The Role of the Distance between Fine Non-Metallic Oxide Inclusions on the Fatigue Strength of Low-Carbon Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion of the Research Results

4. Conclusions

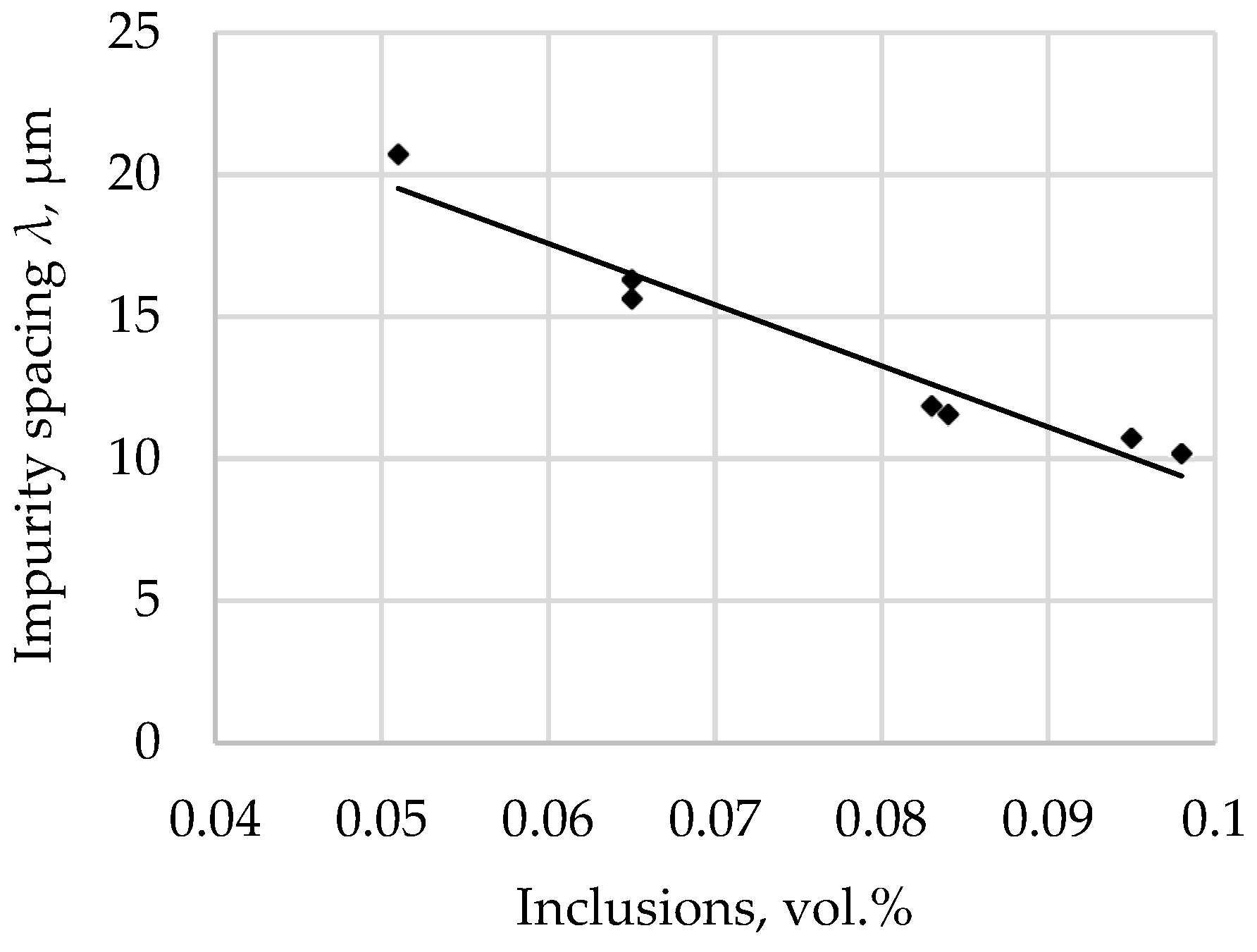

- Has a very small amount of impurities, i.e., approx. 0.18 vol.%;

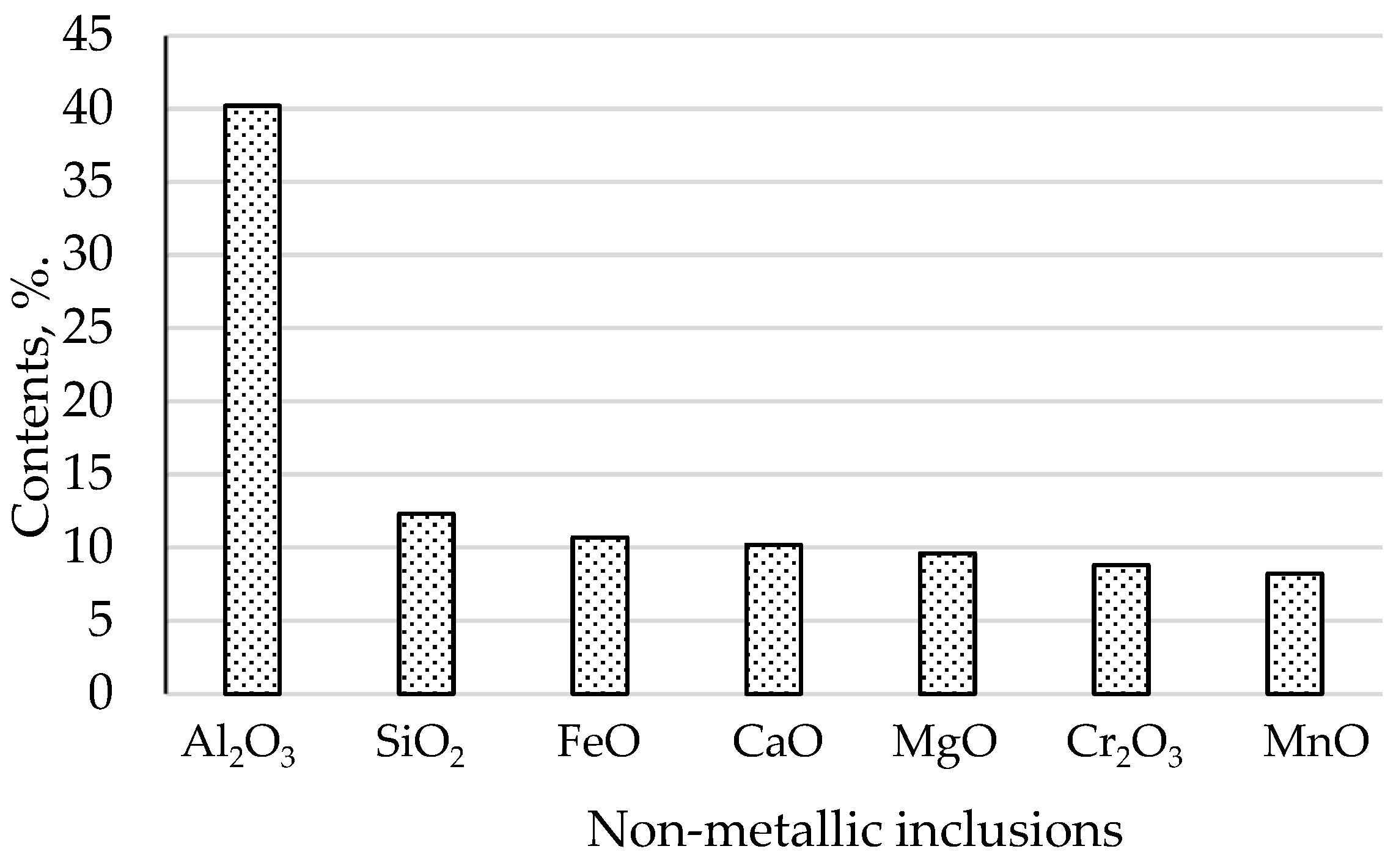

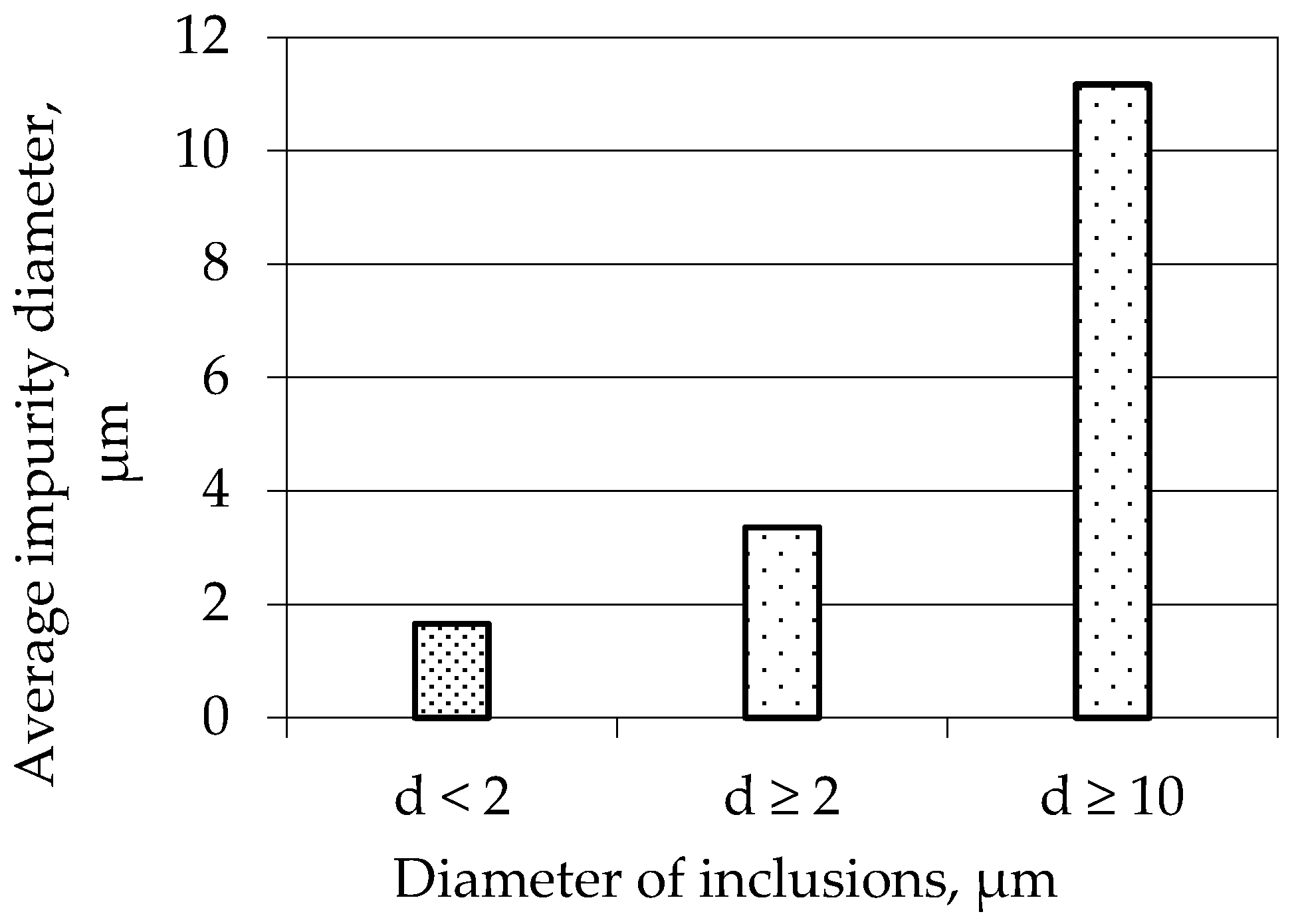

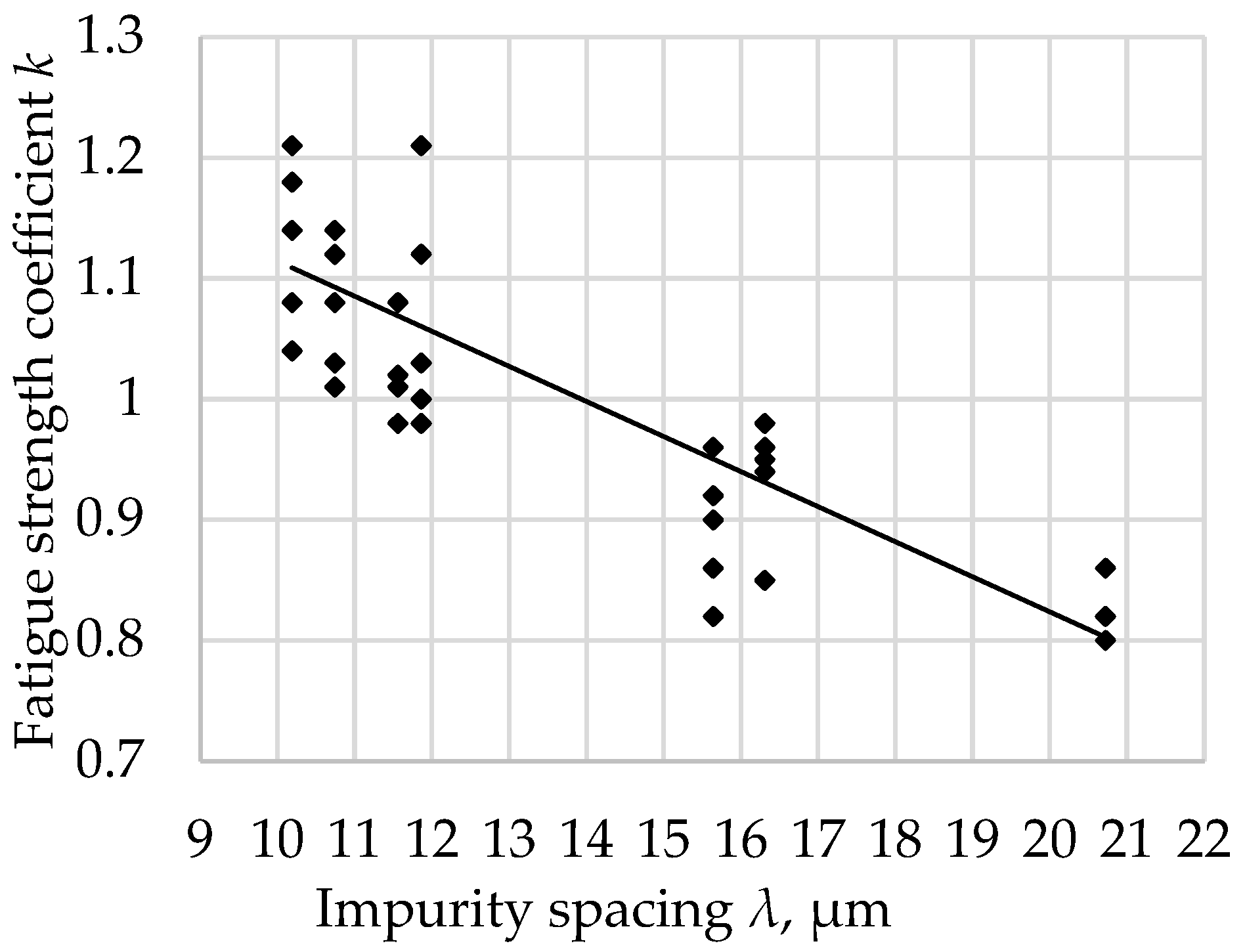

- The largest amount of impurities is Al2O3, and the main fraction of this oxide is impurities with an arithmetic mean diameter of 1.8 µm and an arithmetic mean distance between these inclusions of 12 µm;

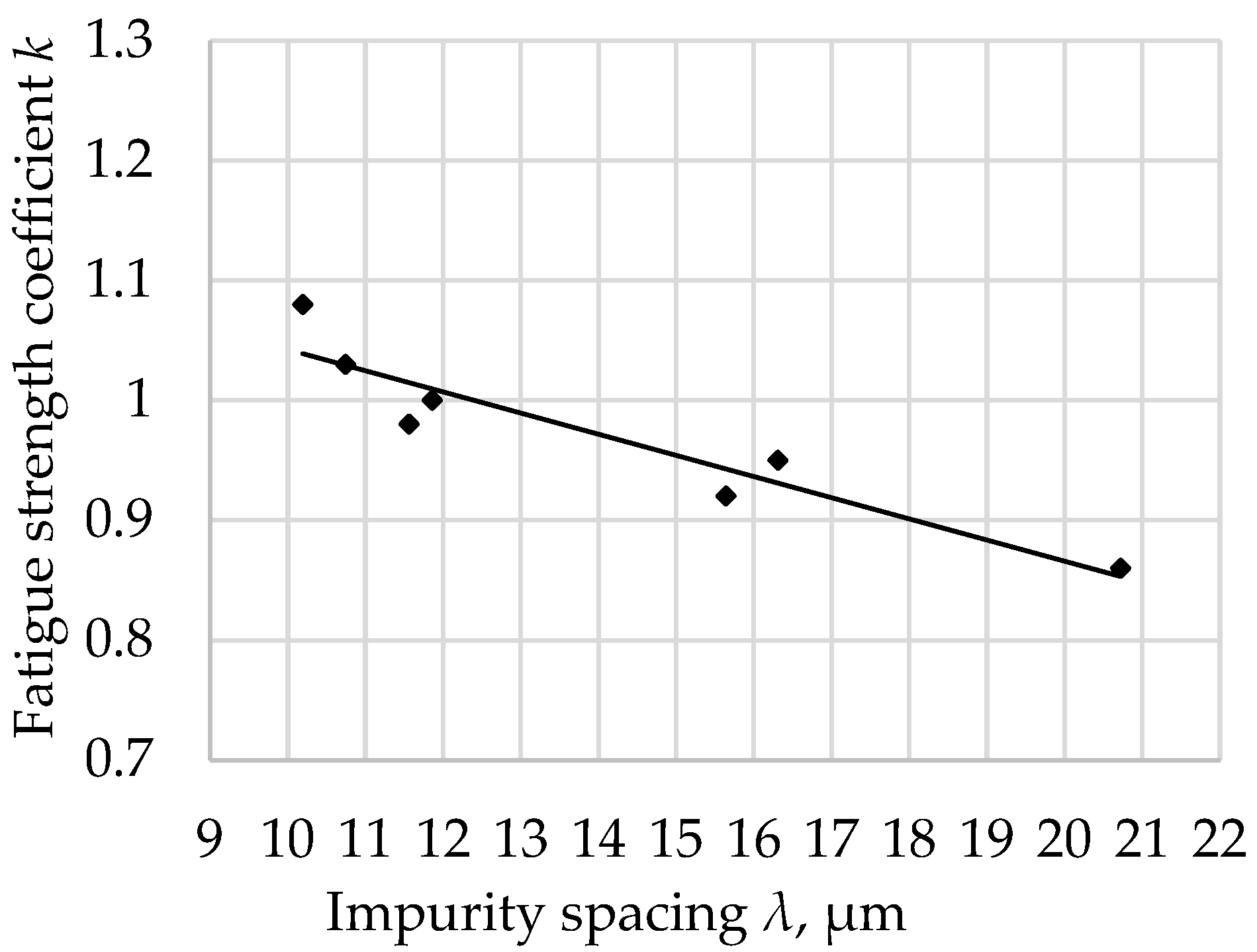

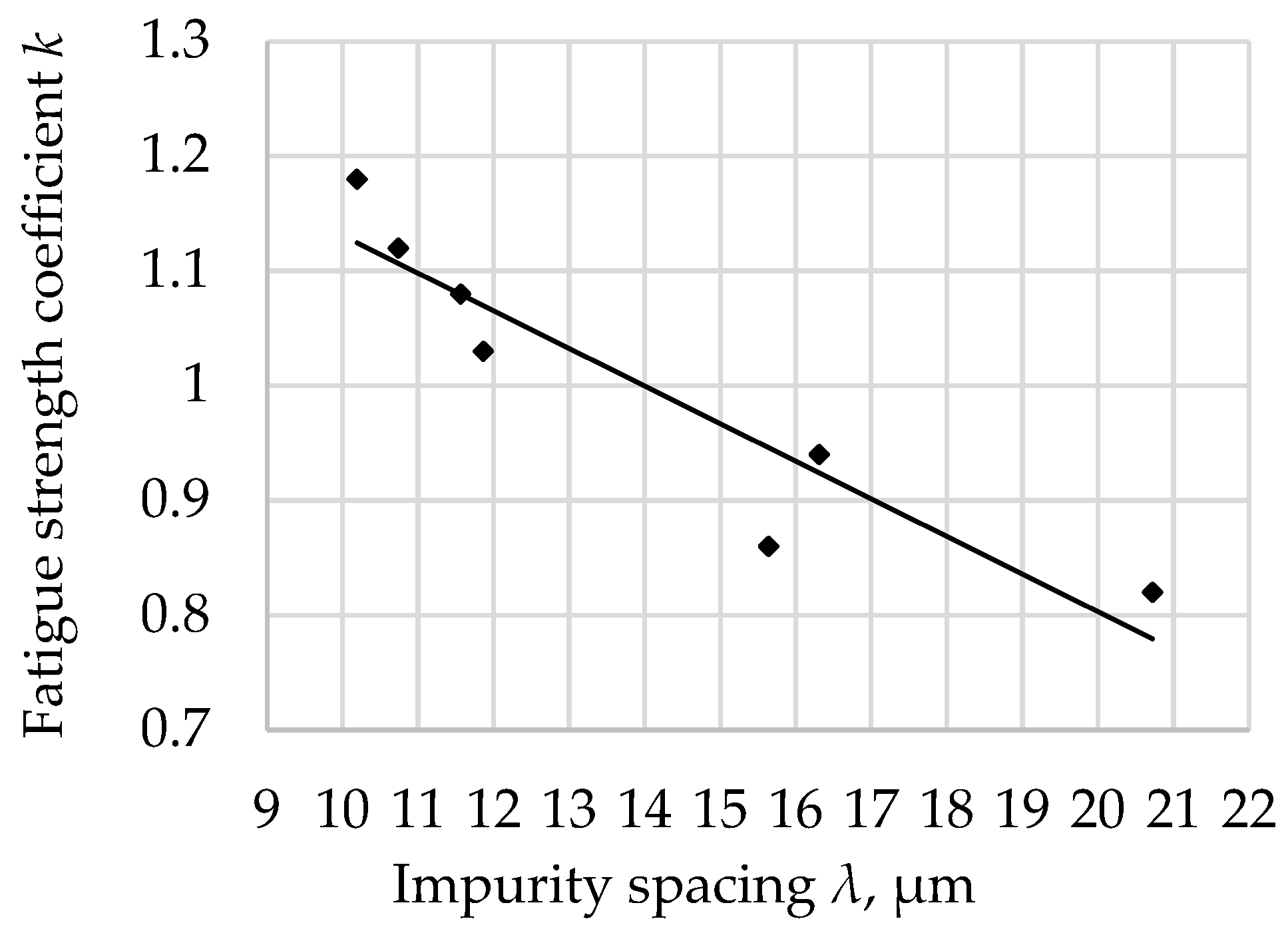

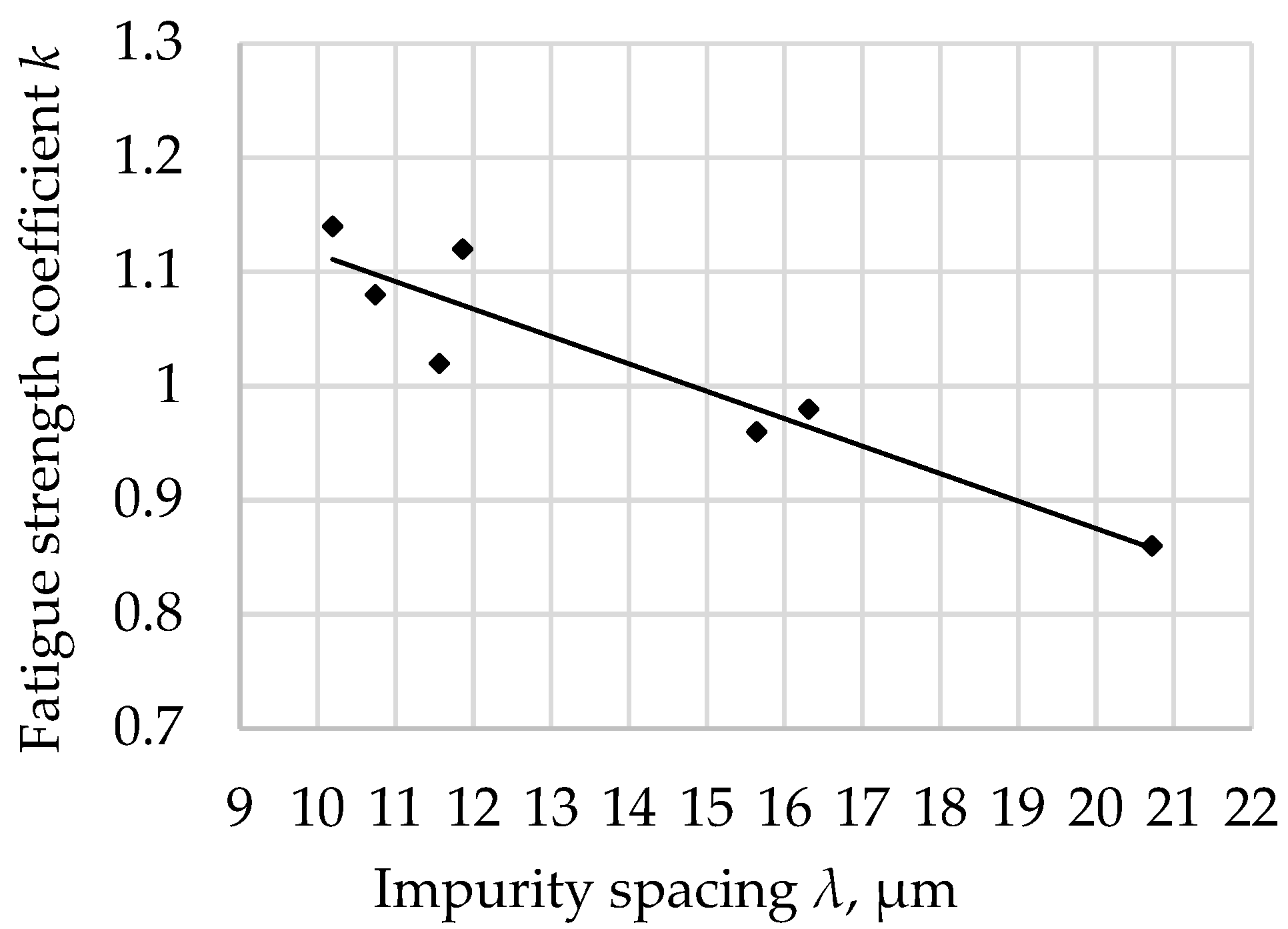

- The fatigue resistance factor k for non-metallic inclusions with a diameter below 2 µm is inversely proportional to impurity spacing λ.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bricín, D.; Kříž, A. Influence of the Boriding Process on the Properties and the Structure of the Steel S265 and the Steel X6CrNiTi18-10. Manuf. Technol. 2021, 21, 37–44. [Google Scholar] [CrossRef]

- Hua, L.; Deng, S.; Han, X.; Huang, S. Effect of material defects on crack initiation under rolling contact fatigue in a bearing ring. Tribol. Int. 2013, 66, 315–323. [Google Scholar] [CrossRef]

- Dobrzański, L.A. Heat treatment as the fundamental technological process of formation of structure and properties of the metallic engineering materials. In Proceedings of the 8th Seminar of the International Federation for Heat Treatment and Surface Engineering IFHTSE, Dubrovnik-Cavtat, Croatia, 12–14 September 2001; pp. 1–12. [Google Scholar]

- Yanase, K.; Endo, M. Multiaxial high cycle fatigue threshold with small defects and craks. Eng. Mech. 2014, 123, 182–196. [Google Scholar]

- Ivanytskyj, Y.L.; Lenkovskiy, T.M.; Molkov, Y.V.; Kulyk, V.V.; Duriagina, Z.A. Influence of 65G steel microstructure on crack faces friction factor under mode fatigue fracture. Arch. Mater. Sci. Eng. 2016, 82, 49–56. [Google Scholar] [CrossRef]

- Blikharskyy, Y.; Selejdak, J.; Kopiika, N. Corrosion fatigue damages of rebars under loading in time. Materials 2021, 14, 3416. [Google Scholar] [CrossRef]

- Jonšta, P.; Jonšta, Z.; Brožová, S.; Ingaldi, M.; Pietraszek, J.; Klimecka-Tatar, D. The Effect of Rare Earth Metals Alloying on the Internal Quality of Industrially Produced Heavy Steel Forgings. Materials 2021, 14, 5160. [Google Scholar] [CrossRef]

- Halford, G.L. Low Cycle Thermal Fatigue; NASA: Washington, DC, USA, 1986.

- Lipiński, T. Influence of non-metallic inclusions on bending fatigue strength of high-quality carbon constructional steel heated in an industrial electric arc furnace. Materials 2022, 15, 6140. [Google Scholar] [CrossRef]

- Qayyum, F.; Umar, M.; Elagin, V.; Kirschner, M.; Hoffmann, F.; Guk, S.; Prahl, U. Influence of non-metallic inclusions on local deformation and damage behavior of modified 16MnCrS5 steel. Crystals 2022, 12, 281. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Wang, Z.; Xing, Z.; Wang, H.; Shan, D.; Huang, Y.; Xu, Z.; Xie, F. The relationship between inclusions characteristic parameters and bending fatigue performance of 20Cr2Ni4A gear steel. Int. J. Fatigue 2022, 155, 106594. [Google Scholar] [CrossRef]

- Fernandes, M.; Pires, J.C.; Cheung, N.; Garcia, A. Influence of refining time on nonmetallic inclusions in a low-carbon, silicon-killed steel. Mater. Charact. 2003, 51, 301–308. [Google Scholar] [CrossRef]

- Lipiński, T. Effect of Non-Metallic Inclusions on the Fatigue Strength Coefficient of High-Purity Constructional Steel Heated in Industrial Conditions. Appl. Sci. 2022, 12, 9292. [Google Scholar] [CrossRef]

- Srivastava, A.; Ponson, L.; Osovski, S.; Bouchaud, E.; Tvergaard, V.; Needleman, A. Effect of inclusion density on ductile fracture toughness and roughness. J. Mech. Phys. Solids 2014, 63, 62–79. [Google Scholar] [CrossRef]

- Saberifar, S.; Mashreghi, A.; Novel, A. Method for the Prediction of Critical Inclusion Size Leading to Fatigue Failure. Metall. Mater. Trans. 2012, 43, 603–608. [Google Scholar] [CrossRef]

- Petrovic, D.S.; Jenko, M.; Hraes, M. Study of the morphology of non-metallic inclusions in non-oriented electrical steel containing Cu and Se. Vacuum 2003, 71, 33–40. [Google Scholar] [CrossRef]

- Roiko, A.; Hänninen, H.; Vuorikari, H. Anisotropic distribution of non-metallic inclusions in a forged steel roll and its influence on fatigue limit. Int. J. Fatigue 2012, 41, 158–167. [Google Scholar] [CrossRef]

- Zhang, L.; Pluschkell, W. Nucleation and growth kinetics of inclusions during liquid steel deoxidation. Ironmak Steelmak. 2003, 30, 106–110. [Google Scholar] [CrossRef]

- Gulyakov, V.S.; Vusikhis, A.S.; Kudinov, D.Z. Nonmetallic Oxide Inclusions and Oxygen in the Vacuum-Jet Refining of Steel. Steel Transl. 2012, 42, 781–783. [Google Scholar] [CrossRef]

- Zhou, D.G.; Fu, J.; Chen, X.C.; Li, J. Study on oxygen content, inclusions and fatigue properties of bearing steels produced by different processes. J. Univ. Sci. Technol. Beijing 2001, 8, 25–27. [Google Scholar]

- Moiseeva, L.A.; Moiseev, B.P. Composition, Structure, and Sources of Exogenous Inclusions in Steel. Steel Transl. 2007, 37, 607–613. [Google Scholar] [CrossRef]

- Senberger, J.; Zadera, A.; Cech, J. Checking the metallurgy with the aid of inclusion analysis. Arch. Foundry Eng. 2011, 11, 118–122. [Google Scholar]

- Luo, C.; Stahlberg, U. Deformation of inclusions during hot rolling in steels. J. Mater. Process. Technol. 2001, 114, 87–89. [Google Scholar] [CrossRef]

- Alatarvas, T.; Podor, R.; Heikkinen, E.; Shu, Q.; Singh, H. Revealing the Kinetics of Non-metallic Inclusion Reactions in Steel using In-situ High Temperature Environmental Scanning Electron Microscopy. Mater. Des. 2023, 112139. [Google Scholar] [CrossRef]

- Kiessling, R. Non-Metallic Inclusions in Steel; The Institute of Materials: London, UK, 1978. [Google Scholar]

- Hawryluk, M.; Lachowicz, M.; Łukaszek-Sołek, A.; Lisiecki, Ł.; Ficak, G.; Cygan, P. Structural Features of Fatigue Crack Propagation of a Forging Die Made of Chromium–Molybdenum–Vanadium Tool Steel on Its Durability. Materials 2023, 16, 4223. [Google Scholar] [CrossRef] [PubMed]

- Spriestersbach, D.; Grad, P.; Kerscher, E. Influence of different non-metallic inclusion types on the crack initiation in high-strength steels in the VHCF regime. Int. J. Fatigue 2014, 64, 114–120. [Google Scholar] [CrossRef]

- Lv, B.; Xia, S.; Zhang, F.; Yang, G.; Long, X. Comparison of Novel Low-Carbon Martensitic Steel to Maraging Steel in Low-Cycle Fatigue Behavior. Coatings 2022, 12, 818. [Google Scholar] [CrossRef]

- Gao, S.; Meng, H.; Wu, Y.; Wang, X.; Wang, Y.; Wu, J.; Wang, P. Examination of the Effects of Different Frequencies on Rock Fracturing via Laboratory-Scale Variable Amplitude Fatigue Loading Experiments. Appl. Sci. 2023, 13, 4908. [Google Scholar] [CrossRef]

- Lv, H.; Zhang, Z.; Li, J.; Liu, Y.; Chen, H.; He, H.; Cheng, J.; Chen, Y. The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition. Coatings 2022, 12, 822. [Google Scholar] [CrossRef]

- Ulewicz, R.; Szataniak, P.; Novy, F. Fatigue properties of wear resistant martensitic steel. In Proceedings of the METAL 2014–23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014; pp. 784–789. [Google Scholar]

- Zhang, X.; Liu, F.; Shen, M.; Han, D.; Wang, Z.; Yan, N. Ultra-High-Cycle Fatigue Life Prediction of Metallic Materials Based on Machine Learning. Appl. Sci. 2023, 13, 2524. [Google Scholar] [CrossRef]

- Gocál, J.; Vičan, J.; Jošt, J. Real Stiffness and Fatigue Resistance of Stringer-to-Cross-Girder Connection of Riveted Steel Railway Bridges. Appl. Sci. 2023, 13, 2278. [Google Scholar] [CrossRef]

- Concli, F.; Maccioni, L.; Fraccaroli, L.; Cappellini, C. Effect of Gear Design Parameters on Stress Histories Induced by Different Tooth Bending Fatigue Tests: A Numerical-Statistical Investigation. Appl. Sci. 2022, 12, 3950. [Google Scholar] [CrossRef]

- Velázquez, J.C.; Hernández-Huerta, J.J.; Diaz-Cruz, M.; Hernández-Sánchez, E.; Cervantes-Tobón, A.; Capula-Colindres, S.I.; Cabrera-Sierra, R. Study on the Influence of Non-Metallic Inclusions on the Pitting Corrosion of API 5L X60 Steel. Coatings 2023, 13, 1040. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue, Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Oxford, UK, 2002; pp. 57–115. [Google Scholar]

- Lipiński, T. Influence of the Scatter Index of Non-Metallic Inclusions in Structural Steel on the Fatigue Resistance Coefficient. Materials 2023, 16, 2758. [Google Scholar] [CrossRef]

- Jovičević-Klug, P.; Jovičević-Klug, M.; Rohwerder, M.; Godec, M.; Podgornik, B. Complex Interdependency of Microstructure, Mechanical Properties, Fatigue Resistance, and Residual Stress of Austenitic Stainless Steels AISI 304L. Materials 2023, 16, 2638. [Google Scholar] [CrossRef]

- Lipiński, T. Effect of Impurities Spacing on Fatigue Strength Coefficient. Coatings 2023, 13, 242. [Google Scholar] [CrossRef]

- Bermond, A.; Roume, C.; Stolarz, J.; Lenci, M.; Carton, J.-F.; Klocker, H. Low Cycle Fatigue of G20Mn5 Cast Steel Relation between Microstructure and Fatigue Life. Materials 2022, 15, 7072. [Google Scholar] [CrossRef]

- Lipiński, T.; Ulewicz, R. The effect of the impurities spaces on the quality of structural steel working at variable loads. Open Eng. 2021, 11, 233–238. [Google Scholar] [CrossRef]

- Murakami, Y.; Kodama, S.; Konuma, S. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels, I: Basic fatigue mechanism and fatigue fracture stress and the size and location of non-metallic inclusions. Int. J. Fatigue 1989, 11, 291–298. [Google Scholar] [CrossRef]

- Kocańda, S. Fatigue Failure of Metals; WNT: Warsaw, Poland, 1985. (In Polish) [Google Scholar]

- Guide engineer. Mechanic; Scientific and Technical Publishing: Warsaw, Poland, 1970. (In Polish) [Google Scholar]

- PN-74/H-04327; Metals Testing for Fatigue. Axial Tensile-Compression Test at a Constant Cycle of External Loads. Polish Committee for Standardization: Warsaw, Poland, 1974.

| Chemical Element | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | B |

|---|---|---|---|---|---|---|---|---|---|---|

| Contents | 0.20–0.25 | 0.22–0.32 | 1.05–1.40 | 0.014–0.24 | 0.010–0.016 | 0.43–0.55 | 0.42–0.50 | 0.20–0.25 | 0.13–0.17 | 0.002–0.004 |

| Standard deviation | 0.017 | 0.046 | 0.123 | 0.0039 | 0.0036 | 0.056 | 0.040 | 0.016 | 0.014 | 0.0008 |

| Tempering Temperature, °C | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|

| Vickers hardness, HV | 432 | 412 | 372 | 333 | 275 |

| Maximum load, MPa | 650 | 600 | 600 | 600 | 540 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipiński, T. The Role of the Distance between Fine Non-Metallic Oxide Inclusions on the Fatigue Strength of Low-Carbon Steel. Appl. Sci. 2023, 13, 8354. https://doi.org/10.3390/app13148354

Lipiński T. The Role of the Distance between Fine Non-Metallic Oxide Inclusions on the Fatigue Strength of Low-Carbon Steel. Applied Sciences. 2023; 13(14):8354. https://doi.org/10.3390/app13148354

Chicago/Turabian StyleLipiński, Tomasz. 2023. "The Role of the Distance between Fine Non-Metallic Oxide Inclusions on the Fatigue Strength of Low-Carbon Steel" Applied Sciences 13, no. 14: 8354. https://doi.org/10.3390/app13148354

APA StyleLipiński, T. (2023). The Role of the Distance between Fine Non-Metallic Oxide Inclusions on the Fatigue Strength of Low-Carbon Steel. Applied Sciences, 13(14), 8354. https://doi.org/10.3390/app13148354