1. Introduction

Earthquakes can trigger high-intensity vibrations in a short time, producing tremendous amounts of energy that may result in structural damage or even destruction. To reduce the degree of damage to superstructures under seismic excitation, researchers have developed various types of isolation devices, including rubber, friction, and composite isolation bearings.

The most typical passive isolation device is the rubber isolation system (RIS). The RIS is composed of rubber and steel plates laminated together, which is widely used in practical projects because of the elasticity of rubber and the bearing capacity of steel plates with excellent isolation performance. Over the past two decades, researchers have conducted experiments and finite element studies on the stiffness, shear deformation, temperature, and hysteresis curve properties of RIS from multiple perspectives, e.g., [

1,

2,

3,

4,

5]. Taking a steel frame structure with FRP rubber bearings as the research object, WU [

6] obtained the ground vibration response of the base-isolated structure under different vertical loads, different structural height and width ratios, and different site factors by shaking table testing. Meanwhile, they established a finite element model of the seismic isolated structure with OpenSees to compare the ground vibration response analysis, ensuring the correctness of the results, which showed that FRP rubber isolation bearings can effectively reduce the influence of earthquakes on the superstructure. SUN [

7] verified the influence of temperature on the seismic isolation effect by analyzing the correlation between temperature and the bearing performance and stiffness of the rubber bearing, providing a theoretical reference for the engineering application and development of rubber seismic isolation bearings.

Friction isolation bearings take friction as the damping force of the isolation layer and have good isolation performance, among which the friction pendulum has a bright development prospect because of its automatic reset capability. On this basis, researchers have developed various forms of friction pendulum bearings and conducted mechanical model derivations and experimental testing to promote the development of friction isolation bearings [

8,

9,

10]. For example, Harvey [

11] proposed a coupled two-way dynamic non-linear model to numerically analyze the dynamic performance of horizontal two-way systems based on considering the rotation degree of freedom factor. Zhang [

12] studied the effects of two types of vibration isolation bearings, ball and roller, on the rolling friction coefficient and analyzed the effects of the friction coefficient on the vibration isolation effect by modeling with SAP2000 software. The results showed that the seismic isolation performance is most effective when the rolling friction coefficient is within a certain range.

In recent years, composite isolation systems have become a research focus in the field of engineering earthquake resistance due to their advantages of gathering various types of seismic isolation devices and innovative combinations to improve seismic isolation performance to the maximum extent [

13,

14,

15,

16,

17,

18,

19]. In terms of innovative combinations, Gao [

20] studied the mechanical properties and seismic isolation performance of a disc spring-high damping rubber three-dimensional composite seismic isolation bearing. Numerical simulations were conducted to analyze the mechanical properties of the disc spring using ABAQUS finite element software, and test data were used to analyze the mechanical properties of the high-damping rubber seismic isolation bearing. Li [

21] conducted horizontal and vertical seismic isolation performance tests on proposed disc-spring-stacked rubber three-dimensional composite seismic isolation bearings under different working conditions. In the horizontal direction, the hysteresis performance of the bearing under simple harmonic excitation was tested, and the effects of shear strain, vertical pressure, and loading frequency on its horizontal mechanical properties were investigated. In the vertical direction, the equivalent stiffness and equivalent damping ratio of the bearing were investigated, and the effects of loading amplitude, pressure, and loading frequency on its vertical hysteresis performance were investigated, as well as how changes in vertical stiffness affect the horizontal mechanical properties of the laminated rubber bearing. Hui developed a new type of variable-frequency rolling pendulum bearing consisting of a rolling bearing and an additional viscous damper to protect acceleration-sensitive equipment. The authors conducted comparative analyses using computer software and vibration table tests on different types of ground motion, including short-period (high-frequency), medium-frequency, and long-period (low-frequency) ground motion. They tested the effects of different parameters on device acceleration and relative displacement responses and the accuracy of the model.

With the advancement of science, technology, and engineering design, composite isolation bearings are constantly innovating and developing in the field of seismic resistance. In this study, a new type of composite seismic isolation system is proposed that is based on the flexibility of ball bearings and solves the limitations of traditional sliding isolation bearings. In order to analyze the dynamic friction performance of sliding and rolling, compression-shear tests were conducted. By controlling variables such as vertical pressure, horizontal velocity, number of pads, and number of rolling balls, the influence of these factors on the dynamic friction coefficient of the composite isolation bearing was studied. The obtained data can be used to analyze the structural response under earthquake excitation.

2. Design of the Isolation System

2.1. Description of the Designed Isolation System

The hybrid isolation system designed to isolate vibration comprises rolling friction and sliding friction. The physical diagram of the isolation device is shown in

Figure 1, while its individual components are displayed in

Figure 2. The bearing capacity is distributed by compressing the spring.

When the lower surface of the upper plate of this composite vibration isolation bearing contacts the friction surface of the upper surface of the lower plate, the spring in the upper part of the ball roller group receives extrusion, as per Hooke’s law:

where

is the compression of the spring, mm;

is the coefficient of elasticity of the spring, kN/mm; and

is the pressure of a single spring, KN.

Then, the upper load borne by the rolling ball group is

where

is the number of springs in the upper part of the ball group.

The friction sliding surface of the upper load is

where

is the total upper structure load.

The distribution of the load-bearing capacity is controlled by the bearing by changing the number of gimbals and shims. Without balls, the system relies solely on sliding friction, which is equivalent to a planar sliding bearing. With the addition of balls, rolling friction and sliding friction work together to reduce structural damage by decreasing the upward transmission path of earthquakes.

2.2. Design of the Test Bearing

This experiment uses a micro-controlled hydroelectric servo compression shear tester and a combination of two isolation systems and an intermediate steel plate. The arrangement is a double shear combination, with the isolation system located in the middle, as shown in

Figure 3.

This experiment studied the variation law of the friction coefficient of the composite seismic isolation bearing under different variables. The calculation of the friction coefficient was carried out using the following formula:

To facilitate the determination of the tested friction coefficient, a pair of composite isolation bearings with two friction surfaces was used. The assembly of the isolation bearing is shown in

Figure 4. Therefore, the friction coefficient of the composite isolation bearing is given by the test results obtained from this setup.

where

is the friction coefficient of the composite seismic isolation bearing.

The upper connecting plate has a diameter of 250 mm and a thickness of 20 mm. Its lower surface is reserved by five bolt holes of diameter 20 mm and depth 7.5 mm. The middle column has a diameter of 54 mm and a total height of 92 mm, with a bolt column on the upper surface of 20 mm diameter and 7 mm depth, and two cylindrical grooves of diameter 45 mm and depth 32 mm, and diameter 32 mm and depth 43 mm on the lower surface. The lower connecting plate has a diameter of 250 mm and a thickness of 10 mm, with five cylindrical grooves of diameter 54 mm and depth 5 mm on its upper surface, and five cylindrical grooves of diameter 45 mm and depth 5 mm on its lower surface. The two cylindrical axes of the upper and lower grooves are aligned. Bearings will be equipped with different numbers of balls and shims according to the designed working conditions. To ensure the stability of the bearing, the number of balls is set to 1, 4, and 5. The materials of the parts of the bearings are different; the upper and lower connecting plates and intermediate columns are made of 45# steel; the shims, springs, and friction plates are made of 65 mn spring steel; the universal ball is made of turned heavy duty universal ball SP-25; the internal ball material is bearing steel; and the friction material is selected as PTFE.

2.3. Test Loading Procedure

A total of 75 operating conditions were established in this project, mainly focused on four parameters: vertical pressure, horizontal velocity, number of shims, and number of rolling balls. In the loading process, the vertical pressure is applied slowly at a loading rate of 0.04 MPa/s, and the application is stopped when the predetermined loading condition is reached. Then, the horizontal servo actuator drives the middle steel plate to provide horizontal force to the support friction plate with an action speed of 2 mm/s, 5 mm/s, and 10 mm/s, respectively, and ensures the horizontal uniform motion. The effect of different factors on the friction coefficient is calculated by the friction formula.

2.4. Test Results

2.4.1. Friction Performance Test under the Action of No Ball

When no ball is placed, the friction characteristics of the bearing under different pressures and speeds are investigated by a standard compression shear test, which is conducted under the action of vertical pressures of 39, 59, 102, and 204 KN and speeds of 2 mm/s, 5 mm/s, and 10 mm/s, respectively.

Figure 5 shows the relationship between the sliding speed and the sliding friction coefficient under different pressures. At a certain vertical pressure, the friction coefficient tends to decrease and then increase as the speed increases. It can be seen that the minimum sliding friction range is 0.04548–0.0516.

Figure 6 shows the relationship between the vertical pressure and the sliding friction coefficient at different velocities. The results show that at a certain speed, the friction coefficient shows a decreasing trend with an increase in vertical pressure. Obviously, the optimal friction parameters are 0.04548–0.04629, and the minimum friction coefficient is 0.04548.

2.4.2. Friction Performance Test under the Action of Balls

The ball in the system, combined with the spring and shim, plays a role. The main role played by the spring and shim is to adjust the force of the ball so that the total upper load is proportionally distributed to the ball group and PTFE.

This part of the study focuses on the effect of the bearing ratio on the dynamic friction coefficient. The effect of the number of shims and balls on the dynamic friction coefficient is shown in

Figure 7 and

Figure 8. The relationship between the number of shims and friction coefficient for four-roller ball and five-roller ball isolation bearings with horizontal velocities of 2 mm/s, 4 mm/s, and 10 mm/s, respectively, under different vertical pressures.

In

Figure 7a, when the horizontal speed is 2 mm/s, the friction coefficients under the action of three bearing ratios show different changes with an increase in the number of shims. When the ball group occupies 25%, the friction coefficient increases first and then decreases, and the minimum is 0.5516; when the ball group occupies 50%, the friction coefficient increases continuously, and the minimum is 0.05805; when the ball group occupies 100%, the friction coefficient decreases gradually, and the minimum is 0.06757.

In

Figure 7b,c, when the horizontal velocity is 5 mm/s and 10 mm/s, the friction coefficient has a tendency to increase and then decrease with the increase in the number of shims, and the minimum friction range occurs when the number of shims is 2 and the pressure-bearing ratio is between 25% and 50%, which are 0.05514–0.05614 and 0.05759–0.05804, respectively.

In

Figure 8, at a certain horizontal velocity, the friction coefficients under the action of different bearing ratios showed a trend of decreasing and then increasing, and the minimum ranges, respectively, were 0.03458–0.03947, 0.03047–0.03869, and 0.02883–0.04169. Most of them were found when the number of shims was 4 and the pressure-bearing ratio was between 25 and 50%.

In

Figure 7 and

Figure 8, comparing the data of a four-roller ball and a five-roller ball, it can be found that the coefficient of friction decreases with the increase in the number of balls, and there is a difference in the influence of the parameters of the minimum coefficient of friction; the four-roller ball mostly appears when the number of shims is 2, the five-roller ball mostly appears when the number of shims is 4, and the pressure-bearing ratio is 25–50%.

4. Conclusions

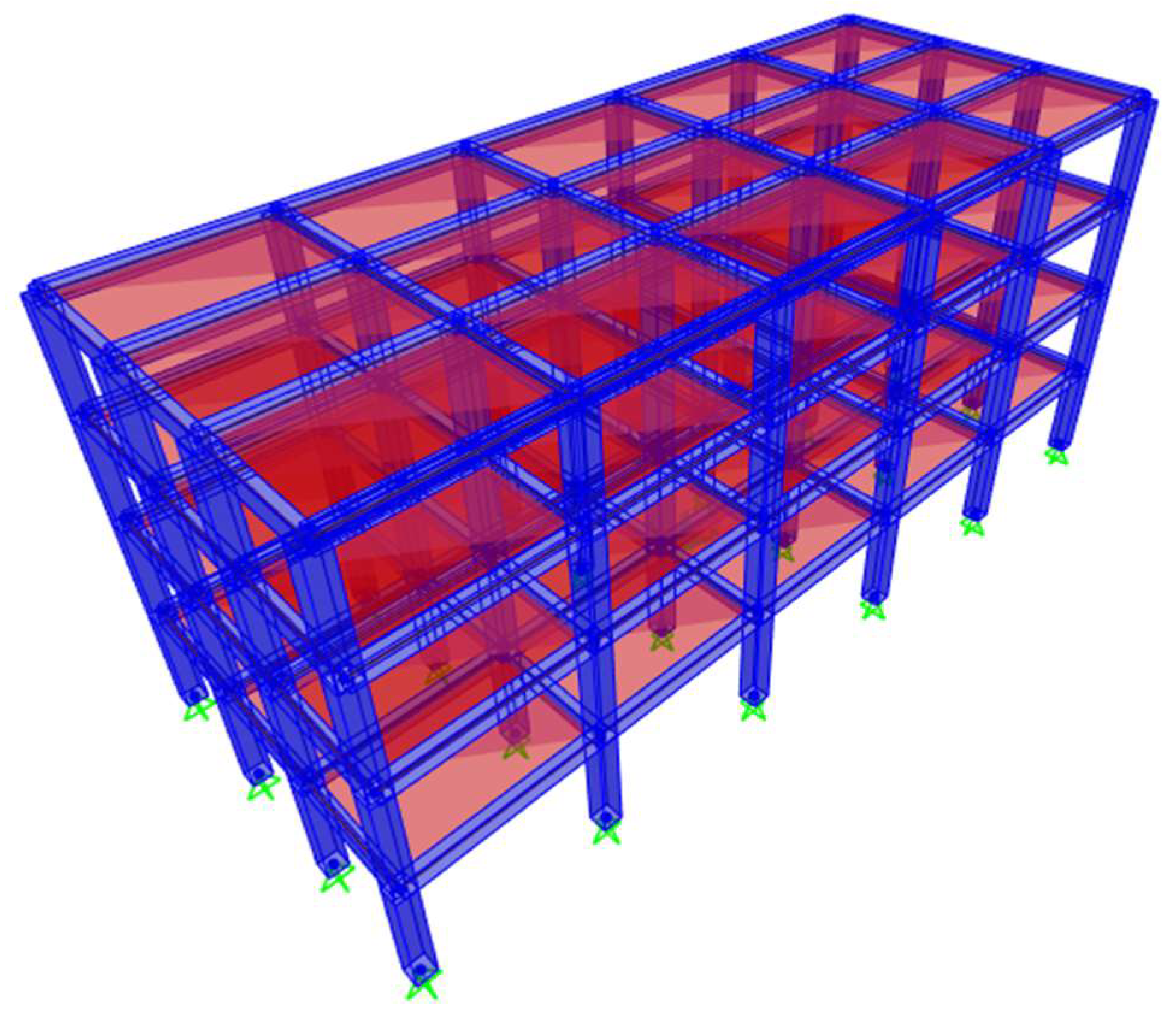

This article introduces a new type of isolation system that takes into account the potential impact of parameters, such as the number of spheres, on the friction coefficient. Based on this, numerical simulations were conducted for both the base isolation structure and traditional seismic-resistant structures under earthquake excitation to determine their dynamic characteristics.

Firstly, in the experimental test data, we found that the number of spheres and pads has a certain influence on the friction coefficient. Without spheres, the minimum friction coefficient occurs when the horizontal velocity is 5 mm/s and the vertical pressure is 204 KN. With the involvement of spheres, there is little difference in the friction coefficient range between five and four spheres. In addition, the minimum friction coefficient appears in the bearing ratio of 25–50%, indicating that the number of spheres and pads can reduce the friction coefficient within a certain range. These results indicate that the number of spheres and pads is an important factor affecting the friction coefficient of the isolation system.

Secondly, after conducting numerical simulations for the base isolation structure and traditional seismic-resistant structures under earthquake excitation, we found that the new composite isolation system can effectively reduce the dynamic response of the model compared to traditional seismic-resistant structures. This indicates that the new isolation system has good seismic performance.

Finally, it should be pointed out that this experiment mainly studied the influence of parameters such as the number of balls on the friction coefficient of the isolation support. However, in order to better apply the new isolation support in practical engineering, we still need to further study the shear performance of the isolation support using ABAQUS finite element software and explore its applicability under different parameter conditions. These research results will help provide a theoretical basis for the practical application of the new isolation support.