Evolution Laws of Stress–Energy and Progressive Damage Mechanisms of Surrounding Rock Induced by Mining Disturbance

Abstract

:1. Introduction

2. Similarity Simulation Experiment Design

2.1. Experimental Similarity Ratio

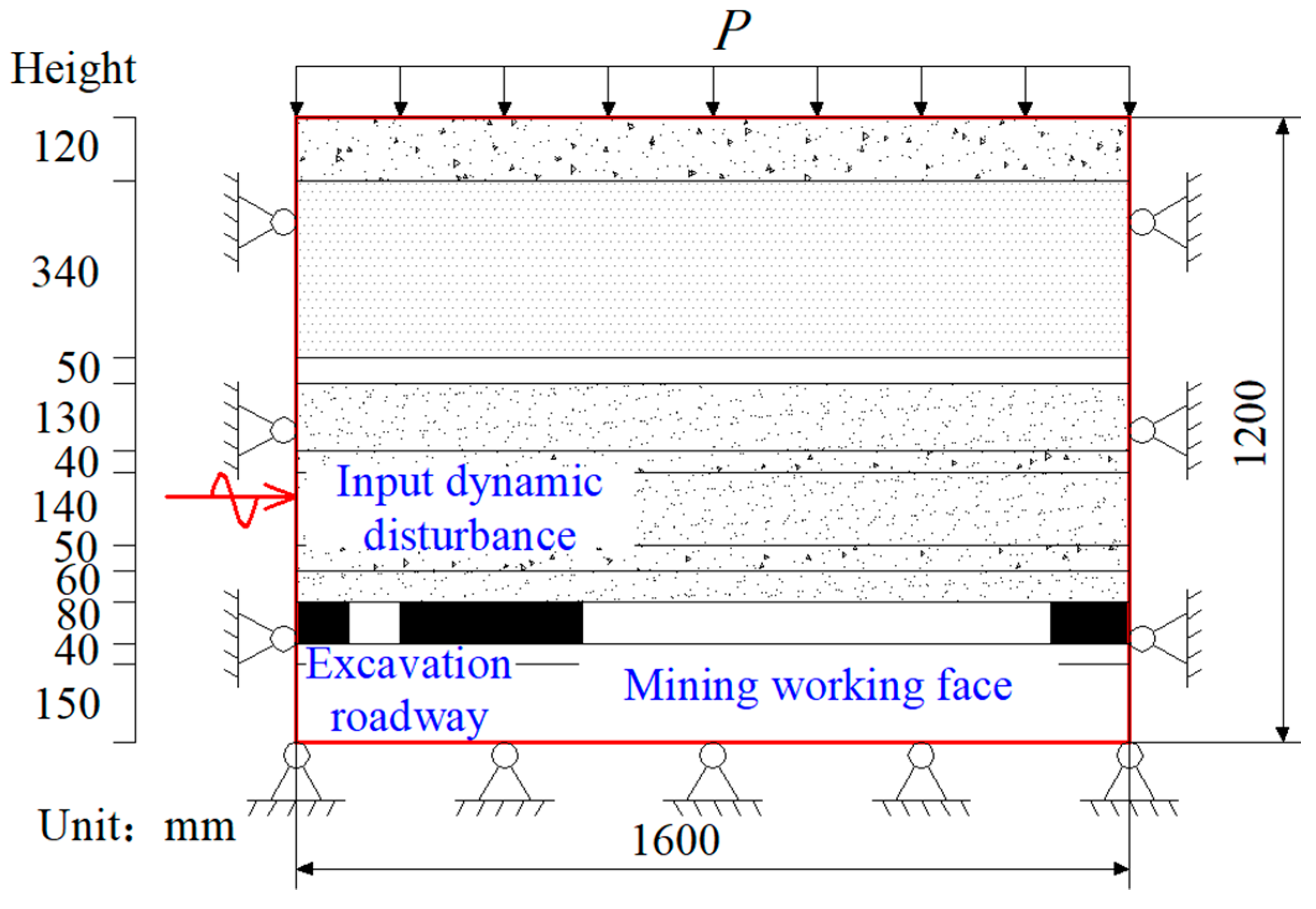

2.2. Model Building Scheme

2.3. Experiment Data and Methods

- (1)

- Start the electric control loading system and control the hydraulic cylinder to apply a uniform load on the top of the model to simulate the initial ground stress field;

- (2)

- Connect the pressure sensor connection line with the static resistance strain gauge acquisition channel one by one according to the number in the layout scheme, calibrate and zero the reading of the pressure test system, and start recording. A total of 40 pressure sensors are installed;

- (3)

- According to the layout plan, the four acceleration sensors are arranged in the designated positions respectively, and the acceleration sensors relate to the vibration signal acquisition instrument. After the quasi-static excavation is completed, the recording starts before the impact dynamic load is applied;

- (4)

- Adjust the optimal position of the dynamic high-speed camera system, and start recording before the impact dynamic load is applied;

- (5)

- Excavation roadway, section size of 80 mm × 60 mm (height × length). Then, the stope face is excavated step by step, with a total length of 900 mm. For the excavation method of driving in the opposite direction and stopping face, the driving face is first excavated, and then the stopping face is excavated after standing for 8 h. Each cycle of excavation is 5 cm, representing the actual advancing distance of the stopping face is 5 m. A total of 18 cycles of excavation are completed. At the same time, the internal pressure, surface displacement, and roadway deformation and failure characteristics of the model were observed;

- (6)

- After the mining face excavation is in place, the electric control system controls the pendulum falling freely from different heights to simulate the impact dynamic load. At the same time, the internal pressure, surface displacement, roadway deformation and failure characteristics, acceleration, and velocity of the model are observed and recorded until the surrounding rock of the roadway is destroyed, and the test is finished.

3. Result

3.1. Progress of Stress–Energy of Surrounding Rock during Mining Excavation Disturbance

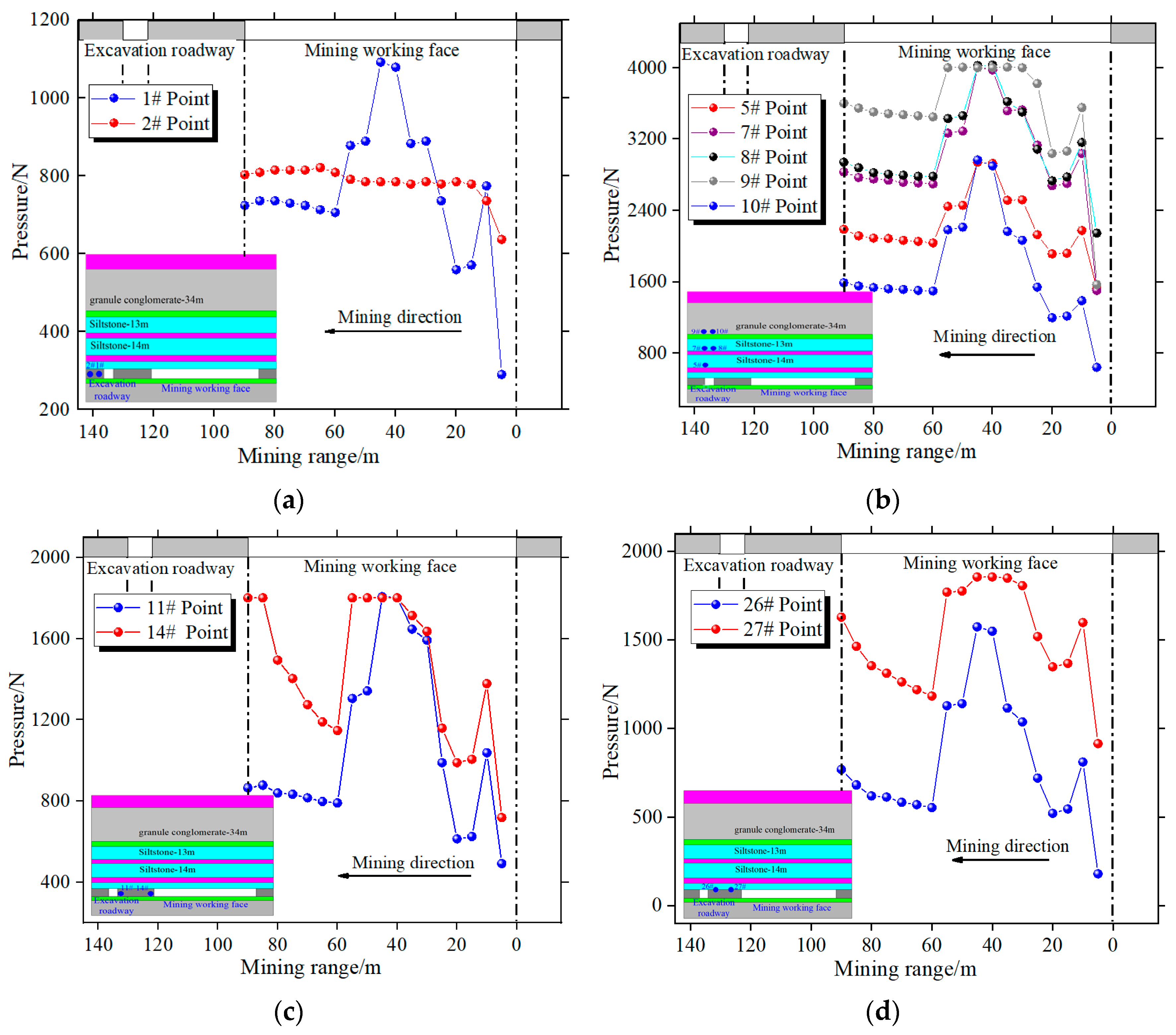

3.1.1. Stress Evolution in the Process of Mining Excavation Disturbance

- (1)

- The internal stress evolution of the excavation face, central coal pillar, and mining face surrounding rock can be divided into four stages: the rapid rise and a slight decline in the early stage, continuous rise to the extreme value later, the step-like decline in the middle stage, and rise in the late stage;

- (2)

- Around the roadway excavation, the farther away from the roadway, the smaller the impact of mining and excavation, and the lower the stress concentration;

- (3)

- Under the influence of mining, the integrity of the surrounding rock is damaged, and the cracks expand gradually, leading to a certain degree of pressure reduction;

- (4)

- The stress peak of the mining face appears at a place about 20~25 m ahead of the mining face, and the impact risk is the highest when superimposed with the mining stress field of the mining face, which is consistent with the theoretical calculation results;

- (5)

- Under the influence of quasi-static stopping, the upper key stratum has not reached the breaking condition, and the pressure is stable.

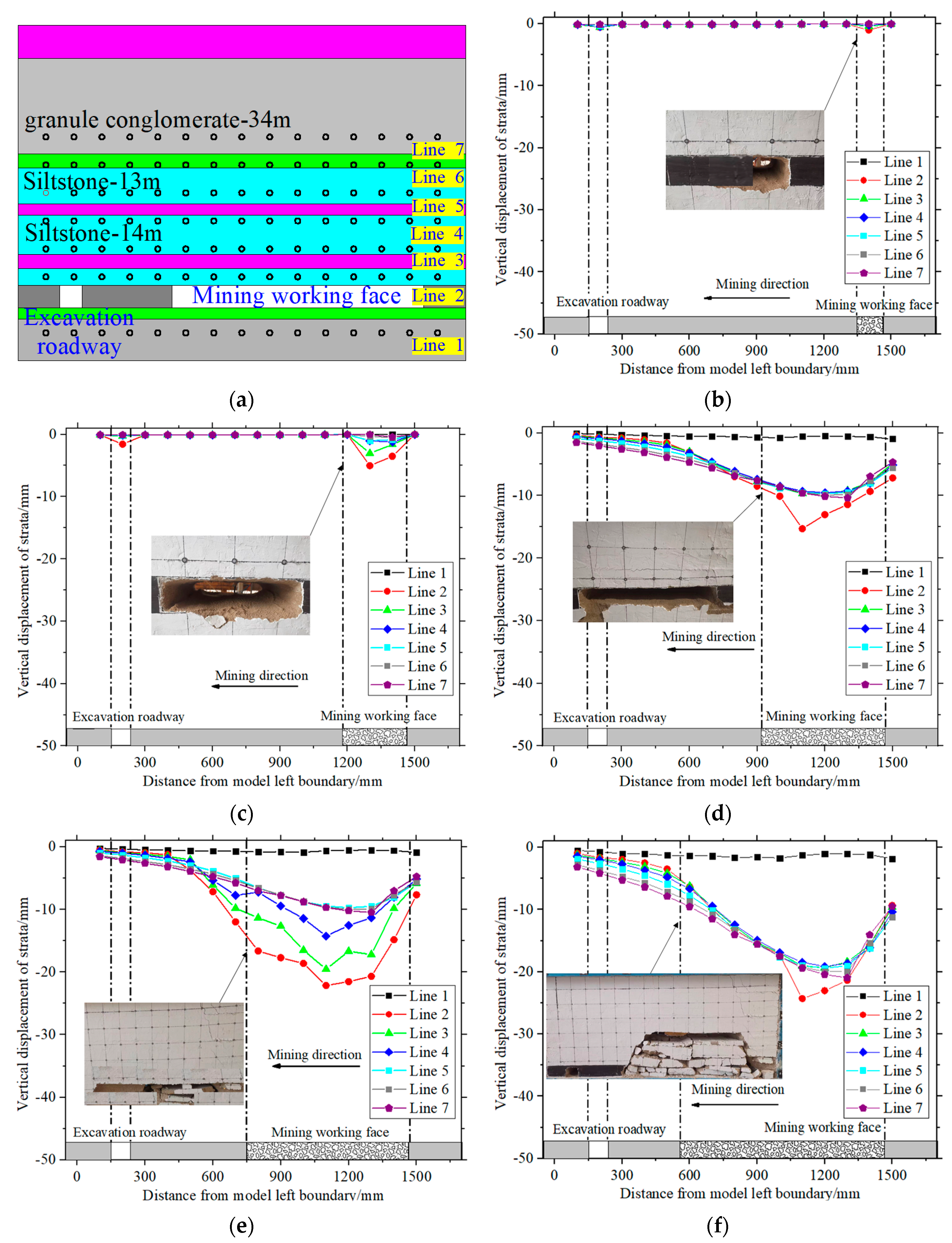

3.1.2. Overburden Migration Law in the Process of Mining and Excavation Disturbance

3.2. Dynamic Response Characteristics of Disturbed Surrounding Rock under Impact Load

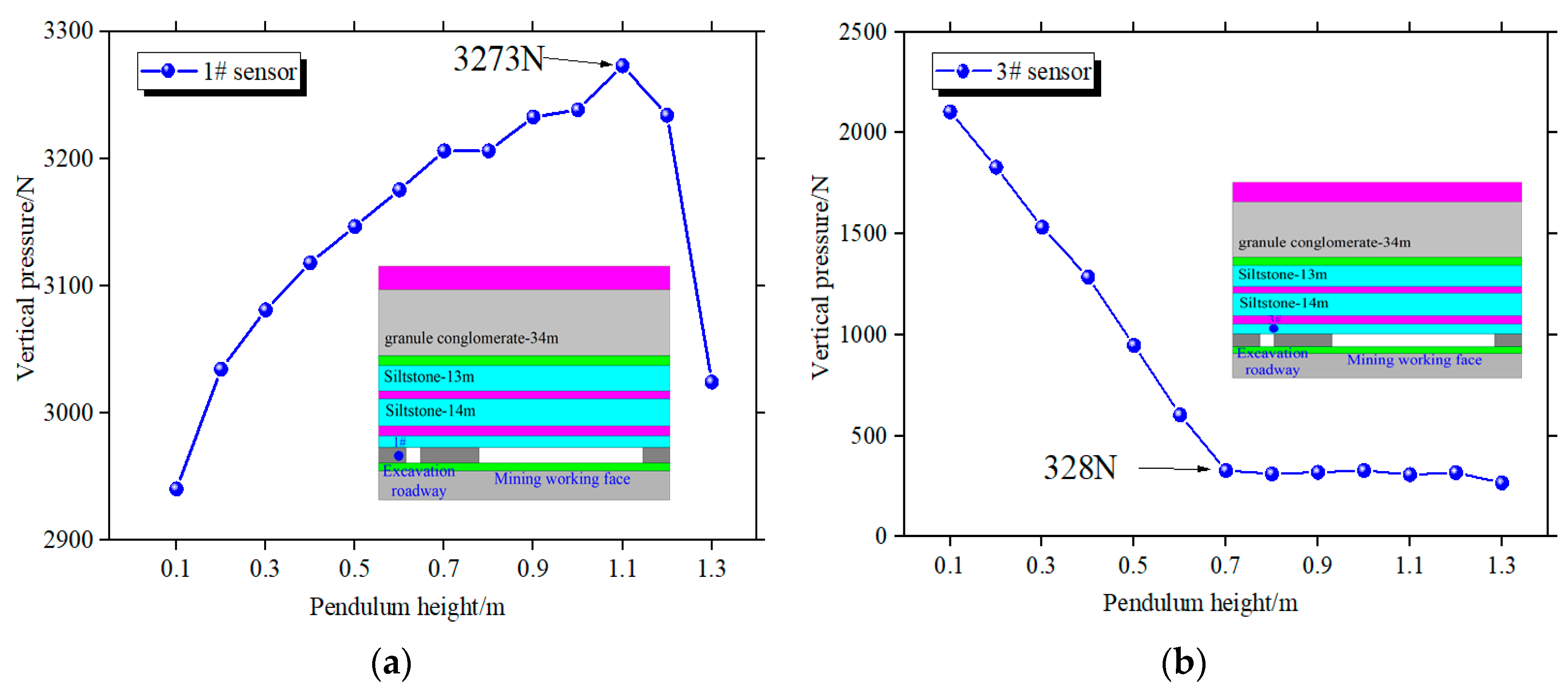

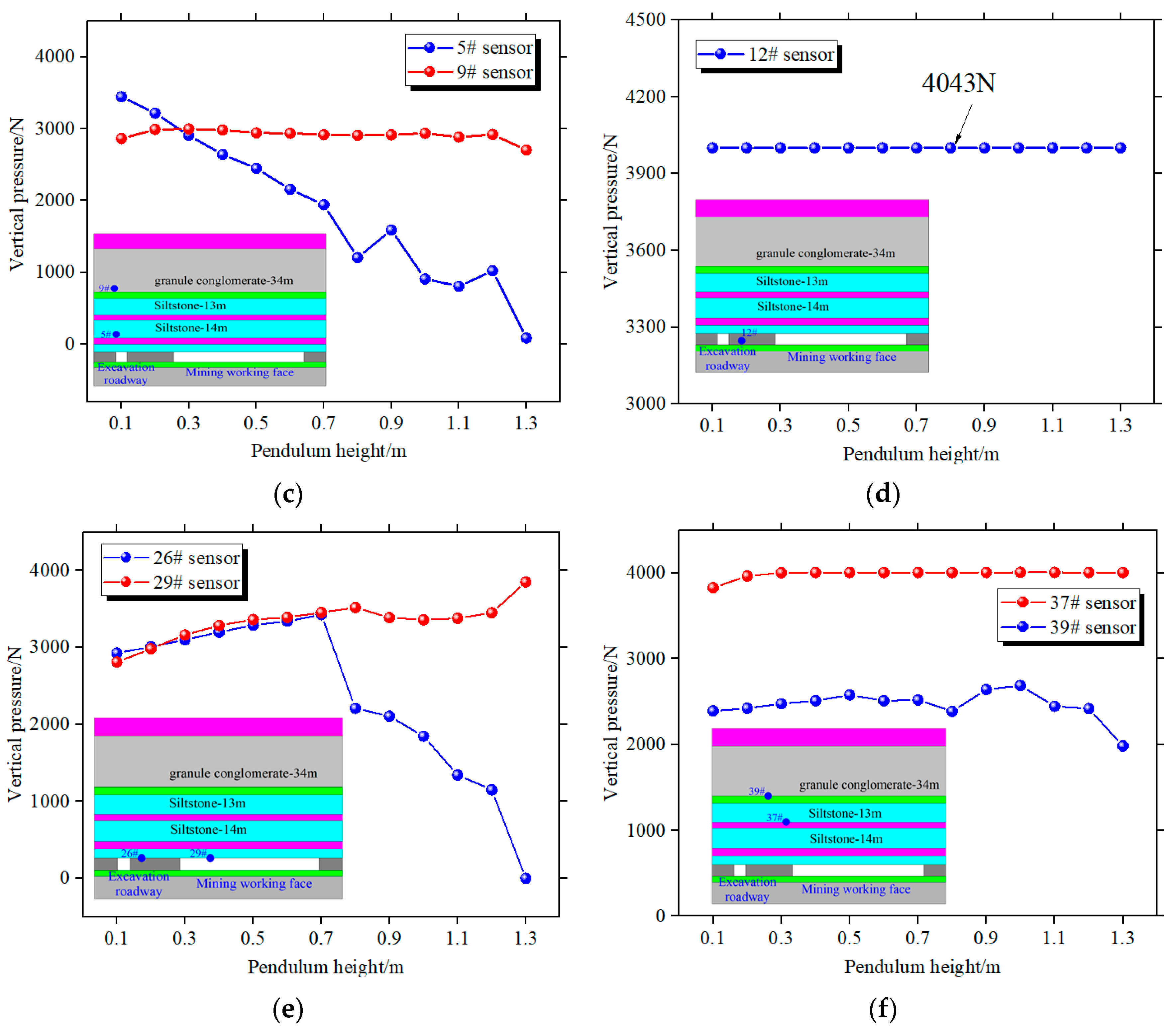

3.2.1. Stress Evolution Law of Disturbed Surrounding Rock under Impact Dynamic Load

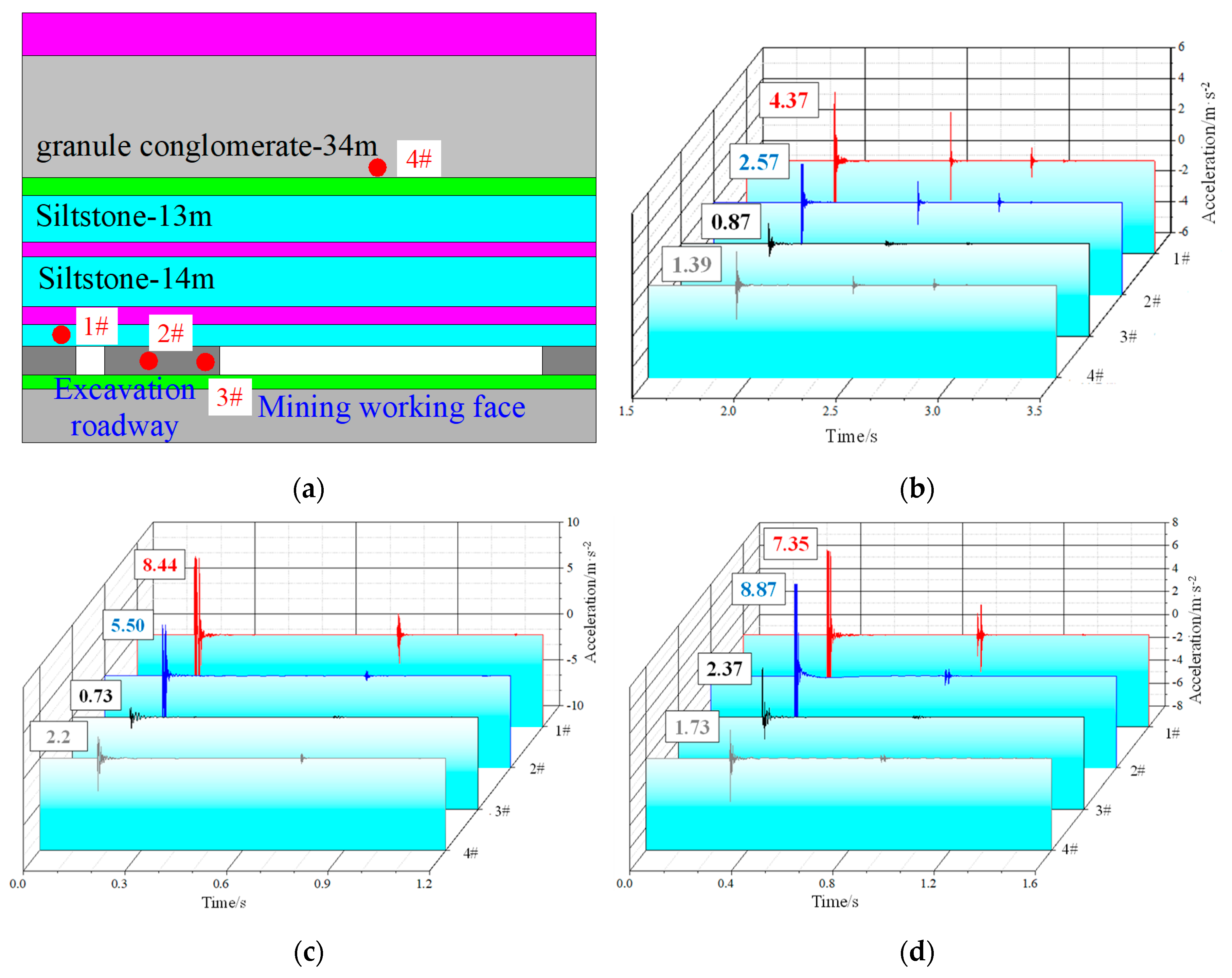

3.2.2. Dynamic Response Characteristics of Disturbed Surrounding Rock under Impact Dynamic Load

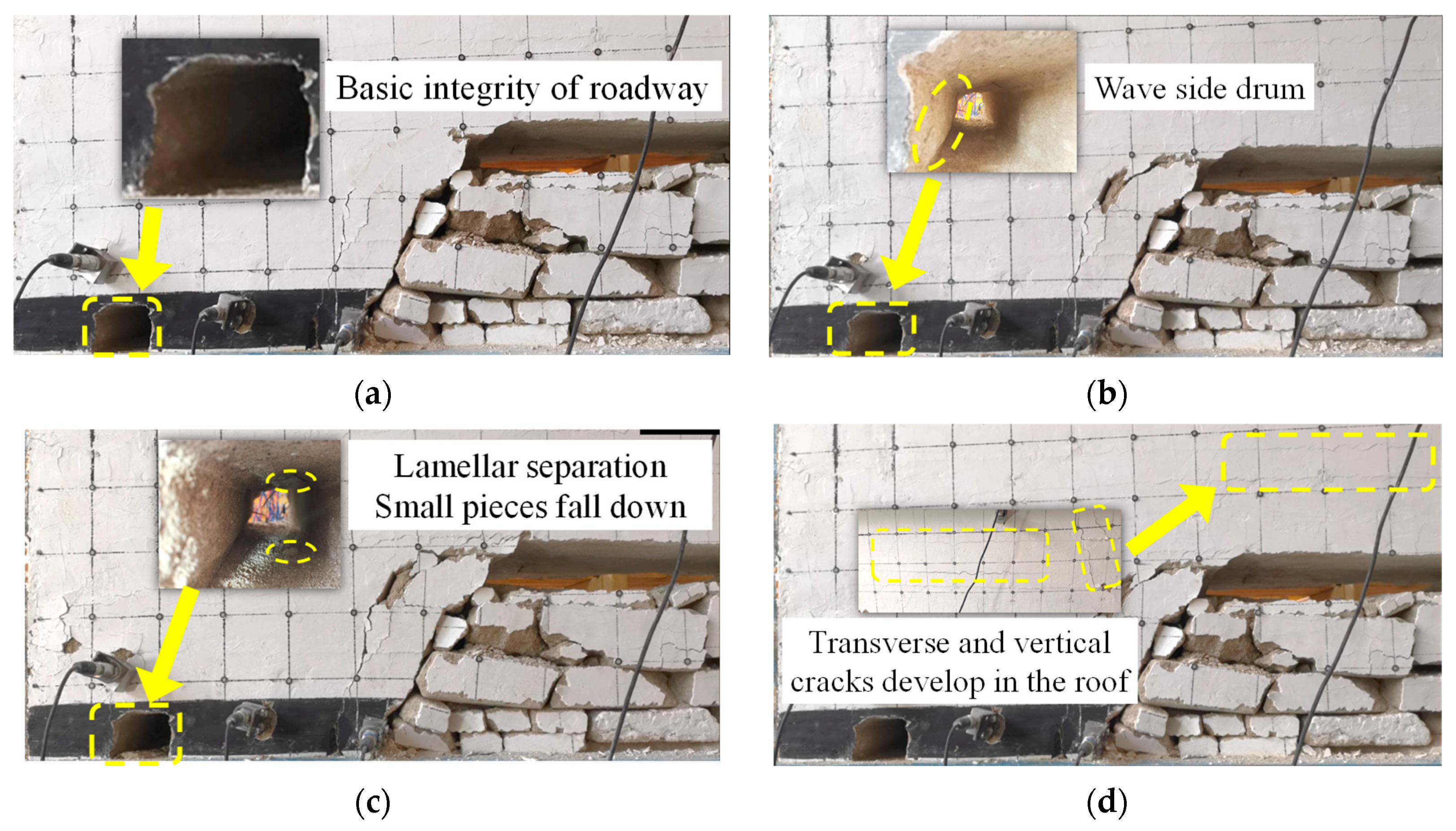

3.3. Mechanism of Progress Damage of Surrounding Rock during Mining Excavation Disturbance

4. Conclusions

- The evolution law of rock force and energy and the migration characteristics of overburdened rock in the process of excavation is revealed. Under the action of dynamic and static stress in the mining face, the stress evolution process of surrounding rock along with mining can be roughly divided into three stages: the rapid rise and slight decrease in the early stage, continuous increase to the peak in the middle stage and then step-like decline, and slow rise in the late stage;

- The stress distribution characteristics of disturbed surrounding rock under impact dynamic load with different strengths are analyzed. The oncoming side of the roadway is greatly affected by the impact of dynamic load disturbance, and the energy of the vibration wave at the back side is absorbed after transmission attenuation, and the disturbance influence is reduced. The measured critical induced thrusting energy of the driving face is 2.29 × 106 J, while the measured critical induced thrusting energy of the mining face is 5.24 × 106 J, indicating that the disturbance effect of the same external dynamic load on the stability of surrounding rock in the driving face is significantly stronger than that of the mining face;

- The dynamic response characteristics of parameters such as acceleration of roadway surrounding rock in different regions are compared and analyzed. The left side of the heading face is closest to the source, the acceleration duration is short and the attenuation is relatively fast, and it is also the area prone to the earliest impact failure among the disturbance objects facing the mining. When the pendulum height is greater than 0.9 m, the roadway begins to appear in a progressive damage trend and the plastic damage degree of the roadway surrounding rock increases until it becomes completely unstable. The impact risk of the central roadway is the highest under the superimposed influence of the static mining stress and the input dynamic stress of the opposite mining face.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dou, L.M.; He, J.; Cao, A.Y.; Gong, S.Y.; Cai, W. Rock burst prevention methods based on theory of dynamic and static combined load induced in coal mine. J. China Coal Soc. 2015, 40, 1469–1476. [Google Scholar]

- Cai, M. Principles of rock support in burst-prone ground. Tunn. Undergr. Space Technol. 2013, 36, 46–56. [Google Scholar] [CrossRef]

- Qi, Q.X.; Li, Y.Z.; Zhao, S.K.; Zhang, N.B.; Zheng, W.Y.; Li, H.T.; Li, H.Y. Seventy years development of coal mine rockburst in china: Establishment and consideration of theory and technology system. Coal Sci. Technol. 2019, 47, 1–40. [Google Scholar]

- Kaiser, P.K.; Cai, M. Design of rock support system under rockburst condition. J. Rock Mech. Geotech. Eng. 2012, 4, 215–227. [Google Scholar] [CrossRef] [Green Version]

- Fujii, Y.; Ishijima, Y.; Deguchi, G. Prediction of coal face rockbursts and microseismicity in deep longwall coal mining. Int. J. Rock Mech. Min. 1997, 34, 85–96. [Google Scholar] [CrossRef]

- Cai, W.; Bai, X.X.; Si, G.Y.; Cao, W.Z.; Gong, S.Y.; Dou, L.M. A Monitoring Investigation into Rock Burst Mechanism Based on the Coupled Theory of Static and Dynamic Stresses. Rock Mech. Rock Eng. 2020, 53, 5451–5471. [Google Scholar] [CrossRef]

- Bai, J.Z.; Dou, L.M.; Cai, W.; Gong, S.Y.; Shen, W.; Tian, X.Y.; Ma, H.J. An integration method of bursting strain energy and seismic velocity tomography for coal burst hazard assessment. Lithosphere 2022, 2022, 2070540. [Google Scholar] [CrossRef]

- Manouchehrian, A.; Cai, M. Numerical modeling of rockburst near fault zones in deep tunnels. Tunn. Undergr. Space Technol. 2018, 80, 164–180. [Google Scholar] [CrossRef]

- Małkowski, P.; Juszyński, D. Roof fall hazard assessment with the use of artificial neural network. Int. J. Rock Mech. Min. 2021, 143, 104701. [Google Scholar] [CrossRef]

- Bai, J.Z.; Dou, L.M.; Małkowski, P.; Zhou, K.Y.; Chai, Y.J. Mechanical properties and damage behavior of rock-coal-rock combined samples under coupled static and dynamic loads. Geofluids 2021, 2021, 3181697. [Google Scholar] [CrossRef]

- Ji, H.G.; Ma, H.S.; Wang, J.A.; Zhang, Y.H.; Cao, H. Mining disturbance effect and mining arrangements analysis of near-fault mining in high tectonic stress region. Saf. Sci. 2012, 50, 649–654. [Google Scholar] [CrossRef]

- Cai, M.F.; Ji, H.G.; Wang, J.A. Study of the time-space-strength relation for mining seismicity at Laohutai Coal Mine and its prediction. Int. J. Rock Mech. Min. 2005, 42, 145–151. [Google Scholar] [CrossRef]

- Li, T.; Zhang, J.W.; Lv, Y.G.; Zhou, P.; Qiao, Z.D.; Chen, S.H. Relationship between mining and mining-induced seismicity. J. China Coal Soc. 2011, 36, 2127–2132. [Google Scholar]

- Nikadat, N.; Fatehi, M.; Abdollahipour, A. Numerical modelling of stress analysis around rectangular tunnels with large discontinuities (fault) by a hybridized indirect BEM. J. Cent. South Univ. 2015, 22, 4291–4299. [Google Scholar] [CrossRef]

- Hu, Y.W. Experimental Investigation into Stress-Acoustic-Deformation Evolution of Fault Activation Process under Coal Mining-Induced Stress Paths; China University of Mining and Technology: Xuzhou, China, 2020. [Google Scholar]

- Han, C.L.; Zhang, N.; Xue, J.H.; Kan, J.G.; Zhao, Y.M. Multiple and long-term disturbance of gob-side entry retaining by grouped roof collapse and an innovative adaptive technology. Rock Mech. Rock Eng. 2019, 52, 2761–2773. [Google Scholar] [CrossRef]

- Peng, Y.J.; Li, Q.F. Floor failure and roadway deformation induced by contiguous coal seams mining at Huopu Mine. Arab. J. Geosci. 2020, 13, 601. [Google Scholar] [CrossRef]

- Guo, P.H.; Li, J.Z.; Hao, X.Q.; Cui, H.; Tian, L.H.; Xie, W.H.; Chu, J.Q. Influence of Mine Earthquake Disturbance on the Principal Stress of the Main Roadway near the Goaf and Its Prevention and Control Measures. Geofluids 2021, 1968846, 2021. [Google Scholar] [CrossRef]

- Liu, S.G.; Bai, J.B.; Wang, X.Y.; Wang, G.H.; Wu, B.W.; Li, Y.H.; Zhao, J.X. Study on the stability of coal pillars under the disturbance of repeated mining in a double-roadway layout system. Front. Earth Sci. 2021, 9, 754747. [Google Scholar] [CrossRef]

- Qi, F.Z.; Yang, D.W.; Zhang, Y.G.; Hao, Y.X. Analysis of failure mechanism of roadway surrounding rock under thick coal seam strong mining disturbance. Shock Vib. 2021, 2021, 9940667. [Google Scholar] [CrossRef]

- Su, R.H.; Shen, H.S. Physical characteristics of section coal and rock pillars under roof shock disturbances from goaf. Front. Phys. 2020, 8, 223. [Google Scholar] [CrossRef]

- Wang, S.C.; Dou, L.M.; Wang, Z.Y.; Bai, J.Z.; Chai, Y.J. Mechanism of coal bursts induced by horizontal section mining of steeply inclined coal seams and application of microseismic multiparameter monitoring in early warning. Adv. Civ. Eng. 2020, 2020, 1048624. [Google Scholar] [CrossRef]

- Wang, G.F.; Gong, S.Y.; Li, Z.L.; Dou, L.M.; Cai, W.; Mao, Y. Evolution of stress concentration and energy release before rock bursts: Two case studies from Xingan coal mine, Hegang, China. Rock Mech. Rock Eng. 2016, 49, 3393–3401. [Google Scholar] [CrossRef]

| Major Variable | Froude Proportionality Coefficient | Numerical Value | Major Variable | Froude Proportionality Coefficient | Numerical Value |

|---|---|---|---|---|---|

| Model length | 100 | Poisson ratio | 1 | ||

| Material density | 1.67 | Frictional angle | 1 | ||

| Acceleration | 1 | Speed | 10 | ||

| Time | 10 | Volume weight | 1.67 | ||

| Stress | 167 | Energy | 1.67 × 104 |

| Test Number | Pendulum Lifting Height/m | Pendulum Angle/° | Simulate Dynamic Load Energy/J | Test Number | Pendulum Lifting Height/m | Pendulum Angle/° | Simulate Dynamic Load Energy/J |

|---|---|---|---|---|---|---|---|

| 1 | 0.1 | 25.9 | 3.27 × 105 | 9 | 0.9 | 84.3 | 2.95 × 106 |

| 2 | 0.2 | 36.8 | 6.55 × 105 | 10 | 1.0 | 90 | 3.27 × 106 |

| 3 | 0.3 | 45.6 | 9.82 × 105 | 11 | 1.1 | 95.6 | 3.60 × 106 |

| 4 | 0.4 | 53.1 | 1.31 × 106 | 12 | 1.2 | 101.1 | 3.93 × 106 |

| 5 | 0.5 | 60.0 | 1.64 × 106 | 13 | 1.3 | 106.5 | 4.26 × 106 |

| 6 | 0.6 | 66.4 | 1.96 × 106 | 14 | 1.4 | 111.8 | 4.58 × 106 |

| 7 | 0.7 | 72.5 | 2.29 × 106 | 15 | 1.5 | 117.0 | 4.91 × 106 |

| 8 | 0.8 | 78.5 | 2.62 × 106 | 16 | 1.6 | 122.1 | 5.24 × 106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Dou, L.; Li, X.; Ma, X.; Lu, F.; Han, Z. Evolution Laws of Stress–Energy and Progressive Damage Mechanisms of Surrounding Rock Induced by Mining Disturbance. Appl. Sci. 2023, 13, 7759. https://doi.org/10.3390/app13137759

Bai J, Dou L, Li X, Ma X, Lu F, Han Z. Evolution Laws of Stress–Energy and Progressive Damage Mechanisms of Surrounding Rock Induced by Mining Disturbance. Applied Sciences. 2023; 13(13):7759. https://doi.org/10.3390/app13137759

Chicago/Turabian StyleBai, Jinzheng, Linming Dou, Xuwei Li, Xiaotao Ma, Fangzhou Lu, and Zepeng Han. 2023. "Evolution Laws of Stress–Energy and Progressive Damage Mechanisms of Surrounding Rock Induced by Mining Disturbance" Applied Sciences 13, no. 13: 7759. https://doi.org/10.3390/app13137759

APA StyleBai, J., Dou, L., Li, X., Ma, X., Lu, F., & Han, Z. (2023). Evolution Laws of Stress–Energy and Progressive Damage Mechanisms of Surrounding Rock Induced by Mining Disturbance. Applied Sciences, 13(13), 7759. https://doi.org/10.3390/app13137759