Abstract

As in any industry exposed to risk, human and organizational factors are the main stakes of maritime safety. Understanding the causes and risks of maritime accidents is integral to the sustainability of shipping. The investigation of marine accidents is a crucial tool for their identification in areas related to operations and ships, including social and situational systems, their design, and technical systems. The authors conducted a cause–effect analysis of marine incidents. For this purpose, case-by-case analysis and an Ishikawa diagram were used, which is a tool that helps identify actual or potential causes of accidents. The study showed that by far the most significant cross-section of causes of accidents were elements of social and situational systems that affect the safety of the ship, crew, and environment. The least significant contribution came from the machinery area. Through the detailed descriptions, a picture emerges not so much of a lack of knowledge of the regulations as of a failure to comply with existing procedures or best practices. In the authors’ opinion, more emphasis is needed on preventive measures, including safety culture, training, competence assessment, and increased awareness of the need for sustainability.

1. Introduction

As in any risk-prone industry, human and organizational factors are a vital component of maritime safety. In most professional analyses carried out by authorized bodies, the human factor is important, if not the most important, out of the numerous factors leading to accidents. To reduce the number of adverse events, intensive research is carried out to identify their causes. Instructions, recommendations, regulations, and so-called checklists are developed. All these activities are intended to lead to the detailed development and strengthening of a safety culture [1,2], a term that first appeared in a preliminary report by the International Atomic Energy Agency (IAEA) after the Chernobyl disaster [3]. The early investigation into the accident initially focused on deficiencies in the power plant’s design. However, more detailed analyses also pointed to problems with managerial and social and situational systems problems. Safety culture’s primary objective is focused on creating and promoting certain habits among employees, following dedicated procedures in the work environment, paying special attention to any shortcomings, being cautious of any inconsistencies within equipment handling, and regarding other employees’ labor. Similar aspects exist for shipping that are related to professions in general and, as per this article, its specific element, navigation. People working in the marine industry selected for interviews by Teperi [4] claim that safety culture has been shaped based on regulations and principles application.

Beyond safety culture, there are several formal international organizations that regulate the organization of maritime labor, with safety as one of the main goals. In order to improve safety across marine areas, The International Safety Management Code has been established, with hopes that an introduction of this ISM code will directly lead to the significant upgrade of safety culture [5].

On top of formal organizations, multiple ship safety procedures are subject to detailed regulations. Their lack or omission usually results in death, pollution of sea and land areas, and damage to the cargo or ship.

Current literature and use cases, e.g., official incident reports, treat the human component in a holistic way as one of the reasons for sea incidents and accidents, next to, for example, hydrometeorological conditions, mechanical failures, or force majeure [6]. They analyze human element subcomponents in a very general way, investigating so-called social and situational systems. These approaches, while having several advantages and being described in multiple sources, due to their general nature do not allow for the detailed analysis of specific root causes of sea incidents and are not suitable for improvement programs, neither for current control procedures nor for screening procedures performed on the ship. They can neither be used directly in marine educational units nor in training programs within STCW centers.

The objective of this research is to build a multilayer taxonomy of isolated and defined elements as components of the human error category, which is one of the main factors behind marine incidents. An investigation was performed that included a review of subject matter literature, analyses of individual cases, and a weighted Ishikawa diagram. The authors also performed a qualitative analysis of selected cases of several various sea accidents, followed by qualitative and quantitative analyses of incidents causes performed using a modified hierarchical Ishikawa diagram, comparison matrix, and stratification analysis. The analysis led to an isolation of key causes of human error which, as already mentioned, is a main factor in marine incidents. This work represents an innovation of how one can investigate the human component as a cause of marine incidents. Examining individual factors such as air quality or perceived pain allows educational and training institutions to modify their programs and focus on top key incident contributors.

2. Marine Safety in Relation to Human Errors and Their Root Causes: Background, Literature Review and the Concept of Social and Situational Systems

2.1. Marine Safety as a Goal of Formal Organizations

Safety is one of the primary goals of multiple organizations around marine space. The most prominent one—The International Maritime Organization (IMO)—has adopted Resolution A.850(20), defining its vision, principles, and goals for the human element [7]. It was updated by Resolution A.947(23), which was adopted in 2003 [8] and assumes that human factors are a complex, multidimensional issue that impacts maritime safety, security, and marine environment protection. Additionally, effective remediation following maritime casualties requires a solid understanding of the human factor’s contribution to causing accidents; that adequate safeguards be put in place; that rules and regulations are simple, clear, and comprehensive; and that communication is flawless. It also recognizes that crew endurance is a function of many complex variables, including personal knowledge, management principles, cultural factors, experience, training, professional skills, and work environment. The resolution has several objectives:

- Implement a structured approach to the proper consideration of the human element.

- Conduct a comprehensive review of selected existing IMO instruments.

- Promote and communicate a maritime safety culture across the marine environment.

- Encourage the development of non-regulatory solutions.

- Implement a system to identify and disseminate human factor analysis and research.

- Provide educational material for seafarers on human factor issues.

- Provide a framework for understanding a highly complex system of interrelated human factors [7,8].

Thus, not only is the human factor being recognized as a key contributor to marine safety but there is also an understanding of how much culture can influence the practical application of formal rules. Another essential organization regulating maritime labor is the International Labour Organisation (ILO). Together with the IMO, they attempt to solve problems regarding the human factor in the marine sector. The result of this cooperation is the Seafarers’ Employment Agreements from 2006, updated in 2016 [9,10].

Other organizations, such as the International Association of Ship Classification Societies (IASCS), are also contributing to improvements in safety on all ships by introducing their set of rules, regulations, and requirements. Also worth mentioning is the International Safety Management (ISM) Code, one of the most robust tools to prevent human errors in shipping, adopted by the IMO by Resolution A741(18), which became effective on 1 July 1998 as Chapter IX of the SOLAS Convention on the management of the safe operation of ships.

Every country has its own framework for ensuring that accidents are analyzed and learning applied. In Poland, for example, the body investigating the causes of incidents is the State Marine Investigation Commission (SMAIC), while in the UK, it is the Marine Accident Investigation Branch (MAIB). However, despite the ongoing detailed inspections of all ships sailing on the seas and oceans, and the detention of non-compliant ships, accidents happen almost every day due to the failure of safety mechanisms, and their number must be reduced. As systems improve, new and convenient technologies are introduced, resulting in excessive human reliance on them. [11]. Unfortunately, safety management systems are often over-regulated, too detailed, and too time-consuming [12]. Sometimes, such procedures are difficult to apply in real life, with multiple conflicting priorities around timeliness, cost, and efficiency [13]. While good practices exist to improve safety on every vessel, it is a common practice in the marine industry to purchase a standard, off-the-shelf safety management system designed and developed for a certain group of vessels or companies. This makes safety audits easier on the one hand, but these systems sometimes do not match the specific profile of a given ship [14,15]. For many seafarers, managing safety is an additional workload (documentation, procedures) requiring their concentration and distracting them from delivering their basic tasks [16,17]. Some researchers claim that managing safety takes time and may decrease seafarers’ levels of concentration [18]. As displayed in multiple publications [19,20,21], safety procedures across many industries have been evaluated as too complex and requiring documentation that is too broad, which in itself could potentially lead to incidents. This leads to the conclusion that simply having formal organizations, regulations, and documented practices might not lead to an increase in safety. The marine industry must more actively adopt a safety culture by better analyzing past incidents and driving improvements to educational and training programs.

2.2. Human Errors as Causes of Incidents

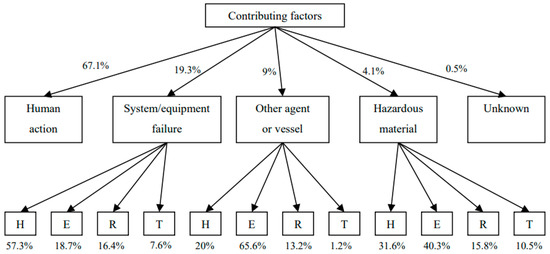

Every marine accident may have one or more causes. More than one accident may be associated with one incident. The five categorized causes are human action, system or equipment failure, other agent or vessel, hazardous material, and unknown. Each accident can also have one or more contributing factors, which are divided into three main categories: external environment, shore management, and ship operation. Studies have shown [21] that human error contributes to the following:

- 84–88% of tanker accidents [22].

- 79% of tugboat accidents [23].

- 89–96% of collisions [24].

- 75% of fires and explosions [24].

Contemporary sources [25] show the following breakdown of accidents and contributing factors:

- Cargo ships—in more than 80% of cases, the human factor was the leading cause or at least a component.

- Fishing vessels—56.5% of accidents were related to human factors.

- Passenger ships—65.4%.

- Specialist, service vessels—65.5%.

- Other ships—71.1%.

As shown in Figure 1, considering the 67.1% of human action in the basic breakdown of accident factors and the corresponding human–related percentages in the groups of: system/equipment failure, other agent or vessel, and hazardous material, there is in total more than 81% impact of the human factor on causes of accidents. It is evident, that the human factor is a direct or indirect cause of almost all marine accidents; thus, a proper analysis of the components that influence such errors can positively influence safety at sea.

Figure 1.

Tree of events of contributing factors to accidents. Source: own study based on [25]. H—Human behavior, E—Environment, R—Rules, procedures, and training, T—Tools and equipment.

2.3. Review of the Literature

A lot of documented research on the influence of the human factor on marine accidents is based on modelling techniques and focuses on the identification and quantification of the probability of human and organizational errors [26,27,28,29]. The HFACS method, being widely used, defines four cause categories: organizational influence, insufficient supervision, initial conditions for risky actions, and risky actions. In order to solve defined problems from a marine area, Chen et al. [30] proposed the HFACS—Maritime Accident (HFACS—MA) method. It uses a SHEL model, which stands for Software (S), Hardware (H), Environment (E), and Liveware (L), to describe initial conditions in a traditional HFACS environment. Another method based on a similar idea, HFACS for passenger vessels (HFACS—PV), has been proposed by Ugurlu et al. [31]. It treats operational conditions as a new HFACS category. The authors of this method believe that operational conditions are not a hidden fault but rather a result of a higher-level component that then leads to the accidental results of dangerous actions. Another modification of the original method is HFACS Fuzzy Cognitive Mapping (HFACS—FCM), proposed by Soner et al. [32], where a fuzzy cognitive map is used to identify and quantify definitions of causes that are initiated in HFACS. It is mainly used to strengthen organizational safety measures for fire accidents and collisions [33]. Other documented techniques that are a modification of HFACS include FAHP [34] and ANP [35], which use a process of fuzzy analytical hierarchy to identify causes contributing to HFACS; HFACS and Chi-square test [36]; HFACS and FTA [37]; and fuzzy FTA, ANN, and HFACS [38].

Another source [39] shows that human-related factors play a significant role in shipboard accidents. For example, in 2020, 63% of accidents were caused by human error and 37% of accidents had a technical cause. Therefore, this problem should still be presented and possible solutions proposed; all components of a ship’s operation should be carefully analyzed, cataloged, and broken down into specific parts along with their source and a set of recommendations provided on how to counteract their negative effects on the safety of life at sea. An essential element is social and situational systems [40,41,42].

Looking further into significant causes of marine accidents, refraining from proper visual observation, over-reliance on GPS, fatigue, commercial pressures, and distraction are other significant causes of accidents. In an archive issue of The Navigator, David Patraiko, project director at The Nautical Institute, argued that new technologies and changing regulations can generate unknown direct causes of accidents [43]. A similar analysis can be found in another report from Acejo [44].

Nevertheless, shipping has maintained a long-term positive safety trend over the past year. Still, the recent COVID-19 pandemic and Russia’s invasion of Ukraine are major impact factors on global supply chain routes and capacity that have placed enormous stress on the system, with potentially detrimental outcomes: loss of life, loss of ships, exacerbated crew crisis, trade disruption, sanctions burden, and increased cost and reduced availability of bunker fuel. The main places of incidents are Southern China, Indochina, Indonesia, and the Philippines. The increasing number of costly problems may be associated with manning larger ships, the challenges of port congestion due to the shipping boom, and managing ambitious decarbonization goals. Port congestion puts pressure on crews and facilities, meaning there is no room for complacency [43]. Additionally, the increased use of non-container ships to carry containers, despite bulk carriers not being designed to carry containers, can affect their maneuverability in bad weather, and crews may need assistance in responding appropriately to incidents.

All the mentioned components result in a situation where crew demand is high; however, many skilled and experienced seafarers are leaving the industry. A serious shortage of qualified staff is expected over the next five years. Among those who remain, morale is low as commercial pressures, cargo operations responsibilities, and workloads are high. This work situation is prone to error, with 75% of incidents involving human error, according to an AGCS analysis [45].

A Dutch study of 100 victims of navigation accidents [46] showed that the number of causes of accidents ranged from 7 to 58, with a median of 23. Therefore, half of the accidents had 7–23 causes and the other half had 23–58. Sometimes, small things go wrong or small mistakes may seem harmless. However, when these seemingly minor events come together, the result is a casualty. The study found that human error contributed to 96 of 100 accidents. In 93 accidents, there were multiple human errors, usually by two or more people, each making approximately two mistakes.

The key finding was that each human error was identified as a precondition for accidents. This means that if only one of these human errors had not occurred, the chain of events would have been broken, and the accident would not have happened.

There are many demanding aspects of shipping, such as the inability of employees to leave the workplace, extreme weather conditions, long periods away from home, and workplace traffic. Some of these are immutable and reflect the nature of the field. Sometimes, very ordinary situations, such as using the toilet, lead to a procedure breach (rest hours) when, for example, there is only a captain and an officer on duty on board the ship.

Nonetheless, it is possible to modify, supplement, and introduce new strategies or interventions to reduce the impact of these factors on the health and well-being of individual seafarers [47].

Maritime transport has a safety level that is comparable to rail transport and much higher than road transport. In the case of passenger transport in Europe, the risk of a fatal accident is estimated to be 1.1 for road transport and 0.33 for ferry transport [48]. In this context, accident risk and, more precisely, the place of the human factor in this risk, are central issues. Indeed, the human factor appears to be the leading cause of accidents at sea [49]. Among the factors that contribute to incidents are productivity loss (fatigue, stress, health problems), insufficient technical and cognitive skills, insufficient interpersonal competencies (communication difficulties, difficulty in mastering a common language), and organizational aspects (safety training, team management, safety culture) [34,49]. Following this, the article “On your watch automation on the bridge” took a closer look at issues of human–machine collaboration and the role of automation in marine accidents [50]. In the case of a collaborative crew or team, a shared mental representation is one of the key elements behind every safe action. Methods developed in cognitive psychology to analyze this mental structure can be used to assess its impact [51] on crew performance. A study of this type was conducted some years ago [51]. However, as presented in [52], this research remains marginal in maritime transport. Since human error (and usually multiple errors by multiple people) contributes to most marine accidents, preventing human error is essential to reduce the number and severity of maritime accidents. Many types of human error have been described, most of which are not the fault of the human operator. Instead, most of these errors occur due to technology, working environments, and organizational factors that do not account for the capabilities and limitations of the people interacting with them, thus setting up the operator for failure.

In general, there are ways to prevent some human errors or at least increase the chance that such errors will be noticed and corrected by improving the safety culture through better education and training for the better analysis of human factor causes of accidents. As such, we can achieve greater safety at sea and fewer casualties. Summarizing the available data, in the years 2014–2020 there were 6921 injuries, which corresponded to 6211 incidents, and crew members accounted for 81% of the victims [53]. These numbers are very high and should be a call to action for the marine industry.

2.4. Social and Situational Systems

To fully describe social and situational systems, it is first necessary to understand what the human factor is—the interaction of humans with the environment and such human behavior that results in an error [54]. Attention must be paid to the cause effect relationship that contributes to an accident, and that the behavior of the people involved need to change to improve the whole system in the future and reduce the number of accidents [55]. People management must be constantly being improved to prevent errors.

Social systems can be defined as complex entities, i.e., interrelated elements linked by a relationship and interacting with each other. They are separated from the external environment by a clear boundary. The most important factor of such a system is people, without which, it cannot function, let alone exist [56]. Elements of the social system, such as social pressure, role, or life stress, are prevalent in a seafarer’s work. Their common denominator is stress, i.e., a reaction responsible for the equilibration of the organism as a result of disturbing external stimuli. This manifests during unusual events or situations not previously encountered. Stress harms the functioning of a person in various spheres of their life and can also cause a deterioration in health. It is essential to realize that anxiety will never disappear from a person’s life; it cannot be eliminated in any way. The average individual only focuses on its adverse effects, but what is usually overlooked is that stress, when controlled, can be a factor in self-improvement.

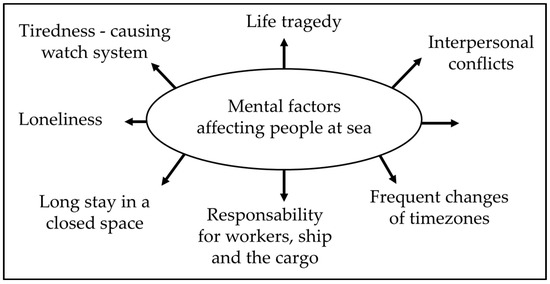

Social pressure exists in every society. In the case of a ship’s crew, a certain attitude, behavior, or mindset is expected from the employee [57,58]. How they cope with this type of pressure depends on their mental state. It will be more stressful for some and for others less so. An example of social anxiety on a ship could be the shipowner’s expectations of the captain, e.g., punctuality, or the chief officer’s expectations of other seafarers, e.g., to complete a task quickly [59]. As competence increases, so does one’s responsibility for the ship and less competent staff. The consequences of poor decisions made under stress can result in an accident or disaster. The essential skill, in this case, is to focus on solving the problem that has arisen and treating it as a challenge rather than on minimizing the stress caused by a problematic situation. In the case of life pressures, there are situations such as the death or illness of a family member, divorce, personal injury, loneliness, and risk of redundancy. These events usually cannot be influenced or changed; thus, adapting to a new situation is complex. With the intense emotional impact of such stress, a person can experience physical and psychological disorders [60] (Figure 2).

Figure 2.

Mental factors that affect a person when working on a ship. Source: own study based on [61].

The situational system is the collection of individual factors that affect a person in a given environment and contribute to mistakes, such as employee fatigue during watch work, long physical work, perceived pain, and arduous hydrometeorological conditions. A tired worker is much more likely to make a mistake. These elements are interrelated to a greater or lesser extent [61].

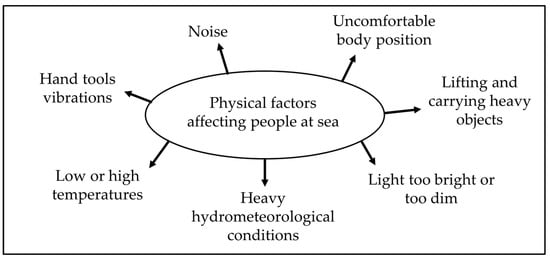

Environmental stress occurs when the place where one works or lives is not organized correctly. Some external stimuli can cause this type of stress, such as air quality (dust, smells, allergic reactions); temperature (tropics or polar zone—high temperatures cause a decrease in employee efficiency and low temperatures increase drowsiness and decrease concentration, which affects one’s ability to think quickly and logically and perform tasks flawlessly [62]); noise (operation of the main engine, navigation in ice); lighting (the polar night and tropical zones can cause eye pain and increase worker fatigue or feelings of drowsiness); and order in the room (personal space, the intrusion of others into one’s living space when they are currently resting, constant intrusion, rocking of the ship, feeling physically threatened). The last example can be particularly stressful for people with seasickness. Even in the cabin, the rocking effect of the vessel can cause significant stress and discomfort. All this can lead to a deterioration in the quality of work and the possibility of mistakes [63].

There are also ergonomic aspects, such as repetitive tasks, hand strain, uncomfortable posture, vibration, and noise, which significantly affect the efficiency of the work performed and can cause adverse effects on human health. For example, repetition of the same activity can lead to monotony and fatigue. Continuous work with an uncomfortable posture can cause fatigue, discomfort, and pain. Vibrations from hand-held devices, such as electric and pneumatic hammers, grinders, and drills, can cause various types of diseases and damage to hand structures as well as fatigue, irritability, insomnia, and coordination problems [64,65]. These components that affect people at sea are pictured in Figure 3.

Figure 3.

Physical factors that affect a person during work on a ship. Source: own study based on [61].

2.5. Ship Safety: Training in Social and Situational Systems

Training centers, universities, and schools related to maritime work teach the subject of Ship Safety, which is required by STCW and aims to provide knowledge of international and national regulations in which a ship’s safety in various operating conditions has been addressed and to develop students’ skills to apply them in hazardous conditions. The syllabus discusses the formal and process frameworks of the safety aspect, i.e., the regulations, organizations, processes, and procedures that are key to those in command of vessels and crews. However, a careful reading of post-accident reports shows that accidents are often caused not by a lack of knowledge of the regulations but by a lack of appropriate behavior. In one case, the commanding officer of the high-speed passenger ship, Express 1, undoubtedly knew the relevant rules, regulations, procedures, and laws. However, pressure from the shipowner—not explicitly stated, but hanging over the vessel in the form of a strict timetable—resulted in dealing with many issues simultaneously. This resulted in the commander being preoccupied with these activities instead of concentrating on navigation and steering in conditions of minimal visibility, leading to a collision with the Baltic Condor. The authors believe that both the captain and the second person at the helm of Express 1 would have been able to correctly apply radar noise reduction in calm conditions and consider the echo’s potential position on the course dash. However, a flurry of tasks not directly related to steering in dense fog at very high speeds of more than 30 knots caused the echo of another craft on course to be overlooked, and a collision ensued [66].

When using any means of transport, accidents are inevitable and happen because of errors, with lasting consequences. Social and situational systems consider 12 types of effects of maritime accidents:

- Collision and resulting oil spill. At dawn on 7 October 2018, approximately 15 nautical miles north of Cap Corse, in international waters, the ro-ro vessel, Ulysse, bound for Radès (Tunis), struck the starboard side of the unloaded Cypriot-flagged container ship, CSL Virginia, at anchor. Shortly after the collision, bunker fuel leaked from the damaged tank into the sea. The following conclusions are drawn from the report:

- The collision resulted from a lack of watchkeeping on the vessel m/v Ulysse and an unreasonable anchoring position by CSL Virginia.

- On the m/v Ulysse, the lack of proper observation was due to the lack of involvement of the officer on watch, who was occupied with his mobile phone. He was sitting in front of an unusable radar, depriving himself of the opportunity to make observations and correctly assess the situation. Using a second operational radar would have given him all the information he needed to evaluate the situation. Moreover, the place where he was sitting was lowered, which did not allow him to see the horizon line correctly.

- COLERG procedures and regulations were not carried out on both vessels.

- The situational factor was the main component that caused the collision. There were other factors involved such as boredom, routine, and monotony associated with the length of periods at sea, which certainly affected the commitment of watch officers to their duties [67].

- 2.

- Cruise ship incidents A blackout and loss of main engine power occurred on the cruise ship, Viking Sky, as it sailed towards Stavanger, Norway, in strong winds and very rough seas. According to maritime lawyer Jim Walker, the focus of Viking Sky’s accident report was whether the ship had any valid reason to sail during such bad weather conditions. In addition, Norwegian officials determined that low oil levels caused the engine to fail. Both social and situational factors led to the accident [68].

- 3.

- Fires on vessels lead to navigation difficulties or even vessel loss. According to statistics, almost 75% of such fires are caused by a simple error of the people working on the vessel. Twelve passengers went missing in a Greece ferry fire on Euroferry Olympia, near Corfu. A company representative stated that the fire started from a truck on the car deck. At the same time, relatives of the 12 missing were concerned and complained to the shipowner about the “miserable conditions” that prevailed on the Euroferry Olympia: there were not enough cabins and the ship was not designed for trucks, adding that the vessel was dirty and had bugs. Thus, again, a combination of both social and situational factors led to the accident [69].

- 4.

- Commercial fishing vessel accidents and navigation. The U.S. Bureau of Labour Statistics collects information on occupations and lists commercial fishing as the most dangerous of all professions. From rough weather to falling overboard to being struck by heavy equipment, working on a fishing boat can harm workers in many ways. Working on a fishing vessel means long, hard hours; exposure to cold weather; and the risk of accidents and injuries. Fatigue is common, especially if workers are not allowed breaks to which they are entitled. A lack of adequate protective equipment against cold and wet weather can also be problematic as fishermen can experience hypothermia or frostbite. The Seiner capsized, causing the deaths of four fishermen. An investigation revealed that the boat was unsuitable for the rough waters in which it was operating, which is considered negligent. The boat should never have gone into these waters, and someone made a bad judgment in deciding to send it out. Four workers paid for this mistake with their lives. Social and situational factors played a part in this unfortunate incident [70].

- 5.

- Accidents on tugboats related to the maneuvering of vessels. Sometimes, accidents occur due to tugs’ visibility being blocked by larger ships. Additionally, human error on the skipper’s part can lead to unwanted and unexpected incidents. Two crew members died after CMA CGM Simba’s tugboat capsized [70]. The maneuver in which CMA CGM Simba’s departure plan was discussed between the pilot and Captain Domingue before commencement was too general. During the maneuver, no one on board CMA CGM Simba monitored the tug’s position. This accident resulted from a social system factor, the captain–pilot–tug skipper relationship, and a situational factor: failure to adapt the type of tug to the situation [71].

- 6.

- Explosions as a cause of accidents on tankers and cargo ships. The very nature of the materials carried on tankers is dangerous. Most ship fires and explosions are the result of human negligence. The fire on board the container ship, X-Press Pearl, which lasted for several days, appeared to be out of control after the explosion. According to Bloomberg, Sri Lankan authorities feared a severe oil spill. The vessel transported 1486 containers, including 25 tons of nitric acid and other chemicals. According to the Sri Lankan Navy, the fire was caused by chemicals on the Singapore-flagged container ship. The general manager of container ship operator MV X-Press Pearl confirmed that the vessel crew carrying the chemicals was aware of the spill. He added that Qatar and India had refused permission to unload the leaking container before a fire broke out on the vessel. The fire consumed most of the cargo, contaminating the surrounding waters and a long stretch of beaches, and the ship sank. There were undisputed social and situational errors [72].

- 7.

- Stranding of a ship. This type of marine accident has a significant impact not only on the ship’s hull but also on the entire ocean area around the incident. For the Shoei Kisena ship accident in the Suez Canal, the vessel’s owner argued that the Suez Canal Authority (SCA) was at fault for allowing the ship to enter the waterway during poor weather. Ahmed Abu Ali, a member of the legal team, told Reuters that the authorities had failed to prove any fault of the vessel. The evidence that was presented to the court showed disagreements between SCA pilots and its control center over whether the ship should enter the canal. Shoei Kisen suggested that the vessel should have been accompanied by at least two tugs suitable for the size of the vessel [73]. Thus, again, an unfortunate set of situational and social errors occurred.

- 8.

- Maritime accidents due to drugs and alcohol. Drug abuse is a severe problem across the world and, in the marine industry, it can cause irreversible damage. If the crew members abuse psychoactive substances or alcohol, this can result in unpredictable behavior and lead to an accident. The Dutch-registered general cargo vessel, Ruyter, ran aground off the north coast of Rathlin Island in the UK. An investigation revealed that Ruyter ran aground because no action was taken to correct the deviation from the ship’s intended track. According to the safety management system records, the shipowner should have arranged alcohol testing of the crew. However, the investigation found no evidence that alcohol testing was ever carried out on the vessel. Once again, we are confronted with problems inherent in social and situational systems as components of human error, resulting in navigational accidents [74].

- 9.

- Navigational accidents are indirectly linked to cargo-handling operations, which are integral to ship operations. One of the leading causes of crane accidents for loading and unloading marine cargoes is operator error. One known example happened when workers onshore were unloading aluminum bars from a ship using a crane. The workers were inexperienced in using a particular lifting system and needed to secure the load better. As the crane operator moved the load towards the quay, they struck the worker on the ground and killed him. A pattern of situational and social errors can be considered a cause of this accident [75].

- 10.

- Accidents in shipyards, where ship assembly and welding accidents are common, may spare workers’ lives but limit their overall ability to work. Similarly, the continuous inhalation of toxic fumes also becomes another cause of shipyard accidents [76].

- 11.

- Marine accidents on dive support vessels. Suppose a dive support vessel is not fully operational and the crew is not adequately qualified. In this case, they cannot effectively supervise and direct the entire operation, which can lead to a severe accident. In one documented case, a large steel frame, known as a cursor, fell from a height of two meters, trapping the rigger and resulting in fatal crush injuries to his chest. Following an investigation, the company noted the following:

- The control system was not fully commissioned before its use.

- The company’s internal project management systems were not fully utilized.

- Communications and reporting lines within the project team and with offshore and onshore management were neither fully utilized nor understood.

- Design intentions and pre-commissioning requirements for the safe operation of the new equipment had not been adequately communicated to the work team.

- There were no secondary means of securing the active cursor.

- A decision was taken to work under the cursor. The hazard of working under a suspended load was not recognized as it was not a typical load suspended from a crane [77].

This again describes an unfortunate set of errors triggered by situational and social systems.

- 12.

- Accidents on barges occur mainly because of their specific design and maneuvering capabilities. These problems can be caused by the inexperience of the person at the barge’s helm or by the improper use of mooring lines. Other causes involving severe injuries while working on board a barge include the following:

- Explosions, suffocation, and hypoxic-ischemic encephalopathy caused by hazardous and noxious fumes and gases.

- Crushing while bunkering or mooring with a tug.

- Trips and falls due to cluttered decks and workspaces [78].

It is evident from the above types of marine accidents that worker and operator errors play a significant role in causing accidents. Investigating a marine accident helps narrow down the actual cause of the accident, which helps those claiming damages assert their rights with absolute clarity. Some authors believe, however, that the complexity of causes of marine incidents and the lack of unified procedures for reporting such incidents makes it difficult to discover the real reasons and factors behind them [79].

3. Materials and Methods

The unique case method and a weighted Ishikawa diagram were used to address the complexity of the problem of the influence of social and situational systems on human error and, consequently, marine accidents considered in this paper.

The unique case method is dedicated to analyzing a specific single phenomenon, event, or person. For example, a special occasion or character can be studied in this way regarding the situation in which the object under study operates. This method is sometimes referred to as an individual case study. This method is often used to characterize an unusual case, often deviating from the norms commonly observed by society. It is widespread in the sciences, based on the analysis of specific issues, through which researchers can determine the causes of a situation. Thus, it has applications in medicine, law, environmental protection, and safety [80]. Using the unique case method, one can gain the necessary knowledge about a situation and obtain conclusions indicating whether a viable solution is possible. It is undoubtedly impossible to generalize based on research using the unique case method. Therefore, the results obtained in this way can only be applied to a select group. Given the above, the authors decided to use the following research methodology:

- Analysis of selected incidents at sea.

- Development of the Ishikawa diagram for the selected problem.

- Determining the importance of each cause.

- Diagram construction based on the stratification analysis and defining the main causes of incidents.

3.1. Analysis of the Causes of Maritime Accidents

The first use case worth highlighting in a discussion about marine incidents is the case of fishing. In just one region, commercial fishermen sail across the Gulf of Mexico in almost all weather conditions as commercial pressure grows. It is a physically demanding and dangerous job, and, unfortunately, some fishing boat owners disregard job safety. Every year, commercial fishing boat crew members die in preventable accidents. Over 10 years, 116 commercial fishermen died in the Gulf of Mexico alone, many due to falling overboard and injuries sustained onboard. Commercial shrimpers were involved in an alarming number of fatalities as well, with many more injured. This is an evident effect of negative social and situational pressures [81].

The Neva accident was the next to be examined regarding the social and situational system elements involved. The vessel departed from the Szczecin ship repair yard with a pilot on board and the assistance of a tugboat. It was heading to the Szczecin-Świnoujście waterway to head for Riga. The tug was slowed down as it passed Huta quay. While attempting to increase the vessel’s speed, it was noticed that the main engine was not working correctly. After some time, the engine stopped working, and the vessel lost speed. The ship was forced to leave the fairway and drop anchor. The senior officer on the bow supervised the anchoring maneuvers. The captain instructed him to throw one shackle of the chain. However, he executed this instruction incorrectly and threw more than two shackles. The additional 30 m of chain released contributed to the vessel partially running aground. At the same time, the ship’s captain and pilot did not pay attention to the ship’s position and the fact that it was not positioned with its bow to the wind. Their subsequent actions were based on poor judgment of the situation, related to the initial lack of communication between the navigation bridge and the bow position, leading to the ship running aground [68]. In analyzing the accident, it was found that the social system had an impact here. One of the two elements of this system that occurred in the described accident was social pressure; the master and the pilot did not obtain explicit information from the senior officer from the very beginning that he had made a mistake and the ship was not where it should be; thus, they made decisions chaotically and under pressure based on a misunderstanding of the situation. The second element was the role played by the senior officer on the bow. A person in such a position is expected to have the appropriate competencies, such as good situational awareness, quick responses, and proper communication skills to relay any relevant factors affecting maneuverability, including the immediate communication of an erroneous command.

The third accident investigated for the presence of social system elements was that of the ships Corvus J and Baltic Ace. Both ships had officers of Polish nationality on navigation watch. Corvus J was sailing from Scotland to Antwerp, Belgium, while Baltic Ace was leaving Belgium from the port of Zeebrugge to head to Finland. At some point during the voyage, the watch officer on the Baltic Ace vessel spotted the vessel Corvus J on the radar; it was about to pass within one nautical mile, and there were no vessels in the vicinity threatening safe passage. The ship Corvus J made a slight turn to the right, which prompted the officer of the watch on the vessel Baltic Ace to call the vessel on very high frequency (VHF) radio to understand its intentions and advised that it would alter course slightly to the left to increase the distance between the vessels. In the meantime, the vessel Corvus J again made a turn to the right and the Baltic Ace to the left. As the distance between the vessels decreased and the dangerous situation developed, it became increasingly difficult for the watch officers to communicate via VHF radio. The actions they agreed with each other during the conversation did not coincide with the actual steps, which resulted in the collision of the two vessels and the sinking of the vessel Baltic Ace [82]. Analyzing the accident studied, it was concluded that one element of the social system influenced the occurrence of the accident. Social pressure significantly impacted the course of events in this case. The watch officers of both ships attempted to communicate in English. However, their communication became increasingly incomprehensible to the other party under the influence of the developing dangerous situation. Actions that were agreed upon using VHF communication should have been followed. Under pressure and confusion, decisions to change course were taken chaotically and without analyzing the situation.

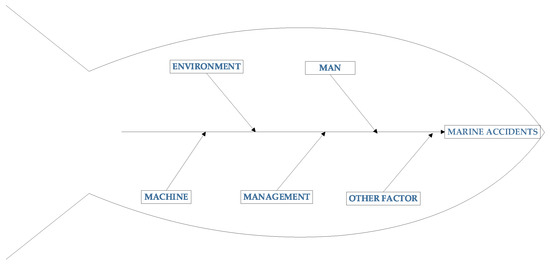

3.2. Ishikawa Diagram

One of the essential tools of quality management is the cause–effect diagram [83,84]. It was developed by Professor Kaoru Ishikawa and was first used by a Japanese company, Sumitomo Electric [85]. The diagram is known as the Ishikawa diagram after its creator [86]. Due to its structure and shape, this diagram is often called a herringbone or fishbone diagram. It visually represents causes and their interrelationships with a problem, error, or inconsistency in the area under investigation [87].

The Ishikawa diagram has a hierarchical structure in which the root causes are closest to the core, while the specific factors directly related to the root causes are their development. The principle of “from the general to the specific” applies in drawing the diagram. The leading causes are determined first, followed by the intermediate reasons: second-order causes and, if necessary, causes of subsequent orders [88]. Depending on the area under study, the diagram may use a layout appropriate to it:

- Object-oriented, used when the effect is analyzed, e.g., of poor product quality, related to technical and organizational aspects, divisible into sub-components;

- Technological, considered by the list of technical process operations;

- Participating factors, which can be used at any stage and level of the investigation of the quality of a process or event.

The primary 5M method can be used to develop a cause-and-effect diagram or it can be extended or modified as appropriate, depending on the area under analysis: 5Ms + E, 6Ms, or 8Ms:

- Man—every aspect of a person’s work, including routine, inexperience, monotony, and fatigue.

- Machine—whether it is working correctly, whether every part is in working order, whether it needs calibration, etc.

- Method (method/technology)—whether the process is as intended, whether the steps are performed correctly, whether the sequence of steps is optimal, etc.

- Material—hidden or visible material defects, product dimensions, missing holes, problems at the supplier, etc.

- Measurement—whether measurements have been carried out correctly, whether measuring instruments are operational and legalized, etc.

- Mother nature (environment)—what effect does the environment have on the process/event, i.e., humidity, temperature, lighting, but also, e.g., noise, dust?

- Management—whether the management of employees and crews is adequate and appropriate to the conditions, whether employees are given proper guidelines, etc.

- Maintenance—whether the maintenance of the machine and its components, facility, tools, networks, pipelines, etc., is being neglected.

The Ishikawa diagram is also used outside its original production environment in the 8P design:

- Product—physical aspects of the product.

- Price.

- Promotion—a type of promotion/advertisement.

- Place—place/location/environment.

- Process.

- People.

- Psychical evidence—physical aspects of customer interaction sites.

- Performance—results compared to the competition.

In services, causes can be grouped according to the 4Ss:

- Surroundings—surroundings, environment.

- Suppliers—suppliers, sub-suppliers.

- Systems—processes.

- Skills—staff skills.

The classic Ishikawa diagram facilitates the analysis of a process in a cause–effect framework, but it does not contain quantitative information, only qualitative information. Gwiazda proposed supplementing the chart with the weights of individual causes. Once sets of primary and sub-causes for each leading cause have been determined, the next course of action is as follows:

- Each cause and sub-cause is assigned an appropriate weight.

- The absolute values of the sub-cause weights are determined.

- The Ishikawa diagram is completed with sub-weights [89].

The weights of the individual causal factors are determined using a matrix of pairwise comparisons using the following rule of thumb: if one of the comparable factors is considered more important, it is assigned a score of 1; the other element is given a score of 0. If both factors are considered equivalent, they are given a score of 0.5. A scale of 0.25 to 0.75 can be used to increase the precision of the assessment. These values denote being slightly less critical or slightly more critical, respectively [90].

4. Results

It is possible to analyze marine accidents using a weighted Ishikawa diagram when considering decision-making methods, including multi-criteria and multidimensional scaling techniques, which often support diagnosed issues and problems in various fields. The methodology above is divided into stages accordingly.

The determination of the problem category, i.e., causes of a marine casualty according to the selected 5Ms, 6Ms, 5Ms + E, or a combined idea is based on the previously conducted literature on the subject, with stages of the full process listed below:

- Definition of first- and second-order causes.

- Definition of the relative weights of the causes at each level.

- Definition of the absolute value of the individual sub-cause weights.

- Stratification analysis.

- Definition of a set of critical causes.

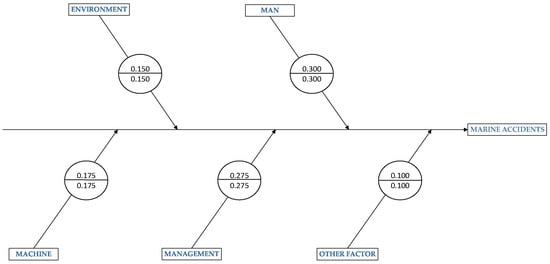

Figure 4 shows the main categories of causes of marine accidents.

Figure 4.

Ishikawa diagram leading causes.

The main cause weights were determined based on a comparison matrix, according to the 4Ms +A approach, i.e., Human, Machine, Management, and Other factor, see Table 1.

Table 1.

Comparison matrix for leading causes.

The standardized weights for the main factors are placed in circles on the Ishikawa diagram. The upper part of the circle contains the relative weight related to the factor in question, while the lower part contains the absolute weight associated with the whole group. The two weights are equal for the main factors (Figure 5).

Figure 5.

Weighted Ishikawa diagram with main cause weights.

Of the main reasons outlined, the group identified as “human” had the most significant weight, followed by “management”, “machine”, “environment”, and “other”. This preliminary assessment represents the beginning of inquiries in the area under investigation.

The next step is to identify the first- and subsequent-order sub-causes. A detailed set of causes with first-, second-, and third-order sub-causes is presented in Table 2.

Table 2.

Marine accidents—leading and sub-causes of I level and sub-causes of II level.

As for the leading causes, i.e., based on the comparison matrix, relative weights were determined for the individual first-, second-, and third-order sub-causes. Subsequently, absolute weights were selected for the sub-causes based on the relative weights. The relative weights were multiplied by the value of the relative weight of the leading cause to which the sub-cause belonged. This can be written with a simple equation [91]:

where

Wa.sn = Wr.i.c Wr. sn

- Wa.sn—Absolute weighting of sub-causes of n order,

- Wr.i.c.—Relative importance of the main cause,

- Wr. sn—Relative weighting of sub-causes of n order.

Based on the results obtained, which were ranked in descending order of importance, cumulative weights were determined for the defined sub-causes. A reference field was calculated, as shown in Table 3. The value of the reference field was obtained by multiplying the value of the cumulative weight by the value of N = (55 − n), where 55 is the number of all reasons, and n is the number of the next sub-reason [92,93]. The grey color indicates the causes with the most significant impact on marine casualties.

Table 3.

Results of the stratification analysis.

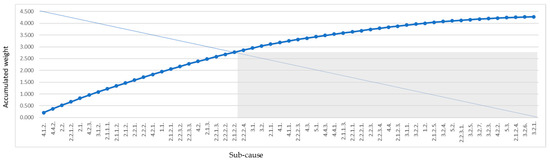

The cumulative weights presented in Table 3 are the coordinates of the Lorentz Curve and the basis for a stratification analysis based on the Pareto Rule. Thus, a group of influential and less essential factors influencing marine casualties was identified. The data obtained were transferred to the graph shown in Figure 6.

Figure 6.

Lorenz diagram and stratification analysis.

The so-called “reference area” was taken as the index of division. This is the rectangle’s area defined by the Lorenz Curve’s inflection point. This area reached its maximum for the 23 sub-causes and amounted to 9.520, thus constituting the limit of stratification and definitively determining the division into the group of essential sub-causes A (marked in grey in Table 3) and the group of less important causes B. The most important and frequent causes included those from the “Management” and “Human” groups.

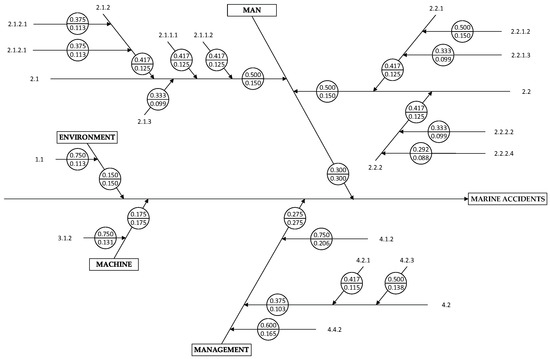

The stratification analysis made it possible to develop the simplified weighted Ishikawa diagram shown in Figure 7. The final version of the diagram presented contains the most critical causes of marine accidents.

Figure 7.

The final version of the Ishikawa diagram for marine accidents.

5. Discussion

The authors opened this article with a long review of the visions, objectives, and procedures in place of key industry organizations, aiming to improve safety across the maritime industry. With multiple checklists, procedures, audits, and inspections, one could think that shipping is as safe as aviation. Following this, there was a deeper dive into the literature on the subject of safety at sea, which contains a vast array of articles, publications, and reports, some from highly specialized agencies, many of which have found that incidents cause breaks down into various aspects and reasons [25]. Despite multiple safety measures and a large number of publications, the detailed descriptions of real-life sea incidents are striking regarding how trivial, simple, and obvious key root causes are. Hence, the objective of the authors was to go much deeper than an industry approach [6,25], whereby human errors are broken down into a few main categories, and, in reality, each category represents its own ecosystem of possible causes, triggers, and incident starters. This article goes as deep into the breakdown of components of human error as ‘the death of a loved one or uncomfortable posture’ components, analyzing how they potentially impact safety.

In this work, based on expert knowledge, 55 causes of incidents were included and, with the weighted Ishikawa diagram, 23 of causes were identified as playing the most significant role as contributors to accidents. Among them, as many as 16 were directly linked with social and situational systems, while an additional 5 were related to management, which is also a human factor element.

A causal analysis of the problem of the influence of social and situational systems on human error and, consequently, marine accidents based on the individual case method and weighted Ishikawa diagram provided positive evidence that this type of analysis can be applied to solve such complex issues.

A simplified version of the weighted Ishikawa diagram clearly showed the areas that require attention or even intervention by managers on ships and in ports. Decision makers have an impact on conditions. Among the most relevant issues are the following:

- Problems of non-compliance with certified systems and reliability on port inspection, with too few inspections and errors in delegation.

- A whole range of components of situational and social systems, for example, stress in life caused by an external stimulus, worker fatigue that can be a consequence of awkward posture, too much strain on the hands, etc. Strenuous hydrometeorological and meteorological conditions and noise can also cause perceived pain, affecting one’s ability and efficiency in activities performed, exacerbating frustration and errors due to the desire to meet deadlines and speed up action. Illness or death of a loved one, lack of personal space, and social expectations are also examples of this.

- A lack of regular reviews.

The authors were able to demonstrate the influence of social and situational systems on marine incidents, which also corresponds to the known direction of growing situational awareness of seamen by a bottom-up management approach [94]. There is also an opinion shared across several publications that seamen want to have the option of participation in decision-making processes [95]. Experienced crew members can deal with extraordinary situations, are flexible, and are able to adapt [96,97] as, sometimes, safety can be secured by not applying procedures [98,99,100].

Working in a maritime education space, authors now have evidence based on the results of this work, and can discuss with the management teams of learning programs at all levels potential changes and improvements in how they organize, run, and certify students, officers, and practitioners. The aspect of safety culture, going way beyond pure knowledge and awareness of safety procedures and regulations, can be discussed with the current analysis results, thereby reinforcing the need to also adapt the culture at the class level to provide stricter ambiance and approaches, offering students the feeling of real-life stress in controlled situations.

6. Conclusions

Issues concerning the influence of individual components of the entire category of causes classified as human error as sources of marine accidents were discussed. The authors have shown that social and situational systems interact and influence shipboard safety through a case study method. In each case, a detailed analysis of specific subcategories of direct incident sources was necessary to identify potential improvements. Detailed descriptions of the causes of incidents revealed ignorance of regulations and non-compliance with applicable procedures, standards, and good practices. Pure knowledge of regulations should not be the only criteria to ensure safety. The authors cannot find any protocols to be implemented under high pressure nor amid numerous stimuli distracting attention nor requiring decision-making in training programs conducted in simulators. Today, official reports from marine incidents are indeed analyzing step by step the chain of causes behind an incident, but are often not investigating the sub-categories of human factor elements and are not unified across investigations. This is not helping to plan specific improvements to procedures, systems, and legislative solutions. In conclusion, this work provides an honest basis for potential detailed corrective actions and shows the need for constant changes and modifications to prevent people from making the same mistakes.

Human error can be significantly reduced. There is often a time lag between developing safety culture weaknesses and an event with significant safety consequences. These vulnerabilities can interact to create a potentially unstable state that exposes the organization to safety incidents. The organization (which may be a particular vessel) and its regulators must be alert to signs of potential weaknesses in social and situational systems.

A marine accident investigation is now an essential tool for identifying human factor issues which, when investigated with care, can be one of the pillars of preventing accidents and improving marine safety. The long-standing positive trend in ship safety, with year-on-year improvements, has now been reversed [101]. This is worrying. More emphasis is needed on safety culture, safety training, and competence assessment.

Statistics show that the frequency of accidents in the maritime industry, including those related to navigation, has skyrocketed. Still, authors believe that technology, regulations, and compliance can achieve expected safety levels by emphasizing the human element of accidents.

Historically, safety in shipping has focused on technical improvements. Most shipping company personnel involved in shipping operations have a technical background. Audits and inspections pay great attention to technical compliance. This focus on technical issues has led to significant improvements in ship safety. However, the time has come to focus more on other topics that the authors of the article have raised, namely, the very thoroughly analyzed causes of accidents, so far quite commonly classified as human error and more precisely as social and situational systems, which have not yet been sufficiently explored. To improve safety at sea, therefore, a threefold approach must be adopted:

- Improve safety culture.

- Improve training programs.

- Implement formal competence assessment programs.

This study’s results indicate many areas for improvement in all parts of the traditional management system for the safe operation of ships, in which the human factor plays the most crucial role.

Author Contributions

Conceptualization, K.P., A.E.W. and T.K.; methodology, A.E.W. and L.K.; formal analysis, A.E.W. and L.K.; investigation, K.P. and T.K.; resources, K.P. and A.E.W.; data analysis, A.E.W. and L.K.; writing—original draft preparation, K.P. and T.K.; writing—review and editing, L.K. and A.E.W. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the Maritime University of Szczecin.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| IAEA | - | International Atomic Energy Agency |

| IMO | - | International Maritime Organization |

| ILO | - | International Labour Organisation |

| IASCS | - | International Association of Ship Classification Societies |

| ISM | - | International Safety Management Code |

| HFACS-MA | - | Classification System Maritime Accidents |

| SMAIC | - | Composition of the Commission and Commission Experts |

| MAIB | - | Marine Accident Investigation Branch |

| STCW | - | International Convention on Standards of Training, Certification and Watchkeeping |

| SCA | - | Suez Canal Authority |

| MLC | - | Maritime Labour Convention |

References

- Swift, A.J.; Bailey, T.J. Bridge Team Management—A Practical Guide; The Nautical Institute: London, UK, 2004. [Google Scholar]

- Bridge Procedures Guide, 6th ed.; International Chamber of Shipping: London, UK, 2022.

- International Atomic Energy Agency. Safety Culture, A Report by the International Nuclear Safety Advisory Group; Safety Series, No. 75-INSAG-4; IAEA: Vienna, Austria, 1991. [Google Scholar]

- Teperi, A.M.; Lappalainen, J.; Puro, V. Assessing artefacts of maritime safety culture—current state and prerequisites for improvement. WMU J. Marit. Aff. 2019, 18, 79–102. [Google Scholar] [CrossRef]

- Anderson, P. Cracking the Code. The Relevance of the ISM Code and Its Impact on Shipping Practices; Nautical Institute: London, UK, 2003. [Google Scholar]

- Rothblum, A. Human error and marine safety. In Proceedings of the Maritime, Human Factors Conference, Linthicum, MD, USA, 13–14 March 2000. [Google Scholar]

- International Maritime Organization. Human Element Vision, Principles and Goals for the Organization, Resolution A.850(20). 1997. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.850(20).pdf (accessed on 20 February 2023).

- International Maritime Organization. Human Element Vision, Principles and Goals for the Organization, Resolution a.947(23). 2004. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.947(23).pdf (accessed on 20 February 2023).

- IMO Website on Legal Affairs. IMO/ILO Work on Seafarer Issues. Available online: https://www.imo.org/en/OurWork/Legal/Pages/JointIMOILOWorkingGroupsOnSeafarerIssues.aspx (accessed on 3 August 2022).

- International Labour Conference, Maritime Labour Convention, 2006, Consolidated Text Established by the International Labour Office, Including the Amendments of 2014 and 2016 to the Code of the Convention. 2016. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_norm/---normes/documents/normativeinstrument/wcms_554767.pdf (accessed on 10 September 2022).

- Kaber, D.B.; Endsley, M.R. Out-of-the-loop performance problems and the use of intermediate levels of automation for improved control system functioning and safety. Process Saf. Prog. 1997, 16, 126–131. [Google Scholar] [CrossRef]

- Oltedal, H.A.; McArthur, D.P. Reporting practices in merchant shipping, and the identification of influencing factors. Saf. Sci. 2011, 49, 331–338. [Google Scholar] [CrossRef]

- Bye, R.J.; Aalberg, A.L. Why do they violate the procedures?—An exploratory study within the maritime transportation industry. Saf. Sci. 2020, 123, 104538. [Google Scholar] [CrossRef]

- Størkersen, K.V.; Thorvaldsen, T.; Kongsvik, T.; Dekker, S. How deregulation can become overregulation: An empirical study into the growth of internal bureaucracy when governments take a step back. Saf. Sci. 2020, 128, 104772. [Google Scholar] [CrossRef]

- Mišković, D.; Jelaska, I.; Ivče, R. Attitudes of experienced seafarers as predictor of ISM code. Promet-Traffic Transp. 2019, 31, 569–579. [Google Scholar] [CrossRef]

- Österman, C.; Hult, C. Administrative burdens and over-exertion in Swedish short sea shipping. Marit. Policy Manag. 2016, 43, 569–579. [Google Scholar] [CrossRef]

- Bailey, N. Risk perception and safety management systems in the global maritime industry. Policy Pract. Health Saf. 2006, 4, 59–75. [Google Scholar]

- Rae, A.J.; Provan, D.; Weber, D.; Dekker, S. Safety clutter: The accumulation and persistence of ‘safety’ work that does not contribute to operational safety. Policy Pract. Health Saf. 2018, 16, 194–211. [Google Scholar] [CrossRef]

- Bieder, C.; Bourrier, M. Trapping Safety into Rules: How Desirable or Avoidable Is Proceduralization? 1st ed.; Ashgate: Farnnham, UK, 2013. [Google Scholar]

- Dekker, S. Safety Differently: Human Factors for a New Era, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2015. [Google Scholar]

- Størkersen, K.V.; Antonsen, S.; Kongsvik, T.Ø. One size fits all? Safety management regulation of ship accidents and personal injuries. J. Risk Res. 2017, 20, 1154–1172. [Google Scholar] [CrossRef]

- Working Paper on Tankers Involved in Shipping Accidents 1975–1992; Transportation Safety Board of Canada: Ottawa, ON, Canada, 1993.

- Cormier, P.J. Towing Vessel Safety: Analysis of Congressional and Coast Guard Investigative Response to Operator Involvement in Casualties Where a Presumption of Negligence Exists. Master’s Thesis, University of Rhode Island, Kingston, RI, USA, 1994. [Google Scholar]

- Bryant, D.T. The Human Element in Shipping Casualties; Report; Department of Transport, Marine Directorate: London, UK, 1991. [Google Scholar]

- Annual Overview of Marine Casualties and Incidents 2021. Available online: www.emsa.europa.eu/ (accessed on 9 September 2022).

- Wu, B.; Yip, T.L.; Yan, X.; Guedes Soares, C. Review of techniques and challenges of human and organizational factors analysis in maritime transportation. Reliab. Eng. Syst. Saf. 2022, 219, 108249. [Google Scholar] [CrossRef]

- Graziano, A.; Teixeira, A.P.; Guedes Soares, C. Classification of human errors in grounding and collision accidents using the TRACEr taxonomy. Saf. Sci. 2016, 86, 245–257. [Google Scholar] [CrossRef]

- Isaac, A.; Shorrock, S.T.; Kirwan, B. Human error in European air traffic management: The HERA project. Reliab. Eng. Syst. Saf. 2002, 75, 257–272. [Google Scholar] [CrossRef]

- Ung, S. Evaluation of human error contribution to oil tanker collision using fault tree analysis and modified fuzzy Bayesian Network based CREAM. Ocean Eng. 2019, 179, 159–172. [Google Scholar] [CrossRef]

- Chen, S.; Wall, A.; Davies, P.; Yang, Z.; Wang, J.; Chou, Y. A Human and Organisational Factors (HOFS) Analysis Method for Marine Casualties Using HFACS-Maritime Accidents (HFACS-MA). Saf. Sci. 2013, 60, 105–114. [Google Scholar] [CrossRef]

- Ugurlu, O.; Yildiz, S.; Loughney, S.; Wang, J. Modified human factor analysis and classification system for passenger vessel accidents (HFACS-PV). Ocean Eng. 2018, 161, 47–61. [Google Scholar] [CrossRef]

- Soner, O.; Asan, U.; Celik, M. Use of HFACS–FCM in Fire Prevention Modelling on Board Ships. Saf. Sci. 2015, 77, 25–41. [Google Scholar] [CrossRef]

- Chauvin, C.; Lardjane, S.; Morel, G.; Clostermann, J.; Langard, B. Human and organisational factors in maritime accidents: Analysis of collisions at sea using the HFACS. Accid. Anal. Prev. 2013, 59, 26–37. [Google Scholar] [CrossRef]

- Celik, M.; Cebi, S. Analytical HFACS for investigating human errors in shipping accidents. Accid. Anal. Prev. 2009, 41, 66–75. [Google Scholar] [CrossRef]

- Akyuz, E. A marine accident analysing model to evaluate potential operational causes in cargo ships. Saf. Sci. 2017, 92, 17–25. [Google Scholar] [CrossRef]

- Yildirim, U.; Basar, E.; Ugurlu, O. Assessment of collisions and grounding accidents with human factors analysis and classification system (HFACS) and statistical methods. Saf. Sci. 2017, 119, 412–425. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, D.; Goerlandt, F.; Yan, X.; Kujala, P. Use of HFACS and fault tree model for collision risk factors analysis of icebreaker assistance in ice-covered waters. Saf. Sci. 2019, 111, 128–143. [Google Scholar] [CrossRef]

- Qiao, W.; Li, Y.; Ma, X.; Liu, Y. A methodology to evaluate human factors contributed to maritime accident by mapping fuzzy FT into ANN based on HFACS. Ocean Eng. 2020, 197, 106892. [Google Scholar] [CrossRef]

- Galieriková, A. The human factor and maritime safety. Transp. Res. Procedia 2019, 40, 1319–1326. [Google Scholar] [CrossRef]

- Porathe, T.; Hoem, Å.S.; Rødseth, Ø.J.; Fjørtoft, K.; Johnsen, S.O. At Least as Safe as Manned Shipping? Autonomous shipping, safety and “human error”. In Safety and Reliability—Safe Societies in a Changing World; Haugen, S., Barros, A., Gulijk, C.V., Kongsvik, T., Vinnem, J., Eds.; CRC Press: London, UK, 2018. [Google Scholar]

- Endsley, M.R. Toward a theory of situation awareness in dynamic systems. Hum. Factors 1995, 37, 32–64. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety-I and Safety-II: The Past and Future of Safety Management; Ashgate: Farnham, UK, 2014. [Google Scholar]

- Patraiko, D. Into the Future, the Technology of Tomorrow, The Navigator, Issue 24. The Nautical Institute. 1 June 2020. Available online: https://www.nautinst.org/resources-page/into-the-future-the-technology-of-tomorrow.html (accessed on 21 September 2022).

- Acejo, I.; Sampson, H.; Turgo, N.; Ellis, N.; Tang, L. The Causes of Maritime Accidents in the Period 2002–2016; Seafarers International Research Centre (SIRC), Cardiff University: Cardiff, UK, 2018. [Google Scholar]

- Covid-19 losses settle, but pandemic effects linger. In Global Claims Review 2022; Available online: www.agcs.allianz.com/ (accessed on 8 July 2022).

- Wagenaar, W.A.; Groeneweg, J. Accidents at sea: Multiple causes and impossible consequences. Int. J. Man-Mach. Stud. 1987, 27, 587–598. [Google Scholar] [CrossRef]

- Parker, A.W.; Huhinger, L.M.; Sargent, L.; Boyd, R. Health Stress and Fatigue in Shipping; Australian Maritime Safety Agency: Brisbane, Australia, 2002. [Google Scholar]

- Maekay, M. Safer Transport in Europe: Tools for Decision-Making; European Transport Safety Council Lecture; The European Transport Safety Council: Etterbeek, Belgium, 2000. [Google Scholar]

- Hetherington, C.; Flin, R.; Mearns, K. Safety in shipping: The human element. J. Saf. Res. 2006, 37, 401–411. [Google Scholar] [CrossRef]

- Lülhoft, M.; Dekker, S. On your watch automation on the bridge. J. Navig. 2002, 55, 83–96. [Google Scholar]

- Brun, W.; Johnsen, B.; Iabertg, J.C.; Ekomas, B.; Kobbeltvedt, T. Bridge resource management training enhancing shared mental models and task performance. In How Professionals Make Decisions; CRC Press: Boca Raton, FL, USA, 2004; pp. 183–193. [Google Scholar]

- Salas, E.; Wilson, C.A.; Burke, C.S.; Wighlman, D.C. Does crew resource management training work? An update, an extension, and some critical needs. Hum. Factors 2006, 48, 392–412. [Google Scholar] [CrossRef]

- Kobylinski, L. Risk analysis and human factor in prevention of CRG casualties. Int. J. Mar. Navig. Saf. Sea Transp. 2009, 3, 443–448. [Google Scholar]

- Makarowski, R. Czynnik ludzki w lotnictwie. Przegląd Psychol. 2012, 3, 305–326. [Google Scholar]

- Uzarski, M.; Abramowicz-Gerigk, T. Human factor in air and sea traffic management. Pr. Nauk. Politech. Warsz. -Transp. 2014, 102, 159–169. [Google Scholar]

- Encyklopedia Zarządzania. Available online: www.mfiles.pl (accessed on 12 October 2021).

- Sheridan, T.B. Risk, human error, and system resilience: Fundamental ideas. Hum. Factors 2008, 50, 418–426. [Google Scholar] [CrossRef] [PubMed]

- Pauksztat, B. ‘Only work and sleep’: Seafarers’ perceptions of job demands of short sea cargo shipping lines and their effects on work and life on board. Marit. Policy Manag. 2017, 44, 899–915. [Google Scholar] [CrossRef]

- Dawidziuk, K.; Lishchynskyy, Y.; Wojciechowska, M.; Kopański, Z.; Marczewska, S.; Uracz, W. Stres jako źródło wypalenia zawodowego. J. Public Health Nurs. Med. Rescue 2011, 4, 26–29. [Google Scholar]

- Jasielska, A.; Molińska, M.; Cejrowska, J. Profil zawodowy oficera floty handlowej—udział cech osobowości w radzeniu sobie ze stresem. Humanizacja Pracy. Gaz. Inst. Psychol. 2016, 2, 101–118. [Google Scholar]

- Krystosik-Gromadzińska, A. Safety and ergonomics on board. Logistyka 2015, 5, 1035–1042. [Google Scholar]

- Piechowicz, B.; Stawarczyk, K.; Stawarczyk, M. Temperature as an important factor in the work environment—selected aspects. Bezpieczeństwo Pr. Nauka Prakt. 2013, 7, 8–11. [Google Scholar]

- Przewidywanie Stresu. Available online: www.szybkanauka.net (accessed on 11 July 2021).

- Lubaś, P. Diagnoza Ergonomicznych Czynników Ryzyka; Okręgowy Inspektorat Pracy w Szczecinie: Szczecin, Poland, 2010; pp. 4–14. [Google Scholar]

- Wróblewska, M. Ergonomia, Wydaw; Politechniki Opolskiej: Opole, Poland, 2004; pp. 160–172. [Google Scholar]

- Państwowa Komisja Badania Wypadków Morskich, EXPRESS 1 & BALTIC CONDOR, Summary Report on Collision, 10 May 2019. Available online: https://pkbwm.gov.pl/wp-content/uploads/images/Reports/enFinal-marine-accident-report---EXPRESS-1-og-BALTIC-CONDOR---Collision-on-10-May-2019.pdf (accessed on 15 September 2022).

- CSL Virginia. Available online: https://wwz.cedre.fr/Ressources/Accidentologie/Accidents/CSL-Virginia (accessed on 11 March 2023).

- Walker, J. Cruise Law News. Everything Cruise Lines Don’t Want You to Know. Available online: www.cruiselawnews.com/2019/ (accessed on 23 October 2022).

- Nautilus International. IMO Raises Concern over Euroferry Olympia Ferry Fire, 24 February 2022. Available online: https://www.nautilusint.org/en/news-insight/news/imo-raises-concern-over-euroferry-olympia-ferry-fire/ (accessed on 10 January 2023).

- Seiner Fishing Boat Accidents and Injuries. Available online: www.maritimeinjurycenter.com/accidents-and-injuries/seiner-fishing-boat/ (accessed on 10 January 2023).

- Marine Accident Investigation Branch. Accident Report, Capsize of Tug Domingue while Assisting CMA CGM Simba Resulting in Two Fatalities, July 2017. Available online: https://assets.publishing.service.gov.uk/media/596dd157e5274a0a690001ba/MAIBInvReport16_2017.pdf (accessed on 10 January 2023).

- UN Environment Programme, X-Press Pearl Maritime Disaster Sri Lanka—Report of the UN Environmental Advisory Mission, 6 August 2021. Available online: https://www.unep.org/resources/report/x-press-pearl-maritime-disaster-sri-lanka-report-un-environmental-advisory-mission (accessed on 10 January 2023).

- WION Web Team, Ship Owner Says Suez Canal was at Fault over Ever Given Grouding, Wionews.com, 23 May 2021. Available online: https://www.wionews.com/world/ship-owner-says-suez-canal-was-at-fault-over-ever-given-grounding-lawyer-386811 (accessed on 1 September 2022).

- Accident Report. Marine Accident Investigation Branch. 2018, 11. Available online: https://assets.publishing.service.gov.uk/media/5b30b379ed915d587f69eee6/MAIBInvReport11_2018.pdf (accessed on 20 February 2023).

- Cargo and Crane Accidents in the Maritime Industry. Available online: www.maritimeinjurycenter.com/accidents-and-injuries/cargo-and-crane/ (accessed on 1 December 2022).

- Examining Fatal Shipyard Accidents. Volume 2. Available online: www.osha.gov/video/shipyard-accidents/transcripts#v2_4 (accessed on 12 December 2022).

- Fatal Incident Onboard a Dive Support Vessel. IMCA Safety Flash, 2009, 18. Available online: www.imca-int.com/safety-events/fatal-incident-onboard-a-dive-support-vessel/ (accessed on 1 December 2022).

- Barge Accidents. Available online: www.simmonsandfletcher.com/maritime-law/offshore-accident/barge-injury/ (accessed on 20 February 2023).

- Grech, M.R.; Horberry, T.; Smith, A. Human error in maritime operations: Analyses of accident reports using the Leximancer tool. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2002, 46, 1718–1721. [Google Scholar] [CrossRef]

- Zainal, Z. Case Study as a Research Method. J. Kemanus. 2017, 5. Available online: https://jurnalkemanusiaan.utm.my/index.php/kemanusiaan/article/view/165 (accessed on 23 November 2022).

- Arnold and Itkin. Available online: www.offshoreinjuryfirm.com/ (accessed on 12 December 2022).

- Department of Merchant Shipping, Ministry of Communications and Works, Republic of Cyprus, MARINE ACCIDENT REPORT Collision between “CORVUS J” and “BALTIC ACE” in the North Sea on 5 December 2012. Available online: https://pkbwm.gov.pl/wp-content/uploads/images/uchwaly_raporty/raporty/raporty_obce/Final_report_Corvus_J_WIM_07_12_DMS_Cyprus.pdf (accessed on 15 October 2021).

- Swift, J.A.; Ross, J.E.; Omachonu, V.K. Principles of Total Quality, 2nd ed.; St. Lucie Press: Boca Raton, FL, USA, 1998; pp. 256–262. [Google Scholar]