Abstract

Industry 4.0 will not only change what we are and what we do, but also who we are. As a result of the rapid introduction of new technologies, which is characteristic for Industry 4.0, there will be a change in the labour market. It allows people, things and machines to be connected in real time, thus ensuring that the necessary information is exchanged between them. There are advantages, but also negatives: one of the impacts of Industry 4.0 is the gradual transformation of the labour market, leading to a demand for new professional skills and the digitalisation of work. Thus, it brings with it the need for employees to adapt to the changing sub-conditions of the labour market. The aim of this article is to identify and highlight the need for changes in the field of competences in connection with the application of Industry 4.0 methods and techniques. For the purpose of this research, a valid data collection instrument (questionnaire for the research) was developed and distributed to enterprises in the field of selected industry sectors in the Slovak Republic. In total, the research sample consisted of n = 556 respondents. On the basis of the obtained results, we conclude that early identification of future needs in terms of competences gives the possibility of setting up training activities aimed at acquiring new, missing and needed-for-the-future competences of employees.

1. Introduction

In recent years, a new paradigm—the so-called fourth industrial revolution—has been defined with the potential to take industrial processes to higher level [1]. Industry 4.0 can be defined as an industrial vision that enables the interconnection of people, things, and machines in real time, thus interconnecting the necessary information between them. The new trend represented by the fourth industrial revolution of connecting digital and physical systems creates new challenges for organisations in their search for new ways of how to apply the concepts of Industry 4.0 and to prepare the workforce for it. Realising the full potential of Industry 4.0 is linked to companies’ need to understand the new technologies and their opportunities [2]. Industry 4.0 generates notable benefits which lead to a rise in productivity and customer satisfaction, and an enhanced ability for innovation [3].

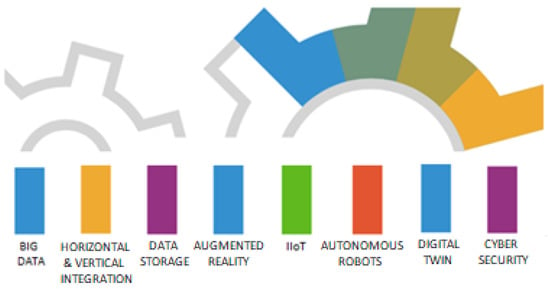

Industry 4.0 concentrates on intelligent processes within the industrial system, these processes being driven by technologies classified as digital such as IoT, Big Data, CPS and Cloud Computing (see Figure 1) provide continuous data capture and also, by utilisation of intelligent sensors, a real-time monitoring of individual processes. The entire system of process monitoring, data collection and data processing is mainly implemented by using the Internet and transferring this captured data to large storages within the organisation [4]. Industry 4.0 brings new solutions to achieve flexibility and high performance, allowing machines to communicate with each other and use all data inside and outside the industrial process. This allows machines and equipment to operate autonomously and efficiently. This also makes the communication between machines and humans easier, whatever their location, and enables the interaction of multiple devices [5].

Figure 1.

Technology pillars of Industry 4.0 (own processing).

Despite the fact that Industry 4.0 is still in its early stages, a lot of business leaders and digital visionaries are already looking ahead to Industry 5.0, which will involve autonomous manufacturing as well as human intelligence and personalisable autonomous manufacturing. Three billion more individuals are expected to access the Internet by 2025 due to the Internet’s rapid growth and dispersion. Because change is inevitable, but success is not, we should put a lot of time and care into what we are doing and what we want to do [6].

Internet of Things (IoT)

As we begin to move towards intelligent organisations in the fourth industrial revolution, communication and simultaneous access to information will take place within the organisation as a whole rather than just between individuals. The Internet of Things will be used by every object (human or machine), defined in a cyber–physical system for communication [7].

With the facilitation of any network or path, the Internet of Things (IoT) makes it possible to link people and things at anytime, anywhere, with anything and anybody. The term “IIoT” refers to the application of IoT in industrial organisations and describes how the technology is being integrated into the industry by connecting sensors, control systems, connected machines and devices, Big Data and security [8].

Cloud Computing

In conjunction with IoT, cloud computing makes it possible to store, process, and analyse enormous amounts of data, which helps to execute large-scale simulations of numerous aspects of industrial organisations [9,10]. According to Legashev’s research, one of the most popular technical approaches for data collection, processing and further usage in the corporate environment is Cloud computing [11].

CPS

Cyber–physical systems integrate data, communications, the Internet, and services with the real world and the virtual world of IT and software. The implementation of CPS by conducting using of the IoT in industrial organisations contributes to the creation of enormous quantities of data that are both difficult to analyse and important. Big Data analysis is used to efficiently analyse enormous data quantities, allowing for the production of useful results and an assessment of Big Data’s genuine value [8].

Big Data

Significant data and information quantities are generated and collected as a result of both the Internet’s and Industry 4.0’s dynamic development. Their processing and analysis are more advanced than what can be done using conventional methods. Big Data enables quick and effective management of a continually expanding database. Big Data technology makes it feasible to analyse and separate significant information and data from less significant ones, helps to reach common conclusions and further supports the effective transfer of knowledge to achieve strategic objectives. This technology also processes and combines data that has been collected from various independent systems, databases, and websites to provide a complete view of the situation [12]. According to Sadiku et al. [13], industrial organisations are utilising big data analytics for the reasons listed below:

- Taking ownership of a lot of generated data;

- Using this data to facilitate decision-making and boost productivity.

In 2020, a survey was conducted on the level of digital transformation in industrial organisations in Slovakia. It revealed that organisations are stagnating in digitalisation and lagging behind in the implementation of Industry 4.0 opportunities. The biggest problem for Slovak organisations is building application teams and preparing implementation strategies. The COVID-19 had also a big impact on the implementation of changes, when organisations realised that they would cope with the situation better if they were digitalised [14]. At the end of 2022, a survey on the level of digitalisation and implementation of Industry 4.0 in Slovak organisations was conducted again, with the results showing that just under a quarter of organisations are implementing changes. There are still problems in Slovak organisations with building application teams and with preparing implementation strategies. However, the difficult economic situation, global crises and especially the lack of knowledge about digitalisation in the industry also contribute to the problems with the introduction of changes. Companies that have Slovak capital and no parent companies abroad have even greater problems as they have no one from whom to take over the knowledge in the field of implementing change [14].

1.1. The Changing Labour Market as a Result of Industry 4.0

The Industry 4.0 will not only change what we are and what we do, but also who we are [15]. The labour market is subject to changes driven by various factors such as demographic developments, performance in economic cycles but also because of the surge in the adoption of new technologies, which is characteristic of Industry 4.0 [16]. Accordingly, one of the impacts of Industry 4.0 is the gradual transformation of the labour market, which leads to a query for new professional skills and the digitalisation of workplaces that the labour force has been a historically performing [17]. The natural consequence is then changes in the skill requirements of the workforce and the labour market in general. This is followed by the need for new principles of work organisation, a change in the employer’s role and, naturally, changes in the structure of most professions [16].

As a result of the development of new technologies and the implementation of the Industry 4.0 concept in industrial processes, we are facing many changes in the form of employment, worker requirements and job creation. Humans will work in better interaction with machines [18]. The basis of Industry 4.0 innovation is the intense connection between the technological subsystem and the human workforce. The positive impact will be a decrease in physically demanding manual jobs [19]. At the same time, it also brings with it the challenges of creating new, more flexible and less physically demanding jobs as well as positions that have not been needed so far, or adjusting those jobs that can be potentially transformed. On the other hand, jobs that can be fully replaced by automation or the implementation of artificial intelligence will in the end disappear.

The introduction of the smart industry is thus steadily creating new jobs that did not exist before. These positions can be directly but also indirectly related to the introduction of Industry 4.0. Directly, the expansion and implementation of Industry 4.0 is having an impact on the creation of new jobs for workers finding employment in scientific and technical fields and also support services. Employees indirectly have more free time and are willing to shift their resources into activities that they previously had more as a hobby (leisure activities, sports, education, various services) and this is where the space for the creation of new jobs opens [20,21].

It is important to understand the essence of the degree of interdependence between technology and other elements of the process. Increasing the productivity of the production system is possible because of the use of sensors, robots and new technologies. In addition, because of the need to analyze and work with huge amounts of data, it is imperative to use new working approaches as discussed in [17,22]:

- Techniques and methods (processes and resources);

- Management (organisation and measurement of performance);

- People (skills, thinking and behaviour).

1.2. COVID-19 as a Catalyst for Labour Market Change

The economic shutdowns triggered by the COVID-19 pandemic and the related global recession in 2020 have created a very uncertain labour market outlook and accelerated the onset of the future of labour. Skilled labour shortages are not a new phenomenon and were already a problem in Slovakia in the days before the COVID-19 crisis [23]. The COVID-19 crisis was specific in that some sectors were severely affected, with workers from these sectors facing large outflows and job instability forcing them to seek other ways of using their labour [24]. The World Economic Forum (WEF) has published the Future of Jobs 2020, which maps the jobs and skills of the future and tracks the pace of these changes [23]. UPSVaR data shows that the COVID-19 crisis also had a major impact on the loss of labour that had previously flowed into Slovakia from other countries at an increased rate [24].

The massive decline was reflected in the reduction of all professions, but the most significant departure from the Slovak market was of machine and equipment operators, who are also the largest number of people employed on the market. The change in labour market trends is also confirmed by the Manpowergroup survey. According to the survey, up to 68% of Slovak employers stated that they have difficulties in recruiting new employees regardless of the company size, and in SMEs this problem is even more noticeable [24].

Currently, the Slovak labour market is struggling with a shortage of employees in certain occupations specified by the most well-known job portals and professional organisations in their internal statistics, namely: teachers, nurses/sanitarians, waiters/waitresses, agricultural and food production technicians, bricklayers, chauffeurs/cooks, machinists, information technology workers and production operators [25].

These statistics are confirmed by the questionnaire surveys carried out so far, the results of which show that there is a clear demand for workers from the industrial engineering/mechanical engineering, manufacturing and construction sectors. The second area where the greatest demand for labour is currently found is information sciences and communication technologies. Another significant area where employers are experiencing a shortage of workers is in the area of health and social services. The next fields of employment where an overwhelming majority of employers are experiencing a shortage of workers are services, natural sciences, mathematics and statistics, agriculture, forestry, fishing and veterinary medicine. On the contrary, employers experience the least shortage of available workforce in fields such as workers with arts and humanities education, as well as graduates of social sciences, journalism and information [16]. Summarising these results, it can be stated that the Slovak labour market is in urgent need of technical workers in engineering, manufacturing, construction, information science and communication technology and specialists in all areas of health care and social care.

Paradoxically, the COVID-19 pandemic accelerated some trends as some activities had to be digitalised. The digitalisation of many areas has also led to a more rapid change in the demands on the workforce. This is also confirmed by the aforementioned Manpowergroup survey. Employers are looking more for employees with soft skills, such as responsibility, resilience, reasoning and creativity. At the same time, they are also looking for people with more knowledge of digital technologies. Processes are changing through robotics and software upgrades, which calls for a greater need to retrain the labour force.

Several employers have already reconsidered their approach to employment based on the experience of the pandemic, and a large number of Slovak companies have expressed a desire to allow their employees greater flexibility even in jobs that are perceived as inflexible. Specific measures taken by employers include: flexible start and end of working hours; a mixed model of remote and on-site working; the introduction of flexible or condensed working hours; shared workplaces; or the possibility of individual choice of the location from which an employee wants to work [24].

1.3. The Future Work Force for Industry 4.0

The Fourth Industrial Revolution affects the requirements of the current workforce, which will in many cases be forced to retrain, but it also affects the requirements of the workforce that is yet to come on the labour market in the future. The impact of Industry 4.0 will be that industrial job positions will decline and many of those positions will move to the service sector. The skills requirements of the workforce will change under the impact of these changes. There will also be a fundamental change in the requirements for education. Inequalities can already be observed today, which in many cases should have been addressed several years ago. Early identification of the need for changes in the educational structure will ultimately help the Slovak economy to remain competitive [16]. These conclusions were also agreed upon by experts, for example at the Skills for an Unknown Future conference. The scientific community is aware of the change in the content of professions: many professions are disappearing, and others are emerging and this is connected with the need for a person to change their profession several times in their lifetime [26].

Industry 4.0 therefore brings with it the need for a workforce to adapt to changing labour market conditions. The ability to learn and adapt to new workplace conditions and the new demands that employers will place on the workforce is coming to the fore [27]. Communication, creativity, technical literacy and learning will become key skills in the new conditions of Industry 4.0 [28].

It is estimated that labour substitution will threaten 55% of jobs in Slovakia [29]. In response to these changes, Slovakia will need to take steps to adapt to this major market shift [30].

The vision of Industry 4.0 will therefore have a major impact on the skills required in the labour market. The need to consider their social impact will become a necessity. These impacts will lead to new principles of work organisation, from changing the employer’s role, to changes in the structure and skills that will be in the job description of most professions, which will be completely changed, and there will be impacts on the development of employment and unemployment, which will require a new policy framework for the labour market and education [31].

The need to improve the digital skills of European citizens has also been addressed by the European Commission, which has called on EU Member States to develop digital skills early at all levels of education and training and to promote quality digital literacy in schools, to promote the development of digital skills in adults and to address shortages in IT professions by adopting inclusive strategies.

This is driven by the rise of automation, which will bring people into new areas of activity. Instead of manual work, employees will be tasked with controlling robots, for example. In the past, working with computers and modern technology was the job of only some professions, but today no one can afford to avoid it. We must also take into account the massive development of artificial intelligence, whose impact on the labour market will be so intense that 65% of today’s children in primary education, after obtaining a diploma or degree, will in the future enter jobs that do not even exist today. Artificial intelligence will not only automate manual work, but experts say it will also change the type of work that employees do [26].

New professions are expected to emerge in the next 10–20 years as a result of the development of new technologies. In particular, they will be used in industrial practice [26]:

- Expert in labour relations between people and machines—new demands will be placed not only on the workers themselves, but also on current and future managers. Managers will have to harmonise the functioning of people and machines in the company, for which they must, in addition to knowledge of HR and psychology, also have at least a partial knowledge of informatics or engineering.

- Drone transport dispatcher—they will coordinate drone transport and analyse or provide service of individual machines. The new generation of transport should move into the air (parcel transport or road traffic control).

- Cyber Attack Predictor—in addition to attacks on individuals and malware, we are already seeing attacks on some governments in modern times. Therefore, the ability of states or organisations to predict such events will be key to ensuring their security. This is also reflected in the growing interest in cybersecurity professionals who can predict such crises.

The digitalisation of jobs will have both positive and negative impacts for employees. Employees performing stereotypical manual jobs will probably be forced to retrain and change jobs, and the group of employees without the required technical skills will not be able to get a job anymore. Research to date confirms that more jobs will be created than lost, but these will be altered or even entirely new (based on data from WEF Future of Jobs 2023 [32]. Several foresight analyses suggest that the positive impacts of technology adoption on job creation offset the job losses associated with automation. Automation affects indirect employment growth in industry and consumer sectors and increases overall demand, which ultimately leads to net employment growth. However, the current labour market is not adapted to the rapid development of technology, especially in terms of the digital skills of employees. Disparities can occur if certain groups of people choose not to adapt to developments, not to widen their skills and expect to be exempted from these changes, which is not the case. It becomes necessary to retrain and supplement the digital skills not only of older people who do not have them yet but also of younger employees who, in many cases, have graduated in fields that are not in demand in the labour market in the long term [33].

1.4. Industry 4.0 and Agility

Industry 4.0 is creating a new, dynamic environment. Leaders should learn new management behaviours for the need to communicate with both the internal and external environment of their organisations. This is possible by adopting the strategies of agile management [34]. According to the literature, Industry 4.0 is a way for enterprises to markedly enhance their dynamic capability of agility [35]. Agility is the ability to create and respond to change. It is a way of dealing with, and ultimately succeeding in, an uncertain and turbulent environment [36]. According to The Oxford English Dictionary: “agility is a term meaning the ability to think quickly and in an intelligent way” [37].

The terminology of agility is understood in a number of different ways. It can be viewed as a set of behaviors, concepts, and techniques that are characteristic of agile ways of working. At the core of agile management are shared values and behaviours. Agile teams are mixed, consisting of developers, analysts, testers and customer representatives. Team members have diverse skills and experience and are motivated to move forward together [38]. The agile team must be self-organised [39] and is responsible for managing the planning process, independently assigning activities and ensuring that all assigned activities are carried out to a high quality and as agreed in advance with those involved in the project [40,41]. The agile team is formed of experts from different fields. However, there is a certain set of competencies that is common to them. In the context of the needs of Industry 4.0, people with competences that cannot be replaced by automation and digitalisation will increasingly be in demand on the labour market. At the same time, it is also necessary to adapt employees to the new demands. Universal, so-called transferable competences are considered to be the most required competences [42]. The key competencies (Table 1—completely self-processed, based on IPMA guide [43]—a table with competencies is not included in this guide) that organisations need to foster in Industry 4.0 and for agility are:

Table 1.

Key competences in the context of Industry 4.0 and Agile (Own processing based on [43]).

- Social competences: Social competences are determined by empathy and social skills [44]. They create social behaviours that enable and facilitate the establishment and maintenance of positive interpersonal relationships [45].

- Technical competencies: Up-to-date knowledge, technical skills, process knowledge, media skills, coding, understanding of cyber security [42]. Agile technical competencies also include agile development. Agile development competencies help define success in any role that requires expertise of the agile method: agile frameworks and concepts, agile planning, agile product management, agile scaling frameworks, agile team management, agile tooling, building agile acumen [46].

- Behavioural competences: Behavioral competencies help make better talent decisions based on the specific behaviors and soft skills that drive organisation forward. This type of competencies can be explained as the sum of traits, abilities and motivations needed to deliver effective performance, regardless of job in an organisation [47].

If you want to achieve business agility, it is recommended that you master the competencies defined in SAFe® (ScaledAgile framework) [48]. SAFe® is a set of organisational and workflow patterns for implementing agile practices [49]. SAFe® talks about seven competencies. For each competency there is a series of practices, activities or artifacts that help to improve that competency: lean–agile leadership, team and technical agility, agile product delivery, organisation solution delivery, lean portfolio management, organisational agility, continuous learning culture [48]. SAFe® is a body of knowledge that incorporates frameworks such as Scrum, Extreme Programming, Kanban and Lean at the team level [50].

2. Materials and Methods

The aim of this research is to identify and highlight the need for changes in the area of competences in the context of the application of Industry 4.0 methods and techniques.

Empirical data on the subject of this research were collected on the basis of a scientific questionnaire, which was designed on the basis of a study of the literature, available publications in the field and the experience of the authors of the paper, and was validated by expert judgement in a pilot survey. It contained 37 closed-ended questions, with the first part focused on the identification and demographic characteristics of the respondents. With regard to the focus of the subject of this research publication, only a part of the obtained data was used, which focused on the problematics of identification, use and the need to expand competences in accordance with the requirements of Industry 4.0. Given a descriptive explanation of pre-existing phenomena and facts, explanatory research that seeks an explanation for a particular phenomenon was used.

Basic thought processes such as analysis, synthesis, abstraction, concretisation, deduction, comparison, etc., were used to elaborate the paper. Data interpretation was handled through descriptive and quantitative statistical methods. Parametric and non-parametric statistical tests were used to test the relationships between dependent and independent variables. The collected data were processed using Microsoft Excel and IBM SPSS 22.0 (Statistical Package for the Social Sciences). The anonymity of the respondents was maintained in the processing of the results.

The research sample consisted of employees of industrial enterprises of all sizes in Slovakia, numbering 556 respondents. Out of this number, 80 (14%) of the respondents work in the public and state administration sector, 138 (25%) in the service sector and 338 (61%) in the industrial production sector. Given the thematic focus of our paper, we focus on selected organisations operating in the industrial sector. The selection of the industries included in the survey is based on the need to filter out industries that are not directly related to the automotive industry; given this, it can be declared that the sample studied is representative of the automotive industry and the supporting industries of this industry. The distribution of respondents operating in the selected sectors of the industry is presented in Table 2.

Table 2.

Selected sectors of industrial production (Source: own processing, 2023).

From the results of the questionnaire survey, we identified that 196 (76%) of the respondents belong to the category of large organisations (250 employees and above), 45 (17%) belong to the category of medium organisations (up to 249 employees) and 19 (7%) belong to the category of small organisations (10 to 49 employees). Micro-organisations (up to 10 employees) were excluded considering the focus of the paper.

In our sample, 57 (22%) employees are working as production employees, 87 (33%) are working as specialist employees, 65 (25%) are working as administrative employees and 51 (20%) respondents are working as managerial (management) employees.

3. Results

In achieving the objective stated above, the following research questions and hypotheses were defined and evaluated, statistically tested and interpreted. The results of the research may be influenced to some extent by the willingness to disclose unfavourable results on the part of the organisations that participated in the survey. Another factor may be the generational changes of managers, which often has a major impact on changes in processes, thinking and perceptions of the need for change.

- RQ1: Do you feel threatened by the introduction of new technologies in your organisation?

Based on the answers from the respondents (see Table 3), we can conclude that as many as 84 (33%) do not feel threatened by the introduction of new technologies into the organisation. Another 66 respondents (25%) assume that the introduction of new technologies will just positively affect their work. Conversely, 40 (15%) respondents think that new technologies will affect their work minimally. Among the respondents, there were also 28 (11%) who do not think about the introduction of new technologies at all. From the above results, we can observe that 42 (16%) of the respondents feel threatened by the introduction of new technologies, whether they are worried about their job, e.g., as a result of the COVID-19 pandemic. The results can be attributed to the fact that organisations do not dedicate enough space to communicate the benefits of the technological changes being introduced and, most importantly, do not communicate enough the fact that the main objective of introducing Industry 4.0 techniques and elements is not the targeted dehumanisation of the production process, but the facilitation of work with the aim of increasing performance.

Table 3.

Responses to the question “Do you feel threatened by the introduction of new technologies?” (Source: own processing, 2023).

Hypothesis 1 (H1).

There is a significant difference between employees in different positions and the feeling of threat from the introduction of new technologies.

The hypothesis was tested on the basis of job positions and the results are shown in Table 4. The hypothesis was tested by ChiSquare test and the strength of the correlation was determined by Cramer’s V and the results are shown in Table 5.

Table 4.

Results of Hypothesis 1 (Source: own processing, 2023).

Table 5.

Results of Hypothesis 1–Cramer’s V (Source: own processing, 2023).

Significance was found to be less than 0.05, meaning that we reject H0 at 0.05 level of significance, implying that there are significant differences among employees in their feelings of threat from the introduction of new technologies. According to the value of Cramer’s V, 0.231, the result is that the dependence between the variables is moderately strong.

- RQ2: In which aspect do you perceive your disadvantage as an employee, or when looking for a new job?

Respondents could select multiple choices for the above question (see Table 6). As many as 100 (20%) of respondents cited a lack of language skills as their biggest disadvantage as an employee or when looking for a new job in any position. The next most frequently identified option was 60 (12%) of respondents citing work experience in only one area. As many as 55 (11%) respondents cited age as a disadvantage. Since we did not examine the age structure of the respondents, both a low or high age are implied here. Interestingly, only 74 (15%) of the respondents stated that they did not feel any disadvantage due to the introduction of new technologies.

Table 6.

Responses to the question “In which aspect do you perceive your disadvantage as an employee, or when looking for a new job?” (Source: own processing, 2023).

Hypothesis 2 (H2).

There is a significant difference in the perception of one’s disadvantage as an employee in different job roles.

The hypothesis was tested on the basis of job positions and the results are shown in Table 7. The hypothesis was tested by ChiSquare test and the strength of the correlation was determined by Cramer’s V and the results are shown in Table 8.

Table 7.

Results of Hypothesis 2 (Source: own processing, 2023).

Table 8.

Results of Hypothesis 2—Cramer’s V (Source: own processing, 2023).

Significance was found to be greater than 0.05, which indicates that we do not reject H0 at the 0.05 level of significance and implies that there are no significant differences between employees in their feelings of disadvantage. Since the value of Cramer’s V is 0.144, the result is that the dependence between the variables is very weak.

- RQ3: Which competences (skills) do you consider most important in the light of digitalisation and automation of work (0 don’t know; 1 least important to 5 most important)?

In the following research question, we focused on the competencies (skills) that employees consider most important in the light of the digitalisation and automation of work. Respondents were given the opportunity to comment on the question using a Likert scale, with individual scores representing 0 (don’t know); 1 (least important) to 5 (most important). Table 9 shows the mean values of the responses, and we have removed the 0 rating (to eliminate distortion of the data due to don’t know responses). Digital skills and technical (‘professional’) skills were ranked as most important. Next in order is the ability to learn, and we can conclude that the most frequently mentioned abilities (skills) are closely related to the introduction of new Industry 4.0 technologies.

Table 9.

Average responses to RQ3 (Source: own processing, 2023).

Hypothesis 3 (H3).

There is a significant gap between employees in different roles in the skills needed in the context of digitalisation and automation of work.

The hypothesis was tested on the basis of job positions and verified using analysis of variance (ANOVA) and the results of the testing are presented in Table 10.

Table 10.

Analysis of variance (ANOVA) (Source: own processing, 2023).

For each skill category, the significance level came out greater than 0.05, i.e., we do not reject H0 at the significance level, which implies that there are no significant differences in the skills of employees in relation to digitisation and automation of work. For all tested jobs, individual skills are important, but their level depends on the nature of the work performed.

4. Discussion

The rapidly changing process of the technological and digital world is taking place in all areas and in all industries, as the business world is being transformed by the fourth industrial revolution [34]. As the conducted surveys have shown, Slovakia falls far behind developed countries in terms of the digital skills of its employees, but their education is the only route of change for future development. Industry 4.0 requires new skills and competences of employees, which is why it is essential to strengthen employee training! They need to have knowledge of ICT systems, self-matching technologies, data analysis, etc., in the context of application changes [14]. The early identification of future needs in terms of competences makes it possible to adjust training activities towards the acquirement of new, missing and necessary competences for the future.

Various studies specify the necessary key skills that successful workers should have in the future. The WEF’s report on the future of jobs identifies 10 key skills that today’s workforce should inevitably already possess, given that more than a third of skills are expected to change over a 5-year timeframe. These include: creativity, emotional intelligence, analytical thinking, active learning, judgement and decision making, interpersonal communication skills, leadership skills, diversity and cultural intelligence, technology skills, embracing change [51].

The need to improve key workforce skills is also being addressed by researchers at the Institute for the Future, who, in collaboration with the University of Phoenix, have released a study naming 10 key skills necessary for a successful workforce in the next decade, which we share, and which we are adding business agility to, based on the partial results of previous research. The qualities needed for success in the coming years are as follows from the IFF Future WorkSkills [52,53]:

- Sense-making—The ability to select only the relevant items from the data. Intelligent machines can take over routine production and services but there will still be demand for activities they do not control, such as understanding what numbers mean from data warehouses and spreadsheets from praxis.

- Social intelligence—Empathy, i.e., the ability to make deep and intense contact with others to sense and stimulate reactions and desired interactions, i.e., listening to them, understanding how they might be feeling and being able to adapt communication according to their needs. Given the globalisation of work, it is necessary to be able to function in an international environment, to understand not only the closest colleagues but also colleagues from different cultures with whom they will meet in the workplace or through virtual teams at a distance.

- Novel and Adaptive thinking—Positions requiring abstract thinking or manual tasks are becoming increasingly important. Both categories of roles require ‘situational adaptation’, i.e., the ability to respond to unique unexpected situations requiring new thinking and the ability to adapt, which will continue to be the domain of the human.

- Cross-cultural competency—The ability to work in different cultural environments. We are already in a globally connected world and businesses are often part of international conglomerates and not limited to just one country. With this comes the need to have the skills and abilities of workers (language skills, ability to adapt to changing circumstances, ability to perceive and respond to new contexts) to work in any geographic environment.

- Computitonal thinking—With the implementation of Industry 4.0 comes the processing of huge amounts of data—“big data”. As the amount of data that will need to be processed grows, businesses will also expect employees to have a basic understanding of programming and statistical methods. Employees will need to be able to select the essential data from the vast amount of data and learn to ignore the remaining information. Workers will need to be able to select the appropriate data, so they will need to be able to use tools that allow data to be filtered automatically.

- New media literacy—new media forms are now being used for communication. Text on the Internet is increasingly being replaced by photographs, videos, blogs and podcasts. This trend will also be transferred to the workplace. A new generation of workers will be forced to be fluent in forms such as video and be able to critically ‘read’ and evaluate in the same way they have previously evaluated texts or presentations. Thus, it will become increasingly important for content consumers not only to be able to select the relevant information from the quantum of information, but also to be able to comfortably create and present their own visual information. Working with graphic editors (video and photo editing), using games in business practice or excellent knowledge of social networking functionalities are prerequisites.

- Transdisciplinarity—Being specialised in only one field will be insufficient. There is a need to understand concepts in multiple disciplines. This implies the need to deepen continuous knowledge of the field in which the worker is an expert but at the same time to take an active interest in developments in other disciplines. Formal education will no longer be sufficient in the future; lifelong learning will become necessary.

- Design mindset—The ability to represent and develop tasks and work processes for desired outcomes. With the use of sensors, communication tools and the computing power of the PC world come new opportunities to apply a design approach to work. Workers will need to become skilled at recognising the kind of thinking that different tasks require and adapt their work environment to enhance their ability to perform these tasks.

- Cognitive load management—Preparing for continuous work environment changes. There is a trend towards work–life blending, which implies that workplaces should be reconfigurable so that employees feel comfortable at work and are able to perform at a high and sustainable level. Related to the virtualisation of work is the necessary ability to differentiate and filter information in terms of relevance and to maximise a human’s cognitive functioning using a variety of tools and techniques. The new generation of workers will need to develop their own techniques to deal with the problem of cognitive overload, and they will also need to become proficient in the use of new tools to help them cope with the onslaught of information.

- Virtual collaboration—Remote working is becoming more and more widespread due to the globalisation of work. The ability to work productively, to manage and demonstrate presence as a member of a virtual team, to be able to communicate with colleagues working from the other side of the world or country, is becoming a necessity. Virtual team leaders must learn to work effectively with people they may never meet in person and be able to apply management tools in a virtual environment. Virtual team members need to improve their skills in finding a supportive environment that promotes productivity and well-being.

- Business Agility—the employee’s ability to compete and thrive in the digital age by responding flexibly to market changes, as well as reflecting on emerging opportunities with innovative and digitally-enabled business solutions [54]. It is a set rganizationalnal skills and work behaviours that allows freedom, flexibility and resilience to achieve goals [55].

The results of our research show that employees themselves are aware of the need for new skills that they do not yet possess or only to a limited extent. This creates a favourable environment for the application of learning on the part of employees who are willing to acquire the necessary skills. Our findings show that employees feel most strongly about the need for digital skills and technical (vocational) skills and the ability to learn. The research results show that on the employees’ side, the skills (“competences”) closely related to the introduction of new Industry 4.0 technologies are perceived as the most needed.

The results also show that the idea that the implementation of Industry 4.0 is not a means of dehumanising work but a way to reduce the physical demands of work needs to be better publicised. This is important so that employees are motivated to acquire the missing skills and do not sabotage the implementation of Industry 4.0 because of the fear of losing their jobs.

However, it is necessary to look at the issue of the skills needed in the future comprehensively, not only from the subjective perspective of employees but also from the perspective of the needs of industrial practice, given the rapid technological innovation where employees will soon share their workplaces with artificial intelligence and robots [51], the need to stay ahead of the competition and also by embracing the idea of the need for lifelong learning.

5. Conclusions

In future research it is possible to continue the specification of the missing key skills of individual generations of employees, including those already working but also entering the labour market, on the basis of which it will be possible to address the preparation of the system of education at all levels of education and training for the acquisition of the required qualifications in the labour market in accordance with the requirements of Industry 4.0, in the new setting of labour market and education policies. Constraints that may have influenced the research results are listed above (see Section 3).

Author Contributions

Conceptualisation, P.M., P.S., M.M., J.S. and S.J.; methodology, validation, resources P.M., P.S., M.M., J.S. and S.J.; data curation, software M.M.; writing—original draft preparation, P.M., P.S., M.M., J.S. and S.J.; writing—review and editing, P.S. and P.M.; visualisation, M.M. and S.J.; supervision, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

The research was realised and partially funded by project VEGA No. 1/0721/20 “Identification of priorities for sustainable human resources management with respect to disadvantaged employees in the context of Industry 4.0”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The paper is a part of project VEGA No. 1/0721/20 “Identification of priorities for sustainable human resources management with respect to disadvantaged employees in the context of Industry 4.0”. This paper has been published with the support of the Operational Program Integrated Infrastructure within project “Research in the SANET network and possibilities of its further use and development”, code ITMS 313011W988, co-financed by the ERDF). The paper is a part of project KEGA No. 027STU-4/2022 “Integration of the requirements of practice in the automotive industry with the teaching of subjects within the study programs Process Automation and Informatization in Industry and Industrial Management”. This paper is a part Young Research Project No. 1368 “Identification of opportunities to integrate selected Industry 4.0 technologies with lean manufacturing management as part of the transformation of conventional industrial organisations into smart ones”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pavlović, D.; Milosavljević, P.; Mladenović, S. Synergy between Industry 4.0 and Lean Methodology. J. Mechatron. Autom. Identif. Technol. 2020, 5, 17–20. [Google Scholar]

- Manyika, J. The Internet of Things: Mapping the Value beyond the Hype. McKinsey&Company. 2015. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Technology (accessed on 8 October 2022).

- Bouchard, S.; Abdulnour, G.; Gamache, S. Agility and Industry 4.0 Implementation Strategy in a Quebec Manufacturing SME. Sustainability 2022, 14, 7884. [Google Scholar] [CrossRef]

- Lukačević, F.; Škec, S.; Martinec, T. Challenges of Utilizing Sensor Data Acquired by Smart Products in Product Development Activities. Acta Polytech. Hung. 2022, 19, 4. [Google Scholar] [CrossRef]

- Velásquez, N.; Estevez, E.; Pesado, P. Cloud Computing, Big Data and the Industry 4.0 Reference Architectures. J. Comput. Sci. Technol. 2018, 18, 258–266. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Koçoğlu, M.Ö.; Demirkol, D. Data in the Context of Industry 4.0. In WHO Runs the World: Data; Gülseçen, S., Sharma, S., Akadal, E., Eds.; Istanbul University Press: Istanbul, Turkey, 2020; pp. 97–118. [Google Scholar] [CrossRef]

- Mourtizs, D.; Vlachou, E.; Milas, N. Industrial Big Data as a result of IoT adoption in Manufacturing. Procedia CIRP 2016, 55, 290–295. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G. Big Data in Cyber-Physical Systems, Digital Manufacturing and Industry 4.0. Int. J. Eng. Manuf. (IJEM) 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Legashev, L.V.; Bolodurina, I.P. An Effective Scheduling Method in the Cloud System of Collective Access, for Virtual Working Environments. Acta Polytech. Hung. 2020, 17, 8. [Google Scholar] [CrossRef]

- Veber, J. Digitalizace Ekonomiky a Společnosti: Výhody, Rizika, Príležitosti; Management Press: Praha, Czech Republic, 2018. [Google Scholar]

- Sadiku, M.; Ashaolu, T.J.; Ajayi-Majebi, A.; Musa, S. Big Data in Manufacturing. Int. J. Sci. Adv. 2021, 2, 63–66. [Google Scholar] [CrossRef]

- Industry4UM. Prieskum Industry 4.0 v SR. Available online: https://industry4um.sk/prieskum-industry-4-0/ (accessed on 24 April 2023).

- Schwab, K. The Fourth Industrial Revolution. 2018. Available online: https://www.foreignaffairs.com/articles/2015-12-12/fourth-industrial-revolution (accessed on 8 October 2022).

- Berkovič, V.; Krajčo, K. Impact industry 4.0 on changes in the labor market. In Proceedings of the Challenges, Trends and Inspirations within the Labor Market 2021, Trenčín, Slovakia, 11 November 2021; Publishing House Alexander Dubček University: Trenčín, Slovakia, 2022. [Google Scholar]

- Eberhard, B.; Podio, M.; Alonso, A.P.; Radovica, E.; Avotina, L.; Peiseniece, L.; Sendon, M.C.; Lozano, A.G.; Solé-Pla, J. Smart work: The transformation of the labour market due to the fourth industrial revolution (I4. 0). Int. J. Bus. Econ. Sci. Appl. Res. (IJBESAR) 2017, 10, 47–66. [Google Scholar]

- Michelacci, C.; Pijoan-Mas, J. Labor supply with job assignment under balanced growth. J. Econ. Theory 2016, 163, 110–140. [Google Scholar] [CrossRef]

- Porubčinová, M.; Fero, M.; Fidlerová, H.; Novotná, I. Industry 4.0 in the human capital optics-empirical findings of Work 4.0 competencies development within the Slovak automotive sector. PP–FAR 2021, 13, 44–67. [Google Scholar] [CrossRef]

- Kordos, M.; Berkovic, V. Applying Automation in Slovak Tourism Industry—Benefits and Issues. AD ALTA-J. Interdiscip. Res. 2020, 10, 132–138. [Google Scholar]

- Kordos, M. Aspects of Robotics Implementation within the Changes on Labor Market in Poland. In Vplyv Industry 4.0 Na Tvorbu Pracovnych Miest; Alexander Dubček University: Trenčín, Slovakia, 2019; pp. 200–212. [Google Scholar]

- Behrendt, A. Keine Revolution, Sondern Eine Weiterentwicklung: Mit Industrie 4.0 Zu Mehr Produktivität; Handelsblatt GmbH: Dusseldorf, Germany, 2017. [Google Scholar]

- WEF. The Future of Jobs Report 2020. World Economic Forum. Available online: https://www.weforum.org/reports/the-future-of-jobs-report-2020/digest (accessed on 25 April 2023).

- Republiková Únia Zamestnávateľov. Kolektív Autorov, COVID-19: Dopady a Cesty z Krízy. 2022. IA MPSVR SR. NÁRODNÝ PROJEKT Centrum Sociálneho Dialógu. Available online: https://www.ruzsr.sk/media/1a0e6ba3-99fa-4aee-ba60-245e8ac4ba41.pdf (accessed on 25 April 2023).

- Oláhová, K. Firmy sú Bezradné. Toto je Desať Povolaní, o Ktoré Slováci Nemajú Záujem. In Trend.sk/Biznis. Zverejnené 28 January 2023. Available online: https://www.trend.sk/biznis/firmy-su-bezradne-toto-je-desat-povolani-ktore-slovaci-nemaju-zaujem (accessed on 25 April 2023).

- Oláhová, K. Dnešné Deti Nastúpia do Práce, Ktorá Ešte Neexistuje. Týchto Desať Povolaní Prinesie Budúcnosť. In Trend.sk/Biznis. Zverejnené 25 March 2023. Available online: https://www.trend.sk/spravy/dnesne-deti-nastupia-prace-ktora-este-neexistuje-tychto-desat-povolani-prinesie-buducnost (accessed on 28 April 2023).

- Katane, I.; Baltusite, R.; Katans, E. Programming engineer profesional development from multi-aspect view. In Proceedings of the International Scientific Conference: Engineering for Rural Development; Book Series: Engineering for Rural Development; Latvia University of Agriculture: Riga, Latvia, 2016. [Google Scholar]

- Grenčíková, A.; Petrušová, D. Labor force competencies within the new communication technologies. In Proceedings of the International Scientific Conference Economic and Social Policy; Vysoká Škola Sociálně Správní: Ostrava, Czech Republic, 2018; pp. 71–80. [Google Scholar]

- Frey, C.B.; Osborne, M. Technology at Work: The Future of Innovation and Employment. Oxford Martin School. Available online: https://www.oxfordmartin.ox.ac.uk/downloads/reports/Citi_GPS_Technology_Work.pdf (accessed on 25 April 2023).

- Ministerstvo Hospodárstva SR. Koncepcia Inteligentného Priemyslu pre Slovensko; Vláda SR: Bratislava, Slovakia, 2016. [Google Scholar]

- Mařík, V. Národná Iniciatíva 4.0, September 2015; Ministerstvo Priemyslu a Obchodu ČR: Praha, Czech Republic, 2015. [Google Scholar]

- Future of Jobs Report 2023. Available online: https://www3.weforum.org/docs/WEF_Future_of_Jobs_2023.pdf (accessed on 8 July 2023).

- Štulajterová, M. Digitalizácia Vezme Prácu Najmä Silným Mladým Mužom. In: Trend.sk/Ekonomika. Zverejnené 21 February 2023. Available online: https://www.trend.sk/ekonomika/lelovsky-financni-poistovaci-agenti-to-maju-zrejme-spocitane (accessed on 23 April 2023).

- Akkaya, B. Leadership 5.0 in Industry 4.0: Leadership in perspective of organizational agility. In Managing Operations throughout Global Supply Chains; IGI Global: Hershey, PA, USA, 2019; pp. 136–158. [Google Scholar] [CrossRef]

- Mrugalska, B.; Ahmed, J. Organizational agility in industry 4.0: A systematic literature review. Sustainability 2021, 13, 8272. [Google Scholar] [CrossRef]

- López-Alcarria, A.; Olivares-Vicente, A.; Poza-Vilches, F. A systematic review of the use of agile methodologies in education to foster sustainability competencies. Sustainability 2019, 11, 2915. [Google Scholar] [CrossRef]

- Morawiec, P.; Sołtysik-Piorunkiewicz, A. ERP System Development for Business Agility in Industry 4.0—A Literature Review Based on the TOE Framework. Sustainability 2013, 15, 4646. [Google Scholar] [CrossRef]

- Agilné Prístupy a Certifikácie. Available online: https://potifob.sk/Agile (accessed on 23 May 2023).

- Ganesh, N.; Thangasamy, S. Lessons learned in transforming from traditional to agile development. J. Comput. Sci. 2012, 8, 389–392. [Google Scholar] [CrossRef]

- da Costa Filho, J.R.; Penha, R.; da Silva, L.F.; Bizarrias, F.S. Competencies for Managing Activities in Agile Projects. Glob. J. Flex. Syst. Manag. 2022, 23, 431–452. [Google Scholar] [CrossRef]

- McIver, D.; Lengnick-Hall, M.L.; Lengnick-Hall, C.A. A strategic approach to workforce analytics: Integrating science and agility. Bus. Horiz. 2018, 61, 397–407. [Google Scholar] [CrossRef]

- Závadský, C.; Olexová, C. Kompetencie zamestnancov pre potreby Industry 4.0. (COMPETENCIES OF EMPLOYEES FOR INDUSTRY 4.0.). Manažment V Teórii A Praxi 2022, 18, 29. [Google Scholar]

- IPMA Reference Guide ICB4 in an AGILE Word. Available online: https://shop.ipma.world/shop/ipma-standards/books-ipma-standards/ipma-reference-guide-icb4-in-an-agile-world/?v=13dd621f2711 (accessed on 23 May 2023).

- Hvizdová, E.; Máchal, P. Vplyv manažmentu ľudských zdrojov na otvorené podnikové inovácie–perspektíva projektového managementu. Econ. Manag. Innov. 2017, 9, 39–47. [Google Scholar]

- Łupicka, A.; Grzybowska, K. Key managerial competencies for industry 4.0-practitioners’, researchers’ and students’ opinions. Logist. Transp. 2018, 39, 39–46. [Google Scholar] [CrossRef]

- Agile Development Competencies. Available online: https://www.competencies.co/competencies/agile-development-competencies (accessed on 23 May 2023).

- Behavioural Competencies. Available online: https://www.competencies.co/competencies/behavioral-competencies (accessed on 23 May 2023).

- Bezpečný Škálovaný Agile so SAFe (Secure Scaled Agile with SAFe). Available online: https://scrum.sk/blog/2021/04/22/bezpecny-agile/ (accessed on 23 May 2023).

- What is SAFe? Available online: https://www.atlassian.com/agile/agile-at-scale/what-is-safe (accessed on 7 July 2023).

- Weichbroth, P. A case study on implementing agile techniques and practices: Rationale, benefits, barriers and business implications for hardware development. Appl. Sci. 2022, 12, 8457. [Google Scholar] [CrossRef]

- The 10 Vital Skills You Will Need for the Future of Work. Available online: https://myfuture.cimaglobal.com/career-insights/the-10-vital-skills-you-will-need-for-the-future-of-work/ (accessed on 7 July 2023).

- Marková, P.; Homokyová, M.; Prajová, V.; Horváthová, M. A view on human capital in industry 4.0. MM Sci. J. 2022, 12, 6205. [Google Scholar] [CrossRef]

- The Re-Working of “Work”. Available online: https://www.iftf.org/projects/future-work-skills-2020/ (accessed on 7 July 2023).

- Business Agility. Available online: https://scaledagileframework.com/business-agility/ (accessed on 7 July 2023).

- The Seven Core Competencies of SAFe. Available online: https://www.qrpinternational.be/blog/agile/safe-core-competencies/ (accessed on 7 July 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).