Advanced Innovation Technology of BIM in a Circular Economy

Abstract

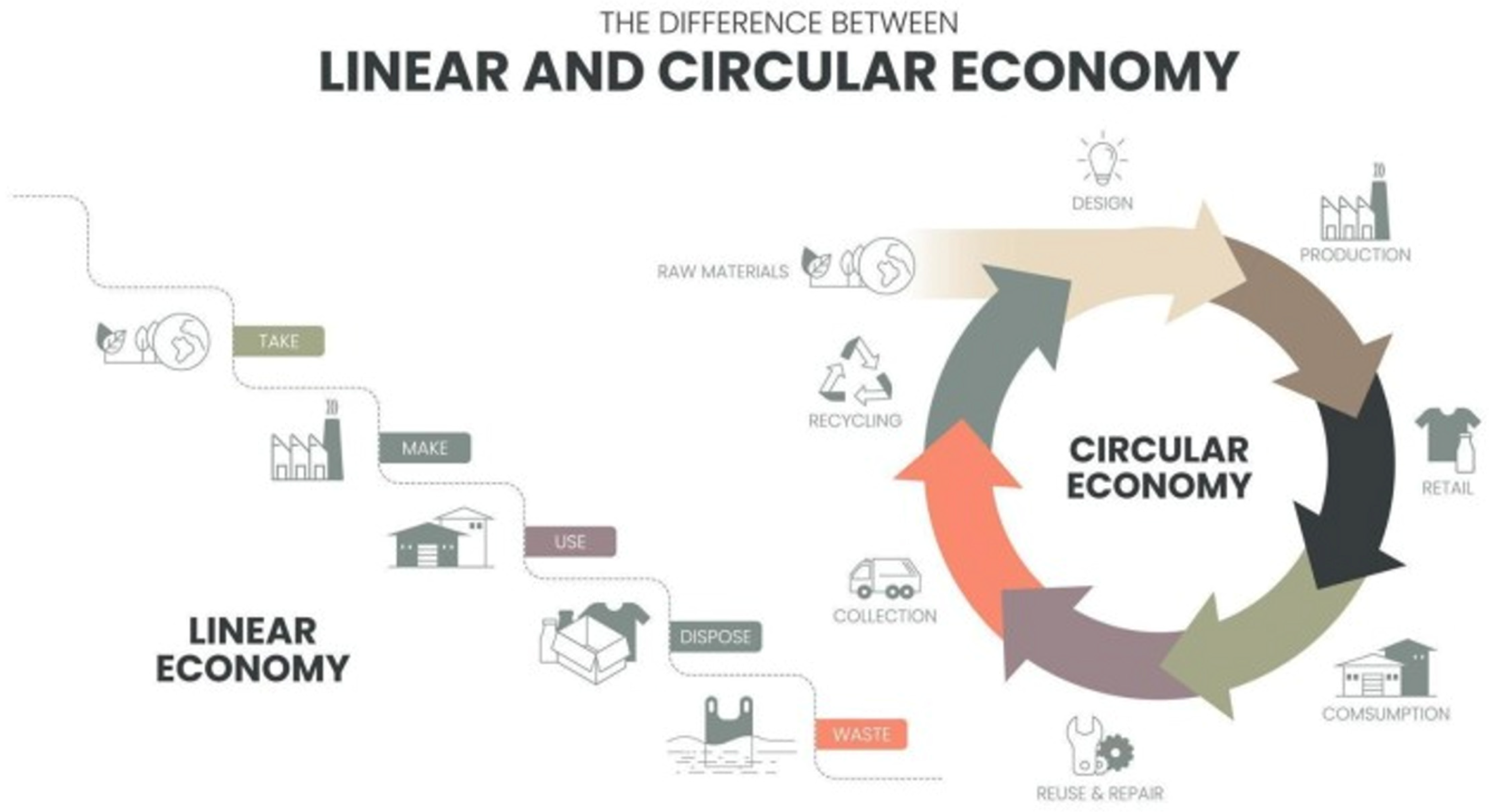

1. Introduction

- reduce—reduce (minimum use of raw materials),

- reuse—reuse (maximum reuse of products and components),

- recycle—to recycle (high-quality reuse of raw materials).

- construction raw materials—Construction minerals usually include aggregates made up of different-sized particles, such as sand, gravel and various types of crushed rock (e.g., chalk, limestone, sandstone, slate, etc.), natural rocks (e.g., marble or granite), as well as a whole range of clays, gypsum or clay-slate. The extraction of construction minerals, especially stone (crushed rock, sand, gravel and aggregate), represents the largest subsector of the extraction of non-energy raw materials in the EU in terms of value and volume. Potential sources of construction mineral raw materials are abundant in all Member States and are mined in large quantities (approximately 3 billion tons per year). A small (but increasing) amount of aggregate is also obtained from by-products of other industrial processes, for example, arc furnaces, residues from mineral processes, such as kaolin sands, and from surface mining of stone, as well as from the repeated processing of materials used in construction. However, the amount mined varies greatly between countries: most construction minerals are mined in Germany, France, Italy, Spain and the United Kingdom. Aggregate has a wide range of uses, including the construction of buildings, roads and railways. The demand for aggregates is, therefore, closely related to the level of construction of new buildings, the maintenance and repairs of existing buildings and the scope of civil engineering projects. Around 22,000 sites are estimated to be mined across the EU, many of which are close to construction areas. In the Netherlands and Belgium, raw materials are often transported over long distances on navigable rivers and canals due to relatively limited aggregate stocks. Similarly, densely populated cities such as London and Paris have to import most of the aggregate from more distant locations. The bulk of the aggregate price comprises transport costs, meaning most markets are local or regional, and international trade is relatively small. Aggregate mining requires an adequate network of surface mines and quarries to shorten transport distances, reduce related costs and reduce the impact on the environment;

- industrial minerals—Minerals form ore and non-ore raw materials. Industrial minerals can be loosely defined as physical minerals (e.g., bentonite, borates, calcium carbonate, diatomites, feldspar, kaolin, plastic clays, quartz and talc) or chemical minerals (e.g., salt, potash and sulphur). Various industrial minerals are mined in the EU, including feldspar, kaolin, magnesite, perlite, potash and salt. While some are found in almost half of the Member States, others (such as fluorite, mica, mineral phosphate and sulfur) are mined in only one or two countries. In the last ten years, the extraction of most industrial minerals has been maintained at a stable level or is growing. Industrial minerals are used in large industries, but unlike base or rare metal minerals, they are not marketed or sold as standardized products through centralized markets. Instead, they are most often sold directly to end users. Although a few industrial minerals are traded worldwide, most are processed and used in production within the EU. The delivery price is significantly affected by relatively high transport costs, which also effectively limit the geographical availability of suitable resources;

- metallic minerals—Metallic minerals include a wide range of ores from which metals or metallic substances are extracted by processing, for example, bauxite, chromium, copper, gold, lithium, manganese, nickel, selenium, silver, tin, tungsten, etc. Relatively few metallic minerals are mined in the EU. These include chromium, copper, iron ore, nickel, lead, silver and zinc. The geology of the European continent is such that other metallic minerals are not found in the EU territory in large quantities or are in places where mining is technically difficult and expensive. For this reason, mines are currently located in only a small number of Member States. Only Austria, Finland, Greece, Ireland, Poland, Portugal and Sweden account for over 1% of the global mining of a particular metallic mineral. Thus, many metallic minerals are imported from other regions of the world. The most important primary outlet for metal ores and concentrates in the EU is the refining and processing industry, which produces semi-finished and finished products for many other product segments. Regarding recycling, the construction minerals sector is the most problematic of the three sub-sectors, given the volume used, while metals provide the most economic opportunities for recycling. Many metals, including iron and steel, copper, tin, lead and aluminium, are relatively easy to recycle as they can be melted down and reworked without losing their significant characteristics. This potential is not yet fully utilized, as products at the end of their life cycle are often exported outside the EU and thus subsequently lost to the European market.

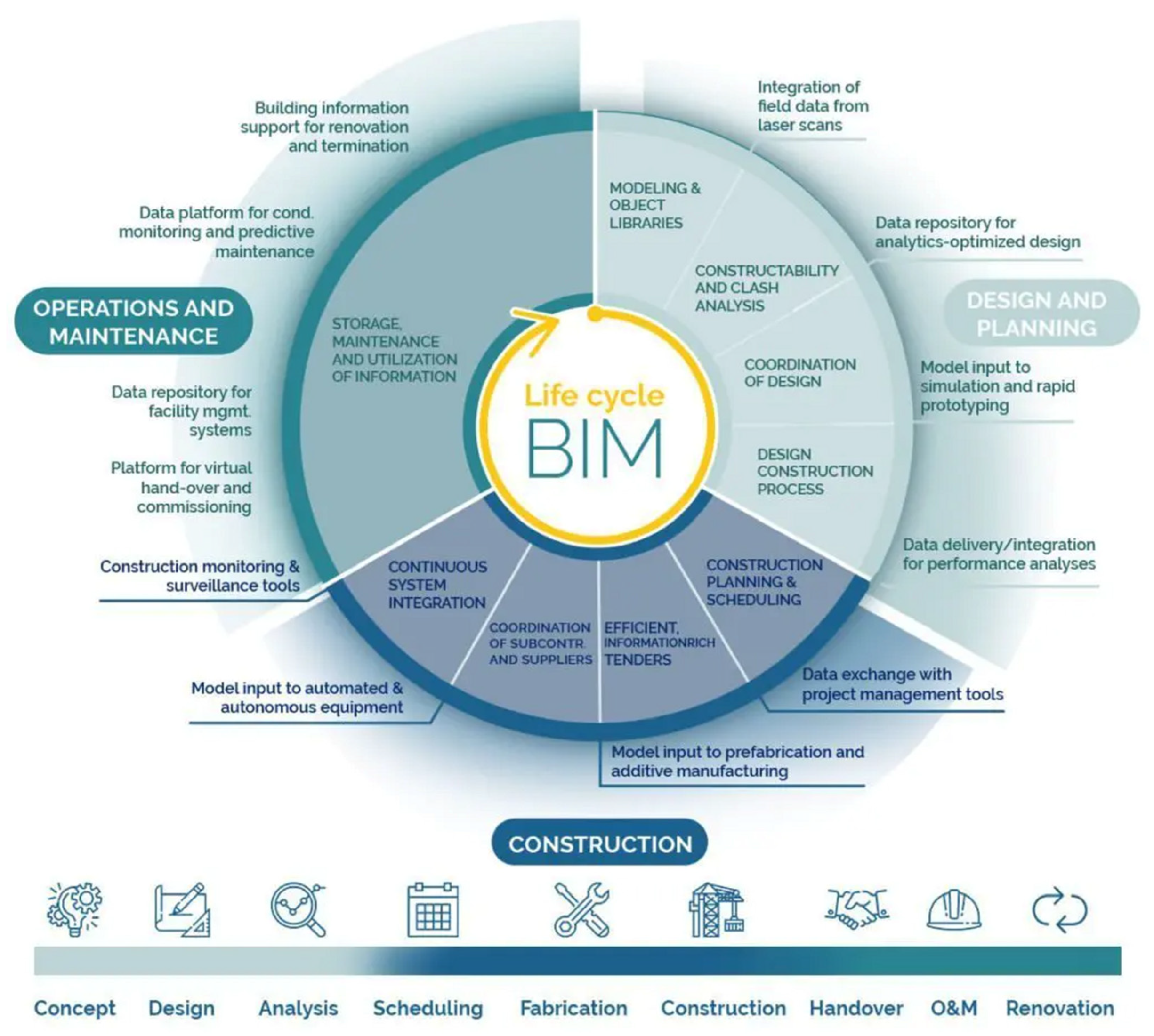

BIM and Circular Economy

2. Materials and Methods

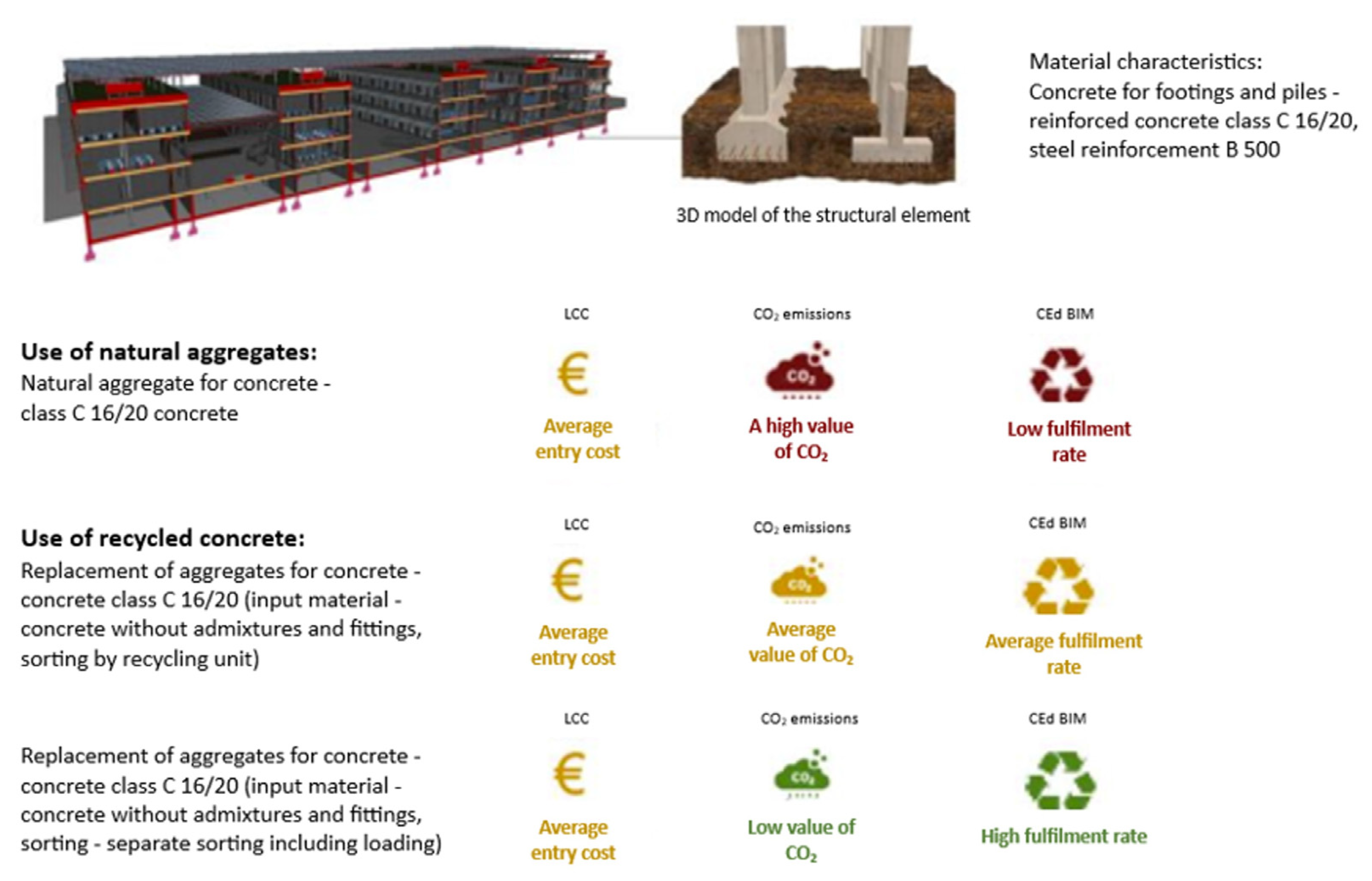

3. Results and Discusion

- aggregate replacement for reinforced concrete footings—made of reinforced concrete class C 16/20, steel reinforcement B 500,

- aggregate replacement for reinforced concrete piles—made of reinforced concrete class C 16/20, steel reinforcement B 500,

- aggregate replacement for reinforced concrete columns (400 × 400 mm)—made of reinforced concrete class C 30/37, steel reinforcement B 500-exposed concrete,

- aggregate replacement for reinforced concrete walls—made of reinforced concrete class C 30/37, steel reinforcement B 500-exposed concrete,

- aggregate replacement for reinforced concrete prefabricated channels (400 × 400 mm)—made of reinforced concrete class C 30/37, steel reinforcement B 500-exposed concrete,

- aggregate replacement for reinforced concrete ceiling slabs—made from reinforced concrete class C 16/20, steel reinforcement B 500-exposed concrete,

- aggregate replacement for the construction of reinforced concrete stairs—made of reinforced concrete class C 30/37, steel reinforcement B 500,

- underfill under the sidewalks,

- underfill under asphalt/concrete surfaces (underground parking lot and driveway),

- filling of sewers,

- creation of drainage layers.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Banerjee, A.V.; Duflo, E. Poor Economics: A Radical Rethinking of the Way to Fight Global Poverty; Public Affairs: New York, NY, USA, 2011; 320p, ISBN 978-1610390934. [Google Scholar]

- Sachs, J. The Age of Sustainable Development; Columbia University Press: New York, NY, USA, 2015; 543p, ISBN 978-0-231-17315-5. [Google Scholar]

- Rosova, A.; Behun, M.; Khouri, S.; Cehlar, M.; Ferencz, V.; Sofranko, M. Case study: The simulation modeling to improve the efficiency and performance of production process. Wirel. Netw. 2020, 28, 863–872. [Google Scholar] [CrossRef]

- Brennan, G.; Tennant, M.; Blomsma, F. Business and Production Solutions: Closing the Loop. In Sustainability: Key Issues; Kopnina, H., Shoreman-Ouimet, E., Eds.; EarthScan/Routledge: London, UK, 2015; pp. 219–239. [Google Scholar]

- Mésároš, P.; Smetanková, J.; Krajníková, K. Sustainability of Buildings and Its Support Through Innovative Technologies. In International Conference Current Issues of Civil and Environmental Engineering Lviv—Košice—Rzeszów, Proceedings of the CEE 2019, Singapore, 23–26 May 2019; Lecture Notes in Civil Engineering; Blikharskyy, Z., Koszelnik, P., Mesaros, P., Eds.; Springer: Cham, Switzerland, 2020; Volume 47, p. 47. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Resources, Conservation & Recycling Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Rusko, M.; Pietrucha, H.D. Manažérstvo v oblasti kvality, životného prostredia, ochrany zdravia a bezpečnosti pri práci v kontexte integrovaného manažérskeho systému. In Recenzovaný Zborník z Medzinárodnej Vedeckej Konferencie, 1st ed.; Slovak Society for Environment: Bratislava, Slovakia, 2016; pp. 126–134. ISBN 978-80-89753-11-6. [Google Scholar]

- Macdonald, C. The Road To Sustainable Digitalization. Linkedin.com. 2022. Available online: https://www.linkedin.com/pulse/shift-from-linear-circular-economy-road-sustainable-caroline/?trk=pulse-article (accessed on 15 January 2022).

- Udržateľná Spoločnosť Vyžaduje aj Zmenu Myslenia, Veda na Dosah. 2021. Available online: https://vedanadosah.cvtisr.sk/ludia/ekonomia/udrzatelna-spolocnost-vyzaduje-aj-zmenu-myslenia/ (accessed on 18 January 2022).

- Di Maio, R.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recycl. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Straka, M.; Taušová, M.; Rosová, A.; Cehlár, M.; Kačmáry, P.; Sisol, M.; Ignácz, P.; Farkas, C. Big data analytics of a waste recycling simulation logistics system. Pol. J. Environ. Stud. 2020, 29, 2355–2364. [Google Scholar] [CrossRef] [PubMed]

- Kjaer, L.; Pigosso, D.; Niero, M.; Bech, N.; McAloone, T. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Bakker, C.; De Pauw, I. Product design and business model strategies for a circular economy. In Proceedings of the Sustainable Design & Manufacturing Conference, Seville, Spain, 12–14 April 2015. [Google Scholar]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Balog, M.; Knapčíková, L. Advances of intelligent techniques used in Industry 4.0: Proposals and testing. Wirel. Netw. 2021, 27, 1665–1670. [Google Scholar] [CrossRef]

- Kúšik, D.; Šoltés, S.; Mižák, J. Nerastné Suroviny Slovenskej Republiky 2018; Štátny Geologický Ústav Dionýza Štúra: Bratislava, Slovakia, 2019; ISBN 978-8174-042-8. [Google Scholar]

- Podiel ťažby Nerastných Surovín na Celkových Zásobách. Enviro Portál, EnviDat–Databáza Environmentálnych Indikátorov. 2021. Available online: https://www.enviroportal.sk/envidat/2007-4-4/podiel-tazby-nerastnych-surovin-nacelkovych-zasobach (accessed on 22 January 2022).

- Pavolová, H.; Čulková, K.; Šimková, Z.; Seňová, A.; Kudelas, D. Contribution of Mining Industry in Chosen EU Countries to the Sustainability Issues. Sustainability 2022, 14, 4177. [Google Scholar] [CrossRef]

- Study on the Competitiveness of the European Steel Sector. Within the Framework Contract of Sectoral Competitiveness Studies—ENTR/06/054. 2008. Available online: http://ec.europa.eu/enterprise/sectors/metals-minerals/files/sec_2007_771_en.pdf (accessed on 22 January 2022).

- Available online: https://ec.europa.eu/environment/nature/natura2000/management/docs/NEEI_Summary_SK.pdf (accessed on 22 January 2022).

- Culkova, K. Development of chosen social and economic indicators of using raw materials in the context of sustainability in Slovakia. In EAI/Springer Innovations in Communication and Computing; Springer: Cham, Switzerland, 2020; pp. 285–297. [Google Scholar]

- BIM—Informační Model Budovy. Available online: https://www.arkancesystems.cz/reseni/stavebnictvi-a-architektura/bim-informacni-model-budovy (accessed on 17 April 2023).

- Mandičák, T.; Mésároš, P.; Kanáliková, A.; Špak, M. Supply Chain Management and Big Data Concept Effects on Economic Sustainability of Building Design and Project Planning. Appl. Sci. 2021, 11, 11512. [Google Scholar] [CrossRef]

- Wan, L.; Bai, Y. Application Research on the BIM and Internet of Things Technology in Construction Logistics Management in the Period of Big Data. In Advances in Intelligent Systems and Computing, Proceedings of the Fourteenth International Conference on Management Science and Engineering Management, ICMSEM 2020, Chisinau, Moldova, 31 July–1 August 2020; Xu, J., Duca, G., Ahmed, S., García Márquez, F., Hajiyev, A., Eds.; Springer: Cham, Switzerland, 2021; Volume 1191. [Google Scholar] [CrossRef]

- LetsBuild. A History of BIM. LetsBuild. 2017. Available online: https://www.letsbuild.com/blog/a-history-of-bim (accessed on 3 July 2023).

- Šuba, Š. Tvorba Prvků Tříd pro Informační Model Budovy. Bakalářská Práce. Vysoké Učení Technické v Brně, Brno. 2020. Available online: http://hdl.handle.net/11012/191327 (accessed on 3 July 2023).

- Černý, M.; Kol, A. BIM Příručka; Odborná Rada Pro BIM a.s. 2013, p. 75. ISBN 978-80-260-5297-5. Available online: https://issuu.com/rozpoctakacallida/docs/bim-prirucka-4projects (accessed on 22 January 2022).

- Mésároš, P.; Spišáková, M.; Mandičák, T.; Cabala, J.; Oravec, M.M. Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study. Sustainability 2021, 13, 799. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, J.; Ren, L. Study on Construction Engineering Management Based on BIM from the Perspective of Big Data. In Proceedings of the 2020 International Conference on Computer Information and Big Data Applications (CIBDA), Guiyang, China, 17–19 April 2020; pp. 111–115. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Udržateľný Rozvoj, Udržateľná Výstavba. Trvalá udržateľnosť, Isover, Saint-Gobain. Available online: https://www.isover.sk/trvala-udrzatelnost (accessed on 20 January 2022).

- Discover How BIM Is Implemented in Each Step of the Construction Value Chain. Cemex Ventures. 2021. Available online: https://www.cemexventures.com/discover-how-bim-is-implemented-in-each-phase-of-the-construction-industry/ (accessed on 20 January 2022).

- Huan, S.H.; Sheoran, S.K.; Wang, G. A review and analysis of supply chain operations reference (SCOR) model. Supply Chain Manag. Int. J. 2004, 9, 23–29. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; Rønholt, J.; Birkved, M.; Birgisdottir, H. Circular Economy potential within the building stock—Mapping the embodied greenhouse gas emissions of four Danish examples. J. Build. Eng. 2020, 33, 101845. [Google Scholar] [CrossRef]

- Základné Informácie o Betóne. Available online: https://vph.sk/assets/Uploads/Page/19/VAHOSTAV-SK-PREFA-Zakladne-informacie-obetone.pdf (accessed on 8 February 2022).

- Stehlík, D. Praktické Aplikace v Pozemních Komunikacích: MODUL 07 Nestmelené Podkladní Vrstvy; Brno University of Technology: Brno, Czech Republic, 2006; Available online: http://dc198.4shared.com/doc/F5voBJIZ/preview.html (accessed on 8 February 2022).

- Buriánek, P. Využití Recyklovaného Betonu Při Odstraňování Fosforu z Vody. 2013. Available online: http://www.vodovod.info/index.php/clanky/vodarenstvi/162-vyuzitirecyklovanehobetonu-pri-odstranovani-fosforu-z-vody (accessed on 8 February 2022).

- Nováková, I. Možnosti Využití Recyklovaného Betonu Jako Náhrady Drobného Kameniva v Cementových Potěrech. Bachelor Thesis, Vysoké Učení Technické v Brně, Fakulta Stavební, Ústav Technologie Stavebních Hmot a Dílců, Brno, Czech Republic, 2012; p. 66. [Google Scholar]

- Soutsos, N.M.; Tang, K.; Millard, S.G. Use of recycled demolition aggregate in precast products, phase II: Concrete paving blocks. Constr. Build. Mater. 2011, 25, 3131–3143. [Google Scholar] [CrossRef]

- Arabani, M.; Azarhoosh, A.R. The effect of recycled concrete aggregate and steel slag on the dynamic properties of asphalt mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

| Description of the Environment | Informative Examples of the Occurrence of the Degree of Environmental Impact | Usability of Recycled Concrete Aggregate |

|---|---|---|

| No risk of corrosion or breakage X0: for concrete without reinforcement or built-in metal elements: all influences except alternating freezing and thawing or chemically aggressive environments for concrete with reinforcement or with built-in metal inserts in a very dry environment | Concrete inside buildings with very low air humidity; foundation concrete without reinforcement in an environment without the influence of frost. | Yes |

| Corrosion of reinforcement due to carbonation Suppose concrete containing reinforcement or other embedded metal elements is exposed to air and moisture. In that case, the degree of environmental influence is determined as follows: Note Moisture conditions refer to the situation inside the cover layer of reinforcement or other embedded metal elements, but in many cases, the conditions in the cover layer can be considered the same as in the surrounding environment. In such cases, it may be appropriate to determine the impact according to the surrounding environment but not if the concrete is separated from the surrounding environment (e.g., by an insulating layer). XC1: dry or constantly wet, XC2: wet, occasionally dry, XC3/4: moderately wet, wet/alternately wet and dry | XC1: concrete inside buildings with low humidity (30–60%) air; concrete permanently immersed in water; XC2: concrete surface exposed to long-term exposure to water or high air humidity; parts of water reservoirs; most basic elements of buildings; indoor spaces with high air humidity (e.g., kitchens for mass catering, bathrooms, large laundries, areas of indoor swimming pools and barns) XC3: concrete inside buildings with medium air humidity; external concrete protected against rain; parts of buildings to which outside air often or constantly have access (e.g., open halls) XC4: concrete surfaces in contact with water, which are not included in the degree of environmental influence XC2 and XC3; parts of buildings directly exposed to precipitation or moisture | |

| Corrosion of reinforcement due to chlorides, but not from seawater Suppose concrete with reinforcement or other built-in elements comes into contact with water containing chlorides, including de-icing agents, except seawater. In that case, the environmental impact must be graded as follows: XD1: medium wet, humid | Concrete surfaces exposed to chlorides dispersed in the air; separate garages | Maybe (if exams prove suitability) |

| Corrosion of reinforcement due to chlorides from seawater If concrete with reinforcement or other built-in elements comes into contact with chlorides from seawater or salty air from seawater, then the environmental impact must be graded as follows: XS1: exposed to salty air but not in direct contact with seawater | Constructions near the sea coast or on the coast | Maybe (if exams prove suitability) |

| Alternating action of freezing and thawing with or without deicing agents If wet concrete is exposed to freezing and thawing (frost cycles), the environmental impact must be graded as follows: XF1: slightly saturated with water without deicing agents | External vertical parts of buildings exposed to rain and frost (facades of buildings, columns), not too wet parts of buildings | Yes |

| Alternating action of freezing and thawing with or without deicing agents If wet concrete is exposed to freezing and thawing (frost cycles), the environmental impact must be graded as follows: XF2: slightly saturated with water with deicing agents XF3: heavily saturated with water without deicing agents XF4: heavily saturated with water with the deicing agents | XF2: external vertical parts of buildings exposed to frost and deicing agents dispersed in the air, which are not directly in contact with the spraying of deicing agents (e.g., parts of anti-noise walls, retaining walls), and which are not included in XF4 XF3: external parts of buildings exposed to rain and frost; external parts of buildings often wet with water and exposed to frost; open water tanks; parts of structures with fluctuating freshwater levels; overflow parts of water structures XF4: parts of buildings directly exposed to deicing agents and frost; building structures near roads exposed to direct spraying with deicing agents (e.g., curbs, drainage gutters); reservoirs near roads, concrete barriers | Maybe (if exams prove suitability) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behún, M.; Behúnová, A. Advanced Innovation Technology of BIM in a Circular Economy. Appl. Sci. 2023, 13, 7989. https://doi.org/10.3390/app13137989

Behún M, Behúnová A. Advanced Innovation Technology of BIM in a Circular Economy. Applied Sciences. 2023; 13(13):7989. https://doi.org/10.3390/app13137989

Chicago/Turabian StyleBehún, Marcel, and Annamária Behúnová. 2023. "Advanced Innovation Technology of BIM in a Circular Economy" Applied Sciences 13, no. 13: 7989. https://doi.org/10.3390/app13137989

APA StyleBehún, M., & Behúnová, A. (2023). Advanced Innovation Technology of BIM in a Circular Economy. Applied Sciences, 13(13), 7989. https://doi.org/10.3390/app13137989