2.1. Problem Formulation

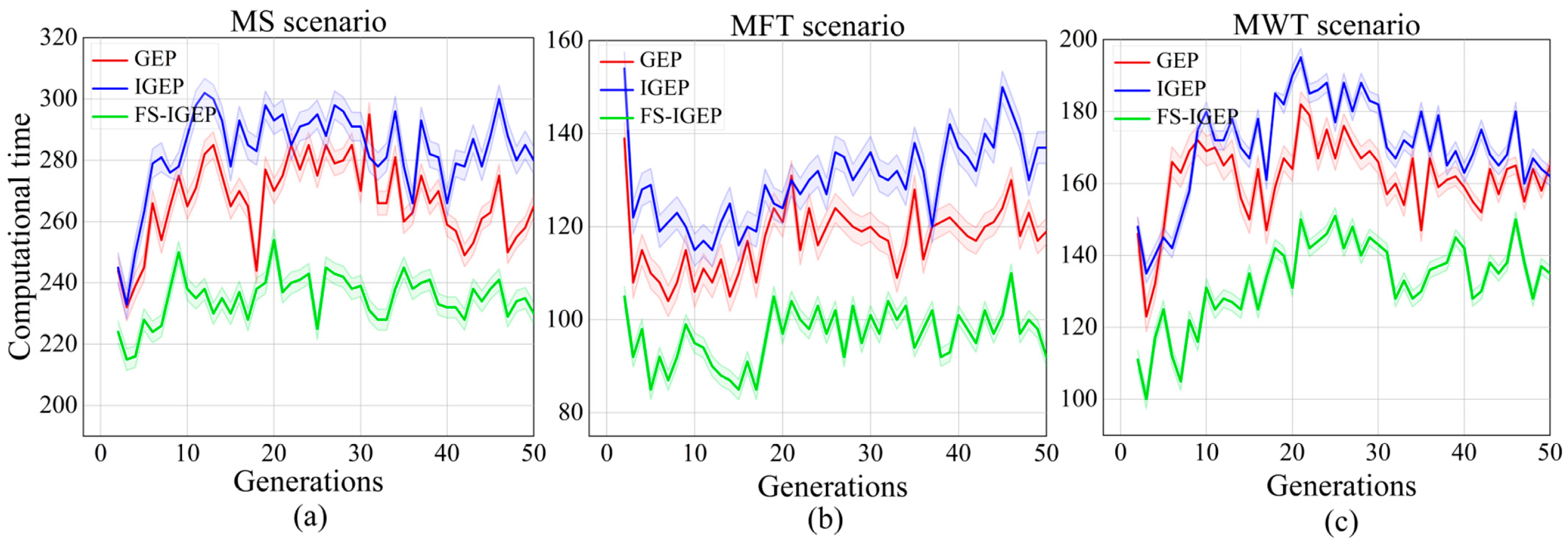

The Dynamic Job-shop Scheduling (DJSS) issue is an example of an optimization problem, and it operates as follows: the job-shop problem is characterized by a set of jobs, denoted as , and machines, denoted as , at every decision point. Each job comprises a set of operations that must be processed in a specified sequence. Each machine can perform no more than one operation simultaneously. Each operation must be performed using a specific machine. The task involves determining an appropriate sequence of operations across all machines in order to establish an appropriate schedule at every point of decision-making. The scheduling effectiveness is evaluated using the Makespan (MS), Mean Flow Time (MFT), and Mean Weighted Tardiness (MWT). The proposed mathematical model is as follows:

S.T.

where,

is the processing time of operation

,

is the completion time of operation

,

is the arrival time of job

,

is the due date of job

,

is the weight of job

,

denotes the completed jobs, and

denotes the tardy jobs. If operation

precedes operation

,

; otherwise

. The primary objectives (1), (2), and (3) are to minimize the makespan, mean flow time, and mean weighted tardiness, respectively. Equation (4) denotes that the starting time of the first operations of jobs must possess a non-negative value. Equation (5) guarantees that every job is executed by a single machine, exclusively. According to Equation (6), there exists a constraint that limits each machine to the processing of a single job at any given time.

2.2. Related Work

(1) Automated design of dispatching rules. Job-shop scheduling (JSS) is a combinatorial optimization problem that falls under the category of nondeterministic polynomial-time (NP) hard problems. It entails the allocation of various manufacturing tasks to machines at specific time intervals, with the aim of minimizing a set of objectives. The complexity of large-scale production issues poses challenges for the implementation of precise optimization techniques [

19]. Hence, various heuristic optimization techniques, including the genetic algorithm [

20], simulated annealing [

21], and the ant colony algorithm [

22], have been devised, to obtain near-optimal solutions for the static job-shop scheduling problem within a reasonable computational timeframe. In DJSS, it is possible for jobs to exhibit stochastic arrival patterns and their corresponding attributes may not be ascertainable prior to their arrival. Hence, conventional techniques for optimizing solutions are not feasible for dynamic scheduling problems, due to the restricted information horizon. Dispatching rules have been applied extensively to solve DJSS problems due to their computational efficiency. The reason for their widespread acceptance can be ascribed to their practical applicability, low computational complexity, and minimal information demands. In most cases, dispatching rules are regarded as a priority function, utilized to allocate priority to every job that is in the queue to be processed by a machine. Consequently, the tasks that hold the highest priority will be given precedence in processing. A large number of dispatching rules have been created by both practitioners and researchers to address diverse manufacturing conditions. Additional information can be found in various scholarly articles [

23].

Dispatching rules are usually designed by experts in a tedious trial-and-error process, with candidate rules being tested in a simulation environment, modified, and retested until they fulfill the requirements for actual implementation in practice. In recent years, several researchers have suggested the automatic design of suitable dispatching rules by means of a hyperheuristic approach for JSS problems. Hyperheuristics combine the components utilized in current heuristics by different operators to build new heuristics, which are then trained on training problem cases and developed to become more successful. Regarding the automated construction of scheduling rules, it has been shown that GP is a promising hyperheuristic method, outperforming conventional machine learning techniques [

24].

(2) GP/GEP-based hyperheuristic for DJSS. GP hyperheuristics have enabled the automatic evolution of high-quality heuristics, resulting in successful problem-solving outcomes in various domains, including (but not limited to) bin packing [

25], cloud computing [

26,

27], and vehicle routing [

28,

29]. Burke et al. [

15] proposed a classification scheme for hyperheuristic methods based on their search procedures, encompassing the selection and generation of hyperheuristics. A succinct summary of the utilization of hyperheuristics in addressing diverse scheduling and combinatorial optimization problems was also devised. According to the authors, GP is a suitable approach for adapting dispatching rules in dynamic scenarios, despite its infrequent utilization for directly addressing production scheduling issues. Branke et al. [

30] designed GP algorithms with the goal of reducing mean flowtime as much as possible and demonstrating that their results are superior to those obtained using traditional dispatching rules. Karunakaran et al. [

31] and Ferreira et al. [

32] are the only authors to have focused on shops with stochastic processing times. However, the former did not benchmark evolving rules against existing methods, while the latter considered deterministic job arrivals. Many researchers have emphasized the significance of increasing algorithmic effectiveness. For example, surrogate models allow for quicker fitness computation. They are used to prevent the use of a substantial amount of computing time when evaluating unpromising rules. Typically, running these models is far more efficient for assessing individual fitness than running full simulations [

19]. A tree-based representation has been shown to be the most effective method for developing robust scheduling heuristics in early investigations. As a consequence of their tendency to grow throughout their evolution, other representation structures have also been explored.

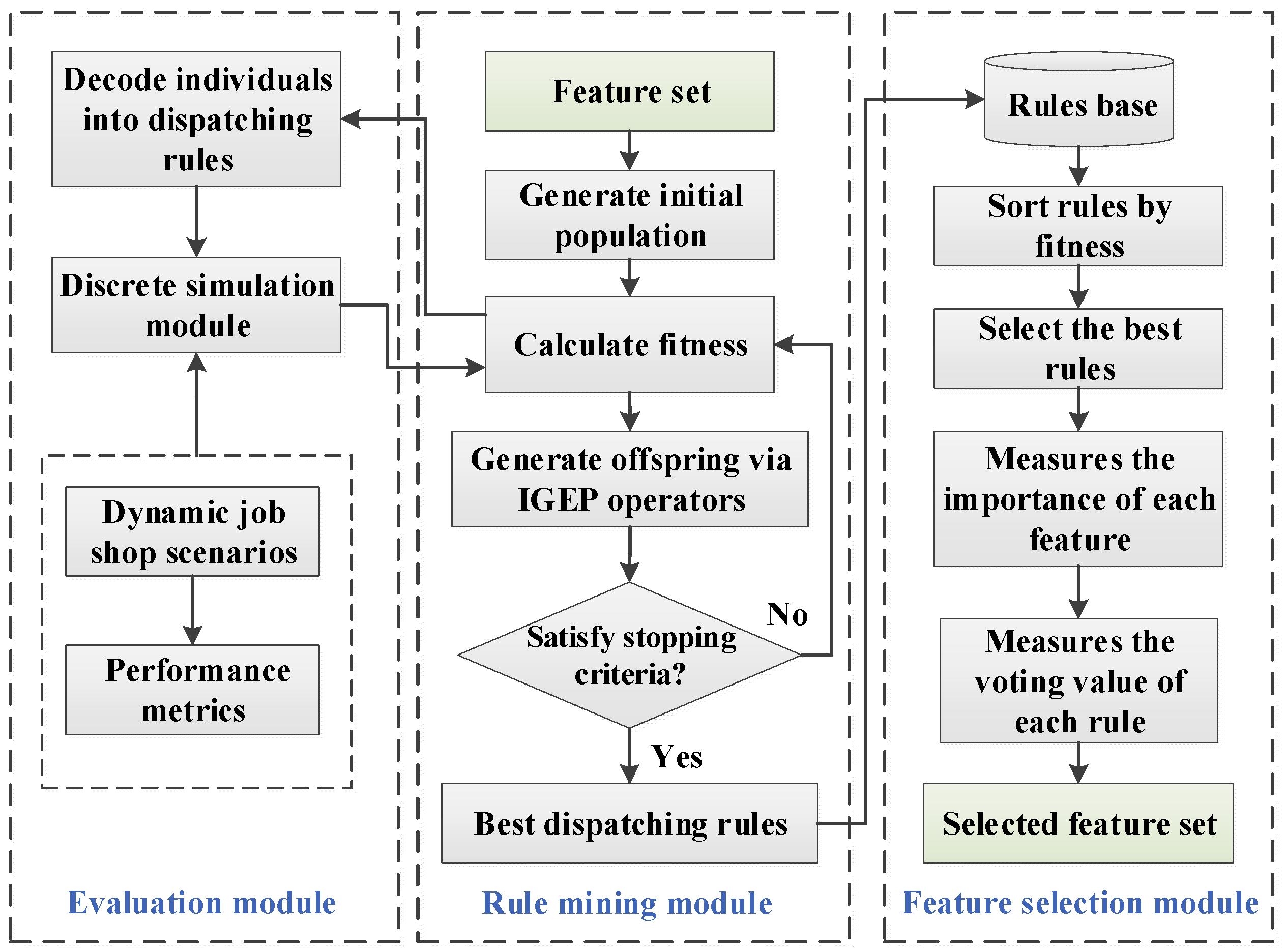

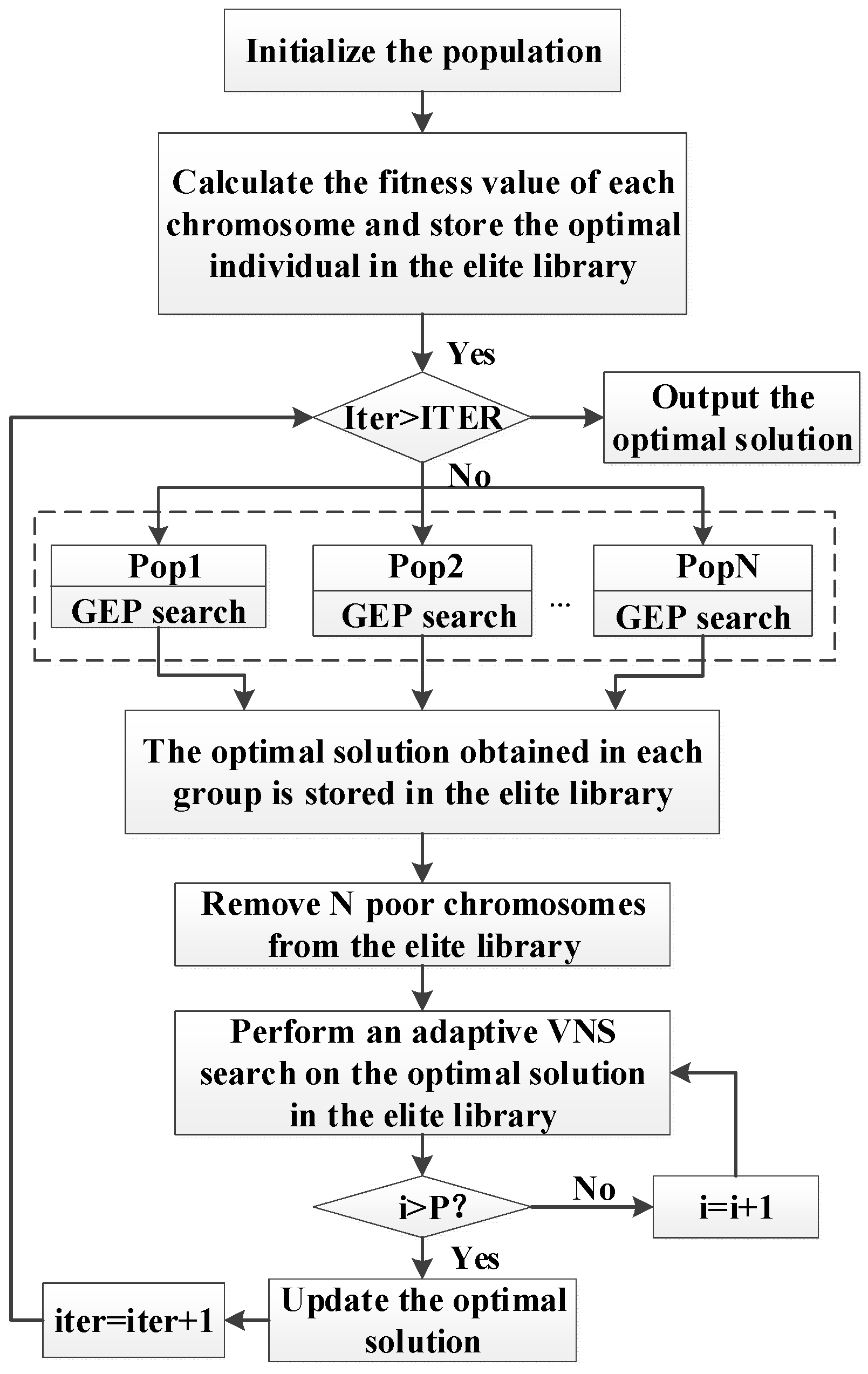

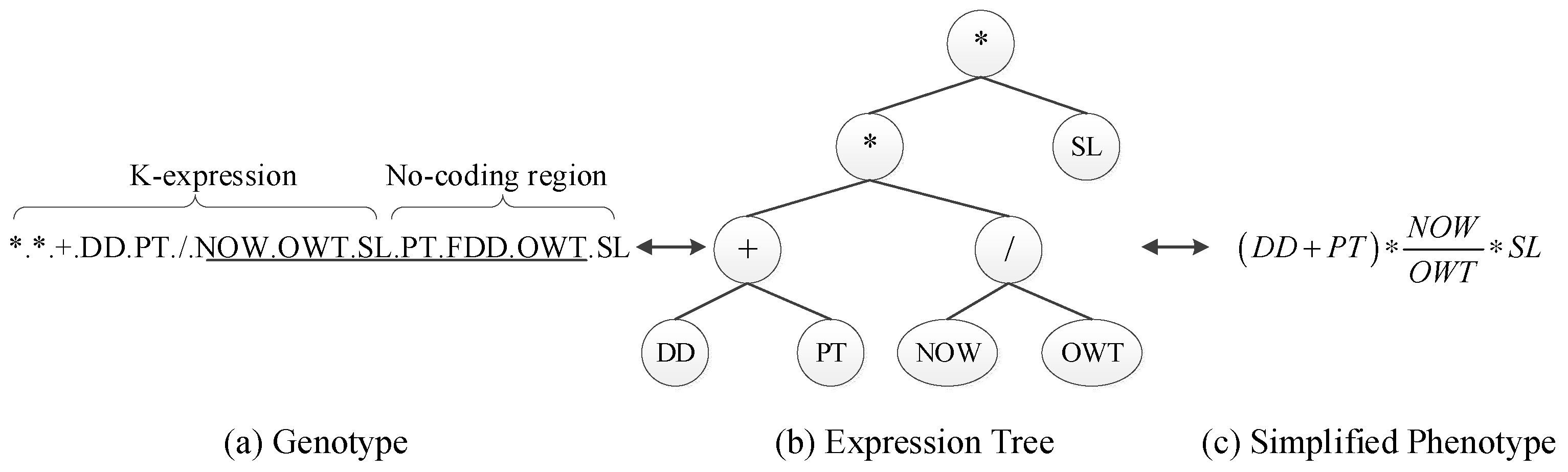

Gene expression programming (GEP), a kind of GP with liner representation, has been employed to design dispatching rules in a wide range of scheduling contexts, including single machine scheduling, parallel machine scheduling, job-shop scheduling, and flexible job-shop scheduling. Nie et al. [

33] designed dispatching rules for dynamic single-machine scheduling issues using the GEP-based hyperheuristic method. Nie et al. [

34] addressed a GEP method for flexible DJSS with job release dates by designing reactive priority rules in a linear representation. The findings demonstrated that GEP is capable of developing appropriate scheduling policies across a broad spectrum of processing circumstances and performance metrics. For dynamic multiobjective scheduling issues, Ozturk et al. [

35] proposed two new approaches to extract composite scheduling rules by applying the GEP method. According to the authors, all the rules developed using GEP for this scenario outperformed the GP-evolved rules and the classical rules from the literature. Later, to construct scheduling policies for multiobjective dynamic job-shop scheduling with the constrained buffer space, Teymourfair et al. [

36] employed GEP in conjunction with a simulation model, which heightened the complexity of the issue. The experimental results proved the superiority of using the GEP algorithm with the existing priority dispatching rules under different operating conditions. To address the issue of flexible job-shop scheduling problems with setup time and unpredictable work arrival, Zhang et al. [

37] suggested a GEP-based dynamic scheduling technique with enhanced features. The variable neighborhood search method was employed in the survey to enhance the local search capacity of GEP, achieving superior results in comparison to the standard GEP and GP algorithms;

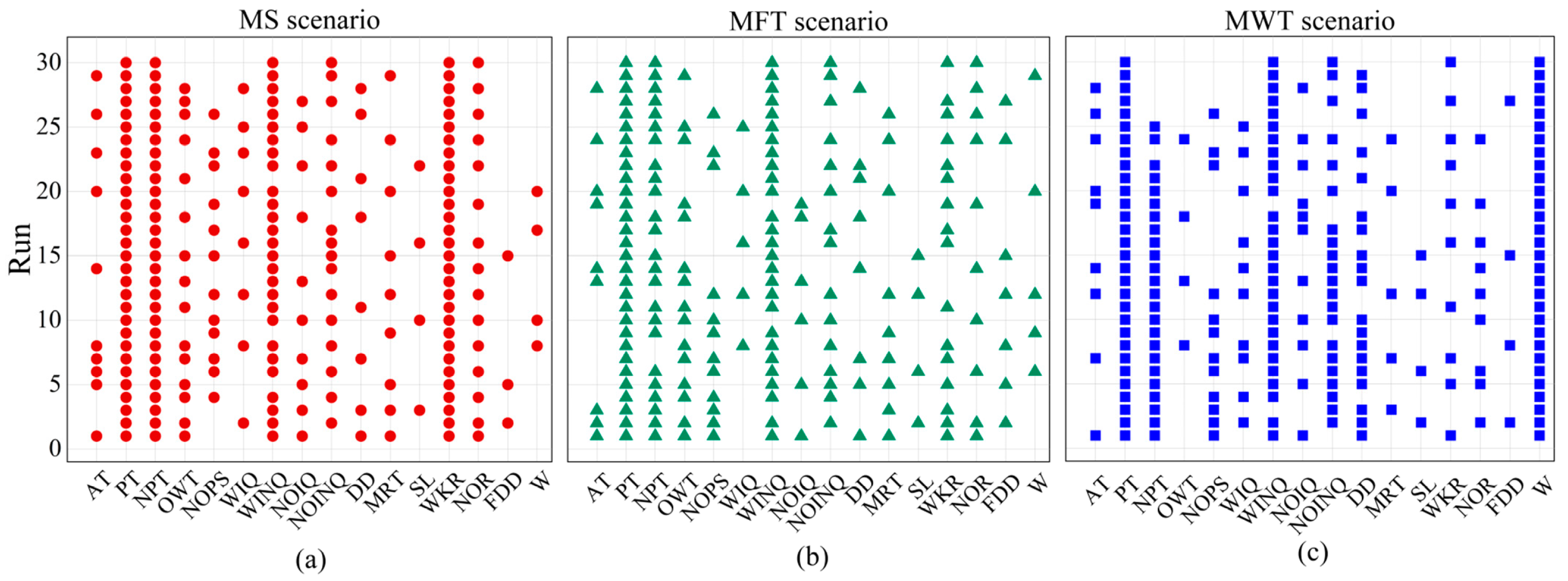

(3) Feature selection approaches. In dynamic job-shop situations, a diverse range of characteristics related to workshop states can be considered as potential features to be incorporated into the terminal set. It can be difficult to determine which features are advantageous for studying scheduling heuristics. Previous studies frequently incorporated any potential characteristic into the ultimate set of terminal features. The scheduling heuristics that have been designed exhibit a diverse range of characteristics, rendering them difficult to comprehend. Moreover, a significant number of terminals with redundant or irrelevant attributes can result in a search space that is both extensive and noisy, thus reducing the efficacy of the search of GP algorithms. Hence, it is essential to choose suitable terminal sets based on the practical requirements of job-shop conditions. The feature selection process is a crucial technique in the field of machine learning, as it enables the identification and selection of relevant data that can effectively reduce the exploration scope of evolutionary algorithms. As the features appearing in the evolved individual can be treated as a set of selected features, GP is considered to have the built-in feature selection ability. Determining the hidden links between a subset of features, however, is neither very efficient nor precise.

Friedlander et al. [

38] suggested a feature selection methodology that relied on frequency analysis, specifically, the frequency of the occurrence of a given terminal in rules. This methodology was subject to certain constraints, whereby particular characteristics may be inaccurately assessed due to their prevalence in the redundant priority function. Therefore, Mei et al. [

18] introduced an offline feature selection method for genetic programming, which evaluates the significance of features by their impact on priority functions. Despite its potential for more precise feature selection, this approach necessitates a significant investment of computational resources to generate a diverse set of high-quality individuals. Mei et al. [

39] conducted a subsequent investigation wherein they developed an efficient feature selection approach that utilized both niching and surrogate techniques to generate superior dispatching rules for DJSS. One potential constraint of this study was that, despite the effectiveness of the methodology in identifying a subset of important features, the size of the evolved rules within the program remained relatively large. Nguyen et al. [

14] augmented the tree-based rule representation by incorporating an attribute vector, which enhanced the interpretability of the rules by selecting important features. The primary limitation lay in its failure to account for situations wherein a particular attribute was not incorporated into the priority function. Shady et al. [

40] suggested a new representation of the GP rules by modifying the attribute vector that abstracts the importance of each terminal during the evolution process. Subsequently, Shady et al. [

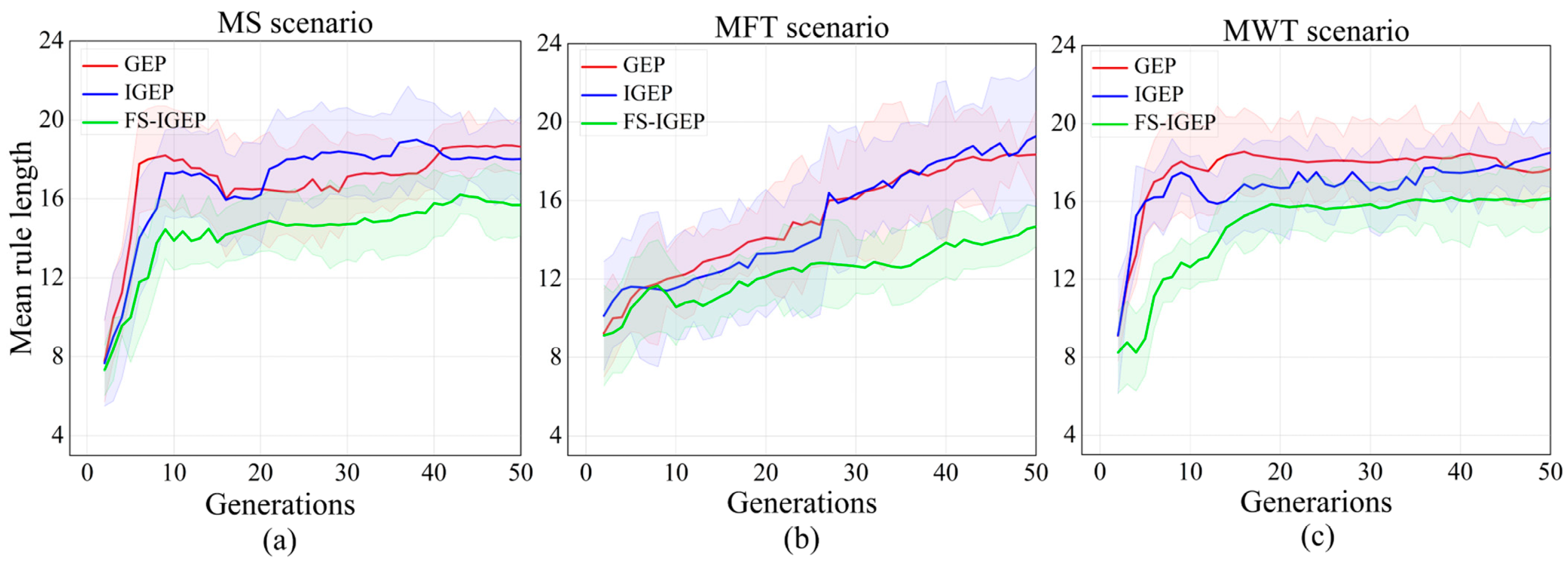

41] expanded upon the attribute vector by incorporating it into the linear representation of GEP. This allowed for the evolution of efficient rules within simplistic structures, while remaining within reasonable computational constraints. Moreover, Panda et al. [

42] proposed a new GP approach that incorporated simplification for the purpose of designing concise and efficient rules for DJSS. In addition to incorporating the conventional algebraic simplification operators, specialized numerical and behavioral simplification operators were also developed in their research. Huang et al. [

43] devised scheduling tactics for multitasking problems by employing the reuse of building blocks in linear genetic programming. Fan et al. [

44] used the GPHH method to solve DJSS with extended technical precedence constraints. The authors proposed a problem-specific approach for enhancing the efficacy of GP-evolved rules by integrating the job-shop state information that was pertinent to scheduling, through GP attribute selection.

In recent years, there has been a growing interest in exploring advanced techniques to improve the effectiveness and comprehensibility of the automated development of dispatching rules for Genetic Programming (GP). However, it has not been extensively studied in GEP. Furthermore, due to the extensive and complex exploration of scheduling heuristics, the identification of efficient scheduling principles represents a highly challenging undertaking. Therefore, this work aims to design interpretable and high-quality rules through an improved GEP algorithm for the DJSS problem.