Application of Digital Engineering Methods in Order to Improve Processes in Heterogeneous Companies

Abstract

:1. Introduction

- creation of a data analysis of each company, in order to evaluate the current state;

- creation of a library consisting of a wide range of models, applicable when compiling simulation studies;

- developing the necessary number of simulation studies with the aim of creating an optimal material flow for selected production halls;

2. Materials and Methods

3. Studies of the Production Process in Enterprises

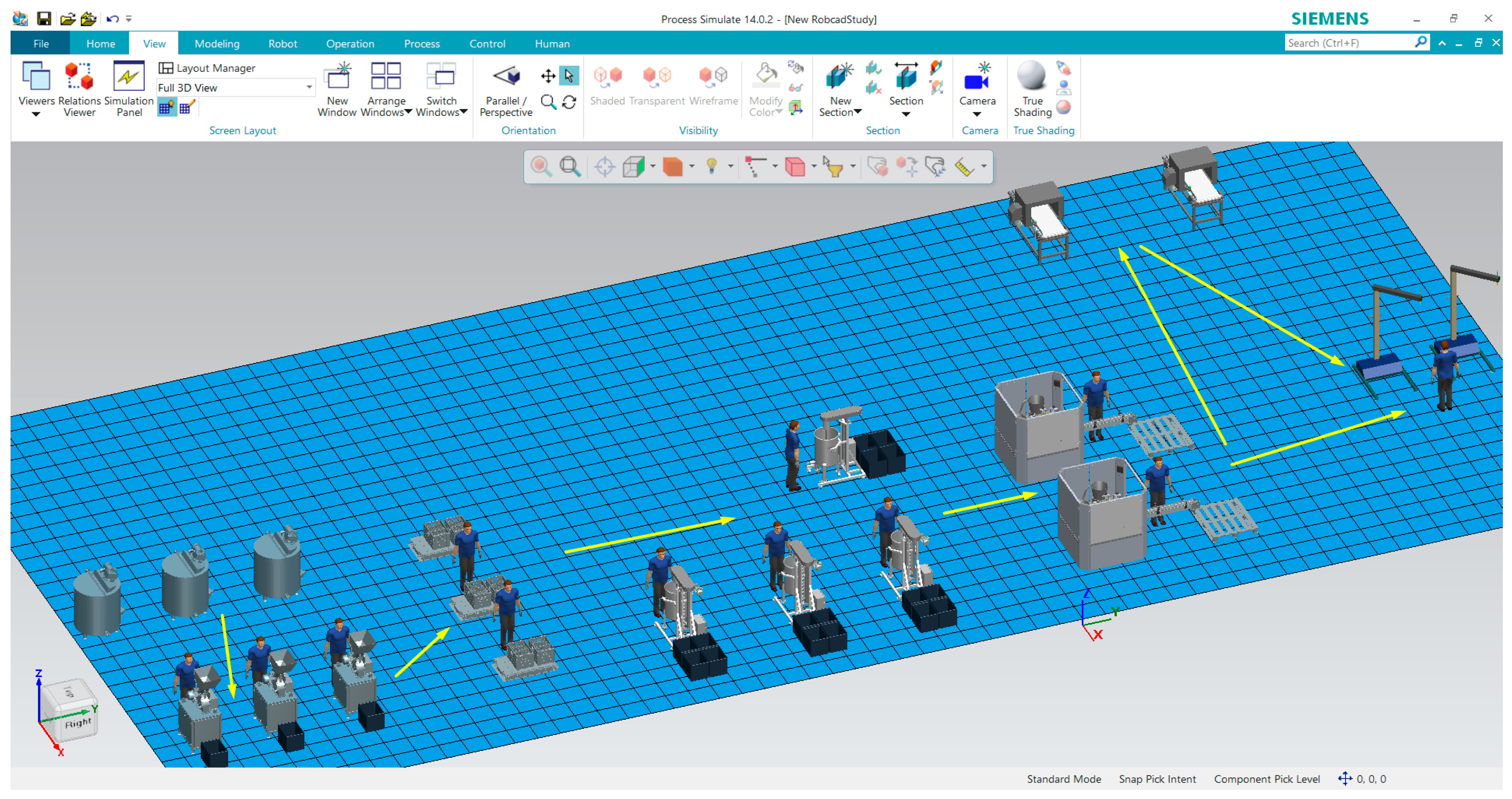

3.1. Notes jsc

3.1.1. Manufacturing Process Processing

3.1.2. Evaluation of the Current State of the Workplace

3.1.3. Proposal for Improvements

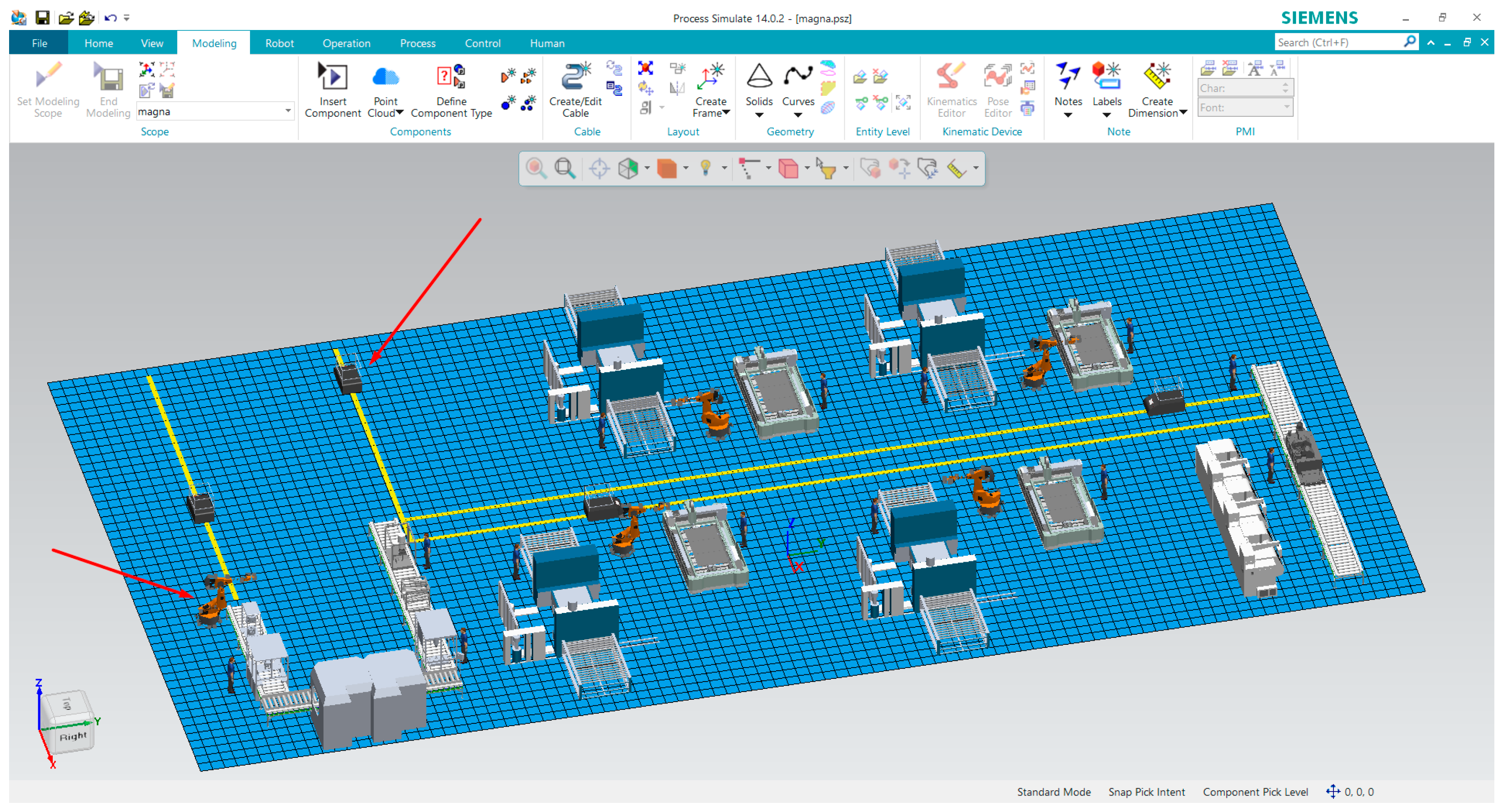

3.2. Magna PT Ltd.

3.2.1. Manufacturing Process Processing

3.2.2. Evaluation of the Current State of the Workplace

3.2.3. Proposal for Improvements

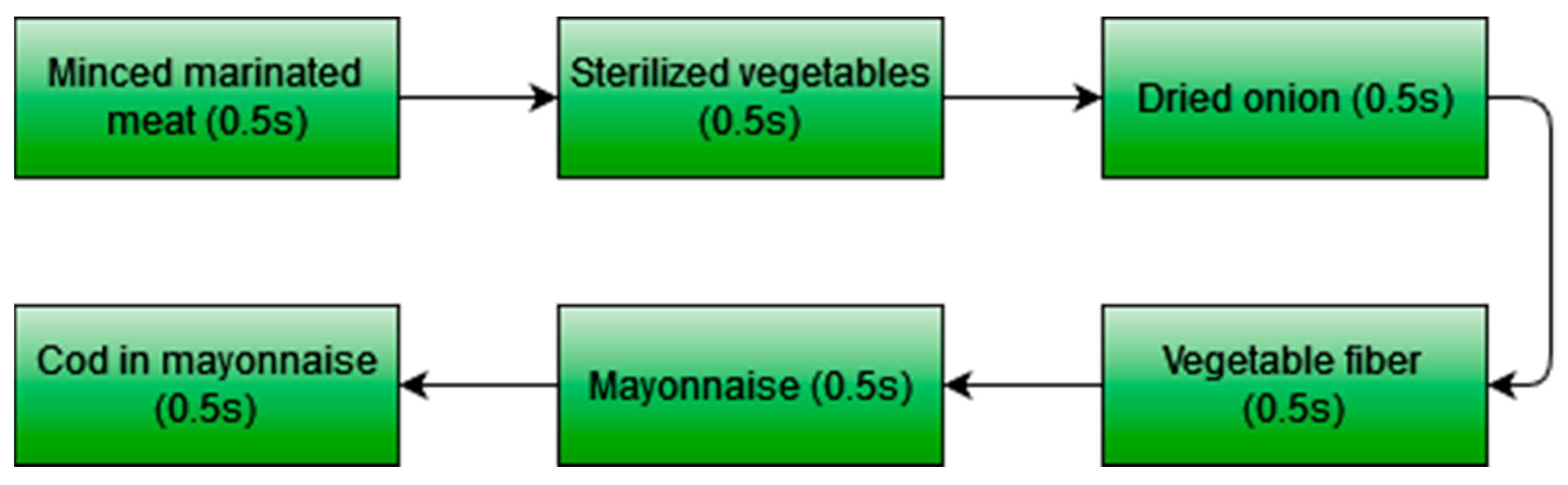

3.3. RYBA Kosice Co., Ltd.

3.3.1. Manufacturing Process Processing

3.3.2. Evaluation of the Current State of the Workplace

3.3.3. Proposal for Improvements

4. Discussion of Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Chromjakova, F.; Bobak, R.; Hrusecka, D. Production process stability—Core assumption of Industry 4.0 concept. In Proceedings of the 5th International Conference on Manufacturing, Optimization, Industrial and Material Engineering, Taiyuan, China, 24–25 June 2017; pp. 143–154. [Google Scholar]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2021, 28, 1410–1450. [Google Scholar] [CrossRef]

- Vieira, A.A.C.; Dias, L.M.S.; Santos, M.Y.; Pereira, G.A.B.; Oliveira, J.A. Setting an Industry 4.0 research and development agenda for simulation—A literature review. Int. J. Simul. Model. 2018, 17, 377–390. [Google Scholar] [CrossRef] [PubMed]

- Manlig, F.; Slaichova, E.; Koblasa, F.; Vavruska, J. Innovation of business processes by means of computer-aided simulation: Novel Trends in Production Devices and Systems. Appl. Mech. Mater. 2014, 474, 67–72. [Google Scholar] [CrossRef]

- Glova, J.; Sabol, T.; Vajda, V. Business Models for the Internet of Things Environment: Emerging Markets Queries in Finance and Business (Emq 2013). Procedia Econ. Financ. 2014, 15, 1122–1129. [Google Scholar] [CrossRef] [Green Version]

- Prester, J.; Buchmeister, B.; Palčič, I. Effects of advanced manufacturing technologies on manufacturing company performance, Strojniski vestnik. J. Mech. Eng. 2018, 64, 763–771. [Google Scholar] [CrossRef]

- Zuzek, T.; Gosar, Z.; Kusar, J.; Berlec, T. New product development model for SMEs: Introducing agility to the plan-driven concurrent product development approach. Sustainability 2021, 13, 12159. [Google Scholar] [CrossRef]

- Witkowski, K.; Saniuk, S. Aspekt logistyczny zarzadzania infrastruktura komunalna miasta. Logistyka 2011, 41, 589–600. [Google Scholar]

- Ojstersek, R.; Javernik, A.; Buchmeister, B. The impact of the collaborative workplace on the production system capacity: Simulation modelling vs. real-world application approach. Adv. Prod. Eng. Manag. 2021, 16, 431–442. [Google Scholar] [CrossRef]

- Straka, M.; Lenort, R.; Khouri, S.; Feliks, J. Design of large-scale logistics systems using computer simulation hierarchic structure. Int. J. Simul. Model. 2018, 17, 105–118. [Google Scholar] [CrossRef]

- Wicher, P.; Stas, D.; Karkula, M.; Lenort, R.; Besta, P. A Computer Simulation-Based Analysis of Supply Chains Resilience in Industrial Environment. Metalurgija 2015, 54, 703–706. [Google Scholar]

- Dulina, L.; Edl, M.; Fusko, M.; Rakyta, M.; Sulirova, I. Digitization in the Technical Service Management System. MM Sci. J. 2018, 2018, 2260–2266. [Google Scholar]

- Gregor, M.; Hercko, J.; Grznar, P. The Factory of the Future Production System Research. In Proceedings of the 21st International Conference on Automation and Computing (ICAC), Glasgow, UK, 11–12 September 2015; pp. 254–259. [Google Scholar]

- Grznar, P.; Gregor, M.; Krajcovic, M.; Mozol, S.; Schickerle, M.; Vavrik, V.; Durica, L.; Marschall, M.; Bielik, T. Modeling and Simulation of Processes in a Factory of Future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Wiecek, D.; Wiecek, D.; Kuric, I.; Buckova, M.; Krajcovic, M. Evaluation of the effectiveness of implementing production logistics automation systems supported by computer simulation tools. In Proceedings of the 14th International Conference on Modern Technologies in Manufacturing, Cape Town, South Africa, 26–28 May 2019; p. 02007. [Google Scholar] [CrossRef] [Green Version]

- Gola, A.; Plinta, D.; Grznar, P. Modelling and simulation of reconfigurable manufacturing system for machining of casing-class parts. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2021; pp. 1563–1568. [Google Scholar] [CrossRef]

- Ojstersek, R.; Acko, B.; Buchmeister, B. Simulation study of a flexible manufacturing system regarding sustainability. Int. J. Simul. Model. 2020, 19, 65–76. [Google Scholar] [CrossRef]

- Frazzon, E.M.; Albrecht, A.; Hurtado, P.A.; de Souza Silva, L.; Pannek, J. Hybrid modelling approach for the scheduling and control of integrated production and logistic processes along export supply chains. IFAC-PapersOnLine 2015, 48, 1521–1526. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Szajna, A.; Szajna, J.; Stryjski, R.; Sąsiadek, M.; Woźniak, W.W. The Application of Augmented Reality Technology in the Production Processes. In Intelligent Systems in Production Engineering and Maintenance: Conference Proceedings ISPEM 2018; Advances in Intelligent Systems and Computing; Burduk, A., Chlebus, E., Nowakowski, T., Tubis, A., Eds.; Springer: Cham, Switzerland, 2019; pp. 316–324. ISBN 9783319974897. [Google Scholar]

- Mula, J.; Peidro, D.; Díaz-Madroñero, M.; Vicens, E. Mathematical programming models for supply chain production and transport planning. Eur. J. Oper. Res. 2010, 204, 377–390. [Google Scholar] [CrossRef]

- Aytug, H.; Bhattacharyya, S.; Koehler, G.J. Genetic learning through simulation: An investigation in shop floor scheduling. Ann. Oper. Res. 1998, 78, 1–29. [Google Scholar] [CrossRef]

- Fleischmann, B.; Meyr, H.; Wagner, M. Supply Chain Management and Advanced Planning; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Chen, Z.-L.; Vairaktarakis, G.L. Integrated scheduling of production and distribution operations. Manag. Sci. 2005, 51, 614–628. [Google Scholar] [CrossRef]

- Byrne, M.D.; Bakir, M.A. Production planning using a hybrid simulation-analytical approach. Int. J. Prod. Econ. 1999, 59, 305–331. [Google Scholar] [CrossRef]

- Kim, B.; Kim, S. Extended model for a hybrid production planning approach. Int. J. Prod. Econ. 2000, 73, 165–173. [Google Scholar] [CrossRef]

- Byrne, M.D.; Hossain, M.M. Production planning: An improved hybrid approach. Int. J. Prod. Econ. 2005, 93–94, 225–229. [Google Scholar] [CrossRef]

| Paper industry | Notes jsc. | overproduction ahead |

| unreasonable downtime | ||

| excessive inter-operational warehouses | ||

| unreasonable movements of employees | ||

| lengthy interoperation transport | ||

| Automotive industry | Magna PT Ltd. | unreasonable movements of employees |

| lengthy interoperation transport | ||

| disturbed fluidity of the material flow | ||

| Food industry | Ryba Košice Co., Ltd. | disturbed fluidity of the material flow |

| redundant lack of supply | ||

| lengthy interoperation transport |

| Paper industry | Notes jsc. | introduce a production planning system |

| applying the SMED method | ||

| purchase and programming of automatic carts | ||

| Automotive industry | Magna PT Ltd. | purchase and programming of automatic carts |

| replacing a manual operation with a robotic one | ||

| rearrangement of machines | ||

| Food industry | Ryba Košice Co., Ltd. | purchase and programming of automatic carts |

| reduction of non-sufficiency by transfer of technology and thus also ensure smooth material flow |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trojan, J.; Trebuňa, P.; Mizerák, M. Application of Digital Engineering Methods in Order to Improve Processes in Heterogeneous Companies. Appl. Sci. 2023, 13, 7681. https://doi.org/10.3390/app13137681

Trojan J, Trebuňa P, Mizerák M. Application of Digital Engineering Methods in Order to Improve Processes in Heterogeneous Companies. Applied Sciences. 2023; 13(13):7681. https://doi.org/10.3390/app13137681

Chicago/Turabian StyleTrojan, Jozef, Peter Trebuňa, and Marek Mizerák. 2023. "Application of Digital Engineering Methods in Order to Improve Processes in Heterogeneous Companies" Applied Sciences 13, no. 13: 7681. https://doi.org/10.3390/app13137681

APA StyleTrojan, J., Trebuňa, P., & Mizerák, M. (2023). Application of Digital Engineering Methods in Order to Improve Processes in Heterogeneous Companies. Applied Sciences, 13(13), 7681. https://doi.org/10.3390/app13137681