Monitoring Hygienic Measures for Decreasing Salmonella Occurrence in Scalding Tank Water of a Turkey Slaughterhouse

Abstract

1. Introduction

2. Materials and Methods

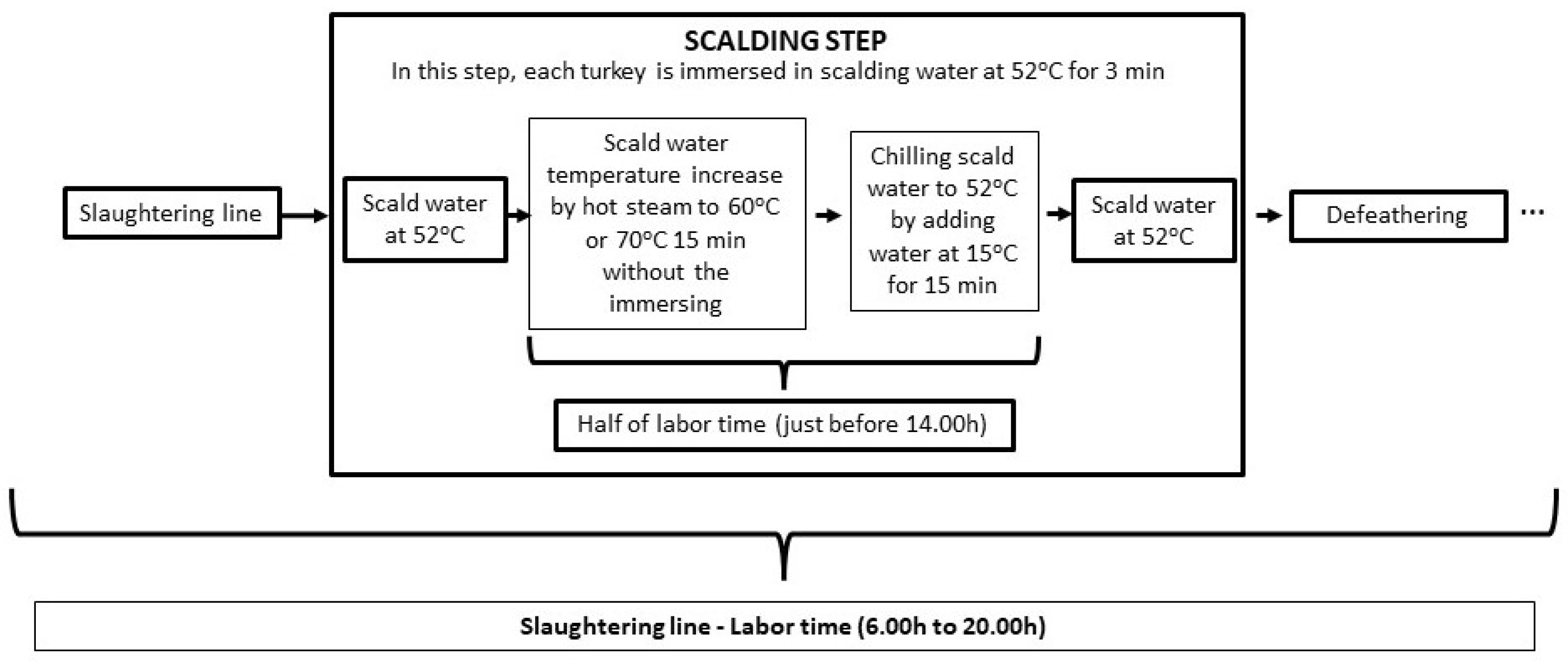

2.1. Experimental Design and Sampling

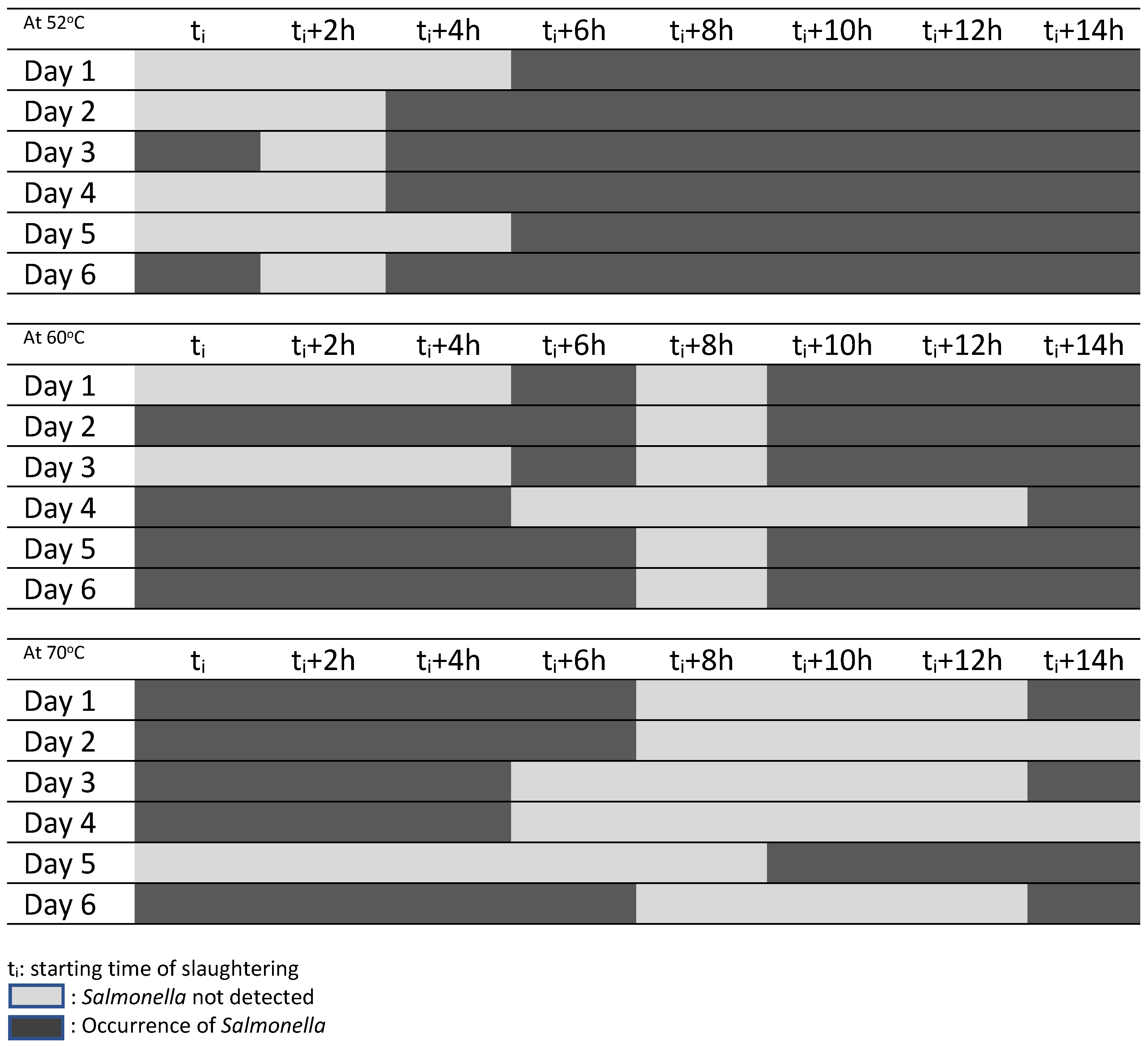

2.2. Heating of Scalding Water

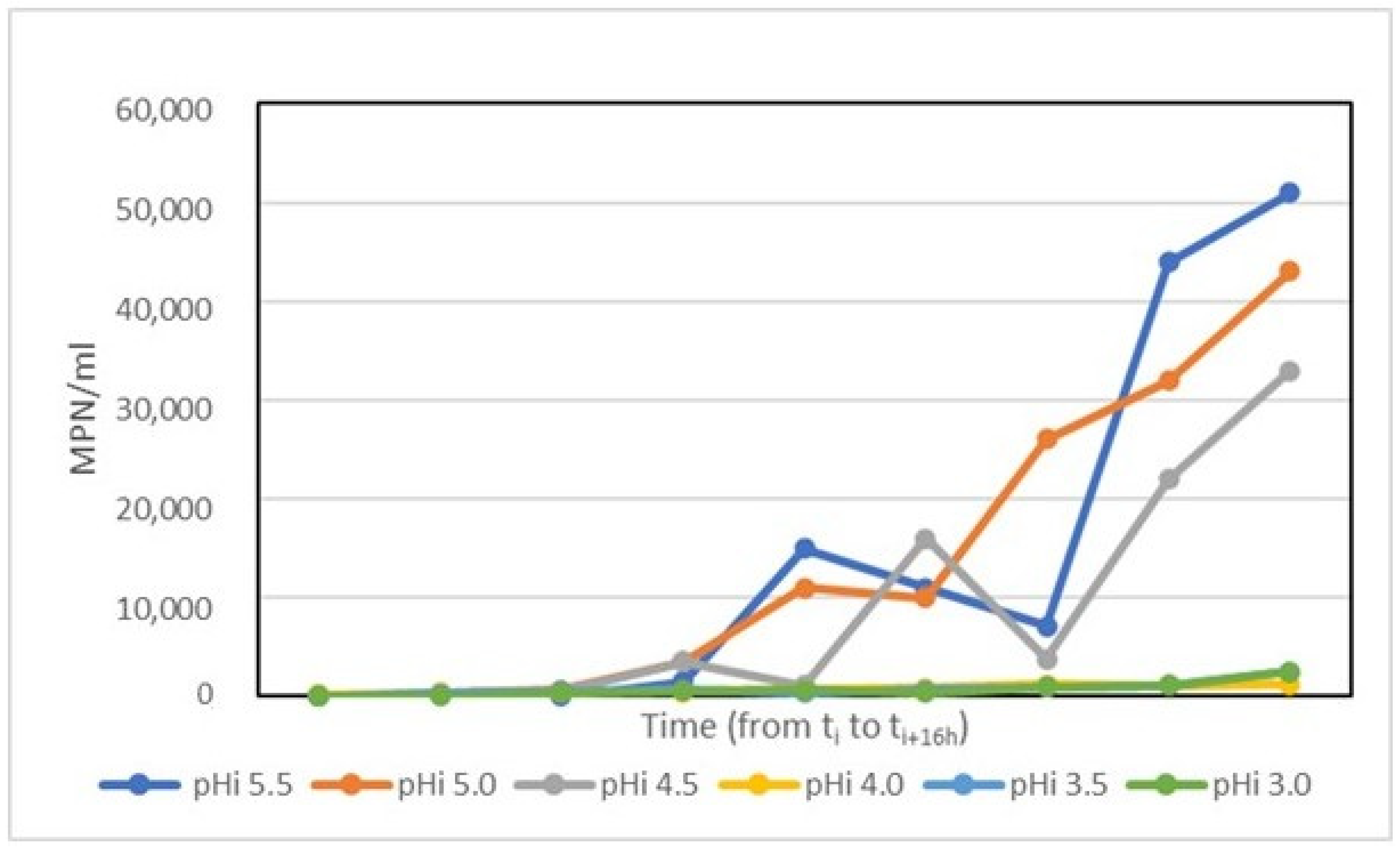

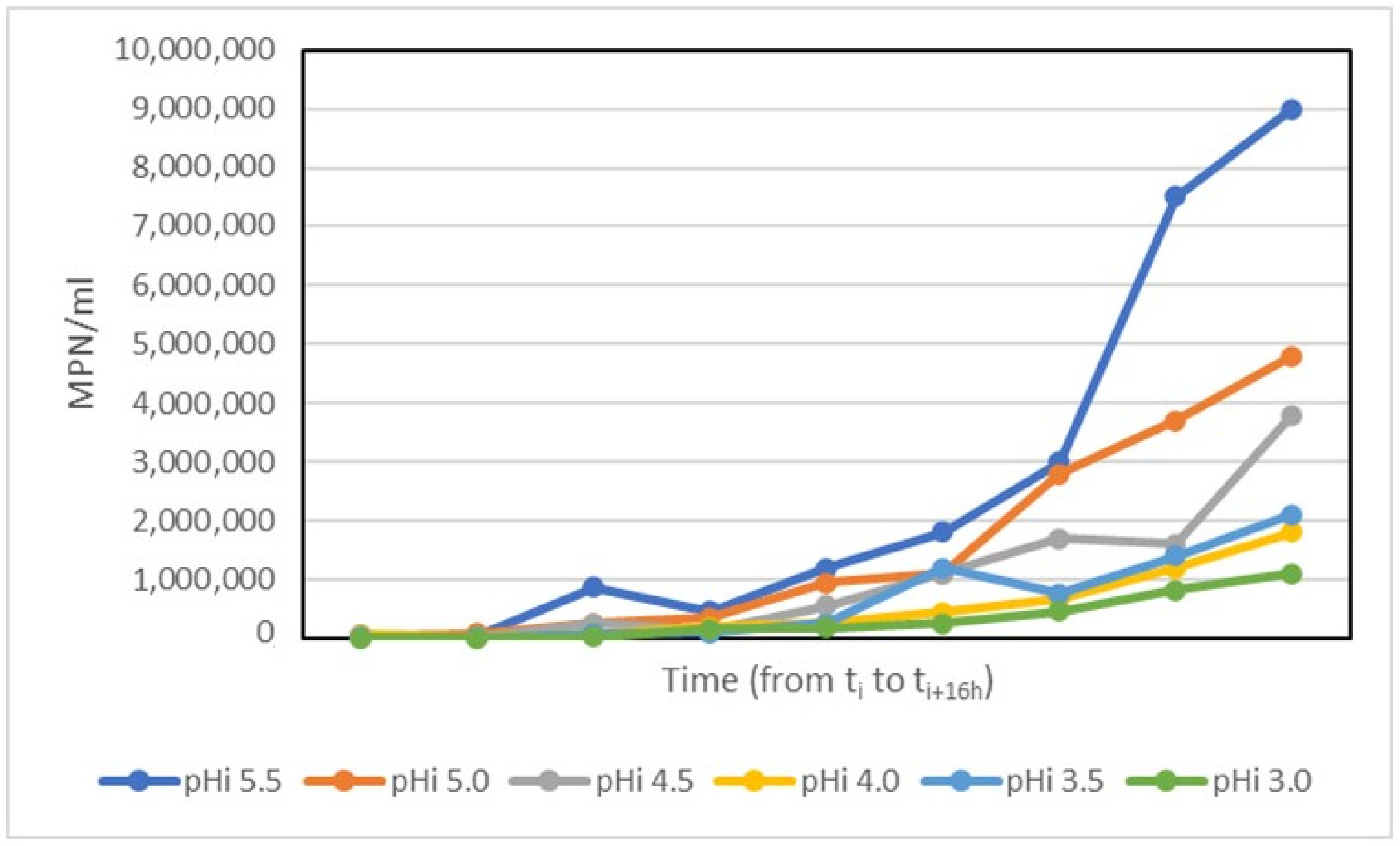

2.3. Acidification of Scalding Water

2.4. Determination of Salmonella, Mesophilic Aerobic Bacteria (MAB), and E. coli

2.5. Sensory Tests

2.6. Statistical Analyses

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, T.; Liu, Y.; Qin, X.; Aspridou, Z.; Zheng, J.; Wang, X.; Li, Z.; Dong, Q. The prevalence and epidemiology of Salmonella in retail raw poultry meat in China: A systematic review and meta-analysis. Foods 2021, 10, 2757. [Google Scholar] [CrossRef] [PubMed]

- Anonymous. EFSA—European Food Safety Authority and European Centre for Disease Prevention and Control. Scientific Report. The European Union One Health 2019 Zoonoses Report. EFSA J. 2021, 19, 6406. [Google Scholar] [CrossRef]

- European Parliament and European Council. Regulation (EC) No 2160/2003 of the European Parliament and of the Council of 17 November 2003 on the Control of Salmonella and Other Specified Food-Borne Zoonotic Agents; European Union: Brussels, Belgium, 2003. [Google Scholar]

- MAPA—Ministerio de Agricultura, Pesca y Alimentación. Royal Decree 1084/2005, 16th September, for the Ordinance of Aviculture for Meat Production; MAPA: Madrid, Spain, 2005.

- Cano, N.; Arispón, F.; Jordano, R.; Medina, L.M. Monitoring hygienic measures for decreasing Salmonella occurrence in turkey barns. Arch. Leb. J. Food Saf. Food Qual. 2020, 71, 75–80. [Google Scholar] [CrossRef]

- European Commission. Regulation (EU) No 1190/2012 of 12 December 2012 Concerning a Union Target for the Reduction of Salmonella Enteritidis and Salmonella Typhimurium in Flocks of Turkeys, as Provided for in Regulation (EC) No 2160/2003 of the European Parliament and of the Council Text with EEA Relevance; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- MAPAMA—Ministerio de Agricultura, Pesca, Alimentación y Medio Ambiente. National Programme for the Vigilance and Control of Certain Serotypes of Salmonella in Turkeys; MAPAMA: Madrid, Spain, 2016.

- Barbut, S. Poultry: Processing. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Elsevier-Academic Press: Amsterdam, The Netherlands, 2015; pp. 458–463. [Google Scholar]

- Buhr, R.J.; Walker, J.M.; Bourassa, D.V.; Caudill, A.B.; Kiepper, B.H.; Zhuang, H. Impact of broiler processing scalding and chilling profiles on carcass and breast meat yield. Poultry Sci. 2014, 93, 1534–1541. [Google Scholar] [CrossRef]

- Cox, J.M.; Pavic, A. Advances in enteropathogen control in poultry production. J. Appl. Microbiol. 2010, 108, 745–755. [Google Scholar] [CrossRef]

- Irshad, T.S.; Arun, A. Scalding and its significance in livestock slaughter and wholesome meat production. Int. J. Livest. Res. 2013, 3, 45–53. [Google Scholar]

- Mulder, R.W.A.W.; Dorrestejin, L.W.J.; Borek, J.V. Cross-contamination during the scalding and picking of broilers. Br. Poult. Sci. 1978, 19, 61–70. [Google Scholar] [CrossRef]

- Gonzalez-Miret, M.L.; Escudero-Gilete, M.L.; Heredia, F.J. The establishment of critical control points at the washing and air chilling stages in poultry meat production using multivariate statistics. Food Control 2006, 17, 935–941. [Google Scholar] [CrossRef]

- Russell, S.M. The effect of an acidic, copper sulfate based commercial sanitizer on indicator, pathogenic and spoilage bacteria associated with broiler chicken carcasses when applied at various intervention points during poultry processing. Poult. Sci. 2008, 87, 1435–1440. [Google Scholar] [CrossRef]

- González-Fandos, E.; Guadalupe, Z.; Jiménez, S.; Pérez, A. Effect of processing and storage on the microbiological quality of poultry. In Microbiological and Chemical Contamination and Alterations of Different Products; Research Signpost: Kerala, India, 2009; pp. 47–64. [Google Scholar]

- Buncic, S.; Sofos, J. Interventions to control Salmonella contamination during poultry, cattle and pig slaughter. Food Res. Int. 2012, 45, 641–655. [Google Scholar] [CrossRef]

- Cason, J.A.; Hinton, A. Coliforms, Escherichia coli, Campylobacter and Salmonella in a counterflow poultry scalder with a dip tank. Int. J. Poult. Sci. 2006, 5, 846–849. [Google Scholar]

- Cason, J.A.; Hinton, A.; Ingram, K.D. Coliform, Escherichia coli, and salmonellae concentrations in a multiple-tank, counter flow poultry scalder. J. Food Prot. 2000, 63, 1184–1188. [Google Scholar] [CrossRef] [PubMed]

- Cason, J.A.; Whittemore, A.D.; Shackelford, A.D. Aerobic bacteria and solids in a three-tank, two pass counterflow scalder. Poult. Sci. 1999, 78, 144–147. [Google Scholar] [CrossRef]

- FAO; WHO. Microbiological Risk Assessment, Series 19. Salmonella and Campylobacter in Chicken Meat; Meeting Report; FAO: Rome, Italy; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- FAO; WHO. Proposed Draft Guidelines for Control of Campylobacter and Salmonella spp. in Chicken Meat (N08-2007). In Joint FAO/WHO Food Standards Programme; Codex Committee on Food Hygiene, Proceedings of the Forty—First Session, Coronado, CA, USA, 16–20 November 2009; FAO: Rome, Italy; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- Schilling, M.W.; Vizzier-Thaxton, Y.; Alvarado, C.Z. Slaughter line operation. Poultry. In Encyclopedia of Meat Sciences, 2nd ed.; Dikeman, M., Devine, C., Eds.; Elsevier: Amsterdam, The Netherlands; Academic Press: Cambridge, MA, USA, 2014; pp. 303–308. [Google Scholar]

- Bird, P.; Fisher, K.; Boyle, M.; Huffman, T.; Juenger, M.; Benzinger, M.J., Jr.; Bedinghaus, P.; Flannery, J.; Crowley, E.; Agin, J.; et al. Evaluation of VIDAS UP Salmonella (SPT) assay for the detection of Salmonella in a variety of foods and environmental samples: Collaborative study. J. AOAC Int. 2013, 96, 808–821. [Google Scholar] [CrossRef] [PubMed]

- Crowley, E.; Bird, P.; Torontali, M.; Agin, J.; Goins, D.; Johnson, R. TEMPO® EC for the enumeration of aerobic mesophilic flora in foods: Collaborative study. J. AOAC Int. 2009, 92, 165–174. [Google Scholar] [CrossRef]

- Crowley, E.; Bird, P.; Torontali, M.; Goetz, K.; Agin, J.; Goins, D.; Johnson, R. TEMPO® EC for the enumeration of Escherichia coli in foods: Collaborative study. J. AOAC Int. 2010, 93, 576–586. [Google Scholar] [CrossRef] [PubMed]

- Mead, G.C. Microbial hazards in production and processing. In Poultry Meat. Processing and Quality; Mead, G.C., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2004; pp. 232–257. [Google Scholar]

- Nunes, F. Scalding and plucking for optimum carcass quality and yield. World Poult. 2011, 5, 4614–4620. [Google Scholar]

- Russell, S.M. Processing Tip…How Can Processors Significantly Improve Processing Yield and Lower Salmonella without Added Expense? University of Georgia, Cooperative Extension Service: Athens, GA, USA, 2007; Available online: https://esploro.libs.uga.edu/esploro/outputs/report/Processing-tip-How-can-processors-significantly-improve-processing-yield-and-lower-salmonella-without-added-expense/9949315897902959#file-0.pdf (accessed on 11 May 2023).

- Corry, J.; James, S.J.; Purnell, G.; Barbedo-Pinto, C.S.; Chochois, Y.; Howell, M.; James, C. Surface pasteurisation of chicken carcasses using hot water. J. Food Eng. 2007, 79, 913–919. [Google Scholar] [CrossRef]

- Humphrey, T.J.; Lanning, D.G.; Leeper, D. The influence of scald water pH on the death rates of Salmonella Typhimurium and other bacteria attached to chicken skin. J. Appl. Bacteriol. 1984, 57, 355–359. [Google Scholar] [CrossRef]

- Mossel, D.A.A.; Moreno, B.; Struijk, C.B. Microbiología de los Alimentos; Editorial Acribia: Zaragoza, Spain, 2006. [Google Scholar]

- Incili, G.K.; Çalicioglu, M. Change in scalding fluids by time in poultry slaughterhouse and its effect on microbiological quality of carcasses. J. Food Saf. 2018, 38, e12485. [Google Scholar] [CrossRef]

- Foster, J.W.; Hall, H.K. Adaptative acidification tolerance response of Salmonella Typhimurium. J. Bacteriol. 1990, 172, 771–778. [Google Scholar] [CrossRef] [PubMed]

- Krulwich, T.A.; Sachs, G.; Padan, E. Molecular aspects of bacterial pH sensing and homeostasis. Nat. Rev. Microbiol. 2011, 9, 330–343. [Google Scholar] [CrossRef] [PubMed]

- Keerthirathne, T.P.; Ross, K.; Fallowfield, H.; Whiley, H. The combined effect of pH and temperature on the survival of Salmonella enterica serovar Typhimurium and implications for the preparation of raw egg mayonnaise. Pathogens 2019, 8, 218. [Google Scholar] [CrossRef] [PubMed]

- Okrend, A.J.; Johnston, R.W.; Moran, A.B. Effect of Acetic acid on the death rates at 52 °C of Salmonella Newport, Salmonella Typhimurium and Campylobacter jejuni in poultry scald water. J. Food Prot. 1986, 49, 500–503. [Google Scholar] [CrossRef] [PubMed]

- Sakhare, P.Z.; Sachindra, N.M.; Yashoda, K.P.; Narasimha Rao, D. Efficacy of intermittent decontamination treatments during processing in reducing the microbial load on broiler chicken carcass. Food Control 1999, 10, 189–194. [Google Scholar] [CrossRef]

| ti | ti + 2 h | ti + 4 h | ti + 6 h | ti + 8 h | ti + 10 h | ti + 12 h | ti + 14 h | ti + 16 h | |

|---|---|---|---|---|---|---|---|---|---|

| pH | 5.5 | 5.65 | 5.75 | 5.86 | 6.05 | 6.15 | 6.35 | 6.38 | 6.45 |

| Salmonella | - | - | - | + | + | + | + | + | + |

| pH | 5.0 | 5.06 | 5.23 | 5.42 | 5.55 | 5.61 | 5.87 | 5.96 | 6.16 |

| Salmonella | - | + | - | + | + | + | + | + | + |

| pH | 4.5 | 4.65 | 4.78 | 4.96 | 5.02 | 5.25 | 5.39 | 5.56 | 5.75 |

| Salmonella | - | - | - | - | + | + | + | - | + |

| pH | 4.0 | 4.12 | 4.37 | 4.51 | 4.75 | 4.86 | 4.91 | 5.05 | 5.26 |

| Salmonella | - | - | - | - | - | + | + | + | + |

| pH | 3.5 | 3.58 | 3.76 | 3.89 | 4.15 | 4.27 | 4.36 | 4.46 | 4.65 |

| Salmonella | - | - | - | - | - | - | - | + | + |

| pH | 3.00 | 3.19 | 3.25 | 3.43 | 3.66 | 3.89 | 3.96 | 4.15 | 4.42 |

| Salmonella | - | - | - | - | - | - | - | - | - |

| 1st Day Shelf Life | Half Shelf Life | End of Shelf Life | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Ov | Ent | Col | Od | Ov | Ent | Col | Od | Ov | Ent | Col | Od | T |

| Carcass 1 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 2 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 3 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 4 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 5 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 6 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 7 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 8 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 9 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Carcass 10 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 1 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 2 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 3 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 4 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 5 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 6 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 7 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 8 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 9 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Breast 10 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 1 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 2 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 3 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 4 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 5 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 6 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 7 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 8 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 9 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| Thigh 10 | N | N | N | N | N | N | N | N | N | N | N | N | N |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arispón, F.; Cano, N.; Jordano, R.; Medina, L.M. Monitoring Hygienic Measures for Decreasing Salmonella Occurrence in Scalding Tank Water of a Turkey Slaughterhouse. Appl. Sci. 2023, 13, 8103. https://doi.org/10.3390/app13148103

Arispón F, Cano N, Jordano R, Medina LM. Monitoring Hygienic Measures for Decreasing Salmonella Occurrence in Scalding Tank Water of a Turkey Slaughterhouse. Applied Sciences. 2023; 13(14):8103. https://doi.org/10.3390/app13148103

Chicago/Turabian StyleArispón, Francisco, Nazaret Cano, Rafael Jordano, and Luis M. Medina. 2023. "Monitoring Hygienic Measures for Decreasing Salmonella Occurrence in Scalding Tank Water of a Turkey Slaughterhouse" Applied Sciences 13, no. 14: 8103. https://doi.org/10.3390/app13148103

APA StyleArispón, F., Cano, N., Jordano, R., & Medina, L. M. (2023). Monitoring Hygienic Measures for Decreasing Salmonella Occurrence in Scalding Tank Water of a Turkey Slaughterhouse. Applied Sciences, 13(14), 8103. https://doi.org/10.3390/app13148103