1. Introduction

During mixed dentition, important dento-alveolar, occlusal and skeletal changes occur and can be diagnosed. Some of these require early treatment (interceptive) in order to prevent the aggravation of the problem during the active growth period. The main clinical problem that often arises is the provision of an anchorage zone with the included permanent tooth. This may be provided by usage of personal rigidly printed dento-alveolar anchorage (PDaA), which connects these teeth. Orthodontic mini-implants are not applicable in vestibular areas with developing tooth germs. The available stable permanent teeth in the early mixed dentition are often an insufficient support unit, which is placed away from the active area. The use of a metal orthodontic PDaA, designed and printed digitally, has expanded the limits of orthodontic treatment, especially in its interceptive phase. The establishment of impacted first permanent molars and incisors in the period of early mixed dentition is most favourable. In this period of dentition development, sufficiently stable supporting teeth are not available, root resorption processes are observed in the temporary molars and the germs of the permanent teeth develop in the alveolar ridges.

Advancements in digitization have created many possibilities for customizing orthodontic appliances. CAD-CAM technologies allow one to perform a momentary intraoral scan of both dental arches and their occlusal relationships and carry out a digital analysis of all paraclinical studies as well as create a computerized individual design of appliances or additional auxiliary devices [

1,

2,

3,

4]. In orthodontics, most printed devices are derived from biocompatible composites or metal. Today, the 3D-printing of laser-sintered metal orthodontic devices is the basis for the development of modern orthodontics [

5,

6]. A reduction in the stages of an appliance’s production (intraoral scanning–computer design–printing) occurs in combination with the minimization of human error and without the necessity of heavy physical activity [

7,

8]. The modern laser-sintered orthodontic appliances provide exceptional detail precision [

9,

10,

11,

12,

13] and have predictable tooth movement geometry [

8]. The construction of the appliances can be adjusted to the geometry of the forces for the biomechanical action and moments produced by it. The extreme accuracy of the devices does not allow for the occurrence of residual tension voltages. There is already a lot of research on the topic in regard to their mechanical properties, electrochemical behaviour and biocompatibility. Most often, the printed devices are made of cobalt–chromium (Co-Cr) alloys [

10], which are strong. Their mechanical properties, such as hardness, strength and elasticity modulus, are known to be optimal for appliance design. The printed devices should not be dangerous to the hard tissues (teeth) on which they are placed and debonded; therefore, they can also undergo deformation [

14]. The appliances must be strong enough to withstand masticatory forces during chewing without any permanent deformation [

15,

16]. They increase the predictability of the result but require the orthodontist’s technical knowledge and equipment financing [

17,

18].

As every orthodontic force produces a reactive force of equal magnitude, the success of the orthodontic treatment depends on the anchorage and elimination of side effects, including unwanted tooth movement or tooth segments.

Our aim is to describe a fully digitally designed appliance for providing anchorage during the orthodontic surgical traction of impacted teeth in the mixed dentition period. We shall critically describe and discuss metal-printed appliances to support the orthodontic treatment.

2. Materials and Methods

2.1. The Method Used to Produce the Appliances Is 3D Additive Printing–Selective Laser Melting/Sintering (SLM/SLS)

After the patient and parents accepted the orthodontic treatment plan, an intraoral digital scan was performed. The digital models were used in the diagnostic phase to develop the design of the device, to track the course of treatment, to compare each stage of the treatment and to be stored in the patient’s electronic file.

The printed dento-alveolar anchorage (PDaA) was designed on the obtained STL file with the help of CAD/CAM software. The anchorage systems in the presented clinical cases were created using Exocad 3.0 Galway software. The generated file with the future grids was exported to the 3D metal printing machine for production. For the fabrication of a Co-Cr grids, we used metallic powder Wirobond C+ (BEGO Medical GmbH) with composition Co-64%, Cr-25%, V-5%, Mo-5% and a laser-sintering machine “Truprint 1000” (Trump Group). In this process, the powder is heated above the melting temperature using a high-energy CO2 beam, thereby sintering/melting the particles together in a set pattern. The next stage is a curing process that proceeds layer by layer until the entire appliance is printed. The last step is to remove the support elements. The offset of 0.08 mm was used for the rings and abutment of appliance. For the palate, the elements were adapted to the morphology without putting any pressure on it (as with digitally fabricated skeleton prosthetics).

2.2. Clinical Presentation

The presented clinical cases were treated with digitally designed and printed metal PDaA, used for anchorage in orthodontic treatments These digital splints for anchorage increase are successors to conventional transpalatal arches with welded extensions and additional elements. Eliminating soldering reduces the risk of fracture of the connection and the inclusion of another alloy in the composition of the material from which they are made. Often, in practice, they are used for the extrusion of retained teeth in a mixed dentition or in segmental treatments. The purpose is to incorporate segments on the same or opposite side with stable permanent teeth. The software allows for the individuality of the elements, as well as compliance with the morphology of the alveolar ridge and palate. Incorporating stable anchorage teeth from different areas of the dental arch into a support system creates a good anchorage unit. A system of fixed and blocked teeth, placed away from the area of action, is built to absorb the generated counter force.

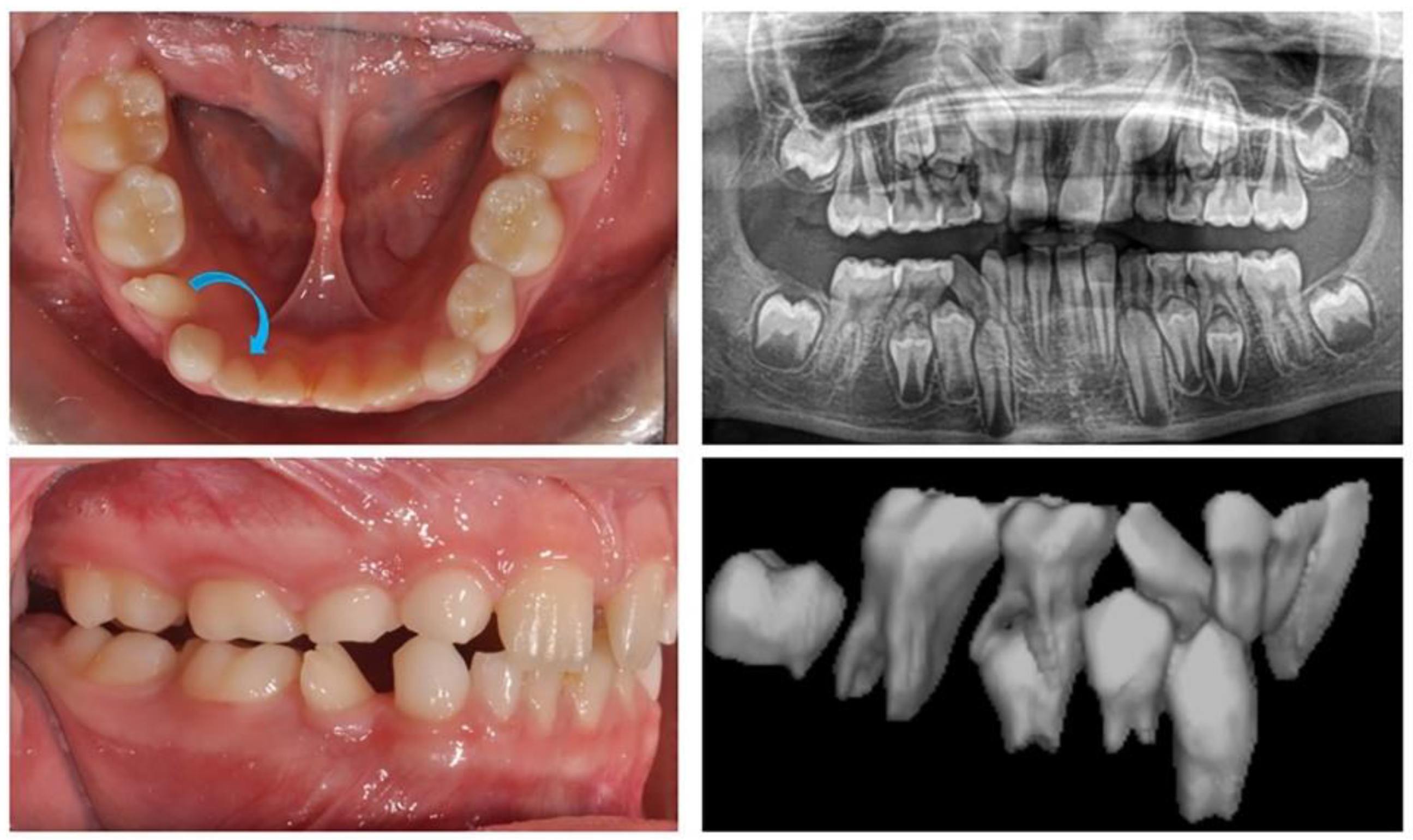

2.2.1. Clinical Case 1–Ectopic Eruption of Lower Right Lateral Incisor

The first clinical case is that of an 8-year-old girl with an ectopic eruption of the lower-right lateral (42) in the area of the first temporary molar. In the lower dental arch, the temporary right lateral incisor and canine are in preserved positions. After an X-ray examination, hypodontia of the upper laterals was established in the upper dental arch. A well-developed and normally positioned germ of right canines and premolars in the lower was found (

Figure 1). In this early phase of mixed dentition, the ectopically erupted lower-right lateral incisor should be positioned in its normal location. This will prevent future canine transposition or canine retention due to the mechanical barrier that the lateral presents. At the same time, it is important to preserve the perimeter of the dental arch in the case of the premature exfoliation of the temporary canine.

The medial movement of the lateral incisor needs to be as lingual as possible along the highest part of the alveolar ridge in order to preserve the canine germ, which is positioned more vestibularly. Therefore, an anchorage point is needed to apply a medially directed force from the lingual side. In this phase of mixed dentition, only the permanent first molars are stable. The anchorage system includes two permanent molars, and the movement of one lateral incisor is favourable from mechanical perspective. Therefore, the solution is a rigid lingual arch with a hook in the area of the central incisors, as a fulcrum to apply force to straighten and move the lower-right lateral incisor.

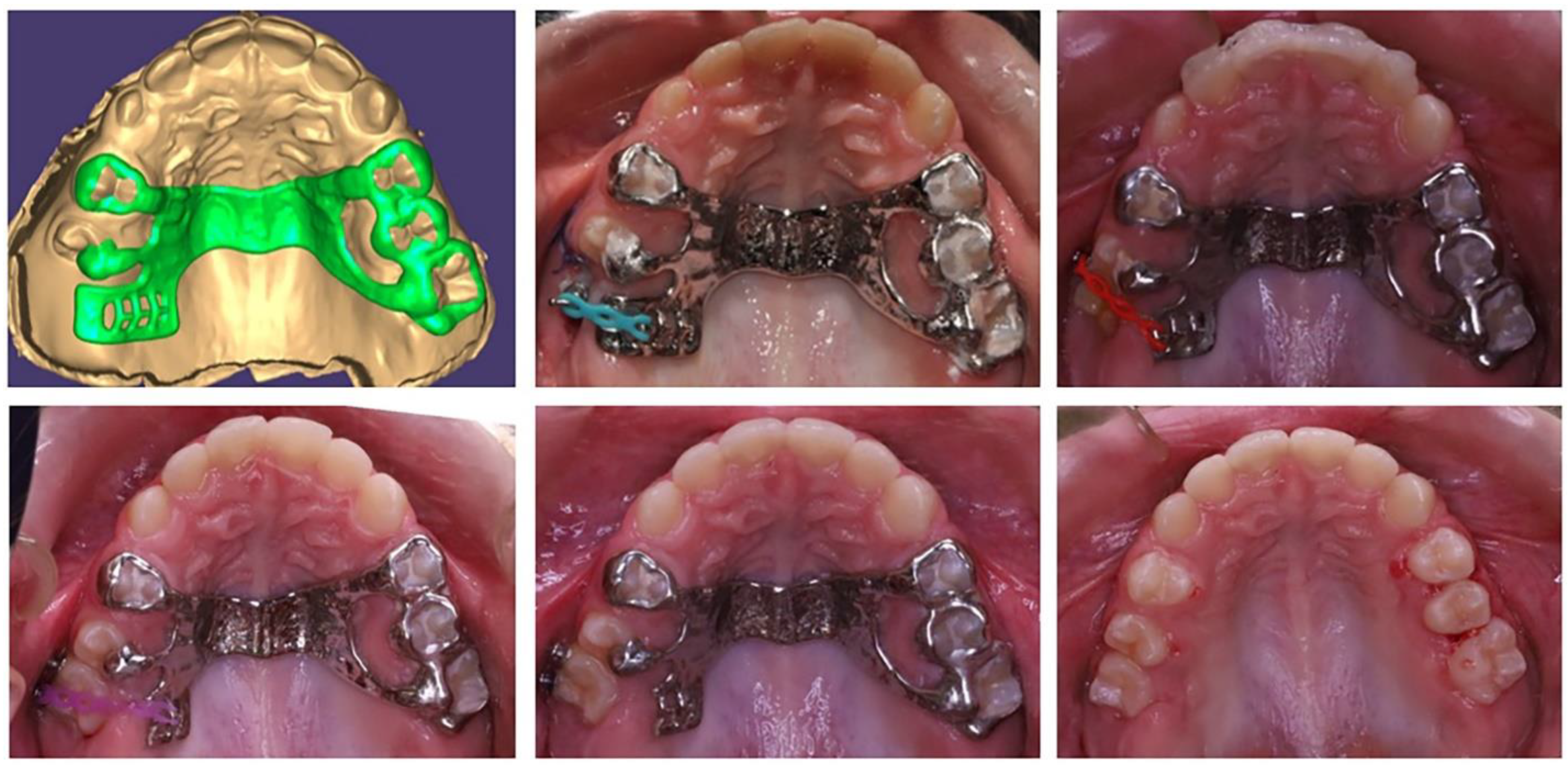

Based on the patient’s digital model, a lingual arch design was made with a hook in suitable location and direction to ensure the desired tooth movement of the lower-right lateral incisor (

Figure 2). The body of the PDaA was maximally reduced, but at the same time, it was stable enough to be an anchorage. The patient adapted to it in a short period of time, and the biomechanical system used showed a good result.

After moving the lateral incisor to its normal location in the lower dental arch, the levelling with the utility arch was able to proceed. This was followed by the eruption of the canine and both premolars. The treatment ended with the complete levelling of the dental arch.

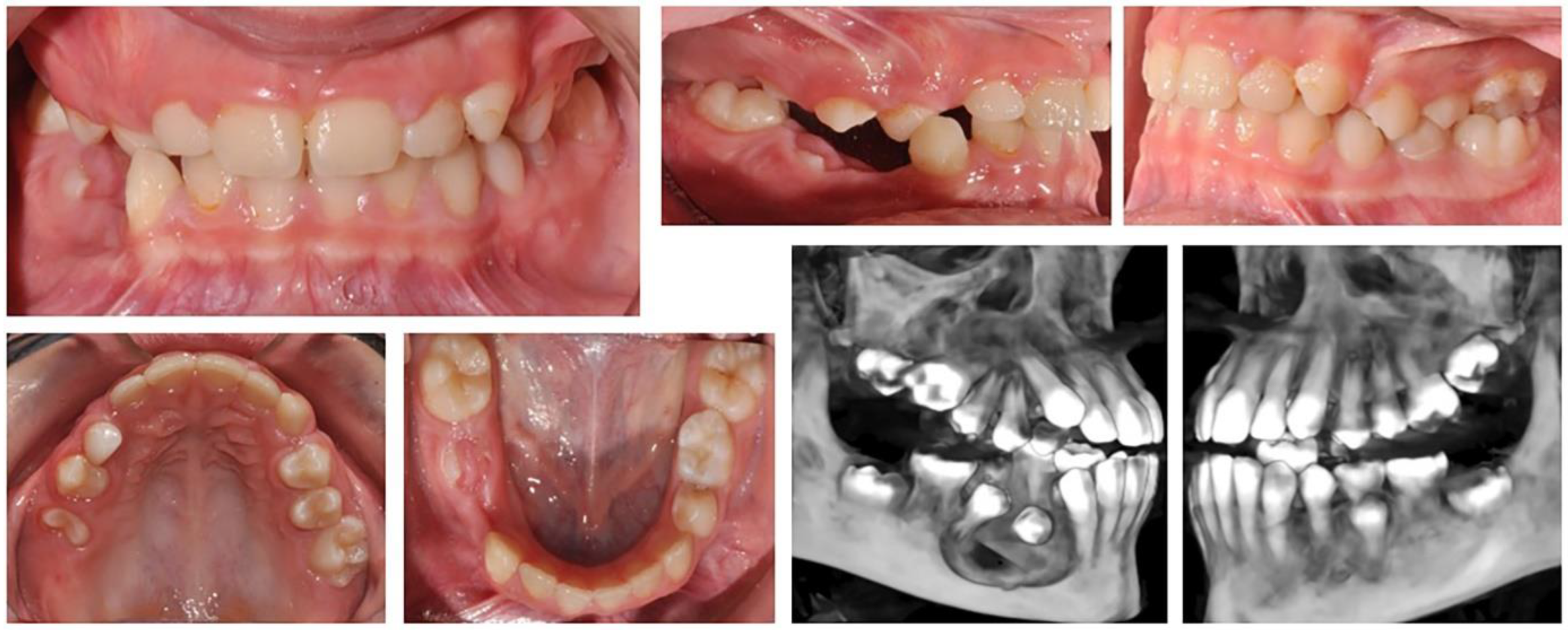

2.2.2. Clinical Case 2–Impaction of Upper-Right First Molar

The second case involved a 10-year-old girl sent for orthodontic treatment by a maxillofacial surgeon. A cystic lesion involving teeth 44 and 45 was detected, operated on and tooth 44 was extracted. A follicle cyst was detected in the upper dental arch around tooth 16, which changed the direction of development of the germ of the upper-right first molar (

Figure 3). The molar was impacted with the crown in vestibular direction. Its orthodontic traction was recommended. For this, it was necessary to construct an anchorage area in the palate. The characteristics of the bone did not allow for the use of mini-implants. Therefore, the plan involved a PDaA, which included the premolars on both sides and the left first molar, as well as part of the hard palate. In the second clinical case, a wider palatal part was used, which engaged the hard palate in the support system. The purpose of this solution is the maximum support for rotational and extrusive movement of the upper-right first molar. During treatment, the patient suffered trauma, and the alveolar bone in the upper-central incisors was fractured. The stable distal segment was a good decision in this case. In the area of tooth 16, a “ladder” was designed with a series of hooks for attaching the elastic chain. The grid was printed from Co-Cr metal.

After the surgical exposure of the upper-right first molar, the PDaA was bonded and molar traction started (

Figure 4). When the position of the molar changed, part of the ladder was removed, so that the bearing area changed along with the movement of the tooth.

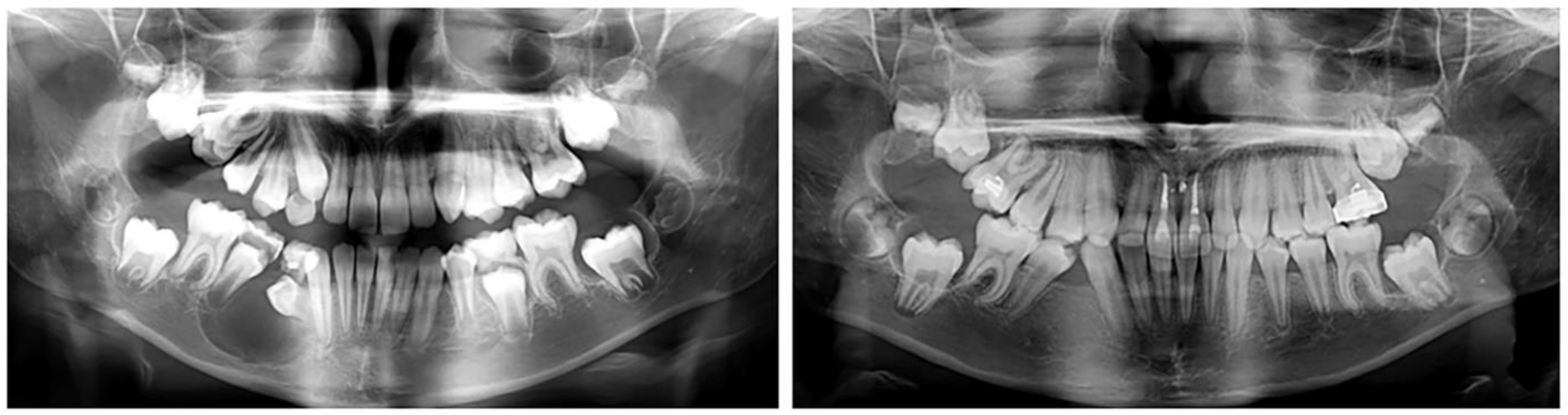

The movements of the upper-first-right molar were first rotation—a change in the direction of the clinical crown from vestibular to occlusal and then vertical movement until reaching the occlusal plane (

Figure 5). The initial position and the change in the fulcrum from the PDaA allowed these movements to occur. After the traction (extrusion) of the upper-right first molar to the level of the occlusal plane, a complete corrective orthodontic treatment with a fixed technique was planned.

2.2.3. Clinical Case 3–Treatment of Patient with Cleft of the Hard Plate

A 17-year-old female patient with a surgically repaired cleft of the hard palate was included. The patient’s complaint was worsened aesthetics. The upper frontal teeth were retruded and extruded; thus, the bite was deep. During the first clinical examination, a reduced perimeter of the upper dental arch was found, crowding was observed both in the frontal and in the middle segment (in the premolar area) and the shape of the dental arch was trapezoidal (

Figure 6).

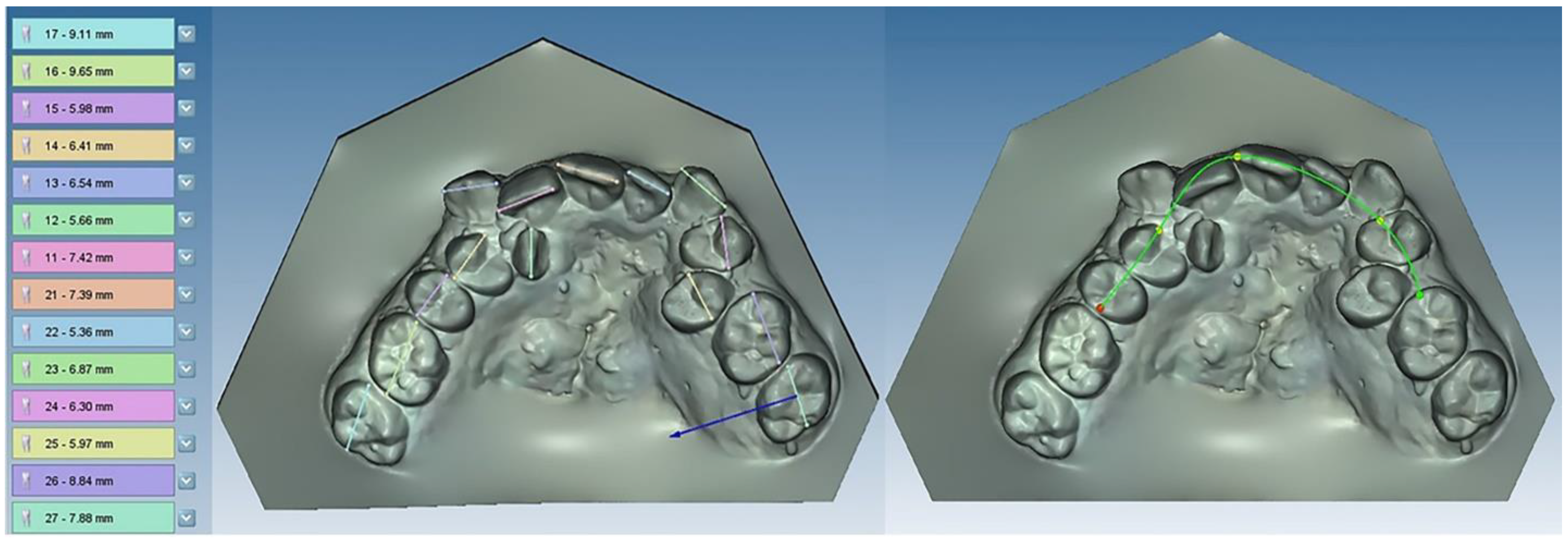

In orthodontic analysis, the count of medio-distal (MD) diameters of ten teeth from 15 to 25 was MD (15–25) = 63.9 mm. The dental arch perimeter was P (15–25) = 53.83 mm. The discrepancy of MD-P = 10.07 mm was observed (

Figure 7). The treatment goal was to provide space in upper dental arch through the extraction of first premolars 14 and 24. The count of first premolar space was almost equal to the discrepancies in perimeter. The upper-right lateral incisor was located on the palate and that resulted in the canine being in contact with the central incisor. The lateral incisor should be included in the dental arch. During the distal movement of the canine, there was a risk of the medialisation of teeth in distal segment and of lost anchorage. Therefore, the use of PDaA was the appropriate decision.

For the purposes of orthodontic treatment, the extraction of two upper premolars (14 and 25) is required, which will provide a space exactly equal to the crowding size (the sizes of the right lateral and left premolar). It was not desirable to design a biomechanical system which would involve the medial displacement of the distal anchorage teeth, as this occurs with the classic distal displacement of canines and anchorage second premolar and first molar (anchorage type A). In this clinical case, a stable distal anchorage zone was required, which could be provided by mini-orthodontic implants or a rigid transpalatal arch involving all available anchorage teeth (

Figure 8). When fabricating this type of digitally planned arch, elements were incorporated into its design to aid in a more bodily movement of the canines, which would reduce the inclination side effects of their movement.

The PDaA construction includes first and second molar rings, right second premolar lingual wall, first molar tube and an extended right first molar hook for a higher level of applied canine distalizing force.

The teeth in the upper and lower dental arch were levelled, and the occlusal relationships were normalized. The aesthetics of the frontal segment were restored. From a smile with five frontal upper teeth (13, 11, 21, 12 and 13), a symmetrical smile was achieved with the inclusion of the palatally located upper-right lateral in a normal position. A well-designed metal anchorage system did not allow for the medialization of the abutment teeth. The complete preservation of the perimeter of the upper dental arch was achieved.

3. Results

In the three clinical cases, individually created anchorage systems were used through design software, and a metal PDaA was sintered. The devices were placed in the oral area, which did not disturb the aesthetics of the patient. Due to the extreme accuracy of the devices, their adjustment was not necessary, and the clinical time for their placement and management was significantly reduced. With the appliances constructed in this way, no deviation was foreseen in the biomechanics of their action. The advantages of custom-made support systems allow for the incorporation of elements in different planes in the same support unit. The moments generated by the tooth movements were significantly reduced compared to the anchorage teeth, and no clinically negative effects were reported for them. Their rigidity was sufficient as a support when using biological orthodontic forces. No movements or other negative changes were detected in the teeth included in the support brackets.

The PDaA is applicable, both in mixed dentition and in complicated clinical cases in permanent dentition. These support systems can be used in the initial stage of the treatment, independently or synchronously with the fixed technique.

Their individuality allows for segmental treatments or treatments for dental conditions requiring additional anchorage further from the active force.

4. Discussion

The digital technologies used in orthodontic practice expand the possibilities of orthodontic treatments by relying on the creativity of the healer, a good technical and software base. New materials for printing, especially resins and plastics, diversify the type of devices used for levelling (aligners). CAD/CAM designs in orthodontic practice are mostly used in the retention phase to produce metal-sintered or -milled retainers [

19], while metal printing or milling helps with complicated orthodontic treatments requiring a sufficient support area or greater forces. It is not unusual to work with printed lingual or transpalatal arches [

7], but the possibilities of their individualization and the expansion of the construction with different hooks, buttons and arms have made them a valuable element of orthodontic therapy.

The use of conventional TPA is most often for a support, but its possibilities have an impact in three directions: transverse expansion in the molars, rotational movements and extrusion and intrusion changes in the molars. The disadvantages faced by orthodontists when working with classical TPA are that it requires good manual skills when bending, adapting and activating the material [

20,

21]. A change in the planned geometry is possible when the arch is activated. The digitally printed arch is rigid and does not allow for corrective movements at the molars but is a stable support. With digital devices, maximum accuracy is possible to achieve. The planned molar rings do not traumatize the papilla. An advantage is that it is possible to plan the inclusion of the second molars in the arch and even the premolars. The alloy from which it is produced can reliably take the required load.

Many experiments and analyses have been conducted concerning their resistance to torsion, which show that their stability and strength can be relied upon [

22]. Zinelis et al. [

14] tested Co-Cr orthodontic grids and obtained results that show that these grids have clinically acceptable mechanical properties that remain unaffected by intraoral aging.

The biggest advantage of the software appliances designed is that the support points (hooks, extensions, buttons, loops, etc.) can be planned in places approximately close to the level or in the area of the centre of resistance of the tooth or tooth group that will be moving. This provides a movement that is very close to the center of resistance of the tooth and, at the same time, a support area that does not change. The vertical extensions, which can be planned in the printed appliances, have a height that is consistent with the centre of resistance of the tooth to be moved. Thus, the power arm is correctly positioned, and the body movement of the tooth is achieved [

23,

24]. The individually planned vertical extension (shoulder) complies with the relief of the alveolar ridge, as well as the required height, and is maximally comfortable for the patient. Such extensions can be made in the design of different orthodontic grids and in different planes. The advantages of custom-made support systems allow for the incorporation of elements in different planes in the same support unit. The moments generated by the tooth movements are significantly reduced compared to the anchorage teeth and no clinically negative effects have been reported for them.

The role of the lingual arch is also not the same as that of a traditional one. With the printed lingual arch, it is not possible to straighten the inclinations of the lower first molars but only to preserve their existing position. Therefore, with the printed form, we can keep the perimeter but not increase or change it.

The advantage of the digitally designed lingual arch is that it improves the support zone during the orthodontic extraction of impacted teeth, even in mixed dentition; in teeth with suspected ankylosis, it can stabilize the adjacent ones and counteract the intruding counter force.

One of the great advantages of digitally printed grids is that their main components can be placed orally, making them more invisible and aesthetic for patients. The support systems used in the presented clinical cases are entirely located in the oral areas and do not disturb the aesthetics of the patient during treatment.

Their other advantages are cost-effectiveness, improved quality, speed, accuracy and predictability [

25]. Appliances produced via the printing method involve less material loss than those made by milling, which also affects their price, making them affordable [

26,

27,

28]. The proposed support systems are suitable in the case of impacted permanent molars and the significant rotations of teeth from the lateral segment.

The created device is of high complexity and in a shape that serves individual treatment. At the same time, this is achieved with less human involvement, which reduces the risk of error. Because of the several machines printing at the same time, the appliance cost is lower.

5. Conclusions

Modern orthodontics use new digital algorithms for diagnosis and treatment planning, as well as for the customized creation and production of orthodontic appliances. Orthodontic treatments in the interceptive phase of mixed dentition are possible because it is not necessary to wait for teeth to erupt from the distal anchorage zone. With custom-designed appliances, more distant teeth can be incorporated into a common unit to support and normalize the position of individual ectopic or impacted teeth.

Author Contributions

Conceptualization, Y.G.; methodology, Y.G. and M.C.; resources, Y.G.; writing—original draft preparation, G.G. and M.G.; writing—review and editing, Y.G. and M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Ethics Committee of KENIMUS, Approval Code: N° 2873 Approval Date: 4 May 2022.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. Written informed consent was obtained from the patient(s) to publish this paper.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, G.G., upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jyosthna, A.; Xavier Dhayananth, L.; Evan, A.C.; Piradhiba, R.; Navaneetha Nambi, A. Review—CAD. CAM Orthod. J. Res. Med. Dent. Sci. 2022, 10, 253–257. [Google Scholar]

- Küffer, M.; Drescher, D.; Becker, K. Application of the Digital Workflow in Orofacial Orthopedics and Orthodontics: Printed Grids with Skeletal Anchorage. Appl. Sci. 2022, 12, 3820. [Google Scholar] [CrossRef]

- Francisco, I.; Ribeiro, M.P.; Marques, F.; Travassos, R.; Nunes, C.; Pereira, F.; Caramelo, F.; Paula, A.B.; Vale, F. Application of Three-Dimensional Digital Technology in Orthodontics: The State of the Art. Biomimetics 2022, 7, 23. [Google Scholar] [CrossRef] [PubMed]

- Su, T.; Zhang, H.; Kang, T.; Zhou, M.; Han, J.; Ning, N.; Lin, H.; Chen, X.; Chen, Q. Application progress of three-dimensional printing technology in orthodontics. Digit. Med. 2022, 8, 31. [Google Scholar] [CrossRef]

- Revilla-León, M.; Meyer, M.J.; Özcan, M. Metal additive manufacturing technologies: Literature review of current status and prosthodontic applications. Int. J. Comput. Dent. 2019, 22, 55–67. [Google Scholar] [PubMed]

- Bartkowiak, T.; Walkowiak-Śliziuk, A. 3D printing technology in orthodontics—Review of current applications. J. Stomatol. 2018, 71, 356–364. [Google Scholar] [CrossRef]

- Tsolakis, I.A.; Gizani, S.; Tsolakis, A.I.; Panayi, N. Three-Dimensional-Printed Customized Orthodontic and Pedodontic Appliances: A Critical Review of a New Era for Treatment. Children 2022, 9, 1107. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.-S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Graf, S.; Tarraf, N.E.; Kravitz, N.D. Three-dimensional metalprinted orthodontic laboratory grids. Semin. Orthod. 2021, 27, 189–193. [Google Scholar] [CrossRef]

- Graf, S. Direct Printed Metal Devices—The Next Level of Computer-aided Design and Computer-aided Manufacturing Applications in the Orthodontic Care. APOS Trends Orthod. 2017, 7, 253–259. [Google Scholar] [CrossRef]

- Graf, S.; Cornelis, M.; Gameiro, G.H.; Cattaneo, P.M. Computer-aided design and manufacture of hyrax devices: Can we really go digital? Am. J. Orthod. Dentofac. Orthop. 2017, 152, 870–874. [Google Scholar] [CrossRef] [Green Version]

- Scribante, A.; Gallo, S.; Pascadopoli, M.; Canzi, P.; Marconi, S.; Montasser, M.A.; Bressani, D.; Gandini, P.; Sfondrini, M.F. Properties of CAD/CAM 3D Printing Dental Materials and Their Clinical Applications in Orthodontics: Where Are We Now? Appl. Sci. 2022, 12, 551. [Google Scholar] [CrossRef]

- Ahmed, N.; Shetty, S.K.; Urukalan, H.; Nikhil, P.M.; Younus, A.; Bhat, R.K.R. Thinking forward: 3-D printing in orthodontics. IP Indian J. Orthod. Dentofac. Res. 2021, 7, 208–215. [Google Scholar] [CrossRef]

- Zinelis, S.; Polychronis, G.; Papadopoulos, F.; Kokkinos, C.; Economou, A.; Panayi, N.; Papageorgiou, S.N.; Eliades, T. Mechanical and electrochemical characterization of 3D printed orthodontic metallic grids after in vivo ageing. Dent. Mater. 2022, 38, 1721–1727. [Google Scholar] [CrossRef]

- Eliaz, N. Corrosion of Metallic Biomaterials: A Review. Materials 2019, 12, 407. [Google Scholar] [CrossRef] [Green Version]

- Goracci, C.; Juloski, J.; D’Amico, C.; Balestra, D.; Volpe, A.; Juloski, J.; Vichi, A. Clinically Relevant Properties of 3D Printable Materials for Intraoral Use in Orthodontics: A Critical Review of the Literature. Materials 2023, 16, 2166. [Google Scholar] [CrossRef]

- Cunha, T.D.M.A.D.; Barbosa, I.D.S.; Palma, K.K. Orthodontic digital workflow: Devices and clinical applications. Dent. Press J. Orthod. 2021, 26, e21spe6. [Google Scholar] [CrossRef]

- Shannon, T.; Groth, C. Be your own manufacturer: 3D printing intraoral grids. Semin. Orthod. 2021, 27, 184–188. [Google Scholar] [CrossRef]

- Petrunov, V.; Chalyovski, M. CAD/CAM retainers—A new era in fixed retention. Digital working protocol for retainer fabrication. Orthod. Rev. 2022, 24, 8–19. [Google Scholar]

- Kuang, Y.; Hu, B.; Feng, G.; Huang, L.; Song, J. The Application of a 3-Dimensional Printing Technique in Refining the Orthodontic Trans-Palatal Arch. Appl. Sci. 2022, 12, 7497. [Google Scholar] [CrossRef]

- Kuang, Y.; Wang, C.; Hu, B.; Feng, G.; Wang, C.; Song, J. Biomechanical analysis of reinstating buccally flared maxillary 2nd molars using 3D printing anchorage supports: A 3D finite element study. Comput. Methods Biomech. Biomed. Eng. 2021, 24, 1085–1096. [Google Scholar] [CrossRef] [PubMed]

- Barbin, T.; Velôso, D.V.; Silva, L.D.R.; Borges, G.A.; Presotto, A.G.C.; Barão, V.A.R.; Mesquita, M.F. 3D metal printing in dentistry: An in vitro biomechanical comparative study of two additive manufacturing technologies for full-arch implant-supported prostheses. J. Mech. Behav. Biomed. Mater. 2020, 108, 103821. [Google Scholar] [CrossRef] [PubMed]

- Grauer, D.; Wiechmann, D.; Heymann, G.C.; Swift, E.J., Jr. Computer-aided design/computer-aided manufacturing technology in customized orthodontic grids. J. Esthet. Restor. Dent. 2012, 24, 3–9. [Google Scholar] [CrossRef] [PubMed]

- Thurzo, A.; Kočiš, F.; Novák, B.; Czako, L.; Varga, I. Three-Dimensional Modeling and 3D Printing of Biocompatible Orthodontic Power-Arm Design with Clinical Application. Appl. Sci. 2021, 11, 9693. [Google Scholar] [CrossRef]

- Nc, S.C.; Kalidass, D.S.; Davis, D.; Kishore, S.; Suvetha, S. Orthodontics in the Era of Digital Innovation—A Review. J. Evol. Med. Dent. Sci. 2021, 10, 2114–2121. [Google Scholar] [CrossRef]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry—State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Subramanian, A.K.; Harikrishnan, S. 3D printing in orthodontics: A narrative review. J. Int. Oral Health 2023, 15, 15. [Google Scholar] [CrossRef]

- Cousley, R.R. Introducing 3D printing in your orthodontic practice. J. Orthod. 2020, 47, 265–272. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).