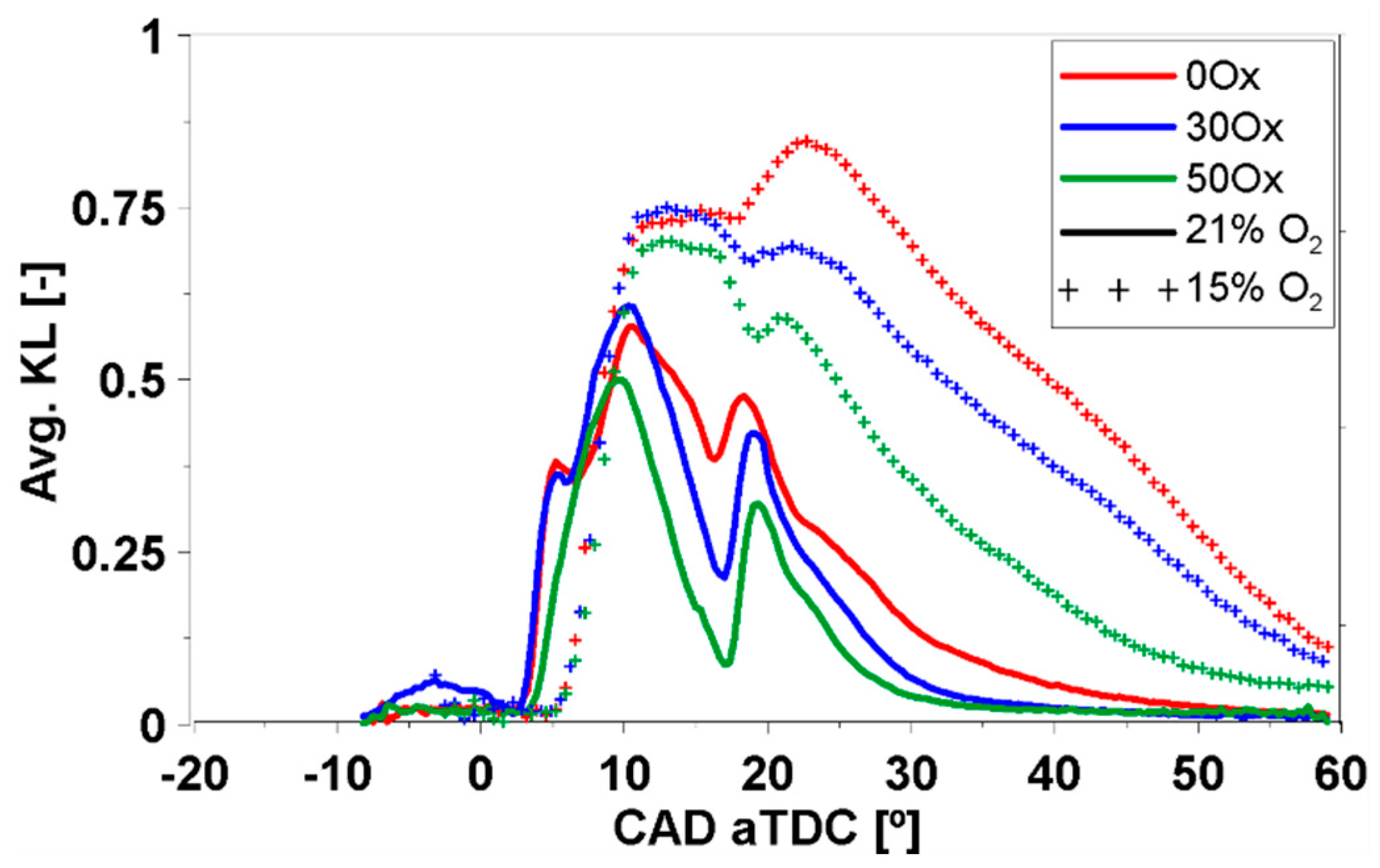

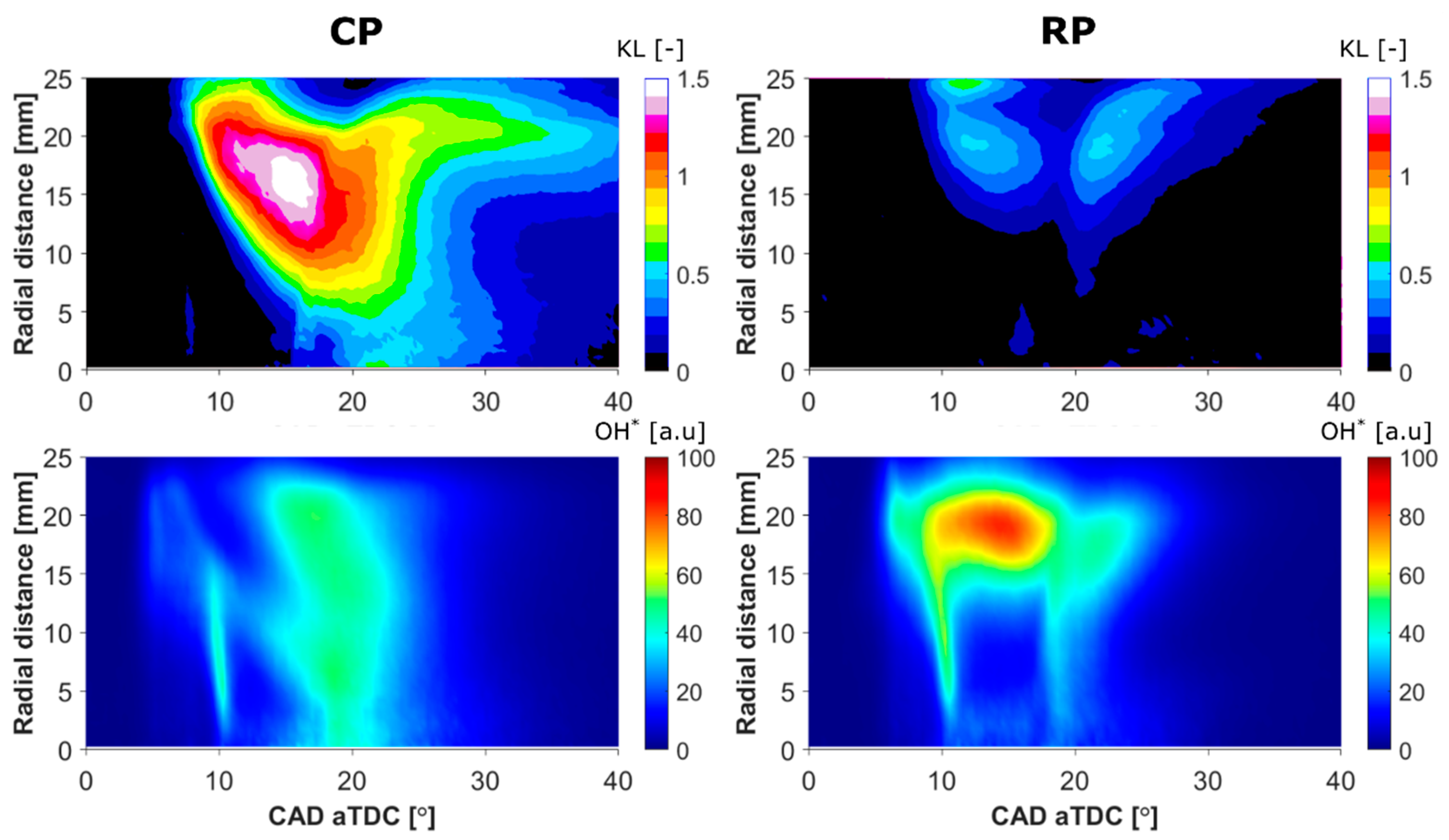

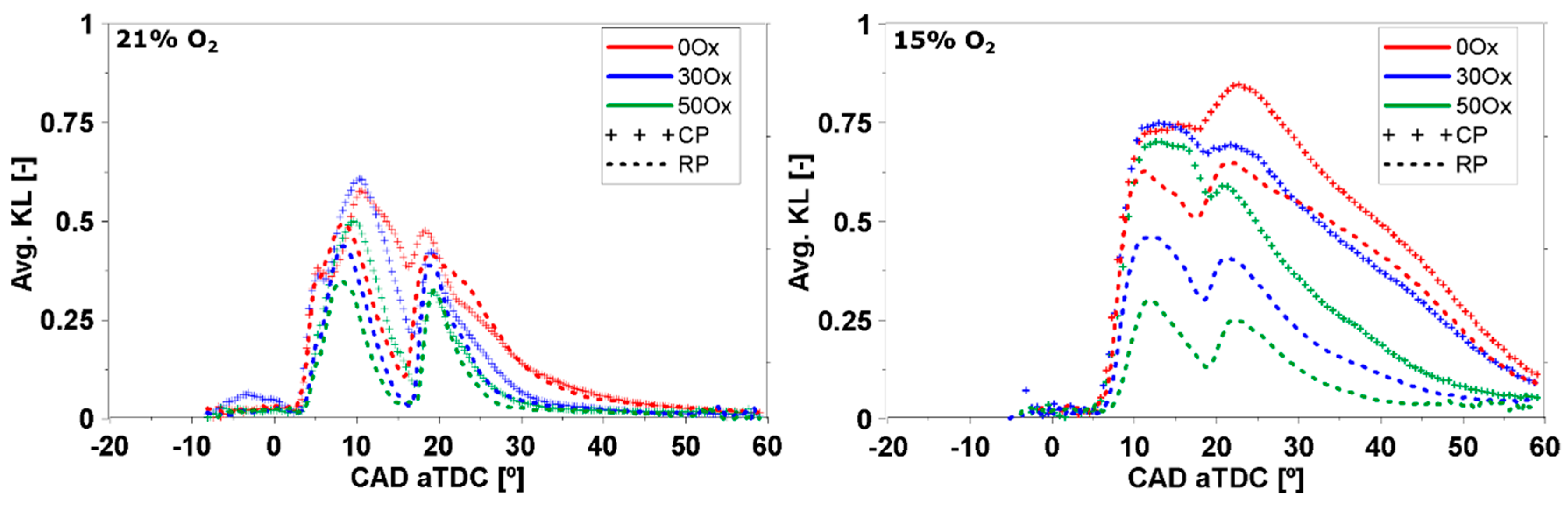

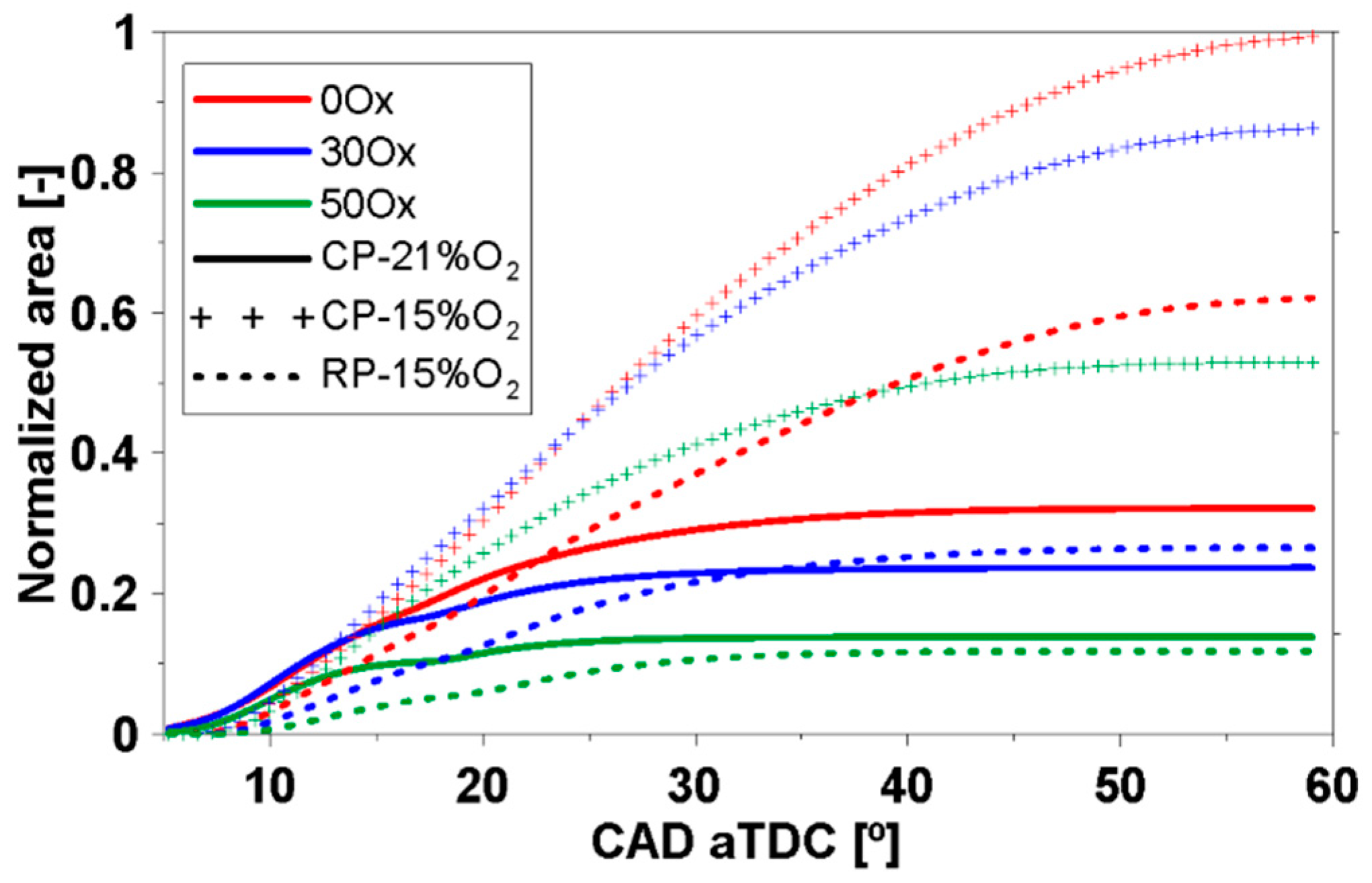

3.1. Conventional Piston

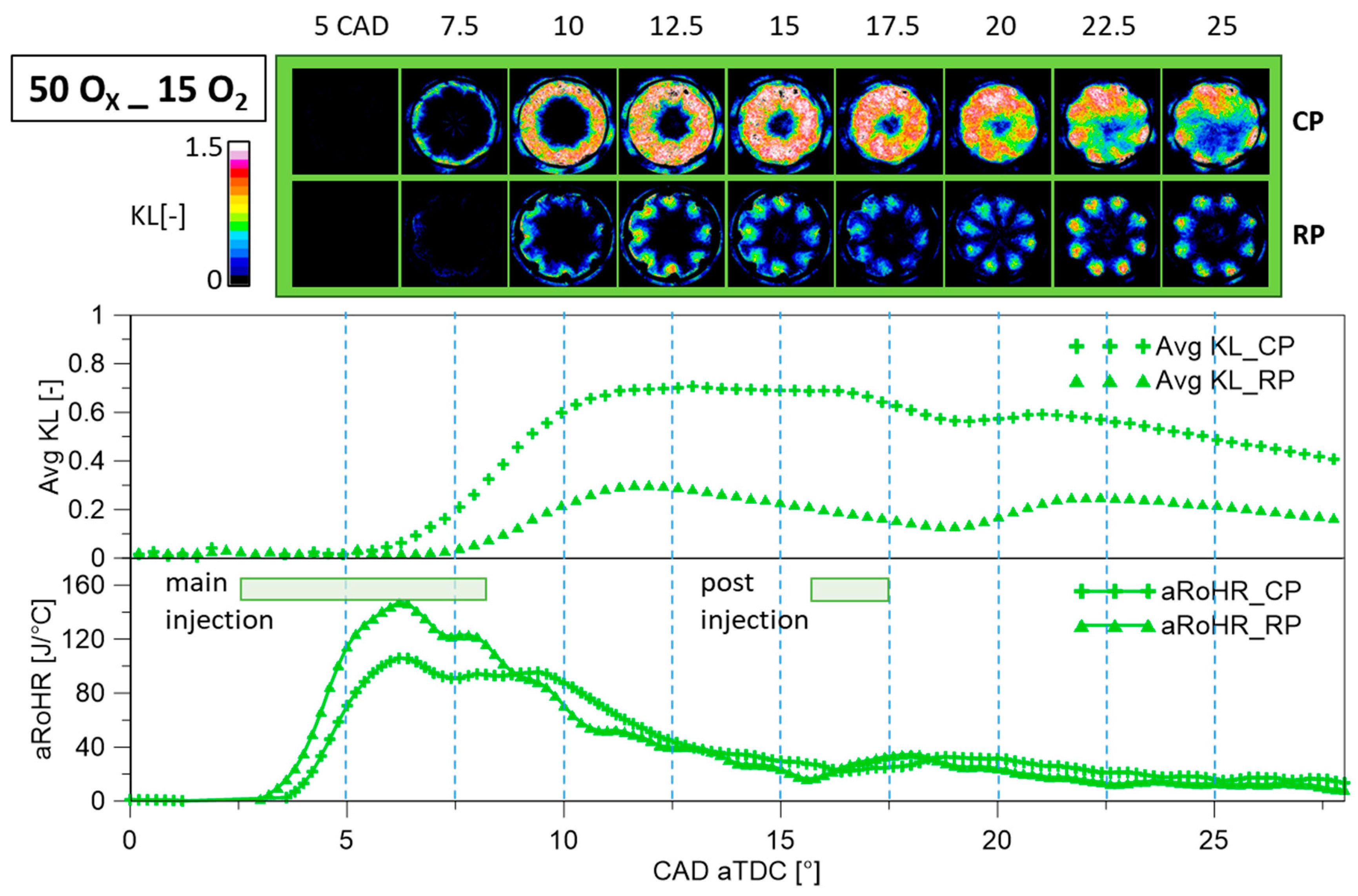

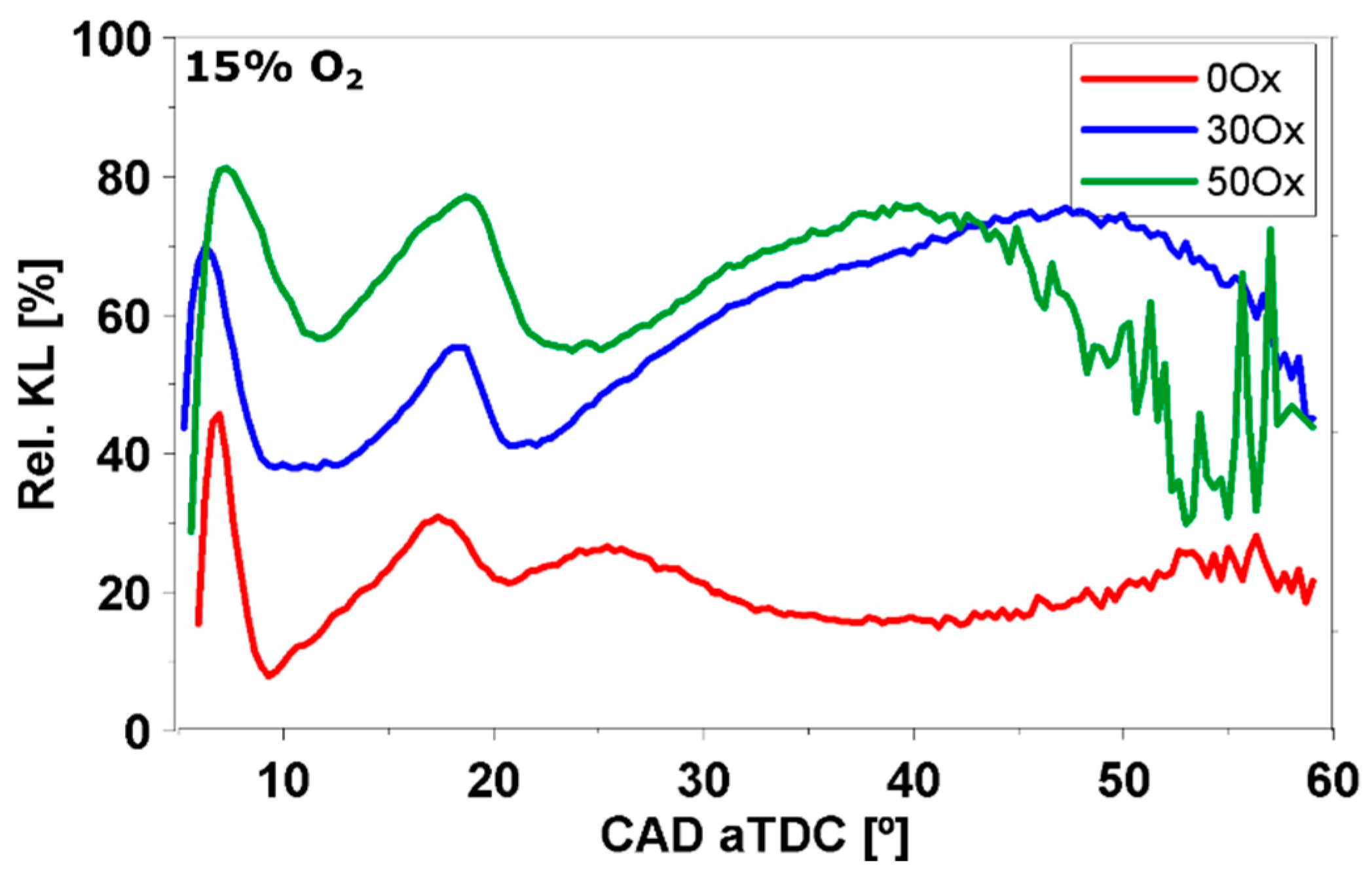

3.2. Radial-Lips Piston

4. Summary and Conclusions

- At no-EGR condition (21% O2), the reduction of KL is more prominent when increasing the OMEX quantity in the blend, which agrees with what can be found in the literature.

- The OMEX content in the blend reduces the amount of soot formed, even at 15% O2. However, results confirm that only OMEX (up to 50%) is insufficient to avoid the increase because of the reduction of ambient oxygen.

- The avoidance of flame-to-flame interaction achieved by the radial-lips feature results in lower soot formation close to the bowl wall. In addition, the redirection of flames toward the center of the piston takes advantage of the oxygen available and significantly improves soot oxidation.

- The addition of OMEX improves the radial-lips piston geometry benefits. In the most unfavorable condition (15% O2), the addition of OMEX can extend the KL reduction achieved by the novel piston geometry from 17% (0 Ox) up to 70% (50 Ox) during the late stage of combustion.

- Results show that 30% and 50% OMEX in the blend, in combination with the radial-lips piston, can provide similar soot levels with 15% and 21% O2. This confirms the potential of this combined solution to reduce soot levels when using EGR significantly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EU | European Union. |

| GHG | Greenhouse gas. |

| ICE | Internal combustion engine. |

| CI | Compression ignition. |

| SI | Spark ignition. |

| FCVs | Fuel cell vehicles. |

| WTW | Well-to-wheels. |

| OMEn | Oxymethylene dimethyl ether |

| CDS | Controlled diffusive spray. |

| UV | Ultraviolet. |

| CMOS | Complementary metal oxide semiconductor. |

| OH* | Excited state hydroxyl radical. |

| 2C | 2-Color pyrometry. |

| CP | Conventional piston. |

| RP | Radial-lips piston. |

| CAD | Crank angle degree. |

| aRoHR | The apparent rate of heat release. |

| BMEP | Break mean effective pressure. |

| Tint | Intake temperature. |

| Pinj | Injection pressure. |

| Pint | Intake pressure. |

| Pexh | Exhaust pressure. |

| SOE | Start of energizing. |

| % O2 | Oxygen concentration (volume) |

| EGR | Exhaust gas recirculation. |

| FWHM | Full width half maximum. |

| KL | Soot optical thickness. |

| LHV | Lower heating value. |

| aTDC | After the top dead center. |

References

- Air Pollution—European Environment Agency n.d. Available online: https://www.eea.europa.eu/themes/air (accessed on 13 December 2022).

- Al Ezzi, A.; Fayad, M.A.; Al Jubori, A.M.; Jaber, A.A.; Alsadawi, L.A.; Dhahad, H.A.; Chaichan, M.T.; Yusaf, T. Influence of fuel injection pressure and RME on combustion, NO emissions and soot nanoparticles characteristics in common-rail HSDI diesel engine. Int. J. Thermofluids 2022, 15, 100173. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Performance analysis and exhaust emissions of aegle methyl ester operated compression ignition engine. Therm. Sci. Eng. Prog. 2019, 12, 100354. [Google Scholar] [CrossRef]

- Chaurasiya, P.K.; Rajak, U.; Veza, I.; Verma, T.N.; Ağbulut, Ü. Influence of injection timing on performance, combustion and emission characteristics of a diesel engine running on hydrogen-diethyl ether, n-butanol and biodiesel blends. Int. J. Hydrogen Energy 2022, 47, 18182–18193. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Li, Y.; Zheng, Y.; He, T.; Wang, J. Recent progress in the application in compression ignition engines and the synthesis technologies of polyoxymethylene dimethyl ethers. Appl. Energy 2019, 233–234, 599–611. [Google Scholar] [CrossRef]

- Chen, H.; Su, X.; He, J.; Zhang, P.; Xu, H.; Zhou, C. Investigation on combustion characteristics of cyclopentanol/diesel fuel blends in an optical engine. Renew. Energy 2021, 167, 811–829. [Google Scholar] [CrossRef]

- Pöllmann, S.; Härtl, M.; Jaensch, M.; Wachtmeister, G. Evaluation of strategies to optimize engine efficiency and NOx emissions with the synthetic diesel fuel oxymethylene ether. Int. J. Engine Res. 2023, 146808742211448. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Sari, R. Clean and efficient dual-fuel combustion using OMEx as high reactivity fuel: Comparison to diesel-gasoline calibration. Energy Convers. Manag. 2020, 216, 112953. [Google Scholar] [CrossRef]

- Xu, Z.; Duan, X.; Liu, Y.; Deng, B.; Liu, J. Spray combustion and soot formation characteristics of the acetone-butanol-ethanol/diesel blends under diesel engine-relevant conditions. Fuel 2020, 280, 118483. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, S.; Guo, X.; Jia, C.; Huang, X.; Wang, Y.; Huang, H. Experimental Research on the Macroscopic and Microscopic Spray Characteristics of Diesel-PODE3–4 Blends. Energies 2021, 14, 5559. [Google Scholar] [CrossRef]

- Lin, Q.; Tay, K.L.; Zhao, F.; Yang, W. Enabling robust simulation of polyoxymethylene dimethyl ether 3 (PODE3) combustion in engines. Int. J. Engine Res. 2022, 2022, 1522–1542. [Google Scholar] [CrossRef]

- Benajes, J.; Garcia-Oliver, J.M.; Pastor, J.M.; De Leon-Ceriani, D. Unsteady Flamelet modeling study on OMEx-type fuels under Engine Combustion Network Spray A conditions. Fuel 2023, 331, 125458. [Google Scholar] [CrossRef]

- Pastor, J.V.; García, A.; Micó, C.; Lewiski, F. Simultaneous high-speed spectroscopy and 2-color pyrometry analysis in an optical compression ignition engine fueled with OMEX-diesel blends. Combust. Flame 2021, 230, 111437. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Wang, P.; Sun, P.; Liu, H.; Meng, Z.; Zhang, L.; Ma, H. An overview of polyoxymethylene dimethyl ethers as alternative fuel for compression ignition engines. Fuel 2022, 318, 123582. [Google Scholar] [CrossRef]

- He, J.; Chen, H.; Su, X.; Xie, B.; Li, Q. Combustion Study of Polyoxymethylene Dimethyl Ethers and Diesel Blend Fuels on an Optical Engine. Energies 2021, 14, 4608. [Google Scholar] [CrossRef]

- García, A.; Gil, A.; Monsalve-Serrano, J.L.; Sari, R.L. OMEx-diesel blends as high reactivity fuel for ultra-low NOx and soot emissions in the dual-mode dual-fuel combustion strategy. Fuel 2020, 275, 117898. [Google Scholar] [CrossRef]

- Martins, J.; Brito, F.P. Alternative Fuels for Internal Combustion Engines. Energies 2020, 13, 4086. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, Y.; Zhu, Z.; Zhu, X.; Gu, H.; Liu, S. Effect of PODE on Emission Characteristics of a China VI Heavy-Duty Diesel Engine. Appl. Sci. 2022, 12, 1108. [Google Scholar] [CrossRef]

- Tornatore, C.; Bozza, F.; De Bellis, V.; Teodosio, L.; Valentino, G.; Marchitto, L. Experimental and numerical study on the influence of cooled EGR on knock tendency, performance and emissions of a downsized spark-ignition engine. Energy 2019, 172, 968–976. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, C.; Zhu, Z.; Zhang, Y.; He, D.; Liu, S. Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends. Appl. Sci. 2022, 12, 12556. [Google Scholar] [CrossRef]

- Kakaee, A.-H.; Nasiri-Toosi, A.; Partovi, B.; Paykani, A. Effects of piston bowl geometry on combustion and emissions characteristics of a natural gas/diesel RCCI engine. Appl. Therm. Eng. 2016, 102, 1462–1472. [Google Scholar] [CrossRef]

- Temizer, I.; Cihan, O. Effect of piston geometry on combustion characteristics of CI engine used Sal seed oil. Int. J. Engine Res. 2022, 146808742211434. [Google Scholar] [CrossRef]

- Pham, V.C.; Kim, J.K.; Lee, W.-J.; Choe, S.-J.; Le, V.V.; Choi, J.-H. Effects of Piston Bowl Geometry on Combustion and Emissions of a Four-Stroke Heavy-Duty Diesel Marine Engine. Appl. Sci. 2022, 12, 13012. [Google Scholar] [CrossRef]

- Pastor, J.V.; Micó, C.; Lewiski, F.; Tejada, F.J.; Vassallo, A. Innovative diesel piston geometries for soot emissions reduction and cleaner combustion: An optical investigation. In Proceedings of the Thiesel 2022 Conference on Thermo- and Fluid Dynamics of Clean Propulsion Powerplants, Valencia, Spain, 13–16 September 2022. [Google Scholar]

- Eismark, J.; Andersson, M.; Christensen, M.; Karlsson, A.; Denbratt, I. Role of Piston Bowl Shape to Enhance Late-Cycle Soot Oxidation in Low-Swirl Diesel Combustion. SAE Int. J. Engines 2019, 12, 233–249. [Google Scholar] [CrossRef]

- Smith, A. Ricardo Low Emissions Combustion Technology Helps JCB Create the Off-Highway Industry’s Cleanest Engine; Ricardo Press: Shoreham-by-Sea, UK, 2010; pp. 4–6. [Google Scholar]

- Neely, G.D.; Sasaki, S.; Sono, H. Investigation of Alternative Combustion Crossing Stoichiometric Air Fuel Ratio for Clean Diesels; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Di Blasio, G.; Ianniello, R.; Beatrice, C.; Pesce, F.C.; Vassallo, A.; Belgiorno, G. Experimental Investigation on an Innovative Additive Manufacturing-Enabled Diesel Piston Design to improve Engine-out Emissions and Thermal Efficiency beyond Euro6. In Proceedings of the THIESEL 2020 Conference on Thermo- and Fluid Dynamic Processes in Direct Injection Engines, Valencia, Spain, 8–11 September 2020. [Google Scholar]

- Di Blasio, G.; Ianniello, R.; Beatrice, C.; Pesce, F.C.; Vassallo, A.; Belgiorno, G. Additive manufacturing new piston design and injection strategies for highly efficient and ultra-low emissions combustion in view of 2030 targets. Fuel 2023, 346, 128270. [Google Scholar] [CrossRef]

- Serizawa, K.; Ueda, D.; Mikami, N.; Tomida, Y.; Weber, J. Realizing Robust Combustion with High Response Diesel Injector with Controlled Diffusive Spray Nozzle and Closed Loop Injection Control; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Tu, P.-W.; Xu, H.; Srivastava, D.K.; Dean, K.; Jing, D.; Cao, L.; Weall, A.; Venus, J.K. Numerical Investigation of GDI Injector Nozzle Geometry on Spray Characteristics; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Payri, R.; De La Morena, J.; Monsalve-Serrano, J.; Pesce, F.C.; Vassallo, A. Impact of counter-bore nozzle on the combustion process and exhaust emissions for light-duty diesel engine application. Int. J. Engine Res. 2018, 20, 46–57. [Google Scholar] [CrossRef]

- Payri, R.; Hardy, G.; Gimeno, J.; Bautista, A. Analysis of counterbore effect in five diesel common rail injectors. Exp. Therm. Fluid Sci. 2019, 107, 69–78. [Google Scholar] [CrossRef]

- Pastor, J.V.; Olmeda, P.; Martín, J.; Lewiski, F. Methodology for Optical Engine Characterization by Means of the Combination of Experimental and Modeling Techniques. Appl. Sci. 2018, 8, 2571. [Google Scholar] [CrossRef]

- Higgins, B.; Siebers, D.L. Measurement of the Flame Lift-Off Location on DI Diesel Sprays Using OH Chemiluminescence; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Dec, J.E.; Coy, E.B. OH Radical Imaging in a DI Diesel Engine and the Structure of the Early Diffusion Flame; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1996. [Google Scholar] [CrossRef]

- Zhao, H. Laser Diagnostics and Optical Measurement Techniques in Internal Combustion Engines; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Lowe, D.G. Distinctive Image Features from Scale-Invariant Keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of cylinders [-] | 1 |

| Number of valves [-] | 4 |

| Compression ratio | 13.3 |

| Stroke/Bore | ~1 |

| Displacement [L] | ~0.8 |

| Operating Conditions | |

|---|---|

| Piston bowl | Conventional/Radial-lips |

| Engine speed [rpm] | 1400 |

| Injector | CDS |

| BMEP [bar] | 6 |

| Inj. Scheduling & Rail Pressure | Multiple @ 1182 bar |

| Intake pressure [bar] | 1.34 |

| Exhaust pressure [bar] | 1.54 |

| EN 590 Diesel | OMEX | |

|---|---|---|

| Density [kg/m3] (T = 15 °C) | 829.20 | 1057.10 |

| Viscosity [mm2/s] (T = 40 °C) | 2.59 | 1.08 |

| Lubricity [µm] | 386 | 320 |

| Cetane number [-] | 52.0 | 68.6 |

| Carbon content [% m/m] | 86.2 | 44.2 |

| Hydrogen content [% m/m] | 13.8 | 8.8 |

| Oxygen content [% m/m] | 0 | 45 |

| Lower heating value [MJ/kg] | 41.92 | 19.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pastor, J.V.; Micó, C.; Lewiski, F.; Tejada, F.J.; Tornatore, C. A Synergic Application of High-Oxygenated E-Fuels and New Bowl Designs for Low Soot Emissions: An Optical Analysis. Appl. Sci. 2023, 13, 8560. https://doi.org/10.3390/app13148560

Pastor JV, Micó C, Lewiski F, Tejada FJ, Tornatore C. A Synergic Application of High-Oxygenated E-Fuels and New Bowl Designs for Low Soot Emissions: An Optical Analysis. Applied Sciences. 2023; 13(14):8560. https://doi.org/10.3390/app13148560

Chicago/Turabian StylePastor, José V., Carlos Micó, Felipe Lewiski, Francisco J. Tejada, and Cinzia Tornatore. 2023. "A Synergic Application of High-Oxygenated E-Fuels and New Bowl Designs for Low Soot Emissions: An Optical Analysis" Applied Sciences 13, no. 14: 8560. https://doi.org/10.3390/app13148560

APA StylePastor, J. V., Micó, C., Lewiski, F., Tejada, F. J., & Tornatore, C. (2023). A Synergic Application of High-Oxygenated E-Fuels and New Bowl Designs for Low Soot Emissions: An Optical Analysis. Applied Sciences, 13(14), 8560. https://doi.org/10.3390/app13148560