Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations

Abstract

1. Introduction

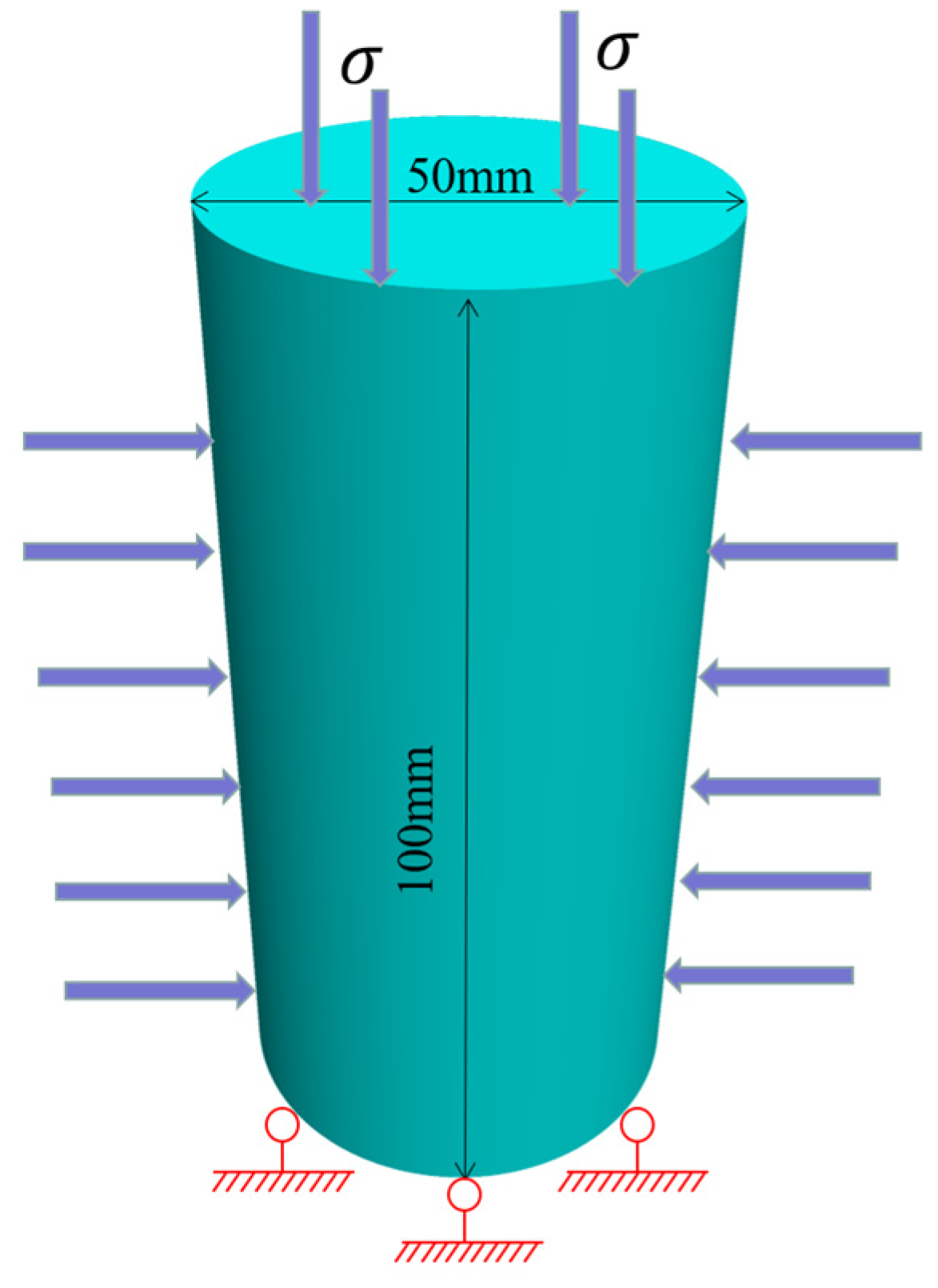

2. Materials and Methods

2.1. Preparation of Coal Specimens

2.2. Testing Equipment and Procedure

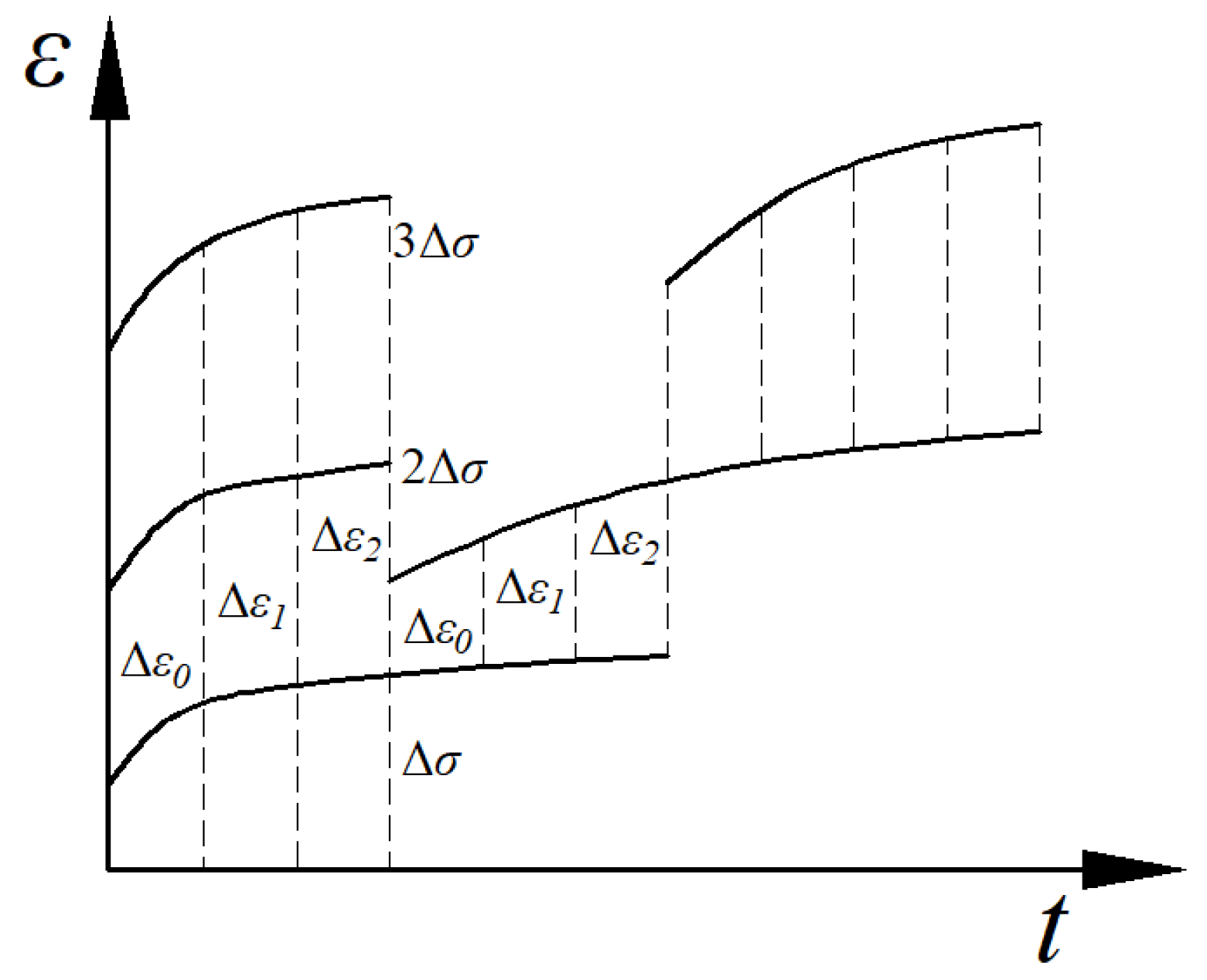

2.3. Definition of Creep Damage

2.3.1. Initial Damage

2.3.2. Long-Term Damage

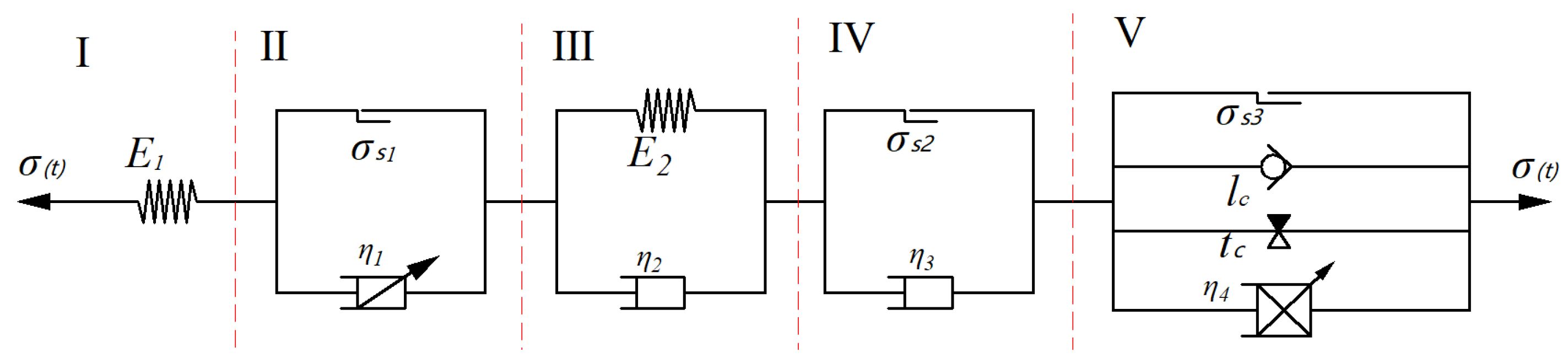

2.4. Combinatorial Model

2.5. Construction of Fractional Order Model for Anthracite Combinations

- Hook body

- 2.

- Fractional-order Bingham body

- 3.

- Kelvin–Voigt body

- 4.

- Bingham body

2.6. Three-Dimensional Extension of NEG

- Hook body

- 2.

- Kelvin–Voigt body

- 3.

- Bingham body

2.7. Finite Difference of Equations

2.8. Programming Outline

- Modifying the .h file by naming the model header file NEG.h, defining the file name as NEG, and modifying the model ID as 520.

- Modifying the .cpp file, mainly by modifying the Strata function, Initialize function, and Run function, including the assignment of each material parameter.

- Producing the .dll file by modifying the UDM folder to NEG, while copying it to the program installation location, opening the udm.veproj file, executing the udm command, modifying the debug/NEG.dll command, and finally running the solution. Figure 4 shows the numerical simulation model.

3. Results and Discussion

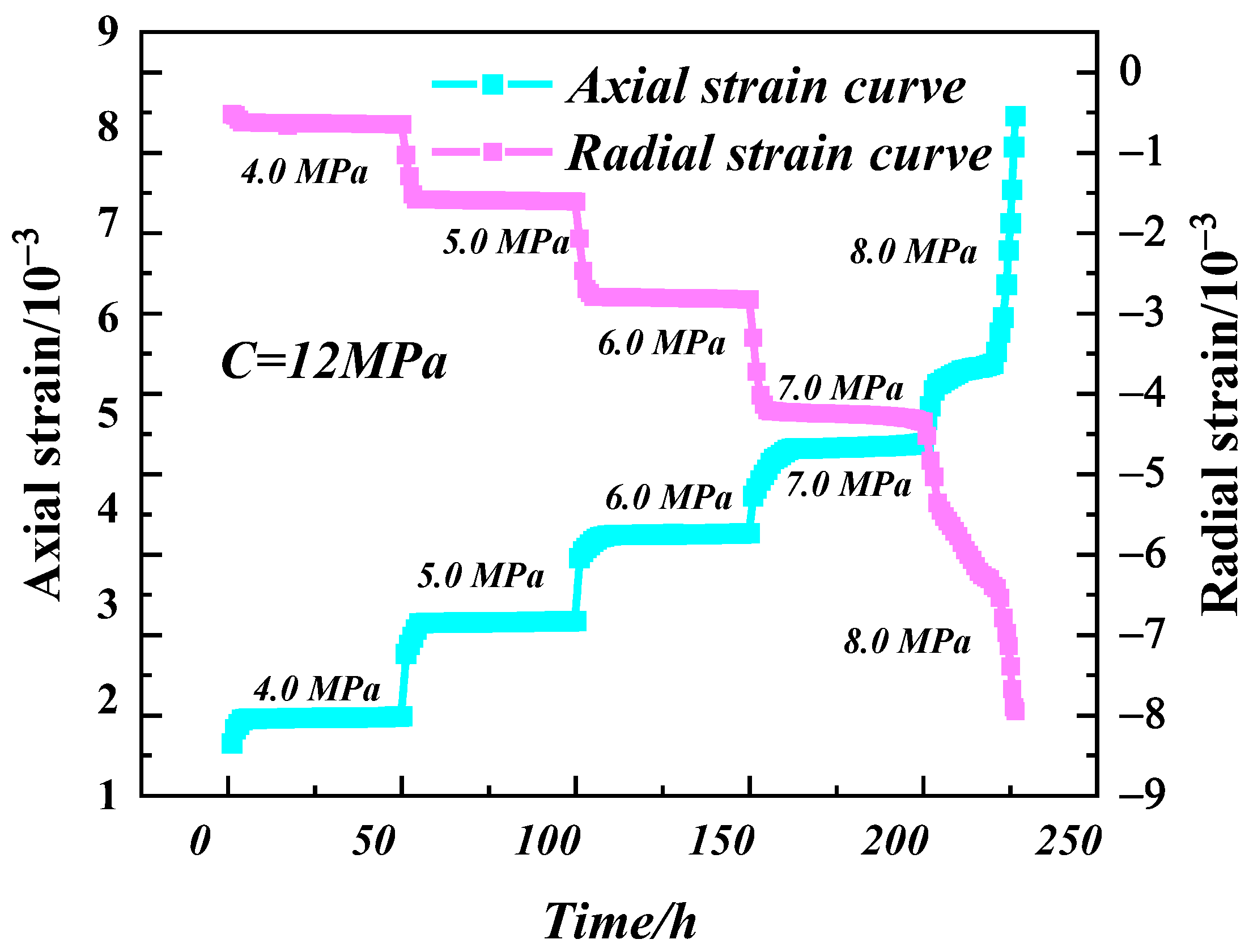

3.1. Test Results

3.2. Determination of Creep Model Parameters

3.3. Simulation Verification

4. Conclusions

- Creep experiments using graded loading and separate loading of anthracite were designed, and the results show that the creep of anthracite under various levels of stress conditions exhibits the creep characteristics of transient deformation, pseudo-acceleration, deceleration, and isotropic acceleration, and the creep acceleration phase exhibits hysteresis characteristics.

- Based on the Heaviside function, an improved fractional-order combinator was proposed by introducing the ‘gyroscope’ unit. Based on creep damage and the improved fractional-order combiner, a combined fractional-order creep model (NEG) that can describe the creep process of anthracite was proposed. The relevant parameters in this model were determined.

- Based on the Burgers model built into FLAC3D, the secondary development of the NEG model was completed, and numerical simulations were performed with the fitted experimental parameters. The results demonstrated the success of the secondary development of the NEG model and the correctness of the parameter selection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.C.; Wang, Q.; Wang, H.T.; Jiang, B.; Wang, D.C.; Zhang, B.; Li, Y.; Ruan, G.Q. Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn. Undergr. Space Technol. 2015, 47, 52–63. [Google Scholar] [CrossRef]

- Hao, J.; Li, X.L.; Song, Y.C.; Zhang, P.Z.; Liu, H.J. Analysis of mining roadway with large deformation of broken soft coal and research on supporting technology: A case study in Xin’an coal mine, China. Eng. Fail. Anal. 2021, 130, 105761. [Google Scholar] [CrossRef]

- Yang, S.Q.; Chen, M.; Jing, H.W.; Chen, K.F.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, G.; Zhang, M.; Ren, H.; Bai, J.; Guo, Y.; Jiang, H.; Kang, L. Residual coal exploitation and its impact on sustainable development of the coal industry in China. Energy Policy 2016, 96, 534–541. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, R.; Jiang, B.; Li, S.C.; He, M.C.; Sun, H.B.; Wang, L.; Qin, Q.; Yu, H.C.; Luan, Y.C. Study on failure mechanism of roadway with soft rock in deep coal mine and confined concrete support system. Eng. Fail. Anal. 2017, 81, 155–177. [Google Scholar] [CrossRef]

- Zhu, S.Y.; Jiang, Z.Q.; Zhou, K.J.; Peng, G.Q.; Yang, C.W. The characteristics of deformation and failure of coal seam floor due to mining in Xinmi coal field in China. Bull. Eng. Geol. Environ. 2014, 73, 1151–1163. [Google Scholar] [CrossRef]

- Xu, J.K.; Wang, E.Y.; Zhou, R. Real-time measuring and warning of surrounding rock dynamic deformation and failure in deep roadway based on machine vision method. Measurement 2020, 149, 107028. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, C.; Zheng, P.Q.; Zhao, W.J.; Li, N. A combined supporting system based on filled-wall method for semi coal-rock roadways with large deformations. Tunn. Undergr. Space Technol. 2020, 99, 103382. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, C.; Zheng, P.Q.; Li, N.; Zhan, Y.B. Deformation and failure mechanism of surrounding rocks in crossed-roadway and its support strategy. Eng. Fail. Anal. 2020, 116, 104743. [Google Scholar] [CrossRef]

- Wang, H.W.; Xue, S.; Jiang, Y.D.; Deng, D.X.; Shi, S.Z.; Zhang, D.Q. Field Investigation of a Roof Fall Accident and Large Roadway Deformation Under Geologically Complex Conditions in an Underground Coal Mine. Rock Mech. Rock Eng. 2018, 51, 1863–1883. [Google Scholar] [CrossRef]

- Abul Khair, H.; Cooke, D.; Hand, M. Seismic mapping and geomechanical analyses of faults within deep hot granites, a workflow for enhanced geothermal system projects. Geothermics 2015, 53, 46–56. [Google Scholar] [CrossRef]

- Xu, X.H.; He, F.L.; Li, X.B.; He, W.R. Research on mechanism and control of asymmetric deformation of gob side coal roadway with fully mechanized caving mining. Eng. Fail. Anal. 2021, 120, 105097. [Google Scholar] [CrossRef]

- Sun, Y.T.; Li, G.C.; Zhang, J.F.; Qian, D.Y. Experimental and numerical investigation on a novel support system for controlling roadway deformation in underground coal mines. Energy Sci. Eng. 2020, 8, 490–500. [Google Scholar] [CrossRef]

- Wang, L.G.; Li, H.L.; Zhang, J. Numerical simulation of creep characteristics of soft roadway with bolt-grouting support. J. Cent. South Univ. Technol. 2008, 15, 391–396. [Google Scholar] [CrossRef]

- Yang, Y.R.; Lai, X.P.; Luo, T.; Yuan, K.K.; Li, G. Study on creep constitutive model of stratified siltstone and its application to instability analysis in mining. Environ. Earth Sci. 2022, 81, 270. [Google Scholar] [CrossRef]

- Zhu, Q.W.; Li, T.C.; Ran, J.L.; Du, Y.T.; Zhang, H.; Jiang, H. Model test on creep deformation and failure characteristics of soft rock roadways. Eng. Fail. Anal. 2022, 141, 106670. [Google Scholar] [CrossRef]

- Danesh, N.N.; Chen, Z.; Connell, L.D.; Kizil, M.S.; Pan, Z.; Aminossadati, S.M. Characterisation of creep in coal and its impact on permeability: An experimental study. Int. J. Coal Geol. 2017, 173, 200–211. [Google Scholar] [CrossRef]

- Shen, B.T. Coal Mine Roadway Stability in Soft Rock: A Case Study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wang, X.F.; Zhang, D.S.; Qin, D.D.; Wang, Y.; Wang, J.Y.; Chang, Z.C. Creep and Control of the Deep Soft Rock Roadway (DSRR): Insights from Laboratory Testing and Practice in Pingdingshan Mining Area. Rock Mech. Rock Eng. 2022, 55, 363–378. [Google Scholar]

- Huang, P.; Zhang, J.X.; Spearing, A.J.S.; Chai, J.; Dong, C.W. Experimental study of the creep properties of coal considering initial damage. Int. J. Rock Mech. Min. Sci. 2021, 139, 104629. [Google Scholar] [CrossRef]

- Jing, W.; Liu, S.X.; Yang, R.S.; Jing, L.W.; Xue, W.P. Mechanism of aging deformation zoning of surrounding rock in deep high stress soft rock roadway based on rock creep characteristics. J. Appl. Geophys. 2022, 202, 104632. [Google Scholar] [CrossRef]

- Wen, J.; Tang, Z.; Dyson, A.P.; Tolooiyan, A. The mechanical behaviour of pre-existing transverse cracks in lignite under uniaxial compression. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–17. [Google Scholar] [CrossRef]

- Jia, Z.; Xie, H.; Zhang, R.; Li, C.; Wang, M.; Gao, M.; Zhang, Z.; Zhang, Z. Acoustic Emission Characteristics and Damage Evolution of Coal at Different Depths Under Triaxial Compression. Rock Mech. Rock Eng. 2020, 53, 2063–2076. [Google Scholar] [CrossRef]

- Zhang, S.G.; Liu, W.B.; Lv, H.M. Creep energy damage model of rock graded loading. Results Phys. 2019, 12, 1119–1125. [Google Scholar] [CrossRef]

- Peng, G.; Chen, Z.Q.; Chen, J.R. Research on Rock Creep Characteristics Based on the Fractional Calculus Meshless Method. Adv. Civ. Eng. 2018, 2018, 1472840. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.B.; Xu, W.Y.; Shao, J.F. Change in the permeability of clastic rock during multi-loading triaxial compressive creep tests. Geotech. Lett. 2015, 5, 167–172. [Google Scholar] [CrossRef]

- Mansour, M.M.; Saad, G.; Wahab, L.A.; Fawzy, A. Indentation creep behavior of thermally aged Sn-5wt%Sb-1.5wt%Ag solder integrated with ZnO nanoparticles. J. Mater. Sci. Mater. Electron. 2019, 30, 8348–8357. [Google Scholar] [CrossRef]

- Yan, B.Q.; Guo, Q.F.; Ren, F.H.; Cai, M.F. Modified Nishihara model and experimental verification of deep rock mass under the water-rock interaction. Int. J. Rock Mech. Min. Sci. 2020, 128, 104250. [Google Scholar] [CrossRef]

- Li, X.B.; Liu, X.S.; Tan, Y.L.; Ma, Q.; Wu, B.Y.; Wang, H.L. Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion. Minerals 2022, 12, 292. [Google Scholar] [CrossRef]

- Li, G.H.; Wang, Y.T.; Hu, Y.M.; Wang, D.; Yang, X.X.; Li, Y.F.; Zhou, Z.W.; Zhang, S.P. Shear creep mechanical properties and damage model of mudstone in open-pit coal mine. Sci. Rep. 2022, 12, 5148. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Cheng, L. Influences of pore pressure on short-term and creep mechanical behavior of red sandstone. Eng. Geol. 2014, 179, 10–23. [Google Scholar] [CrossRef]

- Liu, X.R.; Yang, X.; Wang, J.B. A Nonlinear Creep Model of Rock Salt and Its Numerical Implement in FLAC(3D). Adv. Mater. Sci. Eng. 2015, 2015, 285158. [Google Scholar] [CrossRef]

- Liu, J.S.; Jing, H.W.; Meng, B.; Wang, L.G.; Yang, J.J.; Zhang, X.F. A four-element fractional creep model of weakly cemented soft rock. Bull. Eng. Geol. Environ. 2020, 79, 5569–5584. [Google Scholar] [CrossRef]

- Hou, R.; Zhang, K.; Tao, J.; Xue, X.; Chen, Y. A Nonlinear Creep Damage Coupled Model for Rock Considering the Effect of Initial Damage. Rock Mech. Rock Eng. 2019, 52, 1275–1285. [Google Scholar] [CrossRef]

- Liu, H.Z.; Xie, H.Q.; He, J.D.; Xiao, M.L.; Zhuo, L. Nonlinear creep damage constitutive model for soft rocks. Mech. Time-Depend. Mater. 2017, 21, 73–96. [Google Scholar] [CrossRef]

- Ji, M.; Chen, K.; Guo, H.J. Constitutive Model of Rock Uniaxial Damage Based on Rock Strength Statistics. Adv. Civ. Eng. 2018, 2018, 5047834. [Google Scholar] [CrossRef]

- Yan, X.; Jun, L.; Yijin, Z.; Shidong, D.; Tingxue, J. Research on Lateral Scale Effect and Constitutive Model of Rock Damage Energy Evolution. Geotech. Geol. Eng. 2018, 36, 2415–2424. [Google Scholar] [CrossRef]

- Lv, S.R.; Wang, W.Q.; Liu, H.Y. A Creep Damage Constitutive Model for a Rock Mass with Nonpersistent Joints under Uniaxial Compression. Math. Probl. Eng. 2019, 2019, 4361458. [Google Scholar] [CrossRef]

- Sha, Z.H.; Pu, H.; Li, M.; Cao, L.L.; Liu, D.; Ni, H.Y.; Lu, J.F. Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action. Processes 2018, 6, 110. [Google Scholar] [CrossRef]

- Zhou, J.X.; Zhang, J.W.; Wang, J.A.; Li, F.; Zhou, Y. Research on nonlinear damage hardening creep model of soft surrounding rock under the stress of deep coal resources mining. Energy Rep. 2022, 8, 1493–1507. [Google Scholar] [CrossRef]

- Feng, W.L.; Qiao, C.S.; Niu, S.J. Study on sandstone creep properties of Jushan Mine affected by degree of damage and confining pressure. Bull. Eng. Geol. Environ. 2020, 79, 869–888. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.X.; Damascene, N.J.; Wang, Z.J.; Li, M. Effect of loading rate on mechanical behavior of coal samples with initial damage accumulation. Mech. Time-Depend. Mater. 2022, 26, 309–322. [Google Scholar] [CrossRef]

- Haubold, H.J.; Mathai, A.M.; Saxena, R.K. Mittag-Leffler Functions and Their Applications. J. Appl. Math. 2011, 2011, 298628. [Google Scholar] [CrossRef]

- Kilbas, A.A.; Koroleva, A.A.; Rogosin, S.V. Multi-parametric mittag-leffler functions and their extension. Fract. Calc. Appl. Anal. 2013, 16, 378–404. [Google Scholar] [CrossRef]

- Hamza, O.; Stace, R. Creep properties of intact and fractured muddy siltstone. Int. J. Rock Mech. Min. Sci. 2018, 106, 109–116. [Google Scholar] [CrossRef]

- Shan, R.L.; Bai, Y.; Ju, Y.; Han, T.Y.; Dou, H.Y.; Li, Z.L. Study on the Triaxial Unloading Creep Mechanical Properties and Damage Constitutive Model of Red Sandstone Containing a Single Ice-Filled Flaw. Rock Mech. Rock Eng. 2021, 54, 833–855. [Google Scholar] [CrossRef]

- Yang, S.Q.; Xu, P.; Ranjith, P.G. Damage model of coal under creep and triaxial compression. Int. J. Rock Mech. Min. Sci. 2015, 80, 337–345. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, W.Y.; Gu, J.J.; Wang, W. Triaxial creep tests of weak sandstone from fracture zone of high dam foundation. J. Cent. South Univ. 2013, 20, 2528–2536. [Google Scholar] [CrossRef]

- Zhang, J.X.; Li, B.; Zhang, C.H.; Li, P. Nonlinear Viscoelastic-Plastic Creep Model Based on Coal Multistage Creep Tests and Experimental Validation. Energies 2019, 12, 3468. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Xu, W.Y.; Wang, W.; Wang, R.B. Triaxial creep tests of rock from the compressive zone of dam foundation in Xiangjiaba Hydropower Station. Int. J. Rock Mech. Min. Sci. 2012, 50, 133–139. [Google Scholar] [CrossRef]

- Sattar, M.; Othman, A.R.; Kamaruddin, S.; Akhtar, M.; Khan, R. Limitations on the computational analysis of creep failure models: A review. Eng. Fail. Anal. 2022, 134, 105968. [Google Scholar] [CrossRef]

| Specimen | Diameter (mm) | Height (mm) | Mass (g) | Density (g/cm3) | Mt (%) |

|---|---|---|---|---|---|

| #1 | 49.26 | 99.57 | 301.25 | 1.5875 | 4.5216 |

| #2 | 49.56 | 99.85 | 303.57 | 1.5760 | 4.3845 |

| #3 | 49.81 | 99.91 | 304.82 | 1.5660 | 4.4257 |

| Load (MPa) | (MPa) | (MPa) | (MPa) | (GPa) | (GPa/h) | (GPa) | ||

|---|---|---|---|---|---|---|---|---|

| 4.0 | 0.4 | 2.6 | 3.6 | 2.1831 | 8.414 | 74.92 | 1.5672 | 7.312 |

| 5.0 | 0.5 | 3.25 | 4.5 | 1.0351 | 11.9874 | 34.481 | 1.3394 | 10.7845 |

| 6.0 | 0.6 | 3.9 | 5.4 | 0.7841 | 17.5865 | 151.0281 | 1.9244 | 15.8056 |

| 7.0 | 0.7 | 4.55 | 6.3 | 0.7539 | 28.9005 | 6.9049 | 1.0902 | 26.0005 |

| 8.0 | 0.8 | 5.2 | 7.2 | 0.9228 | 43.616 | 8.023 | 1.5583 | 58.86 |

| (GPa/h) | (GPa/h) | R2 | ||||||

| 4.0 | 406.39 | 203.41 | 5.6094 | 0.6889 | 0.9375 | |||

| 5.0 | 530.69 | 58.742 | 7.9916 | 0.3183 | 0.9620 | |||

| 6.0 | 477.56 | 23.3648 | 11.7123 | 0.3785 | 0.9904 | |||

| 7.0 | 40.06 | 16.29 | 19.267 | 0.7699 | 0.9911 | |||

| 8.0 | 129.336 | 10.7724 | 65.43 | 20.98 | 87.23 | 0.2659 | 0.4216 | 0.9930 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Yan, G.; Kong, S.; Bai, X.; Du, C.; Li, J.; Zhang, J. Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations. Appl. Sci. 2023, 13, 6522. https://doi.org/10.3390/app13116522

Li G, Yan G, Kong S, Bai X, Du C, Li J, Zhang J. Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations. Applied Sciences. 2023; 13(11):6522. https://doi.org/10.3390/app13116522

Chicago/Turabian StyleLi, Gang, Guochao Yan, Shaoqi Kong, Xuyang Bai, Chaofei Du, Jiajun Li, and Jiawei Zhang. 2023. "Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations" Applied Sciences 13, no. 11: 6522. https://doi.org/10.3390/app13116522

APA StyleLi, G., Yan, G., Kong, S., Bai, X., Du, C., Li, J., & Zhang, J. (2023). Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations. Applied Sciences, 13(11), 6522. https://doi.org/10.3390/app13116522