Effects of Toolpath Parameters on Engagement Angle and Cutting Force in Ellipse-Based Trochoidal Milling of Titanium Alloy Ti-6Al-4V

Abstract

1. Introduction

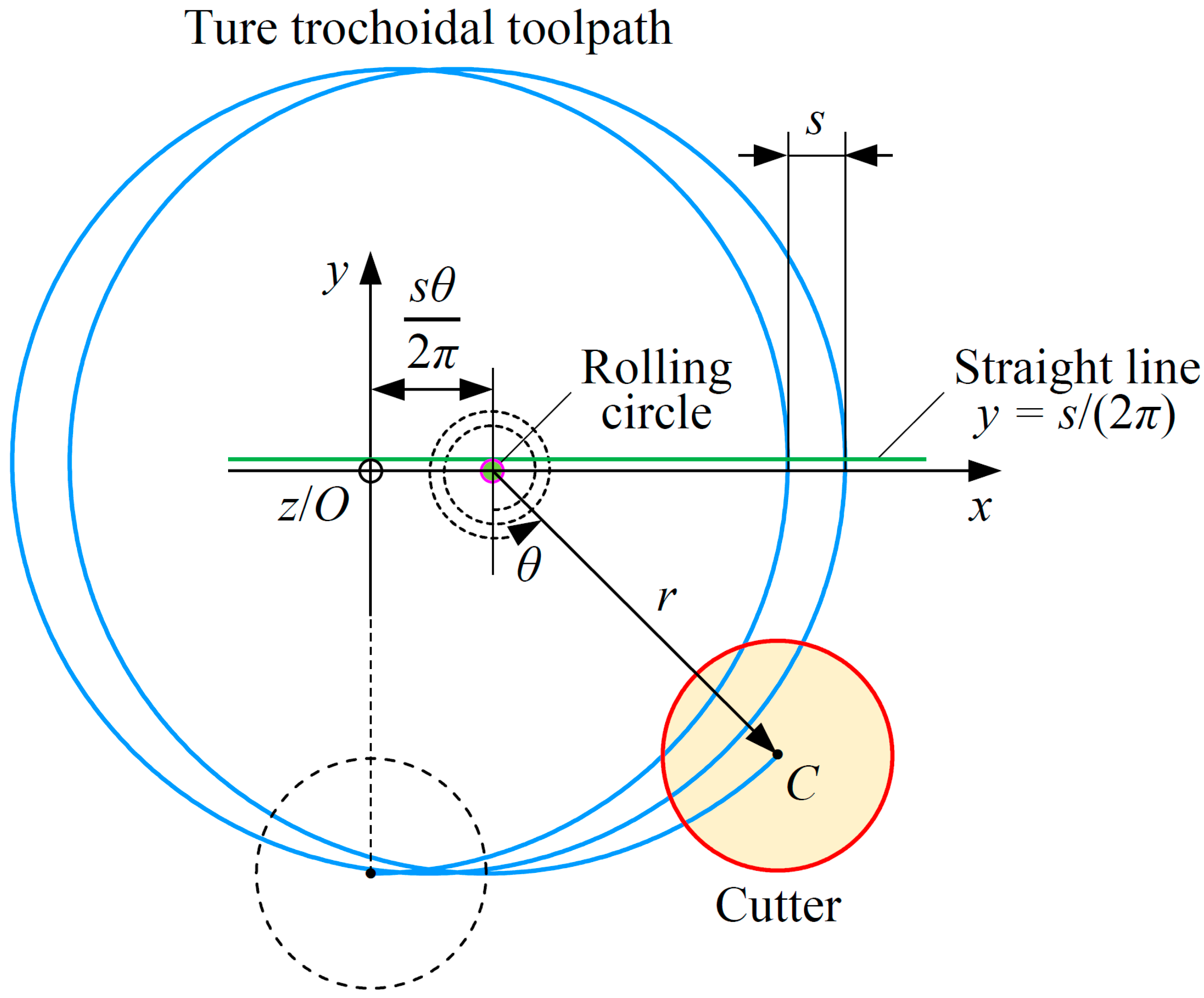

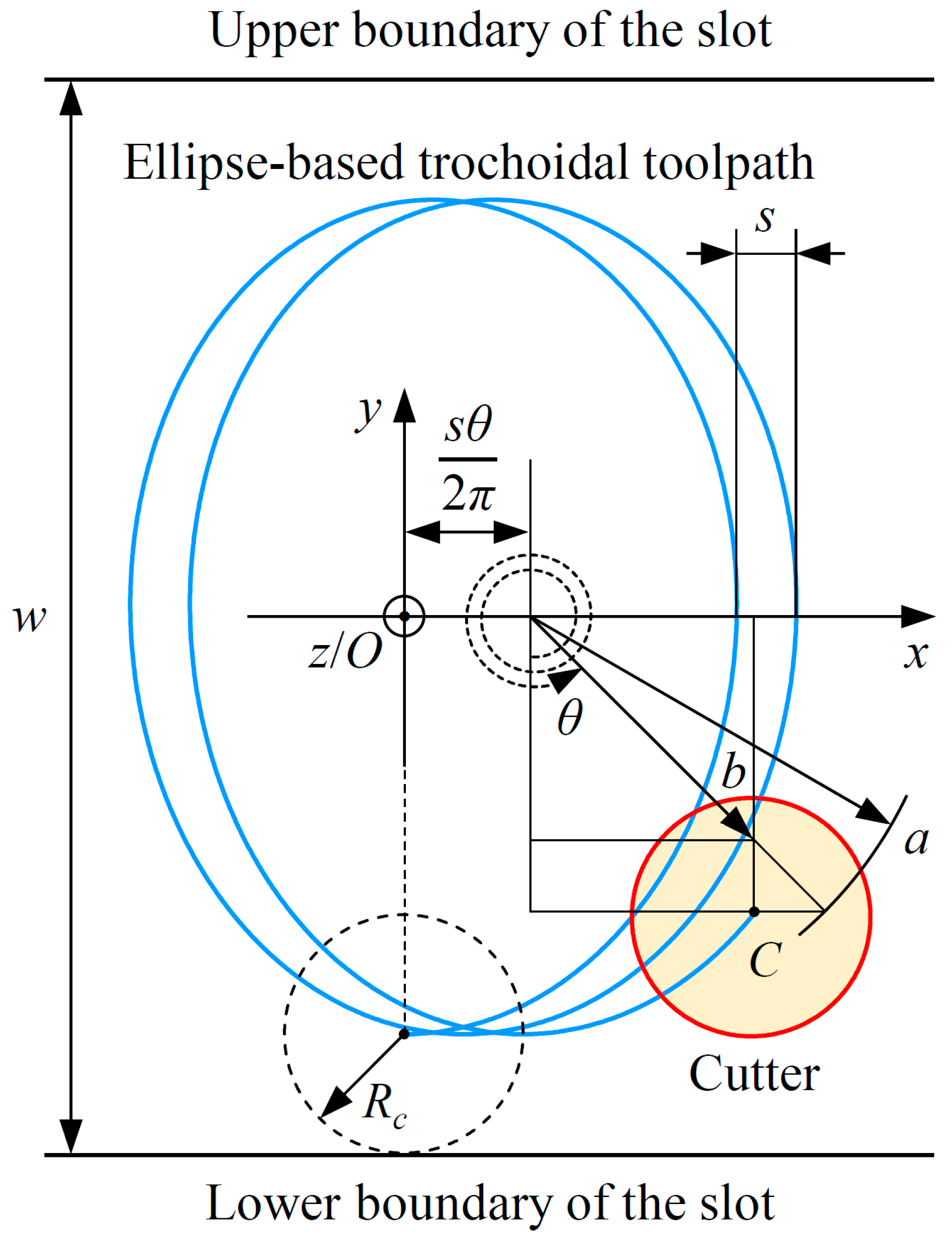

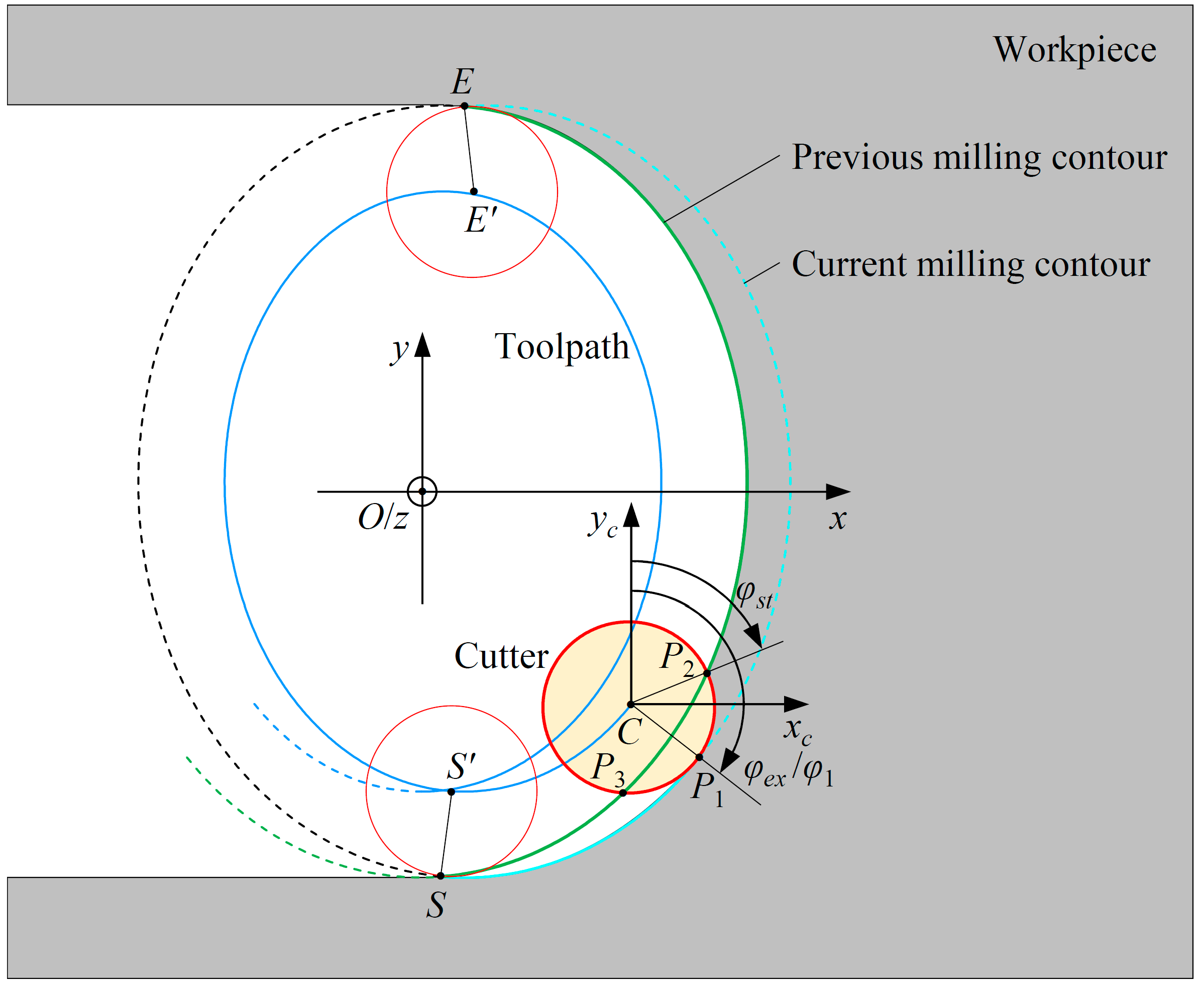

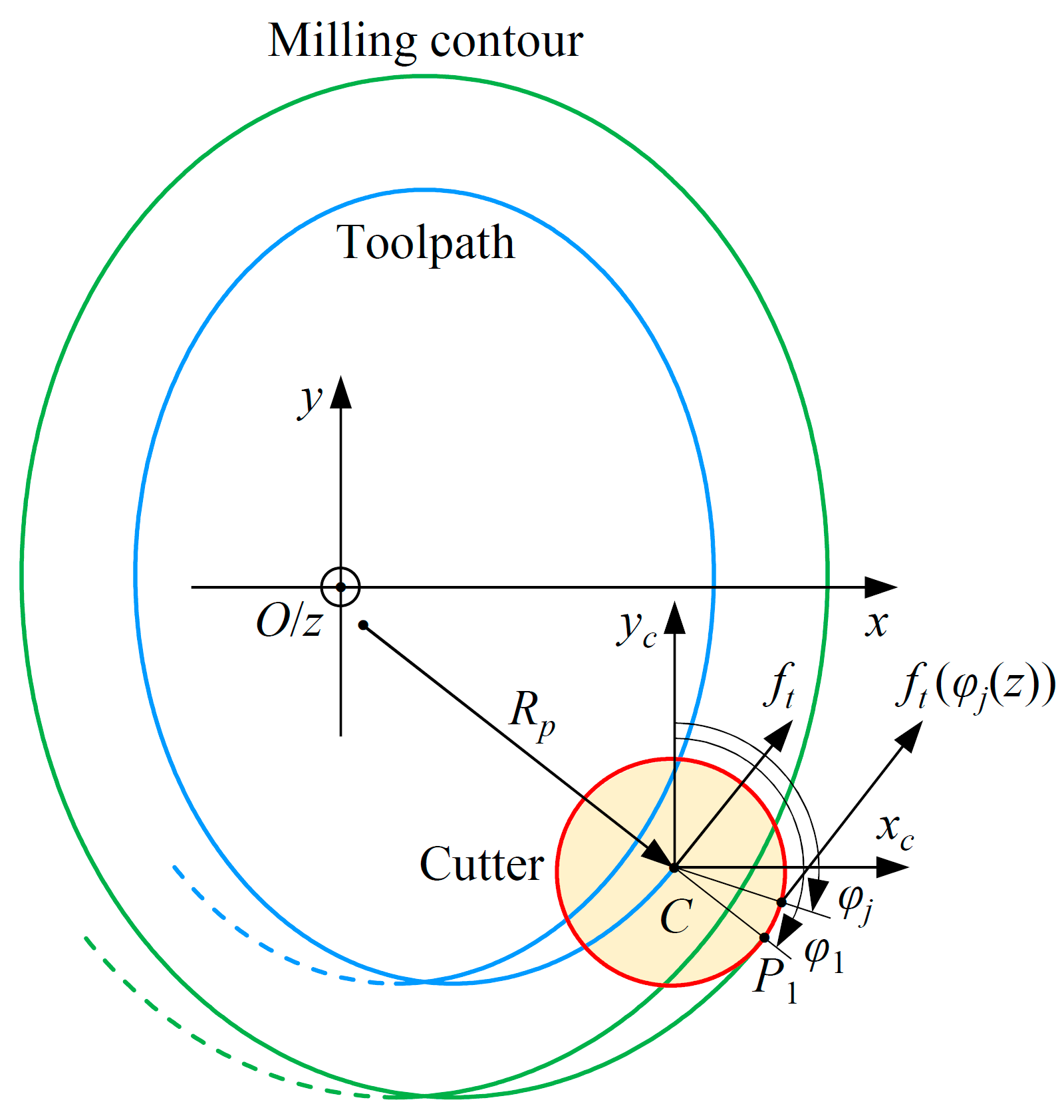

2. Ellipse-Based Trochoidal Toolpath Model

3. Analytical Engagement Angle Model

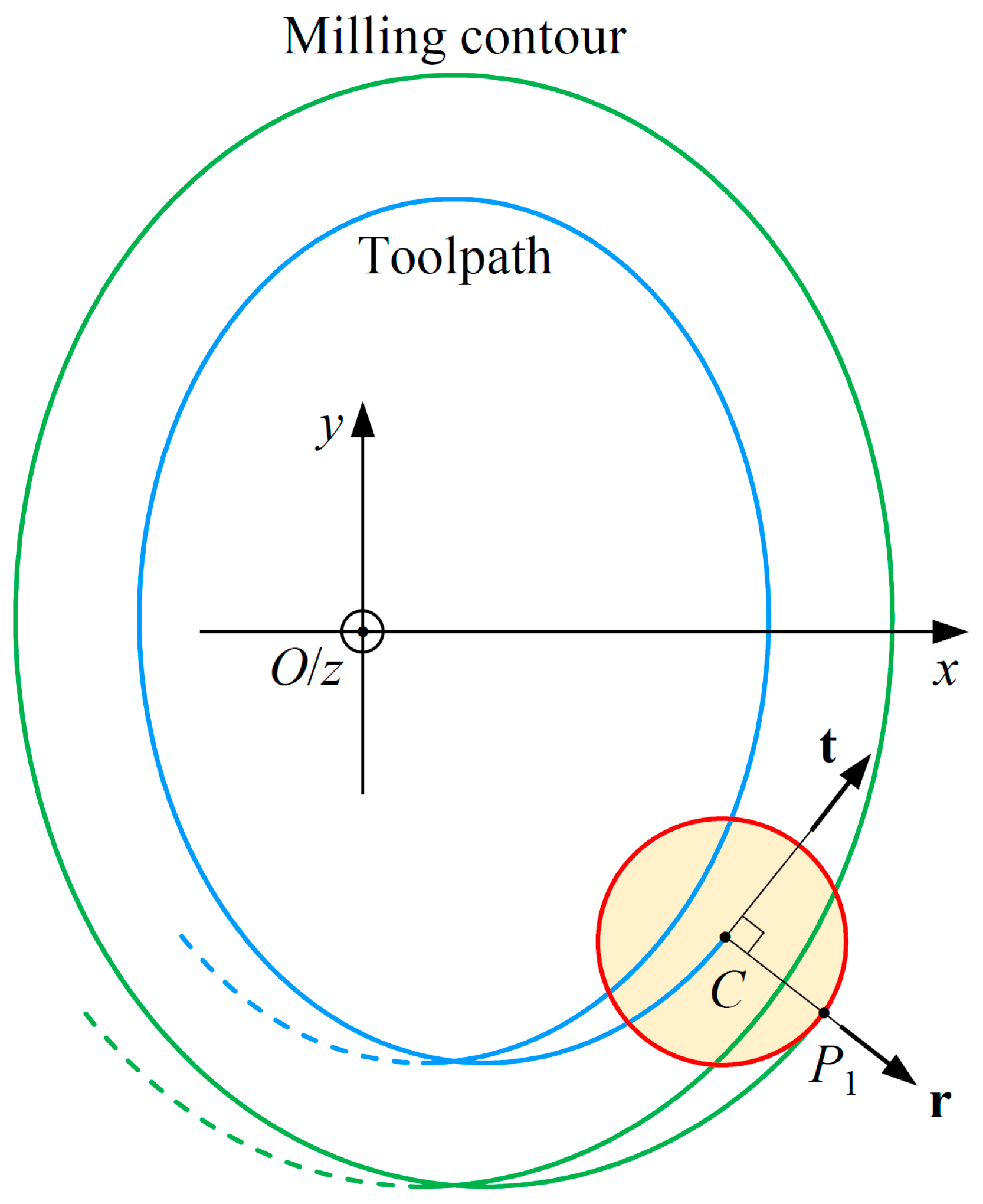

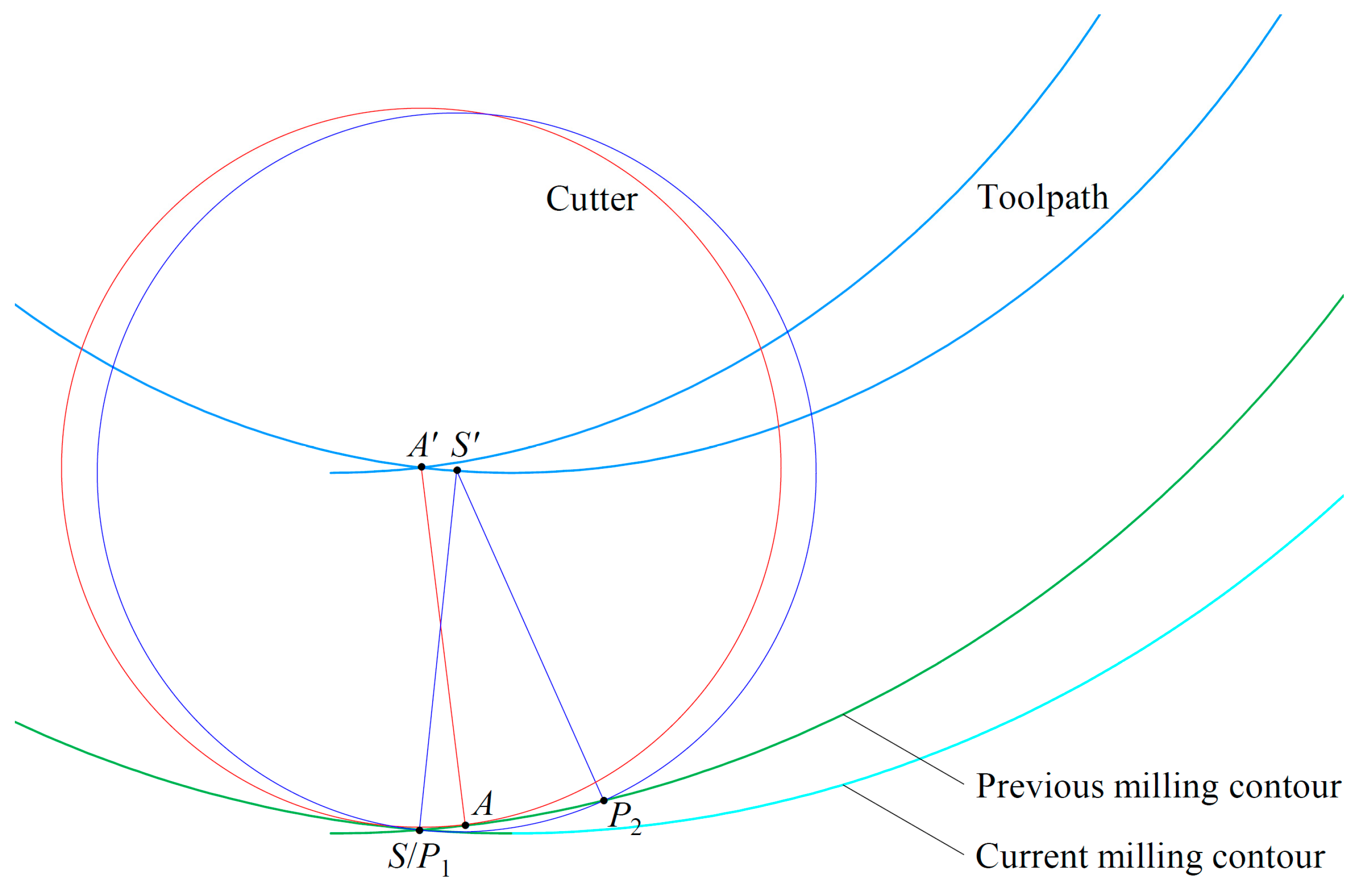

3.1. Effective Cutting Interval of Milling Contour

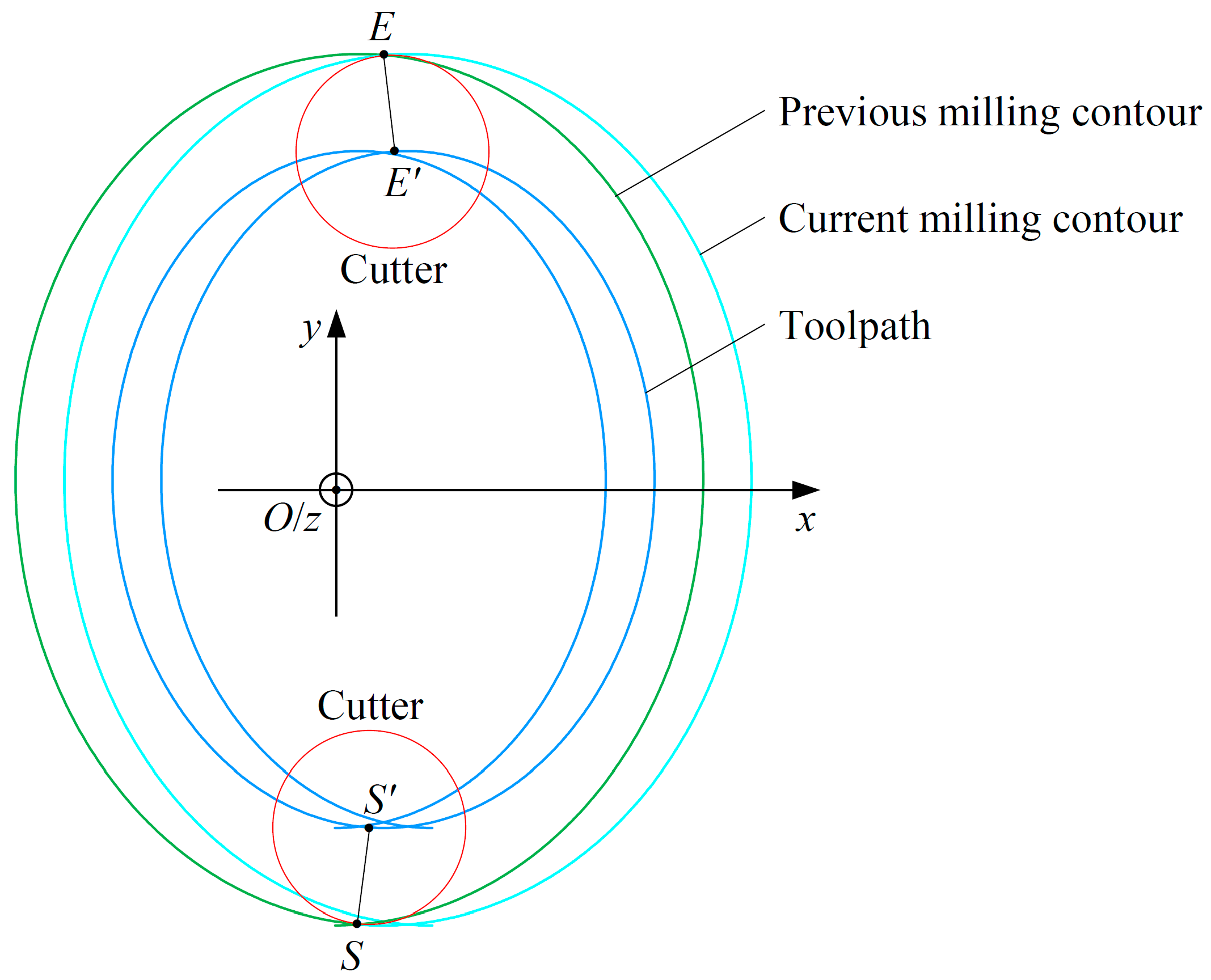

3.2. Calculation of Cutter-Workpiece Engagement Angle

4. Mechanistic Cutting-Force Model

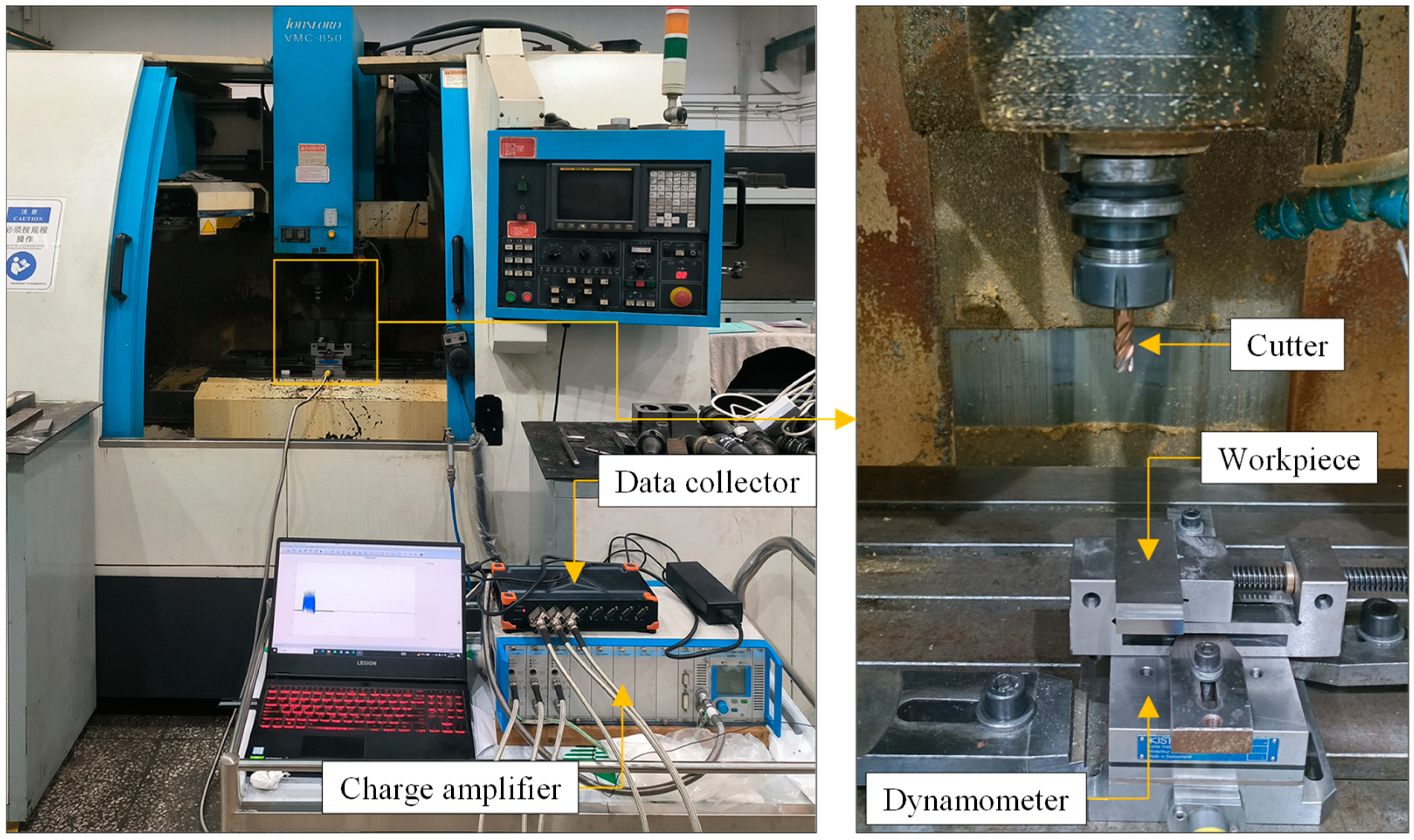

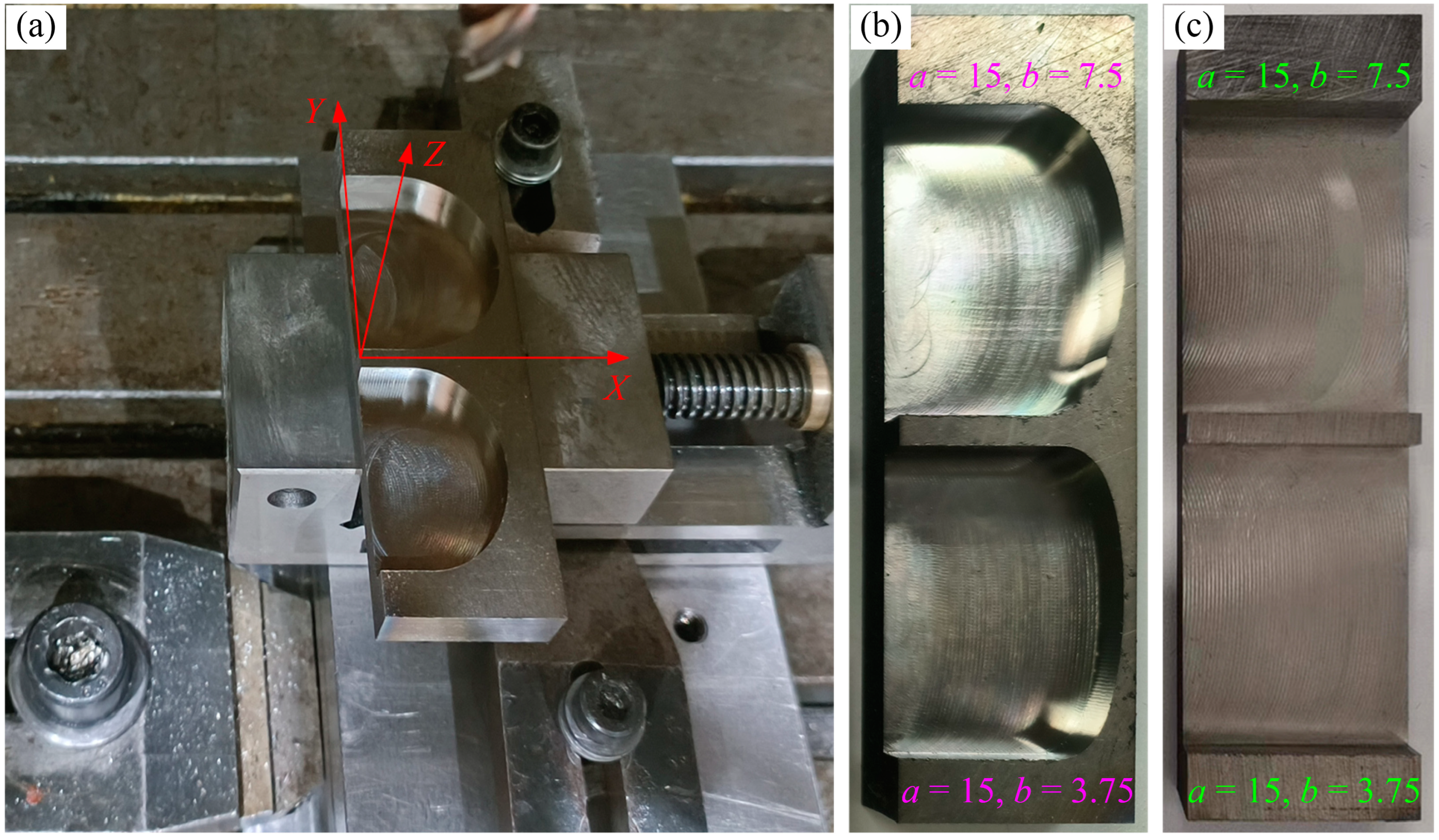

5. Results and Validation

5.1. Ellipse-Based Trochoidal Toolpath

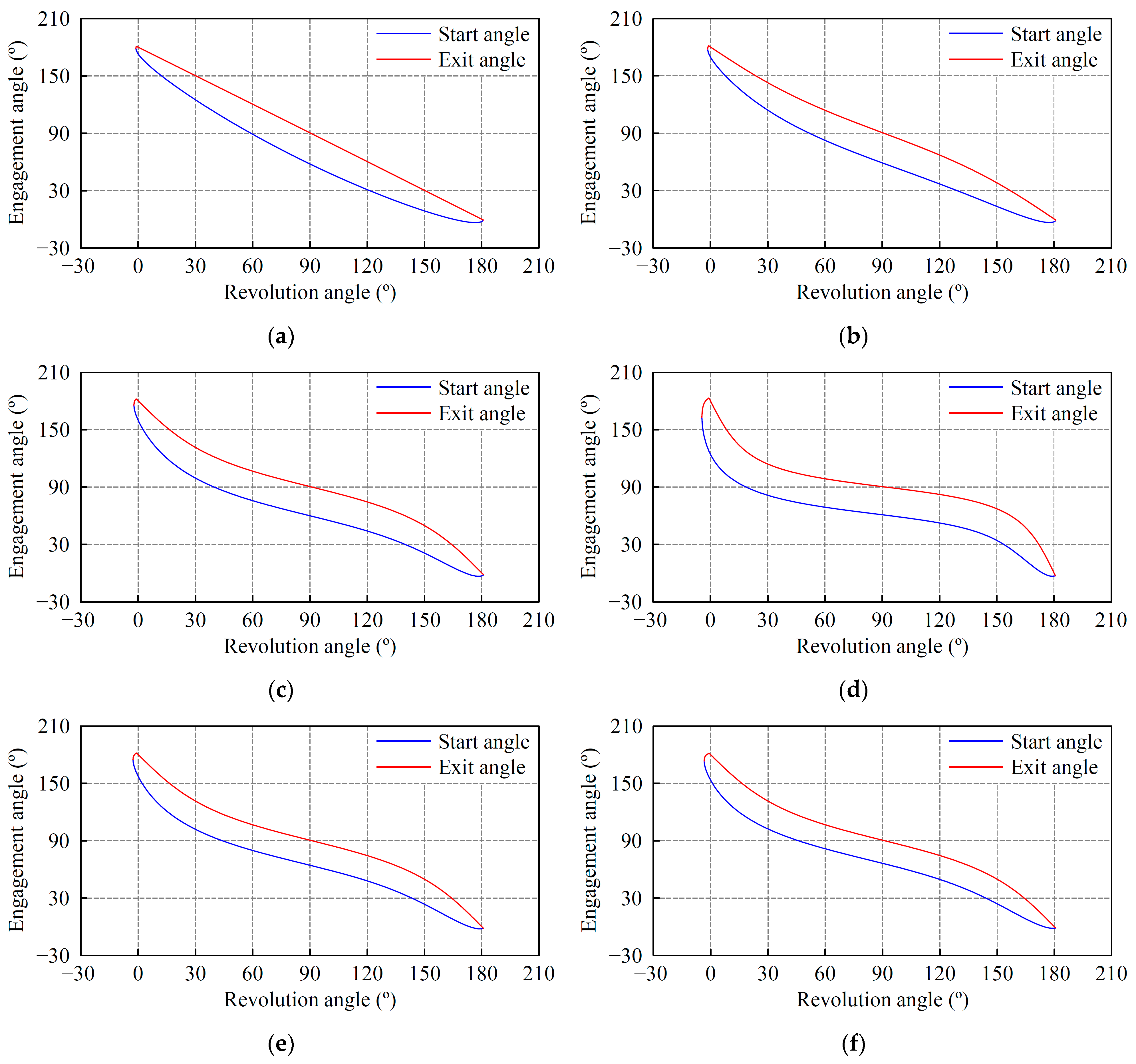

5.2. Cutter-Workpiece Engagement Angle

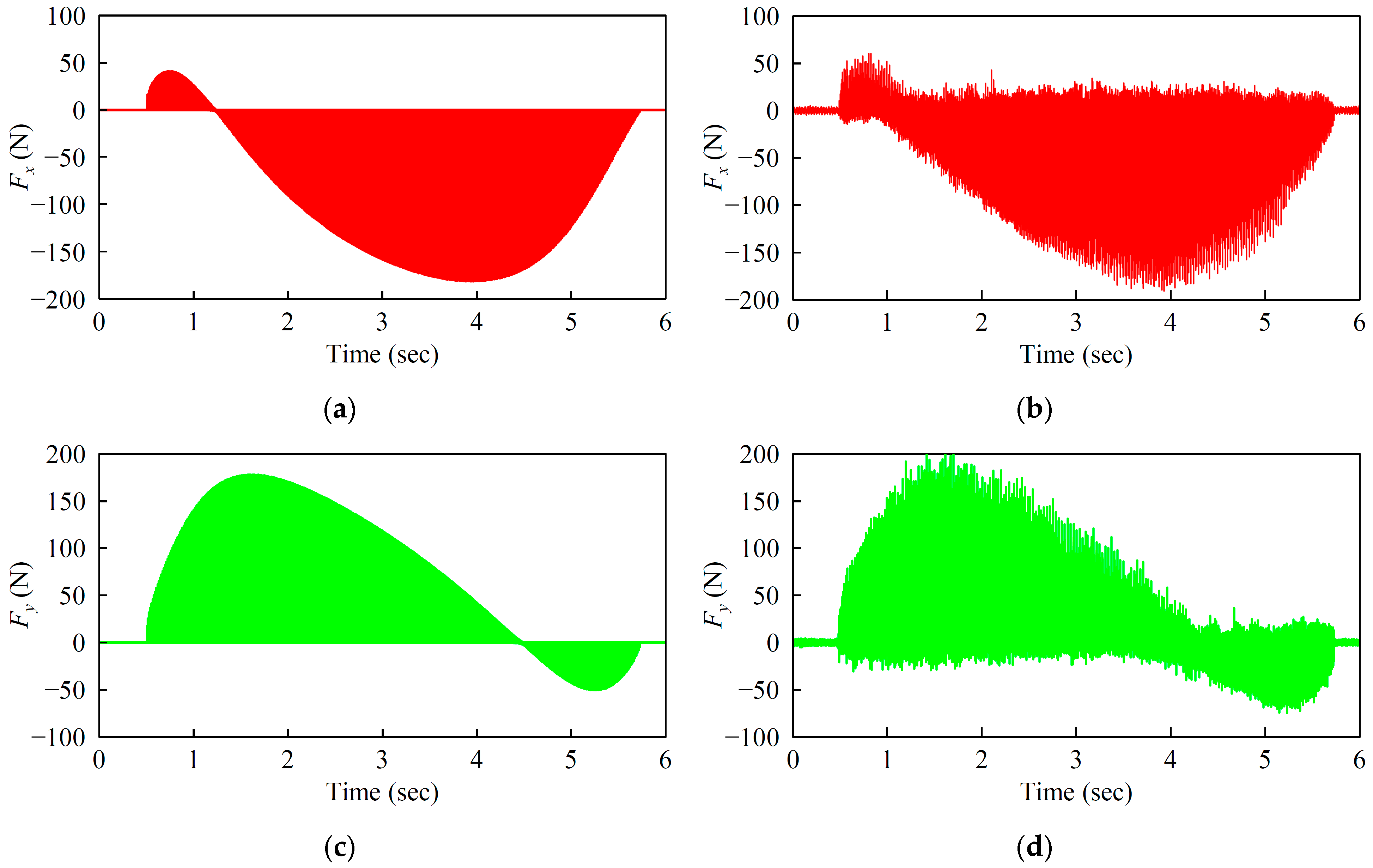

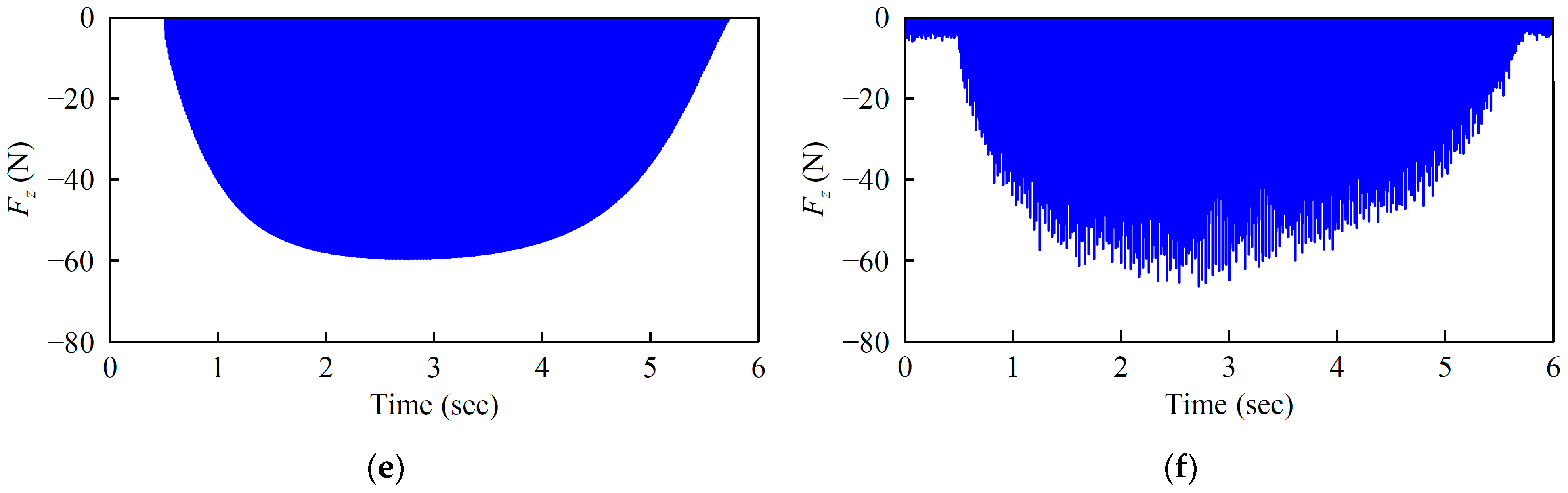

5.3. Cutting-Force Analysis and Experimental Validation

6. Conclusions

- (1)

- An ellipse-based trochoidal toolpath model is developed by extending the true trochoidal toolpath model with a control parameter, namely the compression ratio in the trochoidal step direction.

- (2)

- The analytical milling contour equation corresponding to the ellipse-based trochoidal toolpath is presented and the effective revolution interval within the actual cutting process is determined.

- (3)

- An analytical calculation method for the start and exit angles for the ellipse-based trochoidal milling process is proposed.

- (4)

- The compression ratio has significant effects on the trochoidal toolpath length and the cutter-workpiece engagement angle. The smaller the compression ratio, the shorter the overall trochoidal toolpath length, and the higher the material removal rate. As the compression ratio decreases, the engagement angle first becomes more balanced within the effective milling interval and then increases steeply in the initial and final segments. In this research, a compression ratio of 50% is optimal.

- (5)

- The effect of the cutter radius on the cutter-workpiece engagement angle is minimal. A larger cutter radius does not cause an obvious change in the engagement angle. However, a larger cutter radius results in a smaller semi-major axis of the fundamental ellipse, which helps to shorten the total trochoidal toolpath length.

- (6)

- The cutting-force coefficients for the milling of titanium alloy Ti-6Al-4V with a flat-end cutter are identified. Several ellipse-based trochoidal milling experiments with different toolpath parameters are conducted to verify the accuracy and reliability of the proposed method. It can be found that the predicted results agree well with the experimental data.

- (7)

- The trends in cutting force are consistent with the trends in cutter-workpiece engagement angle for different trochoidal toolpath parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rauch, M.; Duc, E.; Hascoet, J.Y. Improving trochoidal tool paths generation and implementation using process constraints modelling. Int. J. Mach. Tools Manuf. 2009, 49, 375–383. [Google Scholar] [CrossRef]

- Luo, M.; Han, C.; Hafeez, H.M. Four-axis trochoidal toolpath planning for rough milling of aero-engine blisks. Chin. J. Aeronaut. 2019, 32, 2009–2016. [Google Scholar] [CrossRef]

- Ren, J.X.; Yao, C.F.; Zhang, D.H.; Xue, Y.L.; Liang, Y.S. Research on tool path planning method of four-axis high-efficiency slot plunge milling for open blisk. Int. J. Adv. Manuf. Technol. 2009, 45, 101–109. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; Huang, N. A new plunge milling tool path generation method for radial depth control using medial axis transform. Int. J. Adv. Manuf. Technol. 2015, 76, 1575–1582. [Google Scholar] [CrossRef]

- Xu, J.; Sun, Y.; Zhang, X. A mapping-based spiral cutting strategy for pocket machining. Int. J. Adv. Manuf. Technol. 2013, 67, 2489–2500. [Google Scholar] [CrossRef]

- Urbikain Pelayo, G.; Olvera-Trejo, D.; Luo, M.; Tang, K.; López de Lacalle, L.N.; Elías-Zuñiga, A. A model-based sustainable productivity concept for the best decision-making in rough milling operations. Measurement 2021, 186, 110120. [Google Scholar] [CrossRef]

- Xu, K.; Wu, B.; Li, Z.; Tang, K. Time-Efficient Trochoidal Tool Path Generation for Milling Arbitrary Curved Slots. J. Manuf. Sci. Eng. 2019, 141, 031008. [Google Scholar] [CrossRef]

- Deng, Q.; Mo, R.; Chen, Z.C.; Chang, Z. An Analytical Approach to Cutter Edge Temperature Prediction in Milling and Its Application to Trochoidal Milling. Appl. Sci. 2020, 10, 1746. [Google Scholar] [CrossRef]

- Elber, G.; Cohen, E.; Drake, S. MATHSM: Medial axis transform toward high speed machining of pockets. Comput. Aided Des. 2005, 37, 241–250. [Google Scholar] [CrossRef]

- Otkur, M.; Lazoglu, I. Trochoidal milling. Int. J. Mach. Tools Manuf. 2007, 47, 1324–1332. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Ochoa, D.M. A method for generating trochoidal tool paths for 2½D pocket milling process planning with multiple tools. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 1287–1298. [Google Scholar] [CrossRef]

- Wang, Q.H.; Wang, S.; Jiang, F.; Li, J.R. Adaptive trochoidal toolpath for complex pockets machining. Int. J. Prod. Res. 2016, 54, 5976–5989. [Google Scholar] [CrossRef]

- Deng, Q.; Mo, R.; Chen, Z.C.; Chang, Z. A new approach to generating trochoidal tool paths for effective corner machining. Int. J. Adv. Manuf. Technol. 2018, 95, 3001–3012. [Google Scholar] [CrossRef]

- Huang, X.; Wu, S.; Liang, L.; Li, X.; Huang, N. Efficient trochoidal milling based on medial axis transformation and inscribed ellipse. Int. J. Adv. Manuf. Technol. 2020, 111, 1069–1076. [Google Scholar] [CrossRef]

- Jacso, A.; Sikarwar, B.S.; Phanden, R.K.; Singh, R.K.; Ramkumar, J.; Sahu, G.N. Optimisation of tool path shape in trochoidal milling using B-spline curves. Int. J. Adv. Manuf. Technol. 2022, 121, 3801–3816. [Google Scholar] [CrossRef]

- Chang, C.H.; Huang, M.; Yau, H.T. A double-NURBS approach to the generation of trochoidal tool path. Int. J. Adv. Manuf. Technol. 2023, 125, 1757–1776. [Google Scholar] [CrossRef]

- Li, Z.; Xu, K.; Tang, K. A new trochoidal pattern for slotting operation. Int. J. Adv. Manuf. Technol. 2019, 102, 1153–1163. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Xu, K.; Gao, Y.; Tang, K. Five-axis Trochoidal Flank Milling of Deep 3D Cavities. Comput. Aided Des. 2020, 119, 102775. [Google Scholar] [CrossRef]

- Li, Z.; Hu, P.; Xie, F.; Tang, K. A variable-depth multi-layer five-axis trochoidal milling method for machining deep freeform 3D slots. Robot. Comput. Integr. Manuf. 2021, 68, 102093. [Google Scholar] [CrossRef]

- Wu, S.; Ma, W.; Li, B.; Wang, C. Trochoidal machining for the high-speed milling of pockets. J. Mater. Process. Technol. 2016, 233, 29–43. [Google Scholar]

- Liu, D.; Zhang, Y.; Luo, M.; Zhang, D. Investigation of tool wear and chip morphology in dry trochoidal milling of titanium alloy Ti–6Al–4V. Materials 2019, 12, 1937. [Google Scholar] [CrossRef]

- Karkalos, N.E.; Karmiris-Obratański, P.; Kurpiel, S.; Zagórski, K.; Markopoulos, A.P. Investigation on the Surface Quality Obtained during Trochoidal Milling of 6082 Aluminum Alloy. Machines 2021, 9, 75. [Google Scholar] [CrossRef]

- Deng, Q.; Chen, Z.C.; Chang, Z.; Shen, R.; Zhou, Y. A model for investigating the temperature of trochoidal machining. J. Ind. Prod. Eng. 2020, 37, 194–203. [Google Scholar] [CrossRef]

- Pleta, A.; Akhavan Niaki, F.; Mears, L. Investigation of Chip Thickness and Force Modeling of Trochoidal Milling. Procedia Manuf. 2017, 10, 612–621. [Google Scholar] [CrossRef]

- Pleta, A.; Nithyanand, G.; Niaki, F.A.; Mears, L. Identification of optimal machining parameters in trochoidal milling of Inconel 718 for minimal force and tool wear and investigation of corresponding effects on machining affected zone depth. J. Manuf. Process. 2019, 43, 54–62. [Google Scholar] [CrossRef]

- Šajgalík, M.; Kušnerová, M.; Harničárová, M.; Valíček, J.; Czán, A.; Czánová, T.; Drbúl, M.; Borzan, M.; Kmec, J. Analysis and Prediction of the Machining Force Depending on the Parameters of Trochoidal Milling of Hardened Steel. Appl. Sci. 2020, 10, 1788. [Google Scholar] [CrossRef]

- Akhavan Niaki, F.; Pleta, A.; Mears, L. Trochoidal milling: Investigation of a new approach on uncut chip thickness modeling and cutting force simulation in an alternative path planning strategy. Int. J. Adv. Manuf. Technol. 2018, 97, 641–656. [Google Scholar] [CrossRef]

- Akhavan Niaki, F.; Pleta, A.; Mears, L.; Potthoff, N.; Bergmann, J.A.; Wiederkehr, P. Trochoidal milling: Investigation of dynamic stability and time domain simulation in an alternative path planning strategy. Int. J. Adv. Manuf. Technol. 2019, 102, 1405–1419. [Google Scholar] [CrossRef]

- Kardes, N.; Altintas, Y. Mechanics and dynamics of the circular milling process. J. Manuf. Sci. Eng. 2007, 129, 21–31. [Google Scholar] [CrossRef]

- Yan, R.; Li, H.; Peng, F.; Tang, X.; Xu, J.; Zeng, H. Stability Prediction and Step Optimization of Trochoidal Milling. J. Manuf. Sci. Eng. 2017, 139, 091006. [Google Scholar] [CrossRef]

- Zagórski, I.; Kulisz, M.; Kłonica, M.; Matuszak, J. Trochoidal Milling and Neural Networks Simulation of Magnesium Alloys. Materials 2019, 12, 2070. [Google Scholar] [CrossRef] [PubMed]

- Jacso, A.; Matyasi, G.; Szalay, T. The fast constant engagement offsetting method for generating milling tool paths. Int. J. Adv. Manuf. Technol. 2019, 103, 4293–4305. [Google Scholar] [CrossRef]

- Rodriguez-Alabanda, O.; Guerrero-Vaca, G.; Molero, E.; Romero, P.E. Experimental analysis of deep slot milling in EN AW 2024-T3 alloy by stretched trochoidal toolpath and variable helix angle tool. CIRP J. Manuf. Sci. Technol. 2021, 35, 346–360. [Google Scholar] [CrossRef]

- Feng, J.; Wei, Z.; Wang, M.; Wang, X.; Guo, M. Tool path planning for five-axis U-pass milling of an impeller. Int. J. Adv. Manuf. Technol. 2021, 117, 3379–3391. [Google Scholar] [CrossRef]

- Wang, Q.H.; Liao, Z.Y.; Zheng, Y.X.; Li, J.R.; Zhou, X.F. Removal of critical regions by radius-varying trochoidal milling with constant cutting forces. Int. J. Adv. Manuf. Technol. 2018, 98, 671–685. [Google Scholar] [CrossRef]

- Ducroux, E.; Prat, D.; Viprey, F.; Fromentin, G.; D’Acunto, A. Analysis and modeling of trochoidal milling in Inconel 718. Procedia CIRP 2019, 82, 473–478. [Google Scholar] [CrossRef]

- Urbikain, G.; Artetxe, E.; López de Lacalle, L.N. Numerical simulation of milling forces with barrel-shaped tools considering runout and tool inclination angles. Appl. Math. Model. 2017, 47, 619–636. [Google Scholar] [CrossRef]

- Wu, B.; Yan, X.; Luo, M.; Gao, G. Cutting force prediction for circular end milling process. Chin. J. Aeronaut. 2013, 26, 1057–1063. [Google Scholar] [CrossRef]

- Shi, K.; Liu, N.; Wang, S.; Ren, J. Effect of tool path on cutting force in end milling. Int. J. Adv. Manuf. Technol. 2019, 104, 4289–4300. [Google Scholar] [CrossRef]

- Budak, E. Analytical models for high performance milling. Part I: Cutting forces, structural deformations and tolerance integrity. Int. J. Mach. Tools Manuf. 2006, 46, 1478–1488. [Google Scholar] [CrossRef]

| Cutter Type | Cutter Material | Number of Flutes | Diameter (mm) | Helix Angle (°) | Flute Length (mm) | Total Length (mm) |

|---|---|---|---|---|---|---|

| Flat-end mill | 3 μm TiAlN-coated carbide | 4 | 10 | 38 | 25 | 75 |

| Workpiece Material | Geometrical Dimensions (mm) | Density (kg/m3) | Elastic Modulus (GPa) | Yield Strength (MPa) | Poisson’s Ratio | ||

|---|---|---|---|---|---|---|---|

| Slot Width | Slot Length | Slot Depth | |||||

| Ti-6Al-4V | 40 | 30 | 6 | 4430 | 114 | 880 | 0.34 |

| Al | V | Fe | O | C | N | H | Ti |

| 5.5~6.8 | 3.5~4.5 | ≤0.3 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.015 | rest |

| No. | Semi-Major Axis (mm) | Semi-Minor Axis (mm) | Compression Ratio | Cutter Radius (mm) | Trochoidal Step (mm) |

|---|---|---|---|---|---|

| 1 | 15 | 15 | 100% | 5 | 0.6 |

| 2 | 15 | 11.25 | 75% | 5 | 0.6 |

| 3 | 15 | 7.5 | 50% | 5 | 0.6 |

| 4 | 15 | 3.75 | 25% | 5 | 0.6 |

| 5 | 12.5 | 6.25 | 50% | 7.5 | 0.6 |

| 6 | 10 | 5 | 50% | 10 | 0.6 |

| Spindle Speed (rpm) | Axial Depth of Cut (mm) | Radius Depth of Cut (mm) | Feed Rate per Tooth (mm/tooth) |

|---|---|---|---|

| 2000 | 6 | 0.6 | 0.03 |

| 0.06 | |||

| 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Zhou, J.; Qi, Q.; Zhang, C.; Zhang, D. Effects of Toolpath Parameters on Engagement Angle and Cutting Force in Ellipse-Based Trochoidal Milling of Titanium Alloy Ti-6Al-4V. Appl. Sci. 2023, 13, 6550. https://doi.org/10.3390/app13116550

Zhou X, Zhou J, Qi Q, Zhang C, Zhang D. Effects of Toolpath Parameters on Engagement Angle and Cutting Force in Ellipse-Based Trochoidal Milling of Titanium Alloy Ti-6Al-4V. Applied Sciences. 2023; 13(11):6550. https://doi.org/10.3390/app13116550

Chicago/Turabian StyleZhou, Xu, Jinhua Zhou, Qi Qi, Congpeng Zhang, and Dinghua Zhang. 2023. "Effects of Toolpath Parameters on Engagement Angle and Cutting Force in Ellipse-Based Trochoidal Milling of Titanium Alloy Ti-6Al-4V" Applied Sciences 13, no. 11: 6550. https://doi.org/10.3390/app13116550

APA StyleZhou, X., Zhou, J., Qi, Q., Zhang, C., & Zhang, D. (2023). Effects of Toolpath Parameters on Engagement Angle and Cutting Force in Ellipse-Based Trochoidal Milling of Titanium Alloy Ti-6Al-4V. Applied Sciences, 13(11), 6550. https://doi.org/10.3390/app13116550