Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges

Abstract

:1. Introduction

1.1. Construction Methods with CIP Concrete

1.2. Construction Methods with Prefabricated Elements

1.2.1. Full-Depth Elements

1.2.2. Half-Depth Elements

2. Objectives and Scope

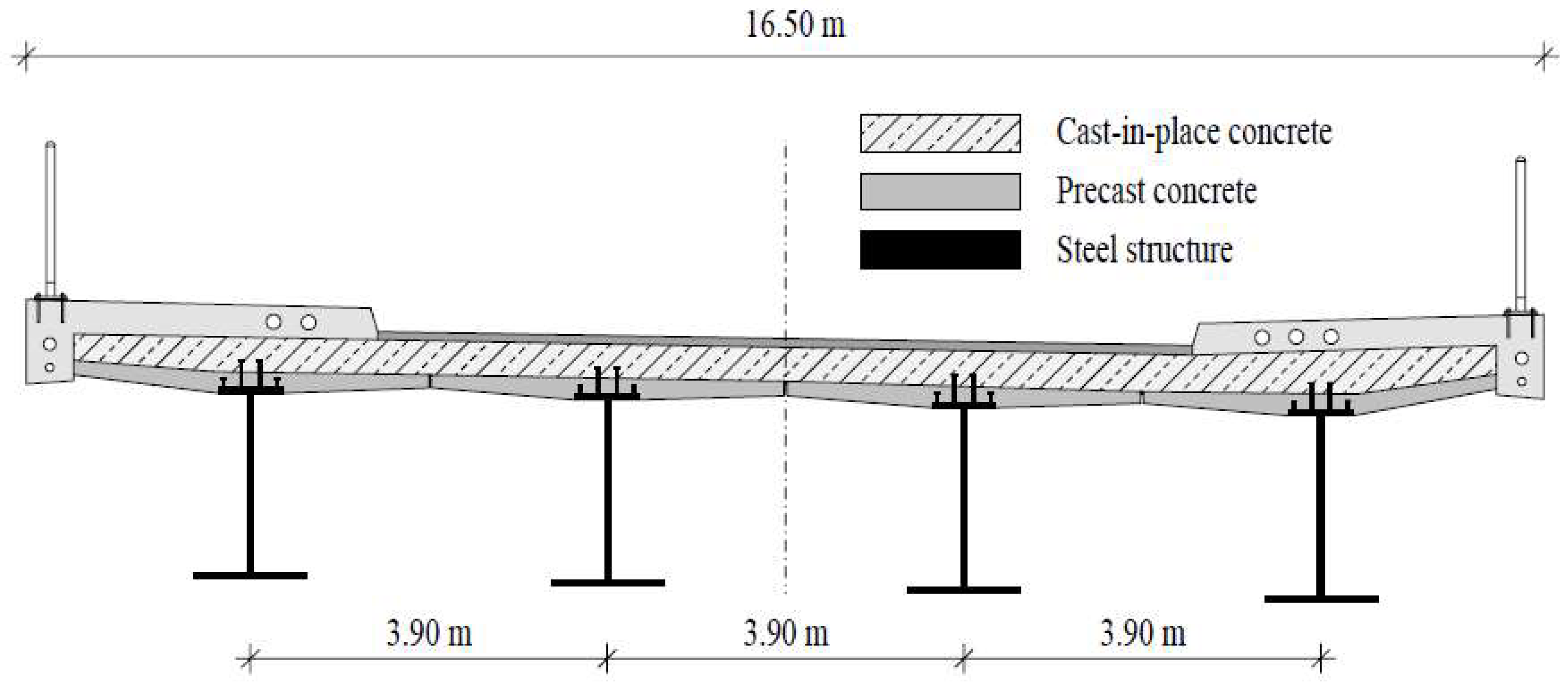

3. New Modular Construction Method

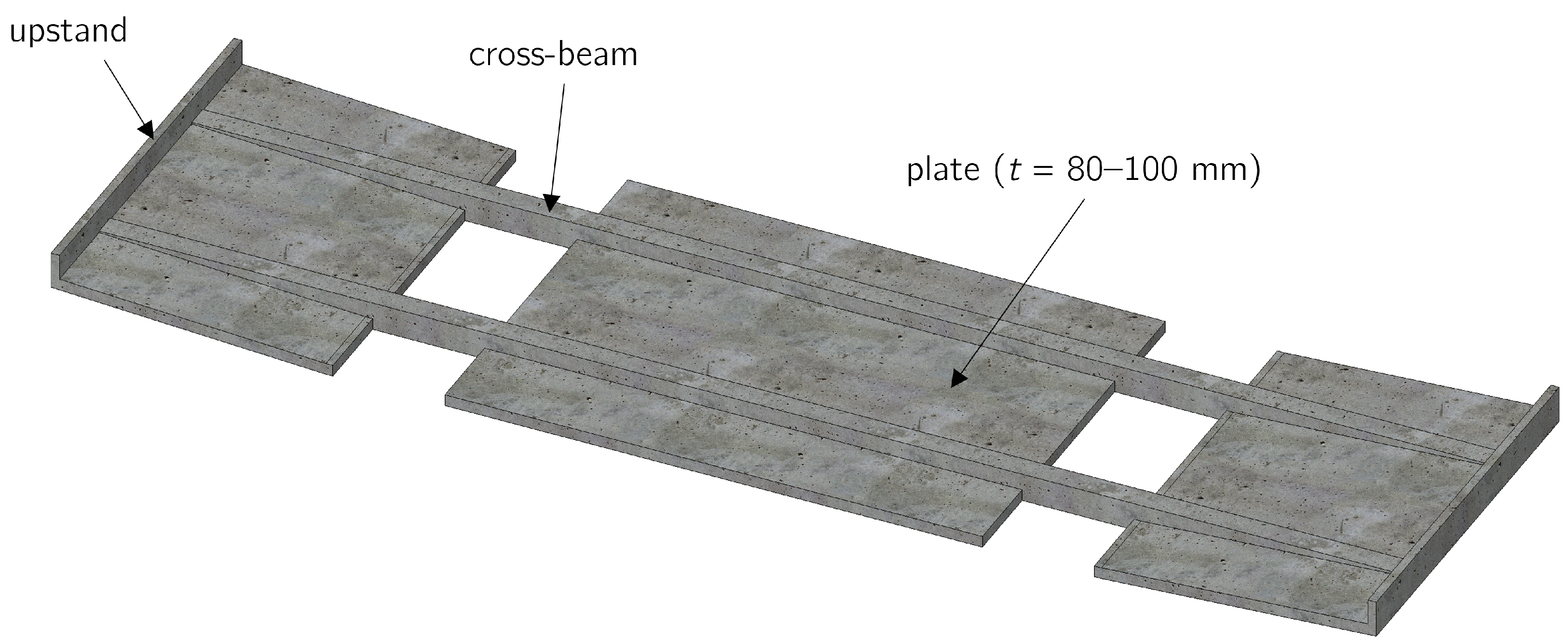

3.1. Innovative Precast Deck Slab Element

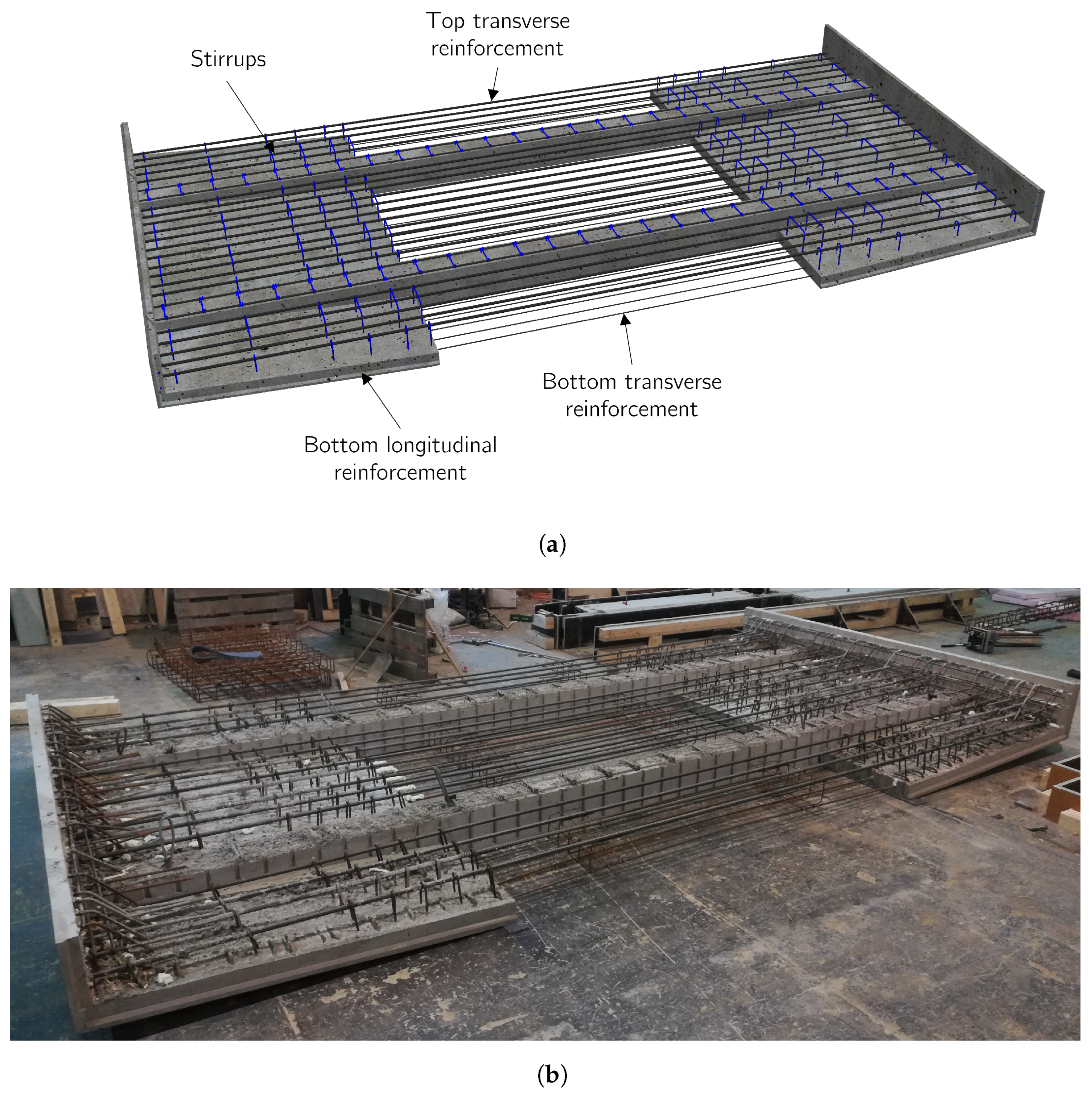

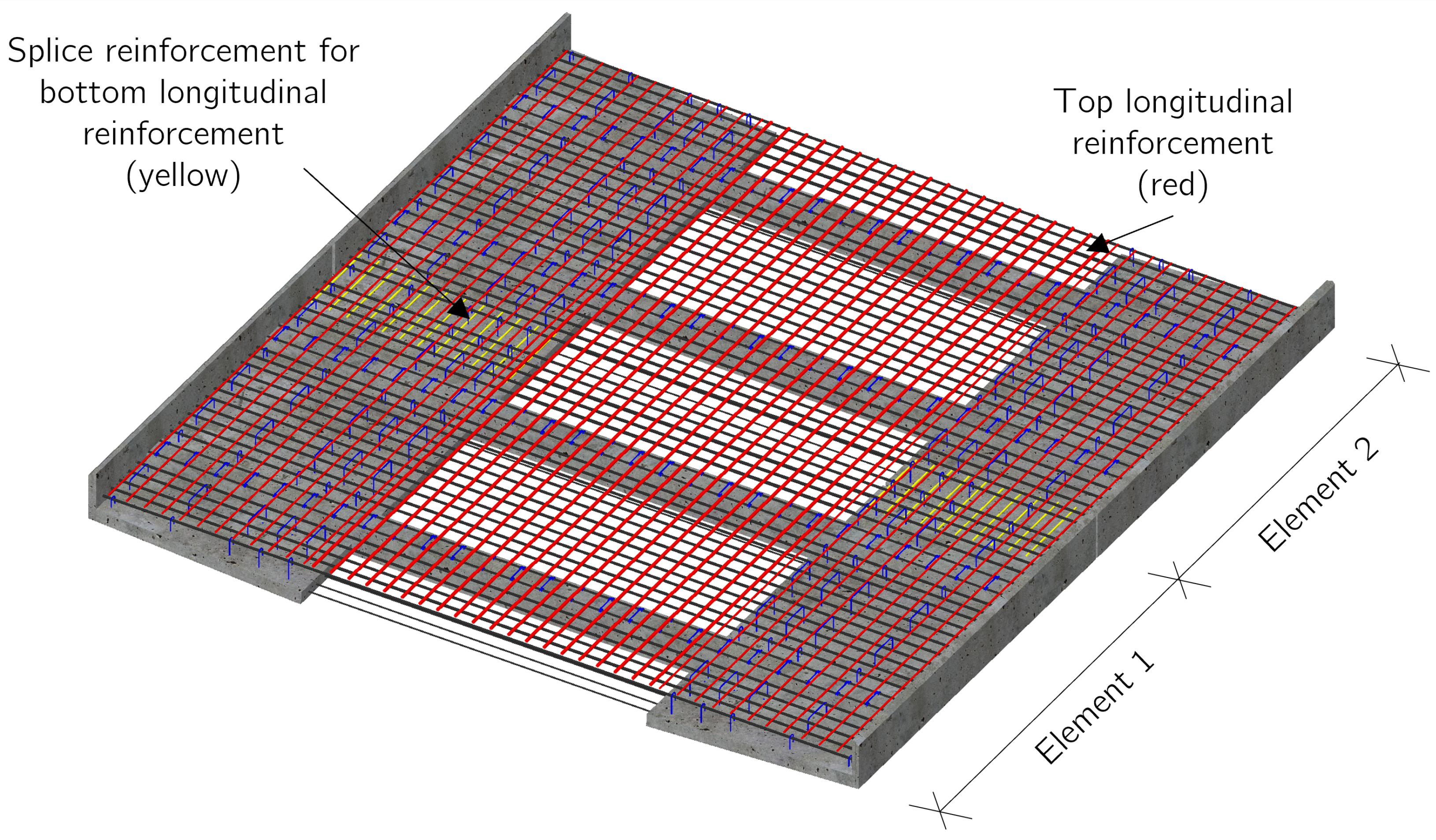

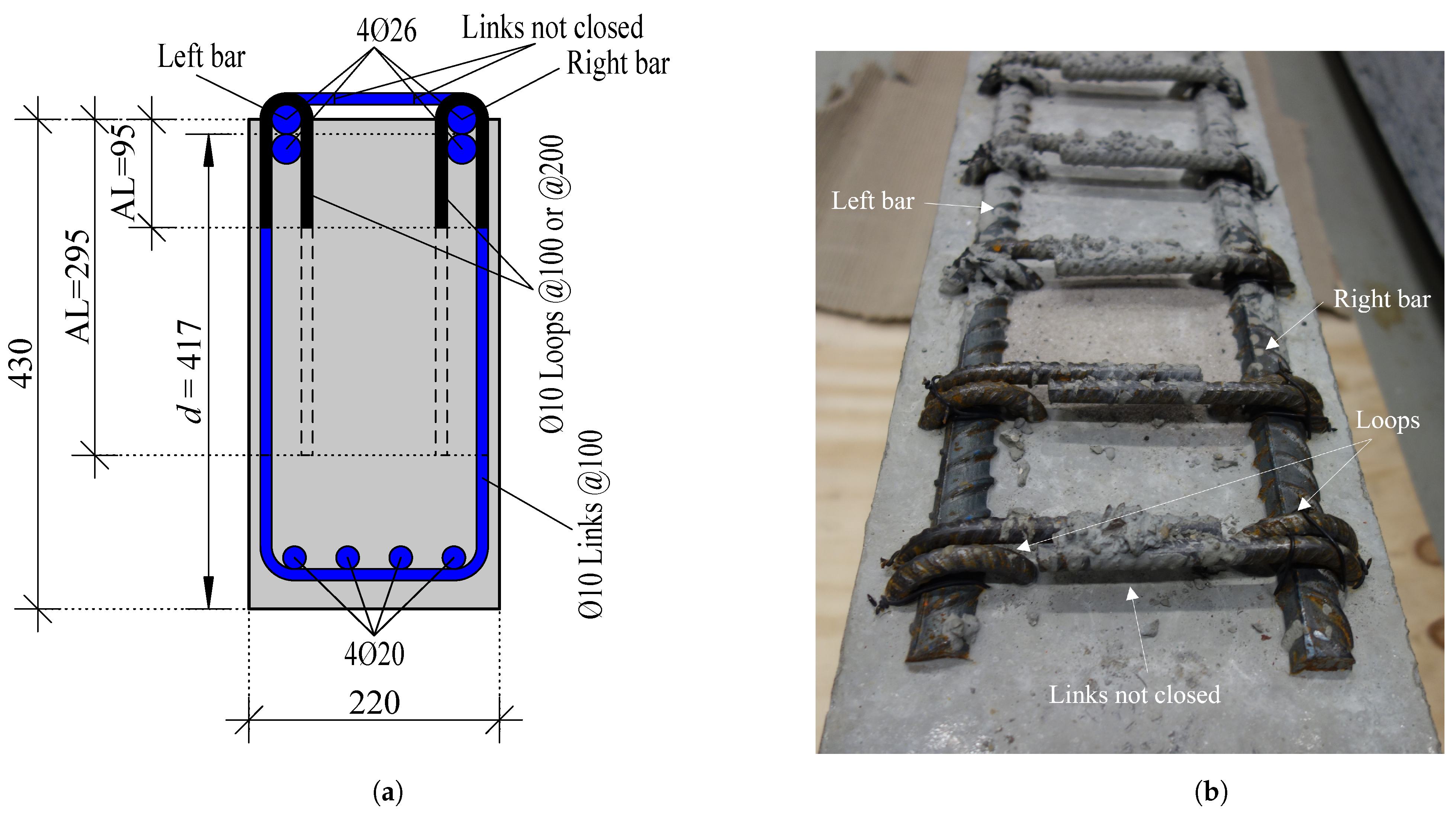

3.2. Reinforcement Layout

3.3. Longitudinal and Transverse Joint Details

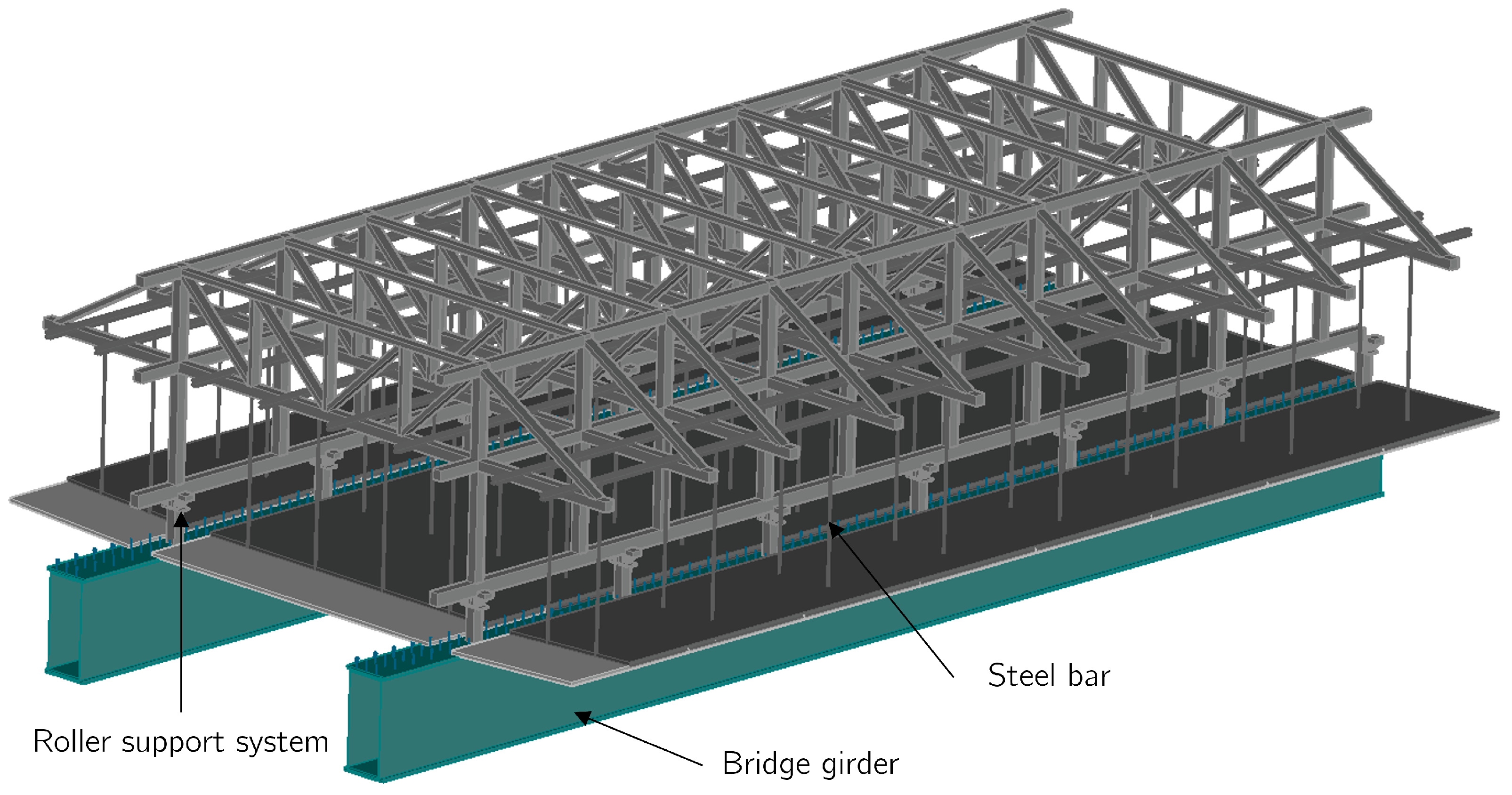

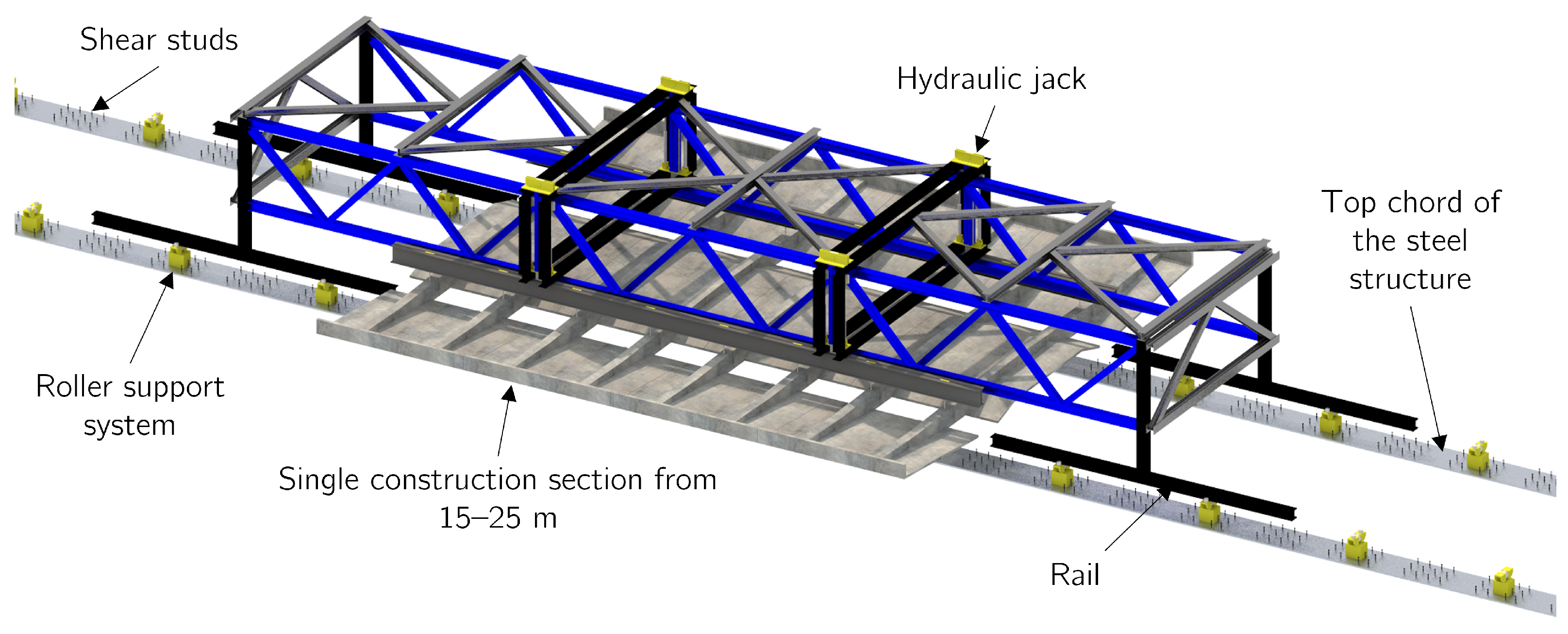

3.4. Transportation Carriage

3.5. Proposals for the Construction

4. Discussion

4.1. Comparison of the New Construction Method with Conventional Variants

4.2. Application Boundaries

5. Experimental Investigations

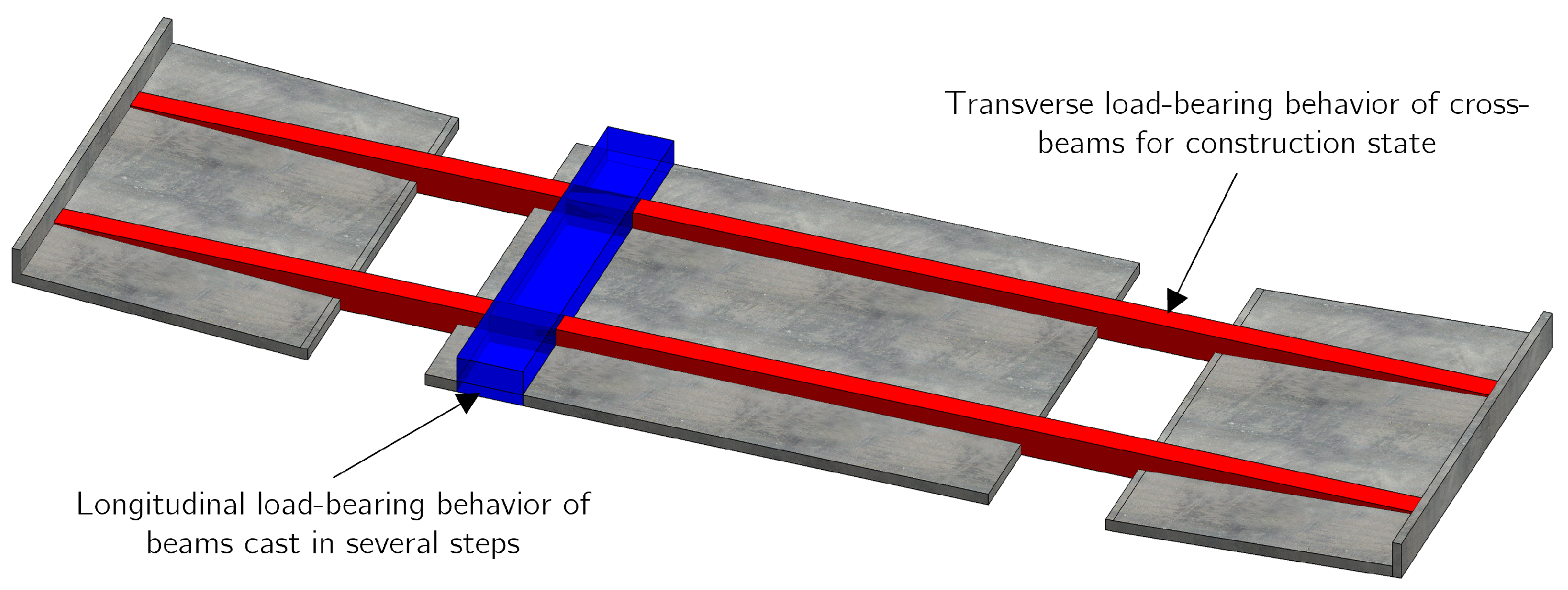

5.1. Transverse Load-Bearing Behavior of Cross-Beams for Construction State

5.1.1. Specimens and Test Set-Up

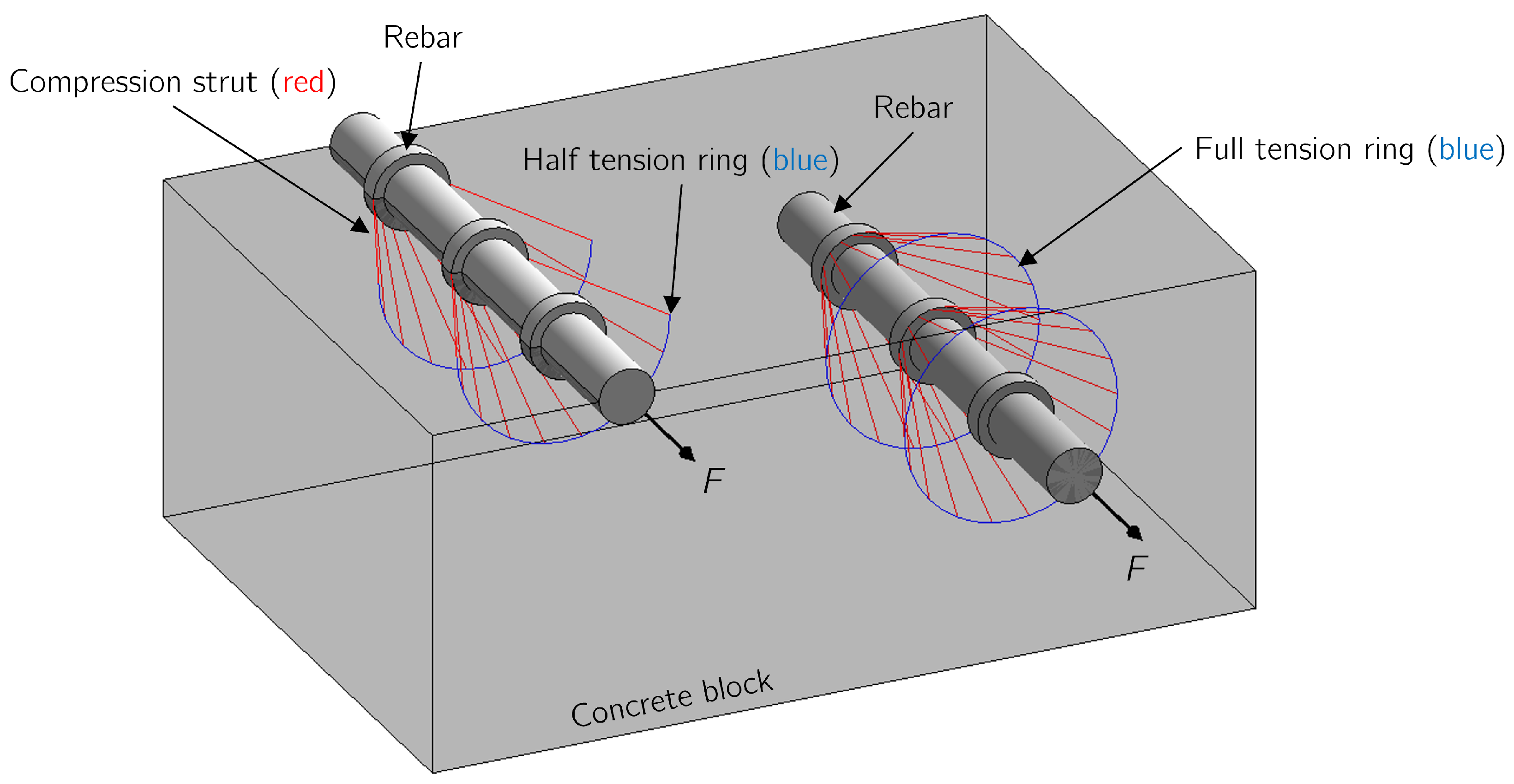

5.1.2. Theoretical Considerations Regarding the Mechanical Operating Principle of the Additional Loops

5.1.3. Material Properties

5.1.4. Measurements

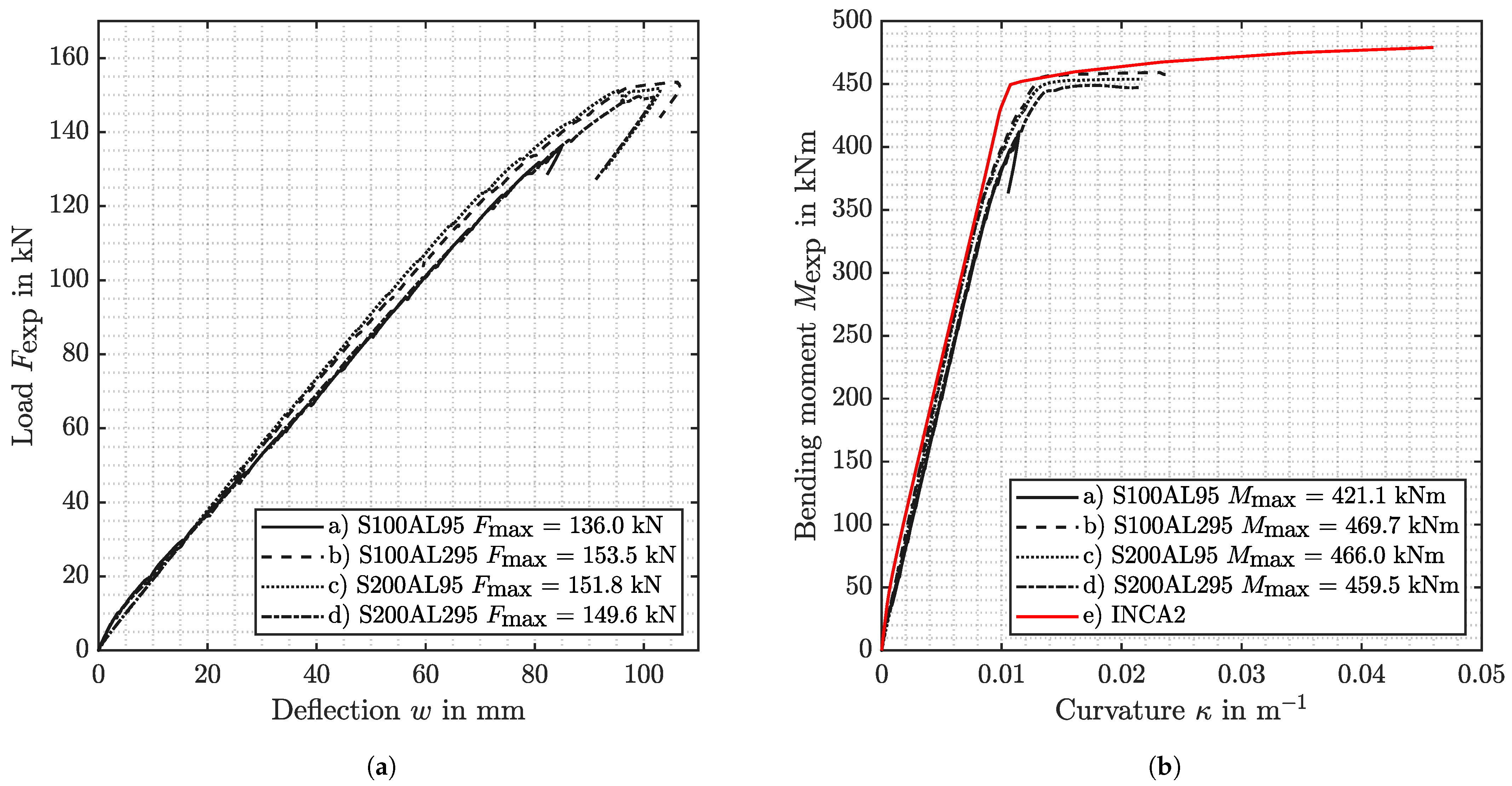

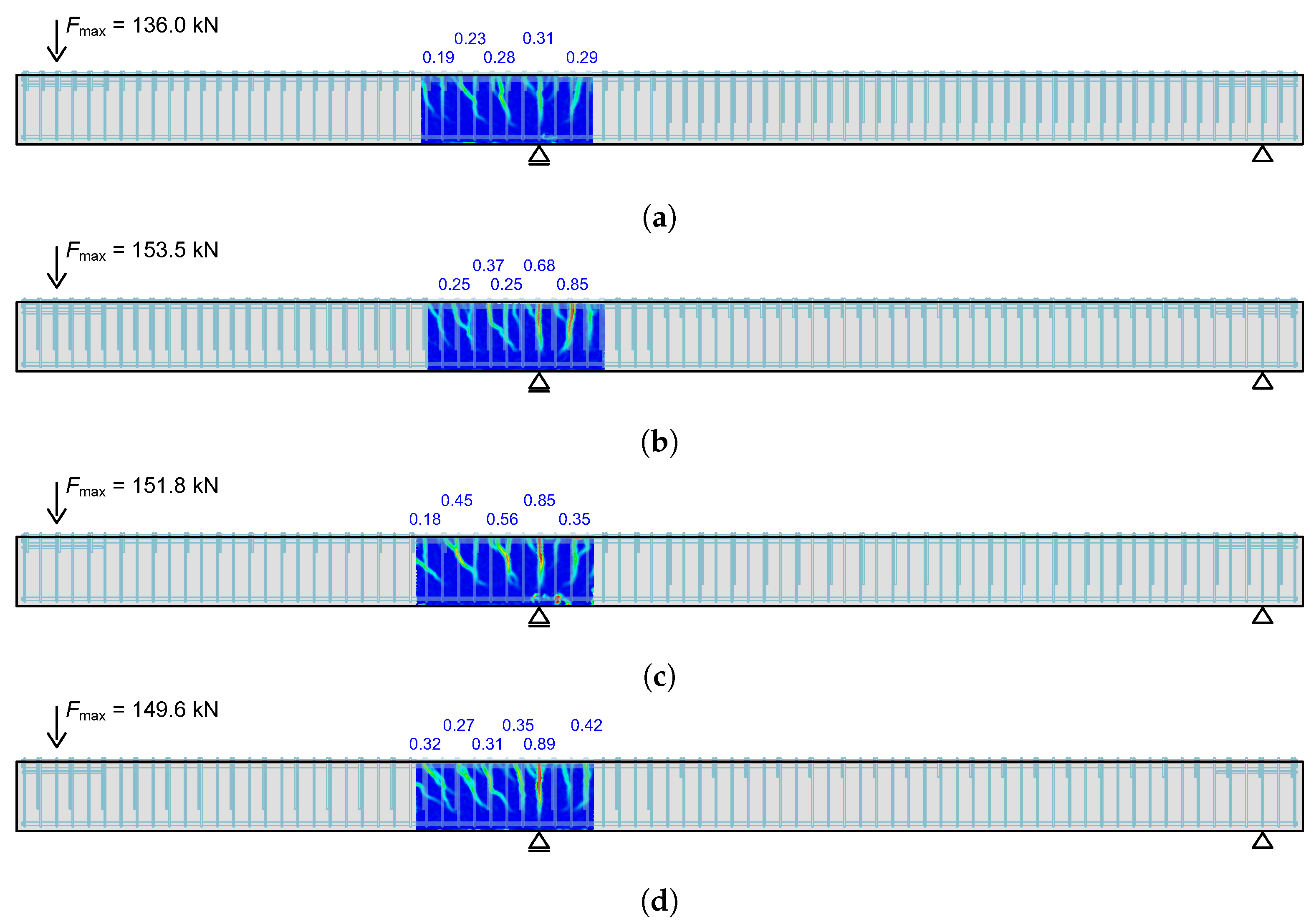

5.1.5. Test Results and Interpretation

5.2. Longitudinal Load-Bearing Behavior of Beams Cast in Several Steps

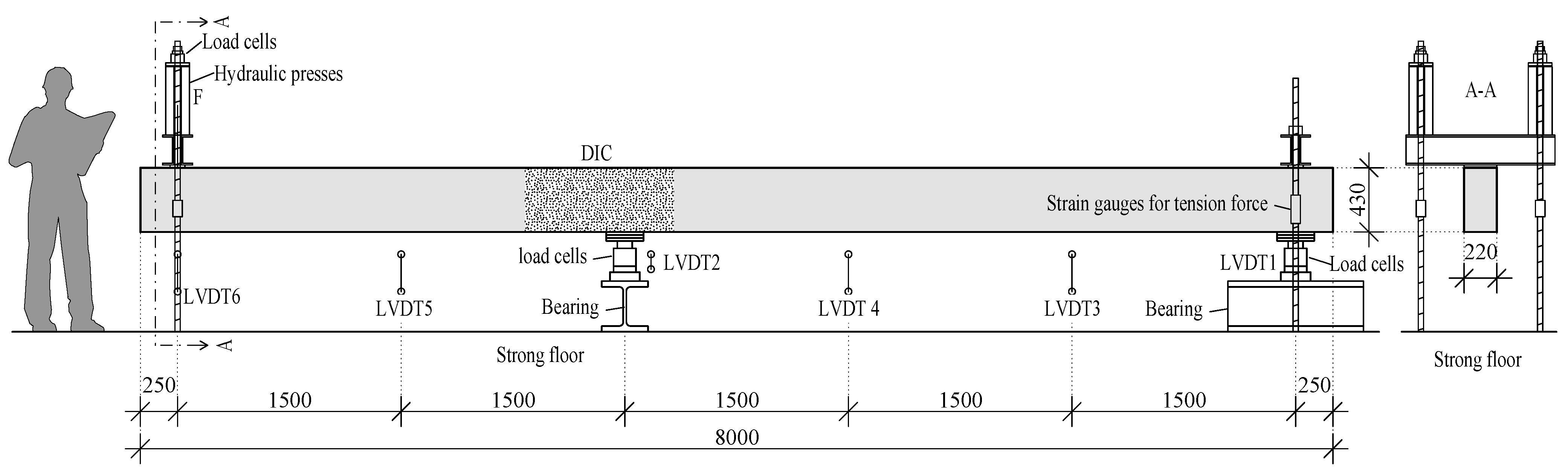

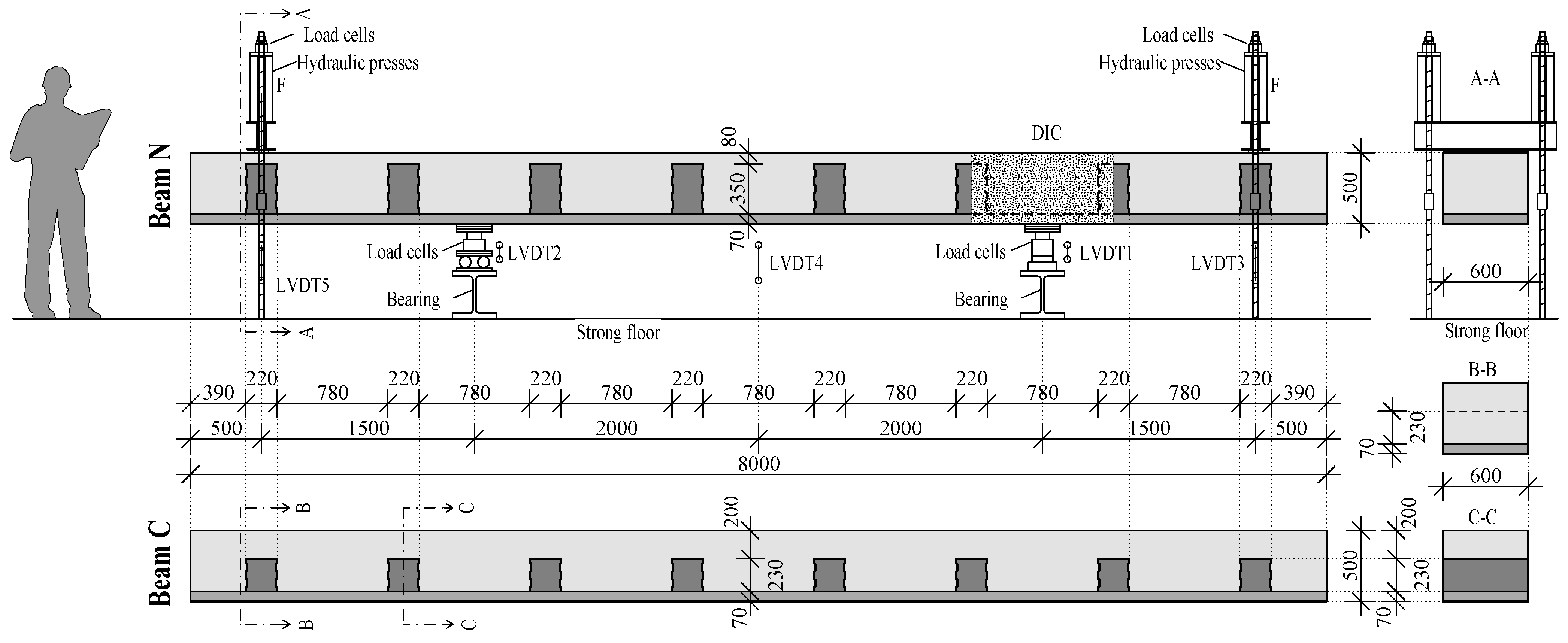

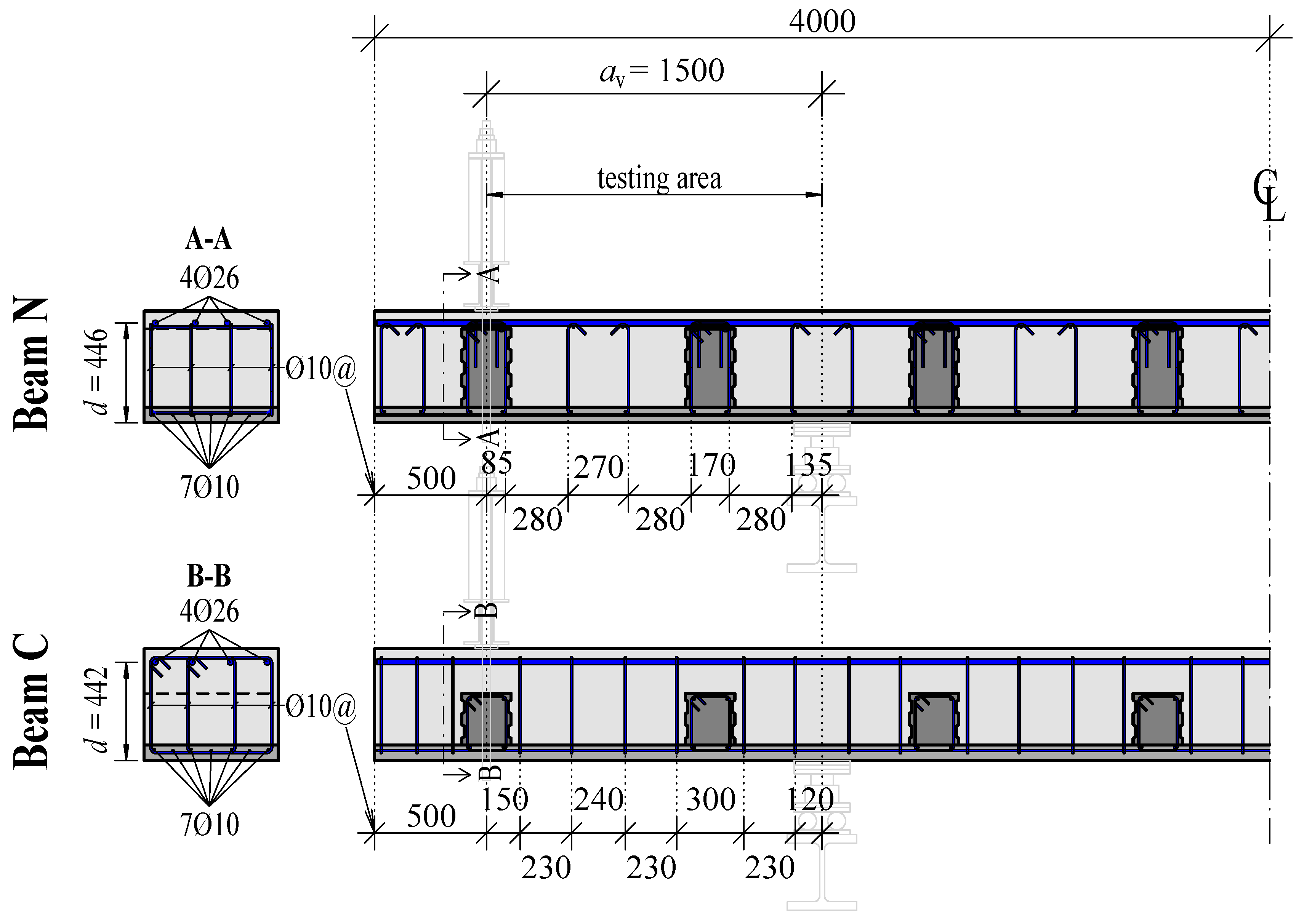

5.2.1. Specimens and Test Set-Up

5.2.2. Reinforcement

5.2.3. Material Properties

5.2.4. Measurements

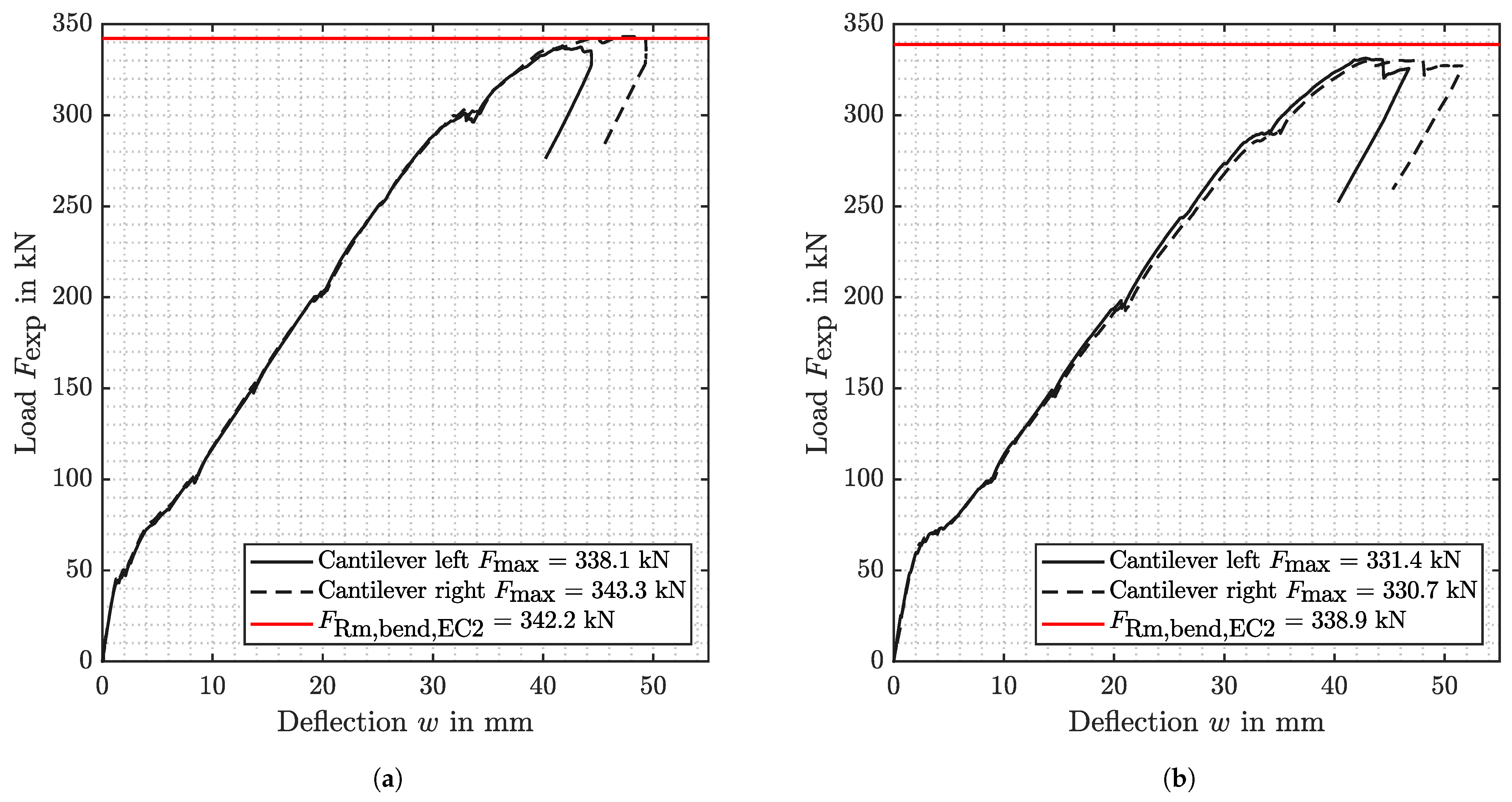

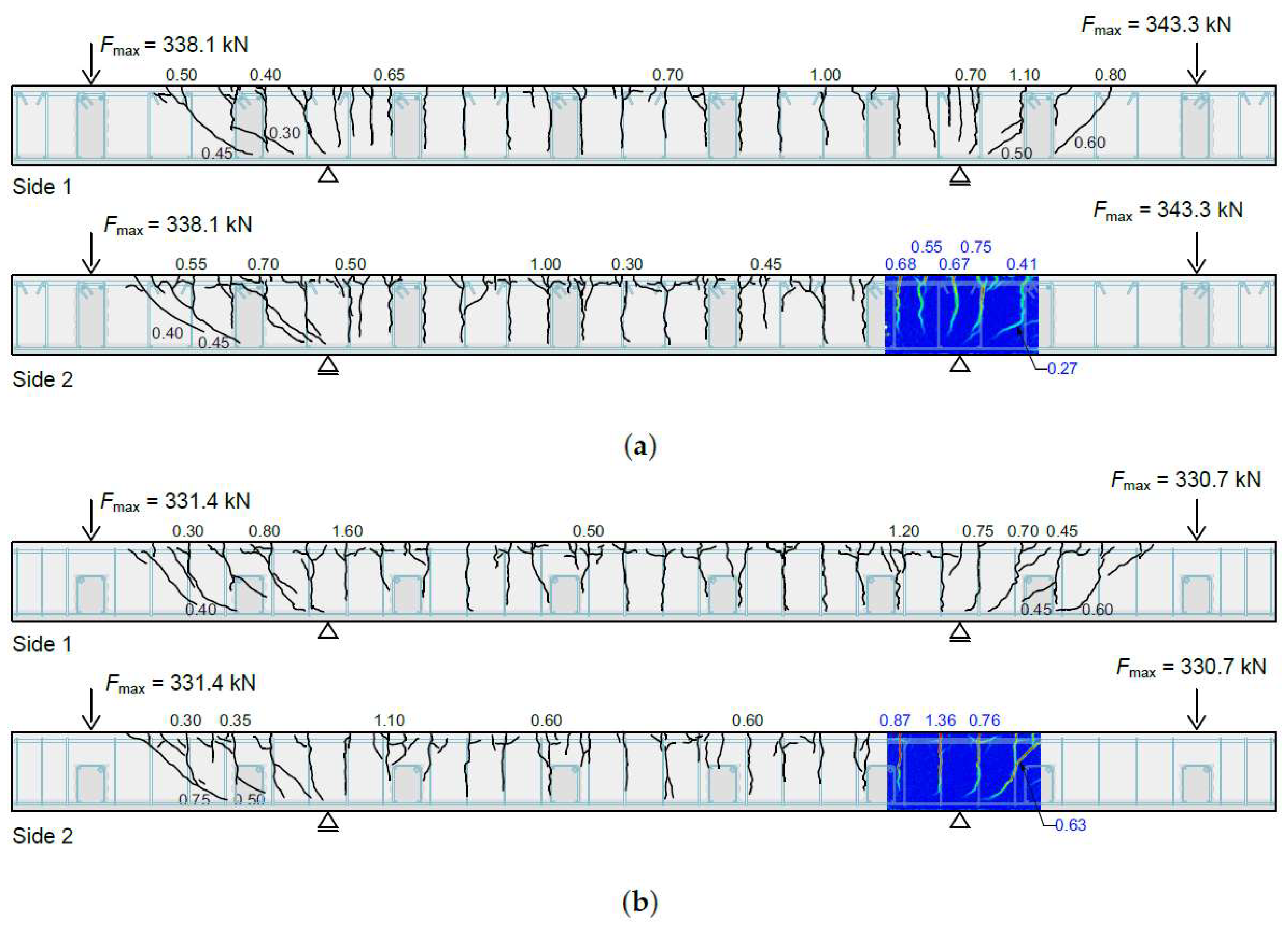

5.2.5. Test Results and Interpretation

6. Summary and Conclusions

- A significant acceleration of the construction process on-site is achieved by using the developed deck slab elements in combination with the newly designed transportation carriage or crane assembly.

- Since the deck slab elements can carry their own weight and do not require support during pouring and curing of the CIP concrete, the reinforcement work and concreting of the CIP concrete layer are independent of the installation of the deck slab element.

- No laborious reinforcement laying operations have to be carried out at the construction site, since the majority of the reinforcement is already placed in the precast deck slab elements.

- The combination of the precast deck slab elements and a continuous top layer of CIP concrete produces deck slabs with the same quality as slabs produced with conventional methods. There is no joint that extends over the entire height of the cross-section.

- Series 1 shows that a bar only half-embedded in a concrete beam can be loaded to its yield strength by a bending load using suitable supplementary reinforcement. The supplementary reinforcement consists of loops that are placed around the projecting bar. The legs of the loops must be sufficiently anchored in the concrete and create an overlap with the shear reinforcement. In addition, care must be taken during production to ensure that there is no gap between the flexural reinforcement and the loop. Even with the lowest reinforcement ratio, the beam could be loaded until its flexural capacity was reached. Further investigations with a smaller loop reinforcement ratio are desired.

- In Series 2 it was shown that a beam cast in several steps structurally behaves as a beam cast in one step, under quasi-static loading in terms of bending. It was also shown that the new reinforcement concept with flexural reinforcement in the first layer from above with the selected shear reinforcement in the beam could be brought to yield. Further investigations with a lower shear reinforcement ratio or stronger longitudinal bending reinforcement are currently being carried out. In addition, dynamic tests would be beneficial to investigate the fatigue behavior of beams cast in several steps.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Variables

| CIP | Cast in place |

| DIC | Digital image correlation |

| FC | Formwork carriage |

| LVDT | Linear variable differential transformer |

| PDSE | Precast deck slab elements |

| TC | Transportation carriage |

| ULS | Ultimate limit state |

| VFT® | Verbund-Fertigteil-Träger (german)/Composite precast beam |

| t | Thickness |

| h | Height of member |

| b | Width of member |

| l | Length of member |

| Distance between load and support | |

| Shear-to-span ratio | |

| Mean value of compressive strength of concrete | |

| a | Side length cube |

| Mean value of cube compressive strength of concrete | |

| Mean value of cylindrical compressive strength of concrete | |

| Mean value of tensile strength of concrete | |

| Mean value of modulus of elasticity of concrete | |

| m | Mass |

| Area of reinforcement | |

| Mean value of yield strength of reinforcing steel in tension | |

| Mean value of tensile strength of reinforcing steel | |

| Mean uniform strain | |

| Mean value of modulus of elasticity of reinforcing steel | |

| Applied load in experiments | |

| Maximum applied load in experiments | |

| w | Deflection |

| Applied bending moment in experiments | |

| Maximum applied bending moment in experiments | |

| curvature of cross-section | |

| Stress in reinforcing steel | |

| s | Spacing of additional loops |

| Embedment length of additional loops | |

| Height of bottom plate | |

| Height of cross-beam stubs | |

| Average spacing of shear reinforcement | |

| Design value of the plastic resistance of the structural steel section to vertical shear | |

| Load necessary to achieve the bending load capacity |

References

- Dauner, H.G. Techniken zum Bau der Fahrbahnplatte bei Verbundbrücken. Stahlbau 2002, 71, 625–631. [Google Scholar] [CrossRef]

- Kuhlmann, U.; Detzel, A.; Hauf, G. Brücken in Verbund- und Mischbauweise. In Handbuch Brücken; Mehlhorn, G., Curbach, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Hällmark, R.; White, H.; Collin, P. Prefabricated Bridge Construction across Europe and America. Pract. Period. Struct. Des. Constr. 2012, 17, 82–92. [Google Scholar] [CrossRef]

- Gordon, S.R.; May, I.M. Precast deck systems for steel-concrete composite bridges. Proc. Inst. Civ. Eng. Bridge Eng. 2007, 160, 25–35. [Google Scholar] [CrossRef]

- Eibl, J. Der Segmentbrückenbau–Eine vorteilhafte Bauweise? Beton Stahlbetonbau 2000, 95, 632–637. [Google Scholar] [CrossRef]

- Ralls, M.; Tang, B.; Bhide, S.; Brecto, B.; Calvert, E.; Capers, H.; Dorgan, D.; Matsumoto, E.; Napier, C.; Nickas, W.; et al. International Technology Exchange Program Report, Prefabricated Bridge Elements and Systems in Japan and Europe. Available online: https://international.fhwa.dot.gov/prefab_bridges/pl05003.pdf (accessed on 14 April 2023).

- Fédération Internationale du Béton (fib). Precast Segmental Bridges—Guide to Good Practice; Bulletin/International Federation for Structural Concrete, Fédération Internationale du Béton (fib): Lausanne, Switzerland, 2017; Volume 82. [Google Scholar]

- Geißler, K.; Reintjes, K.H.; Rodemann, J. Ganzfertigteile bei der Verbundfahrbahnplatte der Bahretalbrücke—Eine Revision nach Ausführung und baubegleitender messtechnischer Überwachung. Stahlbau 2009, 78, 897–906. [Google Scholar] [CrossRef]

- Jung, R.; Heymel, U.; Reintjes, K.-H.; Schreiber, O. Die Bahretalbrücke—Eine Verbundbrücke mit Vollfertigteilen. Stahlbau 2009, 78, 385–393. [Google Scholar] [CrossRef]

- Doss, W.; Gebeshuber, A.; Friedrich, N.; Schmitt, V.; Seidl, G.; Weizenegger, M. VFT-Bauweise—Entwicklung von Verbundfertigteilträgern im Brückenbau. Beton Stahlbetonbau 2001, 96, 171–180. [Google Scholar] [CrossRef]

- Bundesrecht Republik Österreich. Bundesgesetz vom 23. Juni 1967 über das Kraftfahrwesen: KFG, BGBl. Nr. 267/1967; Bundesministerium für Finanzen: Wien, Austria, 1967. [Google Scholar]

- Hamme, M.; Marzahn, G.; Prehn, W.; Swadlo, J. Die Wupper-Talbrücke Oehde—Eine moderne Verbundbrücke. Stahlbau 2006, 75, 558–564. [Google Scholar] [CrossRef]

- Badie, S.S.; Baishya, M.C.; Tadros, M.K. NUDECK An Efficient and Economical Precast Prestressed Bridge Deck System. PCI J. 1998, 43, 56–74. [Google Scholar] [CrossRef]

- Lühr, S.; Morgen, K.; Wieser, M. Stahlbetonfahrbahnplatte aus Fertigteilen mit Ortbetonergänzung beim Ersatzneubau der Straßenbrücke Horsterdamm. Beton Stahlbetonbau 2015, 110, 131–137. [Google Scholar] [CrossRef]

- Gaßner, K. Ein neues Verfahren zur Herstellung von Brückenfahrbahnplatten aus Fertigteilplatten mit Aufbetonschichten. Ph.D. Thesis, Technische Universität Wien, Vienna, Austria, 2020. [Google Scholar] [CrossRef]

- Kollegger, J.; Suza, D.; Proksch-Weilguni, C.; Träger, W. First application of the balanced lowering method to build two bridges in Austria. Struct. Concr. 2022, 23, 1413–1425. [Google Scholar] [CrossRef]

- Kollegger, J. Tilt-Lift Method for Erecting a Bridge and Vertical Lift Bridge Manufactured Accordingly. European Patent EP 2 054 553 B1, 27 April 2016. [Google Scholar]

- Kollegger, J.; Untermarzoner, F.; Rath, M. LT-Brücke: Brückenbau mit dünnwandigen Fertigteilträgern und Fahrbahnplattenelementen. In Proceedings of the 32. Dresdner Brückenbausymposium, Dresden, Germany, 31 May 2023. [Google Scholar]

- Kollegger, J.; Untermarzoner, F.; Rath, M. Verfahren zur Herstellung einer Fahrbahnplatte für eine Brücke. Austrian Patent Application 2023.

- Trost, H.; Wolff, H.J. Zur wirklichkeitsnahen Ermittlung der Beanspruchungen in abschnittsweise hergestellten Spannbetontragwerken. Der Bauing. 1970, 45, 155–169. [Google Scholar]

- Garg, A. Betonspannungen in Fahrbahnplatten weit gespannter Verbundbrücken bei abschnittsweiser Herstellung im Pilgerschrittverfahren. Beton Stahlbetonbau 2005, 100, 61–64. [Google Scholar] [CrossRef]

- Naumann, J. Gestaltung von Brücken, Wettbewerbe, Brückenbaupreise. In Handbuch Brücken; Mehlhorn, G., Curbach, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Kuhlmann, U.; Pelke, E.; Hauf, G.; Herrmann, T.; Steiner, J.; Aul, M. Ganzheitliche Wirtschaftlichkeitsbetrachtungen bei Verbundbrücken unter Berücksichtigung des Bauverfahrens und der Nutzungsdauer. Stahlbau 2007, 76, 105–116. [Google Scholar] [CrossRef]

- Schenkel, M.; Vogel, T. Versuche zum Verbundverhalten von Bewehrung bei mangelhafter Betondeckung. IBK Bericht. 1997, 228. [Google Scholar] [CrossRef]

- Moccia, F.; Ruiz, M.-F.; Muttoni, A. Spalling of concrete cover induced by reinforcement. Eng. Struct. 2021, 237, 112188. [Google Scholar] [CrossRef]

- Mak, M.W.T.; Lees, J.M. Bond strength and confinement in reinforced concrete. Constr. Build. Mater. 2022, 355, 129012. [Google Scholar] [CrossRef]

- Kani, G. Basic Facts Concerning Shear Failure. J. Am. Concr. Inst. 1966, 63, 675–692. [Google Scholar]

- Goto, Y. Cracks Formed in Concrete Around Deformed Tension Bars. ACI J. Proc. 1971, 68, 244–251. [Google Scholar] [CrossRef]

- Tepfers, R. Cracking of concrete cover along anchored deformed reinforcing bars. Mag. Concr. Res. 1979, 31, 3–12. [Google Scholar] [CrossRef]

- International Federation for Structural Concrete. Bond and Anchorage of Embedded Reinforcement: Background to the fib Model Code for Concrete Structures 2010; Bulletin/International Federation for Structural Concrete Technical Report; International Federation for Structural Concrete: Lausanne, Switzerland, 2014; Volume 72. [Google Scholar] [CrossRef]

- EN 1992-1-1:2015; Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spannbetontragwerken—Teil 1-1: Allgemeine Bemessungsregeln und Regeln für den Hochbau (konsolidierte Fassung). Austrian Standards International: Vienna, Austria, 2015.

- Goller, M. Correlation between Cylinder Compressive Strength and Cube Compressive Strength. Master’s Thesis, Technische Universität Wien, Vienna, Austria, 2019. [Google Scholar]

- Pfeiffer, U. Non-Linear Cross-Section Analysis Software: INCA2. Software 2021. Available online: http://www.u-pfeiffer.de/inca2/inca2-09.html (accessed on 4 April 2023).

- Schuster, D. Study for the Application of a New Construction Method for the Erection of the Deck Slab of the Jauntal Bridge. Master’s Thesis, Technische Universität Wien, Vienna, Austria, 2022. [Google Scholar]

- EN 1994-2:2009; Eurocode 4: Bemessung und Konstruktion von Verbundtragwerken aus Stahl und Beton—Teil 2: Allgemeine Bemessungsregeln und Andwendungsregeln für Brücken (konsolidierte Fassung). Austrian Standards International: Vienna, Austria, 2009.

| Component | m |

|---|---|

| Sand 0/4 | 858 |

| Fine gravel 4/16 | 828 |

| CEM I 52.5R | 374 |

| Limestone powder | 178 |

| Water | 182 |

| Superplasticizer | 7 |

| 2427 |

| Specimen | in N/mm2 | in N/mm2 | in N/mm2 | in N/mm2 |

|---|---|---|---|---|

| S100AL95/S100AL295 | 41,360 ± 1.76% | |||

| S200AL95/S200AL295 | 40,571 ± 2.05% |

| Type | in mm2 | in N/mm2 | in N/mm2 | in % | in N/mm2 |

|---|---|---|---|---|---|

| Ø26-B550B | 535.10 | 204,600 ± 3.68% |

| Components of Beam | in N/mm2 | in N/mm2 | in N/mm2 | in N/mm2 |

|---|---|---|---|---|

| Bottom plate | 51.2 ± 5.64 | 61.7 ± 3.23 | 3.50 ± 1.62 | 35,913 ± 5.64 |

| Cross-beam stubs | 41.2 ± 8.08 | 50.5 ± 3.97 | 3.18 ± 8.98 | 33,643 ± 8.08 |

| Top layer | 48.9 ± 2.28 | 60.4 ± 3.56 | 3.36 ± 3.55 | 35,426 ± 2.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Untermarzoner, F.; Kollegger, J.; Rath, M.; Gaßner, K.; Huber, T. Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges. Appl. Sci. 2023, 13, 7825. https://doi.org/10.3390/app13137825

Untermarzoner F, Kollegger J, Rath M, Gaßner K, Huber T. Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges. Applied Sciences. 2023; 13(13):7825. https://doi.org/10.3390/app13137825

Chicago/Turabian StyleUntermarzoner, Franz, Johann Kollegger, Michael Rath, Kerstin Gaßner, and Tobias Huber. 2023. "Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges" Applied Sciences 13, no. 13: 7825. https://doi.org/10.3390/app13137825

APA StyleUntermarzoner, F., Kollegger, J., Rath, M., Gaßner, K., & Huber, T. (2023). Deck Slab Elements for the Accelerated Construction of Steel–Concrete Composite Bridges. Applied Sciences, 13(13), 7825. https://doi.org/10.3390/app13137825