A Study on the Impact of DPF Failure on Diesel Vehicles Emissions of Particulate Matter

Abstract

:1. Introduction

2. Experimental Apparatus and Procedure

2.1. Experimental Apparatus

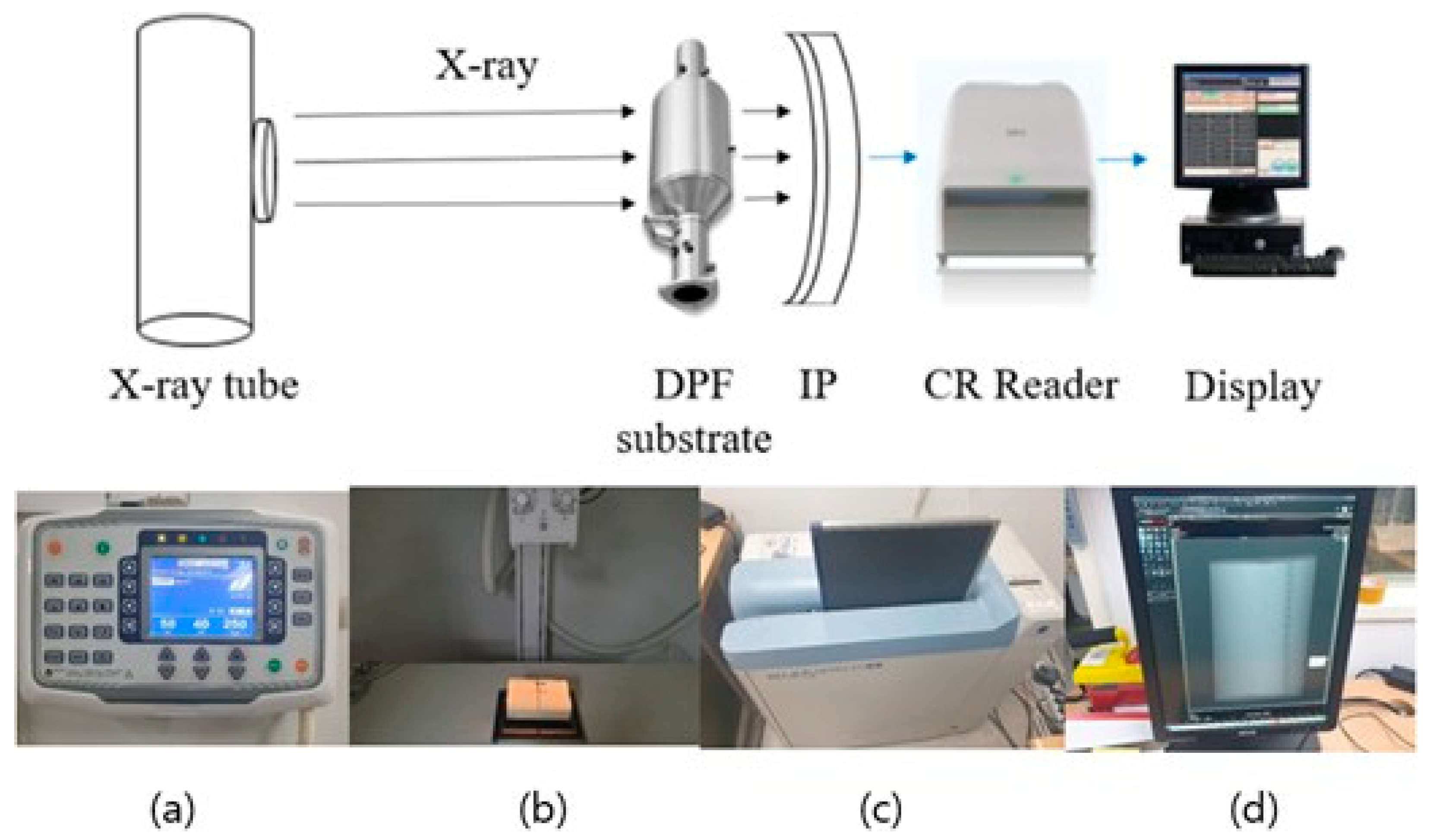

2.1.1. CR X-ray Imaging

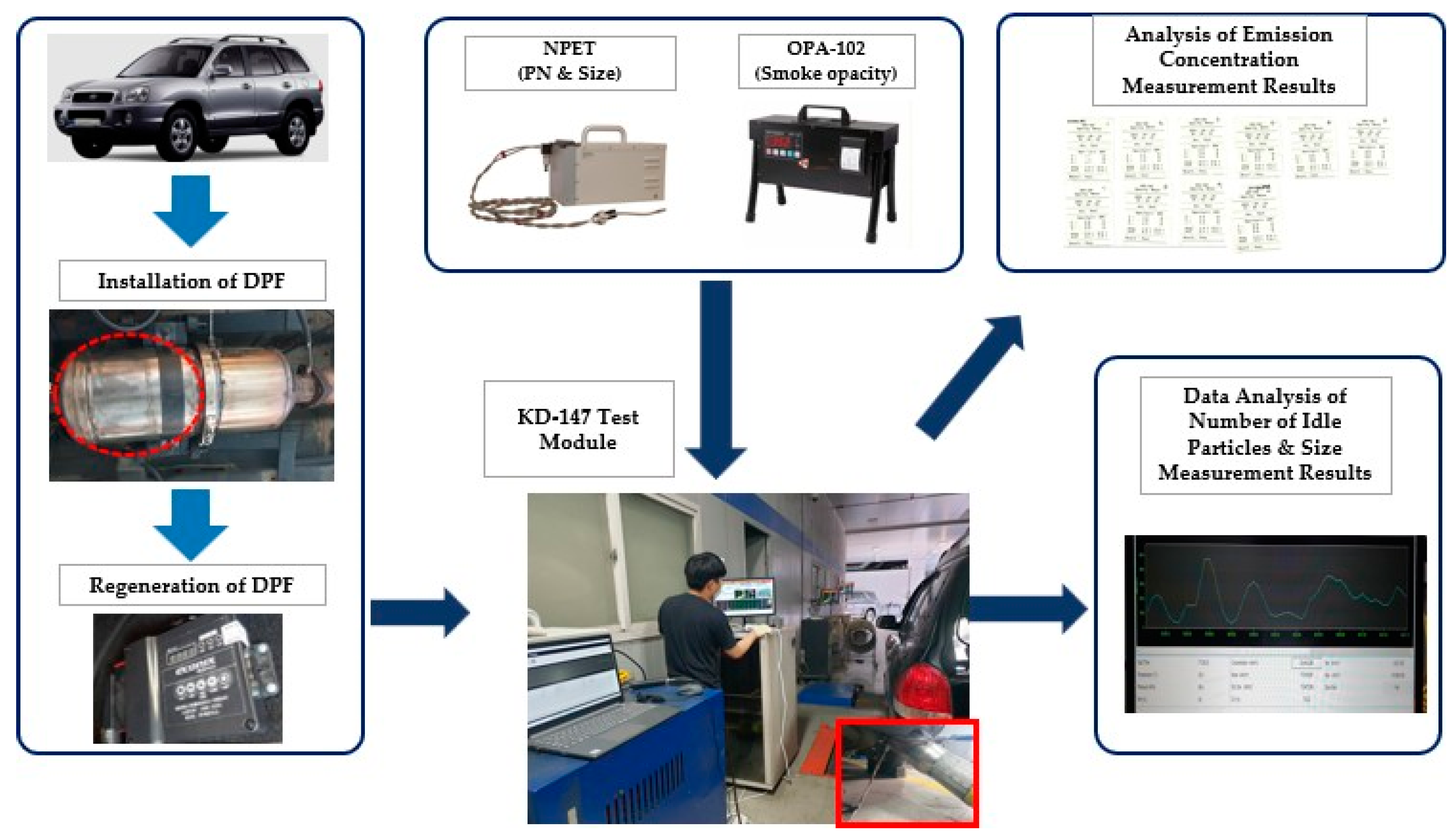

2.1.2. Vehicle Emission Test

2.2. Experimental Method

2.2.1. CR X-ray DPF Imaging Method

2.2.2. KD-147 Inspection Mode for Diesel Vehicles

3. Results

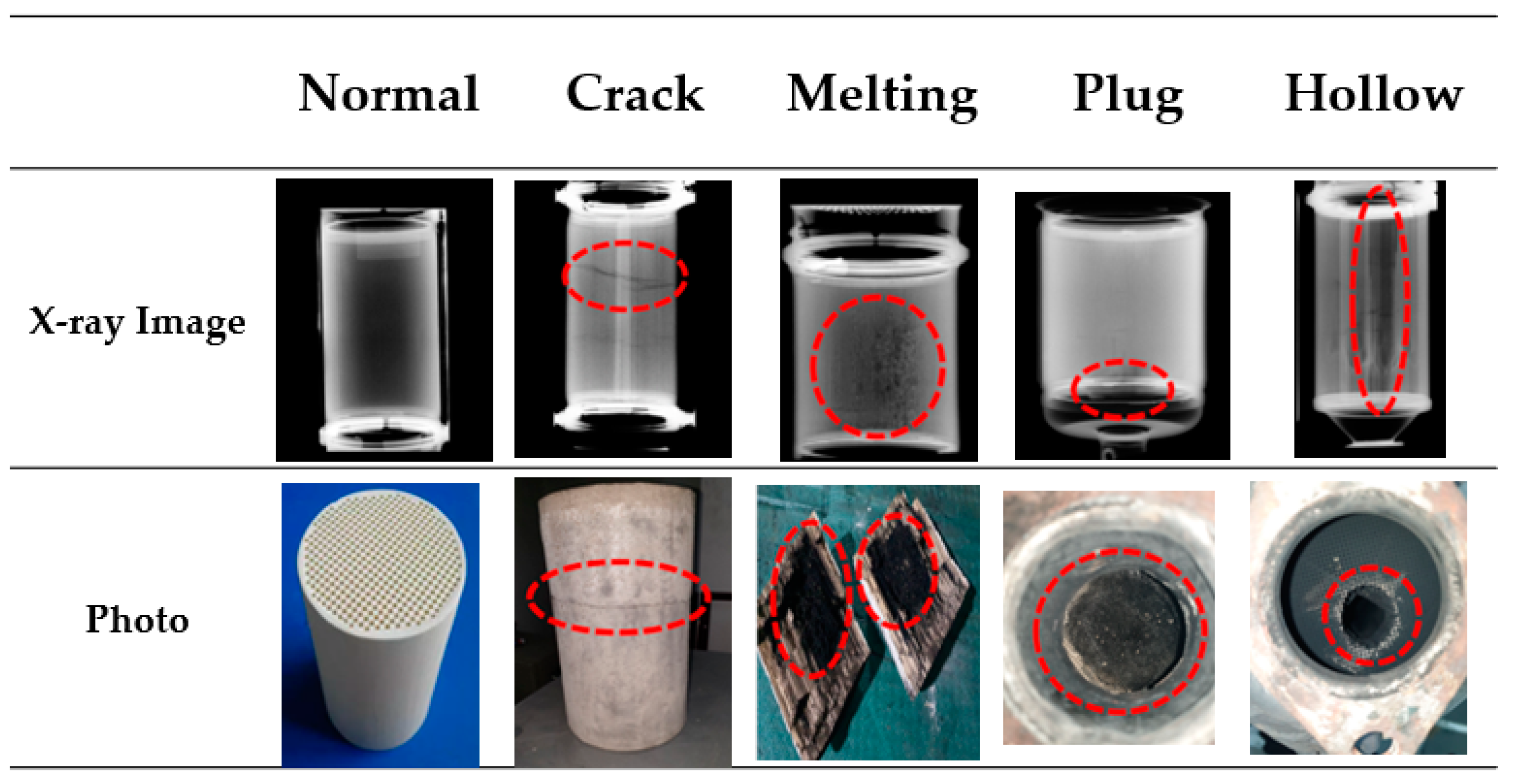

3.1. How to Read Damaged Parts of DPF from Video Material

- Normal

- Crack damage

- Melting damage

- Hollow damage

- Plug damage

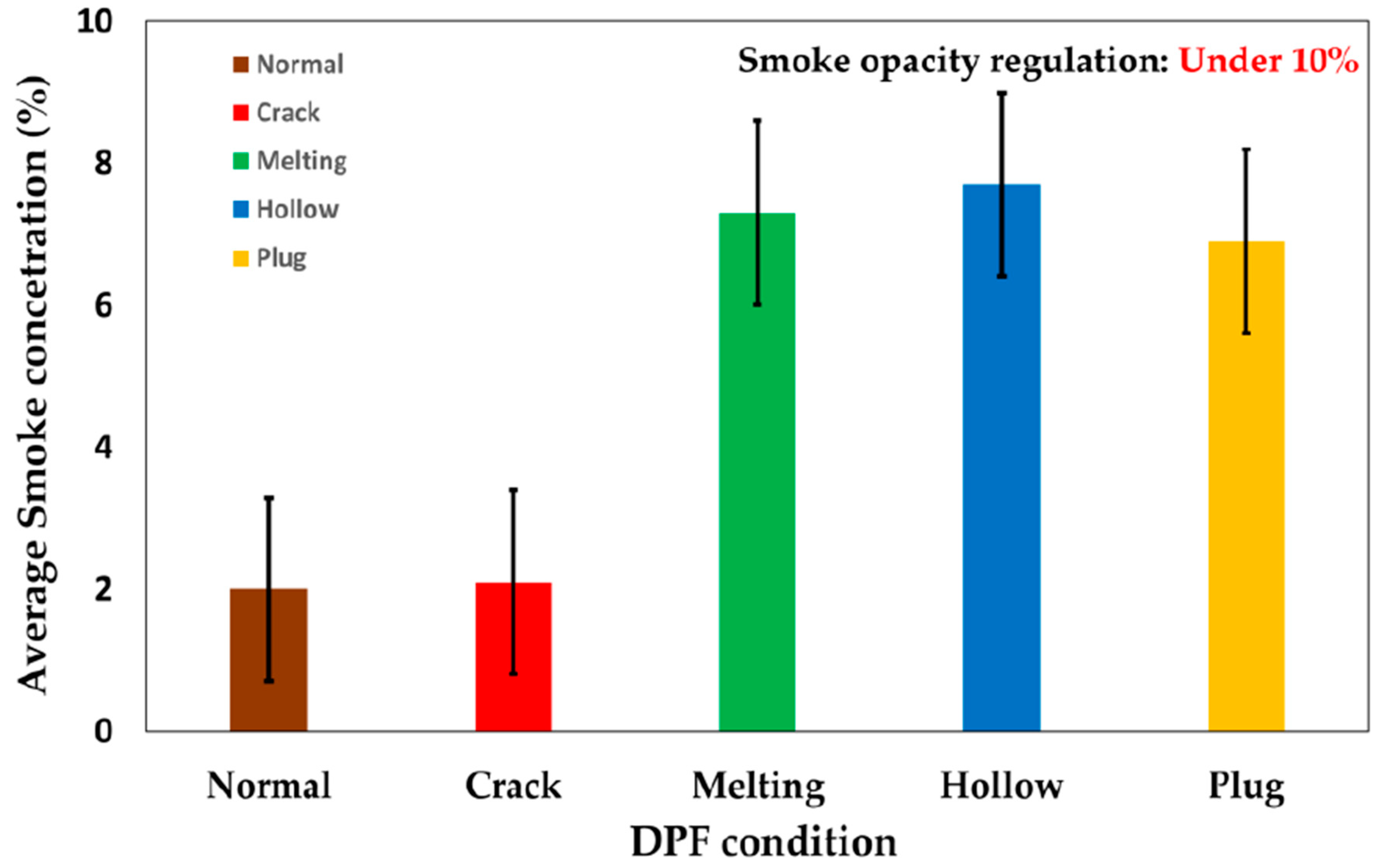

3.2. Measurement of Smoke Concentration by DPF Damage Type

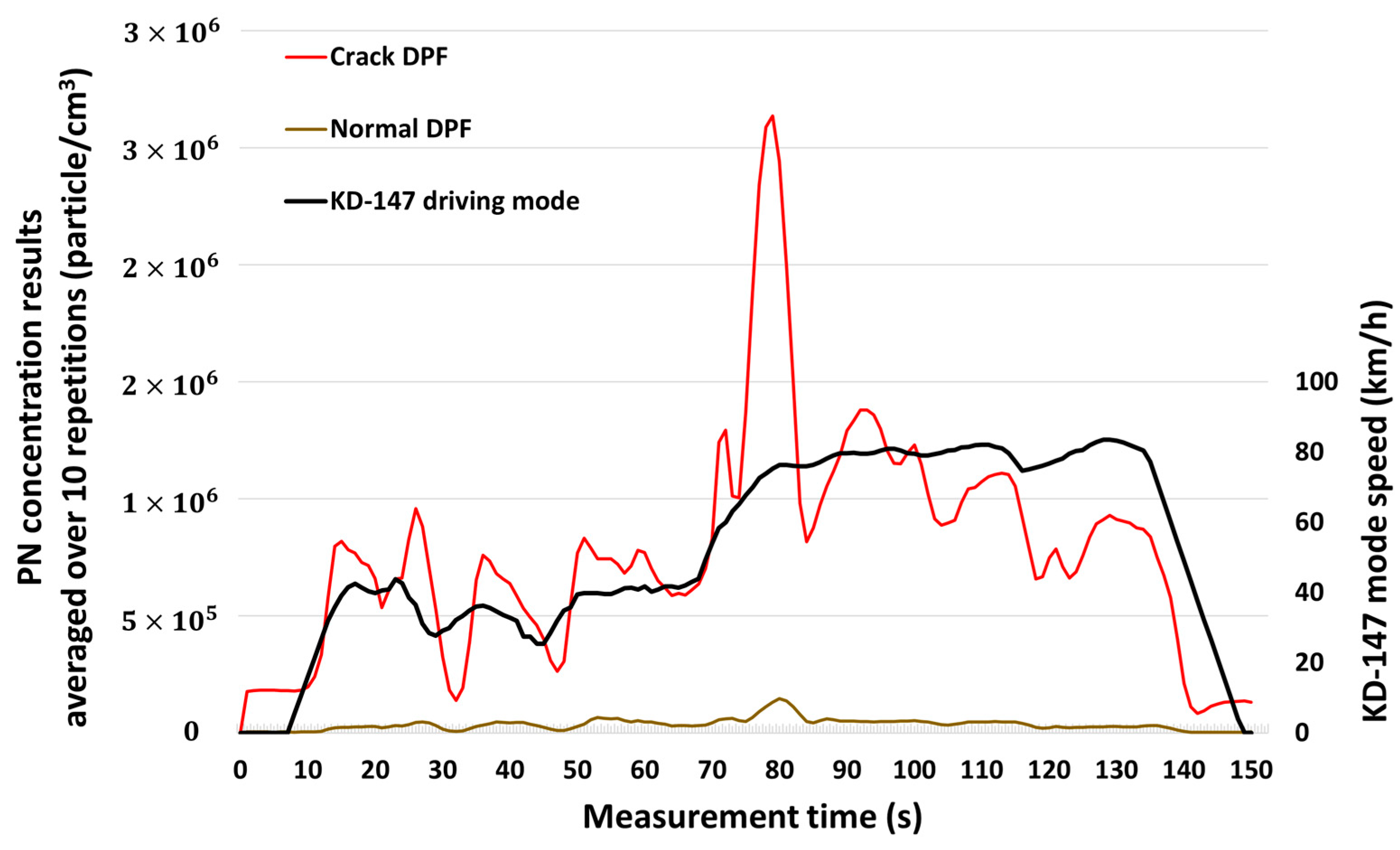

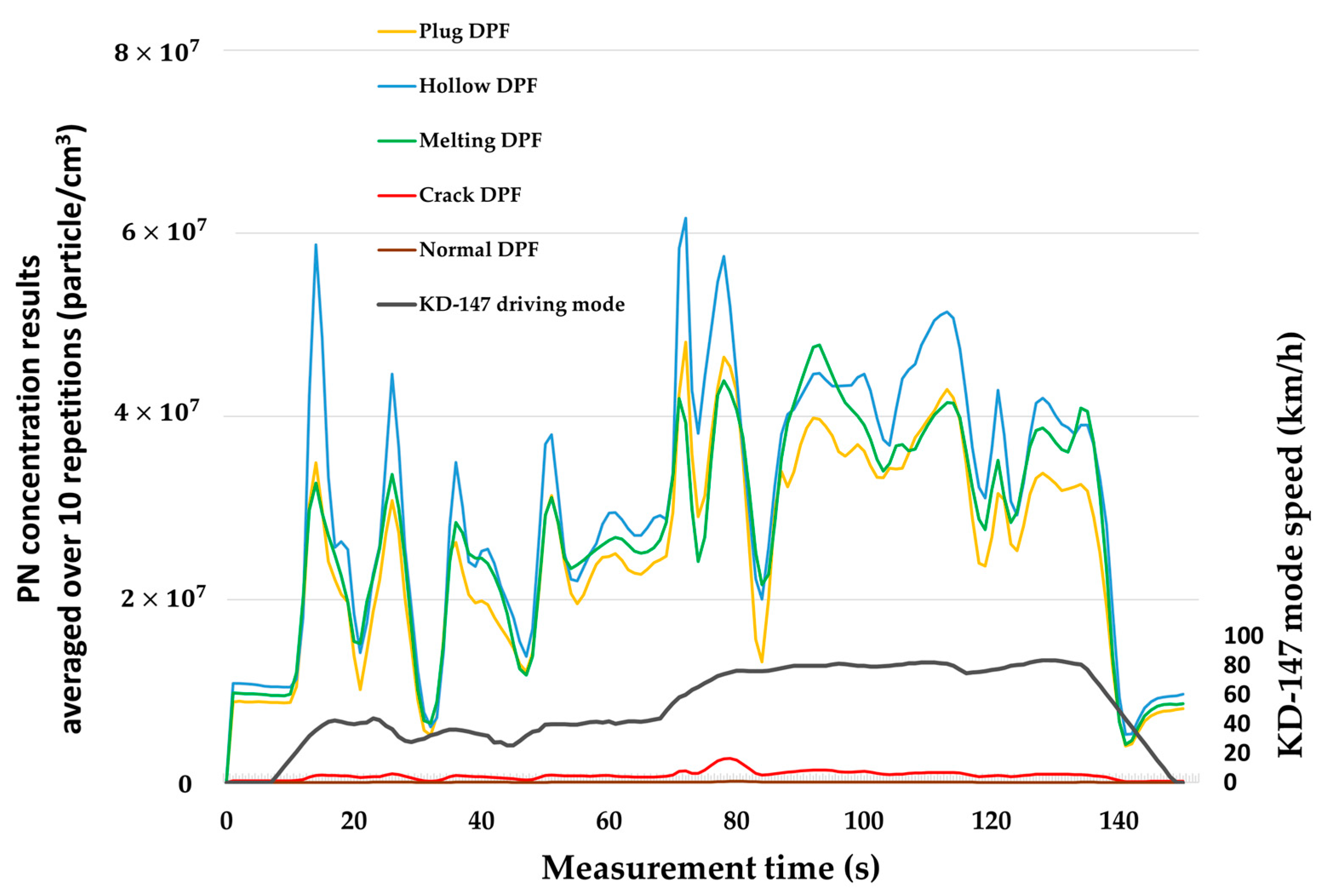

3.3. Results of Emission Particle Number Concentration by DPF Damage Type

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DPF | Diesel Particulate Filter |

| SCR | Selective Catalyst Reduction |

| PM | Particulate Matter |

| OPA-102 | Opacity Meter |

| NPET-3795 | Nanoparticle Emission Tester |

References

- DieselNET_EU: Periodic Technical Inspections (PTI). Available online: https://dieselnet.com/standards/eu/pti.php (accessed on 2 May 2023).

- Korea Ministry of Environment (MOE). Comprehensive Plan Report of Measures for Particulate Matter Management. 2019. Available online: http://www.me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%EB%AF%B8%EC%84%B8%EB%A8%BC%EC%A7%80&menuId=10259&orgCd=&condition.deleteYn=N&seq=7399 (accessed on 13 January 2021).

- Park, J.; Kim, J.; Lee, J.; Kim, S.; Ahn, K.; Han, B. Estimation on Real Driving Emission of Light Duty Truck with Moving Averaging Window Method; National Institute of Environmental Research: Incheon, Republic of Korea, 2018.

- Kwon, M.J.; Park, G.Y.; Kim, S.J.; Han, T.H.; Kim, J.M.; Lee, S.W. Feasibility study on nondestructive measurement of damaged DPF using CR X-ray imaging technique. Trans. Korean Soc. Automot. Eng. 2019, 27, 795–801. [Google Scholar] [CrossRef]

- SAE. Nondestructive X-ray Inspection of Thermal Damage, Soot and Ash Distributions in Diesel Particulate Filters 2009-01-0289; SAE: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Kamp, C.J.; Zhang, S.; Bagi, S.; Wong, V.; Monahan, G.; Sappok, A.; Wang, Y. Ash Permeability Determination in the Diesel Particulate Filter from UltraHigh Resolution 3D X-Ray Imaging and Image-Based Direct Numerical. SAE Int. J. Fuels Lubr. 2017, 10, 608–618. [Google Scholar] [CrossRef]

- Yang, K.; Fox, J.T.; Hunsicker, R. Characterizing Diesel Particulate Filter Failure During Commercial Fleet Use due to Pinholes, Melting, Cracking, and Fouling; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Matsuno, M.; Kitamura, T.; Usui, Y.; Kusaka, J.; Fukuma, T.; Takeda, Y.; Kinoshita, K. Ash accumulation and transport in diesel particulate filters (second report)–Impact of active Regeneration frequency on Ash distribution. Trans. Soc. Automot. Eng. Jpn. 2018, 49, 1199–1204. [Google Scholar]

- Ismail, B.; Ewing, D.; Chang, J.; Cotton, J. Development of a non-destructive neutron radiography technique to measure the three-dimensional Smoke deposition profiles in diesel engine exhaust systems. J. Aerosol Sci. 2004, 35, 1275–1288. [Google Scholar] [CrossRef]

- Merkel, G.A.; Culter, W.A.; Warren, C.J. Thermal Durability of Wall-Flow Ceramic Diesel Particulate Filters. SAE Trans. 2001, 110, 168–182. [Google Scholar]

- Abramoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with Image. J. Biophotonics Int. 2003, 11, 36–42. [Google Scholar]

- Lee, S.-H.; Kim, H.-S.; Park, J.-H. On-Road Investigation of PM Emission of Diesel Aftertreatment Technologies (DPF, Urea-SCR). 2011. Available online: https://www.semanticscholar.org/paper/On-road-Investigation-of-PM-Emissions-of-Diesel-Lee-Kim/563bd9ce03a04795a3fdd0f73e5a82fb9834acd2 (accessed on 2 May 2023).

- Sappok, A.; Wong, V. Ash Effects on Diesel Particulate Filter Pressure Drop Sensitivity to Smoke and Implications for Regeneration Frequency and DPF Control; SAE 2001-01-0811; SAE: Warrendale, PA, USA, 2010. [Google Scholar]

- Roshani, M.; Phan, G.; Jammal, P.; Ali, M.; Roshani, G.H.; Hanus, R.; Duong, T.; Corniani, E.; Nazemi, E.; Kalmoun, E.M. Evaluation of flow pattern recognition and void fraction measurement in two phase flow independent of oil pipeline’s scale layer thickness. Alex. Eng. J. 2021, 60, 1955–1966. [Google Scholar] [CrossRef]

- Cho, J.-G.; Lee, D.-M. Research on the Relation of the Exhaust Gas Concentration between Lug-Down3 Test Mode and D147 Test Mode on the Driving Car Using Diesel Fuel. In Proceedings of the Korea Air Pollution Research Association Conference; Korean Society for Atmospheric Environment: Seoul, Republic of Korea, 2008; pp. 62–65. [Google Scholar]

- Salgado, W.L.; Dam, R.S.D.F.; Teixeira, T.P.; Conti, C.C.; Salgado, C.M. Application of artificial intelligence in scale thickness prediction on offshore petroleum using a gamma-ray densitometer. Radiat. Phys. Chem. 2020, 168, 108549. [Google Scholar] [CrossRef]

- Kim, J.-H.; Oh, K.-C.; Lee, K.-B.; Kim, D.-J.; Lee, C.-H.; Lee, C.B. DPF Crack State. An Experimental Study on PM Emission Characteristics According to Annual Conference and Exhibition. 2010, pp. 921–927. Available online: https://www.nanoparticles.ch/archive/2010_Lee1_PR.pdf (accessed on 2 May 2023).

- Kwon, M.J.; Park, G.Y.; Lim, H.J.; Kim, J.J.; Kim, K.H.; Song, H.Y.; Lee, S.W. A study on the performance deterioration of SCR for heavy-duty diesel vehicles. SAE Pap. 2019, 1, 2235. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018; pp. 606–608. [Google Scholar]

- Clark, N.N.; Kern, J.M.; Atkinson, C.M.; Nine, R.D. Factors affecting heavy-duty diesel vehicle emissions. J. Air Waste Manag. Assoc. 2002, 52, 1026–1034. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Engine Type | D4EA (CRDI VGT) |

|---|---|

| Length | 4500 mm |

| Width | 1845 mm |

| Height | 1740 mm |

| Empty vehicle weight (curb weight) | 1745 kg |

| Gross vehicle weight | 2185 kg |

| Displacement | 1991 cc |

| Rated power | 126/4000 (PS/rpm) |

| Max. number of passengers | 7 |

| Number of cylinders | 4 |

| Type of fuel | Diesel |

| First type exhaust emission reduction | DOC: ceramic type, 400 cpsi DPF: |

| device (DOC + DPF) | cordierite type, 200 cpsi |

| Warm-up mode | Vehicle runs at a speed of 50 ± 6.2 km/h with a load equal to 40% of the rated engine output based on the chassis power and after preheating for 40 s. |

| To form the inspection mode, the set load horsepower and running speed of the vehicle to be measured must be maintained according to the mode configuration requirements. | |

| In the event of any deviation from the mode configuration requirement in the preheating mode, a restart is performed from the time at which the deviation from the mode configuration requirement occurred. | |

| Driving mode | Immediately after the warm-up mode ends and the chassis power meter roller stops, sudden acceleration and acceleration are performed while traveling from the stopped state (idle). |

| Number of regenerations for each DPF | Once (50–600 s) | |

| Vehicle warm-up time | Approximately 10 min | |

| Exhaust emission measurement | Smoke concentration and particle number | |

| Number of tests/ regenerations | Normal | 10/1 |

| Crack | 10/1 | |

| Melting | 10/1 | |

| Hollow | 10/1 | |

| Plug | 10/1 | |

| Nation | Effective Date | PN TLV | Applied Range |

|---|---|---|---|

| Netherlands | July 2022 | 1,000,000 | LD: Euro 3, 4, 5, and 6; HD: Euro 6 |

| Belgium | July 2022 | 1,000,000 | LD: Euro 5b–6 |

| Germany | July 2023 | 250,000 | Diesel: LD: Euro 6; HD: Euro 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, G.; Park, S.; Hwang, T.; Oh, S.; Lee, S. A Study on the Impact of DPF Failure on Diesel Vehicles Emissions of Particulate Matter. Appl. Sci. 2023, 13, 7592. https://doi.org/10.3390/app13137592

Park G, Park S, Hwang T, Oh S, Lee S. A Study on the Impact of DPF Failure on Diesel Vehicles Emissions of Particulate Matter. Applied Sciences. 2023; 13(13):7592. https://doi.org/10.3390/app13137592

Chicago/Turabian StylePark, Giyoung, Saewoong Park, Taewon Hwang, Sangki Oh, and Seangwock Lee. 2023. "A Study on the Impact of DPF Failure on Diesel Vehicles Emissions of Particulate Matter" Applied Sciences 13, no. 13: 7592. https://doi.org/10.3390/app13137592

APA StylePark, G., Park, S., Hwang, T., Oh, S., & Lee, S. (2023). A Study on the Impact of DPF Failure on Diesel Vehicles Emissions of Particulate Matter. Applied Sciences, 13(13), 7592. https://doi.org/10.3390/app13137592