Experimental Study of the Influence of the Interaction of a Conveyor Belt Support System on Belt Damage Using Video Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Equipment

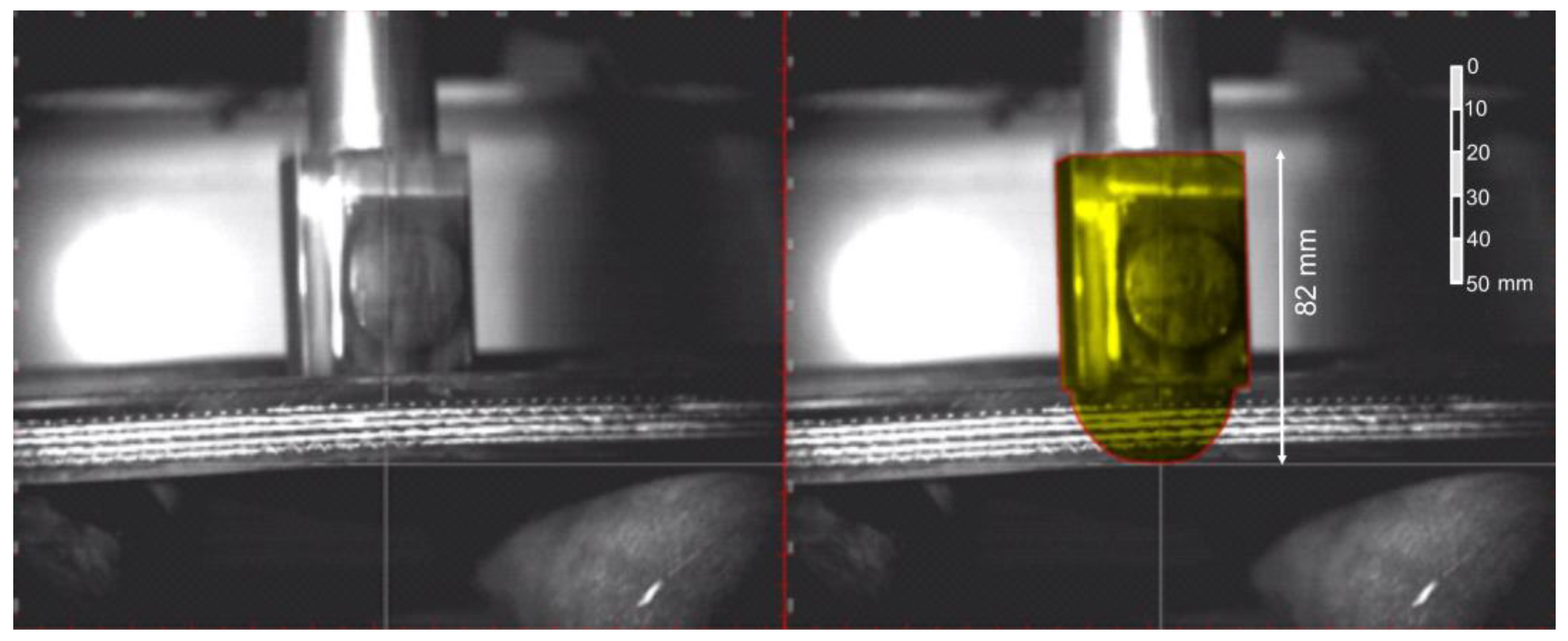

2.2. Video Analysis

3. Theory/Calculation

3.1. Degree of Belt Damage

3.2. Evaluation Methods

4. Results

- To determine the magnitude of the deflection of the CB at the point of impact of the material using video analysis,

- To determine the degree of damage to the CB in relation to the magnitude of the deflection of the CB;

- To create a model of the dependence of the deflection magnitude on selected parameters (weight and impact height).

4.1. Determination of the Magnitude of Deflection of the CB at the Point of Impact of the Material

4.2. Determination of the Degree of Damage to the CB Depending on the Magnitude of the Deflection

4.3. Creation of a Model of the Dependence of the Magnitude of Deflection on Selected Parameters

5. Conclusions

- The impact height has a significant influence on the occurrence of serious damage in the event of an impactor falling on the CB + support system.

- The impact weight and impact height have a significant influence on the occurrence of serious damage in the event of the impactor falling on the CB + support system.

- The presence/absence of a support system has a significant influence on the amount of deflection of the CB and on the type of damage.

- The absence of a support system does not cause serious damage to the set parameters of the experiment. If the deflection value of the CB is less than approximately −100 mm, Damage 1 occurs at most. Otherwise, the conveyor belt is free of visible damage (Damage 0).

- The presence of a support system causes serious damage that significantly affects the smooth operation of the belt. The results of the video analysis show that serious damage (Damage 2 and Damage 3) occurs when the measured value of the CB deflection is less than −70 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alharbi, F.; Luo, S.H.; Zhang, H.Y.; Shaukat, K.; Yang, G.; Wheeler, C.A.; Chen, Z.Y. A Brief Review of Acoustic and Vibration Signal-Based Fault Detection for Belt Conveyor Idlers Using Machine Learning Models. Sensors 2023, 23, 1902. [Google Scholar] [CrossRef]

- Li, X.G.; Zhang, Y.Z.; Li, Y.; Zhan, Y.J.; Yang, L. Health State Prediction and Performance Evaluation of Belt Conveyor Based on Dynamic Bayesian Network in Underground Mining. Shock Vib. 2021, 2021, 6699611. [Google Scholar] [CrossRef]

- Homisin, J.; Grega, R.; Kassay, P.; Fedorko, G.; Molnar, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 199–202. [Google Scholar] [CrossRef]

- Marasova, D.; Cehlar, M.; Ambrisko, L. Innovations in Monitoring Conveyor Belts with Implemented RFID Technology. In Proceedings of the 4th International Innovative Mining Symposium, T F Gorbachev Kuzbass State Tech Univ, Kemerovo, Russia, 14–16 October 2019. [Google Scholar] [CrossRef] [Green Version]

- Fedorko, G. Application possibilities of virtual reality in failure analysis of conveyor belts. Eng. Fail. Anal. 2021, 128, 105615. [Google Scholar] [CrossRef]

- Li, J.; Miao, C.Y. The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm. Optik 2016, 127, 8002–8010. [Google Scholar] [CrossRef]

- Hu, X.; Zong, M. Fault Prediction Method of Belt Conveyor Based on Grey Least Square Support Vector Machine. In Proceedings of the 13th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Beihai, China, 16–17 January 2021. [Google Scholar] [CrossRef]

- Kellis, J.K. Conveyor belt condition monitoring. In Proceedings of the 2000 SME Annual Meeting, Salt Lake City, UT, USA, 28 February–1 March 2000. [Google Scholar]

- Guo, X.Q.; Liu, X.H.; Zhou, H.; Stanislawski, R.; Krolczyk, G.; Li, Z.X. Belt Tear Dete.ction for Coal Mining Conveyors. Micromachines 2022, 13, 449. [Google Scholar] [CrossRef]

- Hrabovsky, L.; Molnar, V.; Fedorko, G.; Tkac, J.; Frydrysek, K. Experimental determination of force acting on a sandwich conveyor’s pressure roller in transport of bulk materials for the needs of failure analysis. Measurement 2022, 202, 111832. [Google Scholar] [CrossRef]

- Wang, M.; Shen, K.J.; Tai, C.W.; Zhang, Q.F.; Yang, Z.W.; Guo, C.B. Research on fault diagnosis system for belt conveyor based on internet of things and the LightGBM model. PLoS ONE 2023, 18, e0277352. [Google Scholar] [CrossRef]

- Guo, X.Q.; Liu, X.H.; Krolczyk, G.; Sulowicz, M.; Glowacz, A.; Gardoni, P.; Li, Z. Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network. Sensors 2022, 22, 3485. [Google Scholar] [CrossRef]

- Zhang, M.C.; Zhang, Y.; Zhou, M.S.; Jiang, K.; Shi, S.; Yu, Y.; Hao, N.N. Application of Lightweight Convolutional Neural Network for Damage Detection of Conveyor Belt. Appl. Sci. 2021, 11, 7282. [Google Scholar] [CrossRef]

- Zhang, M.C.; Shi, H.; Zhang, Y.; Yu, Y.; Zhou, M.S. Deep learning-based damage detection of mining conveyor belt. Measurement 2021, 175, 109130. [Google Scholar] [CrossRef]

- Qu, D.R.; Qiao, T.Z.; Pang, Y.S.; Yang, Y.; Zhang, H.T. Research On ADCN Method for Damage Detection of Mining Conveyor Belt. IEEE Sens. J. 2021, 21, 8662–8669. [Google Scholar] [CrossRef]

- Guo, X.Q.; Liu, X.H.; Gardoni, P.; Glowacz, A.; Klolczyk, G.; Incecik, A.; Li, Z.X. Machine vision based damage detection for conveyor belt safety using Fusion knowledge distillation. Alex. Eng. J. 2023, 71, 161–172. [Google Scholar] [CrossRef]

- Bortnowski, P.; Kawalec, W.; Krol, R.; Ozdoba, M. Types and causes of damage to the conveyor belt—Review, classification and mutual relations. Eng. Fail. Anal. 2022, 140, 106520. [Google Scholar] [CrossRef]

- Kirjanow-Blazej, A.; Jurdziak, L.; Burduk, R.; Blazej, R. Forecast of the remaining lifetime of steel cord conveyor belts based on regression methods in damage analysis identified by subsequent DiagBelt scans. Eng. Fail. Anal. 2019, 100, 119–126. [Google Scholar] [CrossRef]

- Kirjanow-Blazej, A.; Rzeszowska, A. Conveyor Belt Damage Detection with the Use of a Two-Layer Neural Network. Appl. Sci. 2021, 11, 5480. [Google Scholar] [CrossRef]

- Bajda, M.; Hardygora, M. Laboratory tests of operational durability and energy—Efficiency of conveyor belts. In Proceedings of the Annual Conference on Mining of Sustainable Development, Gliwice, Poland, 28 November 2018. [Google Scholar] [CrossRef]

- Ambrisko, L.; Marasova, D. Experimental Research of Rubber Composites Subjected to Impact Loading. Appl. Sci. 2020, 10, 8384. [Google Scholar] [CrossRef]

- Andrejiova, M.; Grincova, A.; Marasova, D. Failure analysis of rubber composites under dynamic impact loading by logistic regression. Eng. Fail. Anal. 2018, 84, 311–319. [Google Scholar] [CrossRef]

- Grincova, A.; Andrejiova, M.; Marasova, D. Measuring and comparative analysis of the interaction between the dynamic impact loading of the conveyor belt and the supporting system. Measurement 2015, 59, 184–191. [Google Scholar] [CrossRef]

- Stachowiak, M.; Koperska, W.; Stefaniak, P.; Skoczylas, A.; Anufriiev, S. Procedures of Detecting Damage to a Conveyor Belt with Use of an Inspection Legged Robot for Deep Mine Infrastructure. Minerals 2021, 11, 1040. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, S.K.; Wang, H.S.; Wang, B.; Lin, J.G.; Sui, Y.P.; Gu, C. Safety Warning of Mine Conveyor Belt Based on Binocular Vision. Sustainability 2022, 14, 3276. [Google Scholar] [CrossRef]

- Che, J.; Qiao, T.Z.; Yang, Y.; Zhang, H.T.; Pang, Y.S. Longitudinal tear detection method of conveyor belt based on audio-visual fusion. Measurement 2021, 176, 109152. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnar, V.; Marasova, D.; Grincova, A.; Dovica, M.; Zivcak, J.; Toth, T.; Husakova, N. Failure analysis of belt conveyor damage caused by the falling material. Part I: Experimental measurements and regression models. Eng. Fail. Anal. 2014, 36, 30–38. [Google Scholar] [CrossRef]

| Non-Serious Damage | Serious Damage | ||

|---|---|---|---|

| Damage 0 | Damage 1 | Damage 2 | Damage 3 |

| No damage is visible | Visible damage to the upper or lower covering layer (cracks and punctures) without visible damage to the skeleton | Visible damage to the upper or lower covering layer and also damage to the skeleton | Puncture (simultaneous complete damage to the upper covering layer, skeleton, and bottom covering layer) |

| Variables | Description |

|---|---|

| Dependent Variables | |

| Damage | Damage type: |

| Damage 0 (D0), Damage 1 (D1), | |

| Damage 2 (D2), Damage 3 (D3) | |

| Independent Variables | |

| Height | Impact height (m) |

| Weight | Weight of impactor (kg) |

| Deflection | Deflection amount (mm) |

| Observed Damage | Classification Determined by the Decision Tree | |||||

|---|---|---|---|---|---|---|

| WSS (n = 78) 1 | SS (n = 67) 2 | |||||

| D0 | D1 | D0 | D1 | D2 | D3 | |

| D0 | 46 | 2 | 23 | 0 | 0 | 0 |

| D1 | 1 | 29 | 1 | 15 | 0 | 0 |

| D2 | x | x | 0 | 1 | 15 | 1 |

| D3 | x | x | 0 | 0 | 2 | 9 |

| Parameter | Estimate | Standard Error | t-Stat | p-Value | 95%-Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| Intercept | −14.624 | 3.939 | −3.712 | 0.0004 | −22.471 | −6.776 |

| Weight | −27.404 | 1.079 | −25.389 | <0.0001 | −29.554 | −25.254 |

| Height | −0.524 | 0.047 | −11.074 | <0.0001 | −0.618 | −0.429 |

| Parameter | Estimate | Standard Error | t-Stat | p-Value | 95%-Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| Intercept | −31.981 | 1.329 | −24.069 | <0.00001 | −34.637 | −29.325 |

| Weight*Height | −0.246 | 0.014 | −17.490 | <0.00001 | −0.274 | −0.218 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marasova, D.; Andrejiova, M.; Grincova, A. Experimental Study of the Influence of the Interaction of a Conveyor Belt Support System on Belt Damage Using Video Analysis. Appl. Sci. 2023, 13, 7935. https://doi.org/10.3390/app13137935

Marasova D, Andrejiova M, Grincova A. Experimental Study of the Influence of the Interaction of a Conveyor Belt Support System on Belt Damage Using Video Analysis. Applied Sciences. 2023; 13(13):7935. https://doi.org/10.3390/app13137935

Chicago/Turabian StyleMarasova, Daniela, Miriam Andrejiova, and Anna Grincova. 2023. "Experimental Study of the Influence of the Interaction of a Conveyor Belt Support System on Belt Damage Using Video Analysis" Applied Sciences 13, no. 13: 7935. https://doi.org/10.3390/app13137935

APA StyleMarasova, D., Andrejiova, M., & Grincova, A. (2023). Experimental Study of the Influence of the Interaction of a Conveyor Belt Support System on Belt Damage Using Video Analysis. Applied Sciences, 13(13), 7935. https://doi.org/10.3390/app13137935