Research Progresses and Application of Biofuel Cells Based on Immobilized Enzymes

Abstract

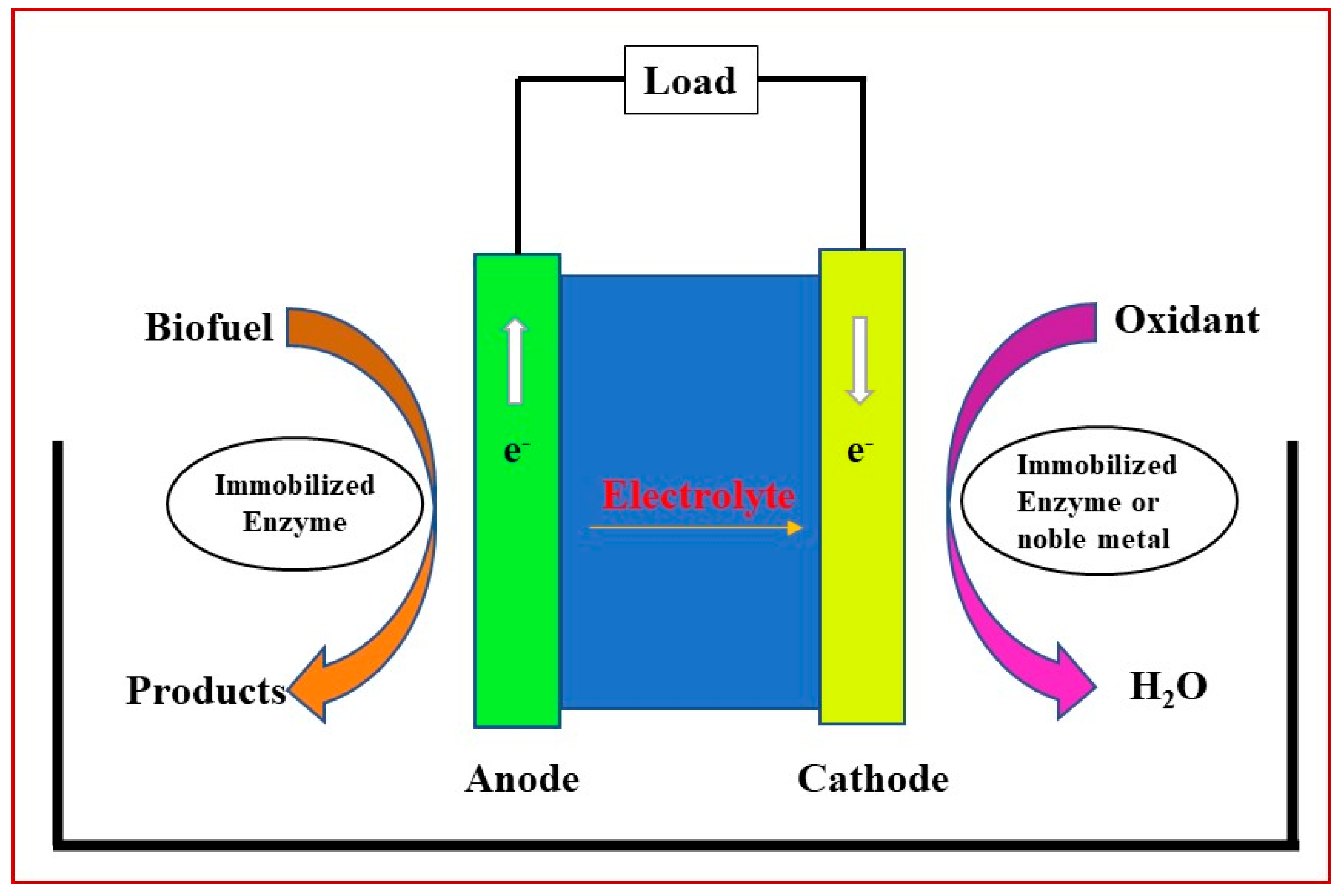

1. Introduction

2. A Variety of Carrier Materials for Enzyme Immobilization in EBFCs

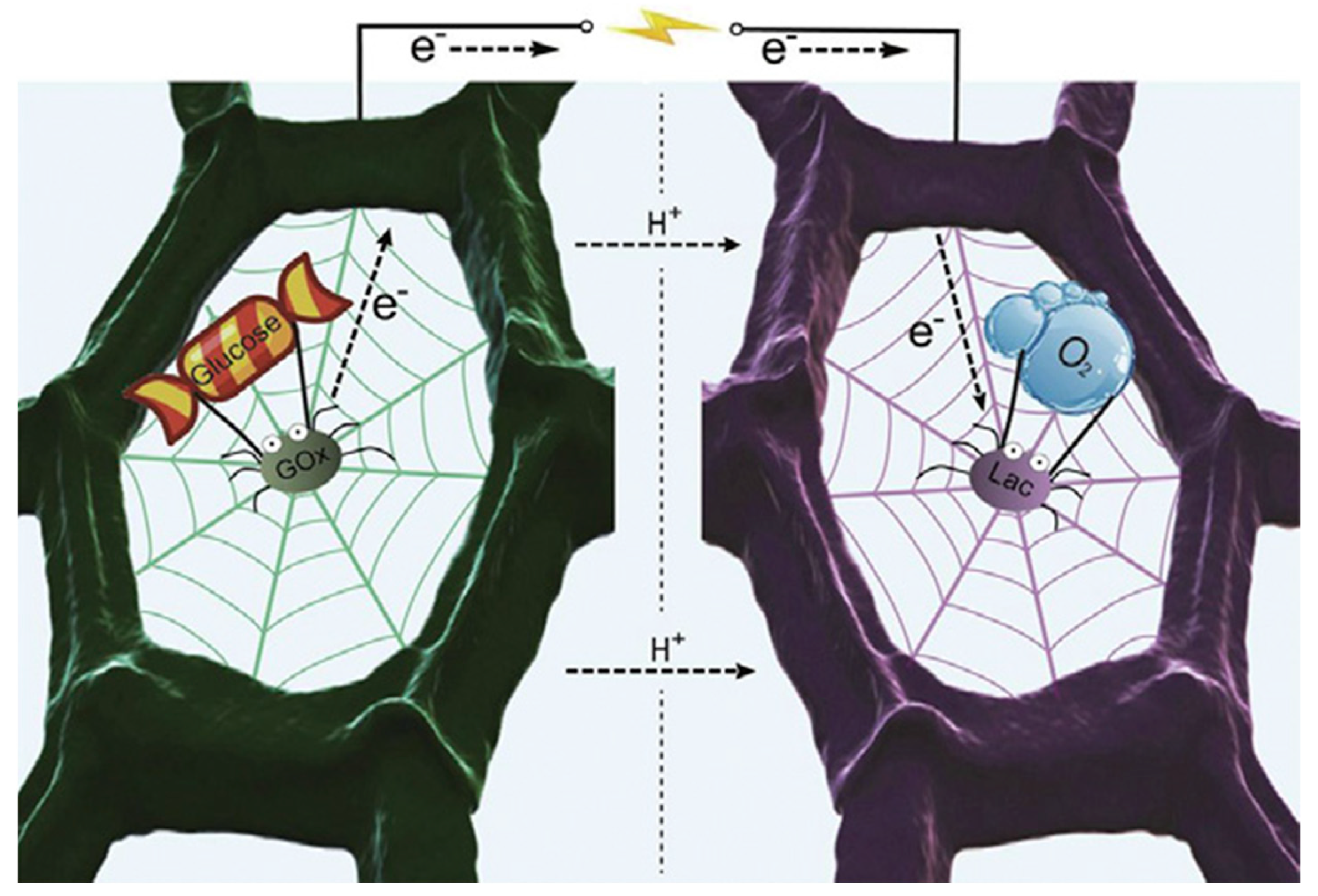

2.1. Some Nanomaterials and Nanocomposites for Enzyme Immobilization in EBFCs

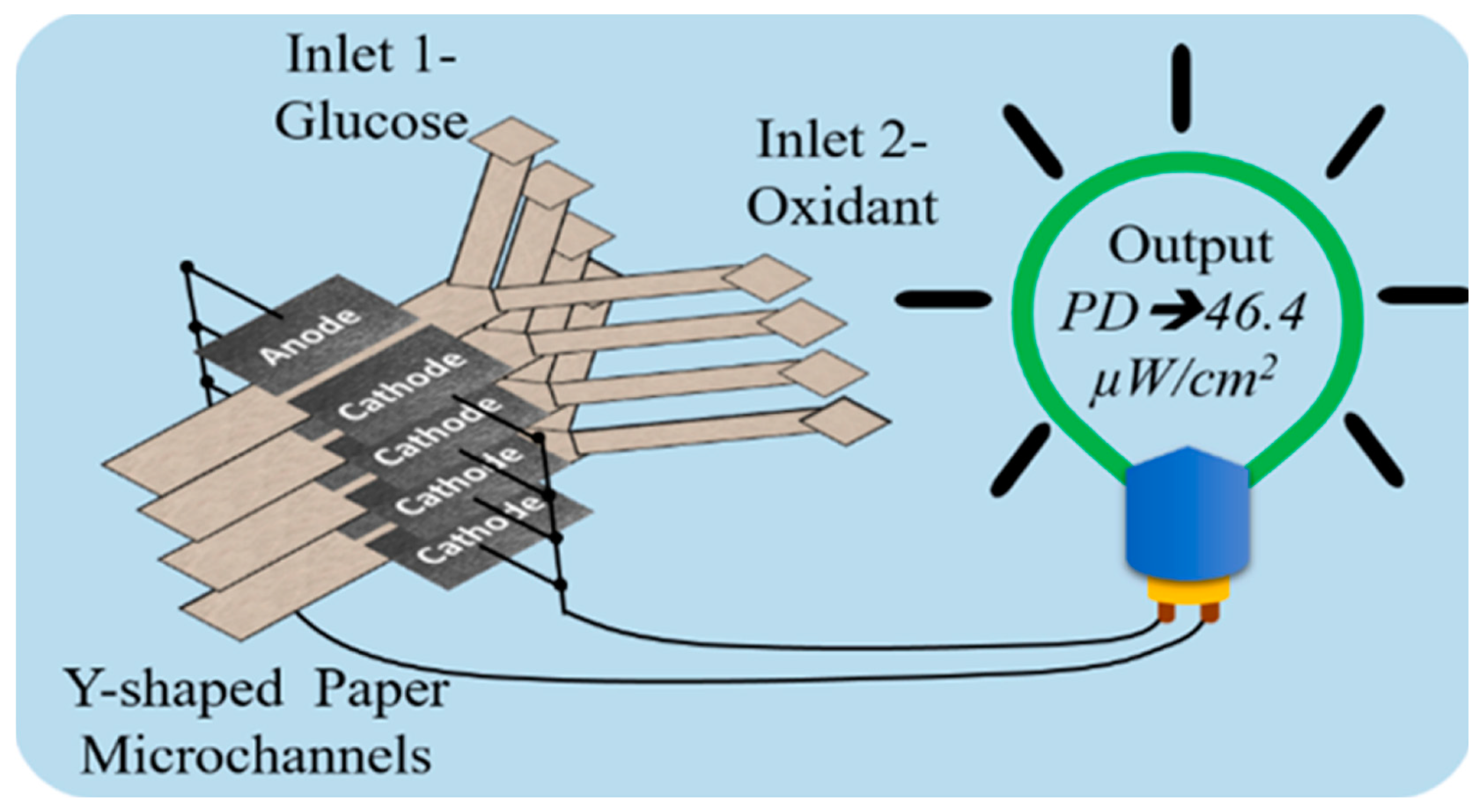

2.2. Some Paper-Based and Other Flexible Materials for Enzyme Immobilization in EBFCs

3. Applications of EBFCs

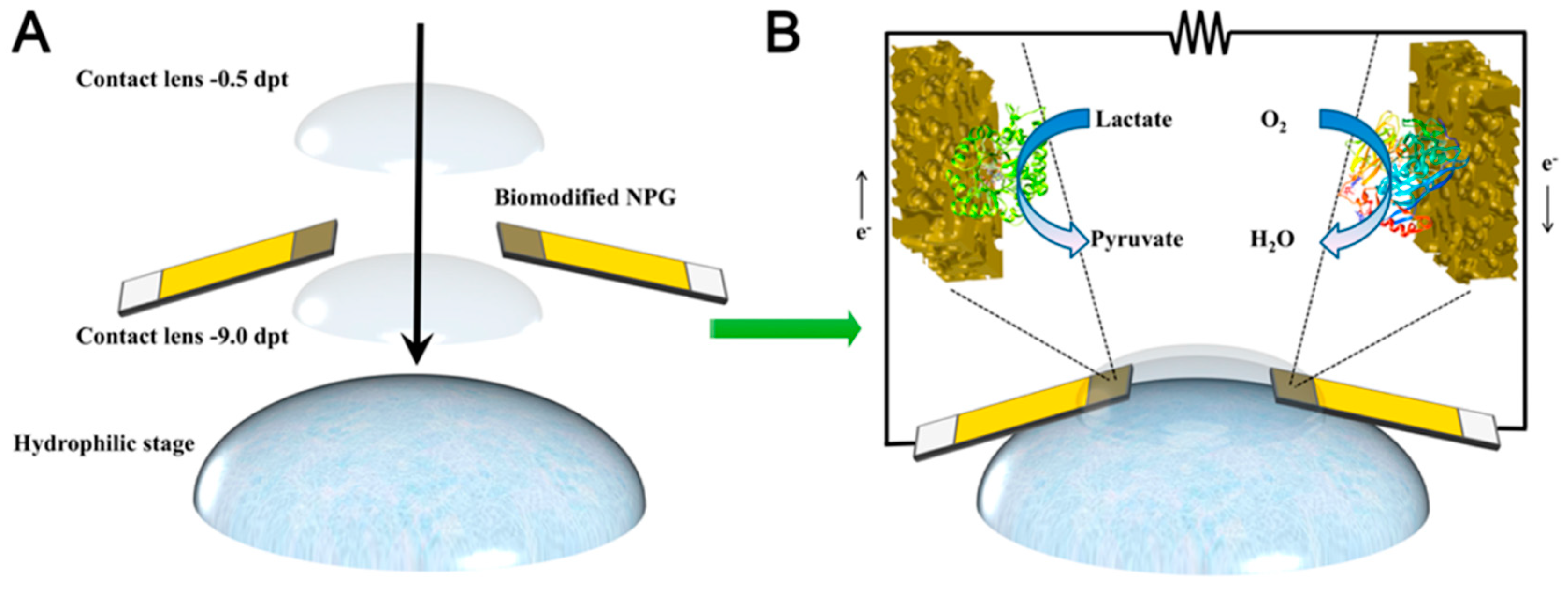

3.1. Implantable EBFCs

3.2. Wearable EBFCs

4. Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rasmussen, M.; Abdellaoui, S.; Minteer, S.D. Enzymatic biofuel cells: 30 years of critical advancements. Biosens. Bioelectron. 2016, 76, 91–102. [Google Scholar] [CrossRef] [PubMed]

- ul Haque, S.; Duteanu, N.; Ciocan, S.; Nasar, A.; Inamuddin. A review: Evolution of enzymatic biofuel cells. J. Environ. Manag. 2021, 298, 113483. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Hou, J.; Wang, K.; Ng, Y.H.; Chen, V. Single-Enzyme Biofuel Cells. Angew. Chem. Int. Ed. 2017, 56, 9762–9766. [Google Scholar] [CrossRef]

- Mano, N.; de Poulpiquet, A. O2 Reduction in Enzymatic Biofuel Cells. Chem. Rev. 2018, 118, 2392–2468. [Google Scholar] [CrossRef]

- Nasar, A.; Perveen, R. Applications of enzymatic biofuel cells in bioelectronic devices—A review. Int. J. Hydrogen Energy 2019, 44, 15287–15312. [Google Scholar] [CrossRef]

- Zhang, J.L.; Wang, Y.H.; Huang, K.; Jiang, H.; Wang, X.M. Enzyme-based biofuel cells for biosensors and in vivo power supply. Nano Energy 2021, 84, 105853. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, L.; Zhang, Z.; Guo, S.; Shang, H.; Li, Y.; Liu, J. Wearable biofuel cells based on the classification of enzyme for high power outputs and lifetimes. Biosens. Bioelectron. 2019, 124–125, 40–52. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Xia, H.-Q.; Wu, R.; Bai, L.; Yan, L.; Magner, E.; Cosnier, S.; Lojou, E.; Zhu, Z.; Liu, A. Tackling the Challenges of Enzymatic (Bio)Fuel Cells. Chem. Rev. 2019, 119, 9509–9558. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Muhammad Nauman Javed, R.; Al-Othman, A.; Almomani, F. The novel advancements of nanomaterials in biofuel cells with a focus on electrodes’ applications. Fuel 2022, 322, 124237. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Al-Lolage, F.A. There is no evidence to support literature claims of direct electron transfer (DET) for native glucose oxidase (GOx) at carbon nanotubes or graphene. J. Electroanal. Chem. 2018, 819, 26–37. [Google Scholar] [CrossRef]

- Lee, J.Y.; Shin, H.Y.; Kang, S.W.; Park, C.; Kim, S.W. Improvement of electrical properties via glucose oxidase-immobilization by actively turning over glucose for an enzyme-based biofuel cell modified with DNA-wrapped single walled nanotubes. Biosens. Bioelectron. 2011, 26, 2685–2688. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.J.; Shin, K.M.; Lee, J.W.; Kwon, C.H.; Lee, S.-H.; Kim, S.I.; Jeon, J.-H.; Kim, S.J. Electrocatalytic characteristics of electrodes based on ferritin/carbon nanotube composites for biofuel cells. Sens. Actuators B Chem. 2011, 160, 384–388. [Google Scholar] [CrossRef]

- Inamuddin; Alamry, K.A. Application of Electrically Conducting Nanocomposite Material Polythiophene@NiO/Frt/GOx as Anode for Enzymatic Biofuel Cells. Materials 2020, 13, 1823. [Google Scholar] [CrossRef] [PubMed]

- ul Haque, S.; Inamuddin Nasar, A.; Asiri, A.M. Fabrication and characterization of electrochemically prepared bioanode (polyaniline/ferritin/glucose oxidase) for biofuel cell application. Chem. Phys. Lett. 2018, 692, 277–284. [Google Scholar] [CrossRef]

- Inamuddin; Kashmery, H.A. Ternary graphene@polyaniline-TiO2 composite for glucose biofuel cell anode application. Int. J. Hydrogen Energy 2019, 44, 22173–22180. [Google Scholar] [CrossRef]

- Inamuddin Shakeel, N.; Imran Ahamed, M.; Kanchi, S.; Abbas Kashmery, H. Green synthesis of ZnO nanoparticles decorated on polyindole functionalized-MCNTs and used as anode material for enzymatic biofuel cell applications. Sci. Rep. 2020, 10, 5052. [Google Scholar] [CrossRef]

- ul Haque, S.; Duteanu, N.; Nasar, A.; Inamuddin. Polythiophene-titanium oxide (PTH-TiO2) nanocomposite: As an electron transfer enhancer for biofuel cell anode construction. J. Power Source 2022, 520, 230867. [Google Scholar] [CrossRef]

- Zebda, A.; Gondran, C.; Le Goff, A.; Holzinger, M.; Cinquin, P.; Cosnier, S. Mediatorless high-power glucose biofuel cells based on compressed carbon nanotube-enzyme electrodes. Nat. Commun. 2011, 2, 370. [Google Scholar] [CrossRef]

- Reuillard, B.; Le Goff, A.; Agnès, C.; Holzinger, M.; Zebda, A.; Gondran, C.; Elouarzaki, K.; Cosnier, S. High power enzymatic biofuel cell based on naphthoquinone-mediated oxidation of glucose by glucose oxidase in a carbon nanotube 3D matrix. Phys. Chem. Chem. Phys. 2013, 15, 4892–4896. [Google Scholar] [CrossRef]

- Çakıroğlu, B.; Chauvin, J.; Le Goff, A.; Gorgy, K.; Özacar, M.; Holzinger, M. Photoelectrochemically-assisted biofuel cell constructed by redox complex and g-C(3)N(4) coated MWCNT bioanode. Biosens. Bioelectron. 2020, 169, 112601. [Google Scholar] [CrossRef]

- Chansaenpak, K.; Kamkaew, A.; Lisnund, S.; Prachai, P.; Ratwirunkit, P.; Jingpho, T.; Blay, V.; Pinyou, P. Development of a Sensitive Self-Powered Glucose Biosensor Based on an Enzymatic Biofuel Cell. Biosensors 2021, 11, 16. [Google Scholar] [CrossRef] [PubMed]

- Christwardana, M.; Chung, Y.; Kwon, Y. Co-immobilization of glucose oxidase and catalase for enhancing the performance of a membraneless glucose biofuel cell operated under physiological conditions. Nanoscale 2017, 9, 1993–2002. [Google Scholar] [CrossRef] [PubMed]

- Elouarzaki, K.; Bourourou, M.; Holzinger, M.; Le Goff, A.; Marks, R.S.; Cosnier, S. Freestanding HRP–GOx redox buckypaper as an oxygen-reducing biocathode for biofuel cell applications. Energy Environ. Sci. 2015, 8, 2069–2074. [Google Scholar] [CrossRef]

- Chung, Y.; Tannia, D.C.; Kwon, Y. Glucose biofuel cells using bi-enzyme catalysts including glucose oxidase, horseradish peroxidase and terephthalaldehyde crosslinker. Chem. Eng. J. 2018, 334, 1085–1092. [Google Scholar] [CrossRef]

- Shakeel, N.; Ahamed, M.I.; Inamuddin; Ahmed, A.; Kanchi, S.; Kashmery, H.A. Hydrothermally synthesized defective NiMoSe2 nanoplates decorated on the surface of functionalized SWCNTs doped polypyrrole scaffold for enzymatic biofuel cell applications. Int. J. Hydrogen Energy 2021, 46, 3240–3250. [Google Scholar] [CrossRef]

- Kang, Z.; Jiao, K.; Cheng, J.; Peng, R.; Jiao, S.; Hu, Z. A novel three-dimensional carbonized PANI1600@CNTs network for enhanced enzymatic biofuel cell. Biosens. Bioelectron. 2018, 101, 60–65. [Google Scholar] [CrossRef]

- Ji, J.; Kim, S.; Chung, Y.; Kwon, Y. Polydopamine mediator for glucose oxidation reaction and its use for membraneless enzymatic biofuel cells. J. Ind. Eng. Chem. 2022, 111, 263–271. [Google Scholar] [CrossRef]

- Lee, J.; Hyun, K.; Park, J.M.; Park, H.S.; Kwon, Y. Maximizing the enzyme immobilization of enzymatic glucose biofuel cells through hierarchically structured reduced graphene oxide. Int. J. Energy Res. 2021, 45, 20959–20969. [Google Scholar] [CrossRef]

- Sun, M.; Gu, Y.; Pei, X.; Wang, J.; Liu, J.; Ma, C.; Bai, J.; Zhou, M. A flexible and wearable epidermal ethanol biofuel cell for on-body and real-time bioenergy harvesting from human sweat. Nano Energy 2021, 86, 106061. [Google Scholar] [CrossRef]

- Prasad, K.P.; Chen, Y.; Chen, P. Three-dimensional graphene-carbon nanotube hybrid for high-performance enzymatic biofuel cells. ACS Appl. Mater. Interfaces 2014, 6, 3387–3393. [Google Scholar] [CrossRef]

- Hui, Y.; Wang, H.; Zuo, W.; Ma, X. Spider nest shaped multi-scale three-dimensional enzymatic electrodes for glucose/oxygen biofuel cells. Int. J. Hydrogen Energy 2022, 47, 6187–6199. [Google Scholar] [CrossRef]

- Li, G.; Ren, G.; Wang, W.A.; Hu, Z. Rational design of N-doped CNTs@C3N4 network for dual-capture of biocatalysts in enzymatic glucose/O2 biofuel cells. Nanoscale 2021, 13, 7774–7782. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, Z.; Li, G.; Zheng, X.; Su, Y.; Yang, Y.; Liao, Y.; Hu, Z. DNA derived N-doped 3D conductive network with enhanced electrocatalytic activity and stability for membrane-less biofuel cells. Anal. Chim. Acta 2021, 1165, 338546. [Google Scholar] [CrossRef] [PubMed]

- Yasujima, R.; Yasueda, K.; Horiba, T.; Komaba, S. Multi-Enzyme Immobilized Anodes Utilizing Maltose Fuel for Biofuel Cell Applications. ChemElectroChem 2018, 5, 2271–2278. [Google Scholar] [CrossRef]

- Kang, S.; Hyun, K.; Chung, Y.; Kwon, Y. A biocatalyst containing chitosan and embedded dye mediator adopted for promoting oxidation reactions and its utilization in biofuel cells. Appl. Surf. Sci. 2020, 507, 145007. [Google Scholar] [CrossRef]

- Li, G.; Li, Z.; Xiao, X.; An, Y.; Wang, W.; Hu, Z. An ultrahigh electron-donating quaternary-N-doped reduced graphene oxide@carbon nanotube framework: A covalently coupled catalyst support for enzymatic bioelectrodes. J. Mater. Chem. A 2019, 7, 11077–11085. [Google Scholar] [CrossRef]

- Song, Y.; Wang, C. High-power biofuel cells based on three-dimensional reduced graphene oxide/carbon nanotube micro-arrays. Microsyst. Nanoeng. 2019, 5, 46. [Google Scholar] [CrossRef]

- Xu, C.; Li, G.; Zhou, M.; Hu, Z. Carbon nanorods assembled coral-like hierarchical meso-macroporous carbon as sustainable materials for efficient biosensing and biofuel cell. Anal. Chim. Acta 2022, 1220, 339994. [Google Scholar] [CrossRef]

- Shi, Y.; Li, L.; Zhang, L. Enhanced Power Density of Alcohol Biofuel Cell by Polymer-assisted Crosslinks of 3D Graphene on Carbon Paper as the Bioanode. Electroanalysis 2022, 34, 640–644. [Google Scholar] [CrossRef]

- Bonfin, C.S.; Franco, J.H.; de Andrade, A.R. Ethanol bioelectrooxidation in a robust poly(methylene green-pyrrole)- mediated enzymatic biofuel cell. J. Electroanal. Chem. 2019, 844, 43–48. [Google Scholar] [CrossRef]

- Pakapongpan, S.; Tuantranont, A.; Poo-arporn, R.P. Magnetic Nanoparticle-Reduced Graphene Oxide Nanocomposite as a Novel Bioelectrode for Mediatorless-Membraneless Glucose Enzymatic Biofuel Cells. Sci. Rep. 2017, 7, 12882. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhou, M.; Wen, D.; Bai, L.; Lou, B.; Dong, S. Small-size biofuel cell on paper. Biosens. Bioelectron. 2012, 35, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Han, Y.; Lou, B.; Zhang, L.; Han, L.; Dong, S. A miniature origami biofuel cell based on a consumed cathode. Chem. Commun. 2016, 52, 13499–13502. [Google Scholar] [CrossRef]

- Hasan, M.Q.; Kuis, R.; Narayanan, J.S.; Slaughter, G. Fabrication of highly effective hybrid biofuel cell based on integral colloidal platinum and bilirubin oxidase on gold support. Sci. Rep. 2018, 8, 16351. [Google Scholar] [CrossRef]

- Rewatkar, P.; U.S., J.; Goel, S. Optimized Shelf-Stacked Paper Origami-Based Glucose Biofuel Cell with Immobilized Enzymes and a Mediator. ACS Sustain. Chem. Eng. 2020, 8, 12313–12320. [Google Scholar] [CrossRef]

- Kim, M.; Kwon, Y.; Ahn, Y. Paper-based mediatorless enzymatic microfluidic biofuel cells. Biosens. Bioelectron. 2021, 190, 113391. [Google Scholar] [CrossRef]

- Shitanda, I.; Nohara, S.; Hoshi, Y.; Itagaki, M.; Tsujimura, S. A screen-printed circular-type paper-based glucose/O2 biofuel cell. J. Power Source 2017, 360, 516–519. [Google Scholar] [CrossRef]

- Shitanda, I.; Momiyama, M.; Watanabe, N.; Tanaka, T.; Tsujimura, S.; Hoshi, Y.; Itagaki, M. Toward Wearable Energy Storage Devices: Paper-Based Biofuel Cells based on a Screen-Printing Array Structure. ChemElectroChem 2017, 4, 2460–2463. [Google Scholar] [CrossRef]

- Duong, N.B.; Wang, C.-L.; Huang, L.Z.; Fang, W.T.; Yang, H. Development of a facile and low-cost chitosan-modified carbon cloth for efficient self-pumping enzymatic biofuel cells. J. Power Source 2019, 429, 111–119. [Google Scholar] [CrossRef]

- Duong, N.B.; Truong, V.M.; Li, Y.-S.; Wang, C.-L.; Yang, H. Improving the Immobilization of Glucose Oxidase on Carbon Cloth via a Hybrid Approach of Cross-Linked Chitosan/TPP Matrices with Na Polymers for High-Performance Self-Pumping Enzyme-Based Biofuel Cells. Energy Fuels 2020, 34, 10050–10058. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Su, H.; Sun, F.; Lu, Z. A wearable self-powered biosensor system integrated with diaper for detecting the urine glucose of diabetic patients. Sens. Actuators B Chem. 2021, 341, 130046. [Google Scholar] [CrossRef]

- Kabir, M.H.; Marquez, E.; Djokoto, G.; Parker, M.; Weinstein, T.; Ghann, W.; Uddin, J.; Ali, M.M.; Alam, M.M.; Thompson, M.; et al. Energy Harvesting by Mesoporous Reduced Graphene Oxide Enhanced the Mediator-Free Glucose-Powered Enzymatic Biofuel Cell for Biomedical Applications. ACS Appl. Mater. Interfaces 2022, 14, 24229–24244. [Google Scholar] [CrossRef] [PubMed]

- Shen, F.; Pankratov, D.; Halder, A.; Xiao, X.; Toscano, M.D.; Zhang, J.; Ulstrup, J.; Gorton, L.; Chi, Q. Two-dimensional graphene paper supported flexible enzymatic fuel cells. Nanoscale Adv. 2019, 1, 2562–2570. [Google Scholar] [CrossRef] [PubMed]

- Escalona-Villalpando, R.A.; Ortiz-Ortega, E.; Bocanegra-Ugalde, J.P.; Minteer, S.D.; Ledesma-García, J.; Arriaga, L.G. Clean energy from human sweat using an enzymatic patch. J. Power Source 2019, 412, 496–504. [Google Scholar] [CrossRef]

- Tominaga, M.; Kuwahara, K.; Tsushida, M.; Shida, K. Cellulose nanofiber-based electrode as a component of an enzyme-catalyzed biofuel cell. RSC Adv. 2020, 10, 22120–22125. [Google Scholar] [CrossRef]

- Hou, C.; Liu, A. An integrated device of enzymatic biofuel cells and supercapacitor for both efficient electric energy conversion and storage. Electrochim. Acta 2017, 245, 303–308. [Google Scholar] [CrossRef]

- Gross, A.J.; Chen, X.; Giroud, F.; Abreu, C.; Le Goff, A.; Holzinger, M.; Cosnier, S. A High Power Buckypaper Biofuel Cell: Exploiting 1,10-Phenanthroline-5,6-dione with FAD-Dependent Dehydrogenase for Catalytically-Powerful Glucose Oxidation. ACS Catal. 2017, 7, 4408–4416. [Google Scholar] [CrossRef]

- Oh, J.Y.; Yang, S.J.; Park, J.Y.; Kim, T.; Lee, K.; Kim, Y.S.; Han, H.N.; Park, C.R. Easy Preparation of Self-Assembled High-Density Buckypaper with Enhanced Mechanical Properties. Nano Lett. 2015, 15, 190–197. [Google Scholar] [CrossRef]

- Lalaoui, N.; Means, N.; Walgama, C.; Le Goff, A.; Holzinger, M.; Krishnan, S.; Cosnier, S. Enzymatic versus Electrocatalytic Oxidation of NADH at Carbon-Nanotube Electrodes Modified with Glucose Dehydrogenases: Application in a Bucky-Paper-Based Glucose Enzymatic Fuel Cell. ChemElectroChem 2016, 3, 2058–2062. [Google Scholar] [CrossRef]

- Mano, N.; Mao, F.; Heller, A. Characteristics of a miniature compartment-less glucose-O-2 biofuel cell and its operation in a living plant. J. Am. Chem. Soc. 2003, 125, 6588–6594. [Google Scholar] [CrossRef]

- Cinquin, P.; Gondran, C.; Giroud, F.; Mazabrard, S.; Pellissier, A.; Boucher, F.; Alcaraz, J.-P.; Gorgy, K.; Lenouvel, F.; Mathé, S.; et al. A glucose biofuel cell implanted in rats. PLoS ONE 2010, 5, e10476. [Google Scholar] [CrossRef] [PubMed]

- Halámková, L.; Halámek, J.; Bocharova, V.; Szczupak, A.; Alfonta, L.; Katz, E. Implanted Biofuel Cell Operating in a Living Snail. J. Am. Chem. Soc. 2012, 134, 5040–5043. [Google Scholar] [CrossRef] [PubMed]

- Szczupak, A.; Halámek, J.; Halámková, L.; Bocharova, V.; Alfonta, L.; Katz, E. Living battery—Biofuel cells operating in vivo in clams. Energy Environ. Sci. 2012, 5, 8891–8895. [Google Scholar] [CrossRef]

- MacVittie, K.; Halámek, J.; Halámková, L.; Southcott, M.; Jemison, W.D.; Lobel, R.; Katz, E. From “cyborg” lobsters to a pacemaker powered by implantable biofuel cells. Energy Environ. Sci. 2013, 6, 81–86. [Google Scholar] [CrossRef]

- Rasmussen, M.; Ritzmann, R.E.; Lee, I.; Pollack, A.J.; Scherson, D. An Implantable Biofuel Cell for a Live Insect. J. Am. Chem. Soc. 2012, 134, 1458–1460. [Google Scholar] [CrossRef]

- Shoji, K.; Akiyama, Y.; Suzuki, M.; Hoshino, T.; Nakamura, N.; Ohno, H.; Morishima, K. Insect biofuel cells using trehalose included in insect hemolymph leading to an insect-mountable biofuel cell. Biomed. Microdevices 2012, 14, 1063–1068. [Google Scholar] [CrossRef]

- Miyake, T.; Haneda, K.; Nagai, N.; Yatagawa, Y.; Onami, H.; Yoshino, S.; Abe, T.; Nishizawa, M. Enzymatic biofuel cells designed for direct power generation from biofluids in living organisms. Energy Environ. Sci. 2011, 4, 5008–5012. [Google Scholar] [CrossRef]

- Yin, S.; Liu, X.; Kobayashi, Y.; Nishina, Y.; Nakagawa, R.; Yanai, R.; Kimura, K.; Miyake, T. A needle-type biofuel cell using enzyme/mediator/carbon nanotube composite fibers for wearable electronics. Biosens. Bioelectron. 2020, 165, 112287. [Google Scholar] [CrossRef]

- Jeon, W.Y.; Lee, J.H.; Dashnyam, K.; Choi, Y.B.; Kim, T.H.; Lee, H.H.; Kim, H.W.; Kim, H.H. Performance of a glucose-reactive enzyme-based biofuel cell system for biomedical applications. Sci. Rep. 2019, 9, 10872. [Google Scholar] [CrossRef]

- Falk, M.; Andoralov, V.; Blum, Z.; Sotres, J.; Suyatin, D.B.; Ruzgas, T.; Arnebrant, T.; Shleev, S. Biofuel cell as a power source for electronic contact lenses. Biosens. Bioelectron. 2012, 37, 38–45. [Google Scholar] [CrossRef]

- El Ichi-Ribault, S.; Alcaraz, J.-P.; Boucher, F.; Boutaud, B.; Dalmolin, R.; Boutonnat, J.; Cinquin, P.; Zebda, A.; Martin, D.K. Remote wireless control of an enzymatic biofuel cell implanted in a rabbit for 2 months. Electrochim. Acta 2018, 269, 360–366. [Google Scholar] [CrossRef]

- Bollella, P.; Lee, I.; Blaauw, D.; Katz, E. A Microelectronic Sensor Device Powered by a Small Implantable Biofuel Cell. Chemphyschem 2020, 21, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.Y.; Yun, J.-H.; Bin Park, Y.; Hyeon, J.S.; Jang, Y.; Choi, Y.-B.; Kim, H.-H.; Kang, T.M.; Ovalle, R.; Baughman, R.H.; et al. Two-Ply Carbon Nanotube Fiber-Typed Enzymatic Biofuel Cell Implanted in Mice. IEEE Trans. Nanobiosci. 2020, 19, 333–338. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Jeong, S.H.; Yun, S.; Kim, S.; Sung, J.; Seo, J.; Son, S.; Kim, J.T.; Susanti, L.; Jeong, Y.; et al. Totally implantable enzymatic biofuel cell and brain stimulator operating in bird through wireless communication. Biosens. Bioelectron. 2021, 171, 112746. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Siepenkoetter, T.; Conghaile, P.O.; Leech, D.; Magner, E. Nanoporous Gold-Based Biofuel Cells on Contact Lenses. ACS Appl. Mater. Interfaces 2018, 10, 7107–7116. [Google Scholar] [CrossRef]

- Niiyama, A.; Murata, K.; Shigemori, Y.; Zebda, A.; Tsujimura, S. High-performance enzymatic biofuel cell based on flexible carbon cloth modified with MgO-templated porous carbon. J. Power Source 2019, 427, 49–55. [Google Scholar] [CrossRef]

- Kong, X.; Gai, P.; Ge, L.; Li, F. Laser-Scribed N-Doped Graphene for Integrated Flexible Enzymatic Biofuel Cells. ACS Sustain. Chem. Eng. 2020, 8, 12437–12442. [Google Scholar] [CrossRef]

- Jia, W.Z.; Valdes-Ramirez, G.; Bandodkar, A.J.; Windmiller, J.R.; Wang, J. Epidermal Biofuel Cells: Energy Harvesting from Human Perspiration. Angew. Chem. Int. Ed. 2013, 52, 7233–7236. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Williams, I.; Li, Y.; Qian, F.; Wang, L.; Lei, Y.; Li, B. Flat enzyme-based lactate biofuel cell integrated with power management system: Towards long term in situ power supply for wearable sensors. Appl. Energy 2017, 194, 71–80. [Google Scholar] [CrossRef]

- Bandodkar, A.J. Review-Wearable Biofuel Cells: Past, Present and Future. J. Electrochem. Soc. 2017, 164, H3007–H3014. [Google Scholar] [CrossRef]

- Yang, Y.; Su, Y.; Zhu, X.; Ye, D.; Chen, R.; Liao, Q. Flexible enzymatic biofuel cell based on 1, 4-naphthoquinone/MWCNT-Modified bio-anode and polyvinyl alcohol hydrogel electrolyte. Biosens. Bioelectron. 2022, 198, 113833. [Google Scholar] [CrossRef]

- Reid, R.C.; Minteer, S.D.; Gale, B.K. Contact lens biofuel cell tested in a synthetic tear solution. Biosens. Bioelectron. 2015, 68, 142–148. [Google Scholar] [CrossRef]

- Jia, W.; Wang, X.; Imani, S.; Bandodkar, A.J.; Ramírez, J.; Mercier, P.P.; Wang, J. Wearable textile biofuel cells for powering electronics. J. Mater. Chem. A 2014, 2, 18184–18189. [Google Scholar] [CrossRef]

- Yin, S.; Liu, X.; Kaji, T.; Nishina, Y.; Miyake, T. Fiber-crafted biofuel cell bracelet for wearable electronics. Biosens. Bioelectron. 2021, 179, 113107. [Google Scholar] [CrossRef]

- Yin, S.; Jin, Z.; Miyake, T. Wearable high-powered biofuel cells using enzyme/carbon nanotube composite fibers on textile cloth. Biosens. Bioelectron. 2019, 141, 111471. [Google Scholar] [CrossRef]

- Chen, X.; Yin, L.; Lv, J.; Gross, A.J.; Le, M.; Gutierrez, N.G.; Li, Y.; Jeerapan, I.; Giroud, F.; Berezovska, A.; et al. Stretchable and Flexible Buckypaper-Based Lactate Biofuel Cell for Wearable Electronics. Adv. Funct. Mater. 2019, 29, 1905785. [Google Scholar] [CrossRef]

| Anode | Cathode | Open-Circuit Voltage | Maximum Current Density | Maximum Power Density | Reference |

|---|---|---|---|---|---|

| GOx/N-G@CNT/TTF/GCE | BOD/N-G@CNT/GCE | 0.68 V (dual-chamber) 0.76 V (single-chamber) | 2 mA cm−2 (dual-chamber) 1.2 mA cm−2 (single-chamber) | 500 µW cm−2 (dual-chamber) 340 µW cm−2 (single-chamber) | [33] |

| MAL@MUT@GOx/CNT/TX/CF | KB/BOD/ABTS/CP | 0.6 V | 17 mA cm−2 | 2300 µW cm−2 | [34] |

| GOx/MR/CTS@CNT/GCE | Pt/C/GCE | 0.64 V | 0.169 mA cm−2 | 94 µW cm−2 | [35] |

| GOx/QN-rGO@CNT/Ni foam | Lac/QN-rGO@CNT/Ni foam | 0.89 V | 2.25 mA cm−2 | 900 µW cm−2 | [36] |

| GOx/rGO@CNT | Lac/rGO@CNT | 0.88 V | 0.844 mA cm−2 | 196.04 µW cm−2 | [37] |

| LOx/TTF/CN-CHMC | BOD/CN-CHMC | 0.65 V | 0.19 mA cm−2 | 112.7 µW cm−2 | [38] |

| ADH/PDDA/rGO | Pt/CP | 0.756 V | 0.04 mA cm−2 | 10.35 µW cm−2 | [39] |

| ADH/poly (MG-py)/CNT/CP | Pt/C | 0.503 V | 2.1 mA cm−2 | 275 µW cm−2 | [40] |

| GOx/Fe3O4-rGO | BOD/Fe3O4-rGO | 0.63 V | 0.24 mA cm−2 | 73.7 µW cm−2 | [41] |

| Anode | Cathode | Open-Circuit Voltage | Maximum Current Density | Maximum Power Density | Reference |

|---|---|---|---|---|---|

| GOx/QN-rGO@CNT/Ni foam | Lac/QN-rGO@CNT/Ni foam | 0.89 V | 2.25 mA cm−2 | 900 µW cm−2 | [36] |

| GOx/Au NPs/CNT/PET | MnO2@CNT | 0.58 V | 0.733 mA cm−2 | 220 µW cm−2 | [51] |

| GOx/rGO/FP | Lac/rGO/FP | 0.04 V | 0.0007 mA cm−2 | 0.004 µW cm−2 | [52] |

| GDH/MB/2D-GP | BOD/2D-GP | 0.665 V | 0.016 mA cm−2 | 4.03 µW cm−2 | [53] |

| FcMe2-LPEI/LOx/PTFE | BOD/CNT/PTFE | 0.55 V | 0.14 mA cm−2 | 20 µW cm−2 | [54] |

| GDH/CNT@CNF | Lac/CNT@CNF | 0.434 V | 0.176 mA cm−2 | 27 µW cm−2 | [55] |

| GDH/PANI/BP | Lac/PANI/BP | 0.71 V | 0.53 mA cm−2 | 204 µW cm−2 | [56] |

| GDH/PLQ/BP | BOD/CNT/BP | 0.5 V | 5.38 mA cm−2 | 650 µW cm−2 | [57] |

| GDH/BP | BOD/BP | 0.59 V | 2.62 mA cm−2 | 1070 µW cm−2 | [58] |

| GDH/BP | BOD/BP | 0.62 V | 0.141 mA cm−2 | 470 µW cm−2 | [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Liu, C.; Yu, H.; Tang, N.; Lei, C. Research Progresses and Application of Biofuel Cells Based on Immobilized Enzymes. Appl. Sci. 2023, 13, 5917. https://doi.org/10.3390/app13105917

Zhou J, Liu C, Yu H, Tang N, Lei C. Research Progresses and Application of Biofuel Cells Based on Immobilized Enzymes. Applied Sciences. 2023; 13(10):5917. https://doi.org/10.3390/app13105917

Chicago/Turabian StyleZhou, Jian, Chang Liu, Hao Yu, Ningli Tang, and Chenghong Lei. 2023. "Research Progresses and Application of Biofuel Cells Based on Immobilized Enzymes" Applied Sciences 13, no. 10: 5917. https://doi.org/10.3390/app13105917

APA StyleZhou, J., Liu, C., Yu, H., Tang, N., & Lei, C. (2023). Research Progresses and Application of Biofuel Cells Based on Immobilized Enzymes. Applied Sciences, 13(10), 5917. https://doi.org/10.3390/app13105917