Research on the Safety Assessment of Corbel Beams of Reservoir Radial Gates Based on Real States

Abstract

:1. Introduction

2. Corbel Beam Structural Quality Inspection and Analysis

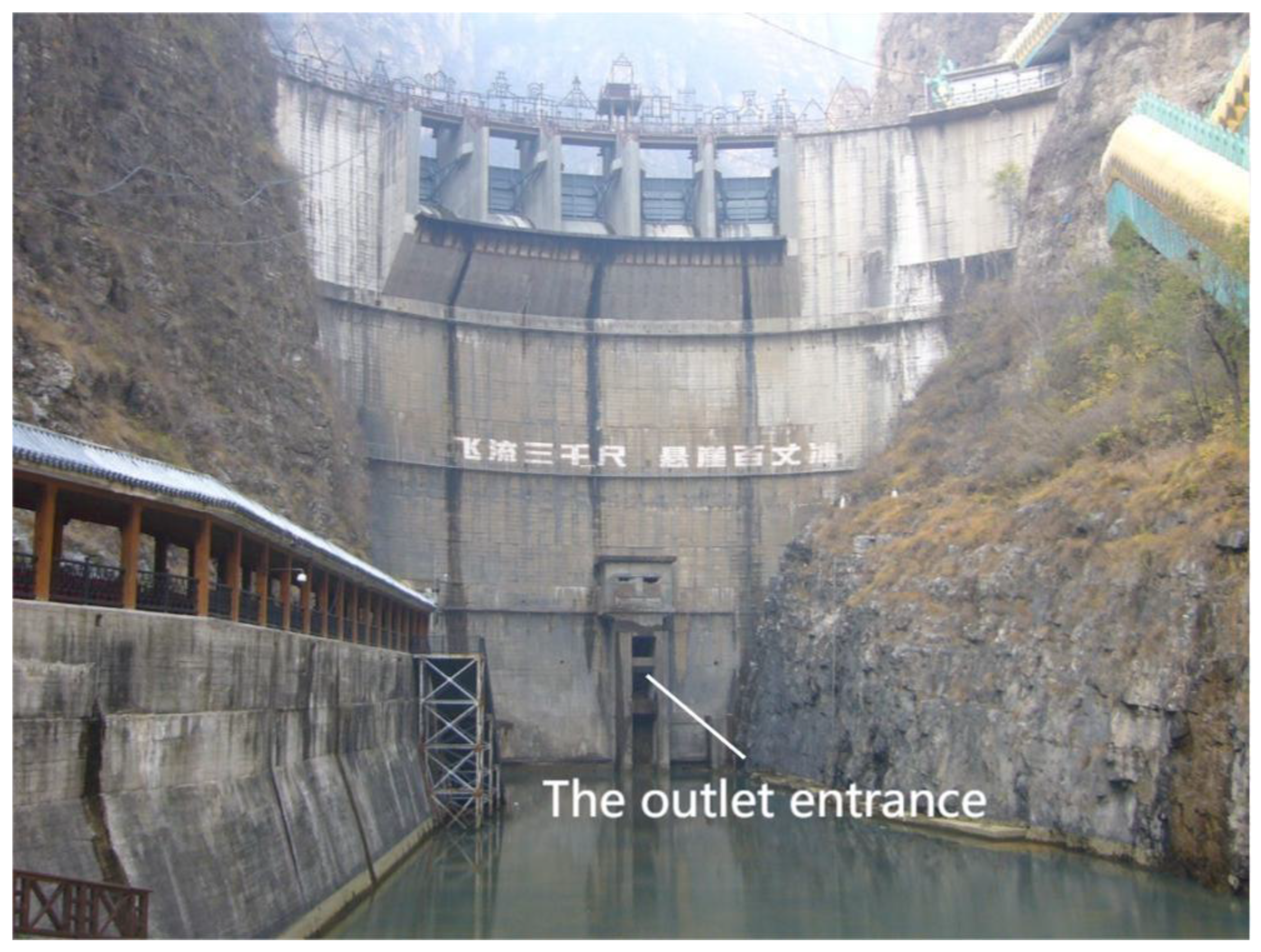

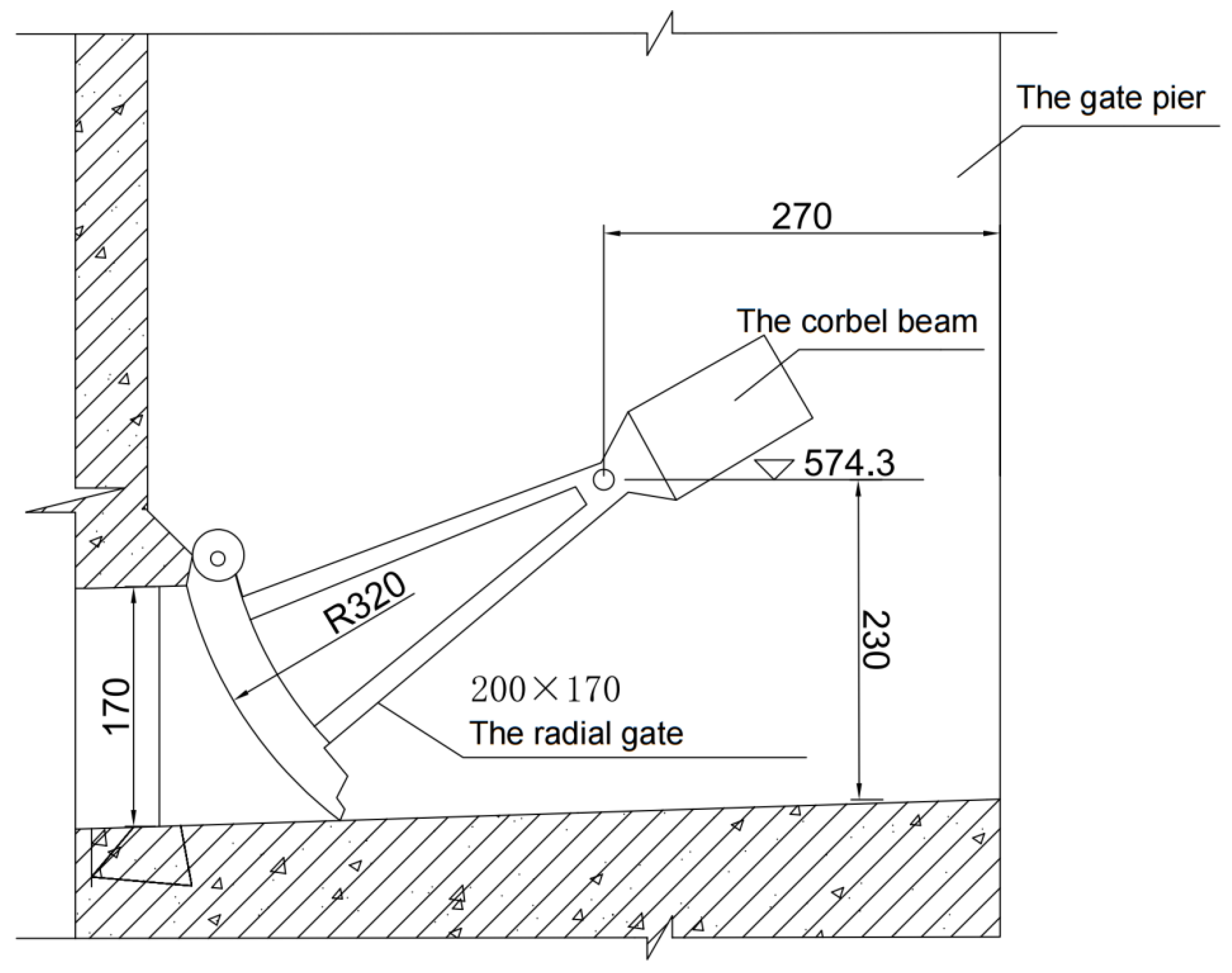

2.1. Project Overview

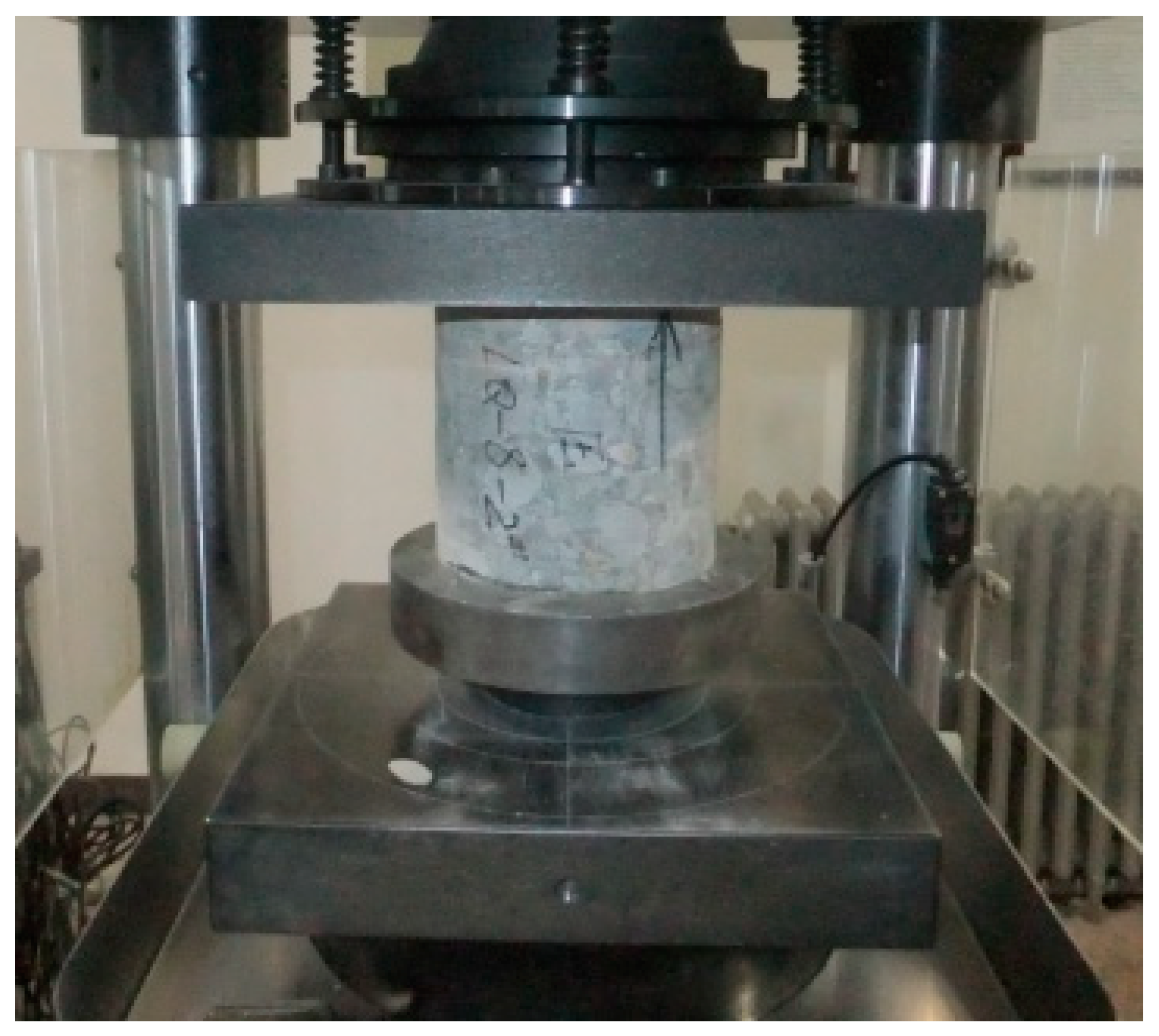

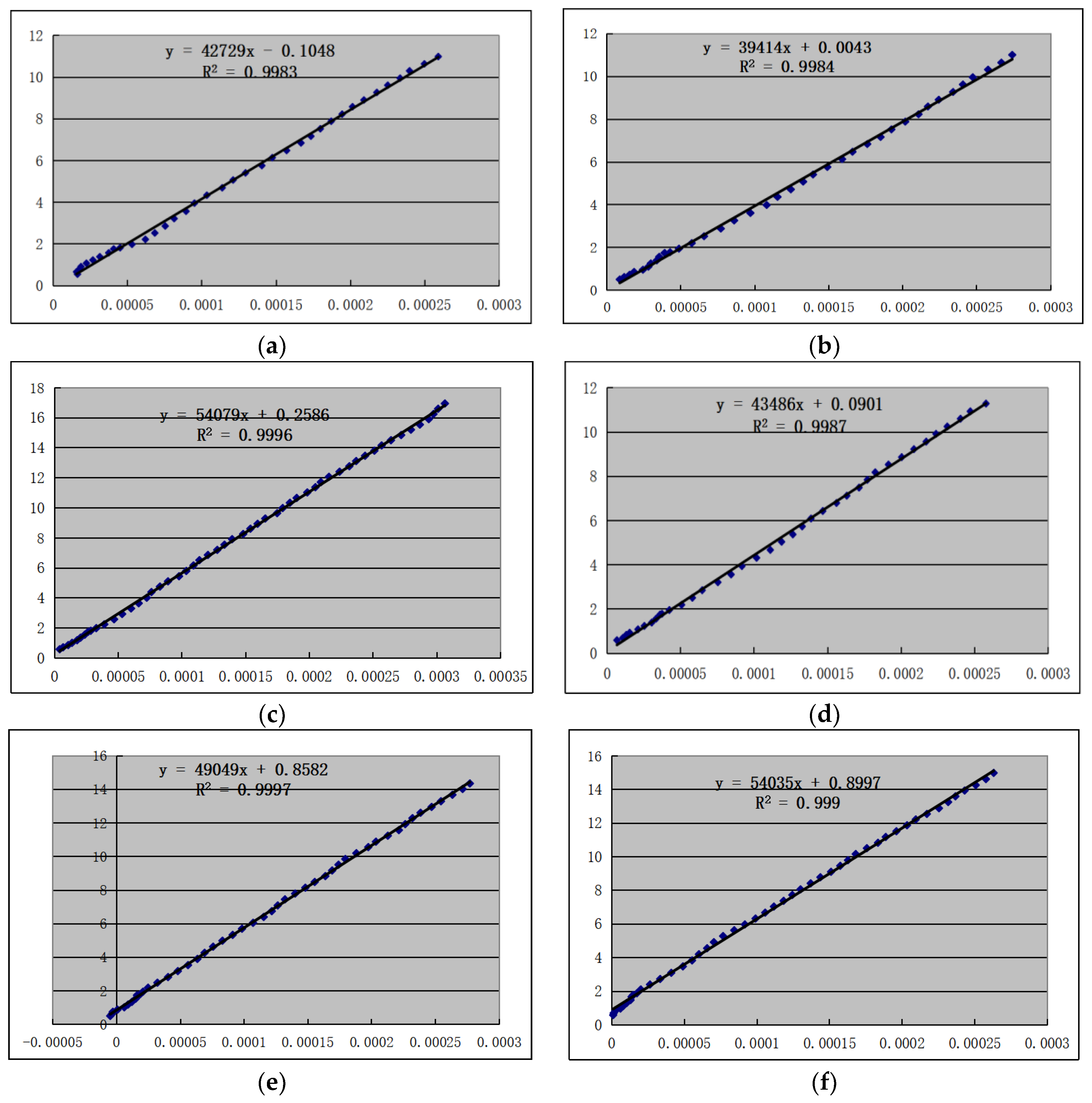

2.2. Concrete Quality Inspection of the Corbel Beam Structure

2.3. Concrete Quality Inspection Results and Analysis of Corbel Beam Structure

- —Static compressive elastic modulus, GPa;

- —Stress increase value from 0.5 MPa to 40% failure stress, MPa;

- —The strain increase value from the corresponding strain of 0.5 MPa to the corresponding strain of 40% failure stress.

- —load, kN;

- —The bearing area of the test piece, mm2;

- —deformation value, mm;

- —Measuring the deformed gauge length, mm.

3. Finite Element Simulation and Safety Review of the Corbel Beam of the Radial Gate

3.1. Load Calculation

3.2. Structural Safety Review Methods for Corbel Beams

- (1)

- Safety assessment by theoretical mechanics method

- (2)

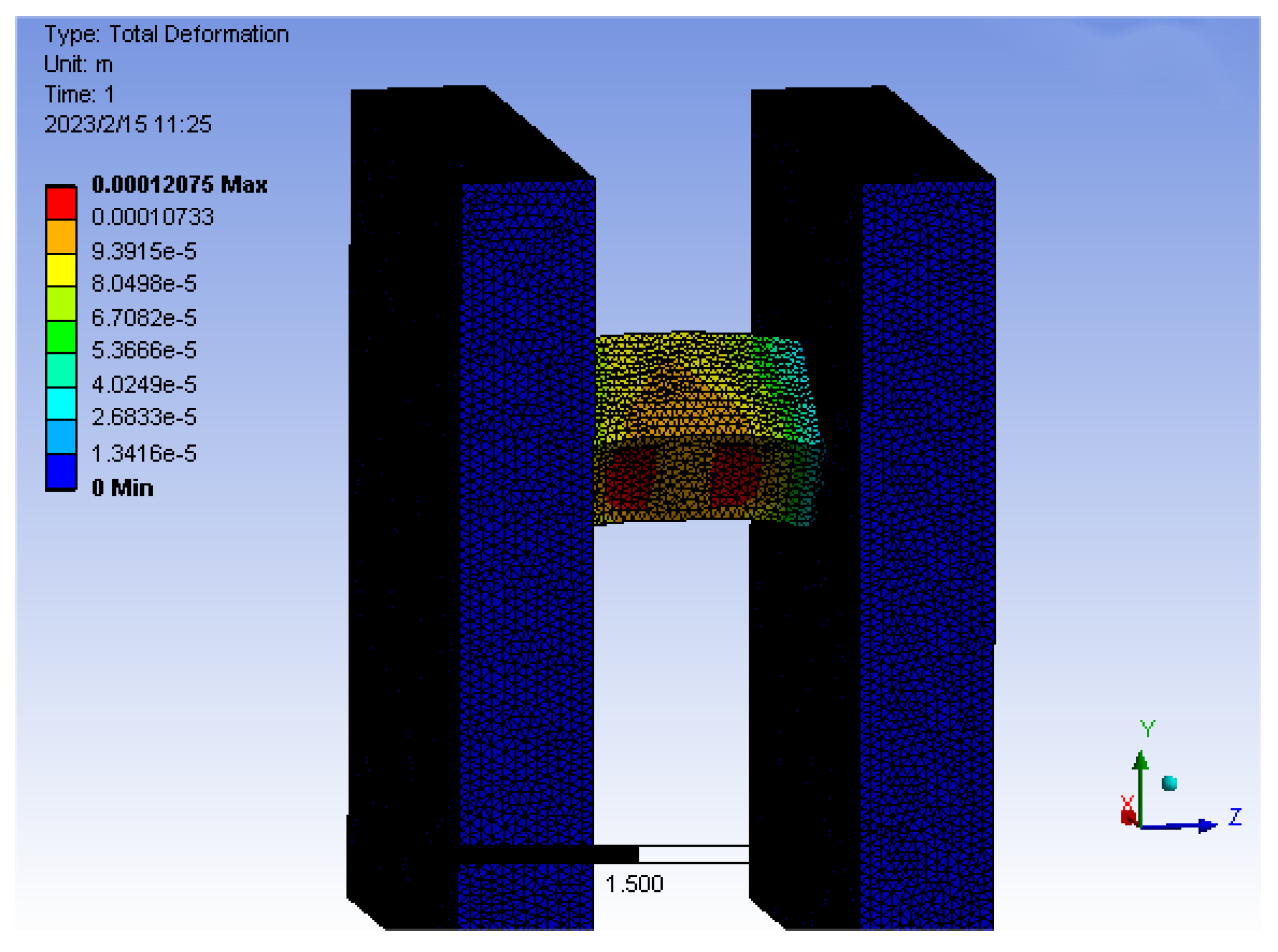

- Structural safety assessment of corbel beams by finite element simulation based on real state

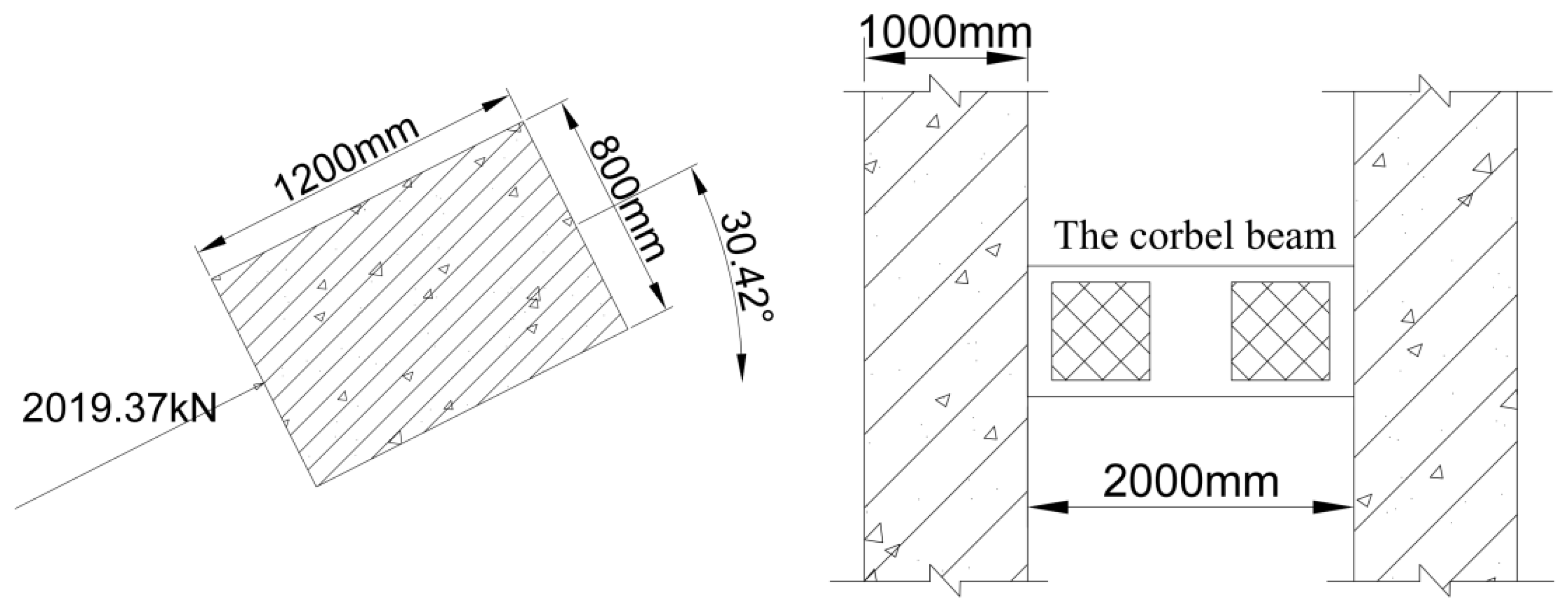

3.3. Computational Model

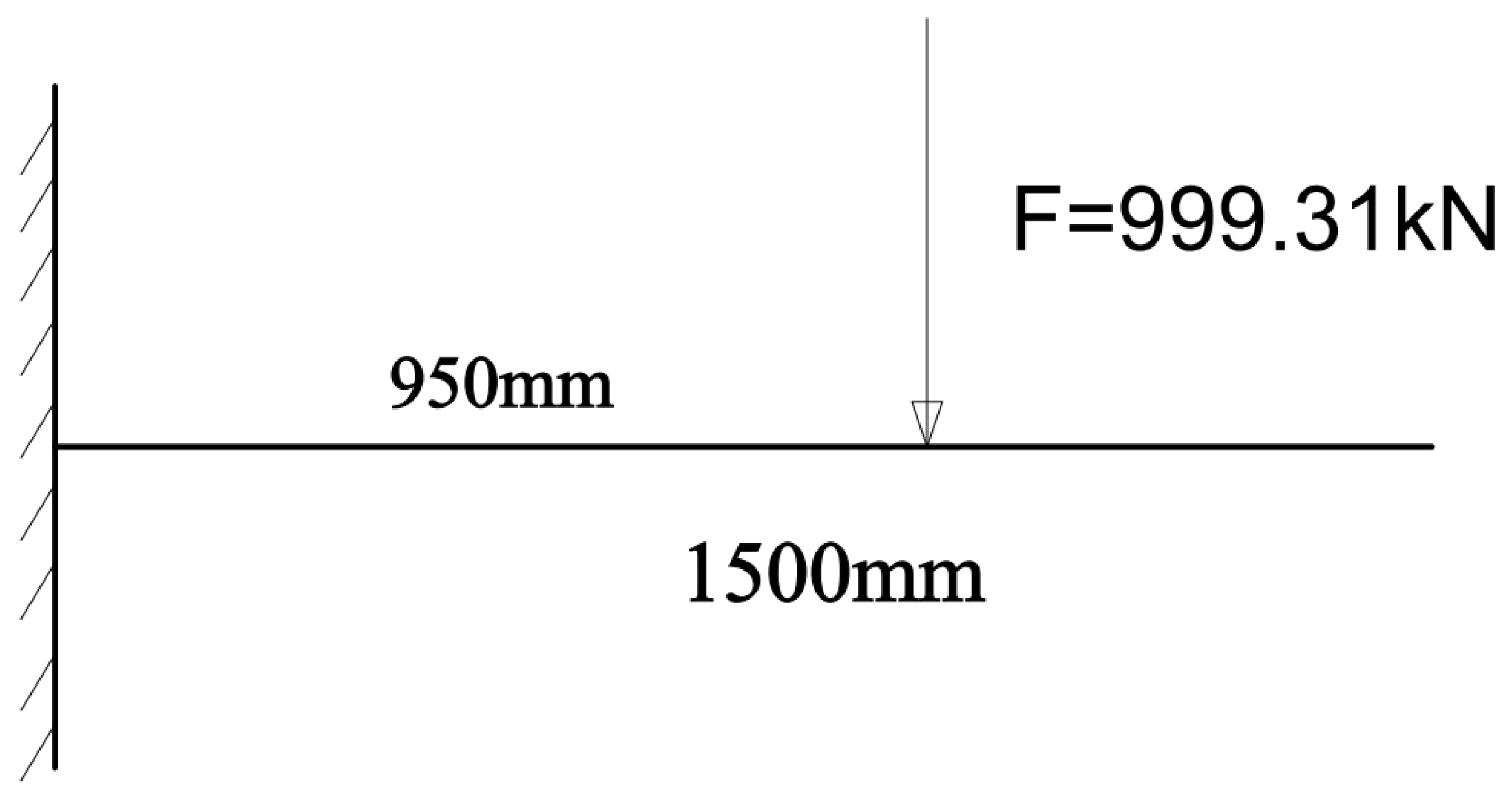

- —The thrust force acting on the corbel, F = 999.31 kN;

- —The distance between the force point and the edge, = 950 mm.

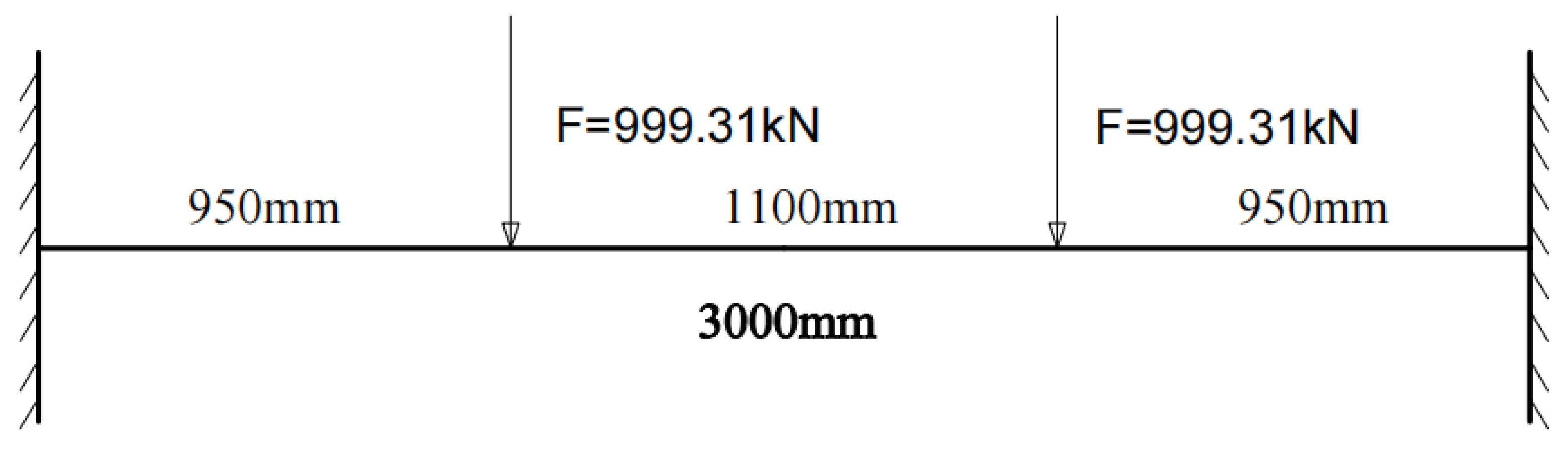

- —The thrust force acting on the corbel beam, F = 999.31 kN.

- —The distance between the force point and the midpoint of the gate pier on both sides, = 950 mm.

- = /, is the distance between the midpoint of the gate pier on both sides, = 3000 mm.

3.4. Analysis of Calculation Results and Safety Review

- (1)

- Safety assessment by theoretical mechanics method

- (2)

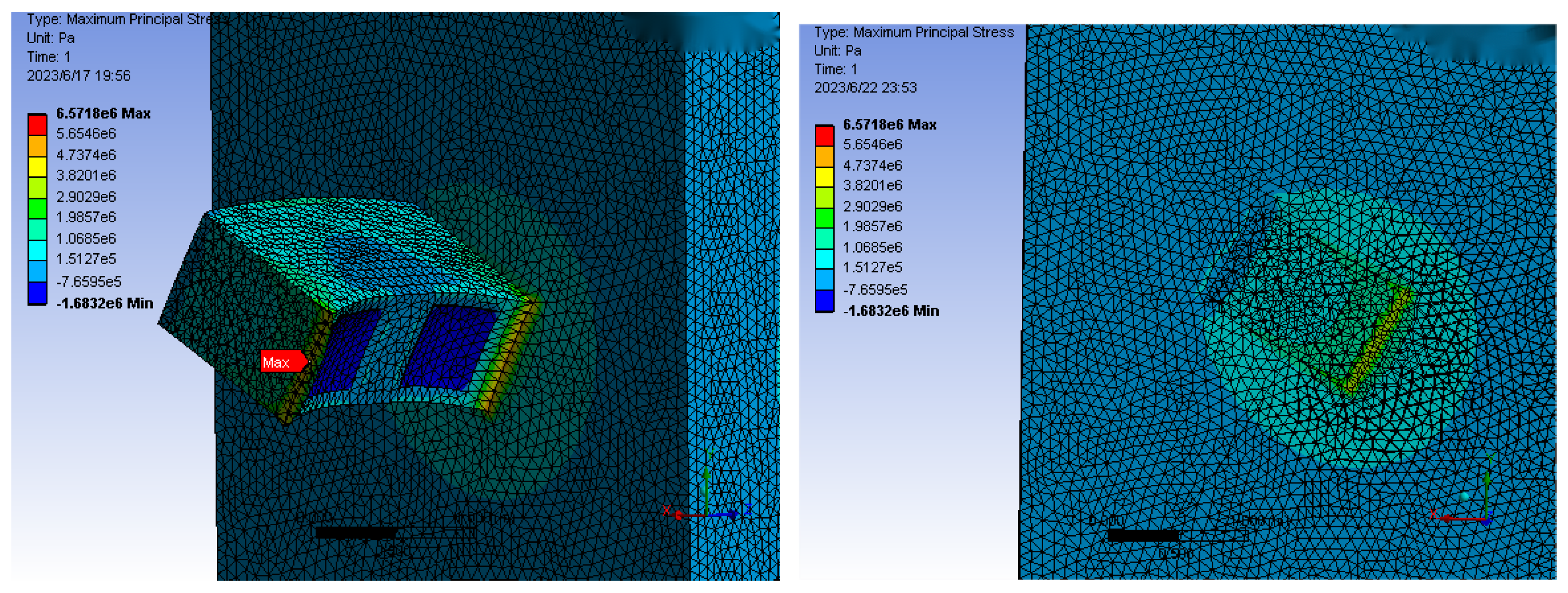

- Structural safety assessment of corbel beams by finite element simulation based on real states

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.L.; Jin, Y.G.; Chen, X.L.; Duan, Q.C.; Zhang, Z.; Lei, X.H.; Chang, W.J. Comparison of LSTM neural network and gauge analysis method in overflow calculation of radial gates. S. N. Water Divers. Water Conserv. Sci. Technol. 2022, 20, 590–599. (In English) [Google Scholar]

- Yang, S.; Tao, G.H.; Qin, Z.Q.; He, W.; Li, Y.F. Static characteristics of table hole radial gate support arm and its supporting structure based on ANSYS. Water Sci. Cold Zone Eng. 2022, 5, 32–34. [Google Scholar]

- Zhang, B.Z.; Jing, X.C. Theoretical analysis and simulation calculation of hydrodynamic pressure pulsation effect and flow induced vibration response of radial gate structure. Sci. Rep. 2022, 12, 21932. [Google Scholar] [CrossRef]

- SL191-2008[S].2008; Code for the Design of Hydraulic Concrete Structures. Ministry of Water Resources: Beijing, China, 2008.

- Abdul-Razzaq, K.S.; Dawood, A.A.; Mohammed, A.H. A Review of Previous Studies on the Reinforced Concrete Corbels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 022057. [Google Scholar] [CrossRef]

- Madhkhan, M.; Bahrami, S. Performance of the modified precast beam to column connection placed on a concrete corbel. Civ. Eng. Infrastruct. J. 2019, 52, 365–377. [Google Scholar]

- Wang, W.D.; Meng, Z.G.; Zhang, Q. The rationality of using corbel support beam in deep-hole radial gates of large and medium-sized reservoirs. Shanxi Water Conserv. Sci. Technol. 1995, 73–76+80. [Google Scholar]

- Zhang, F.D.; Sun, H.J.; Liao, L.B. Spatial force analysis of corbel beam structure of gate pier. In Proceedings of the Sixth National Academic Conference on Structural Engineering; 1997; Volume 2, pp. 468–471. [Google Scholar]

- Liu, W.; Xu, S.H.; Chen, J. Discussion on the design of corbel of radial gate. Heilongjiang Water J. 2002, 42–43. [Google Scholar]

- Yan, D.Q.; Zhang, R. Simplified calculation of corbel beam structure of gate pier. Haihe Water Resour. 2015, 64–66. [Google Scholar]

- He, Z.Q.; Liu, Z.; Ma, Z.J. Investigation of load-transfer mechanisms in deep beams and corbels. ACI Struct. J. 2012, 109, 467–476. [Google Scholar]

- Dawood, A.A.; Kadhum, A.K.; Abdul-Razzaq, K.S. Strength of reinforced concrete corbels-a parametric study. Int. J. Civ. Eng. Technol. IJCIET 2018, 9, 2274–2288. [Google Scholar]

- Dovzhenko, O.; Pohribnyi, V.; Pents, V.; Mariukha, D. Bearing capacity calculation of reinforced concrete corbels under the shear action. MATEC Web Conf. 2018, 230, 02005. [Google Scholar] [CrossRef]

- Abdul-Razzaq, K.S.; Dawood, A.A. Corbel strut and tie modeling-Experimental verification. Structures 2020, 26, 327–339. [Google Scholar] [CrossRef]

- Zhang, G.X. Research on the Real Working State of High Arch Dams and Engineering Applications; China Institute of Water Resources and Hydropower Research: Beijing, China, 2013. [Google Scholar]

- Liu, Y. Study on the Factors Influencing the Real Working State of High Arch Dams; China Institute of Water Resources and Hydropower Research: Beijing, China, 2007. [Google Scholar]

- Chen, S.; Gu, C.; Lin, C.; Hariri-Ardebili, M.A. Prediction of arch dam deformation via correlated multi-target stacking. Appl. Math. Model. 2021, 91, 1175–1193. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Pan, J.W.; Wang, J.T.; Chi, F.D. Temperature field inversion and stress simulation analysis of Xiaowan arch dam during operation. S. N. Water Divers. Water Conserv. Sci. Technol. 2021, 19, 786–794+813. (In English) [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.Q.; Zhang, G.X.; Zhang, L.; Duan, S.H.; Zhang, J. Simulation and inversion analysis of the working properties of Jinping Grade I extra-high arch dam. Water Resour. Hydropower Technol. 2017, 48, 46–51. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Xie, T.; Xu, Y.; Wang, R.L. Evaluation of the mechanical parameters of a reinforced concrete dam based on multi-source data. Struct. Concr. 2022, 23, 652–668. [Google Scholar]

- Ji, Q.W.; Wen, Y.J.; Wang, S.W. Experimental study on strength and permeability of plastic concrete contaminated with lead. People’s Chang. 2022, 53, 158–162+169. [Google Scholar] [CrossRef]

- Saleh, E.; Tarawneh, A.; Dwairi, H.; AlHamaydeh, M. Guide to non-destructive concrete strength assessment: Homogeneity tests and sampling plans. J. Build. Eng. 2022, 49, 104047. [Google Scholar] [CrossRef]

- Lapidus, A.; Bidov, T.; Khubaev, A. The study of the calibration dependences used when testing the concrete strength by nondestructive methods. MATEC Web EDP Sci. 2017, 117, 00094. [Google Scholar] [CrossRef] [Green Version]

- CECS 03-2017[S].2017; Technical Specification for Testing Concrete Strength by Drilling Core Method. China Association for Engineering Construction Standardization: Beijing, China, 2017.

- SL352-2020[S].2020; Test Procedure for Hydraulic Concrete. Ministry of Water Resources of the People’s Republi of China: Beijing, China, 2020.

- Pourbaba, M.; Asefi, E.; Sadaghian, H.; Mirmiran, A. Effect of age on the compressive strength of ultra-high-performance fiber-reinforced concrete. Constr. Build. Mater. 2018, 175, 402–410. [Google Scholar] [CrossRef]

- Conrad, M.; Aufleger, M.; Malkawi, A.I.H. Investigations on the modulus of elasticity of young RCC. In Roller Compacted Concrete Dams; Routledge: Abingdon-on-Thames, UK, 2018; pp. 729–733. [Google Scholar]

- Jin, L.Z.; He, L.; Wu, X.K. Experimental study on flexural performance of HRB500 grade reinforced reactive powder concrete beams. Build. Struct. 2015, 45, 87–92. [Google Scholar] [CrossRef]

- Jing, H. Practical calculation procedures for concrete bending members—Calculation of bending moment, crack width and crack width limit control. Build. Des. Manag. 2009, 26, 31–35. [Google Scholar]

- Pratama, M.M.A.; Suhud, R.K.; Puspitasari, P.; Kusuma, F.I.; Putra, A.B.N.R. Finite element analysis of the bending moment-curvature of the double-layered graded concrete beam. IOP Conf. Ser. Mater. Sci. Eng. 2019, 494, 012064. [Google Scholar] [CrossRef]

- Lu, C.C.; Fan, W.J.; Rui, Y.Q. Study on the factors influencing the load bearing capacity of reinforced concrete beams based on ABAQUS. In Proceedings of the 2022 Industrial Building Academic Exchange Conference; 2022; pp. 357–362+239. [Google Scholar]

- Armaghani, D.J.; Hatzigeorgiou, G.D.; Karamani, C.; Skentou, A.; Zoumpoulaki, I.; Asteris, P.G. Soft computing-based techniques for concrete beams shear strength. Procedia Struct. Integr. 2019, 17, 924–933. [Google Scholar] [CrossRef]

- Marí, A.; Bairán, J.; Cladera, A.; Oller, E.; Ribas, C. Shear-flexural strength mechanical model for the design and assessment of reinforced concrete beams. Struct. Infrastruct. Eng. 2015, 11, 1399–1419. [Google Scholar] [CrossRef]

- Feng, D.C.; Wu, G.; Lu, Y. Finite element modelling approach for precast reinforced concrete beam-to-column connections under cyclic loading. Eng. Struct. 2018, 174, 49–66. [Google Scholar]

- Wei, Z.P.; Wang, H.T.; Liu, Y.; Meng, P.; Qi, Z.P. Hydraulic Performance Analysis of Turbine Based on ANSYS Finite Element Calculation Platform. Hydropower Energy Sci. 2022, 40, 199–202+54. [Google Scholar]

- Earij, A.; Alfano, G.; Cashell, K.; Zhou, X. Nonlinear three-dimensional finite-element modelling of reinforced- concrete beams: Computational challenges and experimental validation. Eng. Fail. Anal. 2017, 82, 92–115. [Google Scholar] [CrossRef]

- Hua, M.; Li, T.C. Research on early warning indicators for monitoring uneven settlement of sluice gate foundations based on three-dimensional finite element simulation. Water Resour. Hydropower Technol. 2022, 53 (Suppl. S1), 282–290. (In English) [Google Scholar]

- Su, C.; Niu, X.X.; Yin, X.M.; Yin, C. Effects of different loading methods on structural stresses in sluice gate renovation projects. Hydropower Energy Sci. 2014, 32, 95–98. [Google Scholar]

- Kolupaev, V.A. Equivalent Stress Concept for Limit State Analysis; Springer: Darmstad, Germany, 2018. [Google Scholar]

- Mei, H.; Kiousis, P.D.; Ehsani, M.R.; Saadatmanesh, H. Confinement effects on high-strength concrete. Struct. J. 2001, 98, 548–553. [Google Scholar]

| Gate Hole Height HG | 1.70 m | Gate Pier Concrete Design Grade | C20 |

|---|---|---|---|

| Support beam section b | 0.8 m | Design grade of corbel concrete | C20 |

| Gate width | 2.00 m | Support beam section h | 1.2 m |

| Upstream head Hs | 49.70 m | The thickness of gate pier B | 1.00 m |

| Design tensile strength of reinforcing steel | Hydrostatic pressure Px (kN) | Hydrostatic pressure Py (kN) | Self-weight of corbel beam (kN) |

| 210 N/mm2 | 1783.6 | 945.9 | 44.1 |

| Core Samples Number | Coring Position | Test Piece Number | Core Sample Diameter (mm) | Compressive Strength (MPa) |

|---|---|---|---|---|

| 1 | The left side of the first layer of the trestle bridge near the shoulder of the dam | LQ-1-1 | 149.4 | 38.6 |

| LQ-1-2 | 148.8 | 40.0 | ||

| LQ-1-3 | 150.8 | 45.9 | ||

| 2 | The middle of the first layer of the trestle | LQ-2-2 | 149.3 | 30.9 |

| 3 | The right side of the first layer of the trestle bridge near the shoulder of the dam | LQ-3-1 | 149.5 | 39.9 |

| LQ-3-2 | 149.9 | 32.8 | ||

| LQ-3-3 | 149.7 | 26.2 | ||

| 4 | The right side of the second layer of the trestle bridge near the shoulder of the dam | LQ-4-1 | 148.7 | 40.6 |

| LQ-4-2 | 150.1 | 42.6 | ||

| LQ-4-3 | 150.2 | 40.6 | ||

| 5 | The middle of the second layer of the trestle | LQ-5-1 | 150.4 | 40.9 |

| LQ-5-2 | 150.4 | 40.5 | ||

| LQ-5-3 | 150.8 | 43.5 | ||

| 6 | The left side of the second layer of the trestle bridge near the shoulder of the dam | LQ-6 | 150.4 | 45.9 |

| 7 | The right side of the third layer of the trestle bridge near the shoulder of the dam | LQ-7-1 | 150.5 | 42.5 |

| LQ-7-2 | 150.3 | 45.4 | ||

| LQ-7-3 | 150.4 | 41.9 | ||

| LQ-7-4 | 150.3 | 49.4 | ||

| 8 | The middle of the third layer of the trestle | LQ-8-1 | 150.3 | 48.4 |

| LQ-8-2 | 150.2 | 55.4 | ||

| 11 | The top of the dam near the right shoulder | LQ-11-1 | 150.1 | 43.9 |

| Core Samples Number | Coring Position | Specimen Number | Modulus of Elasticity | Average Static Modulus |

|---|---|---|---|---|

| (GPa) | (GPa) | |||

| 2 | The middle of the first layer of the trestle | LQ-2-1 | 42.7 | 47.1 |

| 6 | The left side of the second layer of the trestle bridge near the shoulder of the dam | LQ-6 | 39.4 | |

| 9 | The third layer of the trestle bridge near the left shoulder of the dam | LQ-9 | 54.1 | |

| 10 | Upstream face near the left shoulder of the dam | LQ-10 | 43.5 | |

| 11 | The top of the dam near the right shoulder | LQ-11-2 | 49.0 | |

| LQ-11-3 | 54.0 |

| b (mm) | B (mm) | The Standard Value of Concrete Tensile Strength ftk (N/mm2) | Eccentric Distance of Thrust to Gate Pier Thickness Centerline e0 (mm) |

|---|---|---|---|

| 800 | 1000 | 2.01 | 950 |

| Model 2 Equivalent standard value Fk (kN) | Security judgment result | ||

| 769.04 | 679.53 | Normal | |

| Fx (kN) | Fy (kN) | F (Shear Force) (kN) |

|---|---|---|

| 451.44 | 271.73 | 526.91 |

| b (mm) | B (mm) | The Standard Value of Concrete Tensile Strength ftk (N/mm2) | The Eccentricity of Thrust to Gate Pier Thickness Centerline e0 (mm) |

|---|---|---|---|

| 800 | 1000 | 2.01 | 950 |

| Model 4 standard value Fk (kN) | Security judgment result | ||

| 769.04 | 526.91 | Normal | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Wang, R.; Zhao, Y.; Sun, Y. Research on the Safety Assessment of Corbel Beams of Reservoir Radial Gates Based on Real States. Appl. Sci. 2023, 13, 7578. https://doi.org/10.3390/app13137578

Lin J, Wang R, Zhao Y, Sun Y. Research on the Safety Assessment of Corbel Beams of Reservoir Radial Gates Based on Real States. Applied Sciences. 2023; 13(13):7578. https://doi.org/10.3390/app13137578

Chicago/Turabian StyleLin, Jiayi, Ronglu Wang, Yan Zhao, and Yuelin Sun. 2023. "Research on the Safety Assessment of Corbel Beams of Reservoir Radial Gates Based on Real States" Applied Sciences 13, no. 13: 7578. https://doi.org/10.3390/app13137578