1. Introduction

Calibration of flow devices is important in several areas of pharmaceutical, flow chemistry and HPLC applications where the dosage of process-oriented liquids or accurate measurement of flowrate are important. The process-oriented liquid itself might influence the performance of the flow meter. Coriolis flow meters are rather insensitive to the viscosity of the liquid and the flow profile in the piping. Thermal flow meters might be sensitive to the flow profile of the liquid inside the tube, which is influenced by the viscosity of the liquid and the flow regime, but they are obviously extremely sensitive to the thermal properties of the liquids [

1]. Therefore, the calibration of the flow meter with the process-oriented liquid is important and the simultaneous determination of dynamic viscosity under flow conditions is valuable information for viscosity-dependent flow metering methods or other process parameters [

1,

2]. Pipe viscometers are widely used in industrial and research applications for measuring the dynamic viscosity of liquids [

3,

4,

5,

6], either to calculate average dynamic viscosity or determine the flow curve describing dynamic viscosity as a function of shear rate in the piping. Various instruments are available for the determining dynamic viscosity as a function of shear rate for piping diameters of tens of millimeters [

5,

7,

8,

9]. However, these instruments are not available for piping diameters in the order of several millimeters. The globally accepted method for the traceable measurement of the kinematic viscosity of a liquid is by use of a glass capillary viscometer, which requires sampling the liquid, but allows for measuring the temperature dependence of kinematic viscosity. By measuring liquid density as a function of temperature, the dynamic viscosity of the liquid can be calculated. Liquid sampling is not always an advantage in production processes. Currently, several commercially available instruments exist for performing inline measurements of the dynamic viscosity and density process liquids [

10,

11] that fulfill the advantages of inline measurement in small pipes. To monitor the accuracy of these sensors over time, they could be calibrated using a traceable pipe viscometer with any liquid to determine the deviations from reference values traceable to SI units at a given time interval.

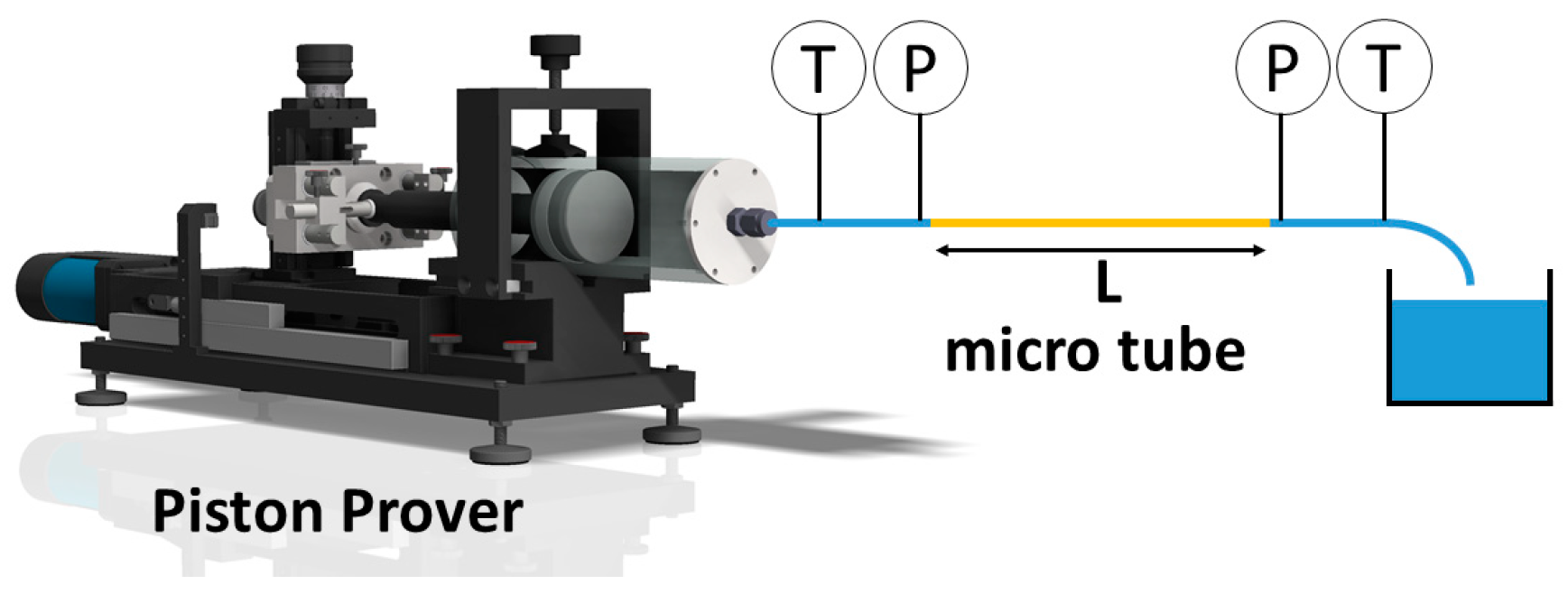

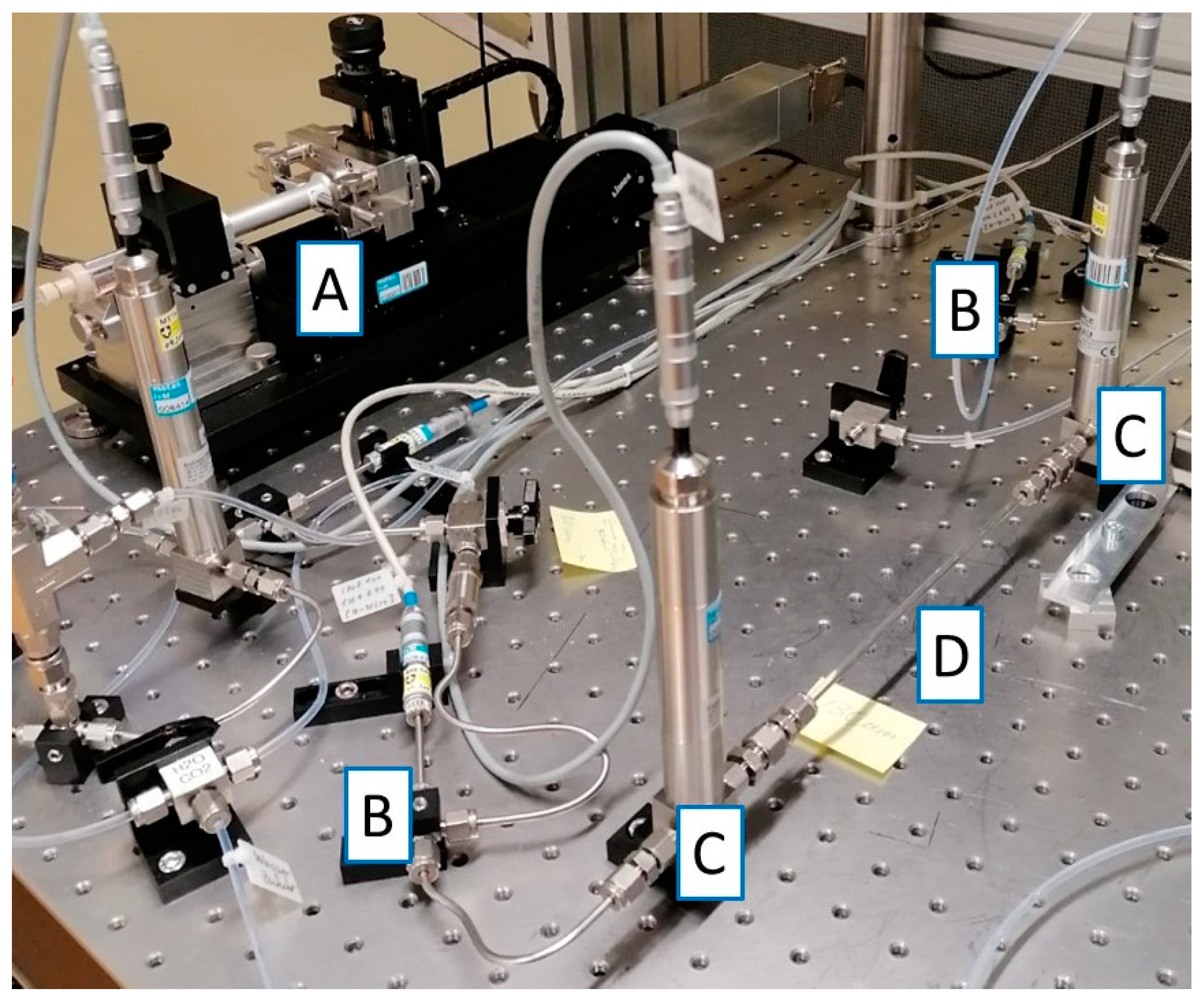

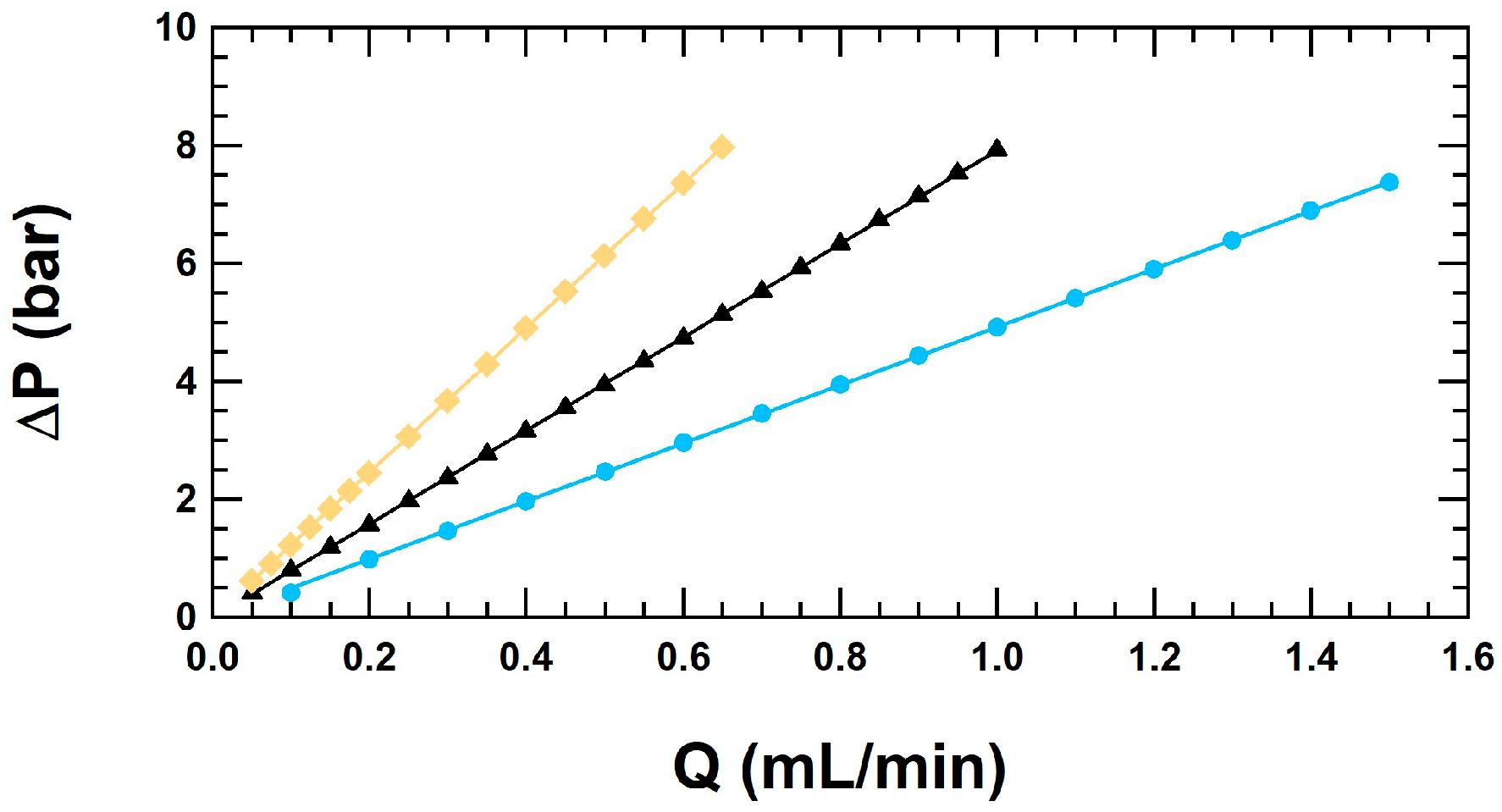

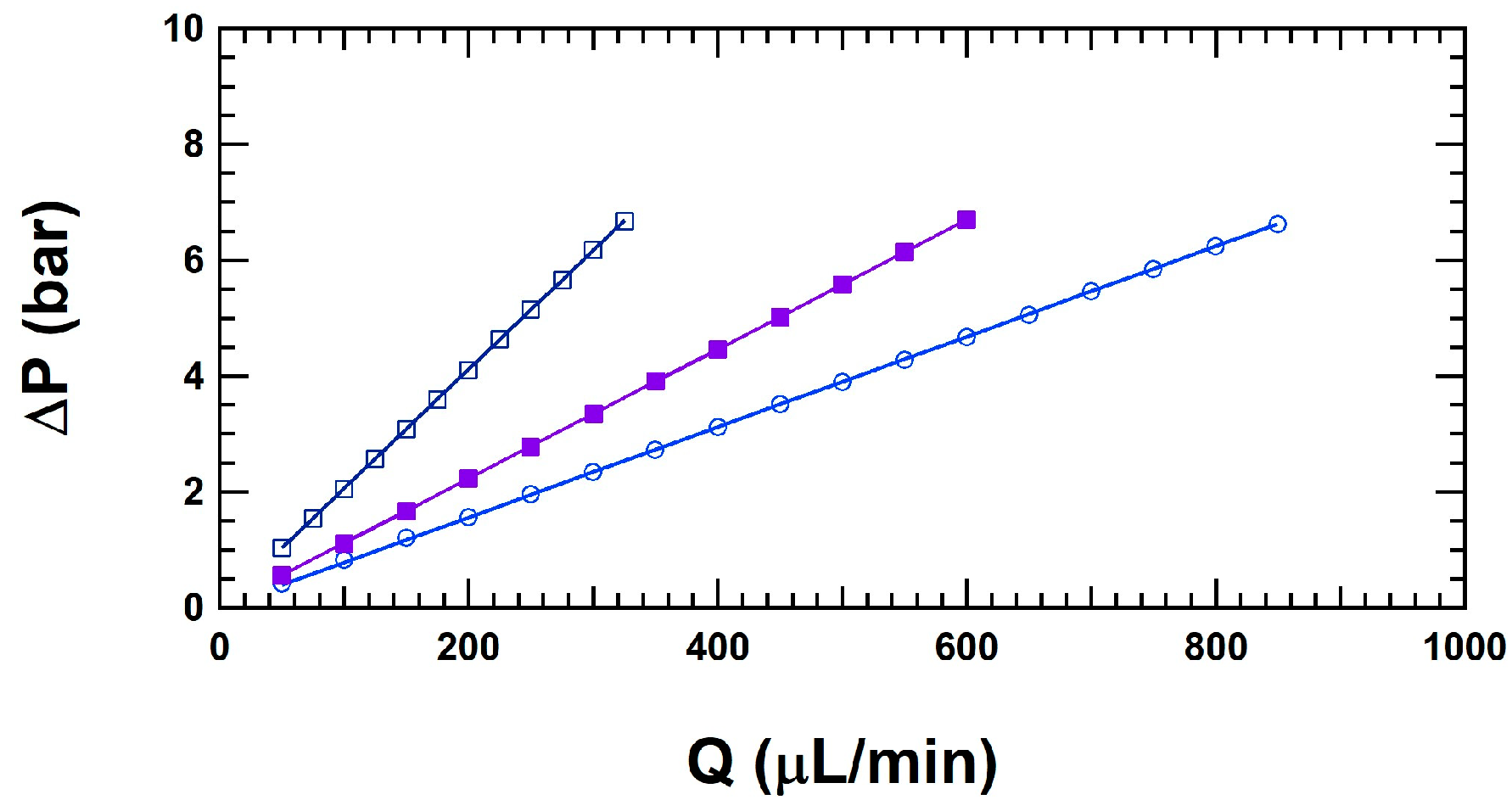

To offer the simultaneous calibration of the dynamic viscosity of a process-oriented liquid at the corresponding flowrate, METAS built a pipe viscometer for the traceable inline measurement of dynamic viscosity in current flow facilities for low flowrates from 1 μL/min to 150 mL/min and pressure drops up to 10 bar [

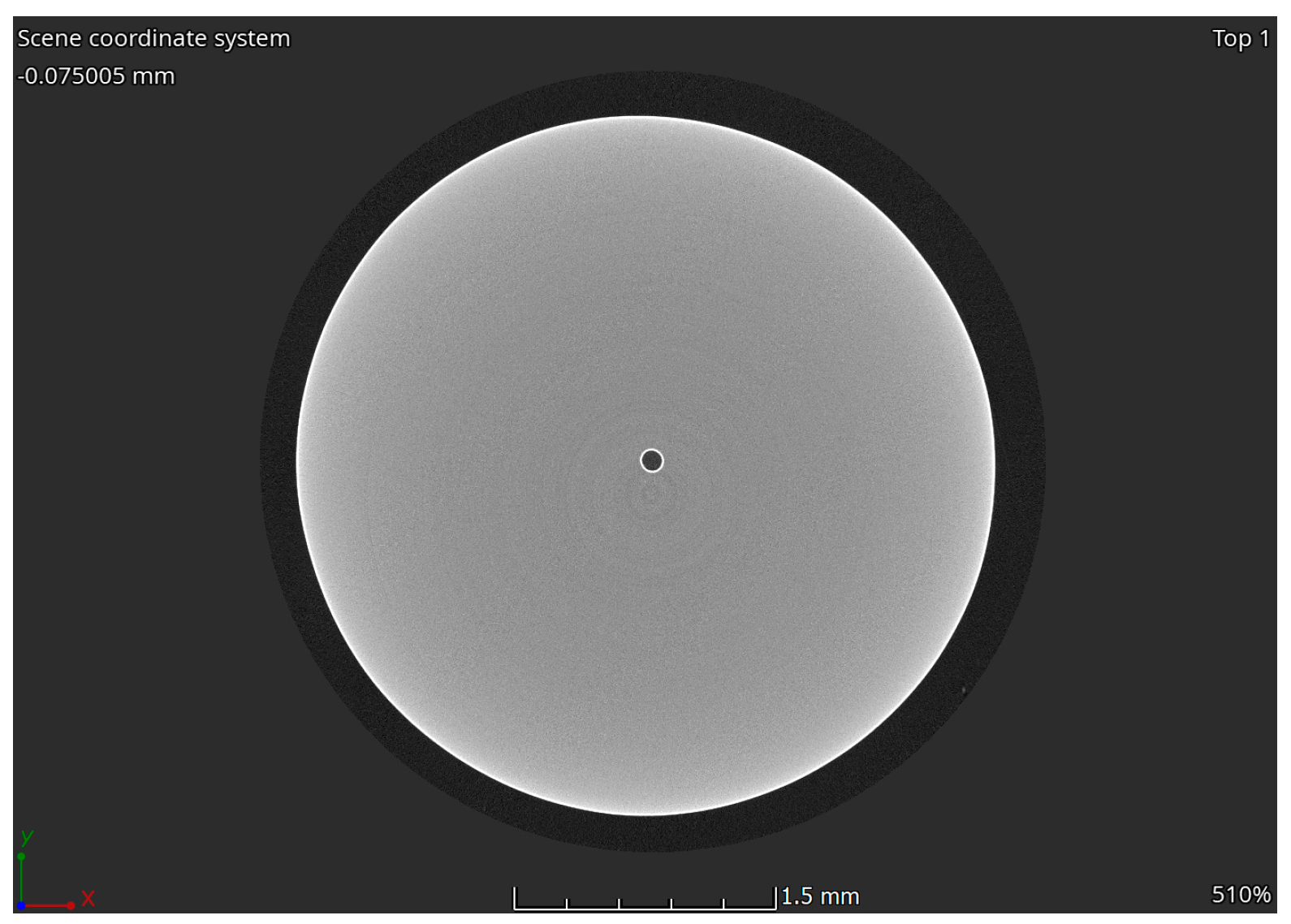

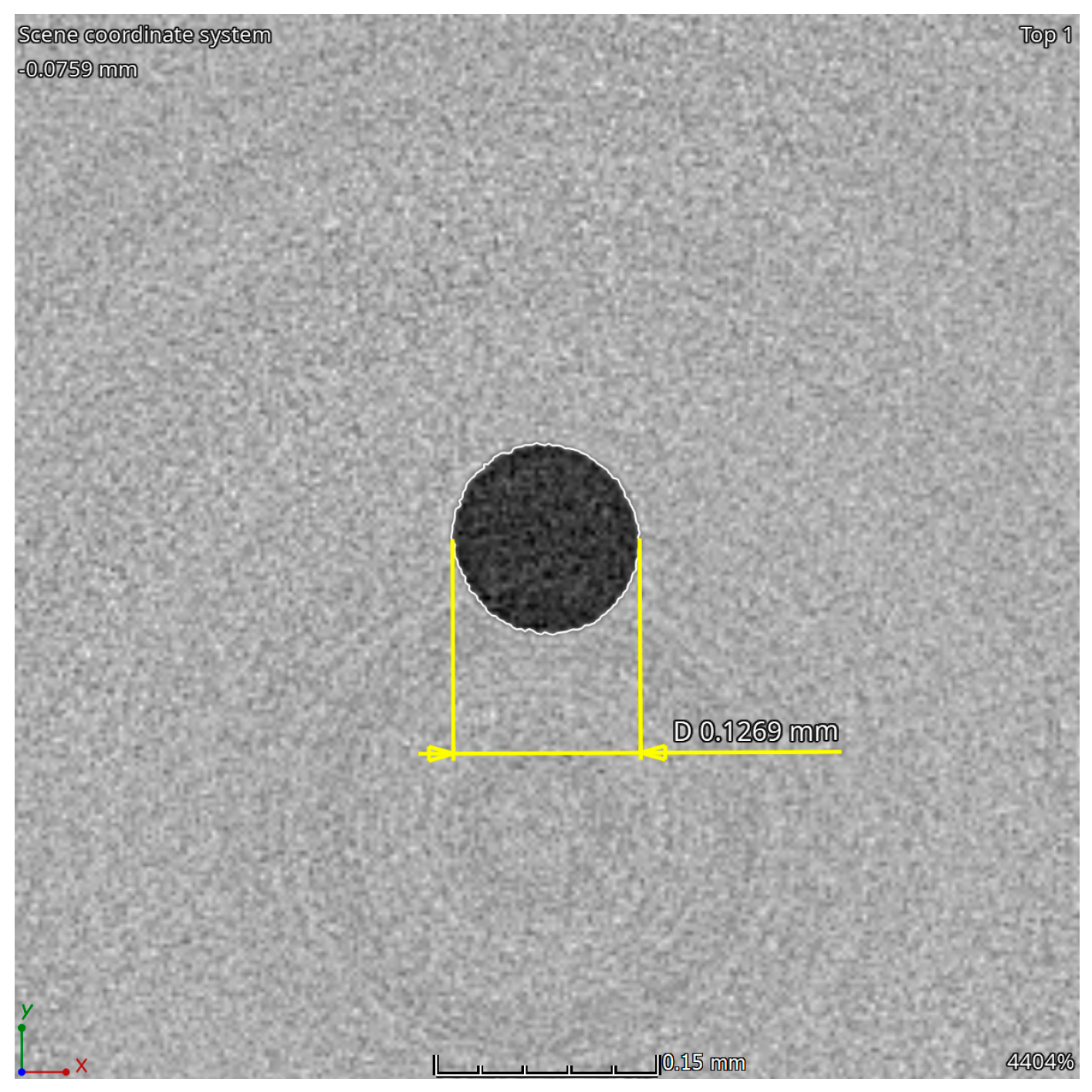

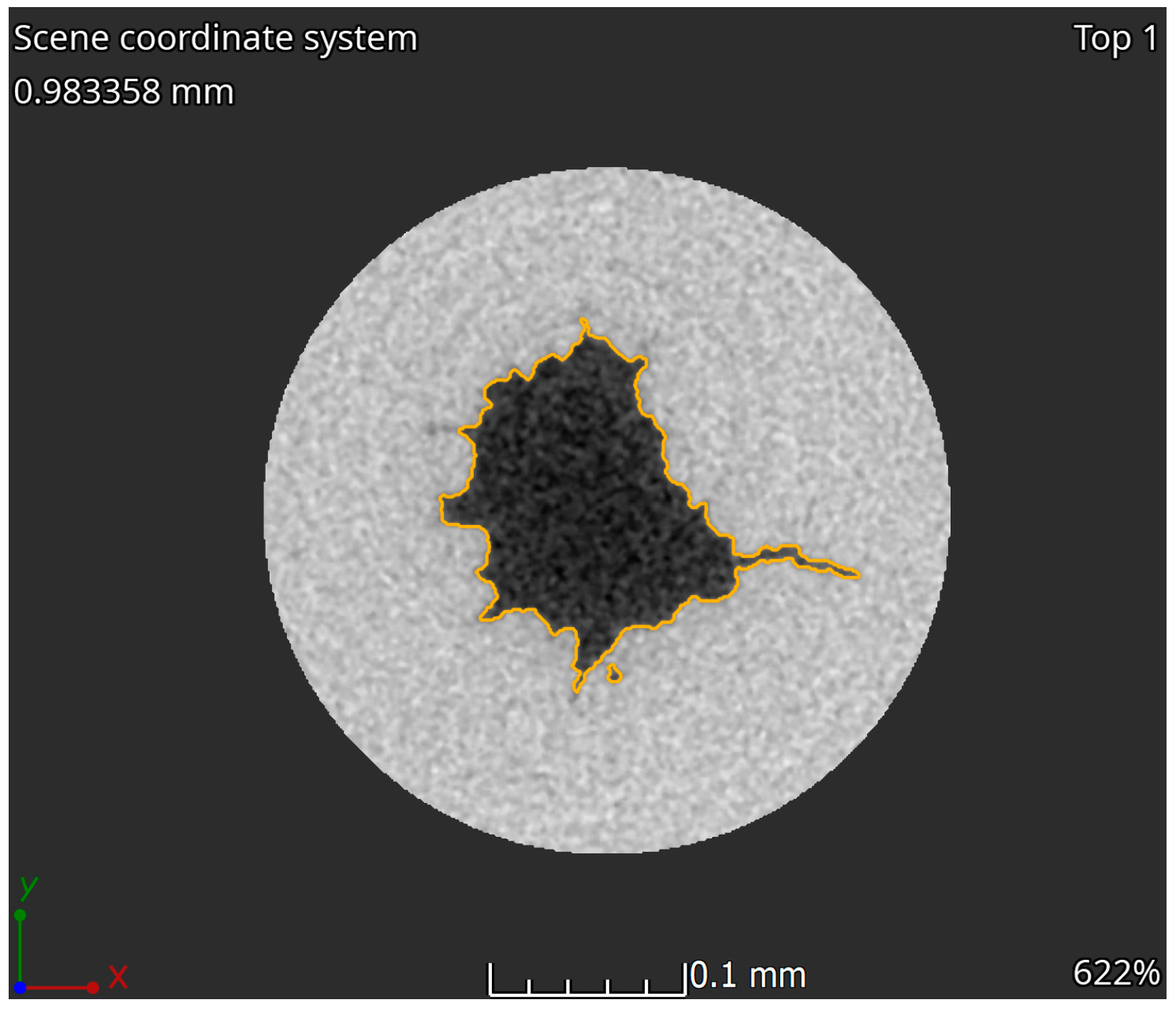

12]. Several microtubes were implemented into the pipe viscometer and characterization tests were performed to test the influence of different materials on the performance of the pipe viscometer. The knowledge of the geometrical dimensions of the microtube are essential for the calculation of the dynamic viscosity according to the Hagen–Poiseuille law. Therefore, characterization of the inner diameter of the microtube was performed by utilizing the μ-CT facility at METAS, where inner diameter is determined using X-ray diffraction [

13,

14]. This technique enables the determination of the inner diameter and the roundness of the micro tube at several sections along the microtube. Thus, a detailed analysis is possible and not only an average inner diameter is obtained. It turns out that glass microtubes are most suitable for the pipe viscometer as the inner diameter is circular and the cross-section revealed excellent roundness. Another method for the determining inner diameter is to measure the pressure drop as a function of flowrate and apply the Hagen–Poiseuille law with a well-known liquid (water), which is referred to as the flow calibration method in this paper. This method provides an average inner diameter of the micro tube and no information on the roundness and the variation of the inner diameter along the micro tube is available. A detailed analysis of both methods is described later in this paper for a soda glass and a stainless steel microtube.

This paper first describes the experimental setup of the pipe viscometer, the calibration procedure for the various sensors, the methods of calibration of the inner diameter of the micro tube with its measurement uncertainty, and the determination of the measurement uncertainty of the micro pipe viscometer. Then, the results of the calibration of the inner diameter of the soda glass, stainless steel and PEEK microtube are presented and the validation of the stated measurement uncertainty of the micropipe viscometer with reference liquids are reported. Finally, single measurement point analysis and a comparison with glass capillary viscometers are discussed.

The procedure for achieving traceability of the micropipe viscometer, its detailed measurement uncertainty description and validation offer new insights into the pipe viscometer method. A detailed description of the flow calibration method for calibrating the inner diameter of the microtube highlights a simple procedure for obtaining this geometrical dimension, which is an important constant in the concept of the micropipe viscometer.

4. Conclusions

Extensive investigations for the characterization of the pipe viscometer for the traceable inline measurement of dynamic viscosity for flowrates from 1 μL/min to 150 mL/min and pressure drops up to 10 bar were presented. The glass microtube is the best option and was therefore integrated in the pipe viscometer, leading to the extended uncertainty of the pipe viscometer being 0.90%. The stated measurement uncertainty was validated with measurements of three traceable reference liquids for the dynamic viscosity, where the deviations were either (0.43 ± 0.90)% or (0.42 ± 0.90)%. Comparison with other pipe viscometers and glass capillary viscosity meters showed consistent results with the reference values within the stated uncertainties, and more details can be found in Reference [

2]. Additionally, the glass microtube was characterized by utilizing the μ-CT facility at METAS. These measurements also showed consistent results for the inner diameter of (0.1269 ± 0.0010) mm compared to the flow calibration method, where an inner diameter of (0.1267 ± 0.0003) mm was determined. These consistent results validate both methods for determining the inner diameter of the glass microtube and the stated measurement uncertainty of the pipe viscometer was validated by the consistent results of the measurements of the dynamic viscosity of the various liquids reported in this paper.

The determination of the dynamic viscosity with the linear fit method over several measurement data or the single-point method with a single measurement is possible as long as the pressure drop is not too small compared to the resolution of the pressure sensors installed.