Experimental Study on Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Three Regression Models for Electric Vehicle Application

Abstract

1. Introduction

2. Electric Vehicles Battery Key Parameters

2.1. Variance of Temperature

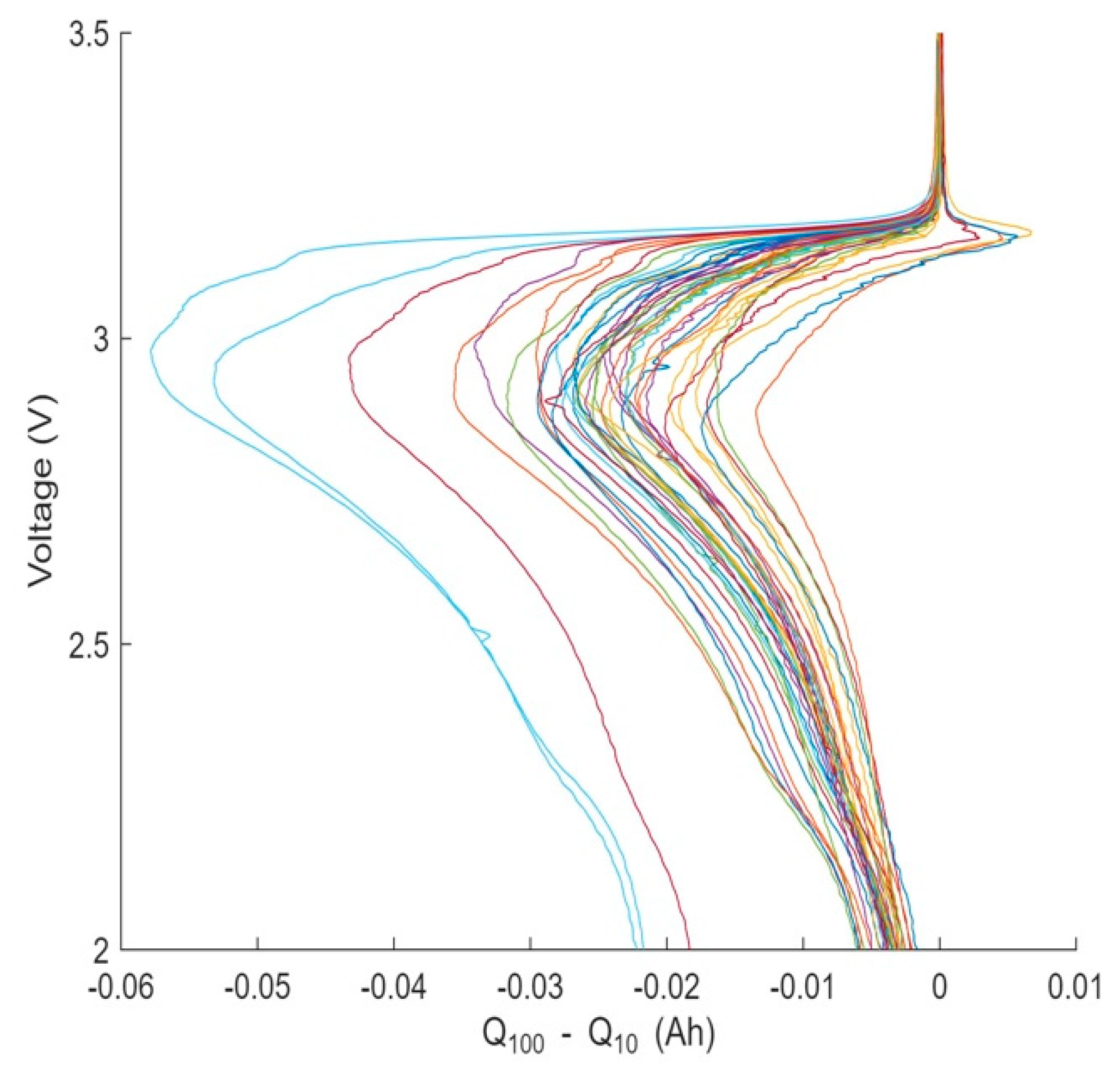

2.2. Discharge Voltage Variance

3. Physical Characteristics of Battery Lithium-Ion

4. Regression Models Life Prediction of Lithium-Ion Batteries

4.1. Linear Regression

- def regression_matrics(y_test, y_pred):

- # calculate errors

- mse = mean_squared_error(y_test, y_pred)

- rmse = mean_squared_error(y_test, y_pred, squared=False)

- mae = mean_absolute_error(y_test, y_pred)

- # report error

- print(f’Mean Squared Error: {mse}’)

- print(f’Root Mean Square Error: {rmse}’)

- print(f’Mean Absolute Error: {mae}’)

4.2. Random Forest Regressor

Build a Random Forest Regression Algorithm

- rfr = RandomForestRegressor(random_state=2301, n_estimators=100)

- rfr.fit(X_train, y_train)

- print(rfr.score(X_train, y_train))

- print(rfr.score(X_test, y_test))

- rfr_pred = rfr.predict(X_test)

- rfr_rmse = np.sqrt(mean_squared_error(y_test, rfr_pred))

- print(rfr_rmse)

4.3. Decision Tree Regressor

- −

- Step 1: Create an empty binary tree;

- −

- Step 2: Select features to split;

- −

- Step 3: If there are no more questions, make a prediction;

- −

- Step 4: Recursion from Step 2.

- (1)

- Feature selection: To solve this problem, we calculate the MSE cost (mixedness). We will rely on this MSE cost to choose the feature accordingly. It will calculate from the root node and then calculate the intermediate nodes; if the error cost of that split feature is the smallest, then choose that feature.

- (2)

- Stop the recursion: The max depth parameter is in this task tree when the request limit is reached, or divide the tree so it cannot be divided anymore.

- dtr = DecisionTreeRegressor(random_state=2301)

- dtr.fit(X_train, y_train)

- dtr.fit(X_train, y_train)

- print(dtr.score(X_train, y_train))

- print(dtr.score(X_test, y_test))

- dtr_pred = dtr.predict(X_test)

- dtr_rmse = np.sqrt(mean_squared_error(y_test, dtr_pred))

- print(dtr_rmse)

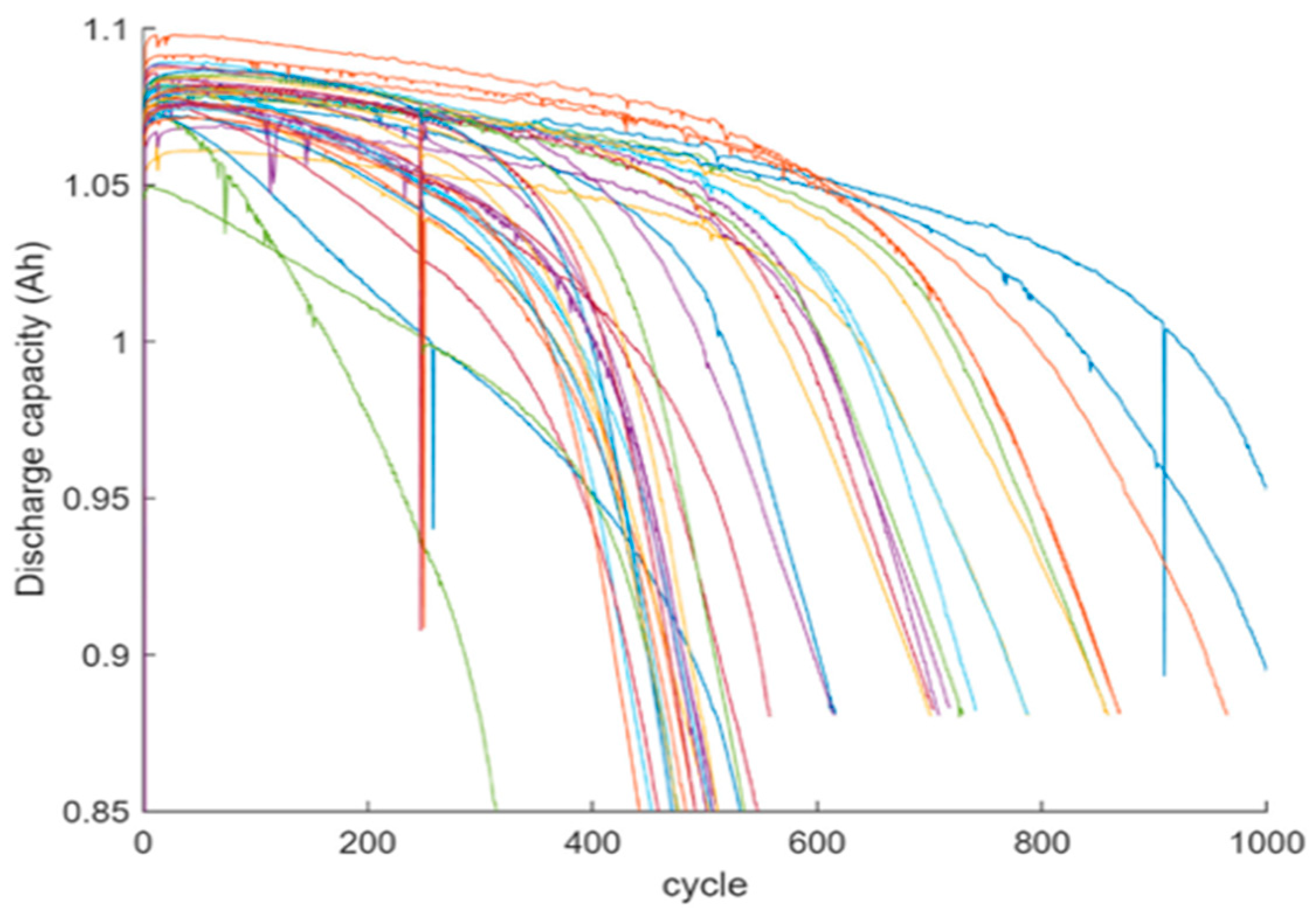

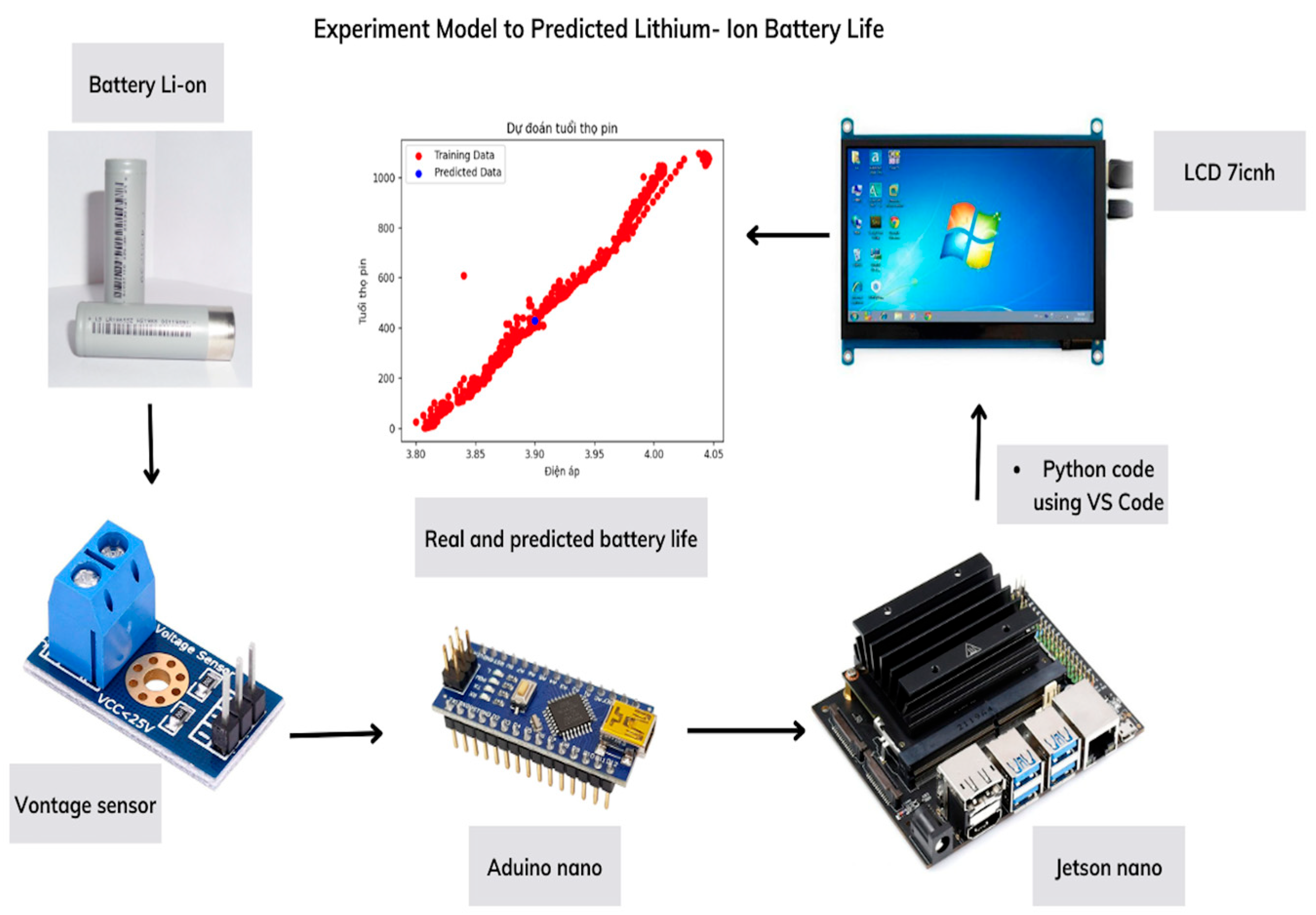

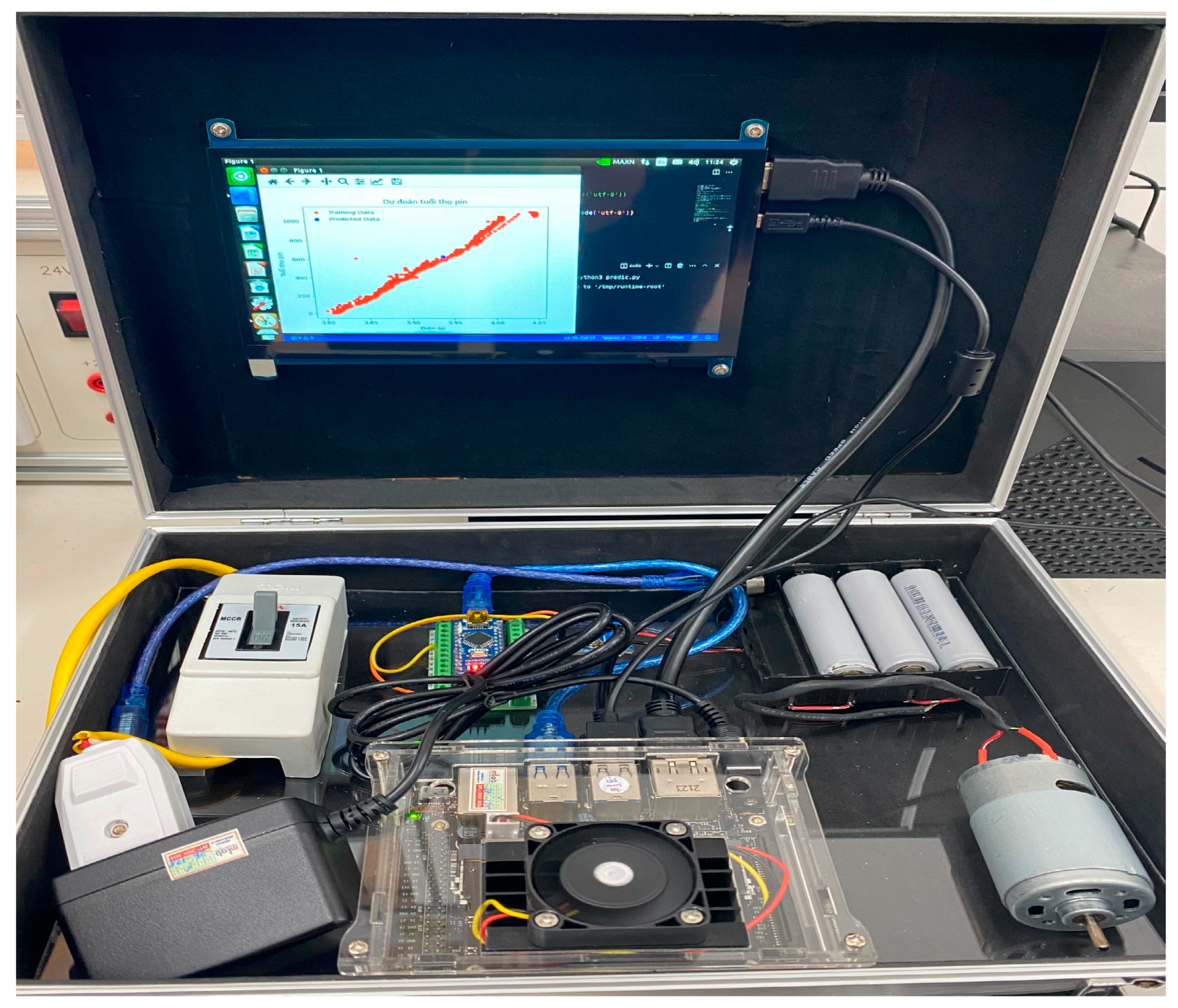

5. Experiment Results and Discussion

- −

- Cycle Index: number of cycles.

- −

- Decrement 3.8–4.05 V(s).

- −

- Max. Voltage Discharge (V): 4.05 V.

- −

- Min. Voltage Charge (V): 3.8 V.

- −

- Combo NVIDIA Jetson Nano Developer Kit B01: GPU: 128-core Maxwell, CPU: Quad-core ARM A57 @ 1.43 GHz, Memory 4 GB 64 bits LPDDR4 25,6 GB/s.

- −

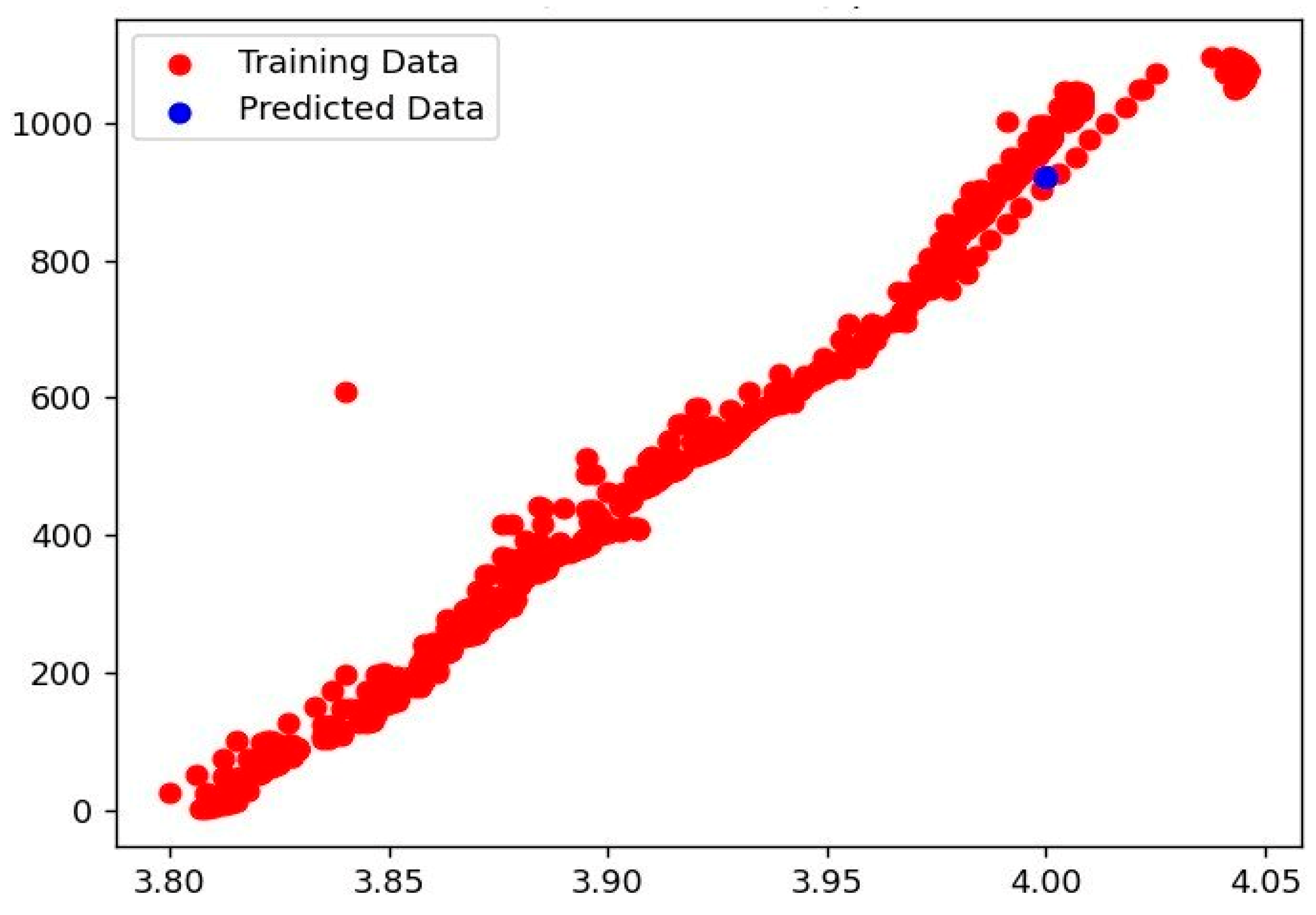

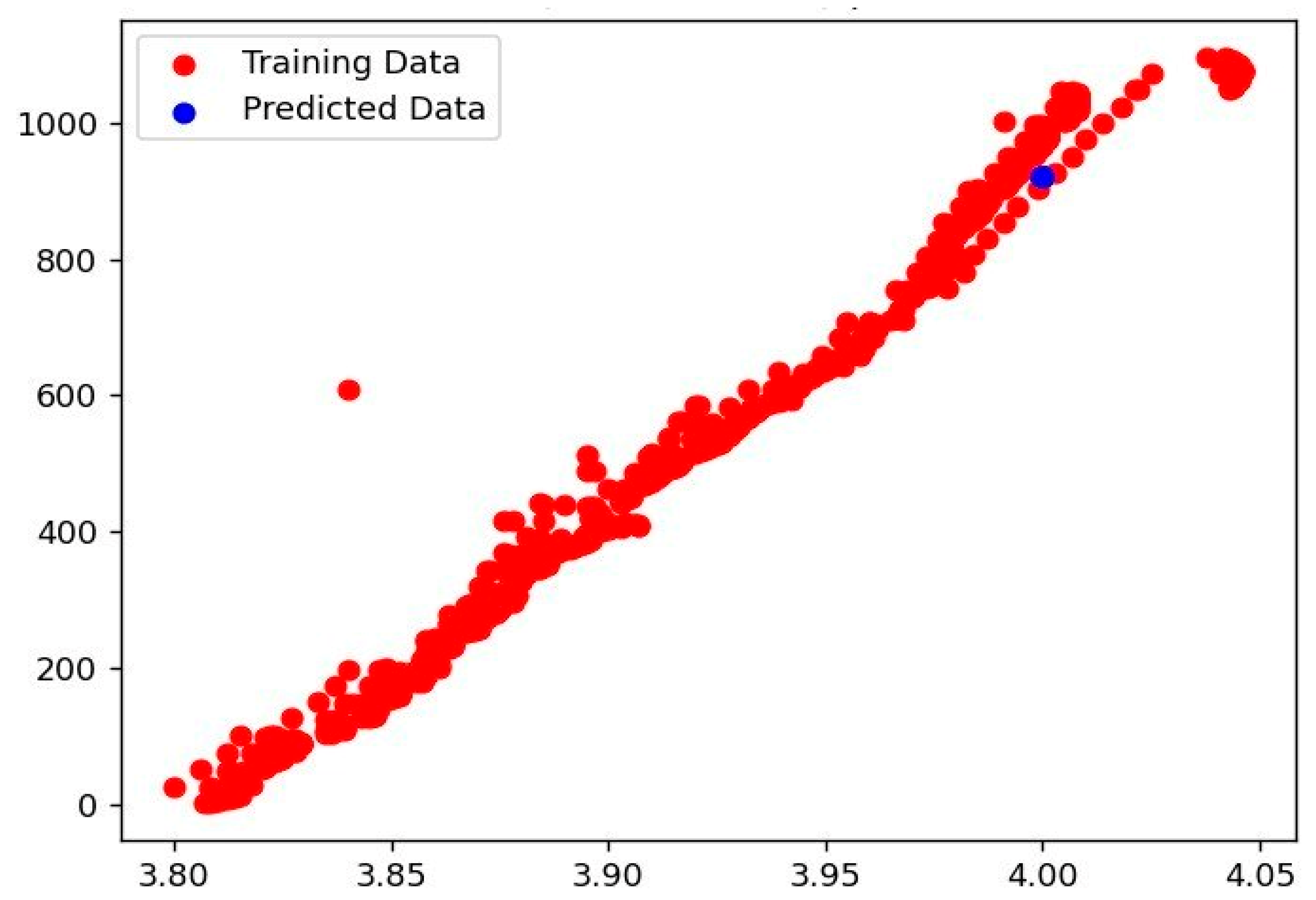

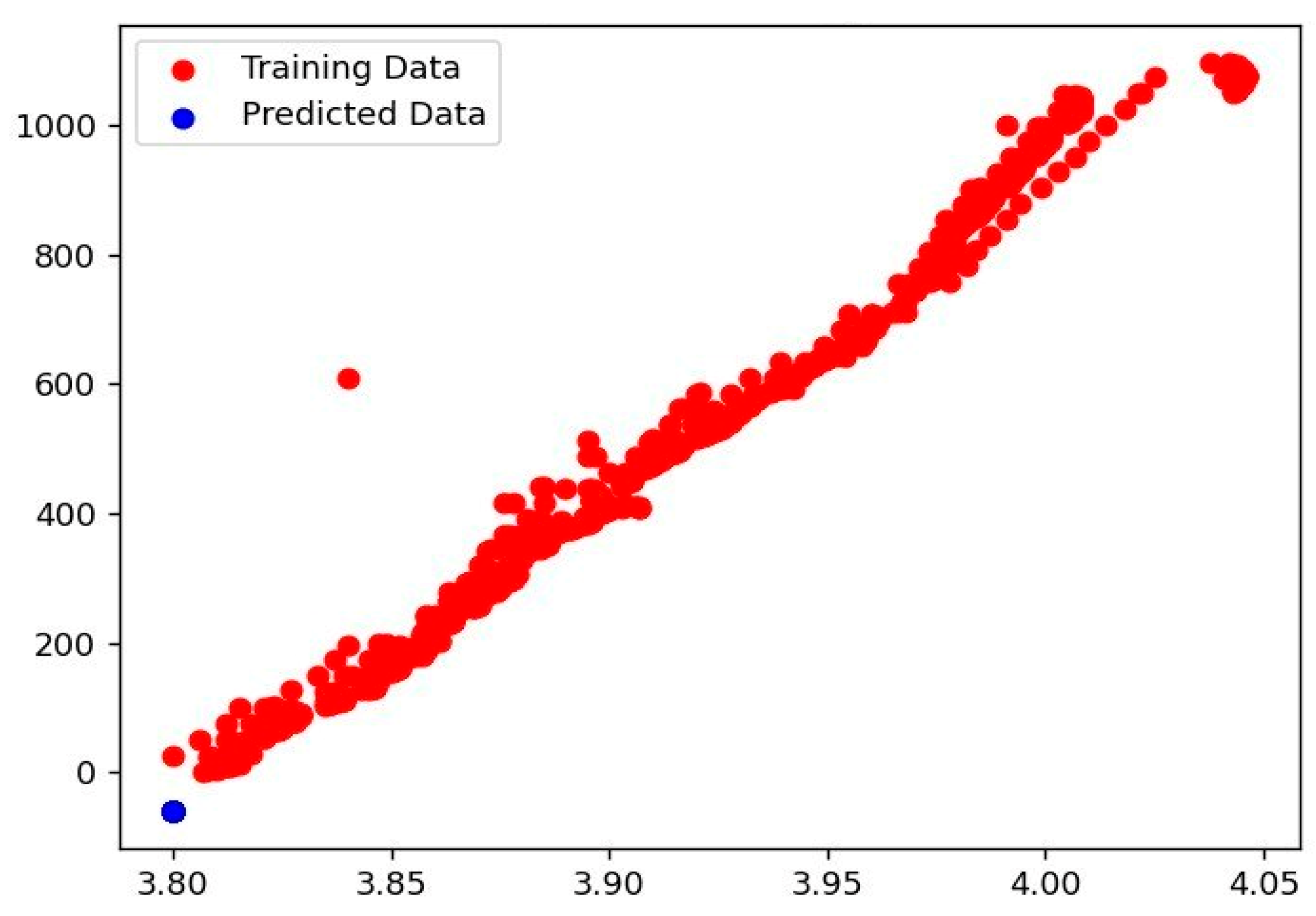

- Case 1: Predict lithium-ion battery capacity when the maximum voltage is equal to 4 V (when the battery is working without load).

- −

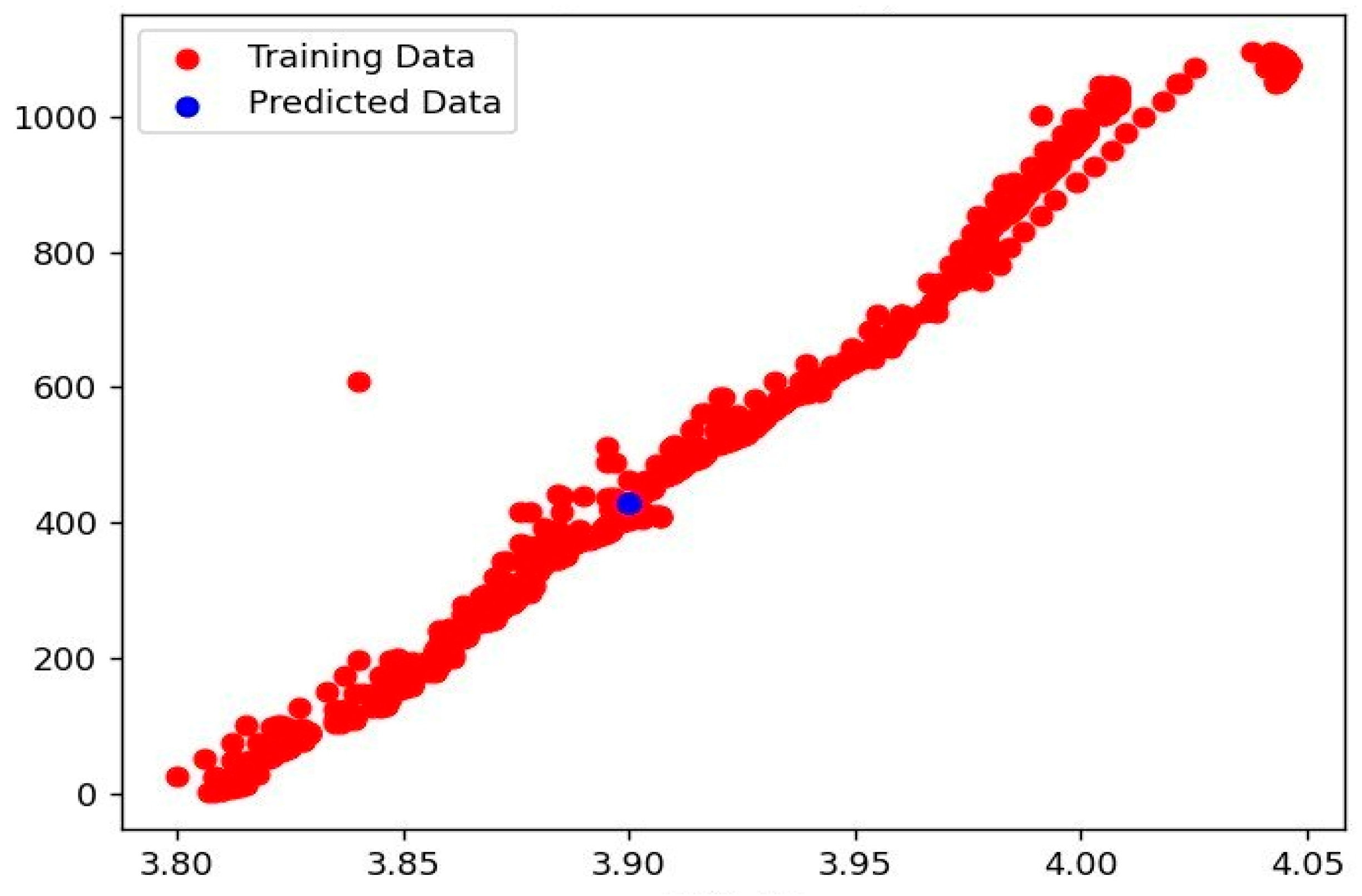

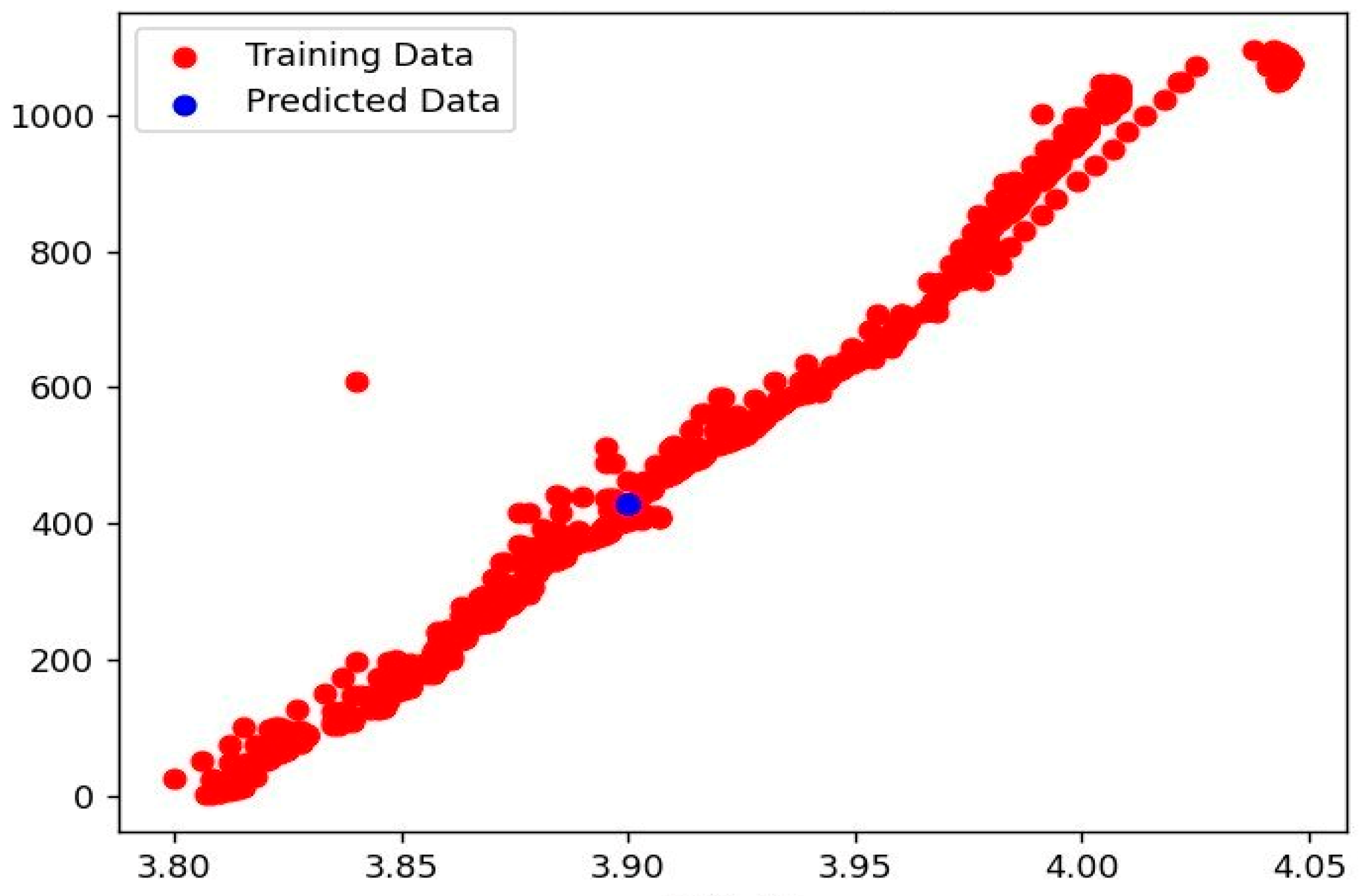

- Case 2: Predict lithium-ion battery capacity at the time of maximum voltage equal to 3.9 V (batteries power a DC motor with parameters: No-load current at 12 V and 0.92 A, no-load speed at 1200 rpm, no-load current at 24 V and 1.46 A, and no-load speed at 2000 rpm. It is recommended to use a 12 V, 10 A source for a stable motor).

- −

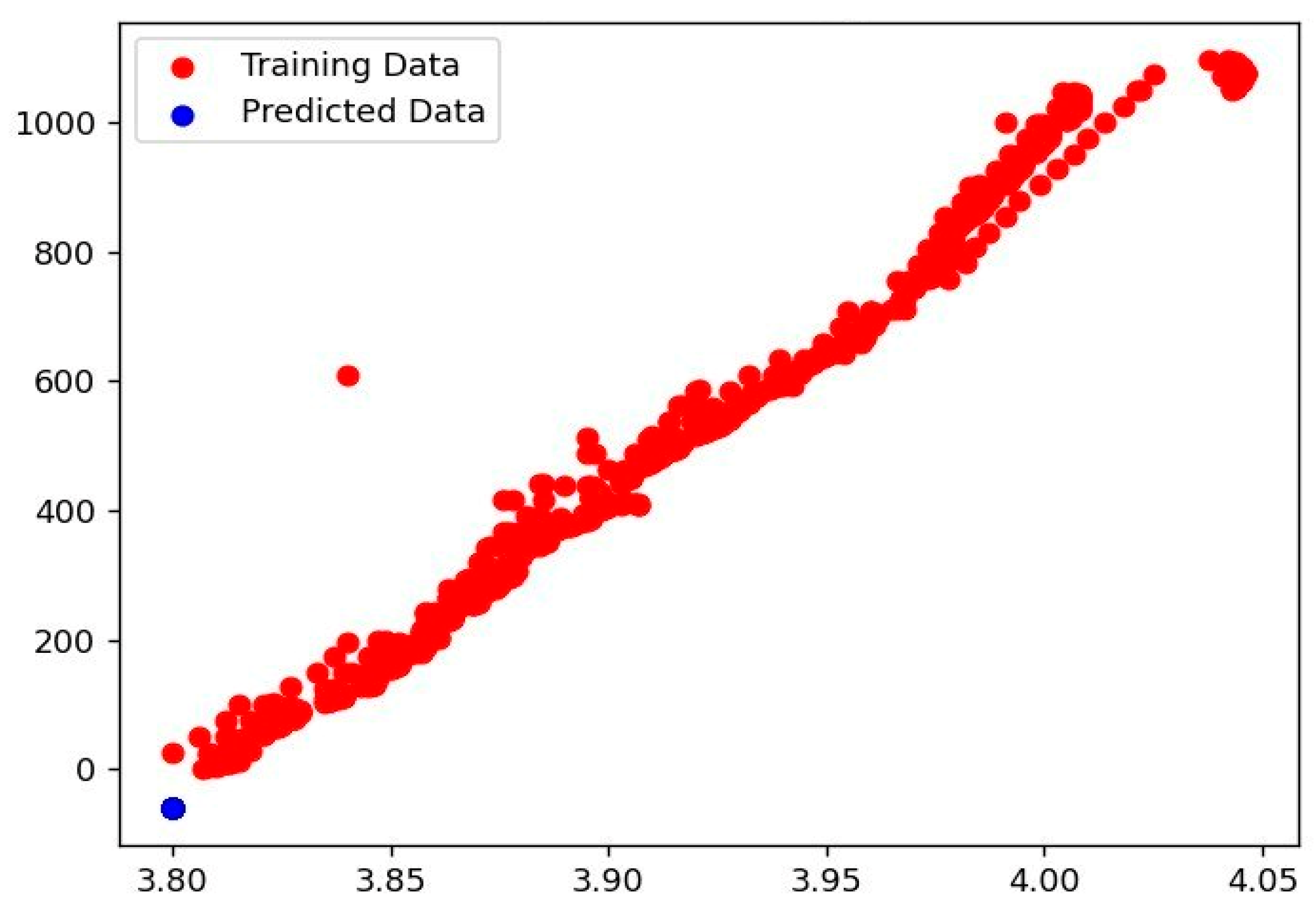

- Case 3: Forecast of Li-ion battery capacity at the time of maximum voltage equal to 3.8 V (No-load current at 12 V and 0.92 A, no-load speed at 1200 rpm, no-load current at 24 V and 1.46 A, and no-load speed at 2000 rpm. It is recommended to use a 12 V, 10 A source for a stable motor).

- (a)

- The experimental results of linear regression model.

- (b)

- The experimental results of random forest regressor

- (c)

- The experimental results for decision tree regressor model.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmuch, R.; Wagner, R.; Hörpel, G.; Placke, T.; Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 2018, 3, 267–278. [Google Scholar] [CrossRef]

- Zhu, C.; Lu, F.; Zhang, H.; Mi, C.C. Robust predictive battery thermal management strategy for connected and automated hybrid electric vehicles based on thermoelectric parameter uncertainty. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1796–1805. [Google Scholar] [CrossRef]

- Peterson, S.B.; Apt, J.; Whitacre, J.F. Lithium-ion battery cell degradation resulting from realistic vehicle and vehicle-to-grid utilization. J. Power Sources 2010, 195, 2385–2392. [Google Scholar] [CrossRef]

- Ramadesigan, V.; Northrop, P.W.; De, S.; Santhanagopalan, S.; Braatz, R.D.; Subramanian, V.R. Modeling and simulation of lithium-ion batteries from a system engineering perspective. J. Electrochem. Soc. 2012, 159, R31–R45. [Google Scholar] [CrossRef]

- Waag, W.; Fleischer, C.; Sauer, D.U. Critical review of the methods for monitoring of lithium-ion batteries in electric and hybrid vehicles. J. Power Sources 2014, 258, 321–339. [Google Scholar] [CrossRef]

- Vidal, C.; Kollmeyer, P.; Chemali, E.; Emadi, A. Li-ion battery state of charge estimation using long short-term memory recurrent neural network with transfer learning. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar]

- She, C.; Zhang, L.; Wang, Z.; Sun, F.; Liu, P.; Song, C. Battery state of health estimation based on incremental capacity analysis method: Synthesizing from cell-level test to real-world application. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 28–41. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Samanta, A.; Chowdhuri, S.; Williamson, S.S. Machine learning-based data-driven fault detection/diagnosis of lithium-ion battery: A critical review. Electronics 2021, 10, 1309. [Google Scholar] [CrossRef]

- Su, X.; Wang, S.; Pecht, M.; Zhao, L.; Ye, Z. Interacting multiple model particle filter for prognostics of lithium-ion batteries. Microelectron. Reliab. 2017, 70, 59–69. [Google Scholar] [CrossRef]

- Sahinoglu, G.O.; Pajovic, M.; Sahinoglu, Z.; Wang, Y.B.; Orlik, P.V.; Wada, T. Battery state-of-charge estimation based on regular/recurrent Gaussian process regression. IEEE Trans. Ind. Electron. 2018, 65, 4311–4321. [Google Scholar] [CrossRef]

- Ng, S.; Xing, Y.; Tsui, K. A naive Bayes model for robust remaining useful life prediction of lithium-ion battery. Appl. Energy 2014, 118, 114–123. [Google Scholar] [CrossRef]

- Wang, D.; Miao, Q.; Pecht, M. Prognostics of lithium-ion batteries based on relevance vectors and a conditional three-parameter capacity degradation model. J. Power Sources 2013, 239, 253–264. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Liao, H.; Peng, Y.; Peng, X. A health indicator extraction and optimization framework for lithium-ion battery degradation modeling and prognostics. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 915–928. [Google Scholar]

- Zhou, Y.; Huang, M.; Chen, Y.; Tao, Y. A novel health indicator for on-line lithium-ion batteries remaining useful life prediction. J. Power Sources 2016, 321, 1–10. [Google Scholar] [CrossRef]

- Lin, Z.; Cai, Y.; Liu, W.; Bao, C.; Shen, J.; Liao, Q. Estimating the state of health of lithium-ion batteries based on a probability density function. Int. J. Electrochem. Sci. 2023, 18, 100137. [Google Scholar] [CrossRef]

- Widodo, A.; Shim, M.; Caesarendra, W.; Yang, B. Intelligent prognostics for battery health monitoring based on sample entropy. Expert Syst. Appl. 2011, 38, 11763–11769. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Saxena, S.; Ward, L.; Kubal, J.; Lu, W.; Babinec, S.; Paulson, N. A convolutional neural network model for battery capacity fade curve prediction using early life data. J. Power Sources 2022, 542, 231736. [Google Scholar] [CrossRef]

- Zhu, J.G.; Sun, Z.C.; Wei, X.Z.; Dai, H.F. A new lithium-ion battery internal temperature on-line estimate method based on electrochemical impedance spectroscopy measurement. J. Power Source 2015, 274, 990–1004. [Google Scholar] [CrossRef]

- Ho-Ta, L.; Liang, T.; Chen, S.M. Estimation of battery state of health using probabilistic neural network. IEEE Trans. Ind. Inform. 2013, 9, 679–685. [Google Scholar]

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted Boltzmann machines. In Proceedings of the International Conference on Machine Learning (ICML), Haifa, Israel, 21–24 June 2010; pp. 807–814. [Google Scholar]

- Liu, J.; Saxena, A.; Goebel, K.; Saha, B.; Wang, W. An Adaptive Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries; Annual Conference of the Prognostics and Health Management Society; National Aeronautics and Space Administration Moffett Field CA Ames Research Center: Moffett Field, CA, USA, 2010. [Google Scholar]

- Rezvani, M.; AbuAli, M.; Lee, S.; Lee, J.; Ni, J. A Comparative Analysis of Techniques for Electric Vehicle Battery Prognostics and Health Management (PHM). No. 2011-01-2247. SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long short-term memory recurrent neural network for remaining useful life prediction of lithium-ion batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Kingma, D.P.; Adam, J.L.B. A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Li, D.; Yang, L. Remaining useful life prediction of lithium battery using convolutional neural network with optimized parameters. In Proceedings of the IEEE 5th Asia Conference on Power and Electrical Engineering, Chengdu, China, 4–7 June 2020; pp. 840–844. [Google Scholar]

- Anagun, Y.; Isik, S.; Seke, E. SRLibrary: Comparing different loss functions for superresolution over various convolutional architectures. J. Vis. Commun. Image Represent. 2019, 61, 178–187. [Google Scholar] [CrossRef]

- Richardson, R.R.; Birkl, C.R.; Osborne, M.A.; Howey, D. Gaussian process regression for in-situ capacity estimation of lithium-ion batteries. IEEE Trans Ind. Inform. 2019, 15, 127–138. [Google Scholar] [CrossRef]

| Regression Model | MSE | RMSE |

|---|---|---|

| Linear Regression | 22,060.500669 | 148.527777 |

| Random Forest Regressor | 516.332762 | 22.722957 |

| Decision Tree Regressor | 1337.112429 | 36.566548 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, V.T.; Giang, P.T. Experimental Study on Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Three Regression Models for Electric Vehicle Application. Appl. Sci. 2023, 13, 7660. https://doi.org/10.3390/app13137660

Ha VT, Giang PT. Experimental Study on Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Three Regression Models for Electric Vehicle Application. Applied Sciences. 2023; 13(13):7660. https://doi.org/10.3390/app13137660

Chicago/Turabian StyleHa, Vo Thanh, and Pham Thi Giang. 2023. "Experimental Study on Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Three Regression Models for Electric Vehicle Application" Applied Sciences 13, no. 13: 7660. https://doi.org/10.3390/app13137660

APA StyleHa, V. T., & Giang, P. T. (2023). Experimental Study on Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Three Regression Models for Electric Vehicle Application. Applied Sciences, 13(13), 7660. https://doi.org/10.3390/app13137660