Recent Progress in Hybrid Additive Manufacturing of Metallic Materials

Abstract

1. Introduction

2. Hybrid Techniques Based on the Use of Other Manufacturing Techniques with AM

2.1. Electron Beam Melting + Computer Numerically Controlled Rapid Prototyping

2.2. Laser Metal Deposition + Computer Numerical Control

2.3. Selective Laser Sintering + Die Substrate

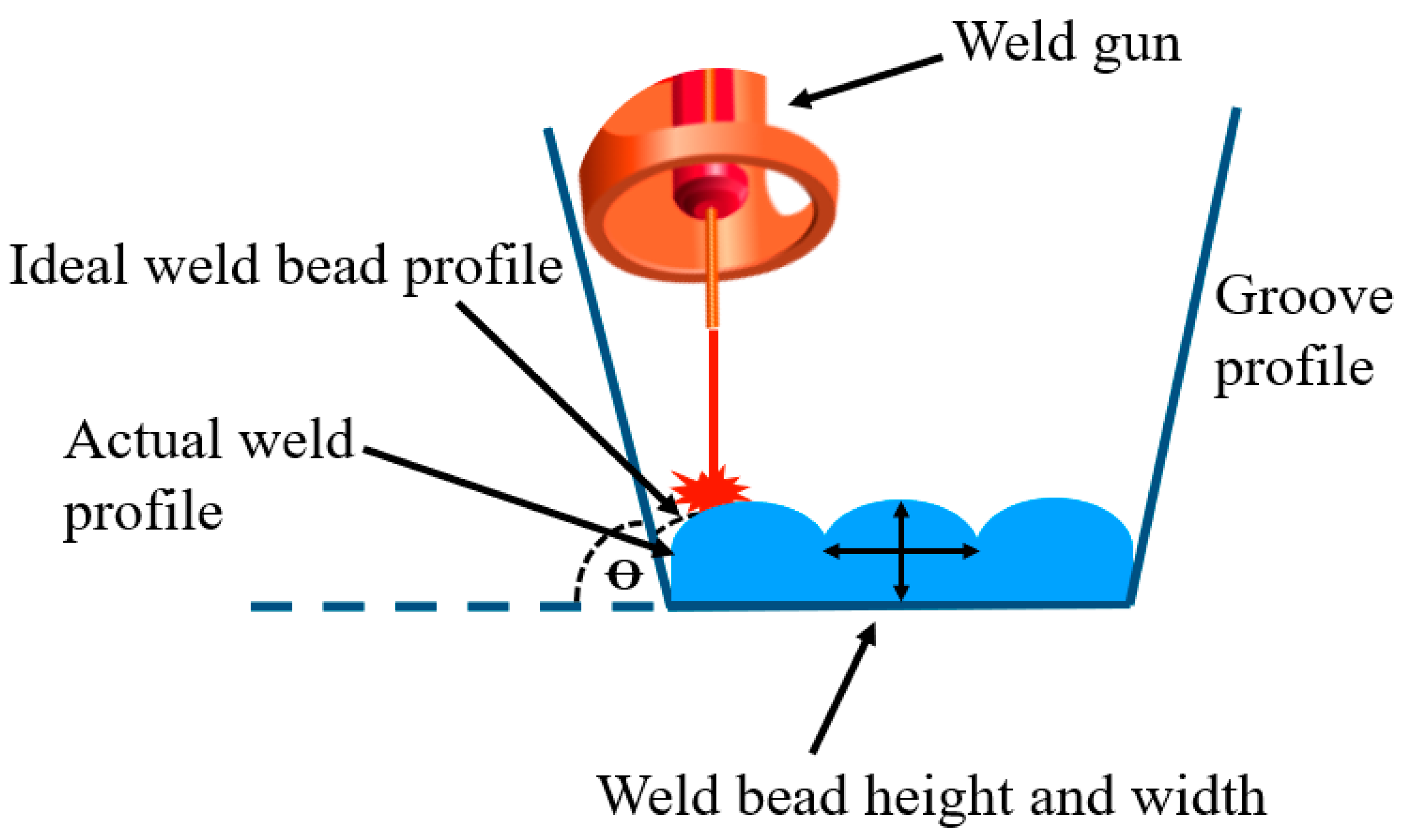

2.4. Wire and Arc Additive Manufacturing Filling + Worn-Out Part

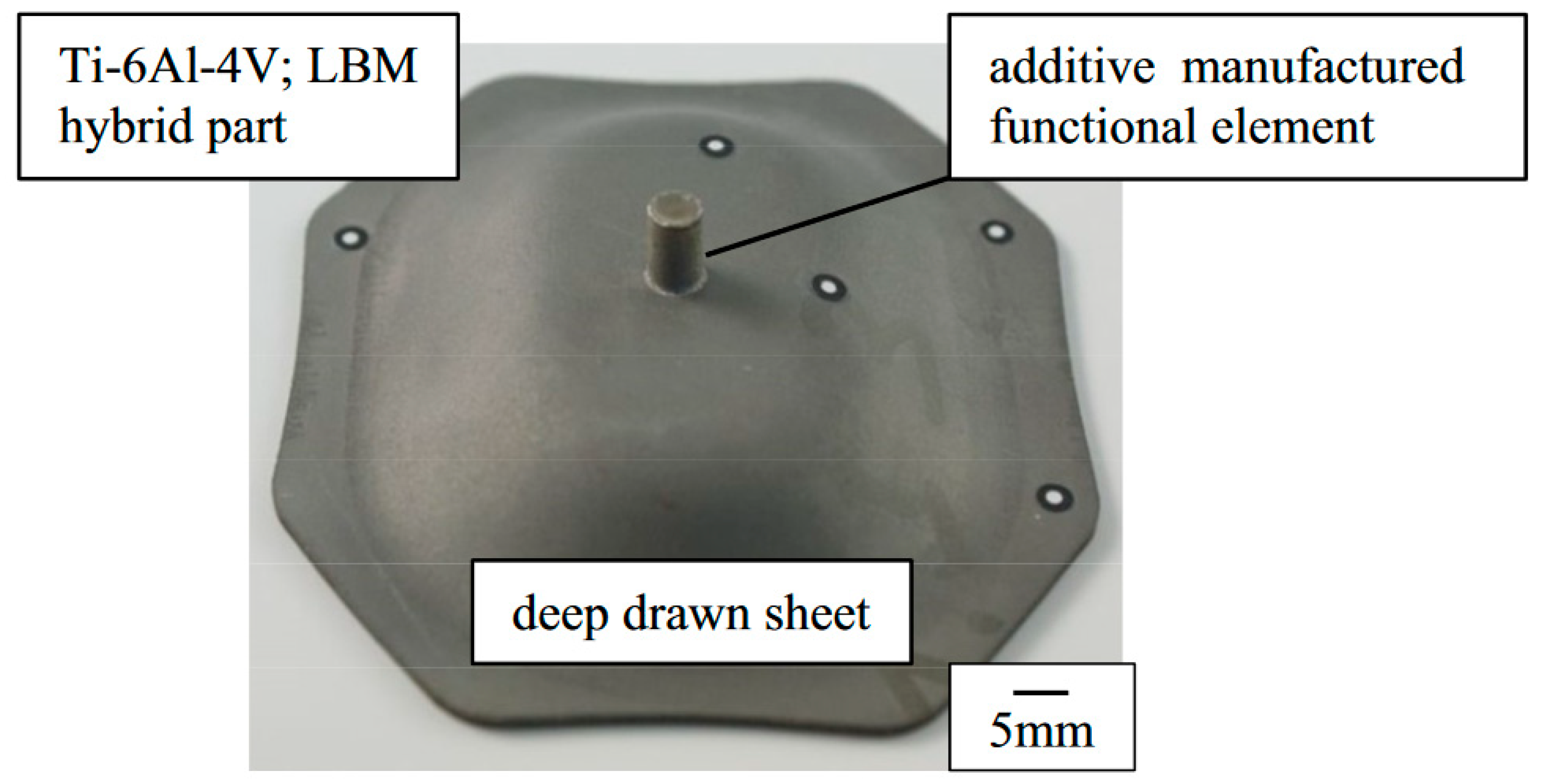

2.5. Laser Powder Bed Fusion + Fused Filament Polymer

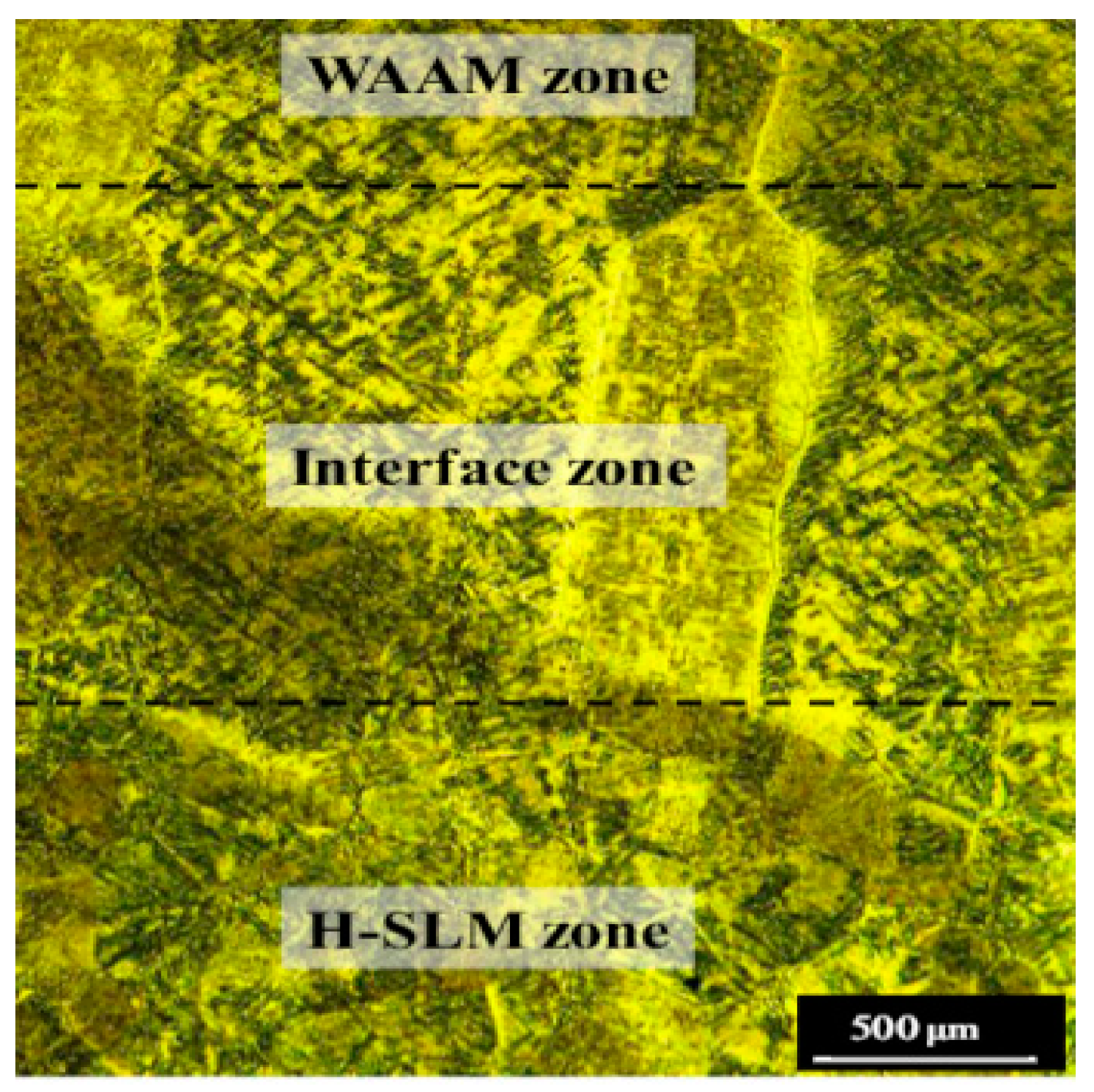

2.6. SLM + WAAM

2.7. Laser Metal Deposition + Turning + Milling

3. Hybrid Additive Manufacturing as a Joining Technique and Its Challenges

3.1. Alloy Compatibility

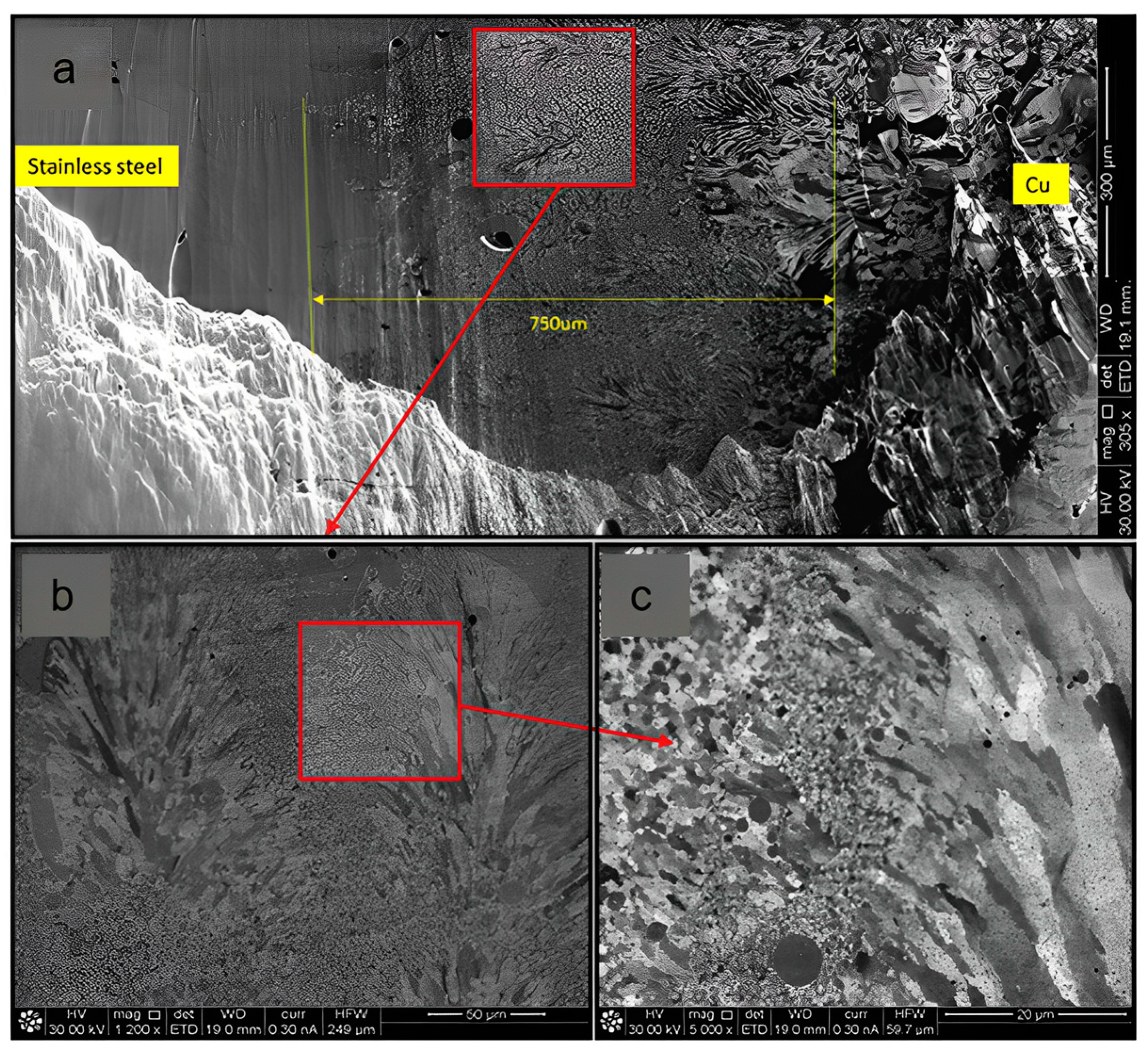

3.1.1. Direct Joining

3.1.2. Gradient Joining

3.1.3. Intermediate Layer Joining

| Joining Method | Materials | Observations | References |

|---|---|---|---|

| Direct sharp interface | 316L/C18400 | Sound metallurgical bonding at the interface; however, cracks were evident because Cu diffused into the austenitic grain boundaries. As a result, low ultimate strength was achieved. | [42] |

| 316L/Cu10Sn | Crack-free interface with a strong metallurgical bond. | [43] | |

| 18Ni300/CuSn | Al2Cu intermetallic phases were observed together with cracks due to non-uniform thermal expansion. | [67] | |

| 1.2709 steel/CuCr1Zr | A 20% of mm powder overlap was achieved, but cracks and pores were unavoidable. | [68] | |

| 316L/In718 | Cross-finger interface produced improved the horizontal bond strength. | [69] | |

| Al12Si/Al3.5Cu1.5 Mg1Si | Some Al12Si powders were unmelted, and Al2Cu intermetallic phase was precipitated. | [70] | |

| Ti5Al2.5Sn/Ti6Al4V | A good metallurgical bond was achieved regardless of HT. The interfacial bond strength was higher than the Ti-5Al-2.5Sn section. | [71] | |

| AlSi10Mg/C18400 | Brittle intermetallic phase Al2Cu was produced with crack formation due to non-uniform CTE. | [42] | |

| 316L/H13 | Fair metallurgical bonding at the interface with improved material intermixing inside the melt pool. | [54] | |

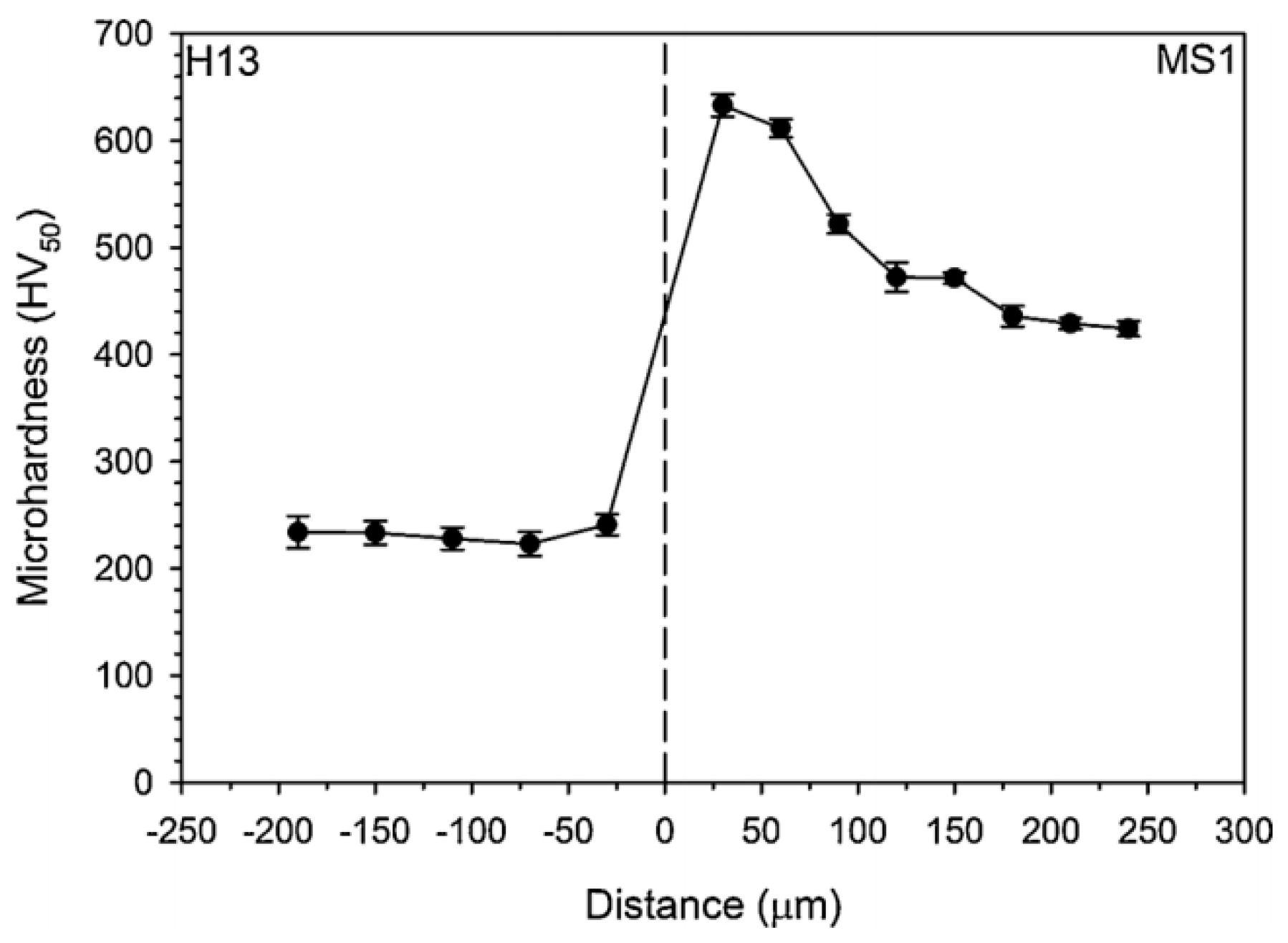

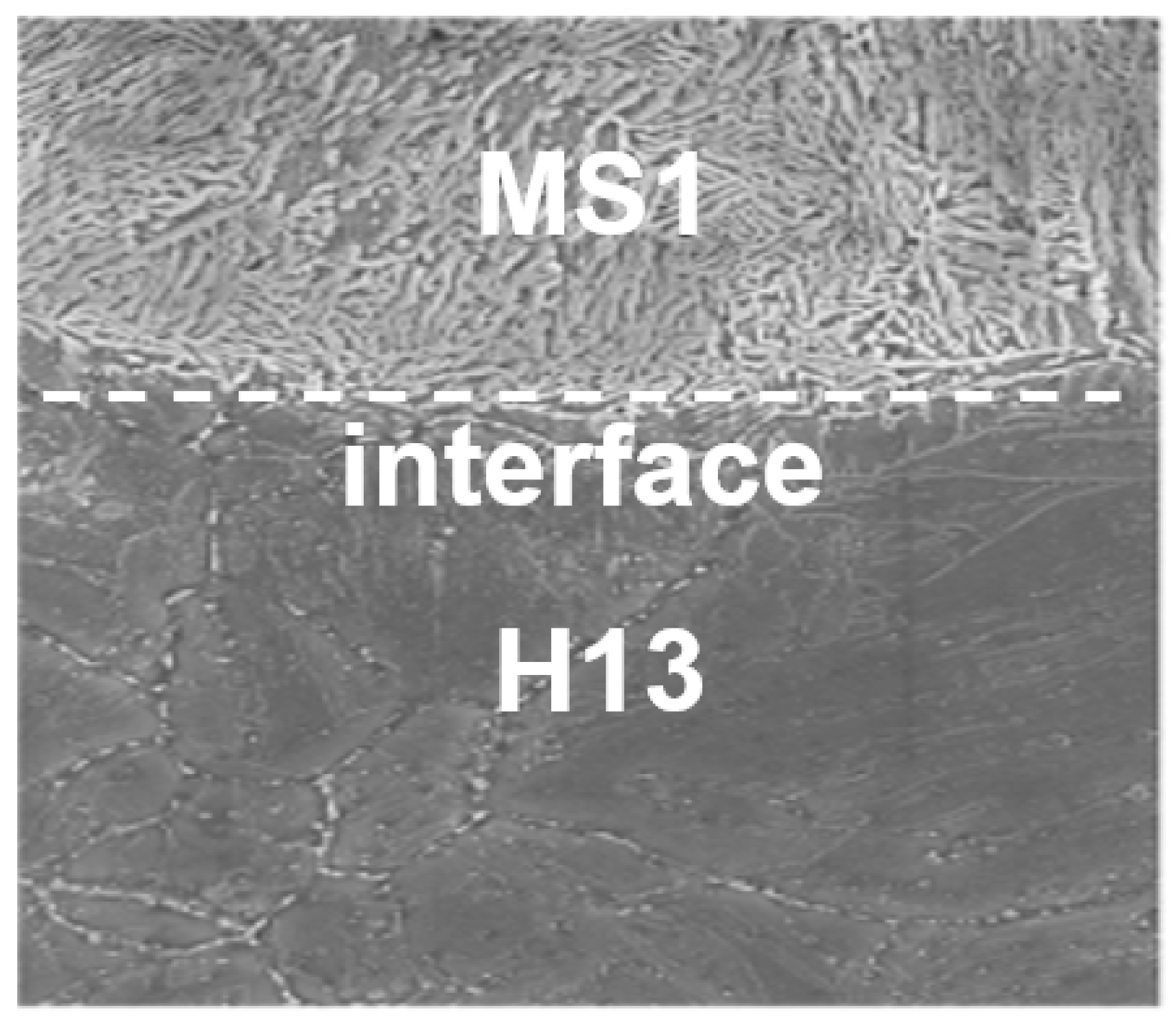

| MS1/H13 | HT potentially removed microstructural inhomogeneity, but did not achieve microstructural evolution at the interface. | [46] | |

| M789/N709 | Failure was away from the interface for both as-printed and heat-treated conditions. | [47,72] | |

| MS1/wrought C300 | Fracture at the built AM layer was caused by void expansion. | [34] | |

| MS1/wrought H13 | Fracture at the interface due to chemical and microstructural inhomogeneity. | [34] | |

| Gradient | 316L/MS1 | Good intermixing between the materials with no visible crack formation. | [73] |

| Ti6Al4V/In718 | Composition of W above 20% promoted the formation of brittle Ti2Ni intermetallic phase. | [74] | |

| 316L/Cu10Sn | Fair metallurgical bonding between the two materials with a presence of unmelted 316L powder. | [75] | |

| Fe/Al12Si | Materials were immiscible in most sections, and macro-cracks were observed. | [76] | |

| In718/Cu10Sn | Good metallurgical bonding due to improved scan strategy and reduced hatch distance, which improved the melting of In718 powders. | [77] | |

| Invar36/Cu10Sn | Significant portions of unmelted Invar36 due to low laser absorptivity and high thermal conductivity of Cu alloy. | [78] | |

| Intermediate section | Ti6Al4V/316L | Copper alloy interlayer insert avoided the intermetallic phase formation between Ti6Al4V/316. | [79] |

3.2. Limited Solubility and Intermetallic Phase Formation

4. Microstructural Characteristics, Mechanical Behavior, and Properties of Hybrid Maraging Steels

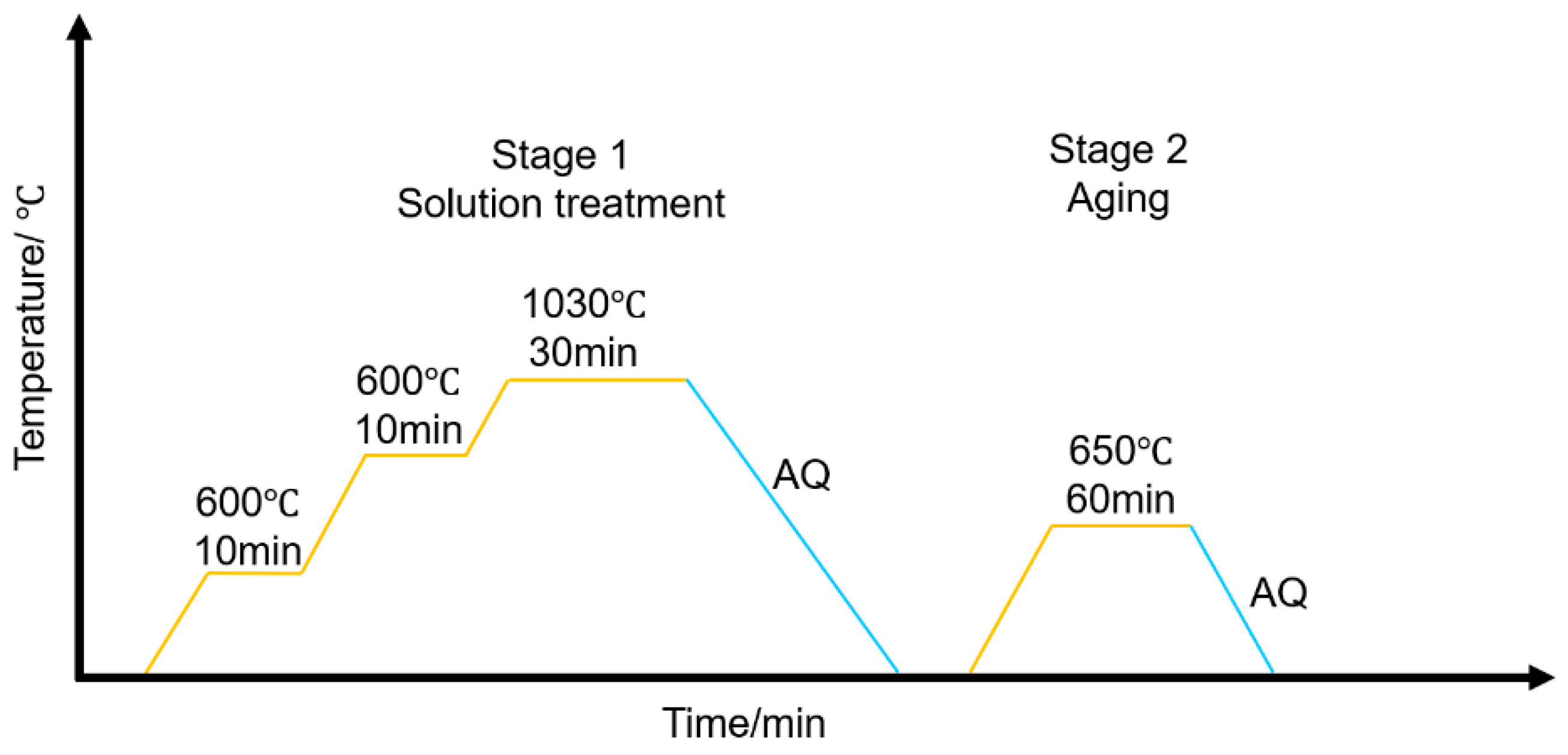

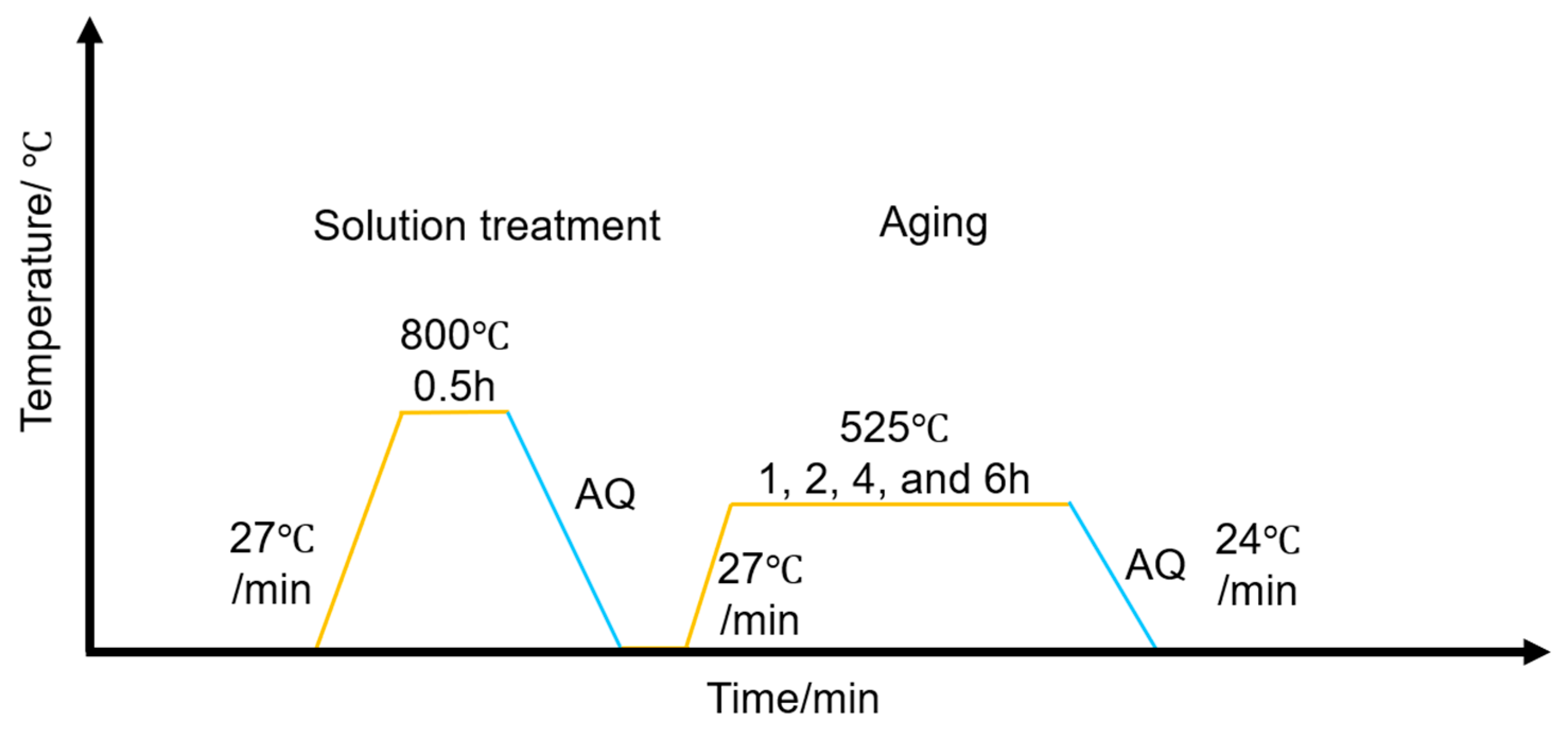

5. Effect of Heat Treatments in AM Processed Maraging Steels

5.1. Strengthening Mechanisms’ Models

5.1.1. Solid-Solution-Strengthening Model

5.1.2. Effective Martensitic Strength

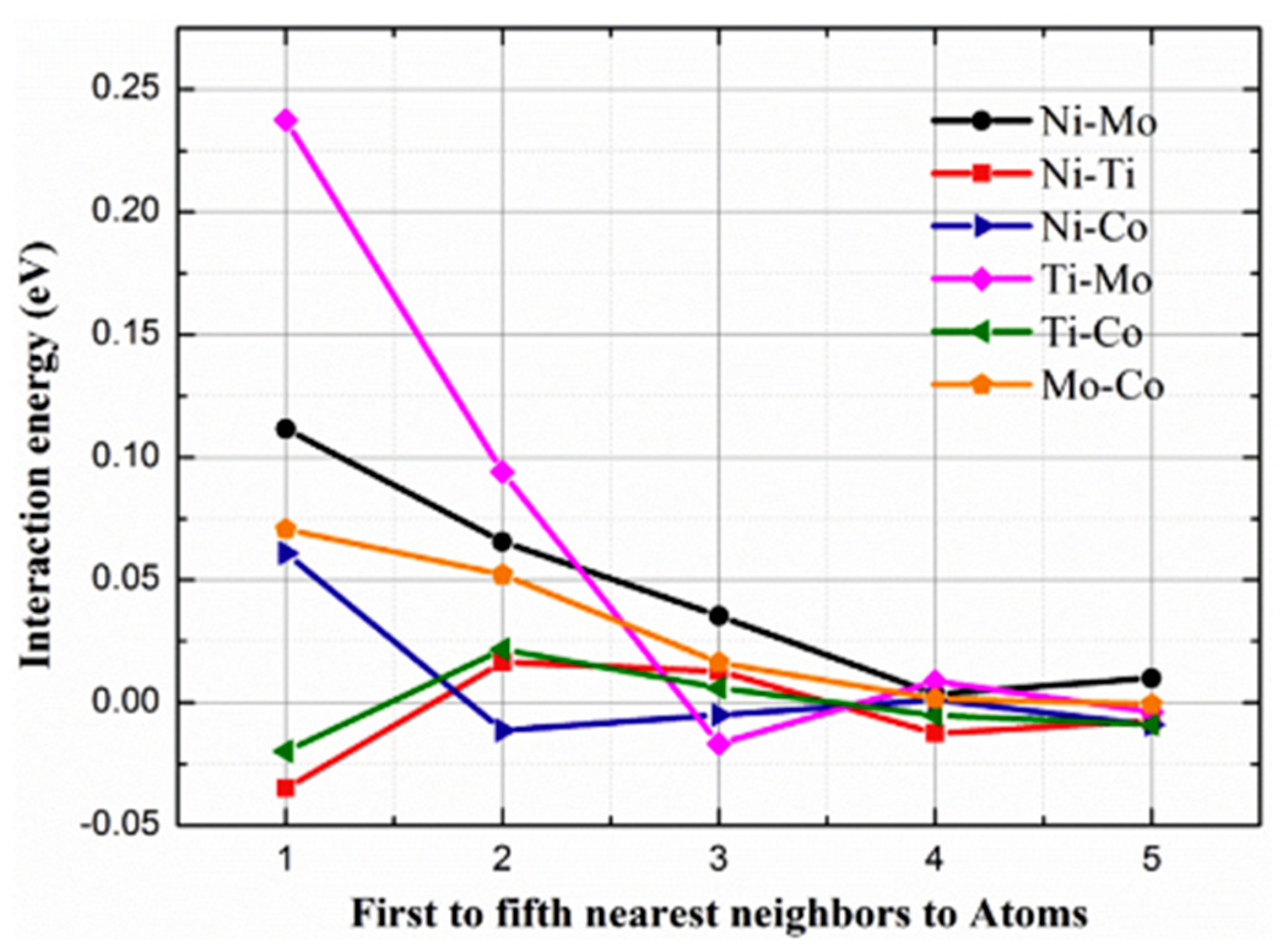

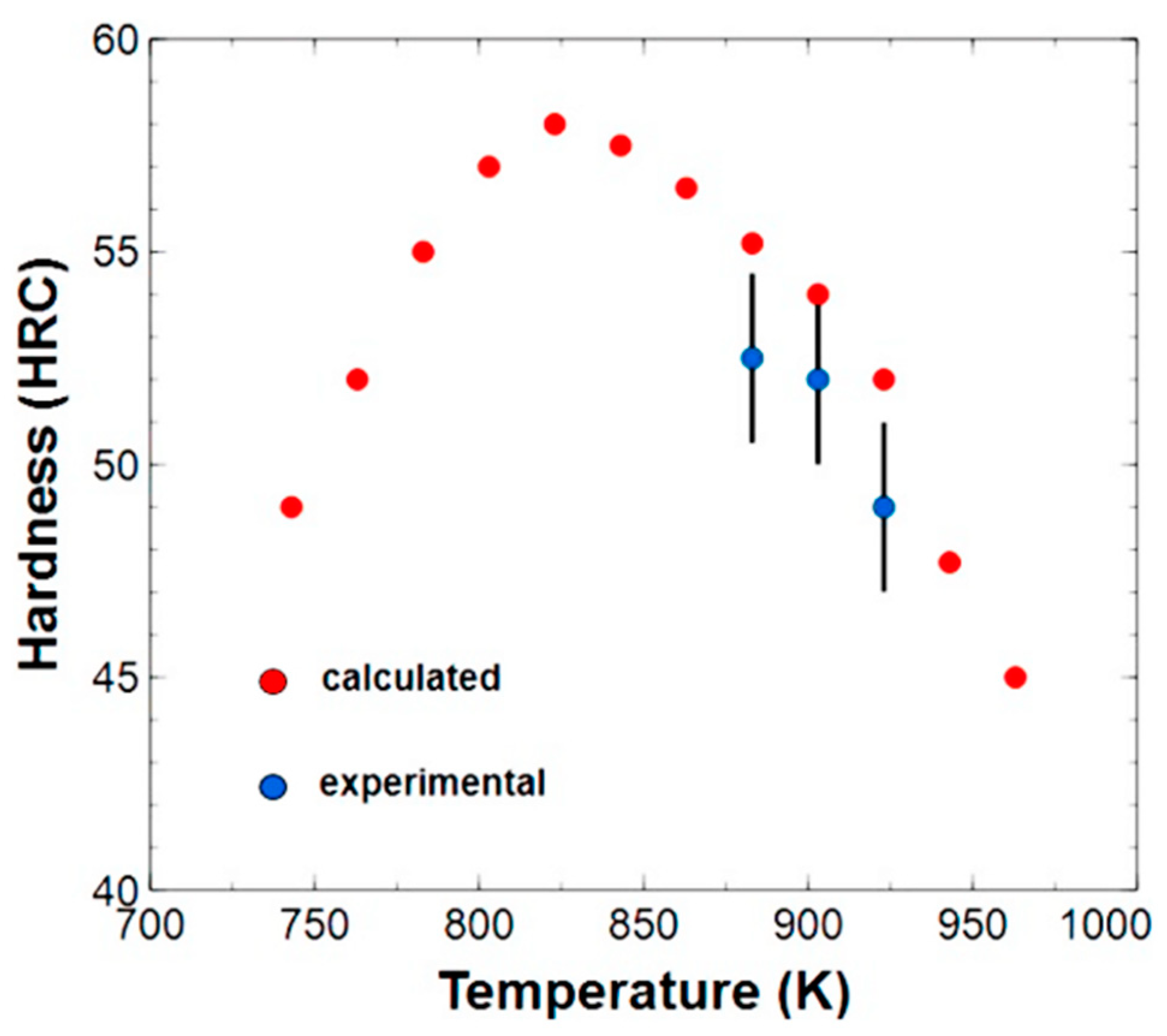

5.1.3. Precipitation Strengthening

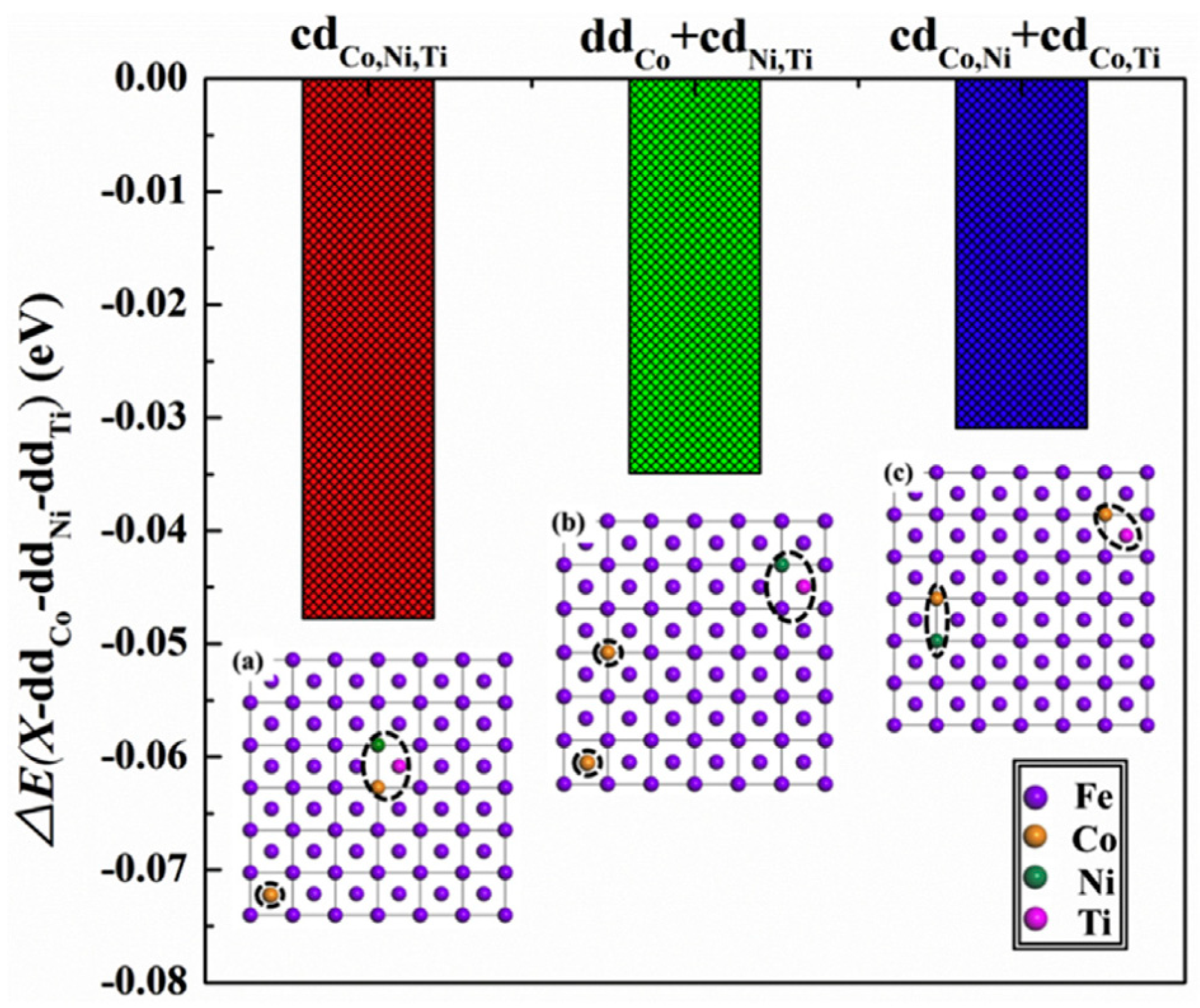

- (a) All three elements form a cluster distribution (cd);

- (b) Ni and Ti combine to form a cluster distribution in the iron-rich region (cd), resulting in Co being dispersed (dd);

- (c) Co, in turn, forms clusters with Ni and Ti.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cardullo, P.; Kitchin, R. Smart Urbanism and Smart Citizenship: The Neoliberal Logic of ‘Citizen-Focused’ Smart Cities in Europe. Environ. Plan. C Polit. Space 2019, 37, 813–830. [Google Scholar] [CrossRef]

- Klocke, F.; Arntz, K.; Teli, M.; Winands, K.; Wegener, M.; Oliari, S. State-of-the-Art Laser Additive Manufacturing for Hot-Work Tool Steels. Procedia CIRP 2017, 63, 58–63. [Google Scholar] [CrossRef]

- Parupelli, S.; Desai, S. A Comprehensive Review of Additive Manufacturing (3D Printing): Processes, Applications and Future Potential. Am. J. Appl. Sci. 2019, 16, 244–272. [Google Scholar] [CrossRef]

- Tian, Y.; Palad, R.; Aranas, C. Microstructural Evolution and Mechanical Properties of a Newly Designed Steel Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2020, 36, 101495. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K.; Laubscher, R.F. Overview of Hybrid Machining Processes. In Hybrid Machining Processes: Perspectives on Machining and Finishing; Gupta, K., Jain, N.K., Laubscher, R.F., Eds.; Springer International Publishing: Cham, Germany, 2016; pp. 1–7. ISBN 978-3-319-25922-2. [Google Scholar]

- Seidel, A.; Straubel, A.; Finaske, T.; Maiwald, T.; Polenz, S.; Albert, M.; Näsström, J.; Marquardt, A.; Riede, M.; Lopez, E.; et al. Added Value by Hybrid Additive Manufacturing and Advanced Manufacturing Approaches. J. Laser Appl. 2018, 30, 032301. [Google Scholar] [CrossRef]

- Luisa, S.; Contuzzi, N.; Angelastro, A.; Domenico, A. Capabilities and Performances of the Selective Laser Melting Process. In New Trends in Technologies: Devices, Computer, Communication and Industrial Systems; Joo, M., Ed.; Sciyo: Rijeka, Croatia, 2010; ISBN 978-953-307-212-8. [Google Scholar]

- Introduction to FDM 3D Printing. Available online: https://www.hubs.com/knowledge-base/introduction-fdm-3d-printing/ (accessed on 8 June 2021).

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Filippo, B.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Petrat, T.; Graf, B.; Gumenyuk, A.; Rethmeier, M. Laser Metal Deposition as Repair Technology for a Gas Turbine Burner Made of Inconel 718. Phys. Procedia 2016, 83, 761–768. [Google Scholar] [CrossRef]

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Popov, V.V.; Fleisher, A. Hybrid Additive Manufacturing of Steels and Alloys. Manuf. Rev. 2020, 7, 6. [Google Scholar] [CrossRef]

- Jayanath, S.; Achuthan, A. A Computationally Efficient Hybrid Model for Simulating the Additive Manufacturing Process of Metals. Int. J. Mech. Sci. 2019, 160, 255–269. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive Manufacturing of Fatigue Resistant Materials: Challenges and Opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Darvish, K.; Chen, Z.W.; Pasang, T. Reducing Lack of Fusion during Selective Laser Melting of CoCrMo Alloy: Effect of Laser Power on Geometrical Features of Tracks. Mater. Des. 2016, 112, 357–366. [Google Scholar] [CrossRef]

- Sterling, A.J.; Torries, B.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Fatigue Behavior and Failure Mechanisms of Direct Laser Deposited Ti–6Al–4V. Mater. Sci. Eng. A 2016, 655, 100–112. [Google Scholar] [CrossRef]

- Johnson, A.S.; Shuai, S.; Shamsaei, N.; Thompson, S.M.; Bian, L. Fatigue Behavior and Failure Mechanisms of Direct Laser Deposited Inconel 718. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Du, W.; Bai, Q.; Zhang, B. A Novel Method for Additive/Subtractive Hybrid Manufacturing of Metallic Parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef]

- Du, C.; Zhao, Y.; Jiang, J.; Wang, Q.; Wang, H.; Li, N.; Sun, J. Pore Defects in Laser Powder Bed Fusion: Formation Mechanism, Control Method, and Perspectives. J. Alloys Compd. 2023, 944, 169215. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, C.; Wang, P.; Meng, W.; Li, C. The Mechanism of In-Situ Laser Polishing and Its Effect on the Surface Quality of Nickel-Based Alloy Fabricated by Selective Laser Melting. Metals 2022, 12, 778. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in Additive Manufacturing of Metal-Based Functionally Graded Materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Grevey, D.; Sallamand, P. Dissimilar Laser Welding of AISI 316L Stainless Steel to Ti6–Al4–6V Alloy via Pure Vanadium Interlayer. Mater. Sci. Eng. A 2015, 622, 37–45. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.A.; Harrysson, O.L.A. Additive Manufacturing–Integrated Hybrid Manufacturing and Subtractive Processes: Economic Model and Analysis. Int. J. Comput. Integr. Manuf. 2016, 29, 473–488. [Google Scholar] [CrossRef]

- Committee F42 on Additive Manufacturing Technologies. Available online: https://www.astm.org/get-involved/technical-committees/committee-f42 (accessed on 5 June 2023).

- Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals 2017, 7, 183. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.; Harrysson, O.; Aman, R. AIMS—A Metal Additive-Hybrid Manufacturing System: System Architecture and Attributes. Procedia Manuf. 2015, 1, 273–286. [Google Scholar] [CrossRef]

- Merklein, M.; Junker, D.; Schaub, A.; Neubauer, F. Hybrid Additive Manufacturing Technologies—An Analysis Regarding Potentials and Applications. Phys. Procedia 2016, 83, 549–559. [Google Scholar] [CrossRef]

- Karunakaran, K.P.; Suryakumar, S.; Pushpa, V.; Akula, S. Low Cost Integration of Additive and Subtractive Processes for Hybrid Layered Manufacturing. Robot. Comput. Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Oter, Z.C.; Coskun, M.; Akca, Y.; Sürmen, Ö.; Yılmaz, M.S.; Özer, G.; Tarakçı, G.; Koc, E. Benefits of Laser Beam Based Additive Manufacturing in Die Production. Optik 2019, 176, 175–184. [Google Scholar] [CrossRef]

- Klueh, R.L.; King, J.F. Austenitic Stainless Steel-Ferritic Steel Weld Joint Failures. Weld. Res. 1982. Available online: http://files.aws.org/wj/supplement/WJ_1982_09_s302.pdf (accessed on 5 June 2023).

- Yeh, T.-K.; Huang, G.-R.; Wang, M.-Y.; Tsai, C.-H. Stress Corrosion Cracking in Dissimilar Metal Welds with 304L Stainless Steel and Alloy 82 in High Temperature Water. Prog. Nucl. Energy 2013, 63, 7–11. [Google Scholar] [CrossRef]

- Azizi, H.; Ghiaasiaan, R.; Prager, R.; Ghoncheh, M.H.; Samk, K.A.; Lausic, A.; Byleveld, W.; Phillion, A.B. Metallurgical and Mechanical Assessment of Hybrid Additively-Manufactured Maraging Tool Steels via Selective Laser Melting. Addit. Manuf. 2019, 27, 389–397. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, H.; Fang, Y.; Wang, H. Microstructure and Mechanical Properties of Hybrid Fabricated 1Cr12Ni2WMoVNb Steel by Laser Melting Deposition. Chin. J. Aeronaut. 2013, 26, 481–486. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, J.; Tian, X.; Wang, H.; Liu, D. Microstructure and Mechanical Properties of Hybrid Fabricated Ti–6.5Al–3.5Mo–1.5Zr–0.3Si Titanium Alloy by Laser Additive Manufacturing. Mater. Sci. Eng. A 2014, 607, 427–434. [Google Scholar] [CrossRef]

- Li, Y.; Han, Q.; Horváth, I.; Zhang, G. Repairing Surface Defects of Metal Parts by Groove Machining and Wire + Arc Based Filling. J. Mater. Process. Technol. 2019, 274, 116268. [Google Scholar] [CrossRef]

- Praniewicz, M.; Kurfess, T.; Saldana, C. Adaptive Geometry Transformation and Repair for Hybrid Manufacturing. Procedia Manuf. 2018, 26, 228–236. [Google Scholar] [CrossRef]

- Chueh, Y.-H.; Wei, C.; Zhang, X.; Li, L. Integrated Laser-Based Powder Bed Fusion and Fused Filament Fabrication for Three-Dimensional Printing of Hybrid Metal/Polymer Objects. Addit. Manuf. 2020, 31, 100928. [Google Scholar] [CrossRef]

- Falck, R.; Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. AddJoining: A Novel Additive Manufacturing Approach for Layered Metal-Polymer Hybrid Structures. Mater. Lett. 2018, 217, 211–214. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q.; Lu, J.; Liu, Y.; Shi, W. Selective Laser Melting-Wire Arc Additive Manufacturing Hybrid Fabrication of Ti-6Al-4V Alloy: Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Sing, S.L.; Lam, L.P.; Zhang, D.Q.; Liu, Z.H.; Chua, C.K. Interfacial Characterization of SLM Parts in Multi-Material Processing: Intermetallic Phase Formation between AlSi10Mg and C18400 Copper Alloy. Mater. Charact. 2015, 107, 220–227. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Hong, Q.; Wen, S.; Zhou, Y.; Yan, C.; Shi, Y. Selective Laser Melting 316L/CuSn10 Multi-Materials: Processing Optimization, Interfacial Characterization and Mechanical Property. J. Mater. Process. Technol. 2020, 283, 116701. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A Hybrid Multi-Tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. A Novel 6-Axis Hybrid Additive-Subtractive Manufacturing Process: Design and Case Studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- Shakerin, S.; Sanjari, M.; Amirkhiz, B.S.; Mohammadi, M. Interface Engineering of Additively Manufactured Maraging Steel-H13 Bimetallic Structures. Mater. Charact. 2020, 170, 110728. [Google Scholar] [CrossRef]

- Tian, Y.; Nyamuchiwa, K.; Chadha, K.; He, Y.; Aranas, C. Laser Powder Bed Fusion of M789 Maraging Steel on Cr–Mo N709 Steel: Microstructure, Texture, and Mechanical Properties. Mater. Sci. Eng. A 2022, 839, 142827. [Google Scholar] [CrossRef]

- Chen, H.-C.; Pinkerton, A.J.; Li, L.; Liu, Z.; Mistry, A.T. Gap-Free Fibre Laser Welding of Zn-Coated Steel on Al Alloy for Light-Weight Automotive Applications. Mater. Des. 2011, 32, 495–504. [Google Scholar] [CrossRef]

- Chen, H.-C.; Pinkerton, A.J.; Li, L. Fibre Laser Welding of Dissimilar Alloys of Ti-6Al-4V and Inconel 718 for Aerospace Applications. Int. J. Adv. Manuf. Technol. 2011, 52, 977–987. [Google Scholar] [CrossRef]

- Murthy, C.V.S.; Gopala Krishna, A.; Reddy, G.M. Microstructure and Mechanical Properties of Similar and Dissimilar Metal Gas Tungsten Constricted Arc Welds: Maraging Steel to 13-8 Mo Stainless Steel. Def. Technol. 2019, 15, 111–121. [Google Scholar] [CrossRef]

- Conde, F.F.; Escobar, J.D.; Oliveira, J.P.; Béreš, M.; Jardini, A.L.; Bose, W.W.; Avila, J.A. Effect of Thermal Cycling and Aging Stages on the Microstructure and Bending Strength of a Selective Laser Melted 300-Grade Maraging Steel. Mater. Sci. Eng. A 2019, 758, 192–201. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive Manufacturing of Functionally Graded Metallic Materials Using Laser Metal Deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial Characterization of SLM Parts in Multi-Material Processing: Metallurgical Diffusion between 316L Stainless Steel and C18400 Copper Alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Holzweissig, M.J.; Aydinöz, M.E.; Taube, A.; Hoyer, K.-P.; Starykov, O.; Tonn, B.; Niendorf, T.; Tröster, T.; et al. Inline Additively Manufactured Functionally Graded Multi-Materials: Microstructural and Mechanical Characterization of 316L Parts with H13 Layers. Prog. Addit. Manuf. 2018, 3, 221–231. [Google Scholar] [CrossRef]

- Nyamuchiwa, K.; Tian, Y.; Chadha, K.; Aranas, C. Laser Powder Bed Fusion of M789 Steel on Wrought N709 Steel Substrate. In Proceedings of the 61st Conference of Metallurgists, COM 2022; Springer International Publishing: Cham, Germany, 2023; pp. 9–14. [Google Scholar]

- Samei, J.; Asgari, H.; Pelligra, C.; Sanjari, M.; Salavati, S.; Shahriari, A.; Amirmaleki, M.; Jahanbakht, M.; Hadadzadeh, A.; Amirkhiz, B.S.; et al. A Hybrid Additively Manufactured Martensitic-Maraging Stainless Steel with Superior Strength and Corrosion Resistance for Plastic Injection Molding Dies. Addit. Manuf. 2021, 45, 102068. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An Overview of Laser-Based Multiple Metallic Material Additive Manufacturing: From Macro- to Micro-Scales. Int. J. Extreme Manuf. 2020, 3, 012003. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally Graded Material of 304L Stainless Steel and Inconel 625 Fabricated by Directed Energy Deposition: Characterization and Thermodynamic Modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Otis, R.A.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; Liu, Z.-K.; Beese, A.M. Additive Manufacturing of a Functionally Graded Material from Ti-6Al-4V to Invar: Experimental Characterization and Thermodynamic Calculations. Acta Mater. 2017, 127, 133–142. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of Microstructures and Mechanical Properties during Dissimilar Electron Beam Welding of Titanium Alloy to Stainless Steel via Copper Interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Sabetghadam, H.; Hanzaki, A.Z.; Araee, A. Diffusion Bonding of 410 Stainless Steel to Copper Using a Nickel Interlayer. Mater. Charact. 2010, 61, 626–634. [Google Scholar] [CrossRef]

- Madhusudhan Reddy, G.; Venkata Ramana, P. Role of Nickel as an Interlayer in Dissimilar Metal Friction Welding of Maraging Steel to Low Alloy Steel. J. Mater. Process. Technol. 2012, 212, 66–77. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Harrison, R.; Carpenter, C.; Bandyopadhyay, A. Stainless Steel to Titanium Bimetallic Structure Using LENSTM. Addit. Manuf. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Bocklund, B.; Otis, R.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; McEnerney, B.; Liu, Z.-K.; Beese, A.M. Characterization of a Functionally Graded Material of Ti-6Al-4V to 304L Stainless Steel with an Intermediate V Section. J. Alloys Compd. 2018, 742, 1031–1036. [Google Scholar] [CrossRef]

- Li, W.; Karnati, S.; Kriewall, C.; Liou, F.; Newkirk, J.; Brown Taminger, K.M.; Seufzer, W.J. Fabrication and Characterization of a Functionally Graded Material from Ti-6Al-4V to SS316 by Laser Metal Deposition. Addit. Manuf. 2017, 14, 95–104. [Google Scholar] [CrossRef]

- Onuike, B.; Bandyopadhyay, A. Additive Manufacturing of Inconel 718—Ti6Al4V Bimetallic Structures. Addit. Manuf. 2018, 22, 844–851. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and Mechanical Properties of CuSn/18Ni300 Bimetallic Porous Structures Manufactured by Selective Laser Melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Anstaett, C.; Seidel, C.; Reinhart, G. Fabrication of 3D Multi-Material Parts Using Laser-Based Powder Bed Fusion. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.-H. 3D Printing of Multiple Metallic Materials via Modified Selective Laser Melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef]

- Wang, P.; Lao, C.S.; Chen, Z.W.; Liu, Y.K.; Wang, H.; Wendrock, H.; Eckert, J.; Scudino, S. Microstructure and Mechanical Properties of Al-12Si and Al-3.5Cu-1.5Mg-1Si Bimetal Fabricated by Selective Laser Melting. J. Mater. Sci. Technol. 2020, 36, 18–26. [Google Scholar] [CrossRef]

- Wei, K.; Zeng, X.; Li, F.; Liu, M.; Deng, J. Microstructure and Mechanical Property of Ti-5Al-2.5Sn/Ti-6Al-4V Dissimilar Titanium Alloys Integrally Fabricated by Selective Laser Melting. JOM 2020, 72, 1031–1038. [Google Scholar] [CrossRef]

- Nyamuchiwa, K.; Tian, Y.; Chadha, K.; Jiang, L.; Dorin, T.; Aranas, C. Precipitation Behaviour at the Interface of an Additively Manufactured M789–N709 Hybrid Alloy. Acta Metall. Sin. Engl. Lett. 2023, 36, 1353–1370. [Google Scholar] [CrossRef]

- Nadimpalli, V.K.; Dahmen, T.; Valente, E.H.; Mohanty, S.; Pedersen, D.B. Multi-Material Additive Manufacturing of Steels Using Laser Powder Bed Fusion. In Proceedings of the Euspen’s 19th International Conference & Exhibition, Bilbao, Spain, 3–7 June 2019. [Google Scholar]

- Scaramuccia, M.G.; Demir, A.G.; Caprio, L.; Tassa, O.; Previtali, B. Development of Processing Strategies for Multigraded Selective Laser Melting of Ti6Al4V and IN718. Powder Technol. 2020, 367, 376–389. [Google Scholar] [CrossRef]

- Wei, C.; Sun, Z.; Chen, Q.; Liu, Z.; Li, L. Additive Manufacturing of Horizontal and 3D Functionally Graded 316L/Cu10Sn Components via Multiple Material Selective Laser Melting. J. Manuf. Sci. Eng. 2019, 141, 081014. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Multi-Material Selective Laser Melting of Fe/Al-12Si Components. Manuf. Lett. 2017, 11, 8–11. [Google Scholar] [CrossRef]

- Sun, H.; Chu, X.; Luo, C.; Chen, H.; Liu, Z.; Zhang, Y.; Zou, Y. Selective Laser Melting for Joining Dissimilar Materials: Investigations of Interfacial Characteristics and In Situ Alloying. Metall. Mater. Trans. A 2021, 52, 1540–1550. [Google Scholar] [CrossRef]

- Wei, C.; Gu, H.; Li, Q.; Sun, Z.; Liu, Z.; Li, L. Understanding of Process and Material Behaviours in Additive Manufacturing Graded Invar36/Cu10Sn Alloys Multiple Components via Laser Powder Bed Fusion. Addit. Manuf. 2020, 37, 101683. [Google Scholar] [CrossRef]

- Tey, C.F.; Tan, X.; Sing, S.L.; Yeong, W.Y. Additive Manufacturing of Multiple Materials by Selective Laser Melting: Ti-alloy to Stainless Steel via a Cu-Alloy Interlayer. Addit. Manuf. 2020, 31, 100970. [Google Scholar] [CrossRef]

- Mianroodi, J.R.; Shanthraj, P.; Kwiatkowski Da Silva, A.; Svendsen, B.; Raabe, D. Combined Modeling and Experimental Characterization of Mn Segregation and Spinodal Decomposition along Dislocation Lines in Fe–Mn Alloys. Acta Mater. 2023, 251, 118873. [Google Scholar] [CrossRef]

- Deevi, S.C.; Sikka, V.K. Nickel and Iron Aluminides: An Overview on Properties, Processing, and Applications. Intermetallics 1996, 4, 357–375. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Epitaxy and Microstructure Evolution in Metal Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 125–149. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Rafi, H.K.; Pal, D.; Patil, N.; Starr, T.L.; Stucker, B.E. Microstructure and Mechanical Behavior of 17-4 Precipitation Hardenable Steel Processed by Selective Laser Melting. J. Mater. Eng. Perform. 2014, 23, 4421–4428. [Google Scholar] [CrossRef]

- LeBrun, T.; Nakamoto, T.; Horikawa, K.; Kobayashi, H. Effect of Retained Austenite on Subsequent Thermal Processing and Resultant Mechanical Properties of Selective Laser Melted 17–4 PH Stainless Steel. Mater. Des. 2015, 81, 44–53. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W. Microstructures and Mechanical Properties of Fe-Cr Stainless Steel Parts Fabricated by Ultrasonic Vibration-Assisted Laser Engineered Net Shaping Process. Mater. Lett. 2016, 179, 61–64. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Mechanical and Microstructural Properties of Selective Laser Melted 17-4 PH Stainless Steel. In Volume 2A: Advanced Manufacturing; American Society of Mechanical Engineers: Houston, TX, USA, 2015; p. V02AT02A014. [Google Scholar]

- Wu, J.-H.; Lin, C.-K. Influence of High Temperature Exposure on the Mechanical Behavior and Microstructure of 17-4 PH Stainless Steel. J. Mater. Sci. 2003, 38, 965–971. [Google Scholar] [CrossRef]

- Shakerin, S.; Hadadzadeh, A.; Amirkhiz, B.S.; Shamsdini, S.; Li, J.; Mohammadi, M. Additive Manufacturing of Maraging Steel-H13 Bimetals Using Laser Powder Bed Fusion Technique. Addit. Manuf. 2019, 29, 100797. [Google Scholar] [CrossRef]

- Cyr, E.; Asgari, H.; Shamsdini, S.; Purdy, M.; Hosseinkhani, K.; Mohammadi, M. Fracture Behaviour of Additively Manufactured MS1-H13 Hybrid Hard Steels. Mater. Lett. 2018, 212, 174–177. [Google Scholar] [CrossRef]

- Dehgahi, S.; Pirgazi, H.; Sanjari, M.; Alaghmandfard, R.; Tallon, J.; Odeshi, A.; Kestens, L.; Mohammadi, M. Texture Evolution during High Strain-Rate Compressive Loading of Maraging Steels Produced by Laser Powder Bed Fusion. Mater. Charact. 2021, 178, 111266. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rainforth, W.M.; Rivera-Díaz-del-Castillo, P.E.J. Predicting Microstructure and Strength of Maraging Steels: Elemental Optimisation. Acta Mater. 2016, 117, 270–285. [Google Scholar] [CrossRef]

- Tian, Y.; Chadha, K.; Kim, S.H.; Aranas, C. Strengthening Mechanisms in a Heatvar Hot Work Tool Steel Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2021, 805, 140801. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. A Model for the Microstructure Behaviour and Strength Evolution in Lath Martensite. Acta Mater. 2015, 98, 81–93. [Google Scholar] [CrossRef]

- Niu, M.; Zhou, G.; Wang, W.; Shahzad, M.B.; Shan, Y.; Yang, K. Precipitate Evolution and Strengthening Behavior during Aging Process in a 2.5 GPa Grade Maraging Steel. Acta Mater. 2019, 179, 296–307. [Google Scholar] [CrossRef]

- Schnitzer, R.; Zickler, G.A.; Lach, E.; Clemens, H.; Zinner, S.; Lippmann, T.; Leitner, H. Influence of Reverted Austenite on Static and Dynamic Mechanical Properties of a PH 13-8 Mo Maraging Steel. Mater. Sci. Eng. A 2010, 527, 2065–2070. [Google Scholar] [CrossRef]

- Viswanathan, U.K.; Dey, G.K.; Sethumadhavan, V. Effects of Austenite Reversion during Overageing on the Mechanical Properties of 18 Ni (350) Maraging Steel. Mater. Sci. Eng. A 2005, 398, 367–372. [Google Scholar] [CrossRef]

- Kim, B.; Boucard, E.; Sourmail, T.; San Martín, D.; Gey, N.; Rivera-Díaz-del-Castillo, P.E.J. The Influence of Silicon in Tempered Martensite: Understanding the Microstructure–Properties Relationship in 0.5–0.6wt.% C Steels. Acta Mater. 2014, 68, 169–178. [Google Scholar] [CrossRef]

- Nembach, E. Particle Strengthening of Metals and Alloys; Wiley: New York, NY, USA, 1997; ISBN 0-471-12072-3. [Google Scholar]

- Ansell, G.S.; Lenel, F.V. Criteria for Yielding of Dispersion-Strengthened Alloys. Acta Metall. 1960, 8, 612–616. [Google Scholar] [CrossRef]

- Schnitzer, R.; Zinner, S.; Leitner, H. Modeling of the Yield Strength of a Stainless Maraging Steel. Scr. Mater. 2010, 62, 286–289. [Google Scholar] [CrossRef]

- Ardell, A.J. Precipitation Hardening. Metall Trans A 1985, 16, 2131–2165. [Google Scholar] [CrossRef]

- Simm, T.H.; Sun, L.; Galvin, D.R.; Gilbert, E.P.; Alba Venero, D.; Li, Y.; Martin, T.L.; Bagot, P.A.J.; Moody, M.P.; Hill, P.; et al. A SANS and APT Study of Precipitate Evolution and Strengthening in a Maraging Steel. Mater. Sci. Eng. A 2017, 702, 414–424. [Google Scholar] [CrossRef]

- Narita, T.; Ukai, S.; Ohtsuka, S.; Inoue, M. Effect of Tungsten Addition on Microstructure and High Temperature Strength of 9CrODS Ferritic Steel. J. Nucl. Mater. 2011, 417, 158–161. [Google Scholar] [CrossRef]

- Sieurin, H.; Zander, J.; Sandström, R. Modelling Solid Solution Hardening in Stainless Steels. Mater. Sci. Eng. A 2006, 415, 66–71. [Google Scholar] [CrossRef]

- Zeisl, S.; Van Steenberge, N.; Schnitzer, R. Strengthening Effect of NiAl and Ni3Ti Precipitates in Co-Free maraging Steels. J. Mater. Sci. 2023, 58, 7149–7160. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shahriari, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Additive Manufacturing of an Fe–Cr–Ni–Al Maraging Stainless Steel: Microstructure Evolution, Heat Treatment, and Strengthening Mechanisms. Mater. Sci. Eng. A 2020, 787, 139470. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation Strengthening at Ambient and Elevated Temperatures of Heat-Treatable Al(Sc) Alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Thorne, J.K.; Dahl, J.M.; Vlack, L.H. Partition Coefficient of Molybdenum in the Fe-Mo-Si-O System. Metall. Trans. 1970, 1, 2125–2132. [Google Scholar] [CrossRef]

- Jägle, E.A.; Choi, P.-P.; Van Humbeeck, J.; Raabe, D. Precipitation and Austenite Reversion Behavior of a Maraging Steel Produced by Selective Laser Melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural Characterization and Properties of Selective Laser Melted Maraging Steel with Different Build Directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in Additive Manufacturing: A Review of Their Microstructure and Properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Lang, F.H.; Kenyon, N. Welding of Maraging Steels; Nickel Institute: Toronto, ON, Canada, 2002. [Google Scholar]

- Bai, Y.; Wang, D.; Yang, Y.; Wang, H. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Maraging Steel by Selective Laser Melting. Mater. Sci. Eng. A 2019, 760, 105–117. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N.M. On the Precipitation Hardening of Selective Laser Melted AlSi10Mg. Metall. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser Additive Manufacturing of Metallic Components: Materials, Processes and Mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Thorsteinsdóttir, E.G.; Primdahl, D.S.; Zhang, Y.B.; Jensen, D.J.; Yu, T. Aging of 3D-Printed Maraging Steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 580, 012047. [Google Scholar] [CrossRef]

- Allam, T.; Pradeep, K.G.; Köhnen, P.; Marshal, A.; Schleifenbaum, J.H.; Haase, C. Tailoring the Nanostructure of Laser Powder Bed Fusion Additively Manufactured Maraging Steel. Addit. Manuf. 2020, 36, 101561. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Ghavidel, M.R.Z.; Nedjad, S.H.; Heidarzadeh, A.; Ahmadabadi, M.N. Aging Behavior and Mechanical Properties of Maraging Steels in the Presence of Submicrocrystalline Laves Phase Particles. Mater. Charact. 2011, 62, 976–981. [Google Scholar] [CrossRef]

- Liu, B.; Lü, Z.; Feng, W.; Ren, T.; Fu, W. Precipitation and Decomposition Behaviors of Carbides in AISI M2 High-Speed Steel with Nitrogen and Mischmetal. J. Cent. South Univ. 2017, 24, 782–788. [Google Scholar] [CrossRef]

- Meredith, S.D.; Zuback, J.S.; Keist, J.S.; Palmer, T.A. Impact of Composition on the Heat Treatment Response of Additively Manufactured 17–4 PH Grade Stainless Steel. Mater. Sci. Eng. A 2018, 738, 44–56. [Google Scholar] [CrossRef]

- Turnier Trottier, W.; Kreitcberg, A.; Brailovski, V. Structure and Mechanical Properties of Laser Powder Bed-Fused and Wrought PH13-8Mo-Type Precipitation Hardening Stainless Steels: Comparative Study. J. Manuf. Mater. Process. 2021, 5, 67. [Google Scholar] [CrossRef]

- Murthy, C.V.S.; Krishna, A.G.; Reddy, G.M. Dissimilar Welding of Maraging Steel (250) and 13-8 Mo Stainless Steel by GTCAW, LBW and EBW Processes. Trans. Indian Inst. Met. 2019, 72, 2433–2441. [Google Scholar] [CrossRef]

| Hybrid Technique | Fe-Based Systems | Other Systems | References |

|---|---|---|---|

| AM + CNC part/CNC as post-processing | Maraging steels, tool steels, and SS316L. | [25,29] | |

| AM as a repairing technique | Maraging steels, SS316L, and tool steels. | Al6061, Ti-6Al-4V; Ni-super-alloys, and brass. | [37,38] |

| Combined AM processes | SS316L | Ti alloys, resin, polymers (PLA, PET), and ceramics. | [37,39,41] |

| Hybrid machine | SS316L | Inconel, PLA, and ABS. | [44,45] |

| AM process on a conventionally made part | Maraging steels | [34,46,47] |

| Process-P (W) | V (mm/s) | H (J/mm) | Orientation | E (GPa) | σy (MPa) | σuts (MPa) | Elongation (%) | HVN |

|---|---|---|---|---|---|---|---|---|

| DED—350 [86] | 8.3 | 36.1 | Absent | 40 ± 10 | 400 ± 100 | 900 ± 200 | 5 ± 3 | 441 |

| PBF—190 [85] | 787 | 0.24 | Longitudinal | Absent | 661 ± 24 | 1255 ± 3 | 16.2 ± 2.5 | 333 ± 2 |

| PBF—195 [82] | 800 | 0.24 | Absent | Transverse | 570 ± 13 | 944 ± 35 | 50 ± 1 | Absent |

| PBF—95 [87] | 350 | 0.27 | Longitudinal | Absent | 610 ± 10 | 1050 ± 20 | 11 ± 0 | Absent |

| Transverse | Absent | 610 ± 10 | 910 ± 10 | 3.5 ± 1.5 | Absent | |||

| Conventional processing—N/A [88] | Wrought, solution annealed and aged | N/A | N/A | 199 | 992 | 1018 | 13.4 | 430 |

| Element | βi (MPa/at) |

|---|---|

| Ni | 708 |

| Mn | 540 |

| Cr | 622 |

| Al | 196 |

| Ti | 2628 |

| Mo | 2368 |

| Sample Treatment | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| As-printed | 1165 ± 12 | 1190 ± 16 | 4 ± 1 |

| Aged | 1660 ± 18 | 1980 ± 20 | 2 ± 1 |

| Solution-treated | 1156 ± 12 | 1369 ± 18 | 15 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nyamuchiwa, K.; Palad, R.; Panlican, J.; Tian, Y.; Aranas, C., Jr. Recent Progress in Hybrid Additive Manufacturing of Metallic Materials. Appl. Sci. 2023, 13, 8383. https://doi.org/10.3390/app13148383

Nyamuchiwa K, Palad R, Panlican J, Tian Y, Aranas C Jr. Recent Progress in Hybrid Additive Manufacturing of Metallic Materials. Applied Sciences. 2023; 13(14):8383. https://doi.org/10.3390/app13148383

Chicago/Turabian StyleNyamuchiwa, Kudakwashe, Robert Palad, Joan Panlican, Yuan Tian, and Clodualdo Aranas, Jr. 2023. "Recent Progress in Hybrid Additive Manufacturing of Metallic Materials" Applied Sciences 13, no. 14: 8383. https://doi.org/10.3390/app13148383

APA StyleNyamuchiwa, K., Palad, R., Panlican, J., Tian, Y., & Aranas, C., Jr. (2023). Recent Progress in Hybrid Additive Manufacturing of Metallic Materials. Applied Sciences, 13(14), 8383. https://doi.org/10.3390/app13148383