Dynamic Modeling of Flue Gas Desulfurization Process via Bivariate EMD-Based Temporal Convolutional Network

Abstract

:1. Introduction

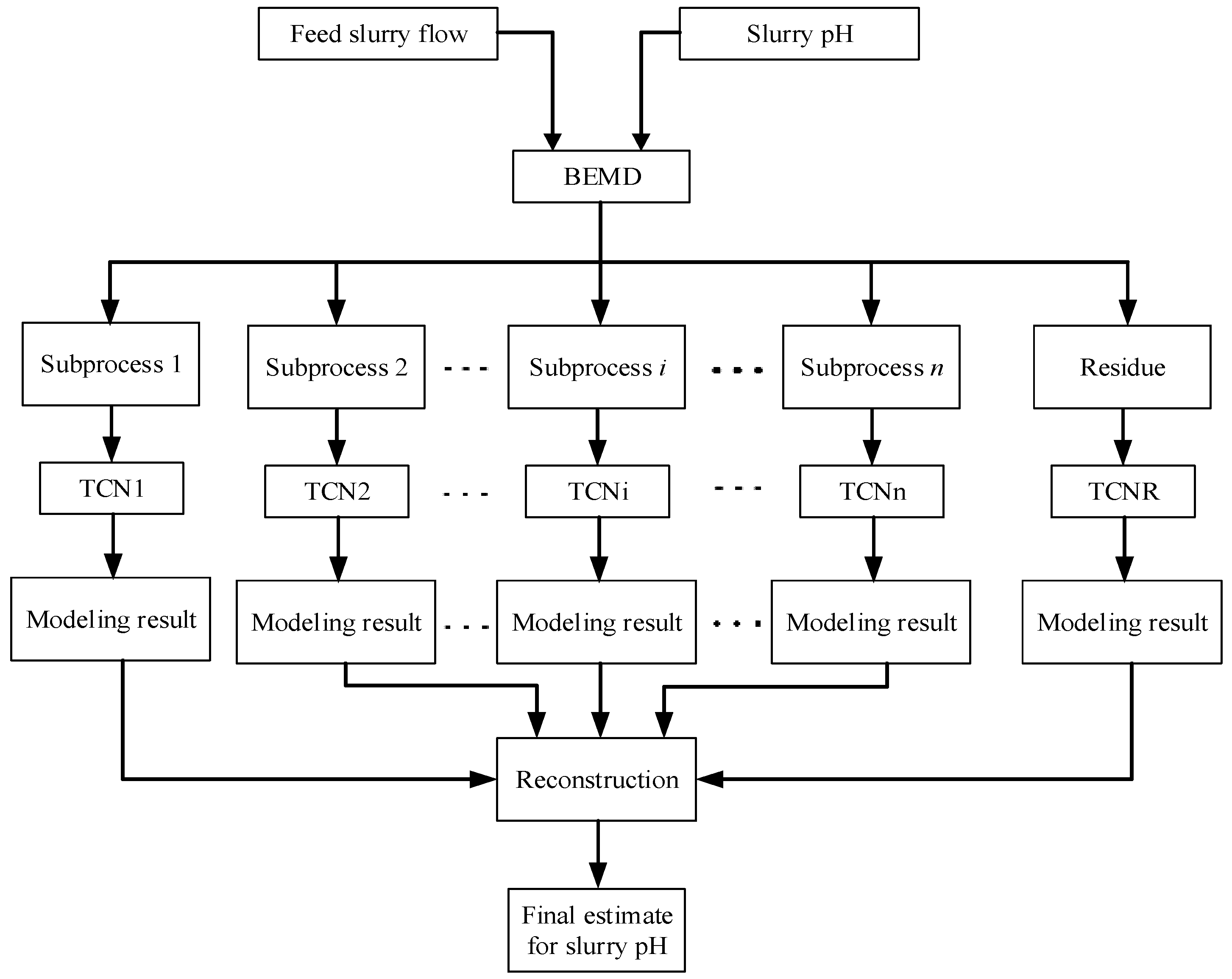

- For the first time, bivariate EMD is used for process identification purposes, which can lower the non-stationary degree and simplify frequency components of the original process, in such a way that the process is more readily identified.

- TCN, which has the capability of learning long-term dependencies between time steps, is innovatively employed in the process identification field. In this work, it serves to model each intrinsic mode function (IMF) as well as residue, and the final modeling result is obtained by summing up all the identified subprocesses.

- Combination of signal processing technique and deep learning model are for the first time used successfully in an IFGD modeling problem.

2. Description of IFGD Process and Modeling Problem

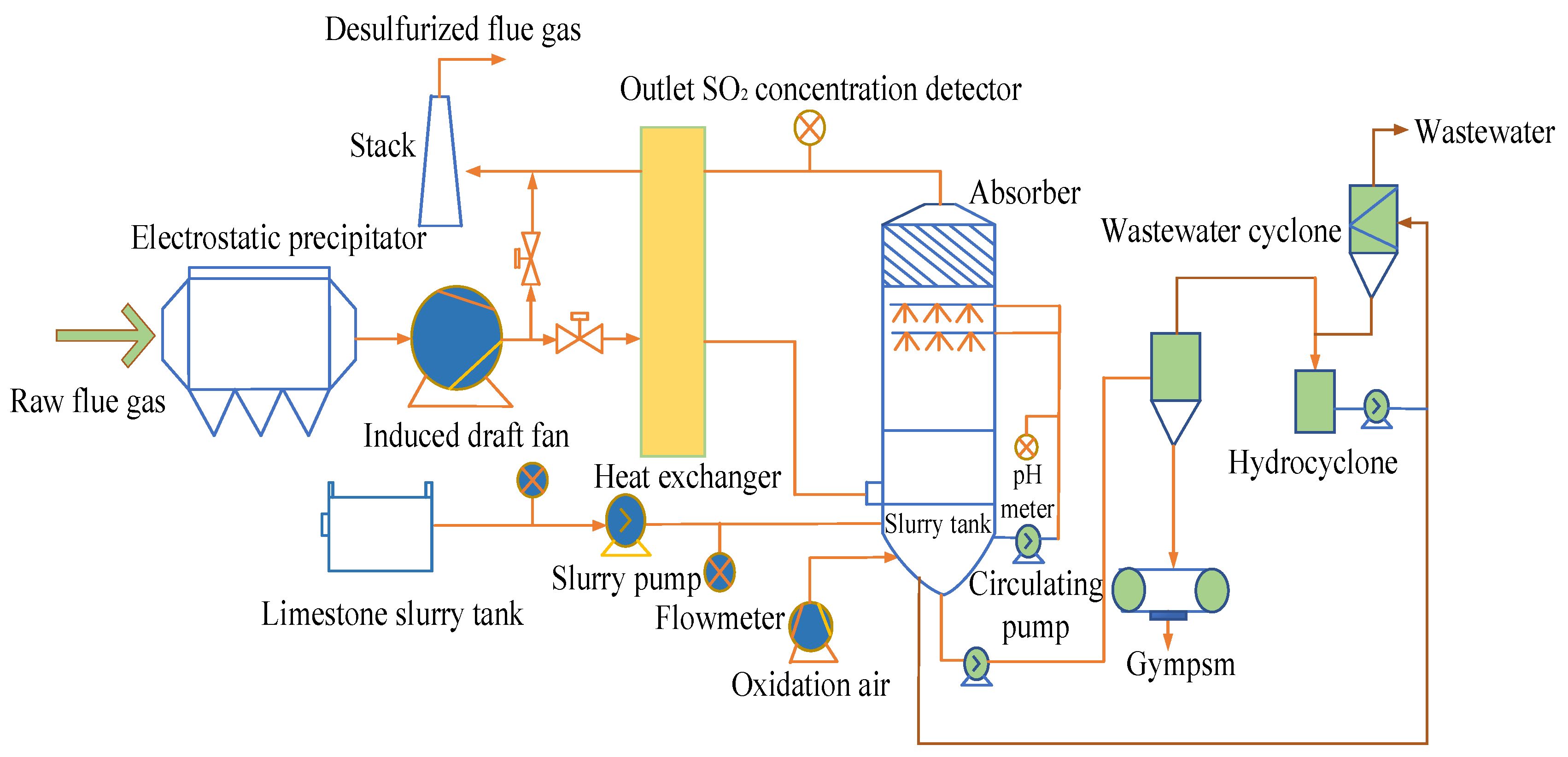

2.1. Limestone Wet IFGD Process

2.2. Description of IFGD Process and Modeling Problem

3. Proposed Approach

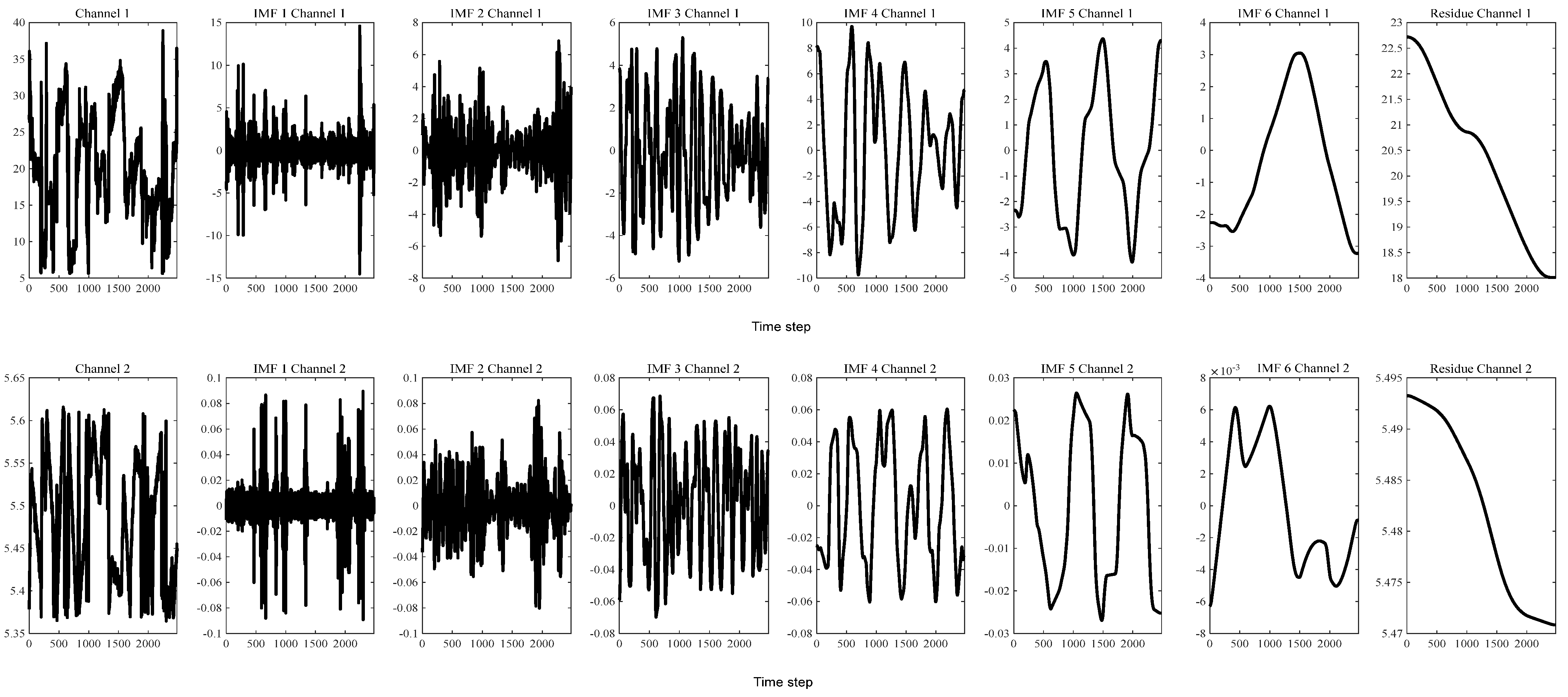

3.1. Multivariate Empirical Mode Decomposition

| Algorithm 1 Multivariate unidimensional EMD | |

|

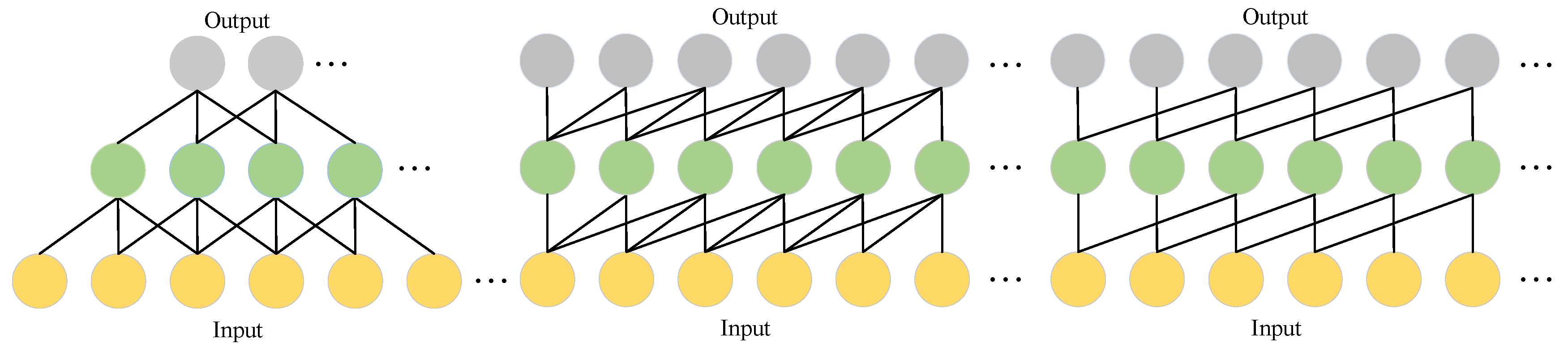

3.2. Temporal Convolutional Network for IFGD Process Identification

4. Case Study and Discussion

4.1. Basic Information for the IFGD Process

4.2. Case Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, L.; Liu, M.; Yuan, X.; Wang, Q.; Ma, Q.; Wang, P.; Hong, J.; Liu, H. Environmental and economic impact assessment of three sintering flue gas treatment technologies in the iron and steel industry. J. Clean. Prod. 2021, 311, 127703. [Google Scholar] [CrossRef]

- Dabadghao, V.; Biegler, L.T.; Bhattacharyya, D. Multiscale modeling and nonlinear model predictive control for flue gas desulfurization. Chem. Eng. Sci. 2022, 252, 117451. [Google Scholar] [CrossRef]

- Zhao, Z.; Fan, H.; Li, Q.; Liu, C.; Tan, C.; Chen, Z.; Yu, L.; Zheng, C.; Gao, X. Hybrid Modeling and Real-time Predictive Scheduling of Wet Flue Gas Desulfurization for Energy Saving and Life Extension. Energy Fuels 2023, 37, 5312–5322. [Google Scholar] [CrossRef]

- Brogren, C.; Karlsson, H.T. Modeling the absorption of SO2 in a spray scrubber using the penetration theory. Chem. Eng. Sci. 1997, 52, 3085–3099. [Google Scholar] [CrossRef]

- Zhao, Z.; Fan, H.; Li, Q.; Liu, C.; Chen, Z.; Li, L.; Zheng, C.; Gao, X. Hybrid modeling and operating optimization method of oxidation process of wet flue gas desulfurization (WFGD) system. Chem. Eng. Res. Des. 2022, 188, 406–416. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, Z.; Zheng, C.; Shu, J.; Dong, H.; Zhang, Y.; Weng, W.; Gao, X. Modeling and optimization of wet flue gas desulfurization system based on a hybrid modeling method. J. Air Waste Manag. Assoc. 2019, 69, 565–575. [Google Scholar] [CrossRef]

- Krzywanski, J.; Nowak, W. Artificial intelligence treatment of SO2 emissions from CFBC in air and oxygen-enriched conditions. J. Energy Eng. 2016, 142, 04015017. [Google Scholar] [CrossRef]

- van Ewijk, S.; McDowall, W. Diffusion of flue gas desulfurization reveals barriers and opportunities for carbon capture and storage. Nat. Commun. 2020, 11, 4298–4308. [Google Scholar] [CrossRef]

- Li, X.; Han, J.; Liu, Y.; Dou, Z.; Zhang, T.A. Summary of research progress on industrial flue gas desulfurization technology. Sep. Purif. Technol. 2022, 281, 119849. [Google Scholar] [CrossRef]

- Liu, S.; Wu, Y.; Xu, Z.; Lu, S.; Li, X. Study on characteristics of organic components in condensable particulate matter before and after wet flue gas desulfurization system of coal-fired power plants. Chemosphere 2022, 294, 133668. [Google Scholar] [CrossRef] [PubMed]

- Grinišin, N.; Bešenić, T.; Kozarac, D.; Živić, M.; Wang, J.; Vujanović, M. Modelling of absorption process by seawater droplets for flue gas desulfurization application. Appl. Therm. Eng. 2022, 215, 118915. [Google Scholar] [CrossRef]

- Lancia, A.; Musmarra, D.; Pepe, F.; Volpicelli, G. SO2 absorption in a bubbling reactor using limestone suspensions. Chem. Eng. Sci. 1994, 49, 4523–4532. [Google Scholar] [CrossRef]

- Tseng, C.C.; Li, C.J. Numerical Investigations for the Two-Phase Flow Structures and Chemical Reactions within a Tray Flue Gas Desulfurization Tower by Porous Media Model. Appl. Sci. 2022, 12, 2276. [Google Scholar] [CrossRef]

- Uddin, G.M.; Arafat, S.M.; Ashraf, W.M.; Asim, M.; Bhutta, M.M.A.; Jatoi, H.U.K.; Niazi, S.G.; Jamil, A.; Farooq, M.; Ghufran, M.; et al. Artificial intelligence-based emission reduction strategy for limestone forced oxidation flue gas desulfurization system. J. Energy Resour. Technol. 2020, 142, 092103–092118. [Google Scholar] [CrossRef]

- Wen, J.; Yan, J.; Zhang, D.; Chi, Y.; Ni, M.; Cen, K. SO2 emission characteristics and BP neural networks prediction in MSW/coal co-fired fluidized beds. J. Therm. Sci. 2006, 15, 281–288. [Google Scholar] [CrossRef]

- Yu, H.; Gao, M.; Zhang, H.; Chen, Y. Dynamic modeling for SO2-NOx emission concentration of circulating fluidized bed units based on quantum genetic algorithm-Extreme learning machine. J. Clean. Prod. 2021, 324, 129170. [Google Scholar] [CrossRef]

- Cai, L.; Xu, Z.; Wang, X.; Bai, H.; Han, L.; Zhou, Y. Numerical simulation and optimization of semi-dry flue gas desulfurization in a CFB based on the two-film theory using response surface methodology. Powder Technol. 2022, 401, 117268. [Google Scholar] [CrossRef]

- Kang, Q.; Yuan, Y. Diagnosis and Traceability Analysis of Slurry Foaming of Limestone-Gypsum Wet Flue-Gas Desulfurization (WFGD) System. Water Air Soil Pollut. 2023, 234, 108. [Google Scholar] [CrossRef]

- Liu, T.; Garcia, P.; Chen, Y.; Ren, X.; Albertos, P.; Sanz, R. New predictor and 2DOF control scheme for industrial processes with long time delay. IEEE Trans. Ind. Electron. 2017, 65, 4247–4256. [Google Scholar] [CrossRef]

- Duan, S.; Zhao, C.; Wu, M. Multiscale partial symbolic transfer entropy for time-delay root cause diagnosis in nonstationary industrial processes. IEEE Trans. Ind. Electron. 2022, 70, 2015–2025. [Google Scholar] [CrossRef]

- Zare, M.; Nouri, N.M. A novel hybrid feature extraction approach of marine vessel signal via improved empirical mode decomposition and measuring complexity. Ocean. Eng. 2023, 271, 113727. [Google Scholar] [CrossRef]

- Kopsinis, Y.; McLaughlin, S. Development of EMD-based denoising methods inspired by wavelet thresholding. IEEE Trans. Signal Process. 2009, 57, 1351–1362. [Google Scholar] [CrossRef]

- Rehman, N.; Mandic, D.P. Multivariate empirical mode decomposition. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 1291–1302. [Google Scholar] [CrossRef]

- Dai, H.; Wang, W. Application of low-discrepancy sampling method in structural reliability analysis. Struct. Saf. 2009, 31, 55–64. [Google Scholar] [CrossRef]

- Mandic, D.P.; Goh, V.S.L. Complex Valued Nonlinear Adaptive Filters: Noncircularity, Widely Linear and Neural Models; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Bai, S.; Kolter, J.Z.; Koltun, V. An empirical evaluation of generic convolutional and recurrent networks for sequence modeling. arXiv 2018, arXiv:1803.01271. [Google Scholar]

- Sen, R.; Yu, H.F.; Dhillon, I.S. Think globally, act locally: A deep neural network approach to high-dimensional time series forecasting. Adv. Neural Inf. Process. Syst. 2019, 32, 241–251. [Google Scholar]

- Wan, R.; Mei, S.; Wang, J.; Liu, M.; Yang, F. Multivariate temporal convolutional network: A deep neural networks approach for multivariate time series forecasting. Electronics 2019, 8, 876. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Li, X.; Dong, J.; Wang, K. Constrained nonlinear model predictive control of pH value in wet flue gas desulfurization process. Optim. Control. Appl. Methods 2023, 44, 1523–1539. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, L.; Zhang, L. Study on nonlinear pH control strategy based on external recurrent neural network. Procedia Eng. 2011, 15, 866–871. [Google Scholar] [CrossRef] [Green Version]

- Werbos, P.J. Backpropagation through time: What it does and how to do it. Proc. IEEE 1990, 78, 1550–1560. [Google Scholar] [CrossRef] [Green Version]

- Zhong, Y.; Yu, C.; Wang, R.; Pei, T.; Lian, L. Adaptive Anti-noise Least-Squares Algorithm for Parameter Identification of Unmanned Marine Vehicles: Theory, Simulation, and Experiment. Int. J. Fuzzy Syst. 2023, 4, 369–381. [Google Scholar] [CrossRef]

- Hao, X.; Wang, S.; Fan, Y.; Xie, Y.; Fernandez, C. An improved forgetting factor recursive least square and unscented particle filtering algorithm for accurate lithium-ion battery state of charge estimation. J. Energy Storage 2023, 59, 106478. [Google Scholar] [CrossRef]

| Season | Statistical Index | ||||

|---|---|---|---|---|---|

| Minimum | Maximum | Mean | SD 1 | Median | |

| Spring | 5.504/5.362 | 40.35/5.613 | 18.84/5.491 | 5.62/0.0675 | 18.84/5.499 |

| Summer | 5.635/5.563 | 37.14/5.823 | 20.61/5.681 | 7.041/0.0582 | 20.54/5.672 |

| Autumn | 5.007/5.446 | 50.53/5.699 | 15.53/5.632 | 5.323/0.0437 | 16.92/5.641 |

| Winter | 5.43/5.526 | 38.22/5.778 | 19.11/5.641 | 7.095/0.0534 | 19.17/5.623 |

| Season | Model Structure | |||

|---|---|---|---|---|

| BP Network | RNN | TCN (k-i-n) | Hammerstein Model | |

| Spring | 8-10-10-12 | 6-11-15 | 8-8-4 | |

| Summer | 12-15-8 | 8-16 | 4-6-3 | |

| Autumn | 5-10-17 | 9-14 | 3-7-3 | |

| Winter | 10-16-9 | 6-12-10 | 8-16-4 | |

| Season | Metrics | Identification Performance for BEMD Results | ||||||

|---|---|---|---|---|---|---|---|---|

| IMF1 1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | Residue | ||

| Spring | MAPE | 0.9970 | 0.1130 | 0.0362 | 0.0067 | 0.0072 | 0.0268 | 0.00015 |

| RMSE | 0.0023 | 0.00078 | 0.00024 | 0.00013 | 0.00086 | 0.00063 | 0.0011 | |

| Summer | MAPE | 1.8731 | 0.4375 | 0.0201 | 0.0080 | 0.0152 | 0.1886 | 0.0016 |

| RMSE | 0.0041 | 0.00066 | 0.00021 | 0.000061 | 0.00019 | 0.0023 | 0.00013 | |

| Autumn | MAPE | 2.0012 | 0.1180 | 0.0112 | 0.0220 | 0.0155 | 0.1302 | 0.0237 |

| RMSE | 0.0047 | 0.0012 | 0.00074 | 0.00027 | 0.00023 | 0.00074 | 0.0052 | |

| Winter | MAPE | 1.3712 | 0.4398 | 0.0211 | 0.0135 | 0.0148 | 0.2443 | 0.0076 |

| RMSE | 0.0050 | 0.00076 | 0.00011 | 0.00032 | 0.00019 | 0.0030 | 0.00073 | |

| Season | Metrics | Approaches | ||||

|---|---|---|---|---|---|---|

| RNN | BP Network | Hammerstein | TCN | BEMD-TCN | ||

| Spring | MAPE | 0.0089 | 0.0128 | 0.0126 | 0.0041 | 0.00058 |

| RMSE | 0.0645 | 0.0829 | 0.0801 | 0.0321 | 0.0059 | |

| Summer | MAPE | 0.0061 | 0.0257 | 0.0103 | 0.0039 | 0.00089 |

| RMSE | 0.0414 | 0.0851 | 0.0761 | 0.0299 | 0.0058 | |

| Autumn | MAPE | 0.0051 | 0.0274 | 0.0109 | 0.0031 | 0.00091 |

| RMSE | 0.0348 | 0.0860 | 0.0775 | 0.0236 | 0.0063 | |

| Winter | MAPE | 0.0058 | 0.0125 | 0.0102 | 0.0025 | 0.00062 |

| RMSE | 0.0404 | 0.0826 | 0.0758 | 0.0199 | 0.0043 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Li, X.; Wang, K. Dynamic Modeling of Flue Gas Desulfurization Process via Bivariate EMD-Based Temporal Convolutional Network. Appl. Sci. 2023, 13, 7370. https://doi.org/10.3390/app13137370

Liu Q, Li X, Wang K. Dynamic Modeling of Flue Gas Desulfurization Process via Bivariate EMD-Based Temporal Convolutional Network. Applied Sciences. 2023; 13(13):7370. https://doi.org/10.3390/app13137370

Chicago/Turabian StyleLiu, Quanbo, Xiaoli Li, and Kang Wang. 2023. "Dynamic Modeling of Flue Gas Desulfurization Process via Bivariate EMD-Based Temporal Convolutional Network" Applied Sciences 13, no. 13: 7370. https://doi.org/10.3390/app13137370

APA StyleLiu, Q., Li, X., & Wang, K. (2023). Dynamic Modeling of Flue Gas Desulfurization Process via Bivariate EMD-Based Temporal Convolutional Network. Applied Sciences, 13(13), 7370. https://doi.org/10.3390/app13137370