Trawl Grid Structure Design and Analysis Using the Finite Element Method

Abstract

:1. Introduction

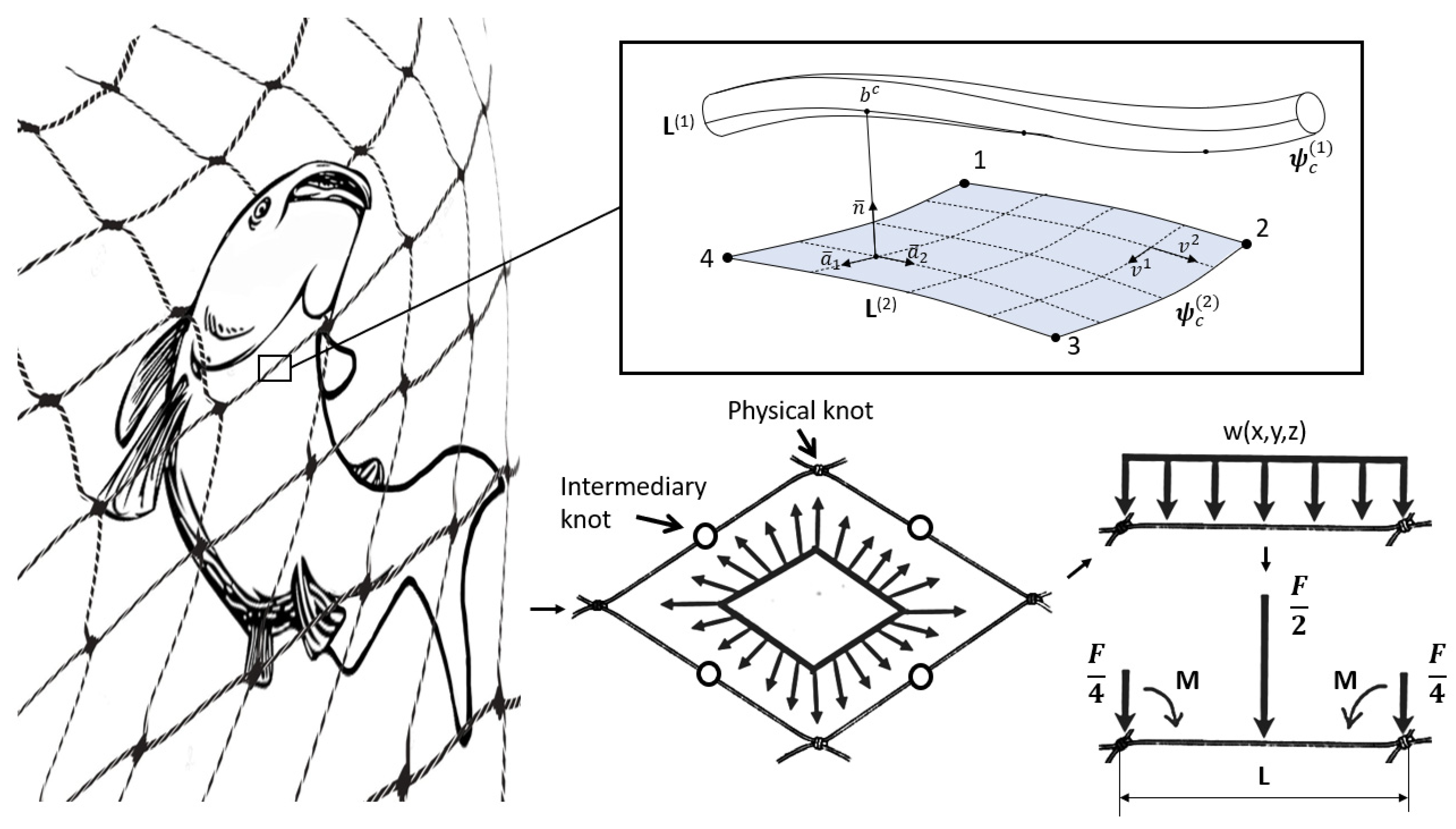

2. The Interaction of the Fishnet Structure

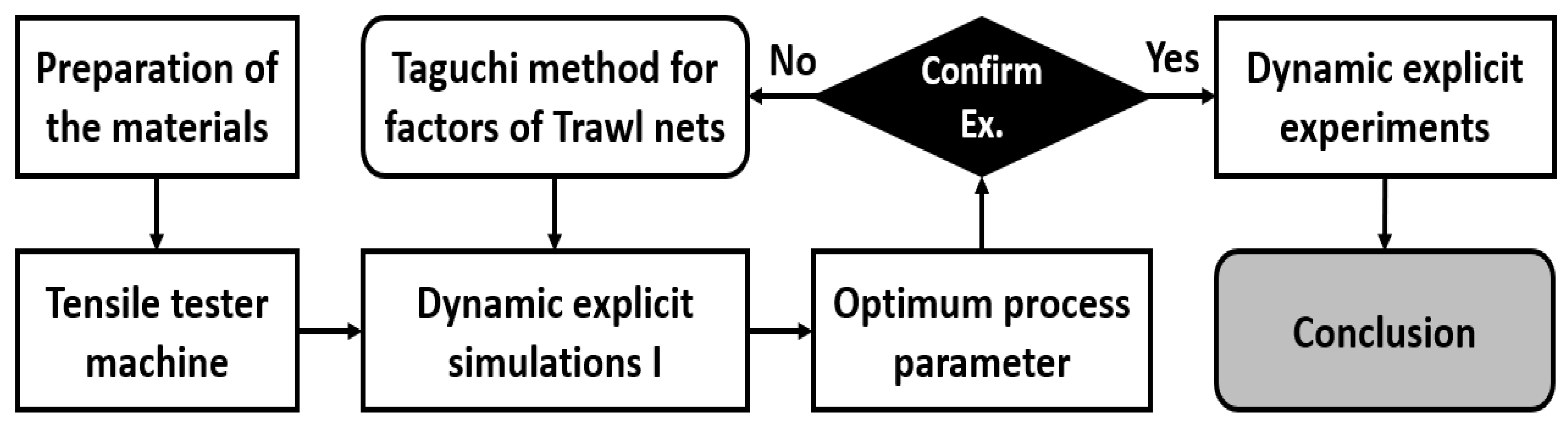

3. Method

3.1. Preparation of the Materials

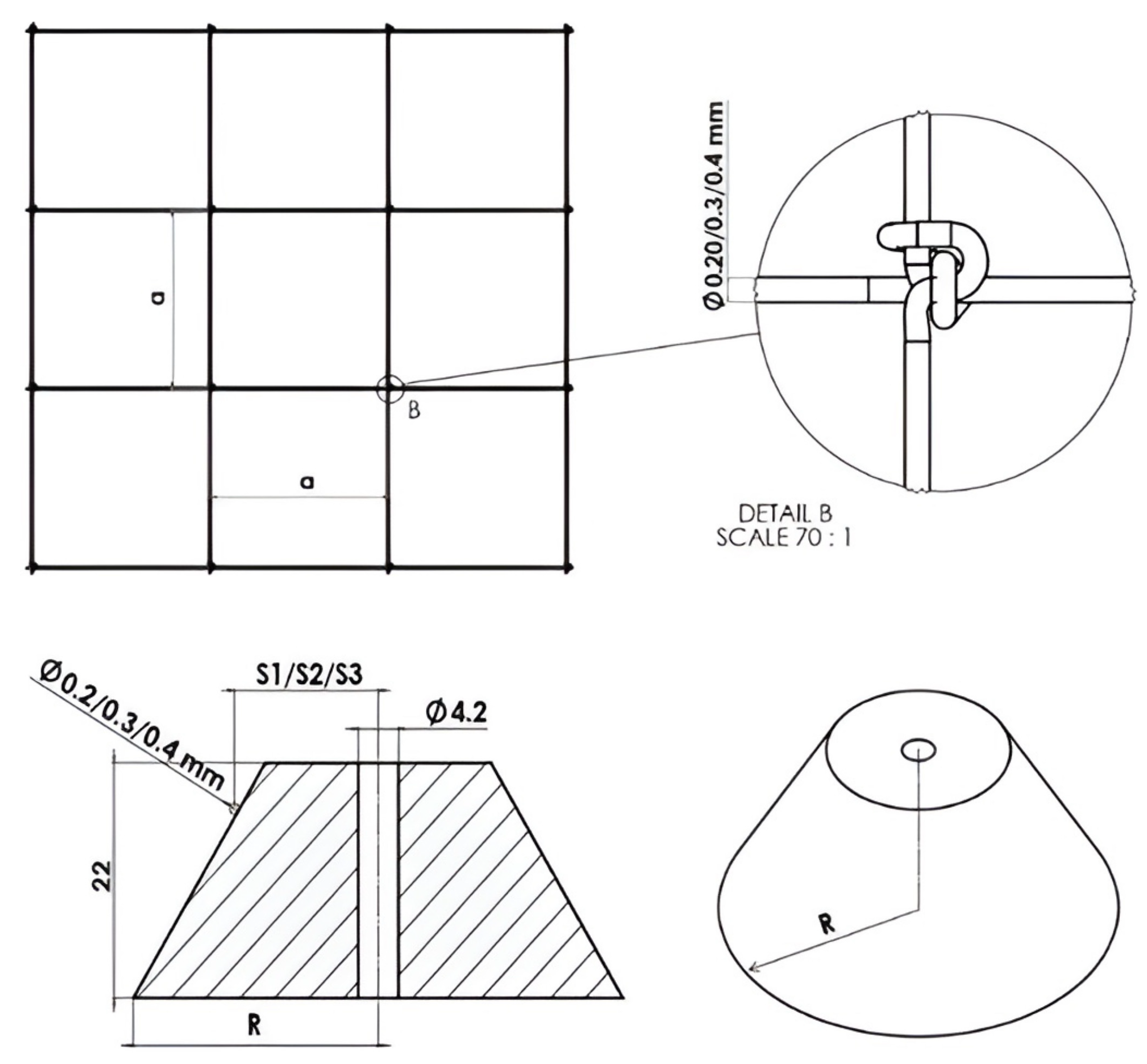

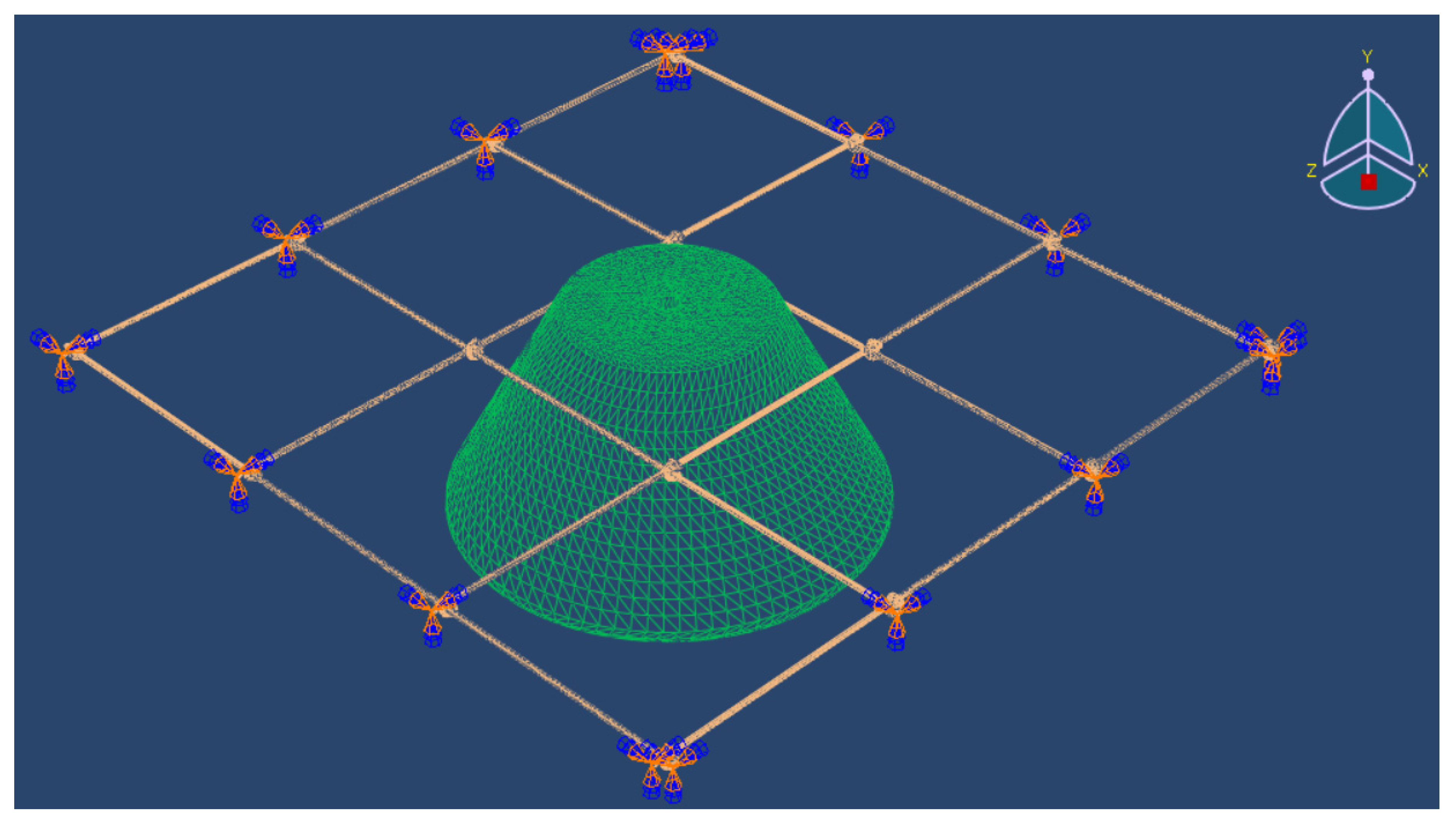

3.2. Modeling the Objects for Simulations

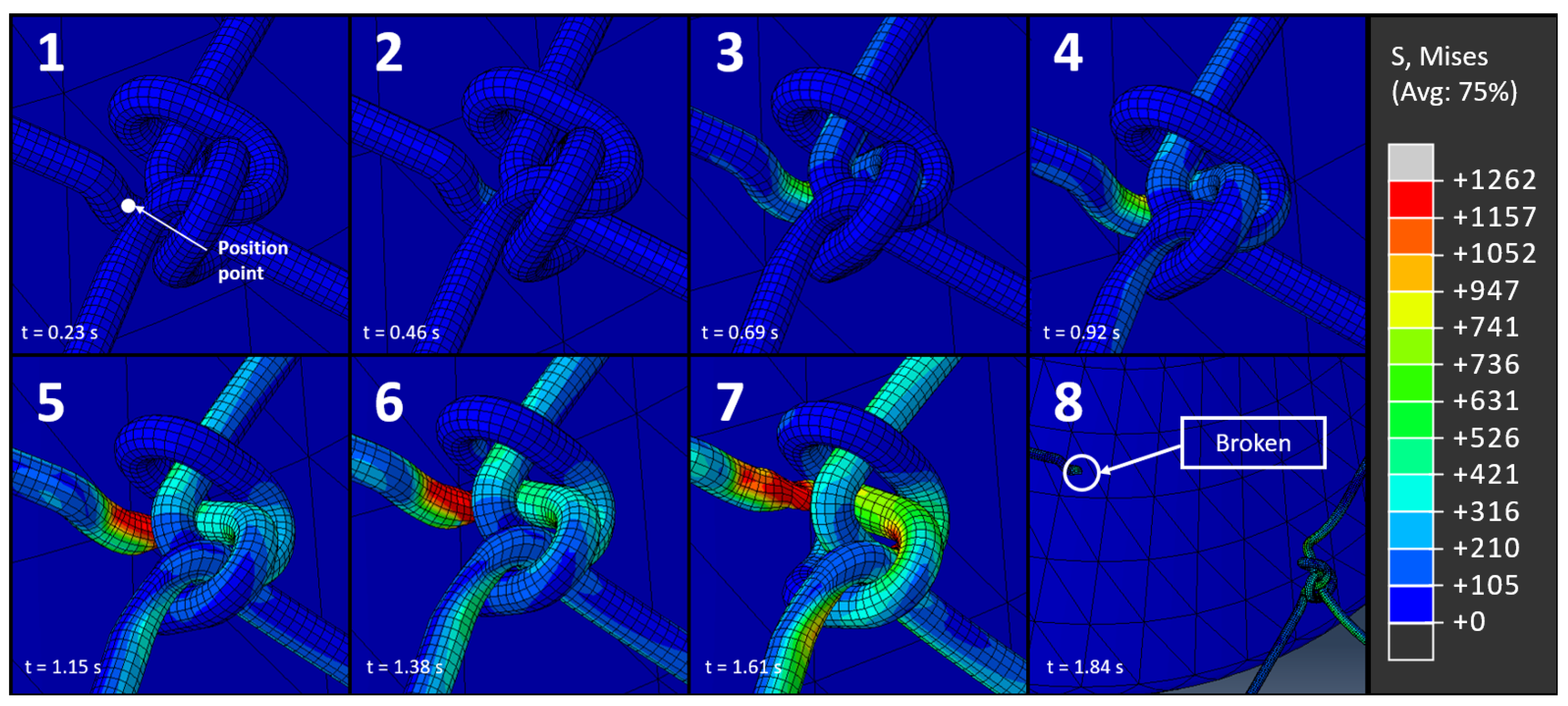

3.3. Using the Finite Element Method (FEM) to Simulate the Grid Cells

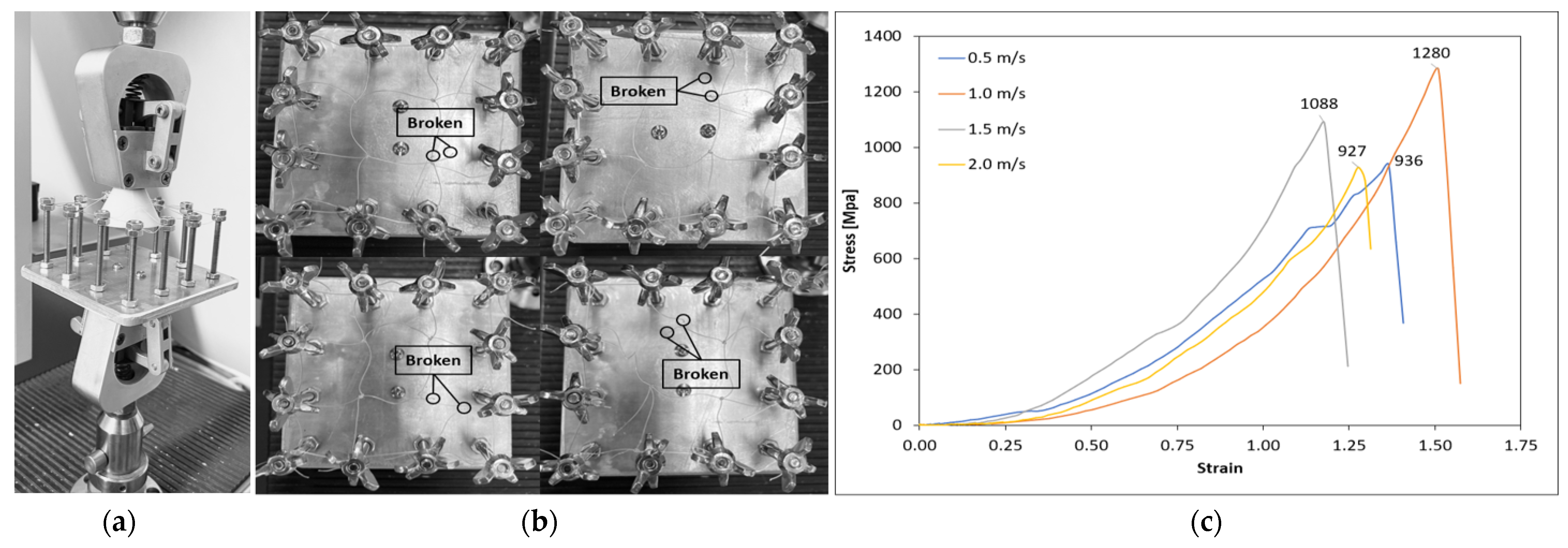

3.4. Confirmation Experiments

4. Results and Discussion

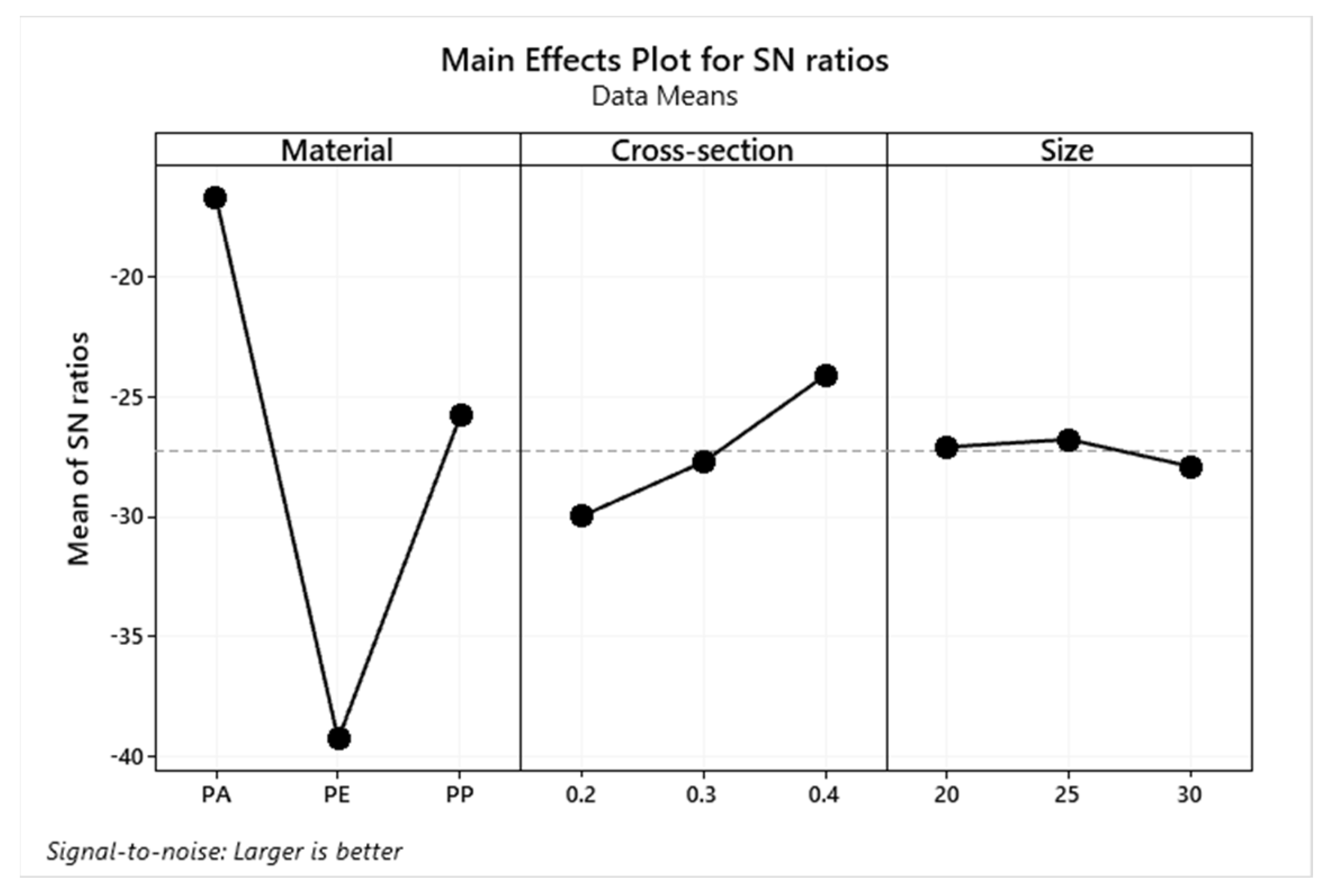

4.1. The Taguchi Method

4.2. Interactions of the Fishnet Structure

5. Conclusions

- -

- The use of the Taguchi approach improved the research on the technological aspects of the trawl grid structure. The findings indicate that the material has a significant impact on the mesh structure of up to 93%. Polyamide (PA) is the suggested material because it has a higher contact stiffness matrix than the other two materials. The next most impactful element is the cross-section (0.4 mm), which impacts 6% of the trawl mesh structure. This level of influence can be increased if the angler selects a wider cross-section because the graph tends to rise gradually. The size of the grid just depends on the size of the type of fish and has a relatively minimal impact. This study advises fishermen to use Equation (11) to choose the grid size.

- -

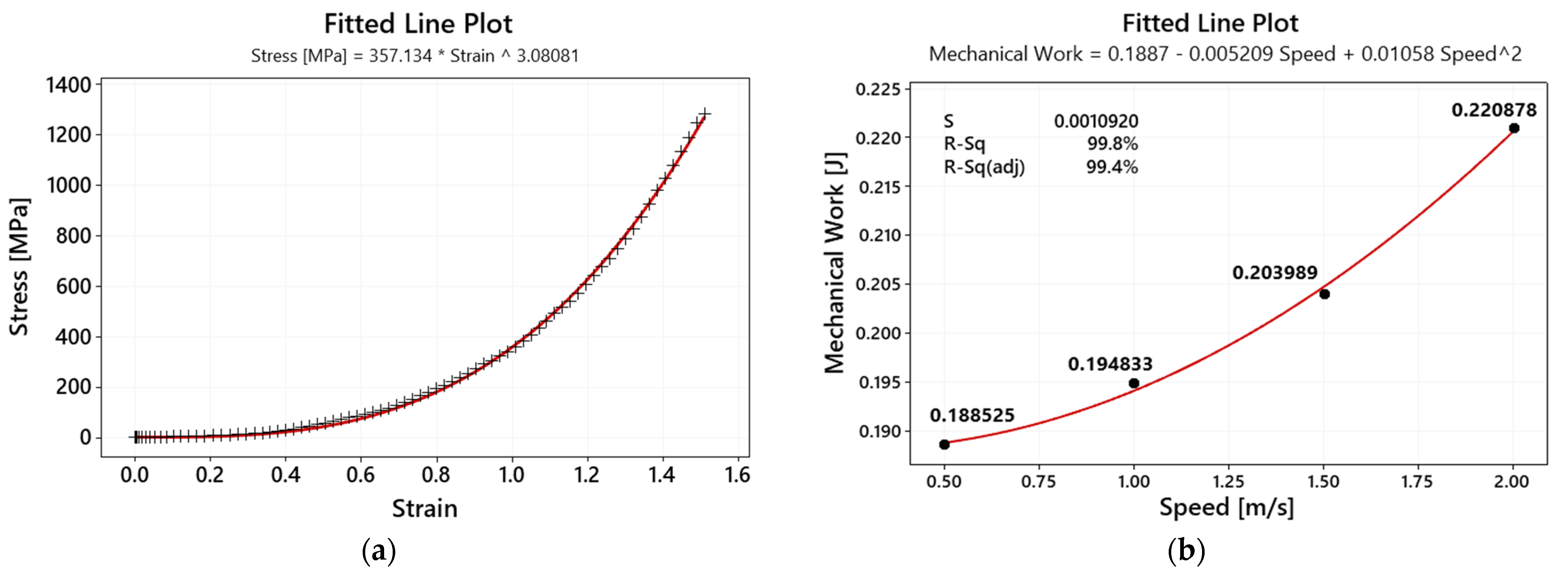

- When a trawl mesh structure is struck by an object, the knots immediately surrounding the impact area experience the highest concentration of stress (Figure 9) and the active rope is simultaneously pulled to affect the object. Breakage is brought on by tension on the passive wire when an object is traveling at 1 m/s, since the maximum stress can reach 1280 MPa. As the object moves away, the stress gradually decreases. Application of the higher-order curve reveals that the stress characteristic curve of the mesh structure is highly reliable, as depicted in Figure 10a.

- -

- In a semi-static environment, the mechanical effort exerted on the mesh structure tends to progressively rise with the increase in the speed of the item exerting the force. Figure 10b depicts the characteristic curve of this factor after the application of the least squares approach, with a confidence level of up to 99.8%.

- -

- Research has significantly improved the reference data for semi-static trawl mesh structures or other forms of grids with comparable structures and features. In the future, the use of more flow factors, water viscosity, and Reynolds coefficient evaluations may lead to more research development.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CSI Research. Report on Vietnam’s Seafood Industry. 2020. Available online: https://finance.vietstock.vn/bao-cao-phan-tich/7566/bao-cao-nganh-thuy-san-viet-nam.html (accessed on 27 August 2020).

- Grottum, J.A.; Beveridge, M. A Review of Cage Aquaculture: Northern Europe; FAO Fisheries Technical Paper; FAO: Rome, Italy, 2007; pp. 126–154. [Google Scholar]

- Sena, S.D.S.; Michael, J.P. A Review of Cage Aquaculture Asia (Excluding China); FAO Fisheries Technical Paper; FAO: Rome, Italy, 2007; pp. 18–48. [Google Scholar]

- Lan, H.Y.; Afero, F.; Huang, C.T.; Chen, B.Y.; Huang, P.L.; Hou, Y.L. Investment Feasibility Analysis of Large Submersible Cage Culture in Taiwan: A Case Study of Snubnose Pompano (Trachinotus anak) and Cobia (Rachycentron canadum). Fishes 2022, 7, 151. [Google Scholar] [CrossRef]

- Bertaglia, E.d.A.; Furtado, W.E.; Silva e Souza, Â.T.; Fernandes, M.C.; Pereira, S.A.; Brasil, E.M.; Mouriño, J.L.P.; Jerônimo, G.T.; Martins, M.L. Influence of Seasonality and Culture Stage of Farmed Nile Tilapia (Oreochromis niloticus) with Monogenean Parasitic Infection. Animal 2023, 13, 1525. [Google Scholar] [CrossRef]

- Tang, H.J.; Chiang, W.S.; Nan, F.H. Engineering Feasibility Assessment of Cage Aquaculture in Offshore Wind Power Generation Areas in Taiwan. Sustainability 2022, 14, 11705. [Google Scholar] [CrossRef]

- Le Bris, F.; Marichal, D. Numerical and experimental study of submerged supple nets: Applications to fish farms. J. Mar. Sci. Technol. 1998, 3, 161–170. [Google Scholar] [CrossRef]

- Xu, Z.; Qin, H. Fluid-structure interactions of cage based aquaculture: From structures to organisms. Ocean Eng. 2020, 217, 107961. [Google Scholar] [CrossRef]

- Cifuentes, C.; Kim, M.J. Numerical simulation of fish nets in currents using a Morison force model. Ocean. Syst. Eng. 2017, 7, 143. [Google Scholar]

- Chen, H.; Christensen, E.D. Development of a numerical model for fluid-structure interaction analysis of flow through and around an aquaculture net cage. Ocean. Eng. 2017, 142, 597–615. [Google Scholar] [CrossRef] [Green Version]

- Su, B.; Kelasidi, E.; Frank, K.; Haugen, J.; Føre, M.; Pedersen, M.O. An integrated approach for monitoring structural deformation of aquaculture net cages. Ocean. Eng. 2021, 219, 108424. [Google Scholar] [CrossRef]

- Jensen, Ø.; Dempster, T.; Thorstad, E.; Uglem, I.; Fredheim, A. Escapes of fishes from Norwegian sea-cage aquaculture: Causes, consequences and prevention. Aquac. Environ. Interact. 2010, 1, 71–83. [Google Scholar] [CrossRef] [Green Version]

- Thierry, B.; Tang, H.; Zhang, J.; Liu, W.; Xu, L.; Hu, F. Experimental Analysis of the Influence of Gear Design and Catch Weight on the Fluid–Structure Interaction of a Flexible Codend Structure Used in Trawl Fisheries. Appl. Sci. 2023, 13, 2505. [Google Scholar] [CrossRef]

- Kristiansen, T.; Faltinsen, O.M. Modelling of current loads on aquaculture net cages. J. Fluids Struct. 2012, 34, 218–235. [Google Scholar] [CrossRef]

- Fujii, F.; Noguchi, H.; Oda, K. Flexible and Incompressive Goal Nets in Soccer. Comput. Methods 2006, 1, 1903–1909. [Google Scholar] [CrossRef]

- Eo, S.; Hong, S.H.; Song, Y.K.; Han, G.M.; Seo, S.; Shim, W.J. Prevalence of small high-density microplastics in the continental shelf and deep sea waters of East Asia. Water Res. 2021, 200, 117238. [Google Scholar] [CrossRef]

- Eimontas, J.; Yousef, S.; Striūgas, N.; Abdelnaby, M.A. Catalytic pyrolysis kinetic behaviour and TG-FTIR-GC–MS analysis of waste fishing nets over ZSM-5 zeolite catalyst for caprolactam recovery. Renew. Energy 2021, 179, 1385–1403. [Google Scholar] [CrossRef]

- Suzuki, K.; Takagi, T.; Shimizu, T.; Hiraishi, T.; Yamamoto, K.; Nashimoto, K. Validity and visualization of a numerical model used to determine dynamic configurations of fishing nets. Fish. Sci. 2003, 69, 695–705. [Google Scholar] [CrossRef] [Green Version]

- Baranowski, P.; Małachowski, J.; Niezgoda, T.; Mazurkewicz, Ł. Dynamic behaviour of Various Fibre Systems During Impact Interaction—Numerical Approach. Fibres Text. East. Eur. 2015, 23, 72–82. [Google Scholar] [CrossRef]

- Logan, D.L. A First Course in the Finite Element Method, 6th ed.; Cengage Learning: Boston, MA, USA, 2017. [Google Scholar]

- Bessonneau, J.S.; Marichal, D. Study of the dynamics of submerged supple nets (applications to trawls). Ocean Eng. 1998, 25, 563–583. [Google Scholar] [CrossRef]

- Crasmareanu, M. Higher-Order Curvatures of Plane and Space Parametrized Curves. Algorithms 2022, 15, 436. [Google Scholar] [CrossRef]

- Li, S.; Jiang, T.; Zeng, X.; Zhu, N.; Shen, C.; Gong, W.; Zhang, C.; He, L. The Effect of α-Olefin–Maleic Anhydride Copolymer on the Rheological and Crystalline Properties and Microcellular Foaming Behavior of Polyamide 6. Polymers 2023, 15, 2056. [Google Scholar] [CrossRef]

- Zuo, Z.; Hao, X.; Li, H.; Wang, W.; Yang, G.; Liu, Y. Experimental Investigations on the Tensile Mechanical Behavior of HDPE Geocell Strip. Sustainability 2023, 15, 7820. [Google Scholar] [CrossRef]

- Qureshi, H.J.; Khurram, N.; Akmal, U.; Arifuzzaman; Habib, M.Q.; Al Fuhaid, A.F. Flexure Performance of Ferrocement Panels Using SBR Latex and Polypropylene Fibers with PVC and Iron Welded Meshes. Polymers 2023, 15, 2340. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- Wagner, R.H.N. ABAQUS Tutorial: Damage for Ductile Metals—Material Model Explained—Ductile Damage. Researchgate. 2021. Available online: https://www.researchgate.net/publication/350124892_ABAQUS_Tutorial_Damage_for_Ductile_Metals_-_Material_Model_Explained_-_Ductile_Damage (accessed on 1 March 2021).

- McIntee, O.M.; Welch, B.C.; Greenberg, A.R.; George, S.M.; Bright, V.M. Elastic modulus of polyamide thin films formed by molecular layer deposition. Polymer 2022, 255, 125167. [Google Scholar] [CrossRef]

- Wölfel, E.; Brünig, H.; Curosu, I.; Mechtcherine, V.; Scheffler, C. Dynamic Single-Fiber Pull-Out of Polypropylene Fibers Produced with Different Mechanical and Surface Properties for Concrete Reinforcement. Materials 2021, 14, 722. [Google Scholar] [CrossRef]

- Fatima, S.; Achraf, W.; Abdelkarim, K.; Hamid, C.; Mohamed, E. Failure Analysis of Acrylonitrile Butadiene Styrene (ABS) Materials and Damage Modeling by Fracture. Int. J. Perform. Eng. 2019, 15, 2285. [Google Scholar] [CrossRef]

- De Morais, J.A.; Gadioli, R.; De Paoli, M.-A. Curaua fiber reinforced high-density polyethylene composites: Effect of impact modifier and fiber loading. Polímeros 2016, 26, 115–122. [Google Scholar] [CrossRef] [Green Version]

- MacDonald, I.R. Fishing with Bottom Gillnets; Food and Agriculture Organization of the United Nations: Rome, Italy, 1980. [Google Scholar]

- Baranowski, P.; Malachowski, J.; Janiszewski, J.; Wekezer, J. Detailed tyre FE modelling with multistage validation for dynamic analysis. Mater. Des. 2016, 96, 68–79. [Google Scholar] [CrossRef]

- Fox, M. Polymer Tribology. In The European Lubricants Industry Magazine; Lube: Chesham, UK, 2016. [Google Scholar]

- Kieu, D.V.N.; Huang, S.C. Dynamic Creep Phenomenon on Polymer Cable with Non-linear Characteristics for Cable-driven Parallel Robots. In Proceedings of the 2020 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 23–25 October 2020. [Google Scholar] [CrossRef]

- Danh, N.N.; Son, T.D. The solution of taking net-wrapper automatically by using principle of suction fan. J. Austrian Soc. Agric. Econ. 2021, 17, 807–816. [Google Scholar]

- Xu, J.; Zheng, S.; Sun, K.; Song, P. Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision. Sensors 2023, 23, 4755. [Google Scholar] [CrossRef]

| Properties | Units | Polymer materials | |||

|---|---|---|---|---|---|

| ABS | Polyamide | Polyethylene | Polypropylene | ||

| Yarn type | - | Solid | Filament | Multifilament | Multifilament |

| Density | g/mm3 | 1050 | 1130 | 960 | 940 |

| Breaking force | N | - | 22.14 | 37.2 | 21.6 |

| Tensile strength | MPa | 43.8 | 177.14 | 296.26 | 178.23 |

| Elongation at break | % | 7.2 | 10.0 | 5.7 | 22.5 |

| Poisson’s ratio | - | 0.30 | 0.40 | 0.46 | 0.42 |

| Young’s modulus | MPa | 1470 | 2540 | 1090 | 1600 |

| Design Variables | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Material | Polyamide | Polyethylene | Polypropylene |

| Section of line (mm) | 0.2 | 0.3 | 0.4 |

| Size of grid cell (mm) | 20 | 25 | 30 |

| Ex. | Material | Cross-Section | Size of Grid Cell | |||

|---|---|---|---|---|---|---|

| 1 | PA | 0.2 | 20 | 10.04 | 0.0102 | 0.102 |

| 2 | PA | 0.3 | 25 | 14.47 | 0.0102 | 0.147 |

| 3 | PA | 0.4 | 30 | 20.44 | 0.0102 | 0.208 |

| 4 | PE | 0.3 | 20 | 11.99 | 0.0008 | 0.009 |

| 5 | PE | 0.4 | 25 | 11.67 | 0.0008 | 0.009 |

| 6 | PE | 0.2 | 30 | 21.00 | 0.0008 | 0.016 |

| 7 | PP | 0.4 | 20 | 11.97 | 0.0029 | 0.035 |

| 8 | PP | 0.2 | 25 | 18.21 | 0.0029 | 0.053 |

| 9 | PP | 0.3 | 30 | 25.05 | 0.0029 | 0.073 |

| Level | Material | Cross-Section | Size |

|---|---|---|---|

| 1 | −16.71 | −29.95 | −27.09 |

| 2 | −39.25 | −27.69 | −26.77 |

| 3 | −25.79 | −24.1 | −27.89 |

| Delta | 22.54 | 5.86 | 1.12 |

| Rank | 1 | 2 | 3 |

| Design Variables | L1 | L2 | L3 | SS | DF | MS | ρ | % | |

|---|---|---|---|---|---|---|---|---|---|

| A | Material | −16.71 | −39.25 | −25.79 | 771.8 | 2 | 385.9 | 0.003 | 93 |

| B | Section | −29.95 | −27.69 | −24.1 | 52.4 | 2 | 26.2 | 0.036 | 6 |

| C | Size | −27.09 | −26.77 | −27.89 | 2.0 | 2 | 1.0 | 0.491 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, N.-D.; Huang, S.-C. Trawl Grid Structure Design and Analysis Using the Finite Element Method. Appl. Sci. 2023, 13, 7536. https://doi.org/10.3390/app13137536

Nguyen N-D, Huang S-C. Trawl Grid Structure Design and Analysis Using the Finite Element Method. Applied Sciences. 2023; 13(13):7536. https://doi.org/10.3390/app13137536

Chicago/Turabian StyleNguyen, Nghia-Danh, and Shyh-Chour Huang. 2023. "Trawl Grid Structure Design and Analysis Using the Finite Element Method" Applied Sciences 13, no. 13: 7536. https://doi.org/10.3390/app13137536

APA StyleNguyen, N.-D., & Huang, S.-C. (2023). Trawl Grid Structure Design and Analysis Using the Finite Element Method. Applied Sciences, 13(13), 7536. https://doi.org/10.3390/app13137536