Pore Structure and Fluid Evaluation of Deep Organic-Rich Marine Shale: A Case Study from Wufeng–Longmaxi Formation of Southern Sichuan Basin

Abstract

:1. Introduction

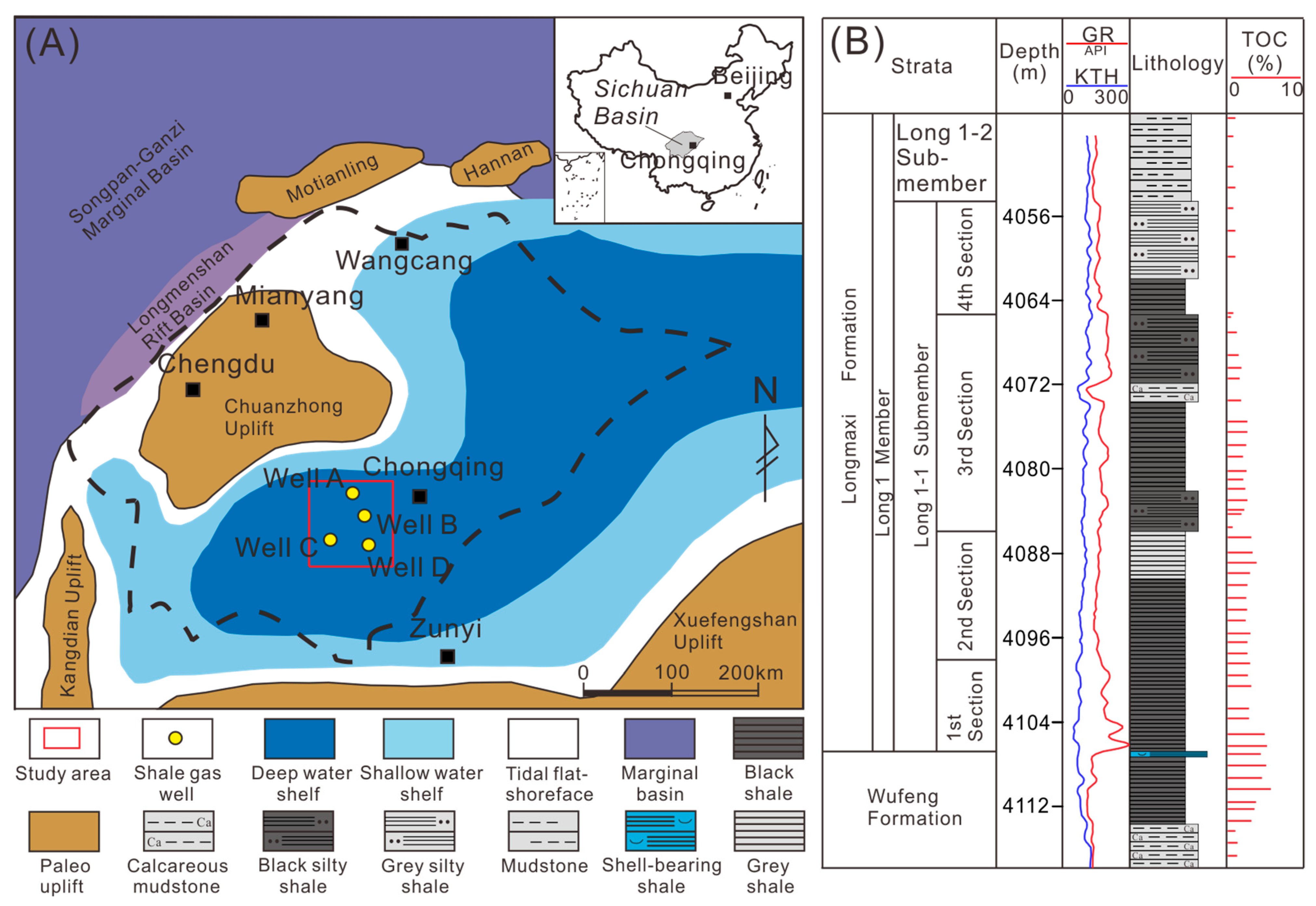

2. Geological Background

3. Materials and Methods

4. Results and Discussion

4.1. Reservoir Space Characterization

4.1.1. Organic Pores

4.1.2. Intraparticle Pores

4.1.3. Interparticle Pores

4.1.4. Microfracture

4.2. Pore Structure Quantitative Characteristics

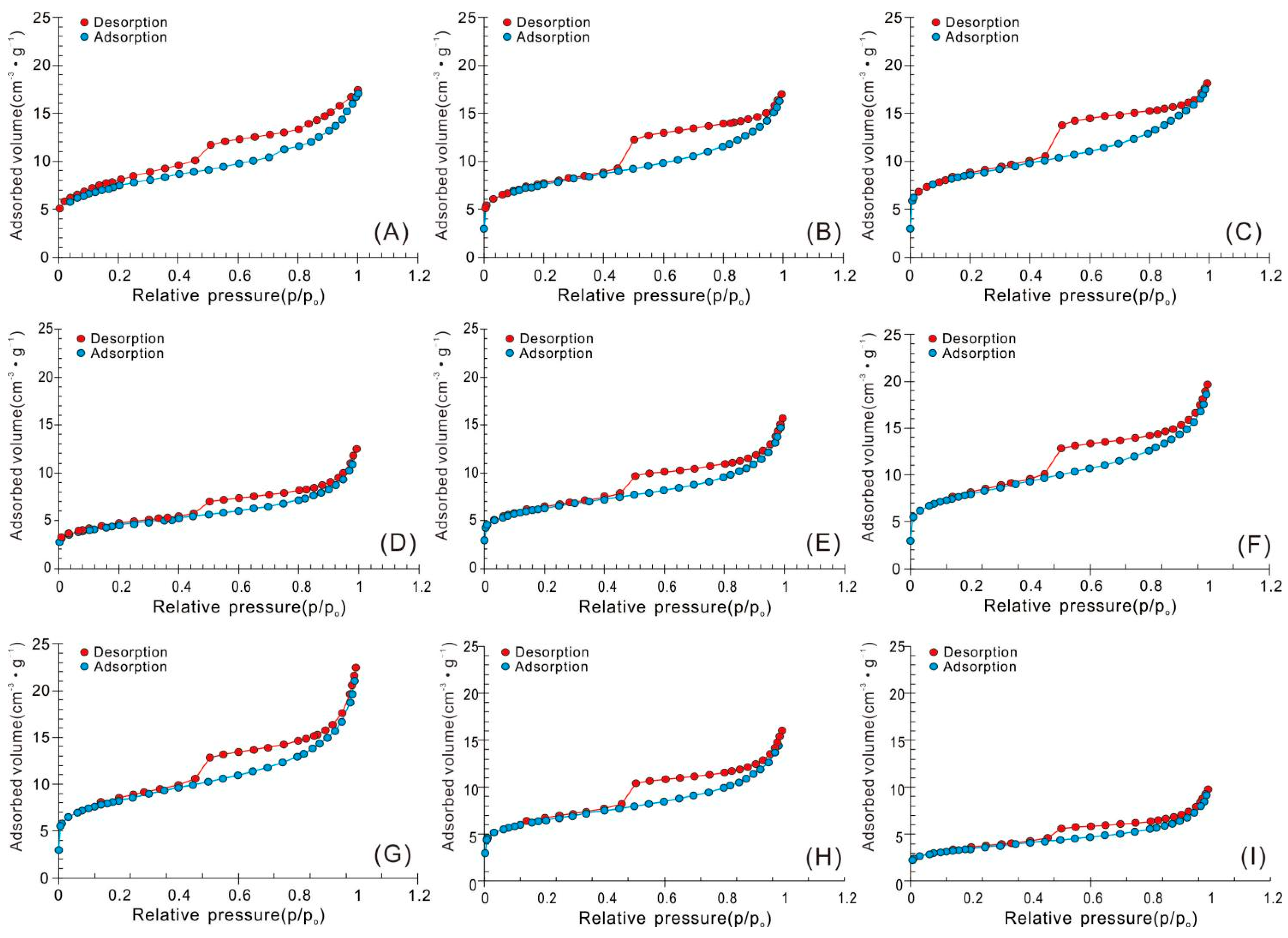

4.2.1. LTNA Isotherms and Pore Geometry

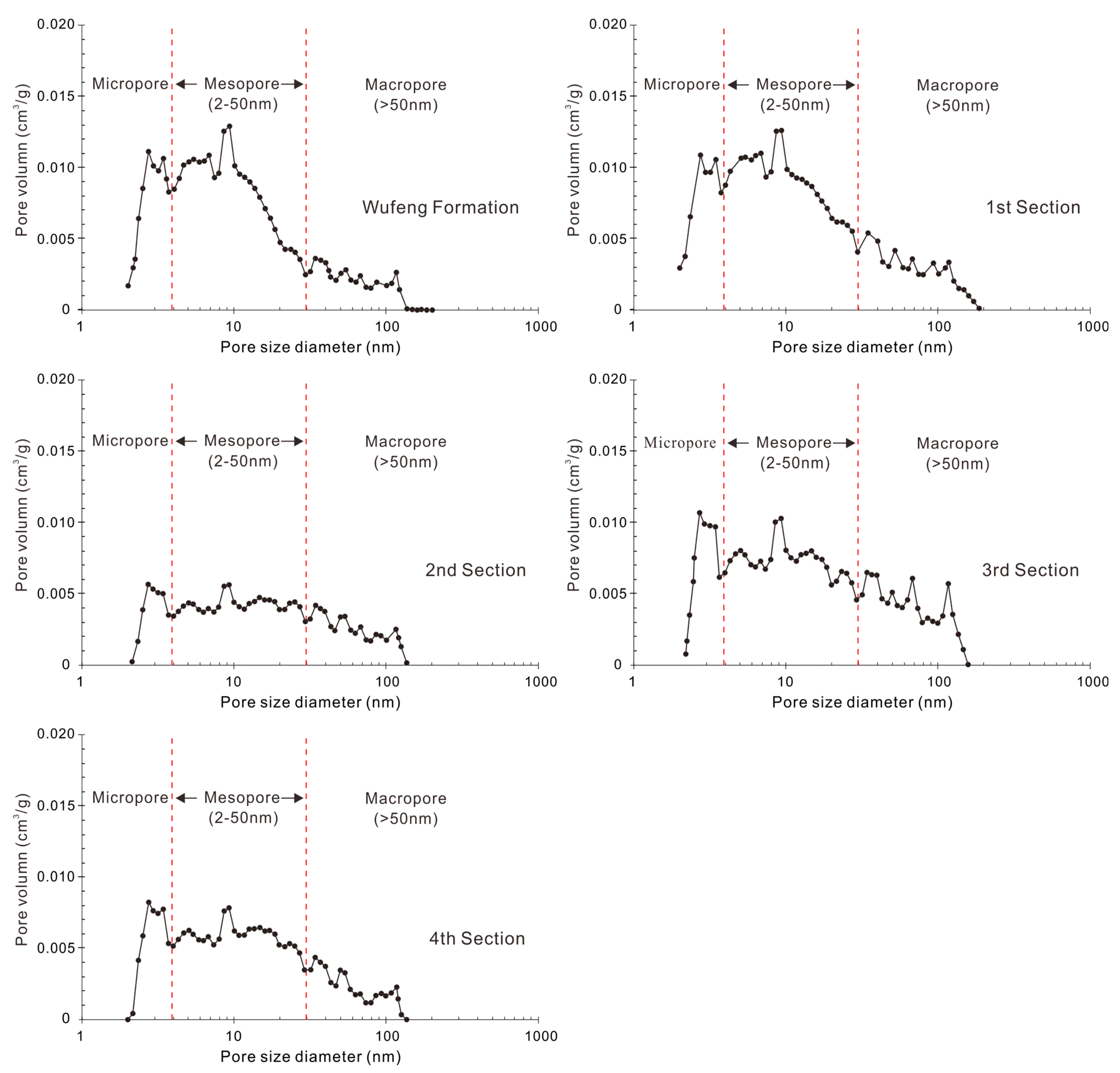

4.2.2. Pore Size Distribution

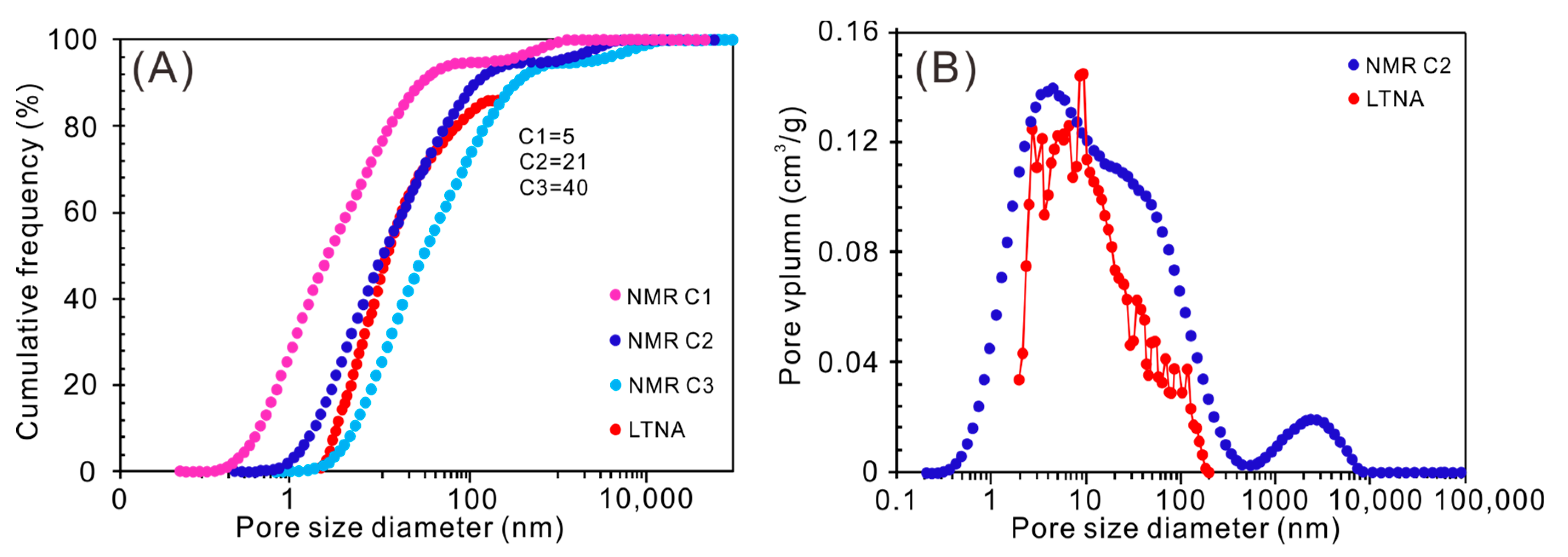

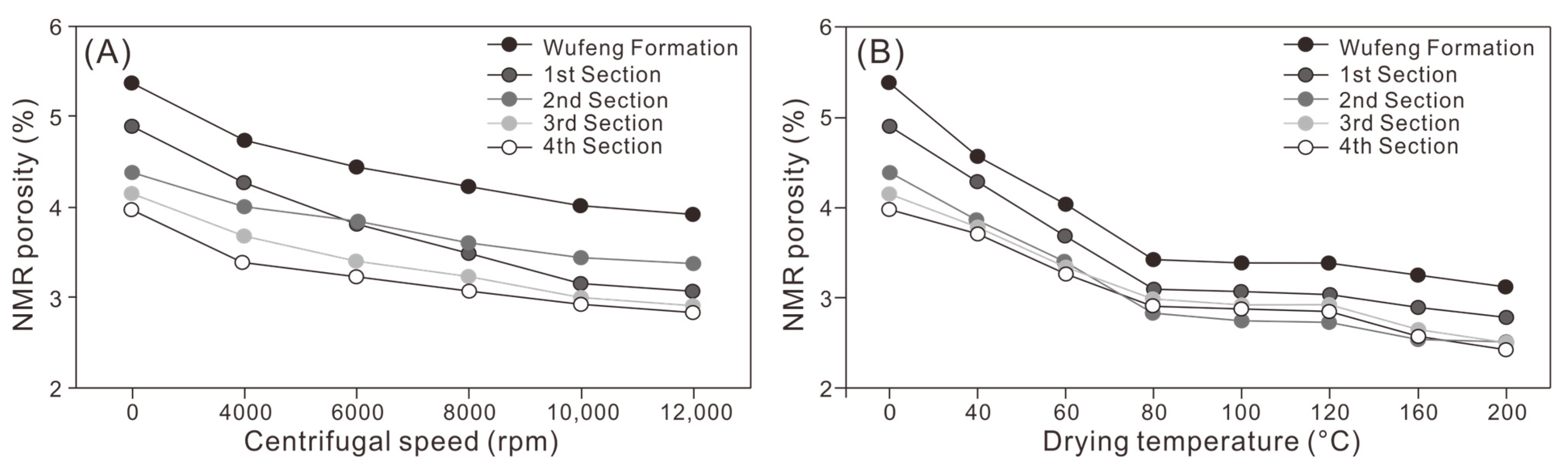

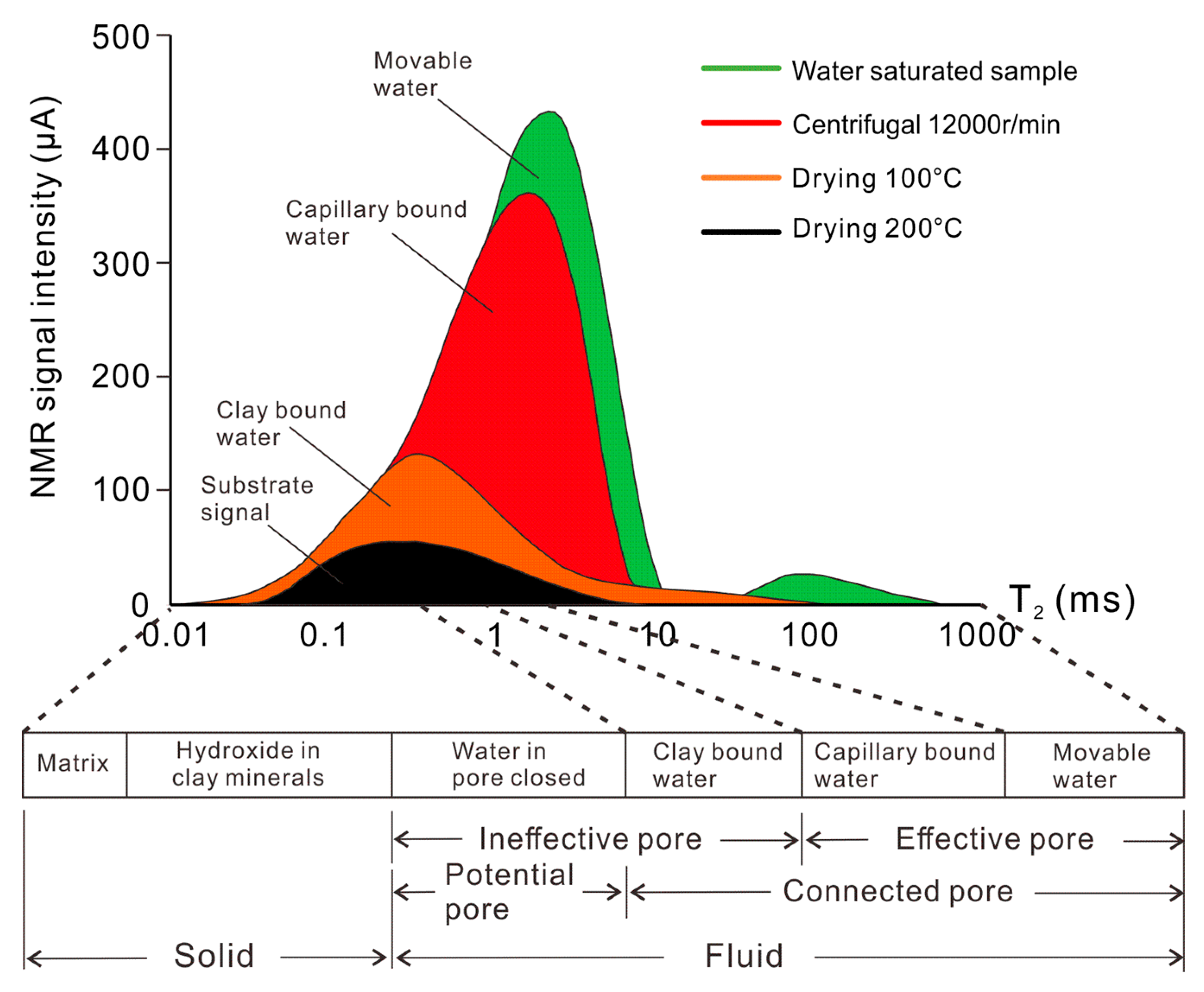

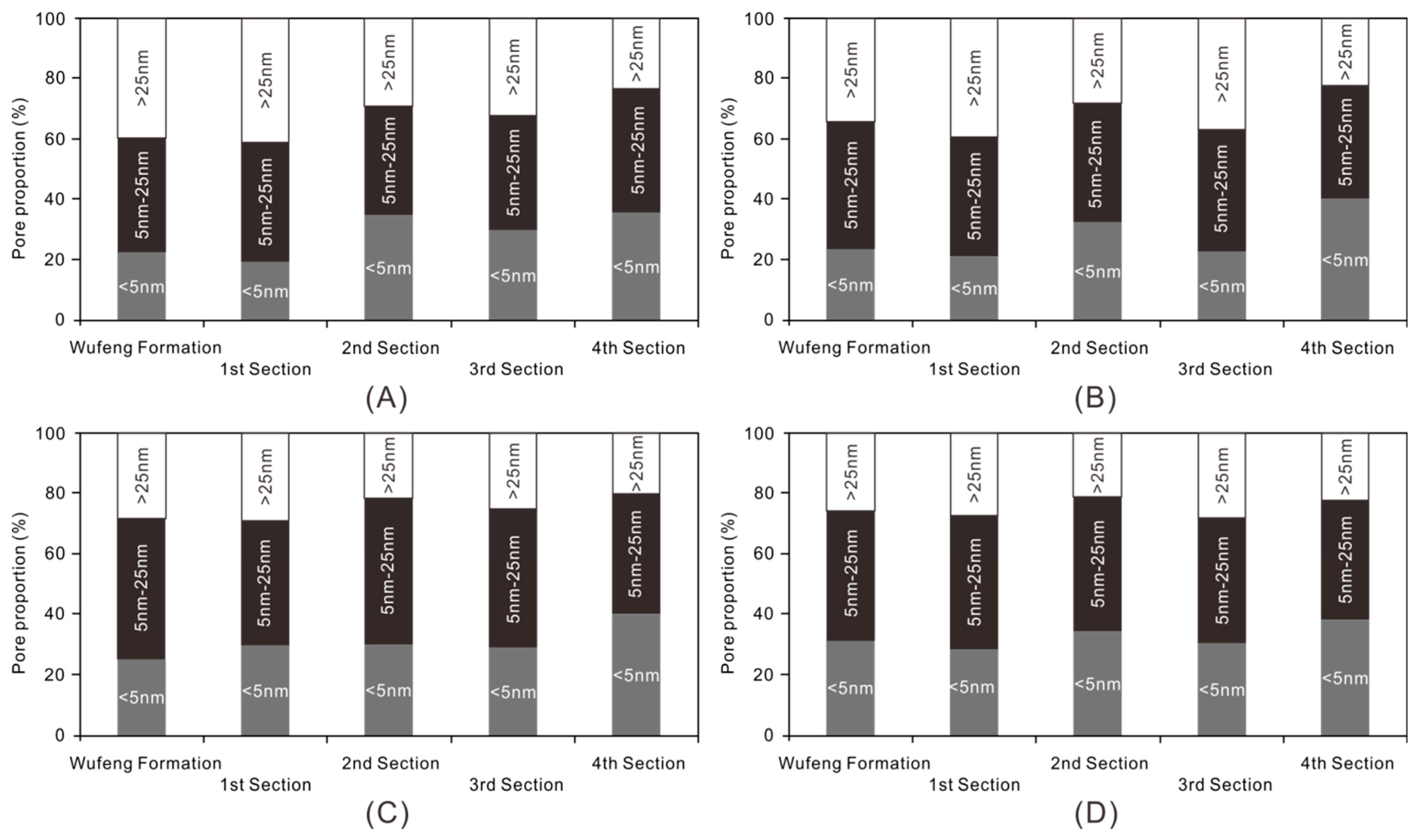

4.3. Pore Fluid Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; Jiang, Y.; Xiong, X.; Li, X.; Li, S.; Qiu, Z.; Sun, X. Lithofacies and sedimentary environment evolution of the Shan23 Submember transitional shale of the Shanxi Formation in the Danilng-Jixian area, eastern Ordos Basin. Coal Geol. Explor. 2022, 50, 104–114. [Google Scholar]

- Dong, D.; Liang, F.; Guan, Q.; Jiang, Y.; Zhou, S.; Yu, R.; Gu, Y.; Zhang, S.; Qi, L.; Liu, Y. Development model and identification evaluation technology of Wufeng-Longmaxi Formation quality shale gas reservoirs in the Sichuan Basin. Nat. Gas Ind. 2022, 42, 96–111. [Google Scholar] [CrossRef]

- Gu, Y.; Li, X.; Qi, L.; Li, S.; Jiang, Y.; Fu, Y.; Yang, X. Sedimentology and geochemistry of the Lower Permian Shanxi Formation Shan 23 Submember transitional shale, Eastern Ordos Basin, North China. Front. Earth Sci. 2022, 10, 859845. [Google Scholar] [CrossRef]

- Gu, Y.; Hu, D.; Wei, Z.; Liu, R.; Hao, J.; Han, J.; Fan, Z.; Jiang, Y.; Wang, Z.; Xu, Q. Sedimentology and geochemistry of the Upper Permian Linghao Formation marine shale, Central Nanpanjiang Basin, SW China. Front. Earth Sci. 2022, 10, 914426. [Google Scholar] [CrossRef]

- Jiang, Y.; Song, Y.; Qi, L.; Chen, L.; Tao, Y.; Gan, H.; Wu, P.; Ye, Z. Fine lithofacies of China’s marine shale and its logging prediction: A case study of the Lower Silurian Longmaxi marine shale in Weiyuan area, southern Sichuan Basin, China. Earth Sci. Front. 2016, 23, 107–118. [Google Scholar]

- Jiang, Y.; Chen, L.; Qi, L.; Luo, M.; Chen, X.; Tao, Y.; Wang, Z. Characterization of the Lower Silurian Longmaxi marine shale in Changning area in the south Sichuan Basin, China. Geol. J. 2018, 53, 1656–1664. [Google Scholar] [CrossRef]

- Li, H.; Zhou, J.; Mou, X.; Guo, H.; Wang, X.; An, H.; Mo, Q.; Long, H.; Dang, C.; Wu, J.; et al. Pore structure and fractal characteristics of the marine shale of the Longmaxi Formation in the Changning Area, Southern Sichuan Basin, China. Front. Earth Sci. 2022, 10, 1018274. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Yang, C.; Wu, Y.; Gao, Z.; Jiang, S. Geological characteristics and controlling factors of deep shale gas enrichment of the Wufeng-Longmaxi Formation in the southern Sichuan Basin, China. Lithosphere 2022, 12, 4737801. [Google Scholar] [CrossRef]

- Li, H. Research progress on evaluation methods and factors influencing shale brittleness: A review. Energy Rep. 2022, 8, 4344–4358. [Google Scholar] [CrossRef]

- Milliken, K.L.; Rudnicki, M.; Awwiller, D.N.; Zhang, T. Organic matter-hosted pore system, Marcellus Formatior (Devonian), Pennsylvania. AAPG Bull. 2013, 97, 177–200. [Google Scholar] [CrossRef]

- Avraam, C.; Chu, D.; Siddiqui, S. Natural gas infrastructure development in North America under integrated markets. Energy Policy 2020, 147, 111757. [Google Scholar] [CrossRef]

- Bazilian, M.; Brandt, A.R.; Billman, L.; Heath, G.; Logan, J.; Mann, M.; Melaina, M.; Statwick, P.; Arent, D.; Benson, S.M. Ensuring benefits from North American shale gas development: Towards a research agenda. J. Unconv. Oil Gas Resour. 2014, 7, 71–74. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Fu, Y.; Chen, H.; Zhang, H.; Yan, J.; Chen, C.; Gu, Y. Evaluation of effective porosity in marine shale reservoir, western Chongqing. Acta Pet. Sin. 2019, 40, 1233–1243. [Google Scholar]

- Liu, S.; Jiao, K.; Zhang, J.; Ye, Y.; Xie, G.; Deng, B.; Ran, B.; Li, Z.; Wu, J.; Li, J.; et al. Research progress on the pore characteristics of deep shale gas reservoirs:An example from the Lower Paleozoic marine shale in the Sichuan Basin. Nat. Gas Ind. 2021, 41, 29–41. [Google Scholar]

- Jiang, C.; Zhang, H.; Zhou, Y.; Gan, H.; Pu, J.; Jiang, Y.; Fu, Y.; Gu, Y.; Li, M.; Wang, Z.; et al. Paleogeomorphic characteristics of Wufeng-Longmaxi formation and its influence on development of high-quality shale in Dazu area, Western Chongqing. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 3628–3640. [Google Scholar]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, Y.B.; Radliński, A.P.; Blach, T.P. Pore structure characterization of North American Shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Ko, L.T.; Ruppel, S.C.; Loucks, R.G.; Hackley, P.C.; Zhang, T.W.; Shao, D.Y. Pore-types and pore-network evolution in Upper Devonian-Lower Mississippian Woodford and Mississippian Barnett mudstones: Insights from laboratory thermal maturation and organic petrology. Int. J. Coal Geol. 2018, 190, 3–28. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Klaver, J.; Desbois, G.; Littke, R.; Urai, J.L. BIB-SEM characterization of pore space morphology and distribution in postmature to overmature samples from the Haynesville and Bossier shales. Mar. Pet. Geol. 2015, 59, 451–466. [Google Scholar] [CrossRef]

- Pommer, M.; Milliken, K. Pore types and pore-size distributions across thermal maturity, Eagle Ford Formation, Southern Texas. AAPG Bull. 2015, 99, 1713–1744. [Google Scholar] [CrossRef]

- Jiang, T.; Bian, X.; Wang, H.; Li, S.; Jia, C.; Liu, H.; Sun, H. Volume fracturing of deep shale gas horizontal wells. Nat. Gas Ind. 2017, 37, 90–96. [Google Scholar] [CrossRef]

- Gu, Y.; Cai, G.; Hu, D.; Wei, Z.; Liu, R.; Han, J.; Fan, Z.; Hao, J.; Jiang, Y. Geochemical and geological characterization of Upper Permian Linghao Formation shale in Nanpanjiang Basin, SW China. Front. Earth Sci. 2022, 10, 883146. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, Y.; Fu, Y.; Lei, Z.; Xu, C.; Yuan, J.; Wen, R.; Wang, Z.; Gu, Y.; Yin, X. Characterization of Pore Structure and Heterogeneity of Shale Reservoir from Wufeng Formation-Sublayers Long-1, in Western Chongqing Based on Nuclear Magnetic Resonance. Earth Sci. 2022, 47, 490–504. [Google Scholar]

- Wang, E.; Guo, T.; Liu, B.; Dong, X.; Zhang, N.; Wang, T. Geological features and key controlling factors of gas bearing properties of deep marine shale in the Sichuan Basin. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 3615–3627. [Google Scholar]

- Gasparik, M.; Bertier, P.; Gensterblum, Y.; Ghanizadeh, A.; Krooss, B.M.; Littke, R. Geological controls on the methane storage capacity in organic-rich shales. Int. J. Coal Geol. 2014, 123, 34–51. [Google Scholar] [CrossRef]

- Korb, J.; Nicot, B.; Louis-Joseph, A.; Bubici, S.; Ferrante, G. Dynamics and wettability of oil and water in oil shales. J. Phys. Chem. C 2015, 118, 23212–23218. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Zubair, H.A.; Chhabra, A.; Ullah, A. Liquid intake of organic shales. Energy Fuels 2012, 26, 5750–5758. [Google Scholar] [CrossRef]

- Ross, D.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Roychaudhuri, B.; Tsotsis, T.T.; Jessen, K. An experimental investigation of spontaneous imbibition in gas shales. J. Pet. Sci. Eng. 2013, 111, 87–97. [Google Scholar] [CrossRef]

- Drummond, C.; Israelachvili, J. Fundamental studies of crude oil-surface water interactions and its relationship to reservoir wettability. J. Pet. Sci. Eng. 2004, 45, 61–81. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, Y.; Zhou, K.; Fu, Y.; Zhong, Z.; Zhang, X.; Qi, L.; Wang, Z.; Jiang, Z. Connectivity of pores in shale reservoirs and its implications for the development of shale gas: A case study of the Lower Silurian Longmaxi Formation in the southern Sichuan Basin. Nat. Gas Ind. 2019, 39, 22–31. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, A.; Xie, W.; Qiu, X.; Dai, Y.; Hu, X.; Cheng, X.; Jiang, Y.; Fu, Y.; Wang, Z. Lithofacies divisionand main controlling factors of reservoir development in Wufeng Formation-Longitsub-member shale in the Luzhou region, South Sichuan Basin. Nat. Gas Ind. 2022, 42, 112–123. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix related pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef] [Green Version]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Song, Y.; Jiang, Z.; Liu, S.; Li, Z.; Shi, D.; Yang, W.; Yang, Y.; Song, J.; Gao, F.; et al. Identification of organic matter components and organic pore characteristics of marine shale: A case study of Wufeng-Longmaxi shale in southern Sichuan Basin, China. Mar. Pet. Geol. 2019, 109, 56–69. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, S.; Zhao, R.; Wang, P.; Jia, C.; Song, Y. Connectivity of organic matter pores in the Lower Silurian Longmaxi Formation shale, Sichuan Basin, Southern China: Analyses from helium ion microscope and focused ion beam scanning electron microscope. Geol. J. 2022, 57, 1912–1924. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.M.; Che, Y.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Testamanti, M.N.; Rezaee, R. Determination of NMR T2 cut-off for clay bound water in shales: A case study of Carynginia Formation, Perth Basin, Western Australia. J. Pet. Sci. Eng. 2017, 149, 497–503. [Google Scholar] [CrossRef] [Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, G.; Gu, Y.; Jiang, Y.; Wang, Z. Pore Structure and Fluid Evaluation of Deep Organic-Rich Marine Shale: A Case Study from Wufeng–Longmaxi Formation of Southern Sichuan Basin. Appl. Sci. 2023, 13, 7827. https://doi.org/10.3390/app13137827

Cai G, Gu Y, Jiang Y, Wang Z. Pore Structure and Fluid Evaluation of Deep Organic-Rich Marine Shale: A Case Study from Wufeng–Longmaxi Formation of Southern Sichuan Basin. Applied Sciences. 2023; 13(13):7827. https://doi.org/10.3390/app13137827

Chicago/Turabian StyleCai, Guangyin, Yifan Gu, Yuqiang Jiang, and Zhanlei Wang. 2023. "Pore Structure and Fluid Evaluation of Deep Organic-Rich Marine Shale: A Case Study from Wufeng–Longmaxi Formation of Southern Sichuan Basin" Applied Sciences 13, no. 13: 7827. https://doi.org/10.3390/app13137827

APA StyleCai, G., Gu, Y., Jiang, Y., & Wang, Z. (2023). Pore Structure and Fluid Evaluation of Deep Organic-Rich Marine Shale: A Case Study from Wufeng–Longmaxi Formation of Southern Sichuan Basin. Applied Sciences, 13(13), 7827. https://doi.org/10.3390/app13137827