Experimental Study of Three-Dimensional Time Domain of Water Evaporation from Goaf

Abstract

1. Introduction

2. Experimental Materials and System

2.1. Experimental Materials

2.2. Experimental System

2.2.1. Project Overview

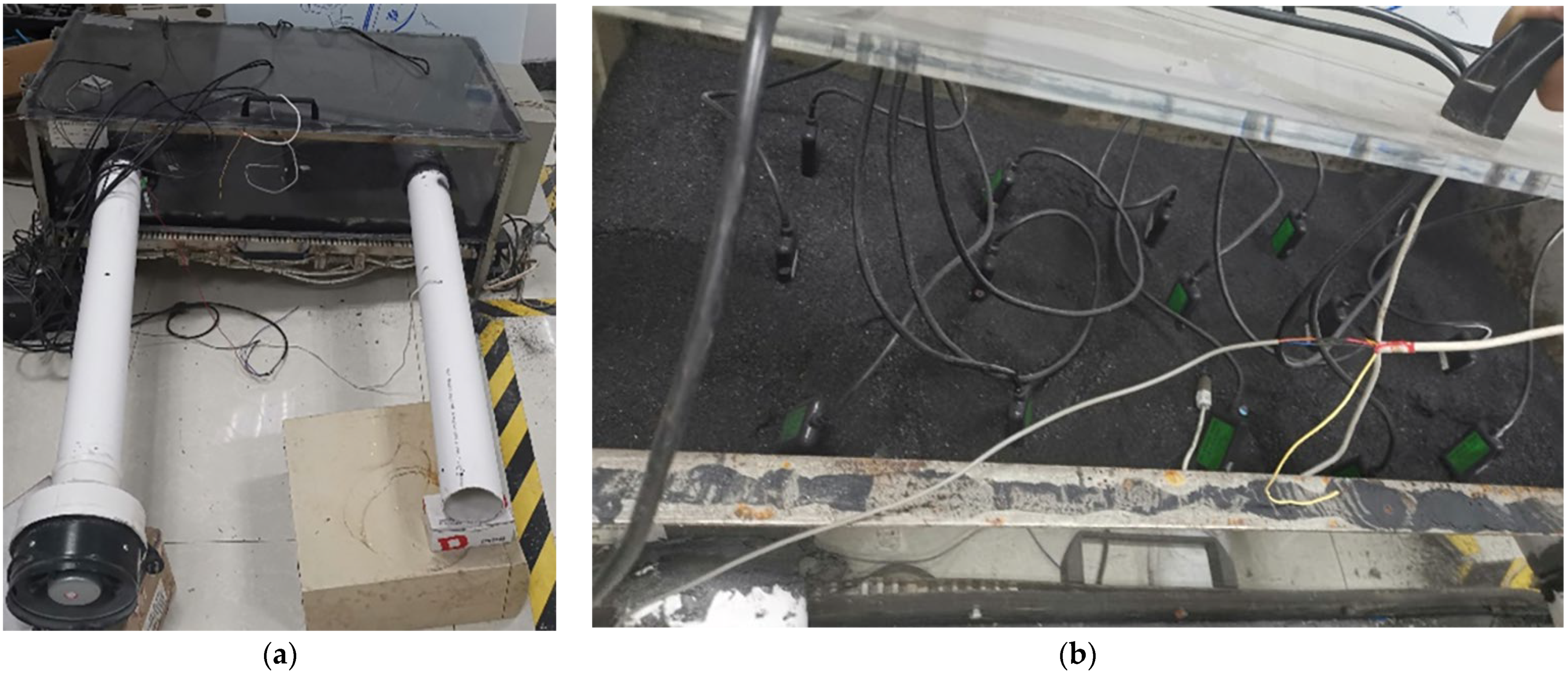

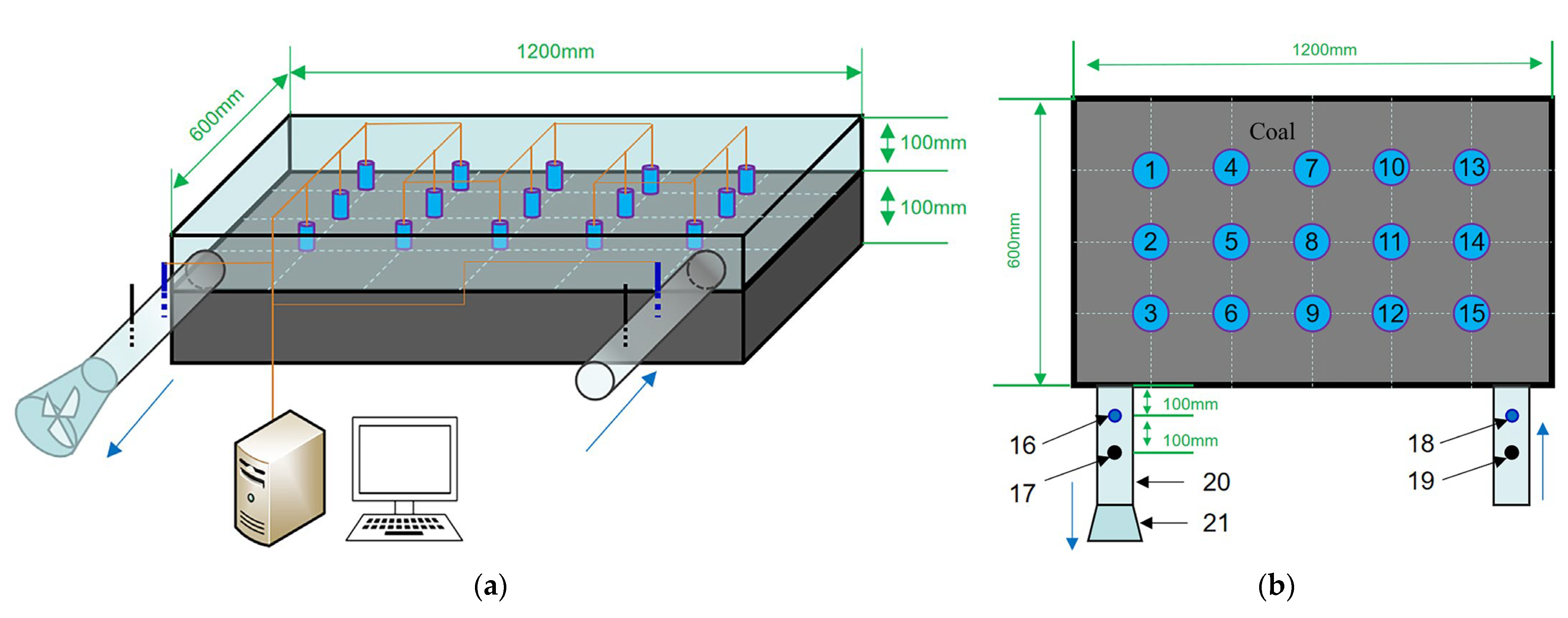

2.2.2. Three-Dimensional Models

- (1)

- Experiment box

- (2)

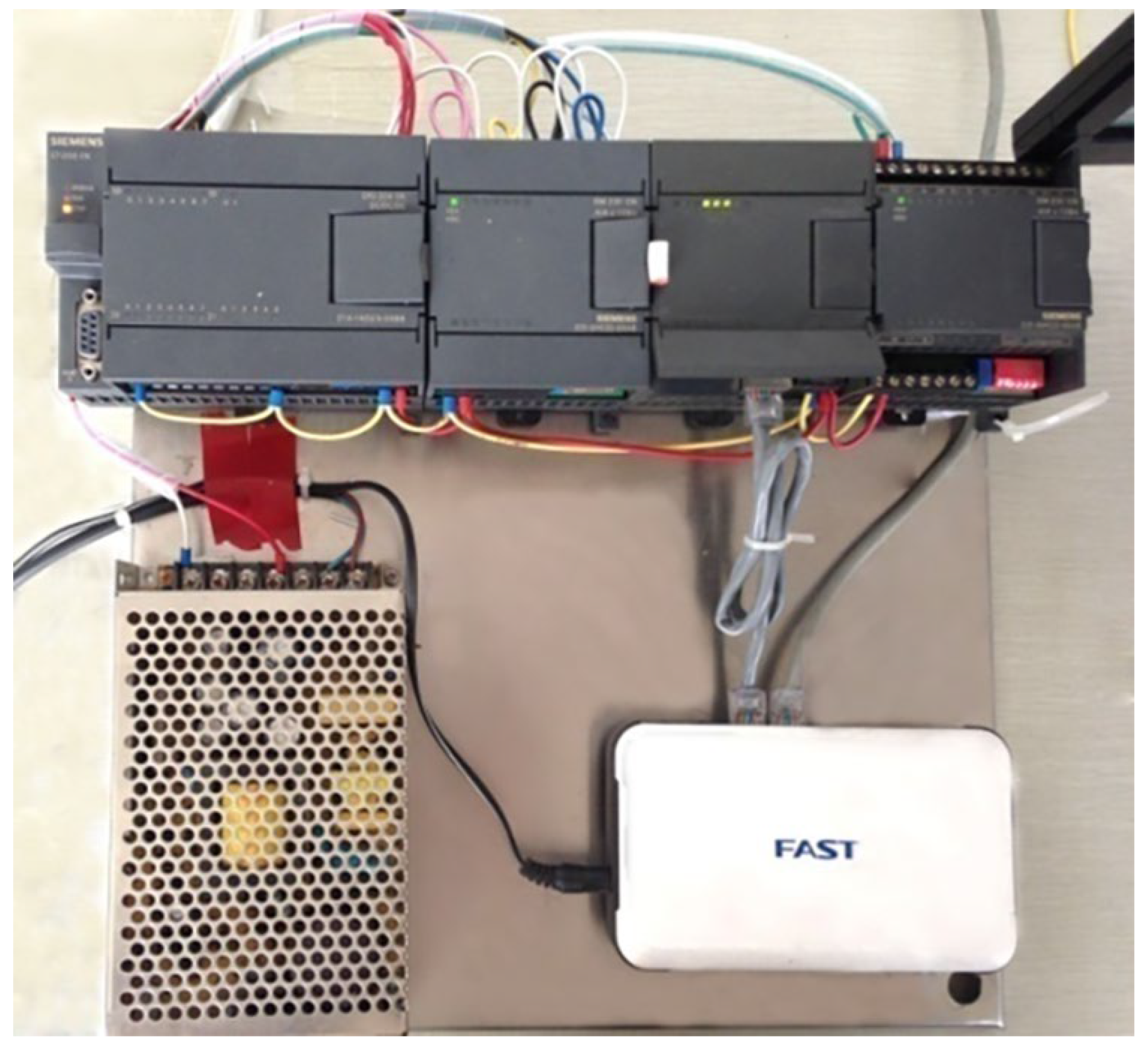

- Monitoring and data acquisition system

3. Experimental Protocol

- (1)

- Moisture Sensor Calibration Experiment

- Step 1: Longdong coal samples with the particle size of 0.18~1 mm were taken and dried under a vacuum environment for 24 h.

- Step 2: Take 4 clean water buckets and pour 5 kg of dried coal samples into each of them.

- Step 3: Take three of the buckets containing coal samples and add 0.714, 1.667 and 3 kg of 20% CaCl2 solution to configure the coal samples with 10, 20 and 30% moisture, respectively.

- Step 4: Insert the moisture sensor to be calibrated into the above four coal samples in turn and obtain their readings.

- Step 5: Find the relationship between the reading value and the theoretical value and perform calibration.

- (2)

- Water Evaporation Experiment in Goaf

- Step 1: Take 60 kg of dried Longdong coal samples with particle size in the range of 0.18~1 mm and lay the coal samples flat into the experimental chamber, as shown in Figure 2.

- Step 2: Insert the 15 moisture sensors into the 15 measurement point locations (M1~M15) as shown in the figure and place the two air temperature and humidity sensors at measurement points 16 and 17.

- Step 3: Connect the moisture sensor and air temperature and humidity sensor to the data acquisition device and turn on the computer for data acquisition. Turn on the stepless variable speed extension.

- Step 4: A solution of CaCl2 with a concentration of 20% was evenly sprinkled into the experimental chamber to bring the moisture from M1 to M15 to 30%.

- Step 5: Use the wind pressure and air volume meter to measure the wind pressure and air velocity at the location of the 17 measuring points of the air inlet and adjust the fan to make the wind pressure and air volume meter indicate 0.2 m3/s.

- Step 6: Make the experiment run continuously until the moisture sensor reading at each measurement point does not change and then end the experiment.

- Step 7: Repeat steps 1–5 and adjust the fan so that the airflow at the air inlet is 0.3 m3/s for data collection. Make the experiment run continuously until the moisture sensor reading at each measurement point does not change and then end the experiment.

- Step 8: Repeat steps 1–5 and adjust the fan so that the airflow at the air inlet is 0.4 m3/s for data collection. Make the experiment run continuously until the moisture sensor reading at each measurement point does not change and then end the experiment.

4. The Effect of Air Leakage on the Evaporation of Water from Goaf

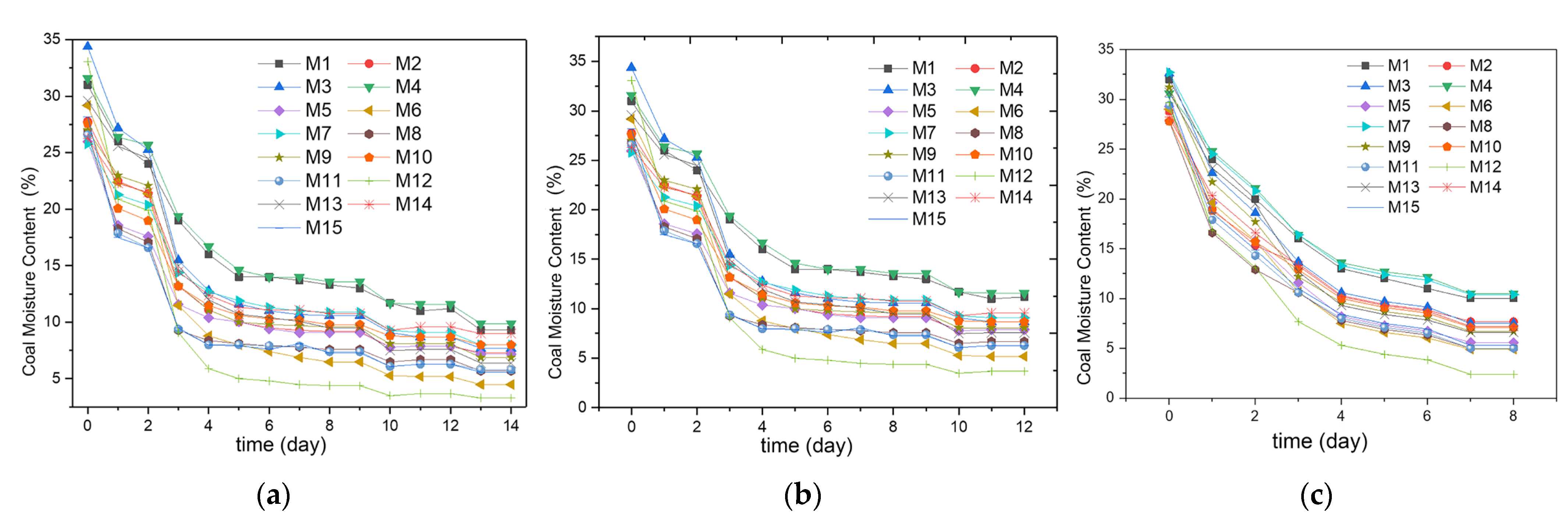

4.1. Effect of Time and Air Leakage Variation on Coal Body Moisture

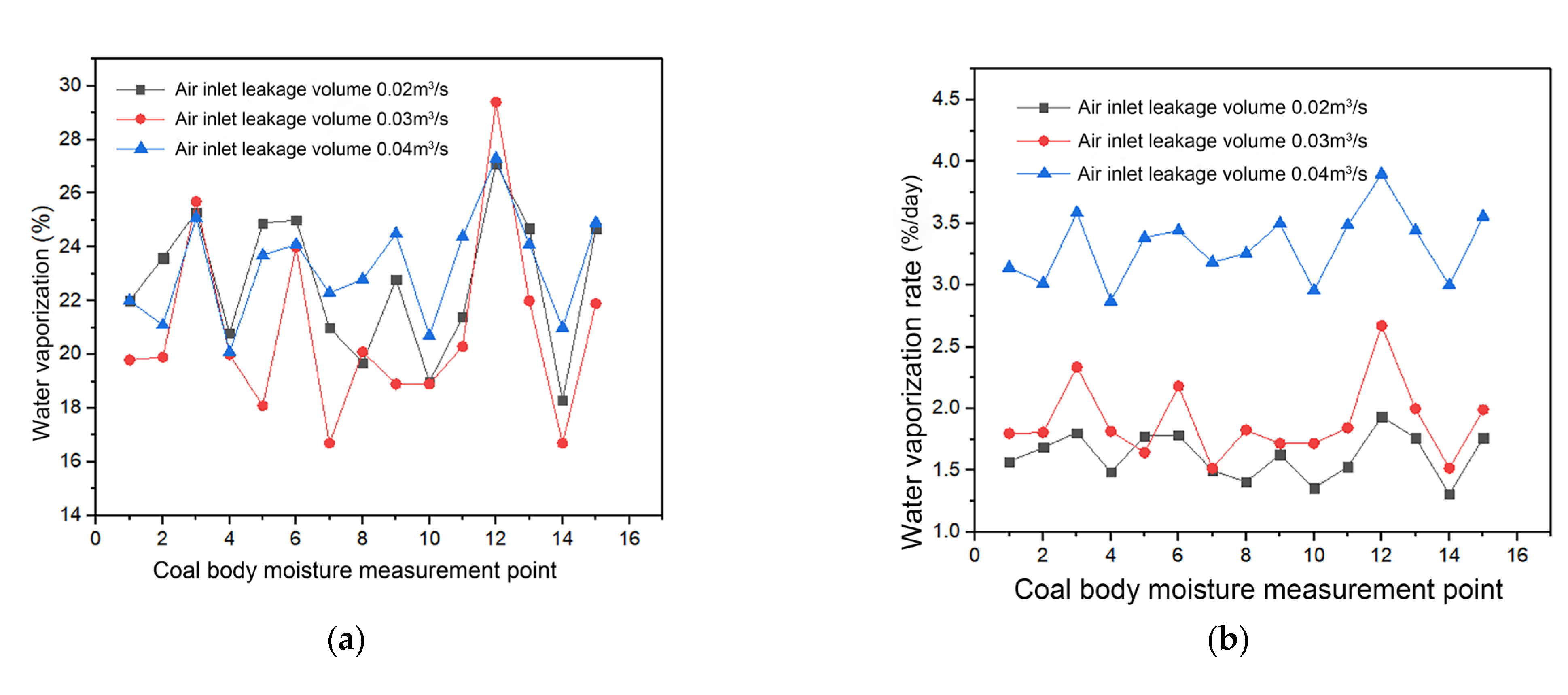

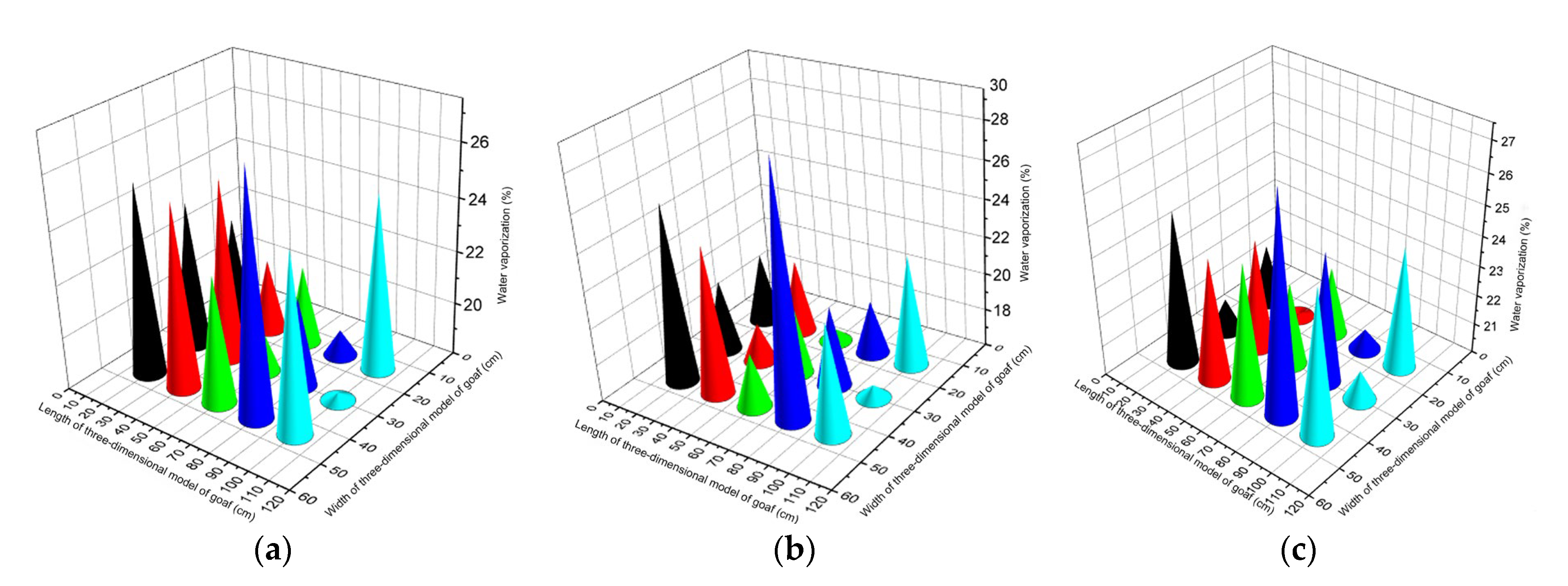

4.2. Influence of Measurement Point Location on the Amount of Water Evaporation

4.3. The Effect of Time and Air Leakage Volume Changes on the Relative Humidity of the Air Inlet and Outlet

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, D.M. Mine Ventilation and Safety; Xuzhou China Mining University Press: Xuzhou, China, 2012. [Google Scholar]

- Deng, J.; Bai, Z.; Xiao, Y.; Song, Z. Present situation and challenge of coal spontaneous combustion disasters prevention and control technology. Saf. Coal Mines 2020, 51, 118–125. [Google Scholar] [CrossRef]

- Qin, B.T.; Jiang, W.J.; Shi, Q.L.; Xu, Y.Z.; Shao, X. Research progress on fly ash foundation technology to prevent and control spontaneous combustion of coal in mines. Coal Sci. Technol. 2023, 51, 329–342. [Google Scholar] [CrossRef]

- Cui, C.B.; Jiang, S.G.; Zhang, W.Q. Experimental study on the effect of a thermoresponsive secundine inhibitor on coal spontaneous combustion. Energy Fuels 2017, 31, 14262–14269. [Google Scholar] [CrossRef]

- Cui, C.; Jiang, S.; Shao, H.; Zhang, W.; Wang, K.; Wu, Z. Experimental study on thermo-responsive inhibitors inhibiting coal spontaneous combustion. Fuel Process. Technol. 2018, 175, 113–122. [Google Scholar] [CrossRef]

- Zhang, J.; Ren, T.; Liang, Y.; Wang, Z. A review on numerical solutions to self-heating of coal stockpile: Mechanism, theoretical basis, and variable study. Fuel 2016, 182, 80–109. [Google Scholar] [CrossRef]

- Liang, Y.T.; Hou, X.J.; Luo, H.Z.; Tian, F.C.; Yu, G.S. Development countermeasures and current situation of coal mine fire prevention&extinguishing in China. Coal Sci. Technol. 2016, 44, 1–6, 13. [Google Scholar] [CrossRef]

- Du, F.R. Research of the Spontaneous Combustion Characteristic and Prevention Technology of Complex Mining Coal Seam in Hegang Mining Area; Liaoning Technical University: Liaoning, China, 2016. [Google Scholar]

- Qin, B.T.; Wang, D.M. Present Situation and Development of Mine Fire Control Technology. China Saf. Sci. J. 2007, 12, 80–85, 193. [Google Scholar] [CrossRef]

- Yang, Y.Y. Discussion on common methods of coal spontaneous combustion prevention and fire extinguishing. In The Collection of Scientific and Technical Papers on Firefighting of the Academic Working Committee of China Firefighting Association (2022); Sinopec Press: Beijing, China, 2022; 4p. [Google Scholar] [CrossRef]

- Shi, Q.L.; Qin, B.T. Study of the formation mechanism and characteristics of elastic hydrogel for preventing spontaneous combustion of coal. J. China Univ. Min. Technol. 2022, 51, 1106–1116. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, F.B. A comprehensive hazard evaluation system for spontaneous combustion of coal in underground mining. Int. J. Coal Geol. 2010, 82, 27–36. [Google Scholar] [CrossRef]

- Wang, H.Y.; Chen, C. Experimental study on greenhouse gas emissions caused by spontaneous coal combustion. Energy Fuels 2015, 29, 5213–5221. [Google Scholar] [CrossRef]

- Yang, F.F.; Wang, H.H.; Gong, H.M.; Bai, G.J.; Zhang, J.F. Research progress of coal spontaneous combustion tendency test and monitoring technology. Coal 2023, 32, 29–32, 53. [Google Scholar]

- Yi, X.; Hu, Z.; Wang, W.F.; Deng, J. Key technologies for intelligent monitoring and early warning of coal spontaneous combustion. Saf. Coal Mines 2022, 53, 31–37. [Google Scholar] [CrossRef]

- Greb, S.F. Coal more than a resource: Critical data for understanding a variety of earth-science concepts. Int. J. Coal Geol. 2013, 118, 15–32. [Google Scholar] [CrossRef]

- Querol, X.; Zhuang, X.; Font, O. Influence of soil cover on reducing the environmental impact of spontaneous coal combustion in coal waste gobs: A review and new experimental data. Int. J. Coal Geol. 2011, 85, 2–22. [Google Scholar] [CrossRef]

- Wang, J.Q.; Ren, W.X.; Zhou, W.; Wang, X.X.; Liu, P.Y. Application of new inhibiting materials in the prevention and control of spontaneous combustion of coal piles in ports. Energy Technol. Manag. 2023, 48, 80–82. [Google Scholar]

- Gao, F.; Bai, Q.H.; Jia, Z.; Teng, Y.F.; Li, Y.D. Study on exothermicity of coal during low temperature oxidation process based on quantum chemical calculation. J. China Coal Soc. 2023, 7, 1–11. [Google Scholar] [CrossRef]

- Luo, D.Y.; Qin, R.X.; Liu, Z. Study on calculation method of critical temperature of coal spontaneous combustion based on numerical analysis. Min. Res. Dev. 2022, 42, 132–136. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Z.; Hou, S.; Gu, F.; Gao, S.; Tang, Y. The shortest period of coal spontaneous combustion on the basis of oxidative heat release intensity. Int. J. Min. Sci. Technol. 2014, 24, 99–103. [Google Scholar] [CrossRef]

- Liu, W.; Qin, Y.P. Multi-physics coupling model of coal spontaneous combustion in longwall gob area based on moving coordinates. Fuel 2017, 188, 553–566. [Google Scholar] [CrossRef]

- Küçük, A.; Kadıoğlu, Y.; Gülaboğlu, M.Ş. A study of spontaneous combustion characteristics of a Turkish lignite: Particle size, moisture of coal, humidity of air. Combust. Flame 2003, 133, 255–261. [Google Scholar] [CrossRef]

- Jia, T.G.; Lou, H.Z.; Liu, J.; Qu, G.N. Experimental study on thermal characteristics of spontaneous combustionprocess of coal with different moisture. J. China Coal Soc. 2020, 45, 346–352. [Google Scholar] [CrossRef]

- Hao, H.D.; Zhang, Y.L.; Ning, L.V.; Wang, J.F.; Zhou, C.S. Experimental study on microscopic action of different form moisture on coalspontaneous combustion. J. Fuel Chem. Technol. 2021, 49, 282–291. [Google Scholar] [CrossRef]

- Liu, X.K.; Wang, G.Z. Numerical Simulation of Water Evaporation Influence on Coal PileSpontaneous Combustion Heating up Process. Coal Technol. 2016, 35, 129–131. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Zhang, Y.L.; Wang, J.F.; Hao, H.D.; Wu, Y.G.; Zhou, C.S. Study on the e ffe ct and me chanism of fore ignmoisture on coal spontane ous combustion. J. Fuel Chem. Technol. 2020, 48, 1–10. [Google Scholar]

- Wang, J.; Zhang, Y.L.; Wang, J.F.; Wu, Y.G.; Zhou, C.S.; Zhang, Z.Q. Synergistic inhibition effect of inorganic salt inhibitor and free radical scavenger on coal spontaneous combustion. J. China Coal Soc. 2020, 45, 4132–4143. [Google Scholar] [CrossRef]

- Wang, D.; Dou, G.; Zhong, X.; Xin, H.; Qin, B. An experimental approach to selecting chemical inhibitors to retard the spontaneous combustion of coal. Fuel 2014, 117, 218–223. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, S.; Wu, Z.; Zhang, W.; Wang, K. Comparative research on the influence of dioxide carbon and nitrogen on performance of coal spontaneous combustion. J. China Coal Soc. 2014, 39, 2244–2249. [Google Scholar] [CrossRef]

| Industrial Analysis (%) | Title 3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Mad | Ad | Vdaf | FC.ad | St.d | Odaf | Cdaf | Hdaf | Ndaf |

| 2.38 | 25.32 | 40.96 | 43.04 | 1.15 | 13.42 | 78.49 | 5.10 | 1.45 |

| Serial Number | Air InletStatic Pressure Value/Pa | Wind Speed Valuem/s | Air Leakage Volumem3/s |

|---|---|---|---|

| 1 | 6 | 2.1 | 0.02 |

| 2 | 10 | 3.2 | 0.03 |

| 3 | 15 | 4.2 | 0.04 |

| Measurement Points | x (cm) | y (cm) |

|---|---|---|

| 1 | 15 | 20 |

| 2 | 30 | 20 |

| 3 | 45 | 20 |

| 4 | 15 | 40 |

| 5 | 30 | 40 |

| 6 | 45 | 40 |

| 7 | 15 | 60 |

| 8 | 30 | 60 |

| 9 | 45 | 60 |

| 10 | 15 | 80 |

| 11 | 30 | 80 |

| 12 | 45 | 80 |

| 13 | 15 | 100 |

| 14 | 30 | 100 |

| 15 | 45 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, C.; Jiao, Z.; Zhou, Y.; Jiang, S.; Yuan, Y.; Li, J.; Song, Z. Experimental Study of Three-Dimensional Time Domain of Water Evaporation from Goaf. Appl. Sci. 2023, 13, 7932. https://doi.org/10.3390/app13137932

Cui C, Jiao Z, Zhou Y, Jiang S, Yuan Y, Li J, Song Z. Experimental Study of Three-Dimensional Time Domain of Water Evaporation from Goaf. Applied Sciences. 2023; 13(13):7932. https://doi.org/10.3390/app13137932

Chicago/Turabian StyleCui, Chuanbo, Zhipeng Jiao, Yuying Zhou, Shuguang Jiang, Yanwei Yuan, Jiangjiang Li, and Zhiqiang Song. 2023. "Experimental Study of Three-Dimensional Time Domain of Water Evaporation from Goaf" Applied Sciences 13, no. 13: 7932. https://doi.org/10.3390/app13137932

APA StyleCui, C., Jiao, Z., Zhou, Y., Jiang, S., Yuan, Y., Li, J., & Song, Z. (2023). Experimental Study of Three-Dimensional Time Domain of Water Evaporation from Goaf. Applied Sciences, 13(13), 7932. https://doi.org/10.3390/app13137932