Numerical Modeling of Cross-Transmission of Airborne Pollutants in a High-Rise Building Induced by Elevator Car Movement

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

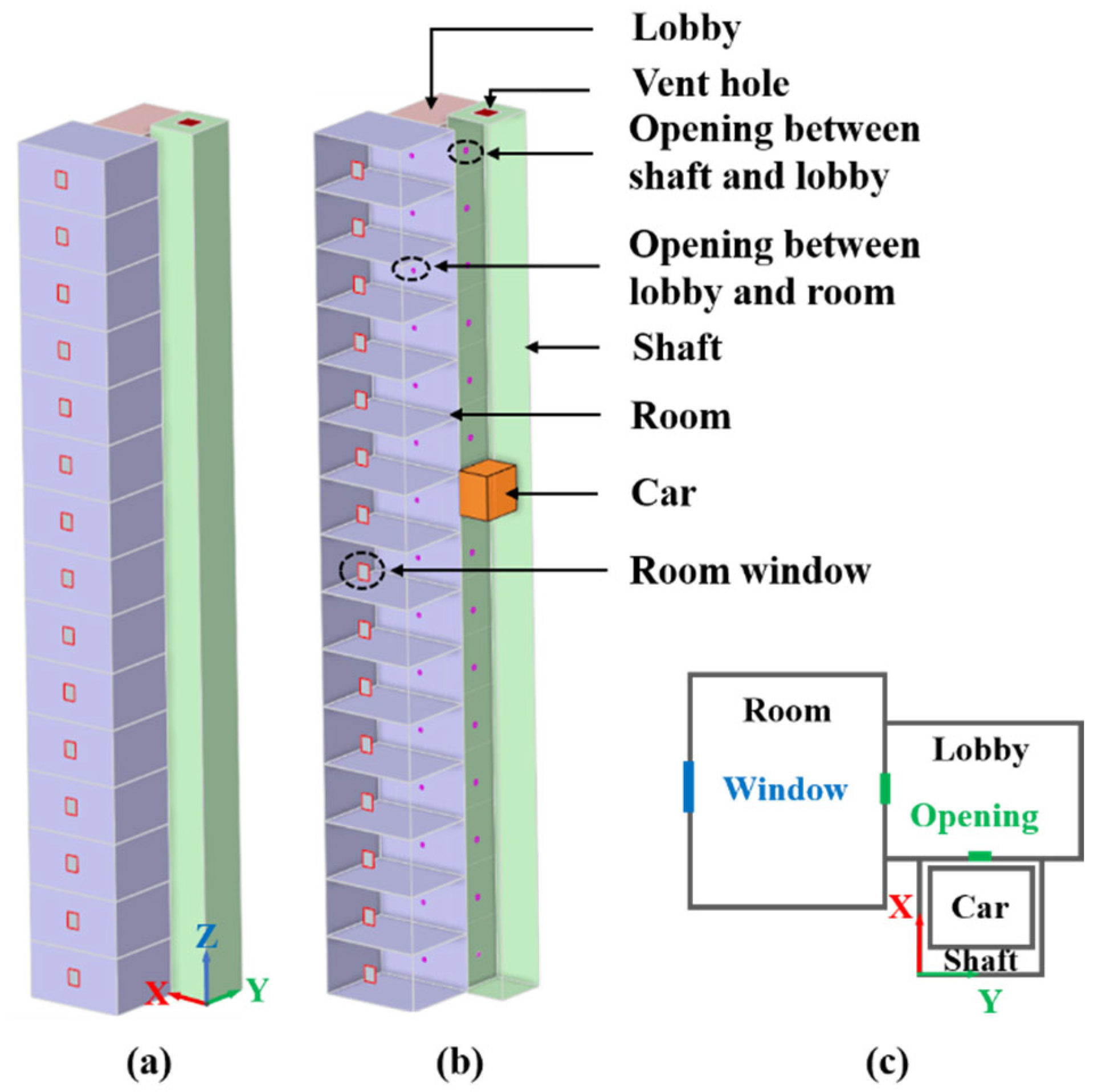

2.1. Geometric Model

2.2. Case Design and Boundary Conditions

2.3. Numerical Procedure

3. Results

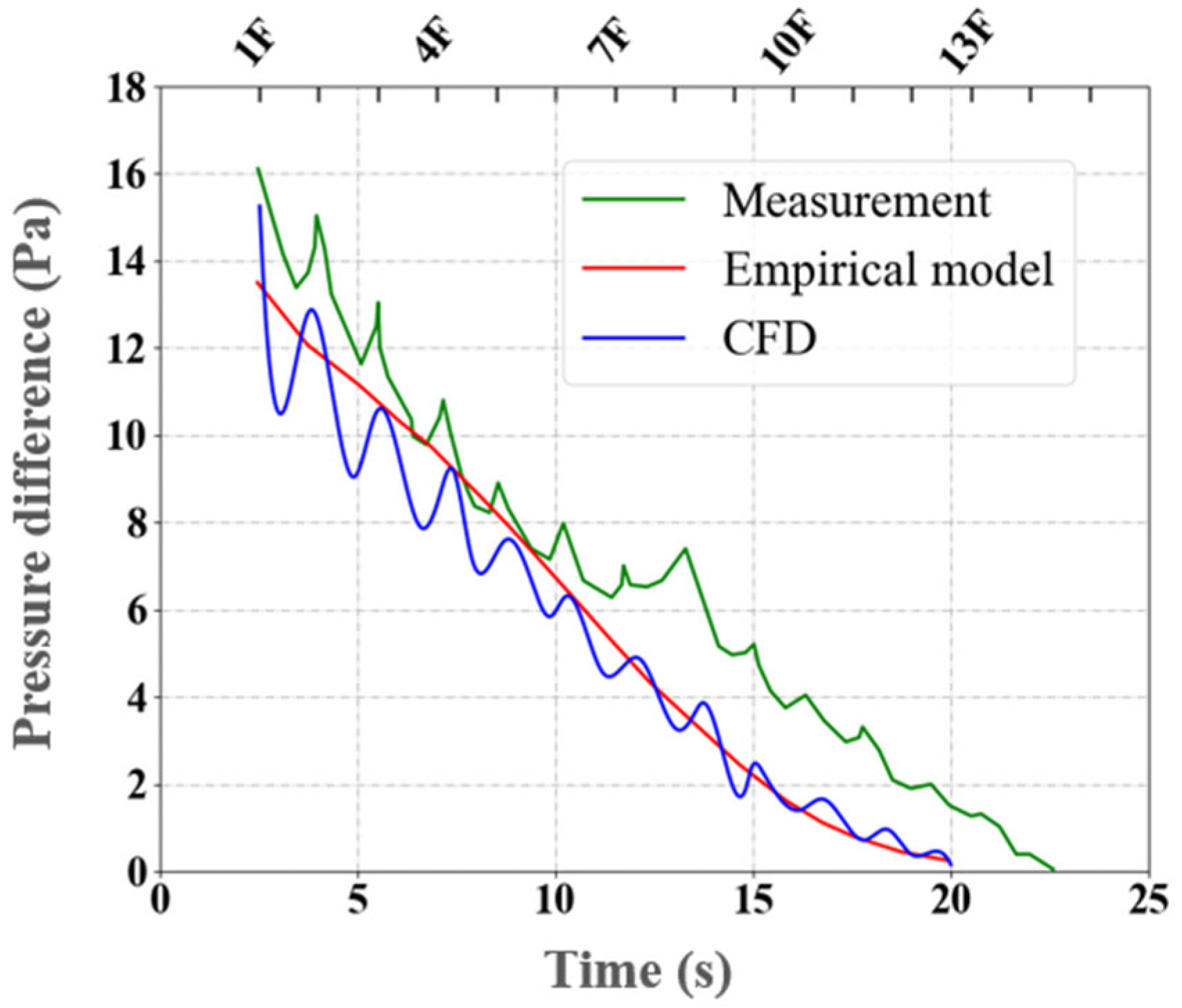

3.1. CFD Modeling Validation

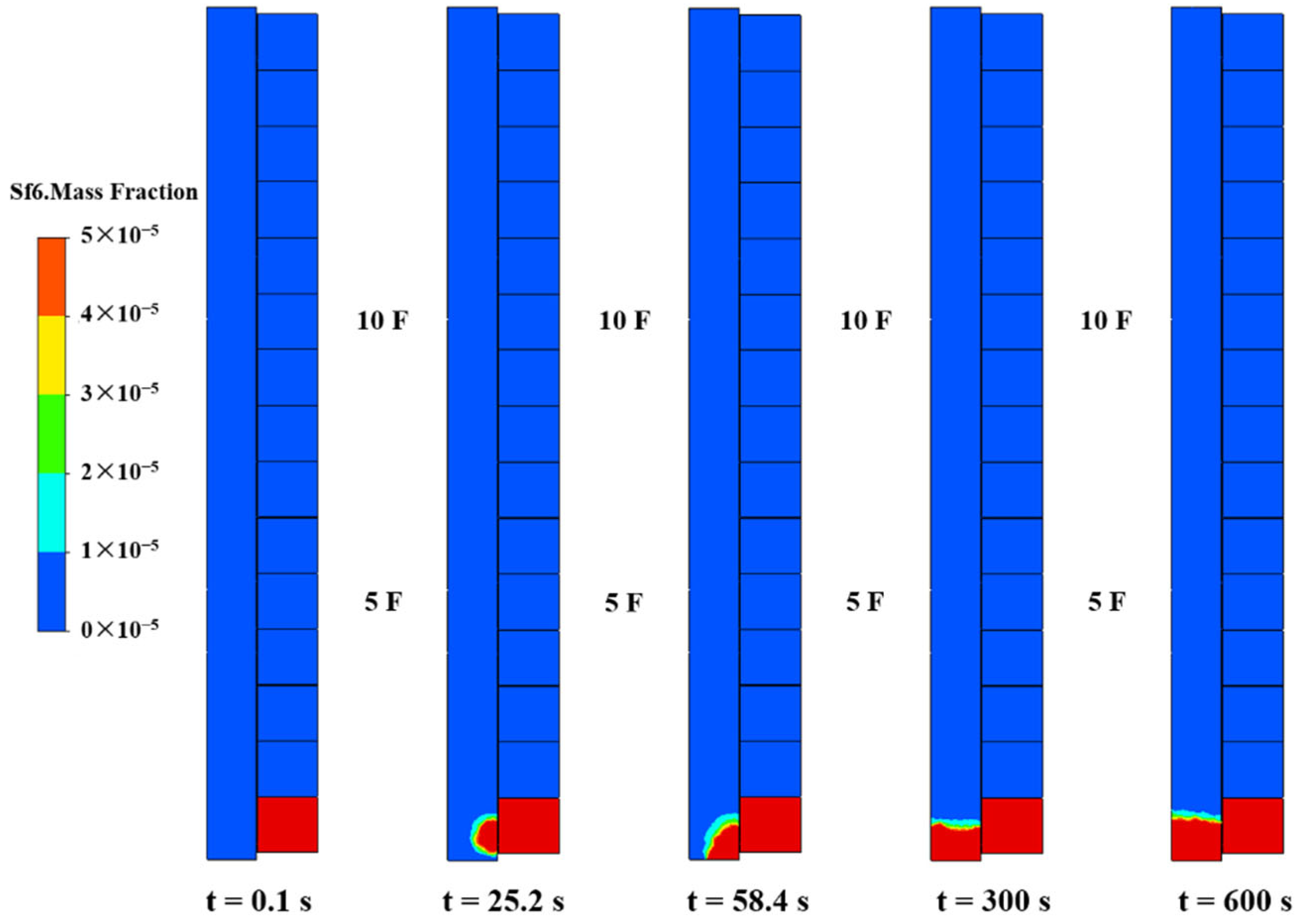

3.2. Reference Case (Case 0)

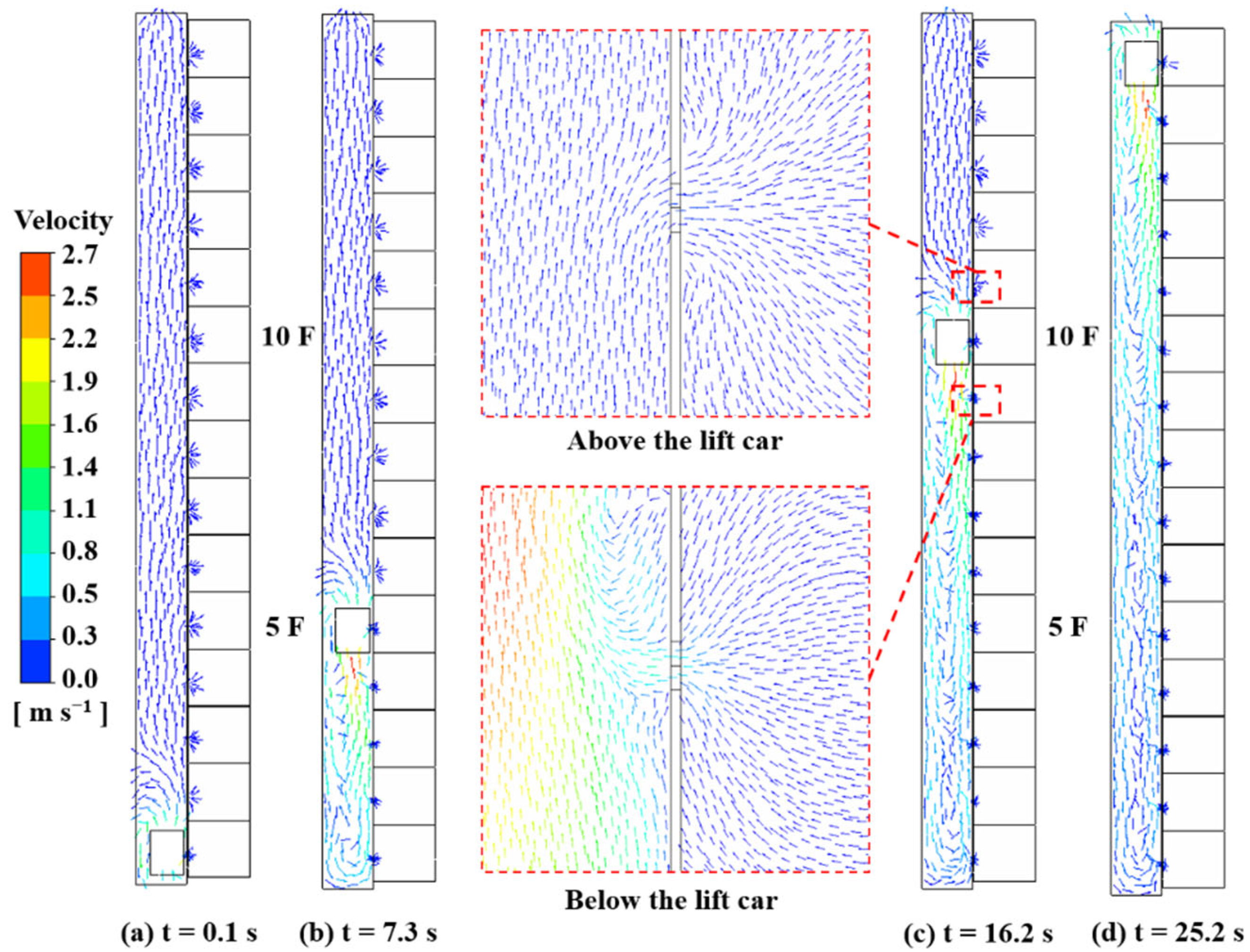

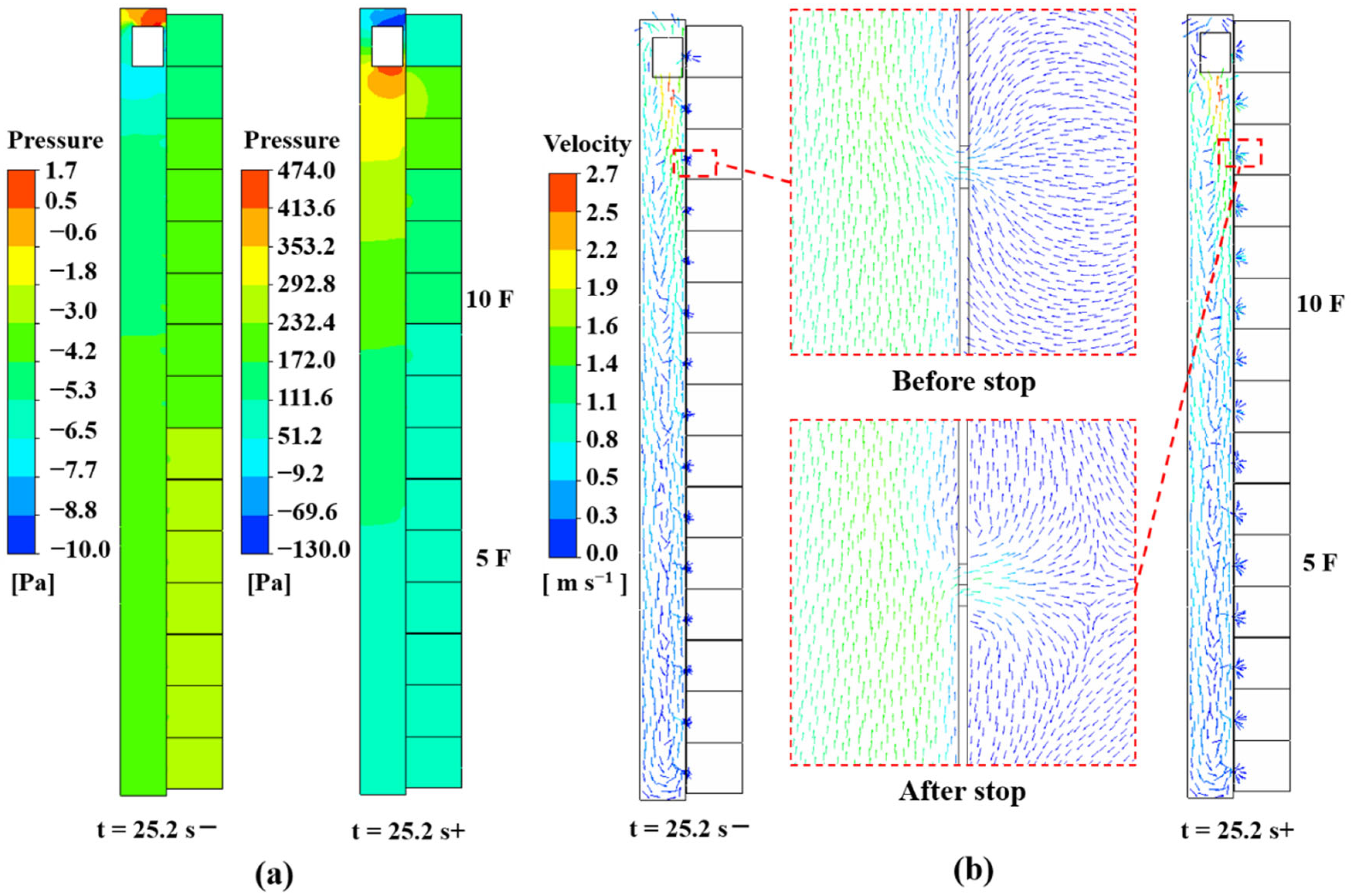

3.3. Impacts of the Elevator Car Upward Motion

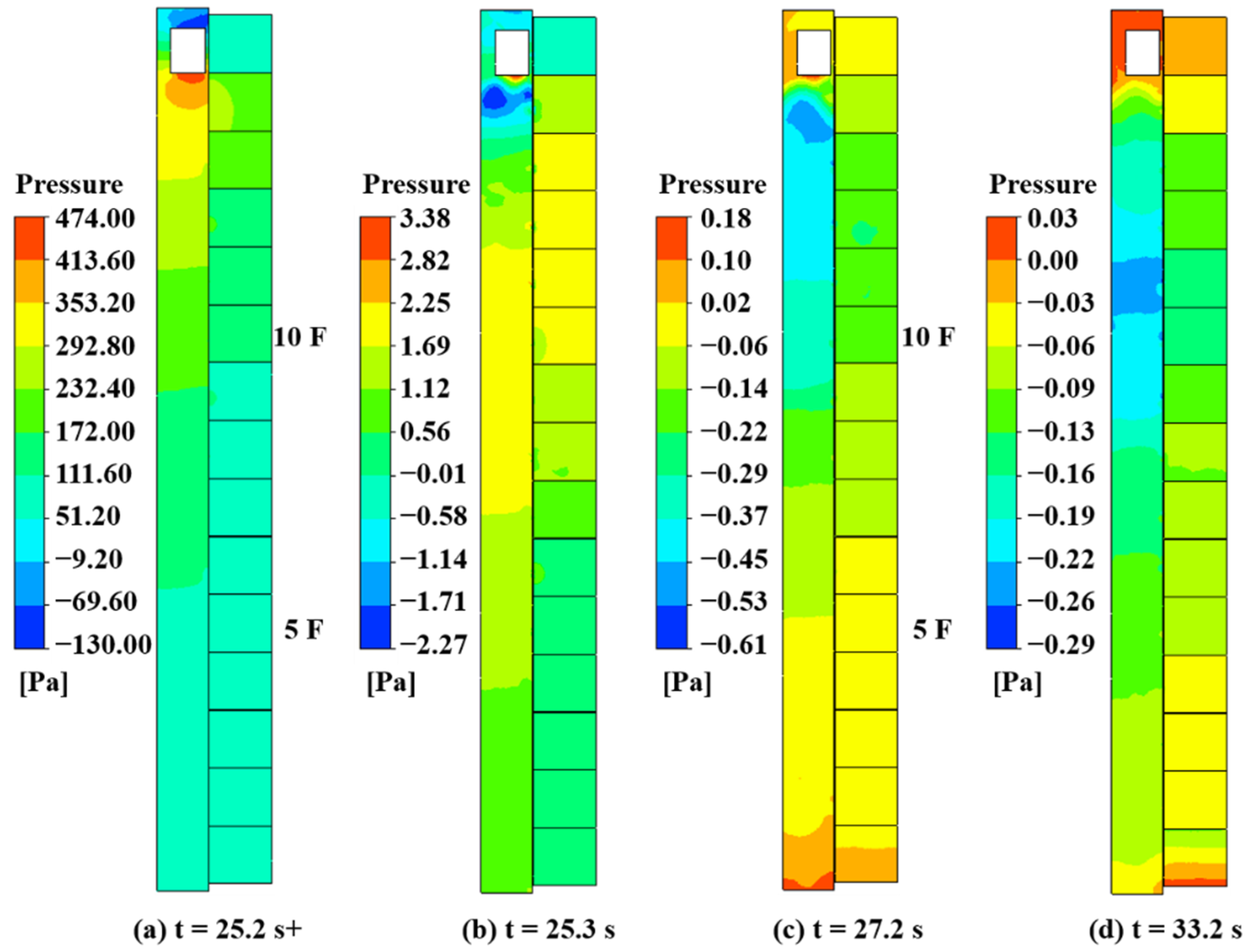

3.4. Impacts of the Elevator Car Parking

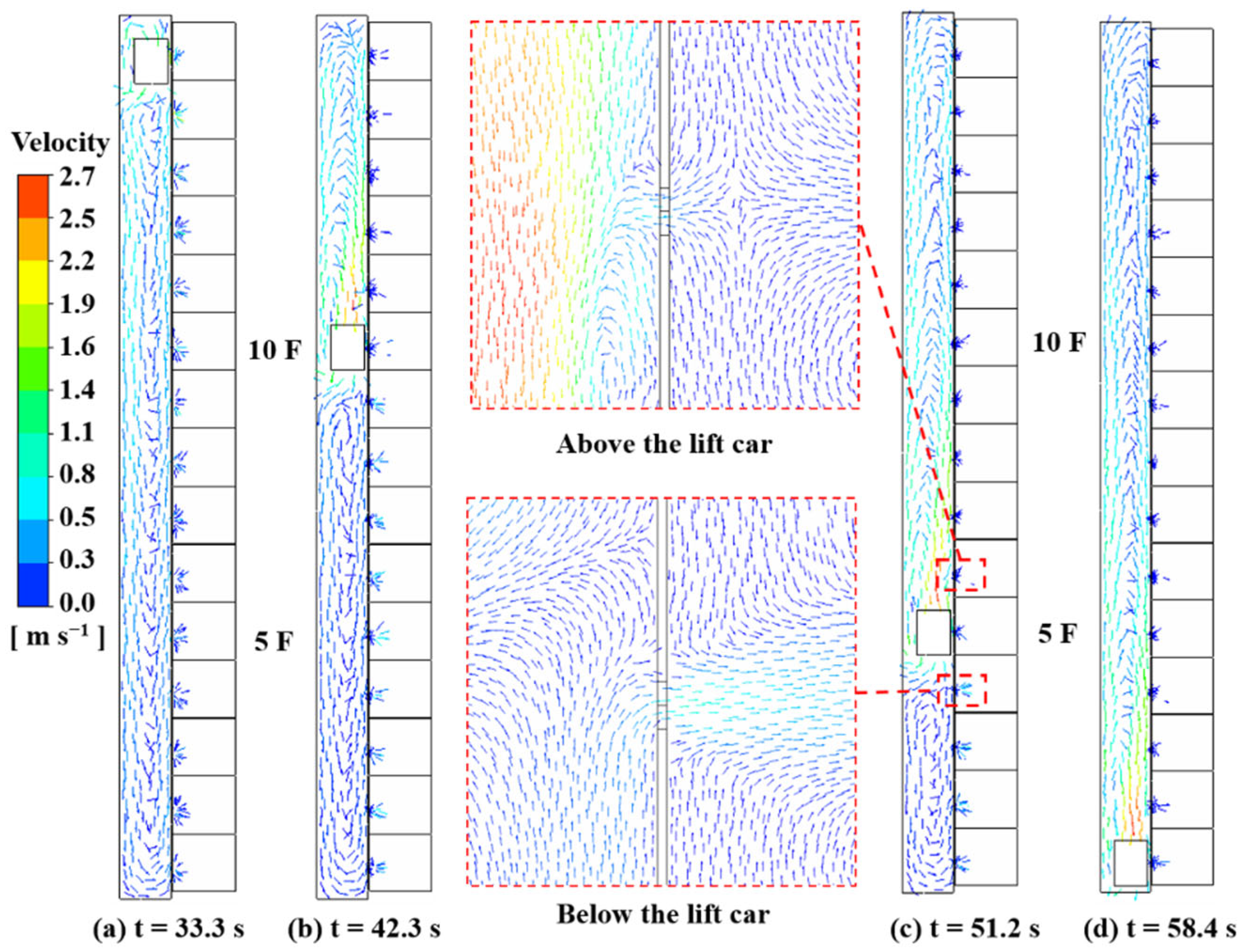

3.5. Impacts of the Elevator Car Downward Motion

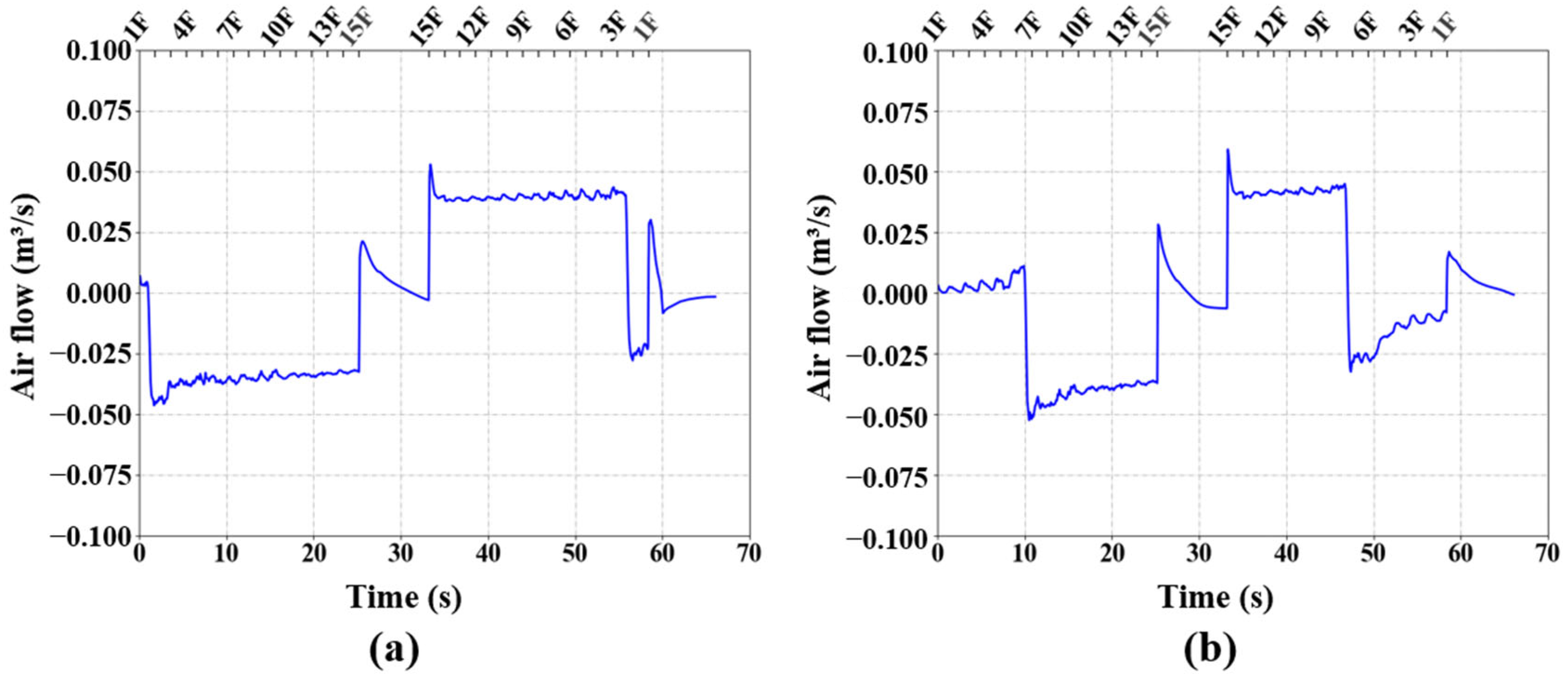

3.6. Exchange Airflow Rate through the Protecting Door’s Clearance Opening

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stadler, K.; Masignani, V.; Eickmann, M.; Becker, S.; Abrignani, S.; Klenk, H.-D.; Rappuoli, R. SARS—Beginning to understand a new virus. Nat. Rev. Microbiol. 2003, 1, 209–218. [Google Scholar] [CrossRef]

- Rewar, S.; Mirdha, D.; Rewar, P. Treatment and prevention of pandemic H1N1 influenza. Ann. Glob. Health 2015, 81, 645–653. [Google Scholar] [CrossRef]

- Mackay, I.M.; Arden, K.E. MERS coronavirus: Diagnostics, epidemiology and transmission. Virol. J. 2015, 12, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Wang, G.; Cai, X.-p.; Deng, J.-w.; Zheng, L.; Zhu, H.-h.; Zheng, M.; Yang, B.; Chen, Z. An overview of COVID-19. J. Zhejiang Univ. Sci. B 2020, 21, 343–360. [Google Scholar] [CrossRef] [PubMed]

- Anderson, E.L.; Turnham, P.; Griffin, J.R.; Clarke, C.C. Consideration of the Aerosol Transmission for COVID-19 and Public Health. Risk Anal. 2020, 40, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Morawska, L. Droplet fate in indoor environments, or can we prevent the spread of infection? Indoor Air 2006, 16, 335–347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nicas, M.; Nazaroff, W.W.; Hubbard, A. Toward understanding the risk of secondary airborne infection: Emission of respirable pathogens. J. Occup. Environ. Hyg. 2005, 2, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Lindsley, W.G.; Blachere, F.M.; Thewlis, R.E.; Vishnu, A.; Davis, K.A.; Cao, G.; Palmer, J.E.; Clark, K.E.; Fisher, M.A.; Khakoo, R.; et al. Measurements of airborne influenza virus in aerosol particles from human coughs. PLoS ONE 2010, 5, e15100. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Sun, W.; Huang, J.; Gamber, M.; Wu, J.; He, G. Indirect virus transmission in cluster of COVID-19 cases, Wenzhou, China, 2020. Emerging Infect. Dis. 2020, 26, 1343. [Google Scholar] [CrossRef]

- Lin, K.; Marr, L.C. Humidity-Dependent Decay of Viruses, but Not Bacteria, in Aerosols and Droplets Follows Disinfection Kinetics. Environ. Sci. Technol. 2020, 54, 1024–1032. [Google Scholar] [CrossRef]

- Pyankov, O.V.; Bodnev, S.A.; Pyankova, O.G.; Agranovski, I.E. Survival of aerosolized coronavirus in the ambient air. J. Aerosol Sci. 2018, 115, 158–163. [Google Scholar] [CrossRef]

- Nhu Nguyen, T.M.; Ilef, D.; Jarraud, S.; Rouil, L.; Campese, C.; Che, D.; Haeghebaert, S.; Ganiayre, F.; Marcel, F.; Etienne, J. A community-wide outbreak of legionnaires disease linked to industrial cooling towers—How far can contaminated aerosols spread? J. Infect. Dis. 2006, 193, 102–111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, T.; Park, H.; Jeong, Y.; Lee, J.; Shon, E.; Park, M.S.; Sung, M. COVID-19 Cluster Linked to Aerosol Transmission of SARS-CoV-2 via Floor Drains. J. Infect. Dis. 2022, 225, 1554–1560. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Lung, D.C.; Chan, P.T.; Dung, C.H.; Jia, W.; Miao, T.; Huang, J.; Chen, W.; Wang, Z.; et al. Aerosol transmission of SARS-CoV-2 due to the chimney effect in two high-rise housing drainage stacks. J. Hazard. Mater. 2022, 421, 126799. [Google Scholar] [CrossRef] [PubMed]

- Lyu, K.; Feng, S.; Li, X.; Wang, Q.; Zhao, X.; Yu, S.; Zheng, P.; Ji, J.; Chen, G.; Liang, J. SARS-CoV-2 Aerosol Transmission through Vertical Sanitary Drains in High-Rise Buildings—Shenzhen, Guangdong Province, China, March 2022. China CDC Wkly. 2022, 4, 489–493. [Google Scholar] [PubMed]

- Hwang, S.E.; Chang, J.H.; Oh, B.; Heo, J. Possible aerosol transmission of COVID-19 associated with an outbreak in an apartment in Seoul, South Korea, 2020. Int. J. Infect. Dis. 2021, 104, 73–76. [Google Scholar] [CrossRef]

- Liu, S.; Deng, Z. Transmission and infection risk of COVID-19 when people coughing in an elevator. Build. Environ. 2023, 238, 110343. [Google Scholar] [CrossRef]

- Black, W. Smoke movement in elevator shafts during a high-rise structural fire. Fire Saf. J. 2009, 44, 168–182. [Google Scholar] [CrossRef]

- Lee, B.H.; Yee, S.W.; Kang, D.H.; Yeo, M.S.; Kim, K.W. Multi-zone simulation of outdoor particle penetration and transport in a multi-story building. Build. Simul. 2017, 10, 525–534. [Google Scholar] [CrossRef]

- Tamura, G.; Wilson, A. Building pressures caused by chimney action and mechanical ventilation. ASHRAE Trans. 1967, 73, 1–12. [Google Scholar]

- Wong, N.H.; Heryanto, S. The study of active stack effect to enhance natural ventilation using wind tunnel and computational fluid dynamics (CFD) simulations. Energy Build. 2004, 36, 668–678. [Google Scholar] [CrossRef]

- Yang, J.; Yang, Y.; Chen, Y. Numerical simulation of smoke movement influence to evacuation in a high-rise residential building fire. Procedia Eng. 2012, 45, 727–734. [Google Scholar] [CrossRef] [Green Version]

- Su, C.; Bai, J. Measurement of the neutral plane of an internal fire whirl using the background-oriented Schlieren technique for a vertical shaft model of a high-rise building. Measurement 2016, 78, 151–167. [Google Scholar] [CrossRef]

- Gao, Y.-J.; Li, Z.-s.; Luo, Y.-y.; Guo, H.-w. Experimental study on smoke characteristics of tunnel fire under effects of longitudinal ventilation and vertical shaft natural smoke exhaust. Fire Sci. Technol. 2022, 41, 185–190. [Google Scholar]

- Tamm, G.; Jaluria, Y. Flow of hot gases in vertical shafts with natural and forced ventilation. Int. J. Heat Mass Transf. 2017, 114, 337–353. [Google Scholar] [CrossRef]

- Black, W.Z. Computer modeling of stairwell pressurization to control smoke movement during a high-rise fire. ASHRAE Trans. 2011, 117, 786. [Google Scholar]

- Miller, R.S. Elevator shaft pressurization for smoke control in tall buildings: The Seattle approach. Build. Environ. 2011, 46, 2247–2254. [Google Scholar] [CrossRef]

- Song, D.; Lim, H.; Lee, J.; Seo, J. Application of the mechanical ventilation in elevator shaft space to mitigate stack effect under operation stage in high-rise buildings. Indoor Built Environ. 2014, 23, 81–91. [Google Scholar] [CrossRef]

- Klote, J.H.; Tamura, G. Elevator piston effect and the smoke problem. Fire Saf. J. 1986, 11, 227–233. [Google Scholar] [CrossRef]

- Klote, J.H. An Analysis of the Influence of Piston Effect on Elevator Smoke Control; Center for Fire Research: Berkeley, CA, USA, 1988. [Google Scholar]

- Chen, Y.; Yang, L.; Fu, Z.; Chen, L.; Chen, J. Gas flow behavior and flow transition in elevator shafts considering elevator motion during a building fire. Build. Simul. 2018, 11, 765–771. [Google Scholar] [CrossRef]

- Strakosch, G.R. Vertical Transportation: Elevators and Escalators; Wiley: Hoboken, NJ, USA, 1983. [Google Scholar]

- Qiao, S.; Zhang, R.; He, Q.; Zhang, L. Theoretical modeling and sensitivity analysis of the car-induced unsteady airflow in super high-speed elevator. J. Wind Eng. Ind. Aerodyn. 2019, 188, 280–293. [Google Scholar] [CrossRef]

- Joung, S.; Oh, W. Analyzing Piston Effect via Superposition Principle and Controlling Pressure Difference. Fire Sci. Eng. 2022, 36, 35–42. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Y. Numerical simulation of the smoke movement in the high-rise building elevator shaft and the lobby impacted by the elevator piston effect. Build. Sci. 2011, 27, 20–23. [Google Scholar]

- Park, Y.; Na, J.; Sung, K.H.; Ryou, H.S. Numerical study on the effect of elevator movement on pressure difference between vestibule and living room in high-rise buildings. Build. Simul. 2019, 12, 313–321. [Google Scholar] [CrossRef]

- Ghidaoui, M.S.; Zhao, M.; McInnis, D.A.; Axworthy, D.H. A review of water hammer theory and practice. Appl. Mech. Rev. 2005, 58, 49–76. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kim, K. Experimental and numerical analyses of train-induced unsteady tunnel flow in subway. Tunn. Undergr. Space Technol. 2007, 22, 166–172. [Google Scholar] [CrossRef]

- Fluent, A. 19.0. User’s and Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2018. [Google Scholar]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ε eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Chen, Q. Comparison of different k-ε models for indoor air flow computations. Numer. Heat Transf. Part B Fundam. 1995, 28, 353–369. [Google Scholar] [CrossRef]

| Structure | Length (m)—X | Width (m)—Y | Height (m)—Z |

|---|---|---|---|

| Elevator shaft | 2.4 | 2.65 | 40.5 |

| Lobby | 3 | 4 | 2.7 |

| Room | 5 | 4 | 2.7 |

| Elevator car | 1.6 | 2.1 | 2.3 |

| Vent hole | 1 | 1 | - |

| Window | - | 0.6 | 0.75 |

| Opening between shaft and lobby | - | 0.2 | 0.2 |

| Opening between lobby and room | - | 0.15 | 0.15 |

| Item | Boundary Type | Boundary Values |

|---|---|---|

| Elevator car | Wall (dynamic mesh) | Moving at 1.5 m/s |

| Window | Pressure outlet | Zero |

| Vent hole | Pressure outlet | Zero |

| Interior openings | Interface | N/A |

| Structure | Length (m)—X | Width (m)—Y | Height (m)—Z |

|---|---|---|---|

| Elevator shaft | 2.2 | 2.5 | 39 |

| Lobby | 2.0 | 4.0 | 2.6 |

| Room | 4.0 | 5.0 | 2.6 |

| Elevator car | 1.784 | 2.0 | 2.6 |

| Window | - | 0.6 | 0.75 |

| Opening between shaft and lobby | - | 0.4 | 0.3275 |

| Opening between shaft and room | - | 0.3 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Wei, G.; Liu, S. Numerical Modeling of Cross-Transmission of Airborne Pollutants in a High-Rise Building Induced by Elevator Car Movement. Appl. Sci. 2023, 13, 7400. https://doi.org/10.3390/app13137400

Zhang T, Wei G, Liu S. Numerical Modeling of Cross-Transmission of Airborne Pollutants in a High-Rise Building Induced by Elevator Car Movement. Applied Sciences. 2023; 13(13):7400. https://doi.org/10.3390/app13137400

Chicago/Turabian StyleZhang, Tengfei (Tim), Guangxing Wei, and Sumei Liu. 2023. "Numerical Modeling of Cross-Transmission of Airborne Pollutants in a High-Rise Building Induced by Elevator Car Movement" Applied Sciences 13, no. 13: 7400. https://doi.org/10.3390/app13137400

APA StyleZhang, T., Wei, G., & Liu, S. (2023). Numerical Modeling of Cross-Transmission of Airborne Pollutants in a High-Rise Building Induced by Elevator Car Movement. Applied Sciences, 13(13), 7400. https://doi.org/10.3390/app13137400