The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion

Abstract

:1. Introduction

2. Materials and Methods

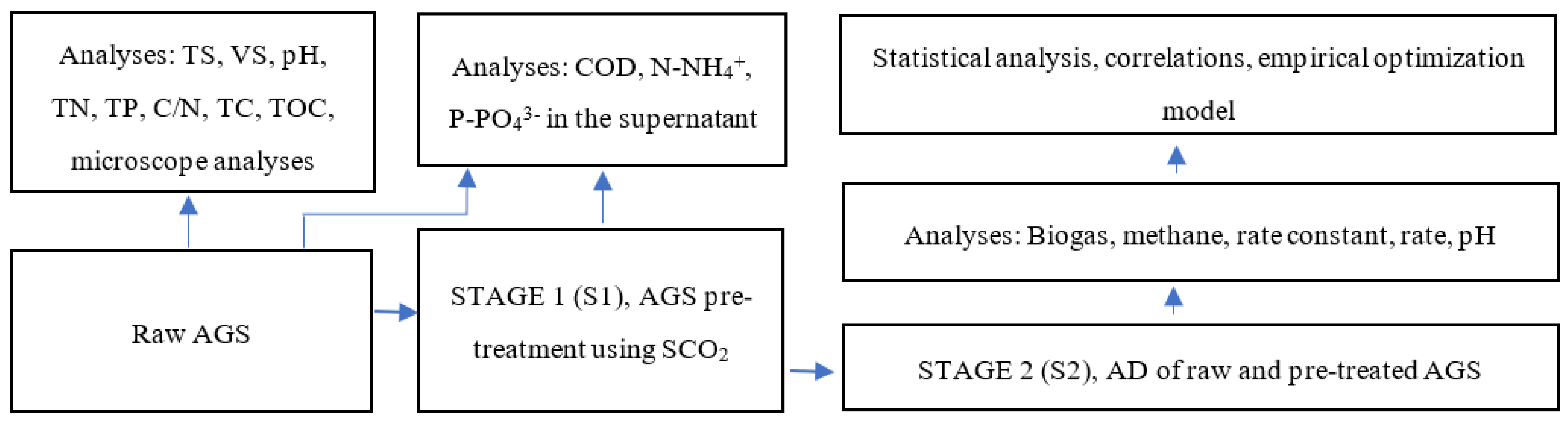

2.1. Experiment Organization

2.2. Materials

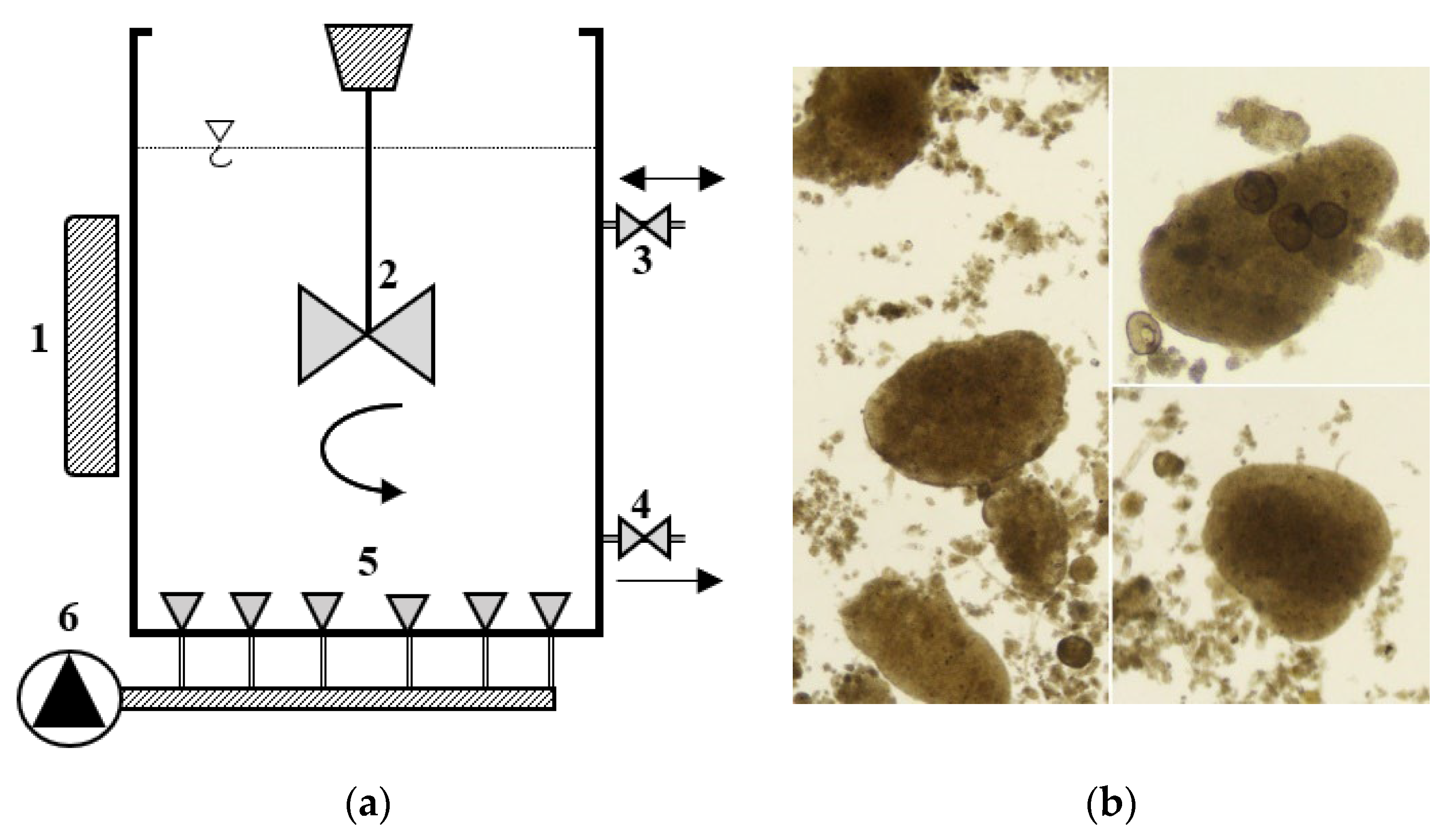

2.2.1. Aerobic Granular Sludge (AGS)

2.2.2. SCO2

2.3. Experimental Reactors

2.4. Analytical Procedures

2.5. Statistical, Calculation and Optimization Methods

3. Results and Discussion

3.1. Stage 1

3.2. Stage 2

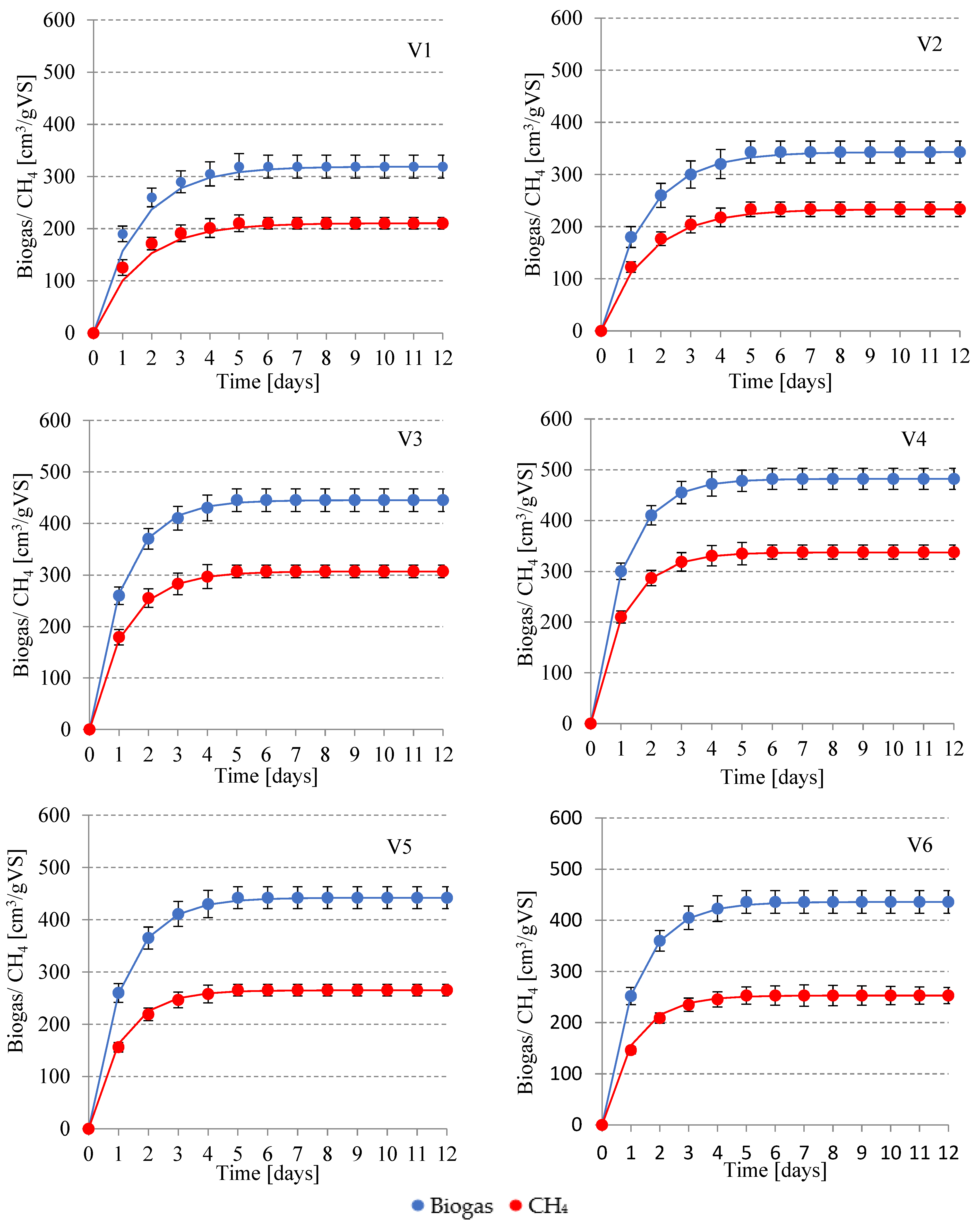

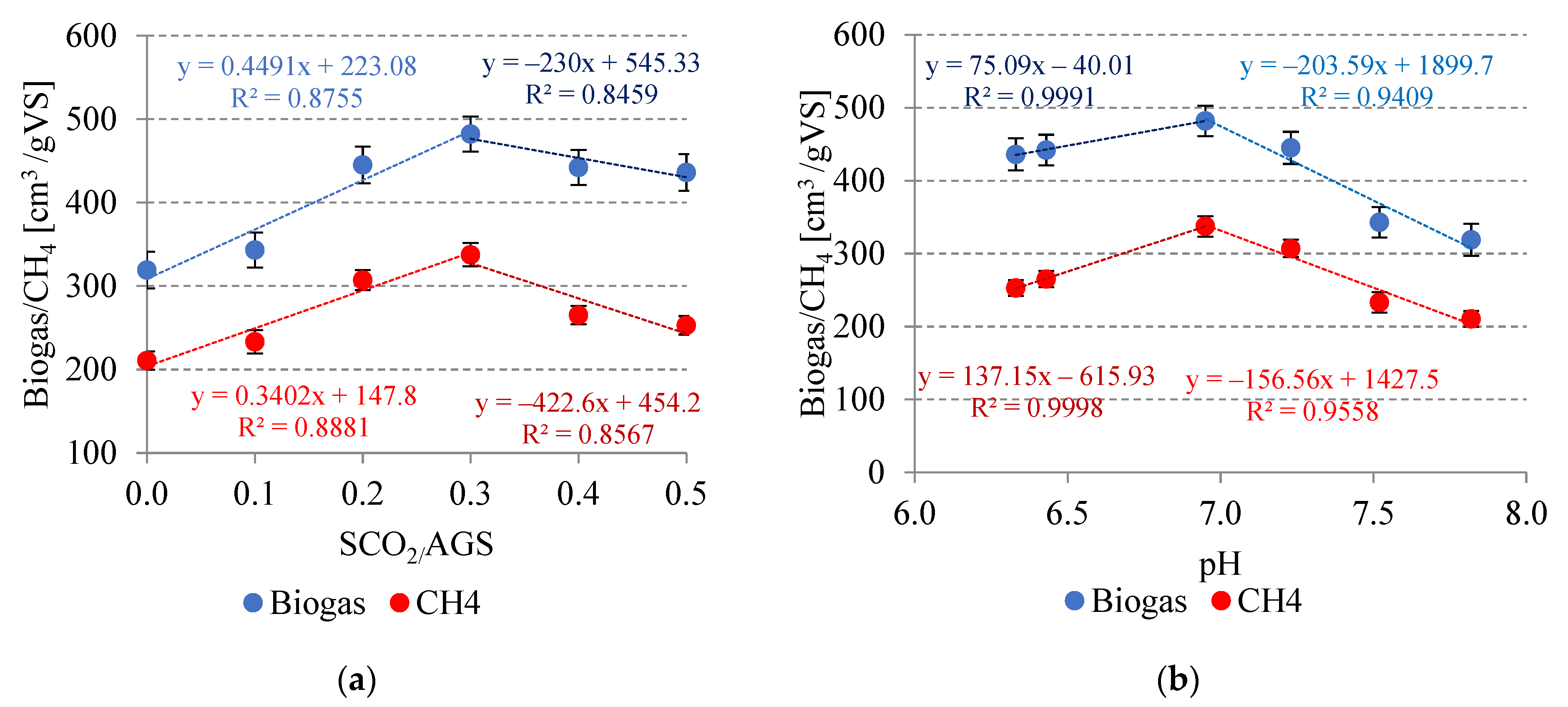

3.2.1. AD Efficiency

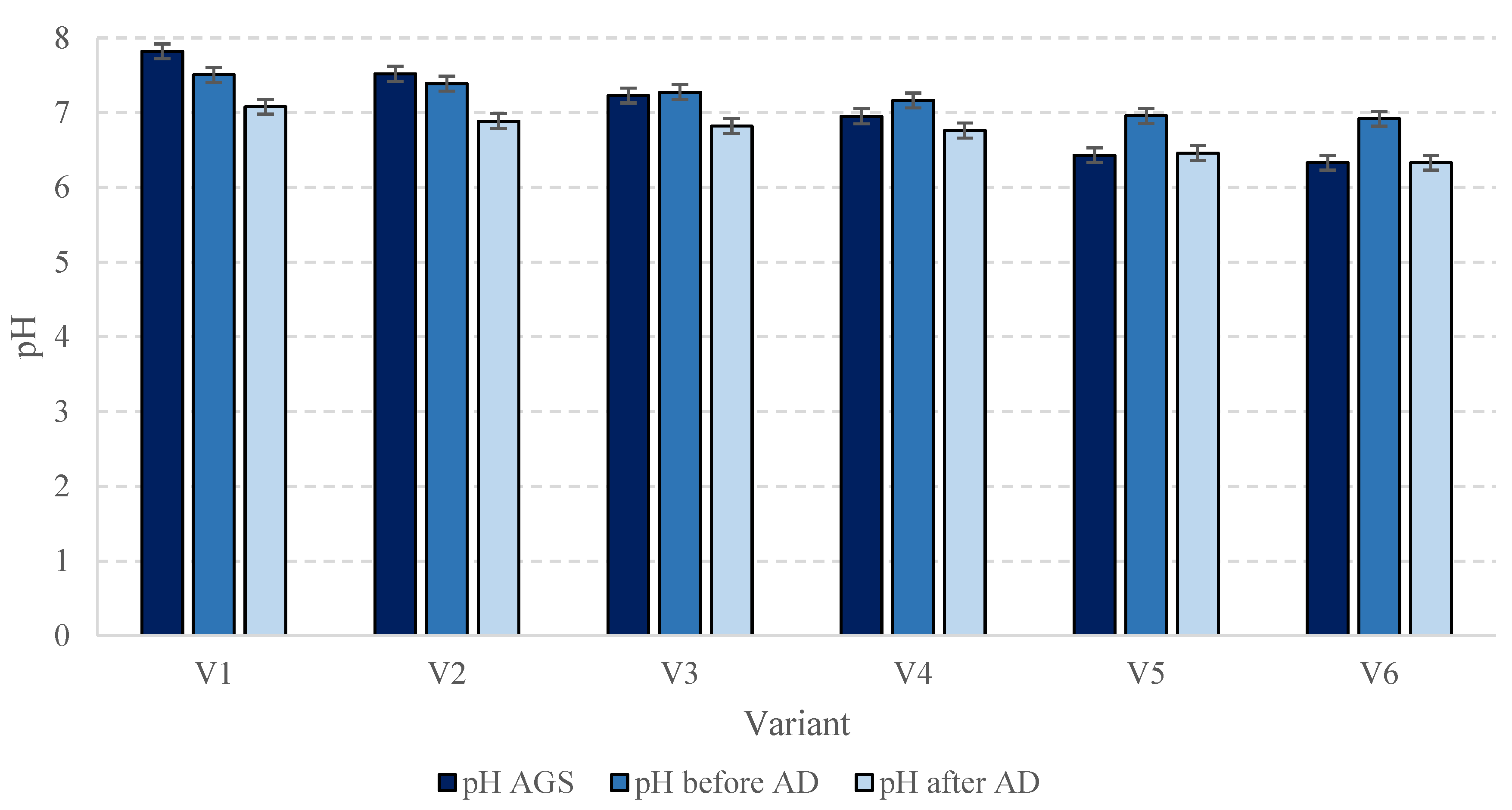

3.2.2. pH

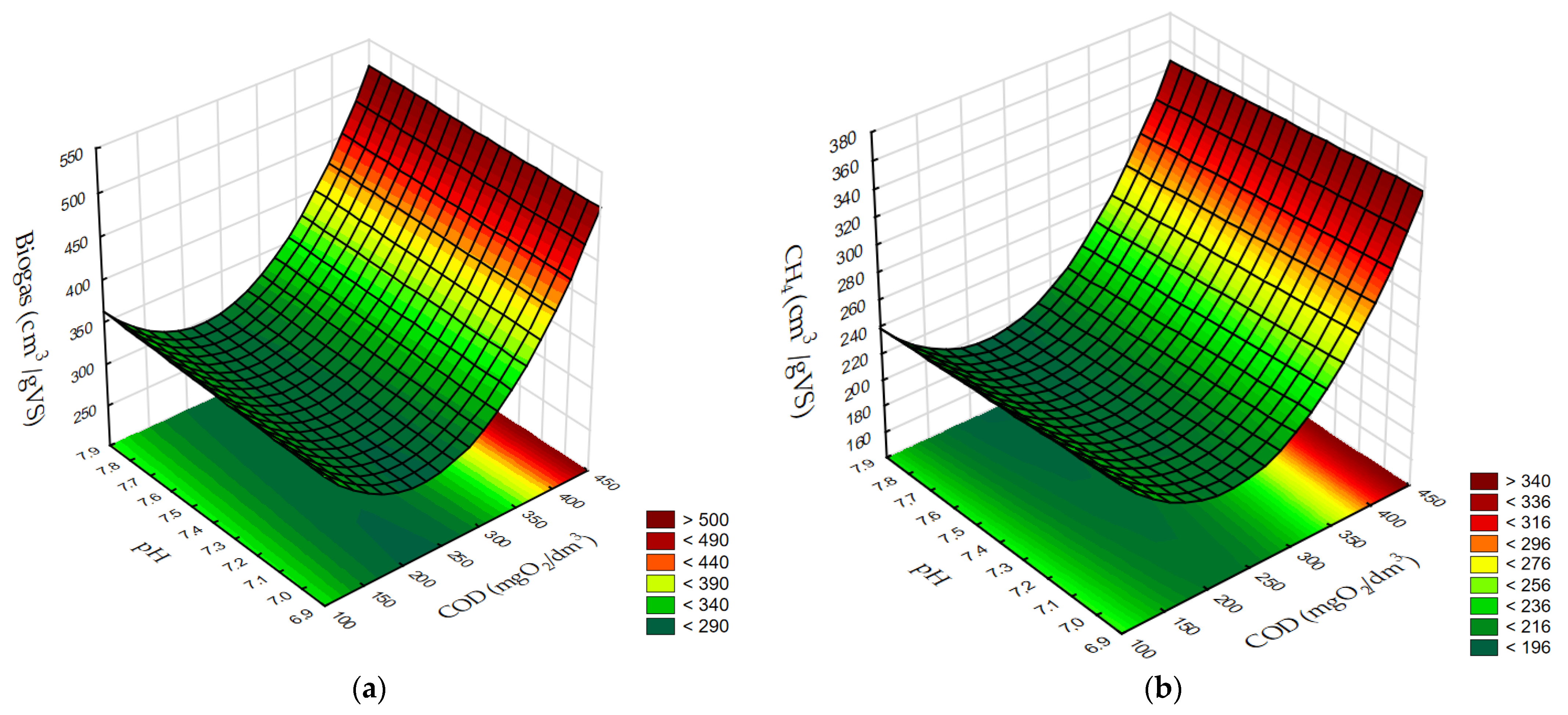

3.2.3. Correlations and Empirical Models

- BIOGAS—the amount of produced biogas (cm3/gVS),

- COD—COD concentration in the dissolved phase, mgO2/dm3,

- pH—pH value (−)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dubey, M.; Mohapatra, S.; Tyagi, V.K.; Suthar, S.; Kazmi, A.A. Occurrence, Fate, and Persistence of Emerging Micropollutants in Sewage Sludge Treatment. Environ. Pollut. 2021, 273, 116515. [Google Scholar] [CrossRef] [PubMed]

- Rosiek, K. Directions and Challenges in the Management of Municipal Sewage Sludge in Poland in the Context of the Circular Economy. Sustainability 2020, 12, 3686. [Google Scholar] [CrossRef]

- Haider, K.M.; Lafouge, F.; Carpentier, Y.; Houot, S.; Petitprez, D.; Loubet, B.; Focsa, C.; Ciuraru, R. Chemical Identification and Quantification of Volatile Organic Compounds Emitted by Sewage Sludge. Sci. Total Environ. 2022, 838, 155948. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Adam, C.; Preisner, M. Circular Economy Model Framework in the European Water and Wastewater Sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef] [Green Version]

- Di Giacomo, G.; Romano, P. Evolution and Prospects in Managing Sewage Sludge Resulting from Municipal Wastewater Purification. Energies 2022, 15, 5633. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Horttanainen, M.; Deviatkin, I.; Havukainen, J.; Klavins, M.; Ozola-Davidane, R.; Kruopienė, J.; Szatkowska, B.; Appels, L.; et al. Indicators for Resource Recovery Monitoring within the Circular Economy Model Implementation in the Wastewater Sector. J. Environ. Manag. 2022, 304, 114261. [Google Scholar] [CrossRef]

- Cecconet, D.; Capodaglio, A.G. Sewage Sludge Biorefinery for Circular Economy. Sustainability 2022, 14, 14841. [Google Scholar] [CrossRef]

- Myszograj, S.; Płuciennik-Koropczuk, E. Thermal Disintegration of Sewage Sludge as a Method of Improving the Biogas Potential. Energies 2023, 16, 559. [Google Scholar] [CrossRef]

- Battista, F.; Frison, N.; Pavan, P.; Cavinato, C.; Gottardo, M.; Fatone, F.; Eusebi, A.L.; Majone, M.; Zeppilli, M.; Valentino, F.; et al. Food Wastes and Sewage Sludge as Feedstock for an Urban Biorefinery Producing Biofuels and Added-Value Bioproducts. J. Chem. Technol. Biotechnol. 2020, 95, 328–338. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Long-Term Pre-Treatment of Municipal Sewage Sludge with Solidified Carbon Dioxide (SCO2)—Effect on Anaerobic Digestion Efficiency. Appl. Sci. 2023, 13, 3075. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. The Effect of Static Magnetic Field on Methanogenesis in the Anaerobic Digestion of Municipal Sewage Sludge. Energies 2021, 14, 590. [Google Scholar] [CrossRef]

- Xu, R.; Yang, Z.H.; Wang, Q.P.; Bai, Y.; Liu, J.B.; Zheng, Y.; Zhang, Y.R.; Xiong, W.P.; Ahmad, K.; Fan, C.Z. Rapid Startup of Thermophilic Anaerobic Digester to Remove Tetracycline and Sulfonamides Resistance Genes from Sewage Sludge. Sci. Total Environ. 2018, 612, 788–798. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.L.; Lin, Z.; Sun, Z.Y.; Gou, M.; Xia, Z.Y.; Tang, Y.Q. A Comparative Study of Mesophilic and Thermophilic Anaerobic Digestion of Municipal Sludge with High-Solids Content: Reactor Performance and Microbial Community. Bioresour. Technol. 2020, 302, 122851. [Google Scholar] [CrossRef] [PubMed]

- Vítěz, T.; Novák, D.; Lochman, J.; Vítězová, M. Methanogens Diversity during Anaerobic Sewage Sludge Stabilization and the Effect of Temperature. Processes 2020, 8, 822. [Google Scholar] [CrossRef]

- Hendriks, A.T.W.M.; Van Lier, J.B.; De Kreuk, M.K. Growth Media in Anaerobic Fermentative Processes: The Underestimated Potential of Thermophilic Fermentation and Anaerobic Digestion. Biotechnol. Adv. 2018, 36, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Ruffino, B.; Cerutti, A.; Campo, G.; Scibilia, G.; Lorenzi, E.; Zanetti, M. Thermophilic vs. Mesophilic Anaerobic Digestion of Waste Activated Sludge: Modelling and Energy Balance for Its Applicability at a Full Scale WWTP. Renew. Energy 2020, 156, 235–248. [Google Scholar] [CrossRef]

- Vidal-Antich, C.; Perez-Esteban, N.; Astals, S.; Peces, M.; Mata-Alvarez, J.; Dosta, J. Assessing the Potential of Waste Activated Sludge and Food Waste Co-Fermentation for Carboxylic Acids Production. Sci. Total Environ. 2021, 757, 143763. [Google Scholar] [CrossRef]

- Zhi, Z.; Pan, Y.; Lu, X.; Zhen, G.; Zhao, Y.; Zhu, X.; Xiong, J.; Zhao, T. Electrically Regulating Co-Fermentation of Sewage Sludge and Food Waste towards Promoting Biomethane Production and Mass Reduction. Bioresour. Technol. 2019, 279, 218–227. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M. Aerobic Granular Sludge as a Substrate in Anaerobic Digestion—Current Status and Perspectives. Sustainability 2022, 14, 10904. [Google Scholar] [CrossRef]

- Cydzik-Kwiatkowska, A.; Bernat, K.; Zielińska, M.; Gusiatin, M.Z.; Wojnowska-Baryła, I.; Kulikowska, D. Valorization of Full-Scale Waste Aerobic Granular Sludge for Biogas Production and the Characteristics of the Digestate. Chemosphere 2022, 303, 135167. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Technological, Ecological, and Energy-Economic Aspects of Using Solidified Carbon Dioxide for Aerobic Granular Sludge Pre-Treatment Prior to Anaerobic Digestion. Int. J. Environ. Res. Public Health 2023, 20, 4234. [Google Scholar] [CrossRef] [PubMed]

- Afridi, Z.U.R.; Wu, J.; Cao, Z.P.; Zhang, Z.L.; Li, Z.H.; Poncin, S.; Li, H.Z. Insight into Mass Transfer by Convective Diffusion in Anaerobic Granules to Enhance Biogas Production. Biochem. Eng. J. 2017, 127, 154–160. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.H.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Tyagi, V.K.; Nghiem, L.D. Biomethane Production from Anaerobic Co-Digestion at Wastewater Treatment Plants: A Critical Review on Development and Innovations in Biogas Upgrading Techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current Status of Biogas Upgrading for Direct Biomethane Use: A Review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Paglini, R.; Gandiglio, M.; Lanzini, A. Technologies for Deep Biogas Purification and Use in Zero-Emission Fuel Cells Systems. Energies 2022, 15, 3551. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M. Characteristics of Solidified Carbon Dioxide and Perspectives for Its Sustainable Application in Sewage Sludge Management. Int. J. Mol. Sci. 2023, 24, 2324. [Google Scholar] [CrossRef]

- Nowicka, E.; Machnicka, A.; Grűbel, K. Improving Of Anaerobic Digestion By Dry Ice Disintegration Of Surplus Activated Sludge. Proc. ECOpole 2014, 8, 239–247. [Google Scholar] [CrossRef]

- Zawieja, I. Effect of Dry Ice Modification of Excess Sludge on the Methane Fermentation Process. Annu. Set Environ. Prot. 2018, 20, 558–573. [Google Scholar]

- Kazimierowicz, J.; Bartkowska, I.; Walery, M. Effect of Low-Temperature Conditioning of Excess Dairy Sewage Sludge with the Use of Solidified Carbon Dioxide on the Efficiency of Methane Fermentation. Energies 2020, 14, 150. [Google Scholar] [CrossRef]

- Ofman, P.; Skoczko, I.; Włodarczyk-Makuła, M. Biosorption of LMW PAHs on Activated Sludge Aerobic Granules under Varying BOD Loading Rate Conditions. J. Hazard. Mater. 2021, 418, 126332. [Google Scholar] [CrossRef]

- Jamil, M.; Iqbal, A.; He, N.; Cheok, Q. Thermophysical Properties and Heat Transfer Performance of Novel Dry-Ice-Based Sustainable Hybrid Lubri-Coolant. Sustainability 2022, 14, 2430. [Google Scholar] [CrossRef]

- PN-EN 15935:2022-01; Soil, Waste, Treated Bio-Waste and Sewage Sludge—Determination of Losses on Ignition. Health, Environment and Medicine Sector, Technical Body of Soil Chemistry: Warsaw, Poland, 2022.

- Zawieja, I.E. The Course of the Methane Fermentation Process of Dry Ice Modified Excess Sludge. Arch. Environ. Prot. 2019, 45, 50–58. [Google Scholar] [CrossRef]

- Machnicka, A.; Grübel, K.; Wacławek, S.; Sikora, K. Waste-Activated Sludge Disruption by Dry Ice: Bench Scale Study and Evaluation of Heat Phase Transformations. Environ. Sci. Pollut. Res. 2019, 26, 26488–26499. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nie, E.; He, P.; Zhang, H.; Hao, L.; Shao, L.; Lü, F. How Does Temperature Regulate Anaerobic Digestion? Renew. Sustain. Energy Rev. 2021, 150, 111453. [Google Scholar] [CrossRef]

- Gavala, H.N.; Yenal, U.; Skiadas, I.V.; Westermann, P.; Ahring, B.K. Mesophilic and Thermophilic Anaerobic Digestion of Primary and Secondary Sludge. Effect of Pre-Treatment at Elevated Temperature. Water Res. 2003, 37, 4561–4572. [Google Scholar] [CrossRef]

- SAFETY DATA SHEET Carbon Dioxide, Solid (Dry Ice) SECTION 1: Identification of the Substance/Mixture and of the Company/Undertaking. Available online: https://produkte.linde-gas.at/sdb_konform/TE_10022548EN.pdf (accessed on 5 May 2023).

- De Meyer, T.; Hemelsoet, K.; Van Speybroeck, V.; De Clerck, K. Substituent Effects on Absorption Spectra of PH Indicators: An Experimental and Computational Study of Sulfonphthaleine Dyes. Dyes Pigments 2014, 102, 241–250. [Google Scholar] [CrossRef] [Green Version]

- Montusiewicz, A.; Lebiocka, M.; Rozej, A.; Zacharska, E.; Pawłowski, L. Freezing/Thawing Effects on Anaerobic Digestion of Mixed Sewage Sludge. Bioresour. Technol. 2010, 101, 3466–3473. [Google Scholar] [CrossRef]

- Srisowmeya, G.; Chakravarthy, M.; Nandhini Devi, G. Critical Considerations in Two-Stage Anaerobic Digestion of Food Waste—A Review. Renew. Sustain. Energy Rev. 2020, 119, 109587. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Effect of Pharmaceutical Sludge Pre-Treatment with Fenton/Fenton-like Reagents on Toxicity and Anaerobic Digestion Efficiency. Int. J. Environ. Res. Public Health 2022, 20, 271. [Google Scholar] [CrossRef]

- Godvin Sharmila, V.; Kumar, G.; Sivashanmugham, P.; Piechota, G.; Park, J.H.; Adish Kumar, S.; Rajesh Banu, J. Phase Separated Pretreatment Strategies for Enhanced Waste Activated Sludge Disintegration in Anaerobic Digestion: An Outlook and Recent Trends. Bioresour. Technol. 2022, 363, 127985. [Google Scholar] [CrossRef]

- Ahn, J.Y.; Chang, S.W. Effects of Sludge Concentration and Disintegration/Solubilization Pretreatment Methods on Increasing Anaerobic Biodegradation Efficiency and Biogas Production. Sustainability 2021, 13, 12887. [Google Scholar] [CrossRef]

- Dębowski, M.; Kazimierowicz, J.; Świca, I.; Zieliński, M. Ultrasonic Disintegration to Improve Anaerobic Digestion of Microalgae with Hard Cell Walls—Scenedesmus sp. and Pinnularia sp. Plants 2022, 12, 53. [Google Scholar] [CrossRef] [PubMed]

| Indicator | Unit | AGS | AS |

|---|---|---|---|

| Total solids (TS) | [%] | 7.38 ± 0.1 | 3.35 ± 0.1 |

| Volatile solids (VS) | [%TS] | 93.88 ± 4.5 | 56.49 ± 6.2 |

| Mineral solids (MS) | [%TS] | 6.12 ± 1.3 | 43.51 ± 5.1 |

| Total carbon (TC) | [mg/gTS] | 652 ± 22 | 311 ± 11 |

| Total organic carbon (TOC) | [mg/gTS] | 601 ± 13 | 296 ± 11 |

| Total nitrogen (TN) | [mg/gTS] | 101 ± 6.2 | 35.5 ± 4.1 |

| C/N ratio | - | 6.46 ± 0.1 | 8,76 ± 0.2 |

| Total phosphorus (TP) | [mg/gTS] | 7.1 ± 1.5 | 1.9 ± 0.1 |

| pH | - | 7.82 ± 0.1 | 7.30 ± 0.1 |

| Indicator | Unit | V | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| COD | [mgO2/dm3] | 150 ± 11 | 330 ± 16 | 412 ± 17 | 435 ± 15 | 440 ± 14 | 445 ± 15 |

| N-NH4+ | [mg/dm3] | 82 ± 4 | 157 ± 7 | 225 ± 8 | 273 ± 10 | 288 ± 9 | 312 ± 11 |

| P-PO43− | [mg/dm3] | 63 ± 3 | 68 ± 4 | 73 ± 3 | 77 ± 4 | 78 ± 3 | 79 ± 3 |

| Indicator | Unit | V | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| Biogas | [cm3/gVS] | 319 ± 22 | 343 ± 21 | 445 ± 22 | 482 ± 21 | 442 ± 21 | 436 ± 22 |

| rbiogas | [cm3/d] | 203.5 | 235.3 | 396.1 | 457 | 390.7 | 380.2 |

| kbiogas | [1/d] | 0.64 | 0.69 | 0.89 | 0.96 | 0.88 | 0.87 |

| CH4 | [%] | 66 ± 3 | 68 ± 3 | 69 ± 2 | 70 ± 2 | 60 ± 3 | 58 ± 1 |

| CH4 | [cm3/gVS] | 211 ± 11 | 233 ± 14 | 307 ± 12 | 337 ± 14 | 265 ± 11 | 253 ± 11 |

| rCH4 | [cm3/d] | 88.65 | 108.8 | 188.5 | 223.9 | 140.7 | 127.9 |

| kCH4 | [1/d] | 0.42 | 0.47 | 0.61 | 0.67 | 0.53 | 0.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazimierowicz, J.; Dębowski, M.; Zieliński, M.; Bartkowska, I.; Wasilewski, A.; Łapiński, D.; Ofman, P. The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion. Appl. Sci. 2023, 13, 7864. https://doi.org/10.3390/app13137864

Kazimierowicz J, Dębowski M, Zieliński M, Bartkowska I, Wasilewski A, Łapiński D, Ofman P. The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion. Applied Sciences. 2023; 13(13):7864. https://doi.org/10.3390/app13137864

Chicago/Turabian StyleKazimierowicz, Joanna, Marcin Dębowski, Marcin Zieliński, Izabela Bartkowska, Adam Wasilewski, Dawid Łapiński, and Piotr Ofman. 2023. "The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion" Applied Sciences 13, no. 13: 7864. https://doi.org/10.3390/app13137864

APA StyleKazimierowicz, J., Dębowski, M., Zieliński, M., Bartkowska, I., Wasilewski, A., Łapiński, D., & Ofman, P. (2023). The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion. Applied Sciences, 13(13), 7864. https://doi.org/10.3390/app13137864