Investigation of Load Environment and Bending Load Capacities of Aged Prestressed Concrete Sleepers

Abstract

:1. Introduction

- (1)

- To investigate the actual load environment of PC sleepers installed on commercial lines by measuring their bending moments.

- (2)

- To verify the effects of various parameters on the bending moments of PC sleepers via numerical analyses.

- (3)

- To collect a wide range of aged PC sleepers on commercial lines and evaluate their bending load capacities by conducting bending tests specified by the Japanese Industrial Standard (JIS) E 1201 [18].

2. Investigation of Load Environment of PC Sleepers

2.1. Investigation Methods

2.1.1. Outline of a PC Sleeper

2.1.2. Methods of Measuring Wheel Loads and Bending Moments of PC Sleepers

2.1.3. Analysis Method

2.1.4. Material Constants and Analysis Cases for Numerical Analysis

2.2. Investigation Results

2.2.1. Measured Wheel Loads and Bending Moments of PC Sleepers

2.2.2. Numerical Analysis Verification Results of Effects of Various Parameters on Bending Moments of PC Sleepers

3. Evaluation of Bending Load Capacities of Aged PC Sleepers

3.1. Test Methods

3.1.1. Collection of PC Sleepers

3.1.2. JIS E 1201 Bending Test

3.2. Test Results

4. Conclusions

- (1)

- According to the field measurement results of the wheel loads and bending moments of the PC sleepers, the maximum wheel load was 79.51 kN and the maximum bending moment at the rail seat section was 3.81 kN·m. The measured values were smaller than the design values. The wheel load was 49.7% of the design wheel load of 160 kN, whereas the bending moment was 34.7% of the DDM of 10.95 kN·m. In addition, neither the wheel load nor the bending moment depended on train speed.

- (2)

- The numerical analysis results indicated that the positive bending moment at the rail seat section was unlikely to exceed the DDM. However, the negative bending moment at the center section may exceed the DDM if center support were provided with a reduced spring constant under the rail (the “hanging” rail seat section). In addition, the bending moment increased with the rail surface roughness, so the rail should be kept smooth.

- (3)

- The results of the JIS E 1201 bending tests on the aged PC sleepers showed that the crack generation load and ultimate load decreased gradually with increases in age and passing tonnage. However, all samples satisfied the JIS standard Pcr and Pu values. Furthermore, the bending moments generated in the PC sleepers during train passage were considerably smaller than the crack generation loads and ultimate loads during the bending tests.

- (4)

- Thus, Japanese PC sleepers aged over 50 years currently satisfy the standard flexural fracture values specified by the JIS, and safety is not immediately compromised.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FIP Commission on Prefabrication. FIP State of the Art Report (Concrete Railway Sleepers); Thomas Telford Ltd.: London, UK, 1987. [Google Scholar]

- Remennikov, A.M.; Kaewunruen, S. Experimental load rating of aged railway concrete sleepers. Eng. Struct. 2014, 76, 147–162. [Google Scholar] [CrossRef]

- Wakui, H.; Okuda, H. A study on limit state design method for prestressed concrete sleepers. Concr. Libr. JSCE 1999, 33, 1–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaewunruen, S.; Remennikov, A.M.; Murray, M.H. Introducing a new limit states design concept to railway concrete sleepers: An Australian experience. Front. Mater. 2014, 1, 8. [Google Scholar] [CrossRef]

- Ruiz, A.E.C.; Edwards, J.R.; Qian, Y.; Dersch, M.S. Probabilistic framework for the assessment of the flexural design of concrete sleepers. Proc. IMechE Part F J. Rail Rapid Transit 2020, 234, 691–701. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2007, 15, 207–234. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Murray, M.H.; Kaewunruen, S. Reliability-based conversion of a structural design code for railway prestressed concrete sleepers. Proc. IMechE Part F J. Rail Rapid Transit 2011, 226, 155–173. [Google Scholar] [CrossRef]

- Hamarat, M.; Papaelias, M.; Silvast, M.; Kaewunruen, S. The Effect of Unsupported Sleepers/Bearers on Dynamic Phenomena of a Railway Turnout System under Impact Loads. Appl. Sci. 2020, 10, 2320. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, T.; Goto, K.; Matsuoka, K.; Minoura, S. Validation of a dynamic wheel load factor and the influence of various track irregularities on the dynamic response of prestressed concrete sleepers. Proc. IMechE Part F J. Rail Rapid Transit 2020, 234, 1275–1284. [Google Scholar] [CrossRef]

- You, R.; Wang, J.; Ning, N.; Wang, M.; Zhang, J. The Typical Damage Form and Mechanism of a Railway Prestressed Concrete Sleeper. Materials 2022, 15, 8074. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Kaewunruen, S.; You, R. Remaining Fatigue Life Predictions of Railway Prestressed Concrete Sleepers Considering Time-Dependent Surface Abrasion. Sustainability 2022, 14, 11237. [Google Scholar] [CrossRef]

- You, R.; Li, D.; Ngamkhanong, C.; Janeliukstis, R.; Kaewunruen, S. Fatigue Life Assessment Method for Prestressed Concrete Sleepers. Front. Built Environ. 2017, 3, 68. [Google Scholar] [CrossRef] [Green Version]

- Goto, K.; Watanabe, T.; Minoura, S.; Ikeda, M. Fatigue Life Evaluation of PC Sleepers Based on Wheel Load Measurement Results. Q. Rep. RTRI 2022, 63, 263–268. [Google Scholar] [CrossRef] [PubMed]

- Kaewunruen, S.; Remennikov, A.M. Investigation of free vibrations of voided concrete sleepers in railway track system. Proc. IMechE Part F J. Rail Rapid Transit 2007, 221, 495–507. [Google Scholar] [CrossRef]

- Lazarević, L.; Vučković, D.; Popović, Z. Assessment of sleeper support conditions using micro-tremor analysis. Proc. IMechE Part F J. Rail Rapid Transit 2016, 230, 1828–1841. [Google Scholar] [CrossRef]

- Quirós-Orozco, R.J.; Edwards, J.R.; Dersch, M.S. Variability of support conditions and effects on the non-linear flexural response of concrete sleepers. Proc. IMechE Part F J. Rail Rapid Transit 2022, 236, 950–959. [Google Scholar] [CrossRef]

- Railway Technical Research Institute. Maintenance Standards for Railway Structures and Commentary (Track Structures); Railway Technical Research Institute: Tokyo, Japan; Maruzen Co., Ltd.: Tokyo, Japan, 2007. [Google Scholar]

- JIS E1201; Prestressed Concrete Sleepers-Pretensioning Type. Japanese Standards Association: Tokyo, Japan, 1997.

- JIS E1101; Flat Bottom Railway Rails and Special Rails for Switches and Crossings of Non-Treated Steel. Japanese Standards Association: Tokyo, Japan, 1980.

- Hajime, W.; Nobuyuki, M.; Makoto, T. A study on dynamic interaction analysis for railway vehicle and structures. Q. Rep. Railw. Tech. Res. Inst. 1994, 35, 96–104. [Google Scholar]

- Tanabe, M.; Matsumoto, N.; Wakui, H.; Sogabe, M. Simulation of a Shinkansen train on the railway structure during an earthquake. Jpn. J. Ind. Appl. Math. 2011, 28, 223–236. [Google Scholar] [CrossRef]

- Tanabe, M.; Komiya, S.; Wakui, H.; Matsumoto, N.; Sogabe, M. Simulation and visualization of high-speed Shinkansen train on the railway structure. Jpn. J. Ind. Appl. Math. 2000, 17, 309–320. [Google Scholar] [CrossRef]

- Matsuoka, K.; Watanabe, T. Application of a frequency-based detection method for evaluating damaged concrete sleepers. In Advances in Structural Health Monitoring; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar]

- Railway Technical Research Institute. Design Standards for Railway Structures and Commentary (Track Structures); Railway Technical Research Institute: Tokyo, Japan; Maruzen Co., Ltd.: Tokyo, Japan, 2012. [Google Scholar]

- Railway Technical Research Institute. Design Standards for Railway Structures and Commentary (Concrete Structures); Railway Technical Research Institute: Tokyo, Japan; Maruzen Co., Ltd.: Tokyo, Japan, 2007. [Google Scholar]

- Zhang, Z.; Wei, S.; Andrawes, B.; Kuchma, D.A.; Edwards, J.R. Numerical and experimental study on dynamic behavior of concrete sleeper track caused by wheel flat. Int. J. Rail Transp. 2016, 4, 1–19. [Google Scholar] [CrossRef]

- Vyas, N.S.; Gupta, A.K. Modeling rail wheel-flat dynamics. In Proceedings of the 1st World Congress on Engineering Asset Management (WCEAM), Ho Chi Minh City, Vietnam, 18–20 October 2006; pp. 11–14. [Google Scholar]

- Bian, J.; Gu, Y.T.; Murray, M. Numerical Study of Impact Forces on Railway Sleepers under Wheel Flat. Adv. Struct. Eng. 2013, 16, 127–134. [Google Scholar] [CrossRef]

| Material Constants | |

|---|---|

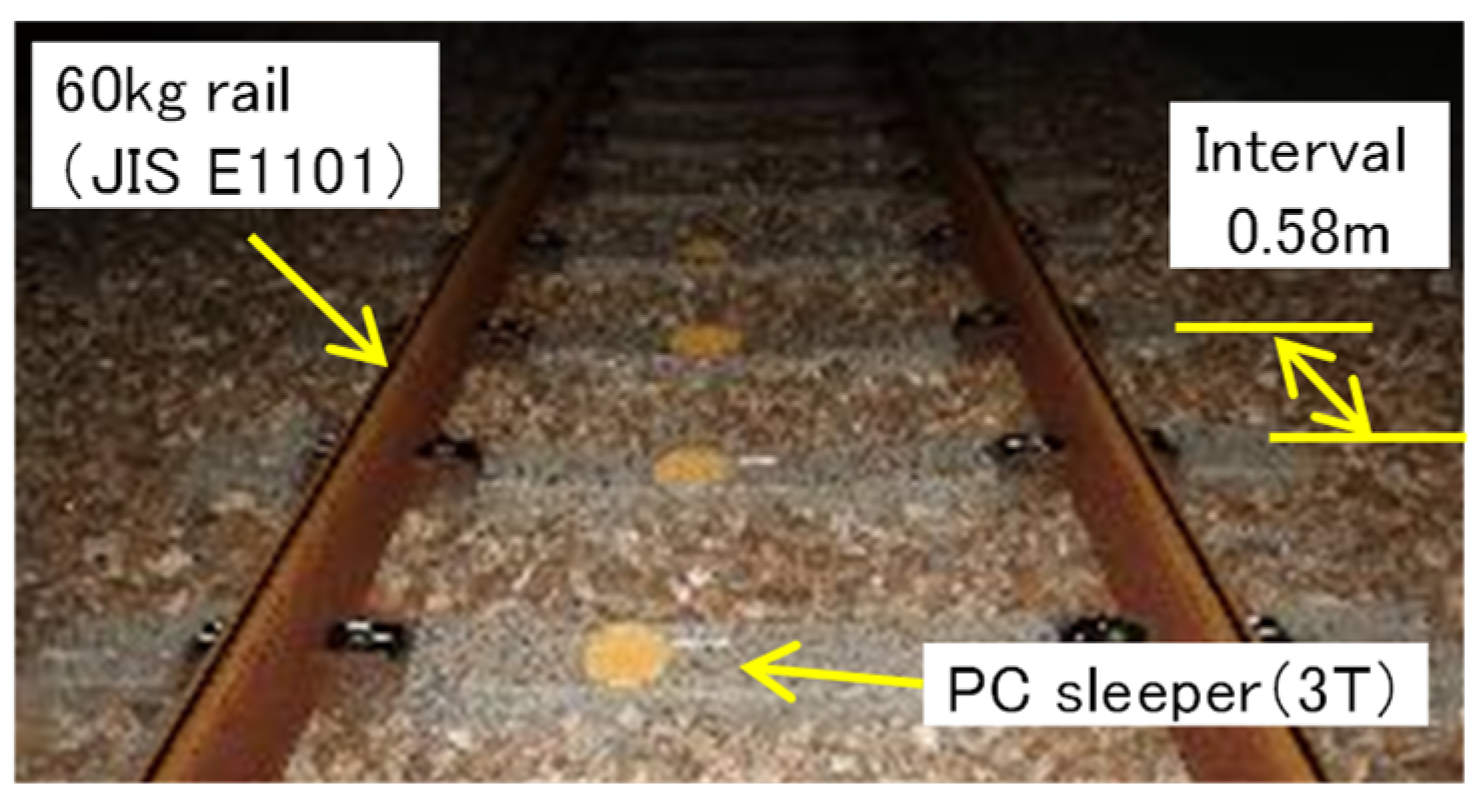

| Rail | 60 kg rail (JIS E 1101; Young’s modulus ES = 200 GPa) Track gauge = 1435 mm |

| Track pad | Spring constant DP = 50 MN/m |

| Sleeper | Type 3T (JIS E 1201), PC steel strand = φ 2.9 mm, N = 16 Length LP = 2400 mm Bottom width BP = 283 mm (rail seat section), 230 mm (center section) Height HP = 190 mm (rail seat section), 175 mm (center section) Young’s modulus EC = 33 GPa |

| Ballast | Ballast thickness h = 250 mm Support spring constant DB = 200 MN/m (per rail) |

| Parameter | Constant |

|---|---|

| Train speed (km/h) | 200, 250, 270, 300, 320 |

| Vehicle occupancy rate (%) | 50, 100, 200 |

| Spring constant of track pad (MN/m) | 50, 100, 150, 250 |

| Spring constant of ballast (MN/m) | 10, 30, 50, 100, 200 |

| Rail surface roughness | None, original (measured on-site), three times the original, and five times the original |

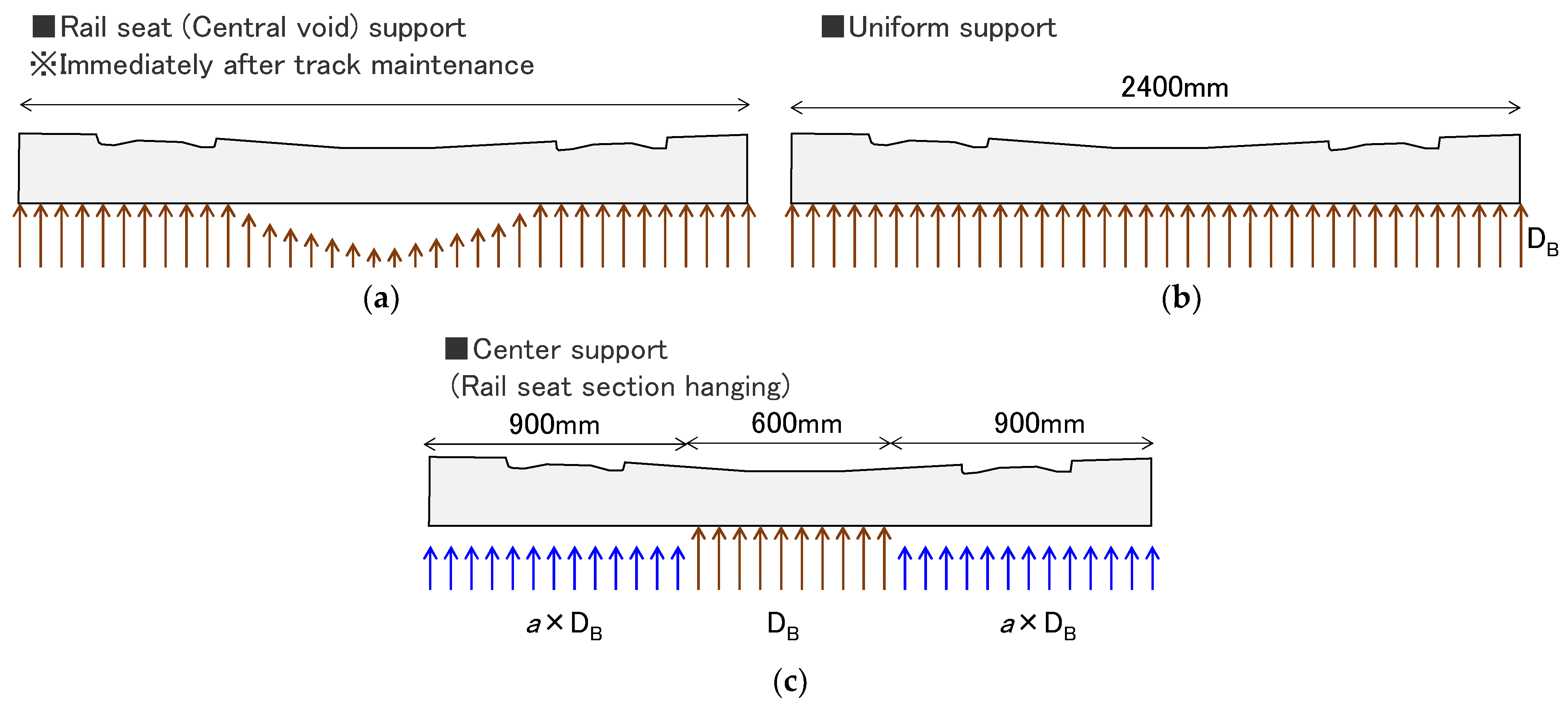

| Support condition of PC sleeper | Uniform support Uniform support with reduced spring constant (α × DB) (support condition R) Center support (α × DB) (support condition C) α = 1/100, 1/10, 1/2, 4/5 |

| Age | ~10 | ~20 | ~30 | ~40 | ~50 | ~60 | Total |

|---|---|---|---|---|---|---|---|

| Number | 3 | 3 | 2 | 14 | 8 | 4 | 34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Watanabe, T.; Goto, K.; Minoura, S. Investigation of Load Environment and Bending Load Capacities of Aged Prestressed Concrete Sleepers. Appl. Sci. 2023, 13, 7828. https://doi.org/10.3390/app13137828

Watanabe T, Goto K, Minoura S. Investigation of Load Environment and Bending Load Capacities of Aged Prestressed Concrete Sleepers. Applied Sciences. 2023; 13(13):7828. https://doi.org/10.3390/app13137828

Chicago/Turabian StyleWatanabe, Tsutomu, Keiichi Goto, and Shintaro Minoura. 2023. "Investigation of Load Environment and Bending Load Capacities of Aged Prestressed Concrete Sleepers" Applied Sciences 13, no. 13: 7828. https://doi.org/10.3390/app13137828

APA StyleWatanabe, T., Goto, K., & Minoura, S. (2023). Investigation of Load Environment and Bending Load Capacities of Aged Prestressed Concrete Sleepers. Applied Sciences, 13(13), 7828. https://doi.org/10.3390/app13137828