Magnetic Permeability Perturbation Testing for Internal Axial Cracks in Small-Diameter Thick-Walled Steel Pipes

Abstract

1. Introduction

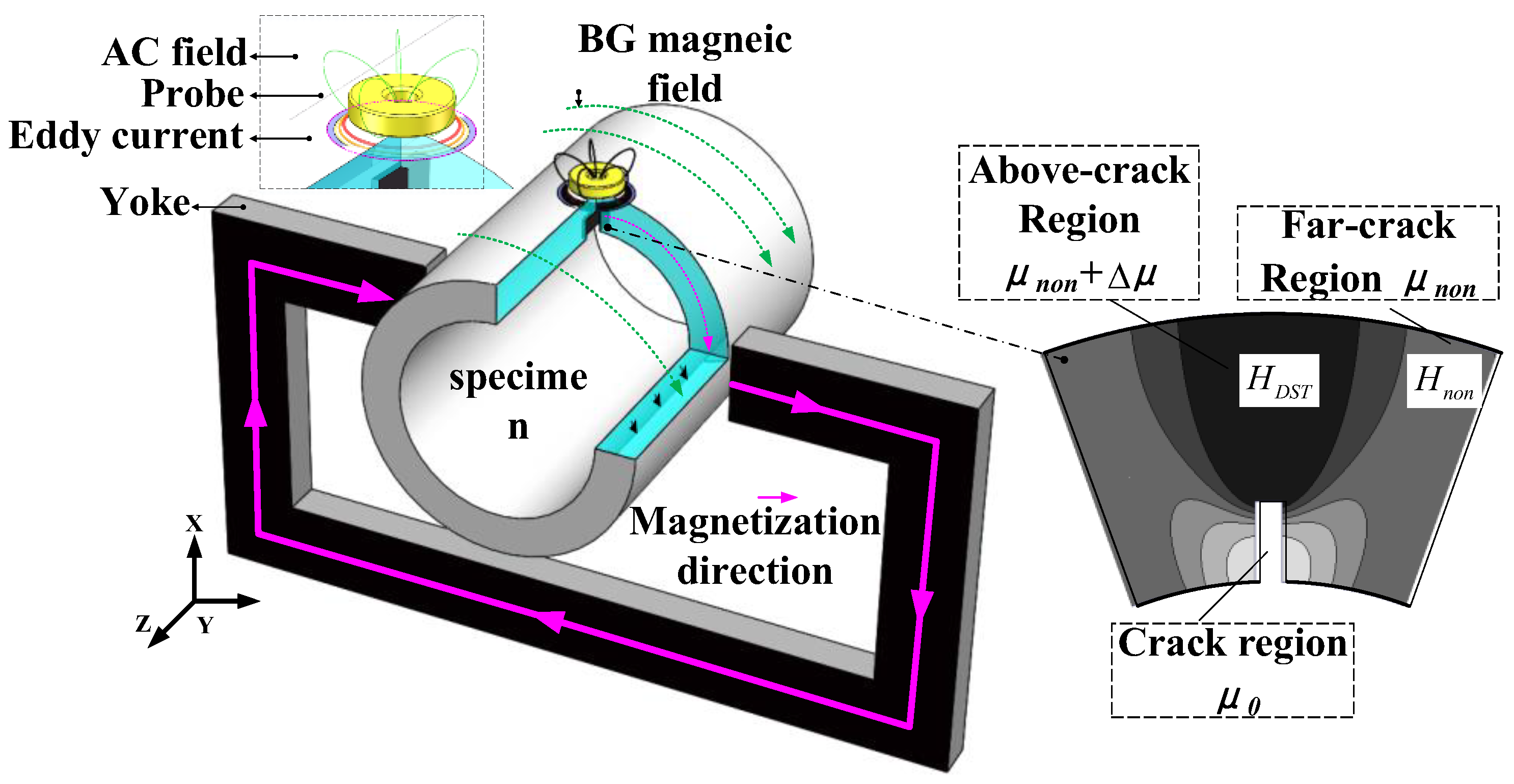

2. Mechanism

3. Simulation

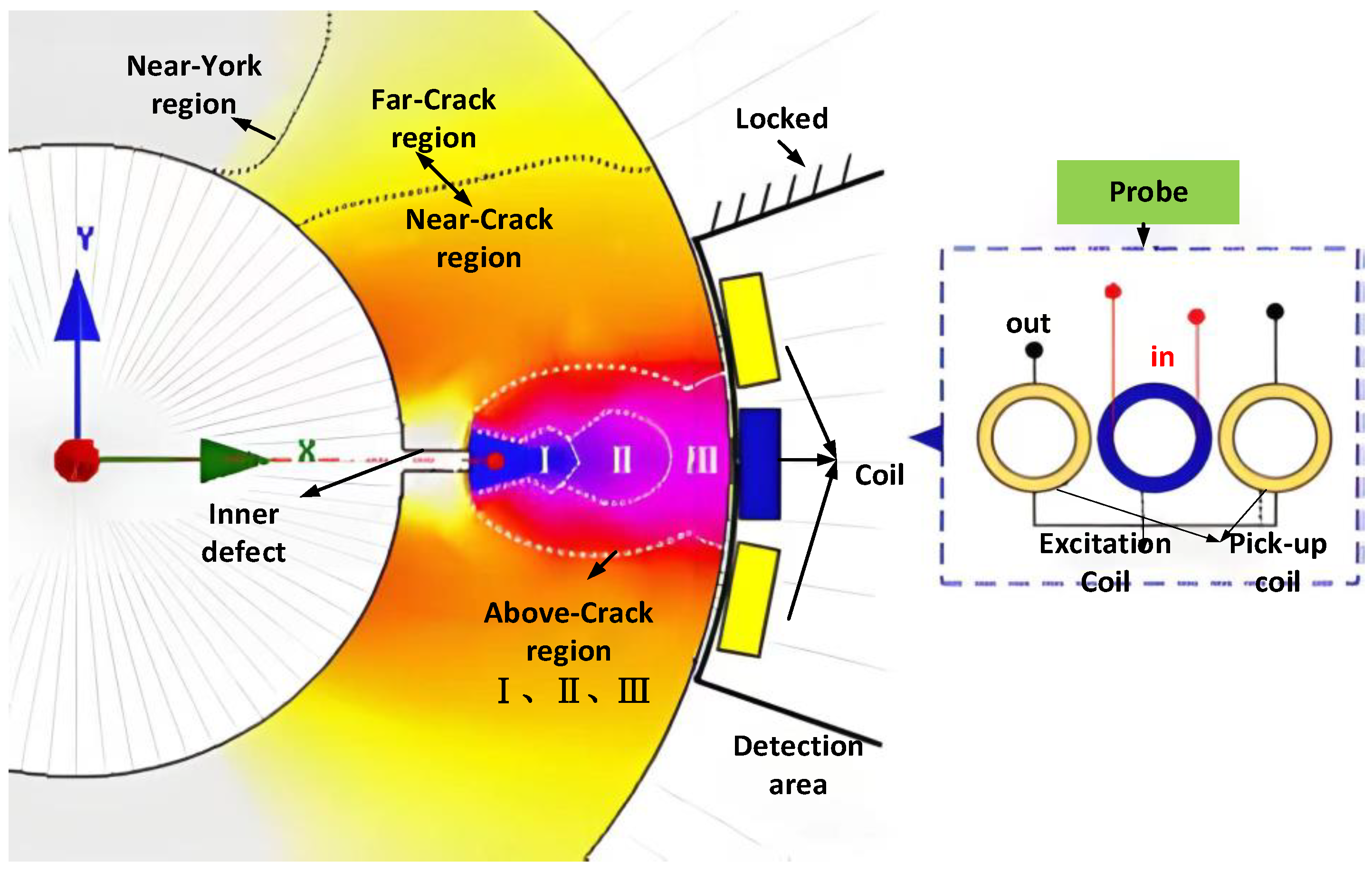

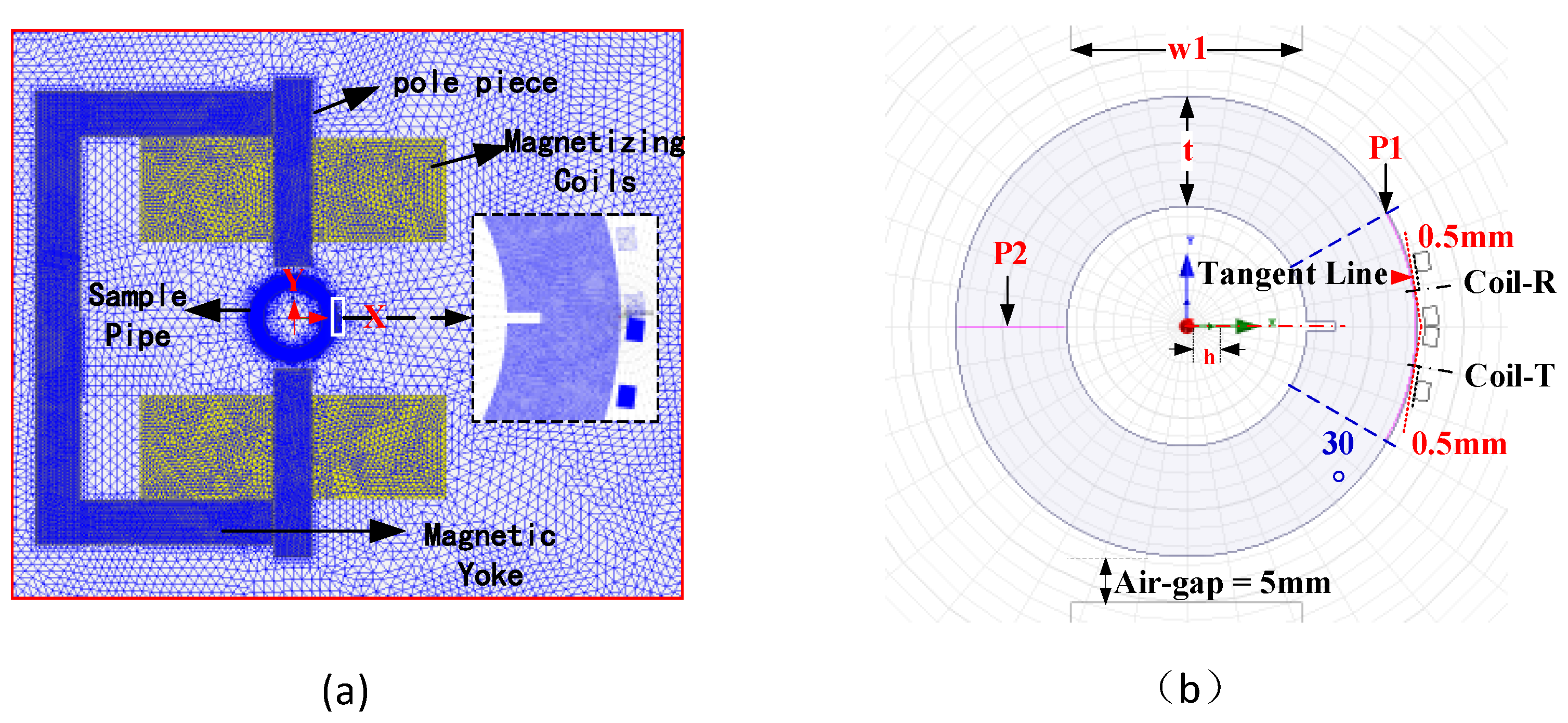

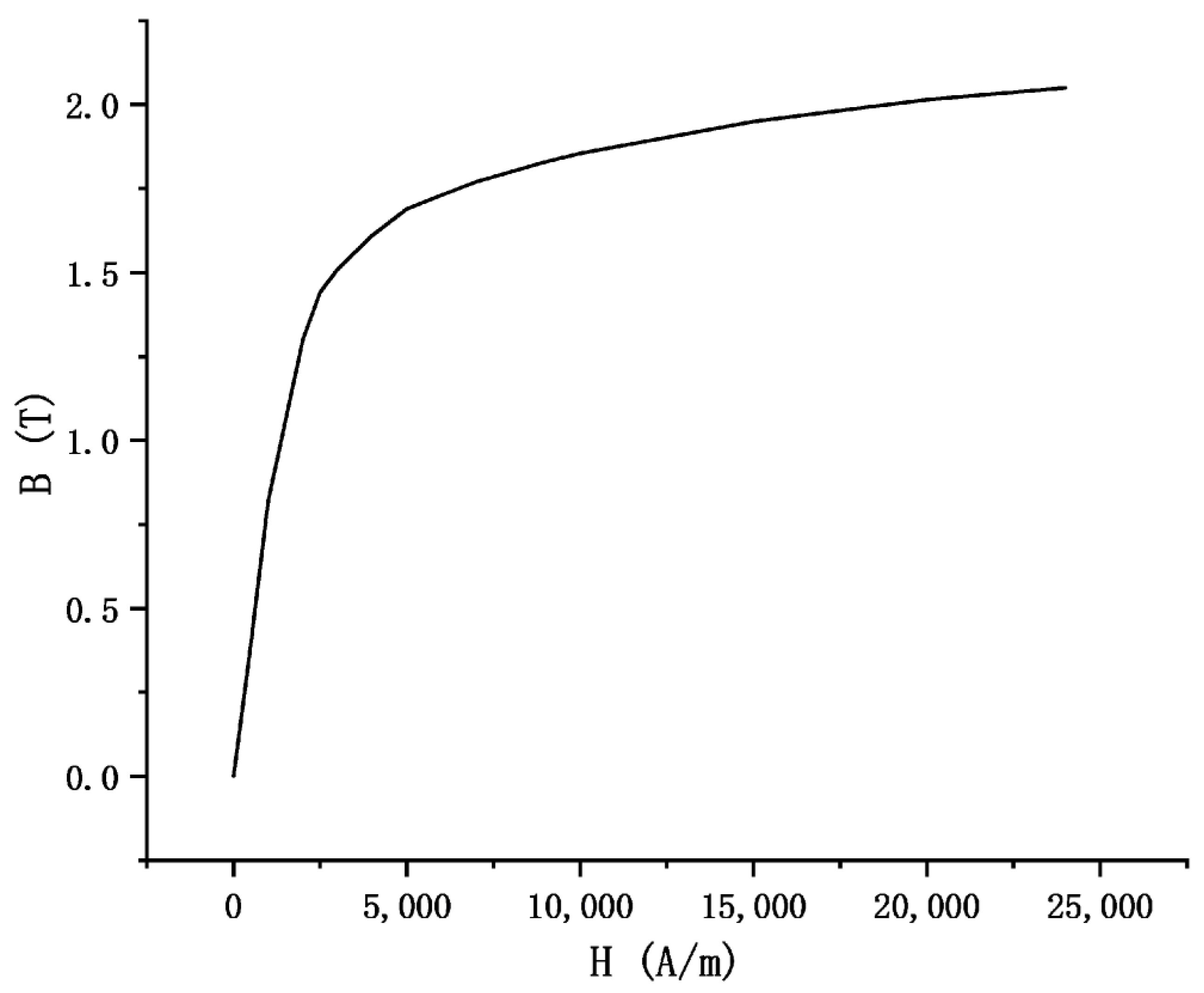

3.1. FEA Model of MPPT for Small-Diameter Thick-Walled Steel Pipes

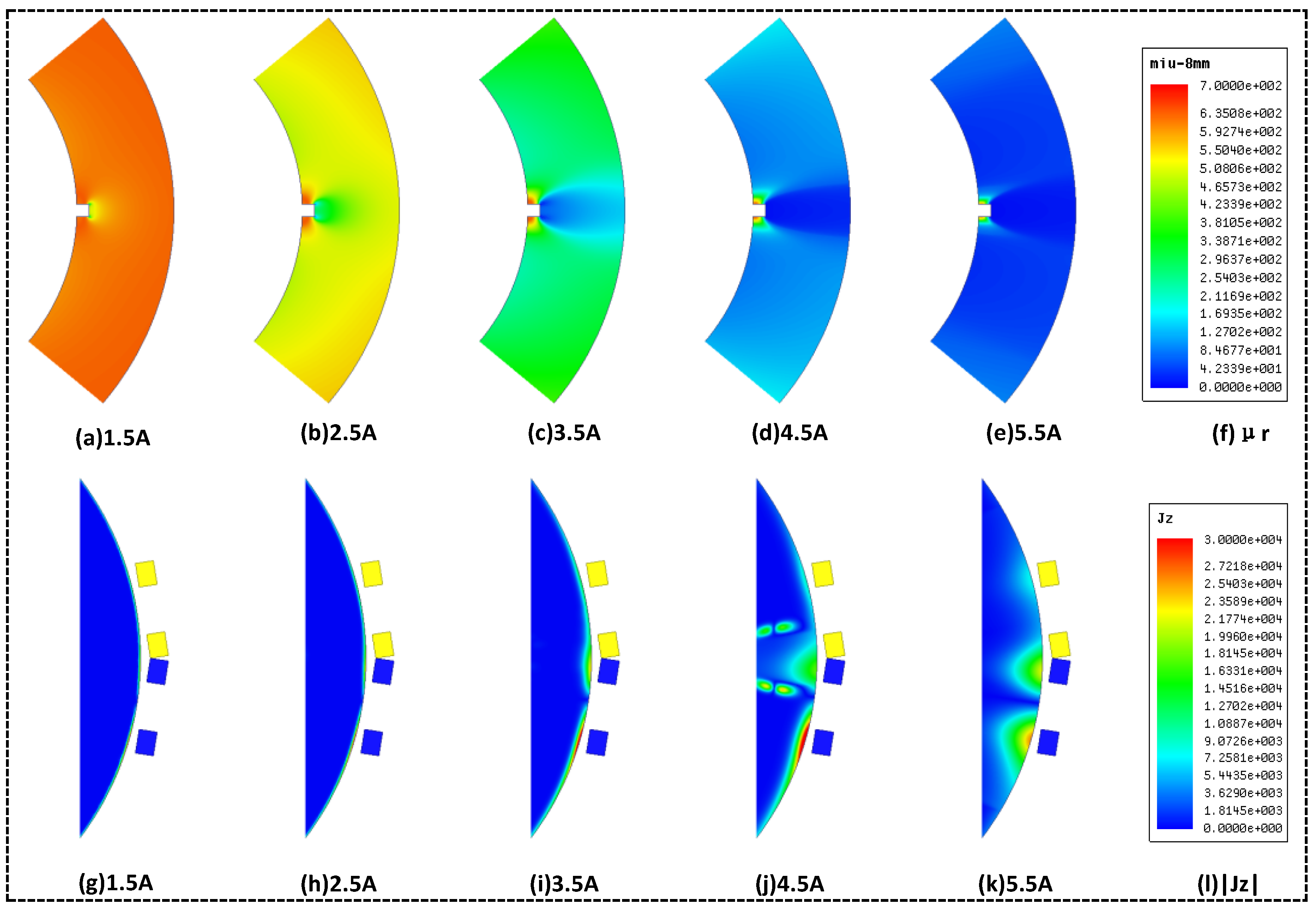

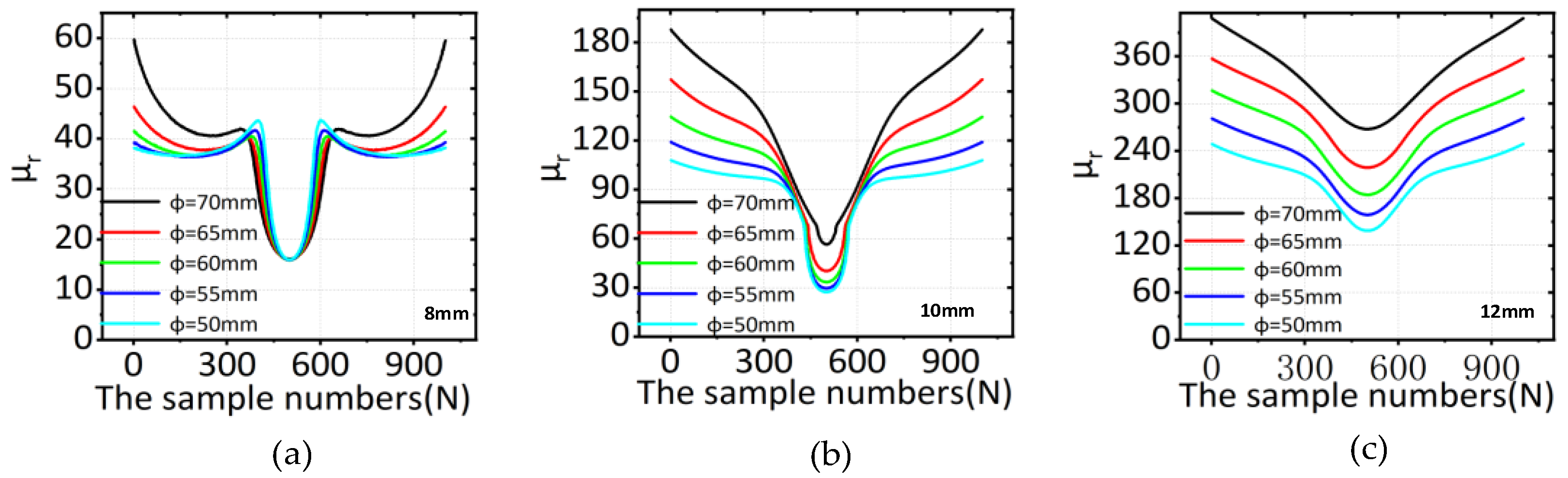

3.2. MPP of Axial Cracks of Different Diameters

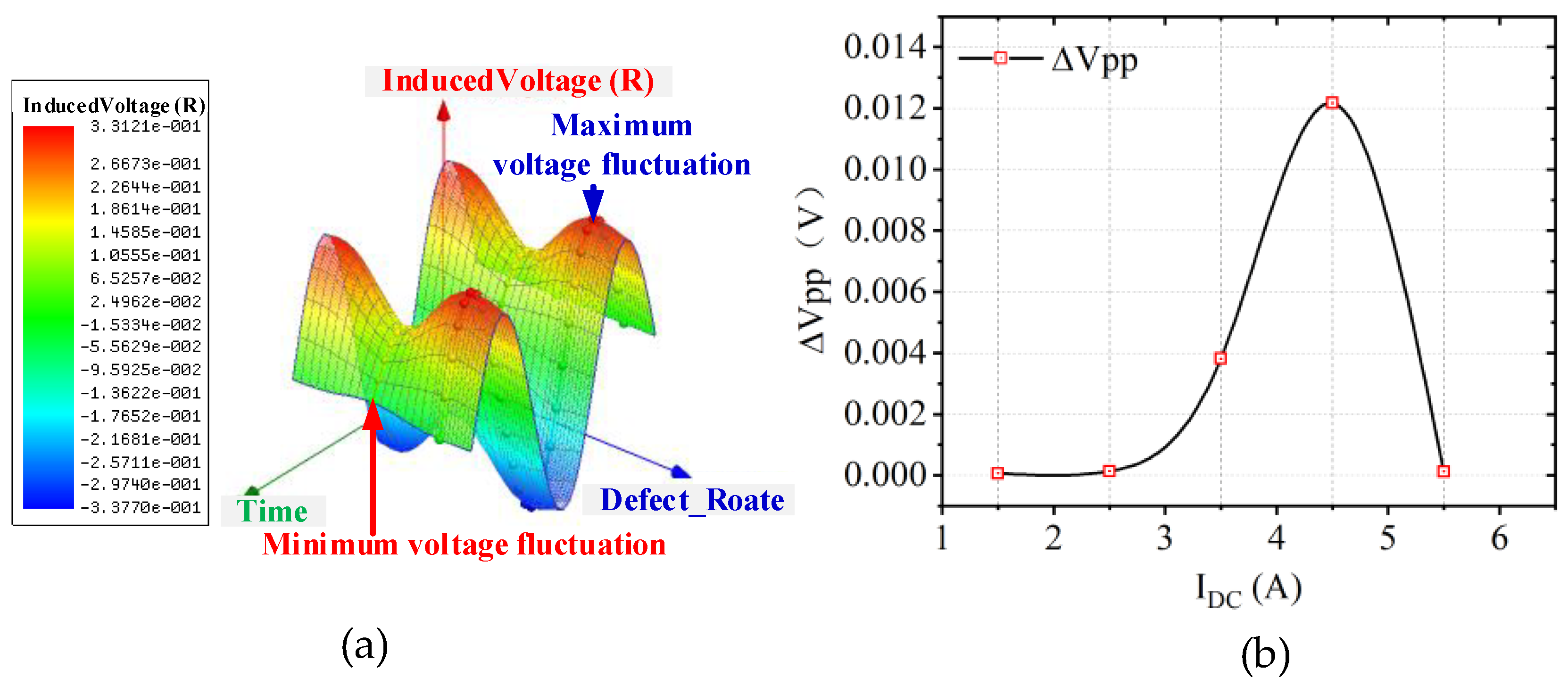

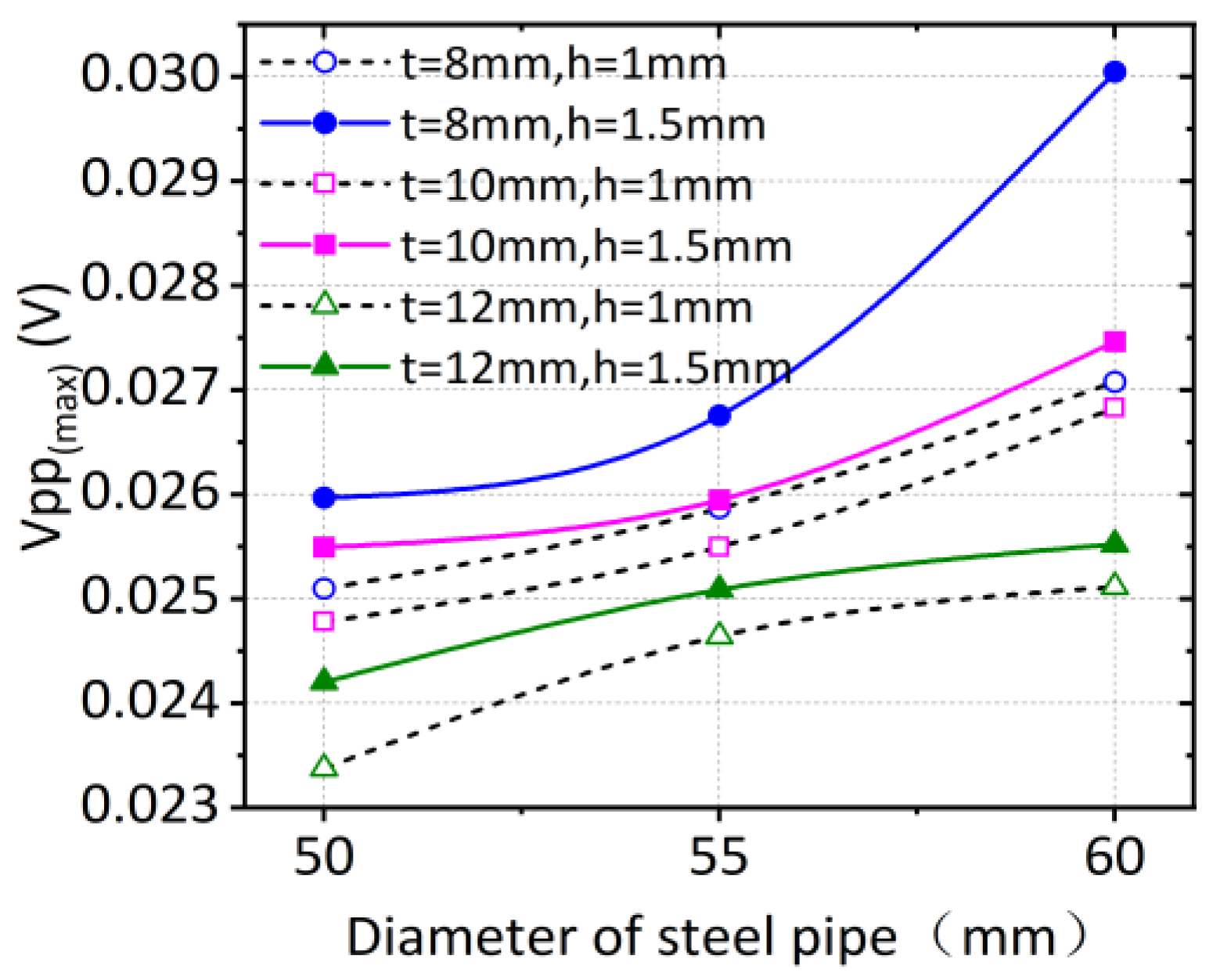

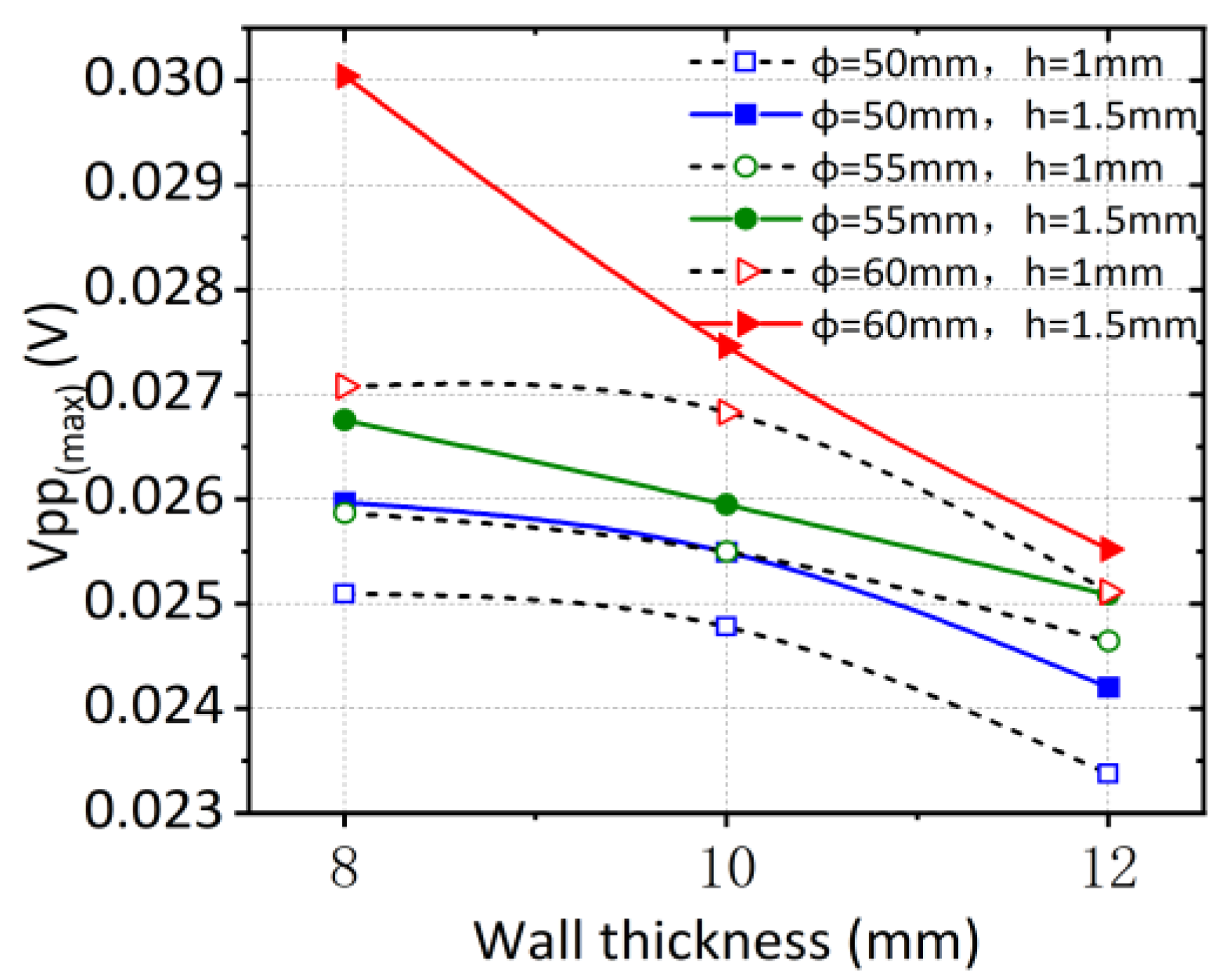

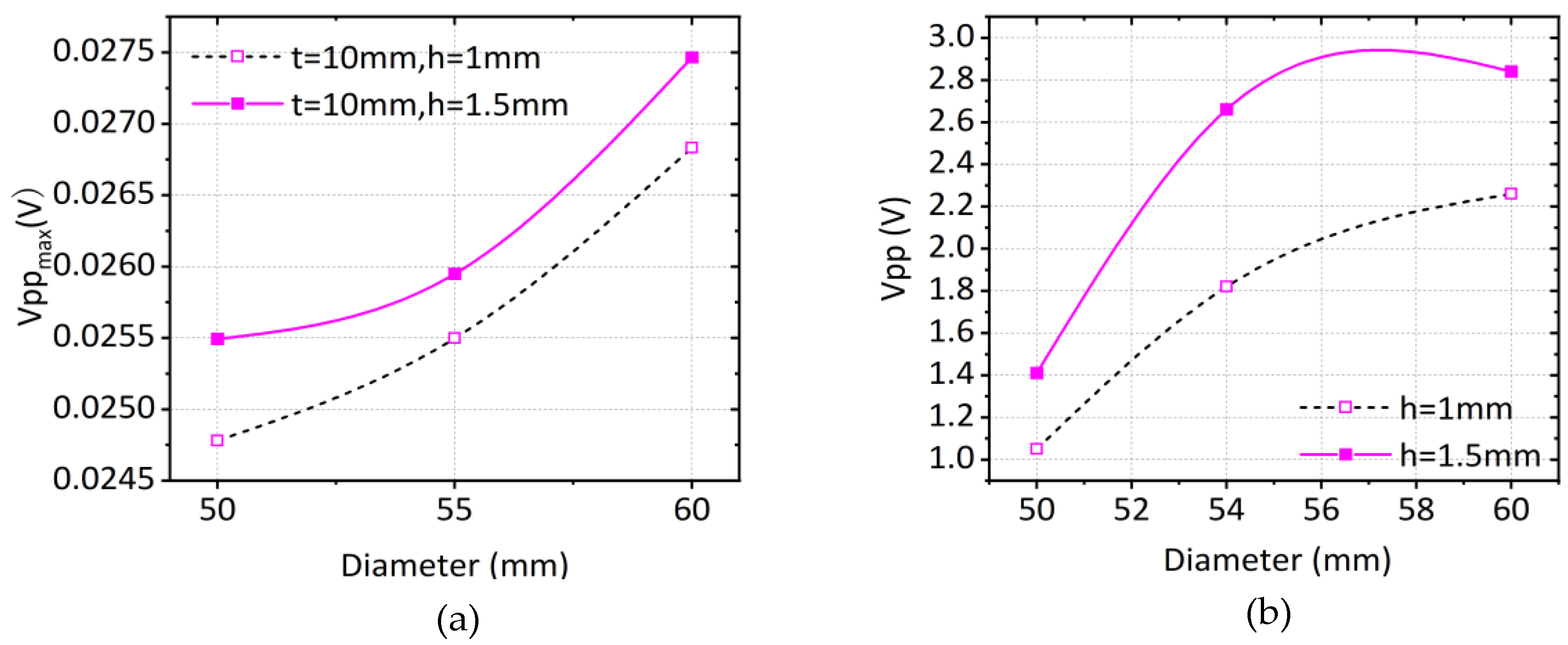

3.3. Effect of Diameter on MPPT Signal

4. Experiment and Results

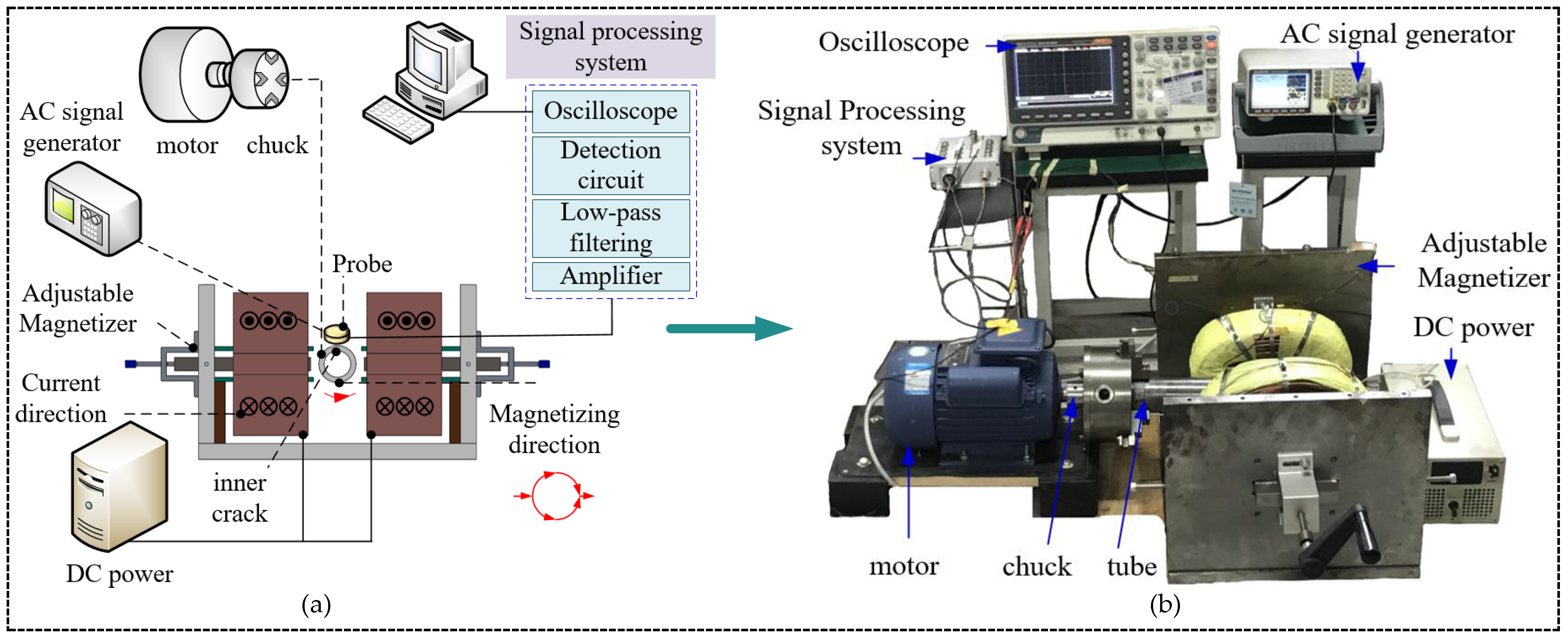

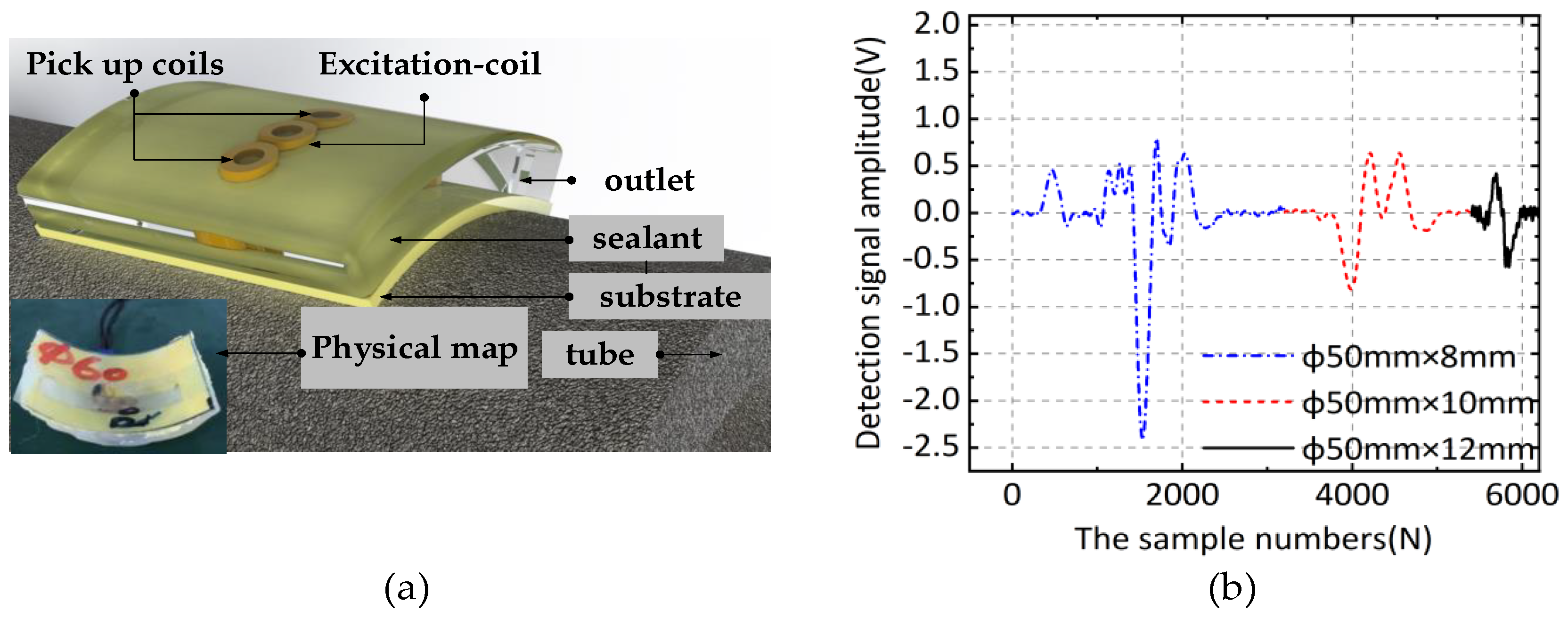

4.1. Experimental Systems and Specimens

4.2. Feasibility of MPPT for Small-Diameter Thick-Walled Pipes

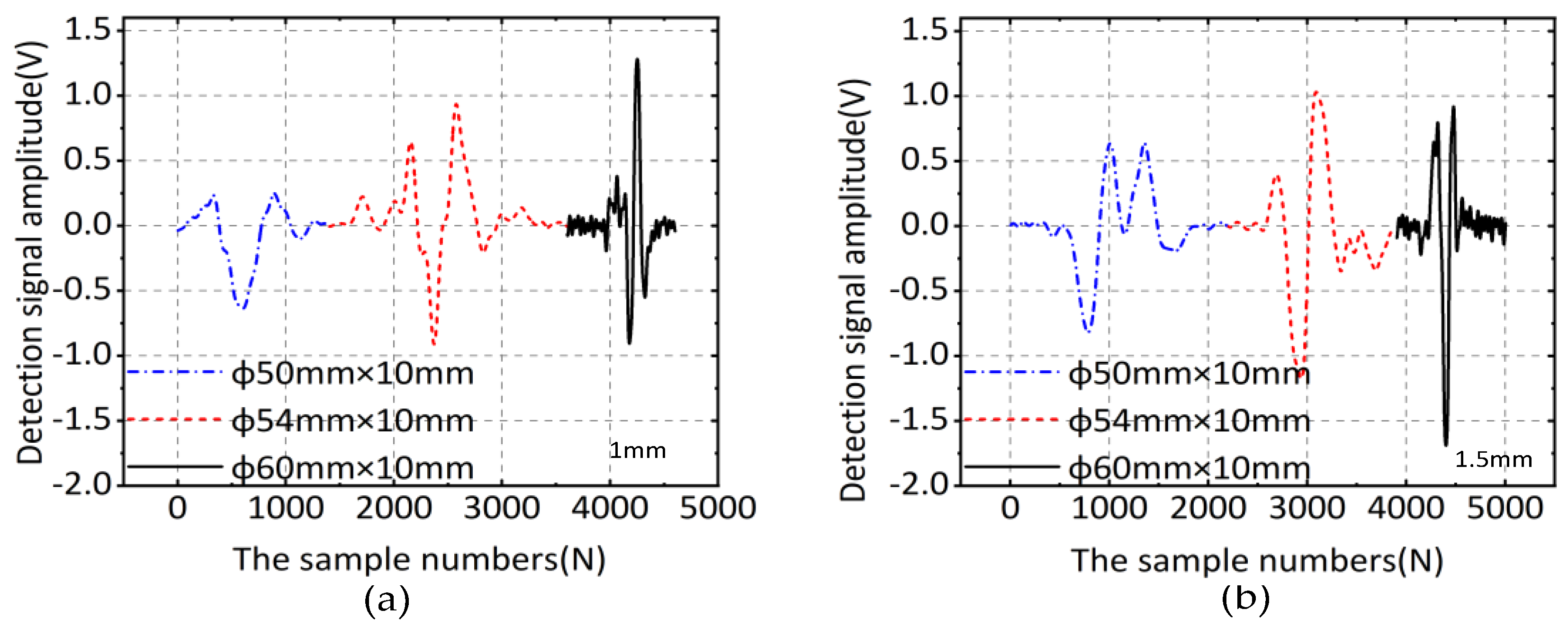

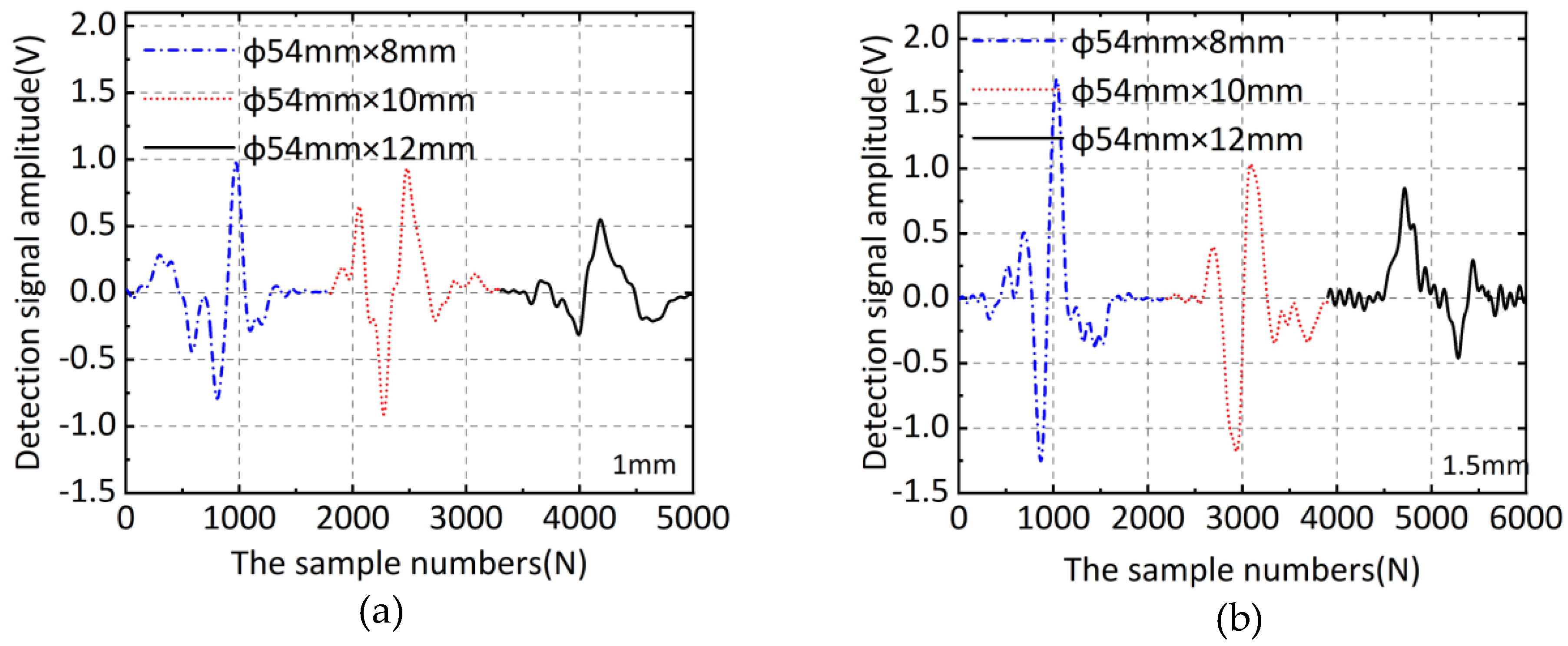

4.3. Effect of External Diameter of Pipes on MPPT Signal

4.4. The Effect of Wall Thickness on the MPPT Signal

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Lian, Z.; Hu, J.; Luo, M. Prediction of the Maximum Erosion Rate of Gas–Solid Two-Phase Flow Pipelines. Energies 2018, 11, 2773. [Google Scholar] [CrossRef]

- Chen, C.; Li, C.; Reniers, G.; Yang, F. Safety and security of oil and gas pipeline transportation: A systematic analysis of research trends and future needs using WoS. J. Clean. Prod. 2020, 279, 123583. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Y.; Li, C.; Sun, S. Effect of salinity on oil production: Review on low salinity waterflooding mechanisms and exploratory study on pipeline scaling. Oil Gas Sci. Technol.–Rev. D’ifp Energ. Nouv. 2021, 75, 50. [Google Scholar] [CrossRef]

- Zou, Y.; Du, D.; Chang, B.; Ji, L.; Pan, J. Automatic weld defect detection method based on Kalman filtering for real-time radiographic inspection of spiral pipe. NDT E Int. 2015, 72, 1–9. [Google Scholar] [CrossRef]

- Yoon, B.; Kim, Y.; Yang, S. An experimental result on flaw sizing of steam generator tube at nuclear power plants using ultrasonic testing. J. Nucl. Sci. Technol. 2012, 49, 760–767. [Google Scholar] [CrossRef]

- Marquez, F.P.G.; Muñoz, C.Q.G. A New Approach for Fault Detection, Location and Diagnosis by Ultrasonic Testing. Energies 2020, 13, 1192. [Google Scholar] [CrossRef]

- Yang, Q.; Xie, S.; He, K.; Chen, Y.-E.; Chen, Z.; Uchimoto, T.; Takagi, T. A novel circumferential eccentric eddy current probe and its application for defect detection of small-diameter tubes. Sens. Actuators A Phys. 2021, 331, 113023. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Lee, S.-S. Eddy current probes of inclined coils for increased detectability of circumferential cracks in tubing. NDT E Int. 2012, 49, 77–82. [Google Scholar] [CrossRef]

- Lysenko, I.; Kuts, Y.; Uchanin, V.; Protasov, A.; Petryk, V.; Alexiev, A. Using the Pulsed Eddy Current Techniques for Monitoring the Aircraft Structure Condition. Trans. Aerosp. Res. 2023, 2023, 22–31. [Google Scholar] [CrossRef]

- Yang, B.; Li, X. Pulsed remote field technique used for nondestructive inspection of ferromagnetic tube. NDT E Int. 2013, 53, 47–52. [Google Scholar] [CrossRef]

- Piao, G.; Guo, J.; Hu, T.; Deng, Y.; Leung, H. A novel pulsed eddy current method for high-speed pipeline inline inspection. Sens. Actuators A Phys. 2019, 295, 244–258. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.; Fan, M. Pulsed Eddy Current Non-destructive Testing and Evaluation: A Review. Chin. J. Mech. Eng. 2017, 30, 500–514. [Google Scholar] [CrossRef]

- Kako, M.; Tomizawa, T.; Ge, J.; Ruan, X.; Nozawa, T.; Yusa, N. The applicability of remote field eddy current testing to outer flaws on cooling tubes in the blanket of a fusion DEMO reactor. Fusion Eng. Des. 2023, 194, 113709. [Google Scholar] [CrossRef]

- Kobayashi, N.; Ueno, S.; Nagai, S.; Ochiai, M.; Jimbo, N. Remote field eddy current testing for steam generator inspection of fast reactor. Nucl. Eng. Des. 2011, 241, 4643–4648. [Google Scholar] [CrossRef]

- Thirunavukkarasu, S.; Arjun, V.; Rao, B.P.C.; Mukhopadhyay, C.K. Development of a High-Sensitive Dual Frequency Remote Field Eddy Current Instrument for Inspection of Ferromagnetic Steam Generator Tubes. IETE Tech. Rev. 2019, 36, 203–208. [Google Scholar] [CrossRef]

- Xiao, Q.; Feng, J.; Xu, Z.; Zhang, H. Receiver Signal Analysis on Geometry and Excitation Parameters of Remote Field Eddy Current Probe. IEEE Trans. Ind. Electron. 2022, 69, 3088–3098. [Google Scholar] [CrossRef]

- Liu, B.; He, L.-Y.; Zhang, H.; Cao, Y.; Fernandes, H. The axial crack testing model for long distance oil-gas pipeline based on magnetic flux leakage internal inspection method. Measurement 2017, 103, 275–282. [Google Scholar] [CrossRef]

- Parra-Raad, J.A.; Roa-Prada, S. Multi-Objective Optimization of a Magnetic Circuit for Magnetic Flux Leakage-Type Non-destructive Testing. J. Nondestruct. Eval. 2016, 35, 14. [Google Scholar] [CrossRef]

- Pham, H.Q.; Le, V.S.; Vu, M.H.; Doan, D.T.; Tran, Q.H. Design of a lightweight magnetizer to enable a portable circumferential magnetic flux leakage detection system. Rev. Sci. Instrum. 2019, 90, 074705. [Google Scholar] [CrossRef]

- Singh, W.S.; Mukhopadhyay, C.K.; Rao, B.P.C. Development of a high sensitive magnetic flux leakage instrument for imaging of localised flaws in small diameter ferromagnetic steel tubes. IET Sci. Meas. Technol. 2018, 12, 932–936. [Google Scholar] [CrossRef]

- Wu, D.; Liu, Z.; Wang, X.; Su, L. Composite magnetic flux leakage detection method for pipelines using alternating magnetic field excitation. NDT E Int. 2017, 91, 148–155. [Google Scholar] [CrossRef]

- Durai, M.; Lan, C.-W.; Chang, H. In-line detection of defects in steel pipes using flexible GMR sensor array. J. King Saud Univ.-Sci. 2022, 34, 101761. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, X.; Kang, Y. Local area magnetization and inspection method for aerial pipelines. NDT E Int. 2005, 38, 448–452. [Google Scholar] [CrossRef]

- Pei, C.; Xiao, P.; Zhao, S.; Chen, Z.; Takagi, T. A flexible film type EMAT for inspection of small diameter pipe. J. Mech. Sci. Technol. 2017, 31, 3641–3645. [Google Scholar] [CrossRef]

- Tu, J.; Zhong, Z.; Song, X.; Zhang, X.; Deng, Z.; Liu, M. An external through type RA-EMAT for steel pipe inspection. Sens. Actuators A Phys. 2021, 331, 113053. [Google Scholar] [CrossRef]

- Capponi, C.; Brunone, B.; Maietta, F.; Meniconi, S. Hydraulic Diagnostic Kit for the Automatic Expeditious Survey of in-line Valve Sealing in Long, Large Diameter Transmission Mains. Water Resour. Manag. 2023, 37, 1931–1945. [Google Scholar] [CrossRef]

- Brunone, B.; Capponi, C.; Meniconi, S. Design criteria and performance analysis of a smart portable device for leak detection in water transmission mains. Measurement 2021, 183, 109844. [Google Scholar] [CrossRef]

- Deng, Z.; Yu, Z.; Yuan, Z.; Song, X.; Kang, Y. Mechanism of Magnetic Permeability Perturbation in Magnetizing-Based Eddy Current Nondestructive Testing. Sensors 2022, 22, 2503. [Google Scholar] [CrossRef]

- Gotoh, Y.; Sakurai, K.; Takahashi, N. Electromagnetic Inspection Method of Outer Side Defect on Small and Thick Steel Tube Using Both AC and DC Magnetic Fields. IEEE Trans. Magn. 2009, 45, 4467–4470. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Taylor, D.; Rudlin, J. Flaw detection and quantification for ferromagnetic steels using pulsed eddy current techniques and magnetization. In WIT Transactions on Engineering Sciences; WIT Press: Ashurst, UK, 2003. [Google Scholar]

- Li, E.; Wu, J.; Zhu, J.; Kang, Y. Quantitative Evaluation of Buried Defects in Ferromagnetic Steels Using DC Magnetization-Based Eddy Current Array Testing. IEEE Trans. Magn. 2020, 56, 6200811. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, J.; Xu, Z.; Xia, H. A DC-Biased Scanning Induction Thermographic System for Characterizing Surface Cracks in Ferromagnetic Components. IEEE/ASME Trans. Mechatron. 2021, 26, 2782–2790. [Google Scholar] [CrossRef]

| Parts | Parameter |

|---|---|

| Excitation coil | Excitation frequency = 50 kHz |

| Voltage = 5 V | |

| Number of turns = 100 turns | |

| Inner diameter = 4 mm | |

| Outside diameter = 8 mm | |

| Magnetized coils | Magnetizing current = 5.5 A |

| N = 3200 | |

| Detection coil | Turn Ratio = 100 turns |

| Inner diameter = 4 mm | |

| Outside diameter = 8 mm | |

| R = 4 Ω; L = 90 μH | |

| Steel pipe material | Material = No. 45 |

| = 675 | |

| Defects in the inner wall | Width = 1 mm |

| Depth = 1 mm, 1.5 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Deng, Z.; Yu, Z.; Li, T.; Song, X. Magnetic Permeability Perturbation Testing for Internal Axial Cracks in Small-Diameter Thick-Walled Steel Pipes. Appl. Sci. 2023, 13, 7107. https://doi.org/10.3390/app13127107

Zhao X, Deng Z, Yu Z, Li T, Song X. Magnetic Permeability Perturbation Testing for Internal Axial Cracks in Small-Diameter Thick-Walled Steel Pipes. Applied Sciences. 2023; 13(12):7107. https://doi.org/10.3390/app13127107

Chicago/Turabian StyleZhao, Xueyu, Zhiyang Deng, Zhiheng Yu, Tingyi Li, and Xiaochun Song. 2023. "Magnetic Permeability Perturbation Testing for Internal Axial Cracks in Small-Diameter Thick-Walled Steel Pipes" Applied Sciences 13, no. 12: 7107. https://doi.org/10.3390/app13127107

APA StyleZhao, X., Deng, Z., Yu, Z., Li, T., & Song, X. (2023). Magnetic Permeability Perturbation Testing for Internal Axial Cracks in Small-Diameter Thick-Walled Steel Pipes. Applied Sciences, 13(12), 7107. https://doi.org/10.3390/app13127107